L6910G

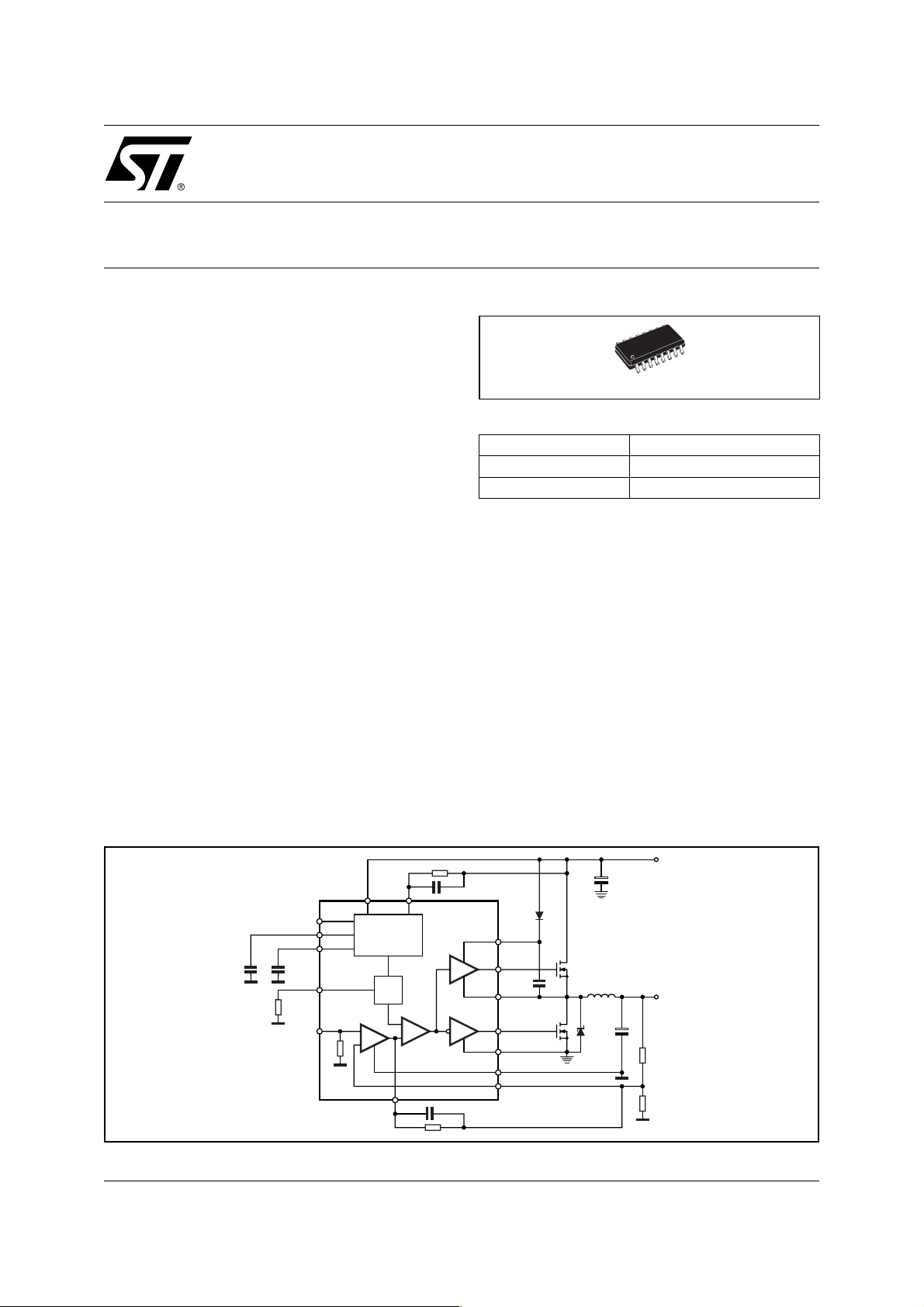

Fi

ADJUSTABLE STEP DOWN CONTROLLER

WITH SYNCHRONOUS RECTIFICATION

1 FEATURES

■ OPERATING SUPPLY VOLTAGE FROM 5V

TO 12V BUSES

■ UP TO 1.3A GATE CURRENT CAPABILITY

■ ADJUSTABLE OUTPUT VOLTAGE

■ N-INVERTING E/A INPUT AVAILABLE

■

0.9V ±1.5% VOLTAGE REFERENCE

■ VOLTAGE MODE PWM CONTROL

■ VERY FAST LOAD TRANSIENT RESPONSE

■ 0% TO 100% DUTY CYCLE

■ POWER GOOD OUTPUT

■ OVERVOLTAGE PROTECTION

■ HICCUP OVERCURRENT PROTECTION

■ 200kHz INTERNAL OSCILLATOR

■ OSCILLATOR EXTERNALLY ADJUSTABLE

FROM 50kHz TO 1MHz

■ SOFT START AND INHIBIT

■ PACKAGE: SO-16

2 APPLICATIONS

■ SUPPLY FOR MEMORIES AND TERMI-

NATIONS

■ COMPUTER ADD-ON CARDS

■ LOW VOLTAGE DISTRIBUTED DC-DC

■ MAG-AMP REPLACEMENT

3 DESCRIPTION

The device is a pwm controller for high performance

gure 1. Packages

SO-16 (Narrow)

Table 1. Order Codes

Part Number Package

L6910G SO-16

L6910GTR SO-16 in Tape & Reel

dc-dc conversion from 3.3V, 5V and 12V buses.

The output voltage is adjustable down to 0.9V;

higher voltages can be obtained with an external

voltage divider.

High peak current gate drivers provide for fast switching to the external power section, and the output

current can be in excess of 20A.

The device assures protections against load overcurrent and overvoltage.

An internal crowbar is also provided turning on the

low side mosfet as long as the over-voltage is detected. In case of over-current detection, the soft start capacitor is discharged and the system works in

HICCUP mode.

Figure 2. Block Diagram

R

T

May 2005

PGOOD

VREF

OSC

EAREF

SS

D03IN1509

VCC OCSET

PROTECTION

E/A

+

-

300K

COMP

MONITOR

& REF

OSC

PWM

-

+

BOOT

UGATE

PHASE

LGATE

PGND

GND

VFB

Vin 5V to 12V

V

O

Rev. 1

1/26

L6910G

Table 2. Absolute Maximum Ratings

Symbol Parameter Value Unit

Vcc Vcc to GND, PGND 15 V

V

BOOT-VPHASE

V

HGATE-VPHASE

T

j

T

stg

P

tot

OCSET PIN Maximum Withstanding Voltage Range

OTHER PINS ±2000 V

Table 3. Thermal Data

Symbol Parameter Value Unit

Boot Voltage 15 V

15 V

OCSET, LGATE, PHASE -0.3 to Vcc+0.3 V

SS, FB, PGOOD, VREF, EAREF, RT 7 V

COMP 6.5 V

Junction Temperature Range -40 to 150 °C

Storage temperature range -40 to 150 °C

Maximum power dissipation at Tamb = 25°C1W

±1000 V

Test Condition: CDF-AEC-Q100-002”Human Body Model”

Acceptance Criteria: “Normal Performance”

R

th j-amb

(*) Device soldered on 1 S2P PC board

Thermal Resistance Junction to Ambient 120 °C/W

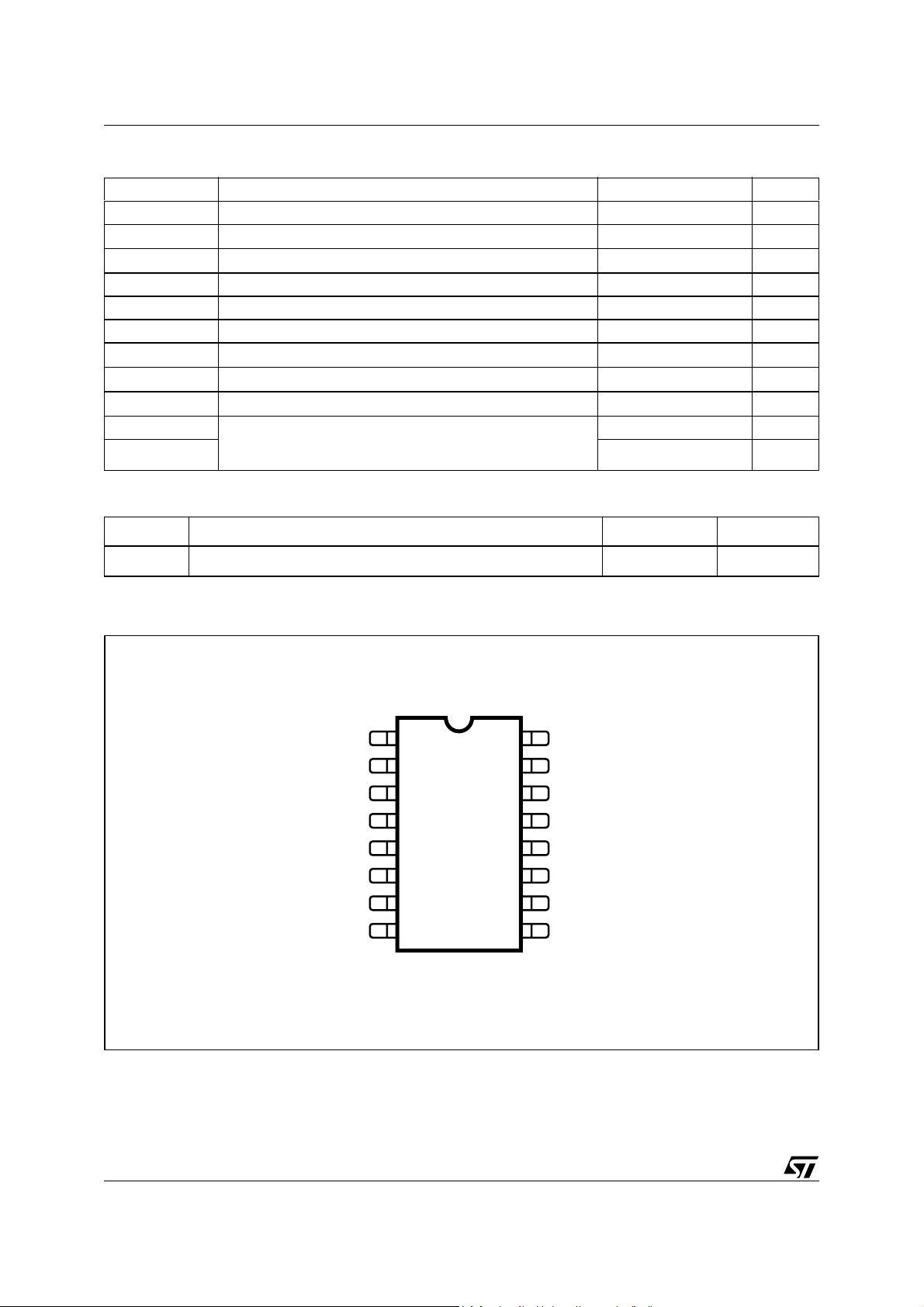

Figure 3. Pins Connection (Top view)

VREF

OSC

OCSET

SS/INH

COMP

FB

GND

EAREF PGOOD

2

3

4

5

6

7

8

D03IN1510

16

15

14

13

12

11

10

N.C.1

VCC

LGATE

PGND

BOOT

HGATE

PHASE

9

2/26

L6910G

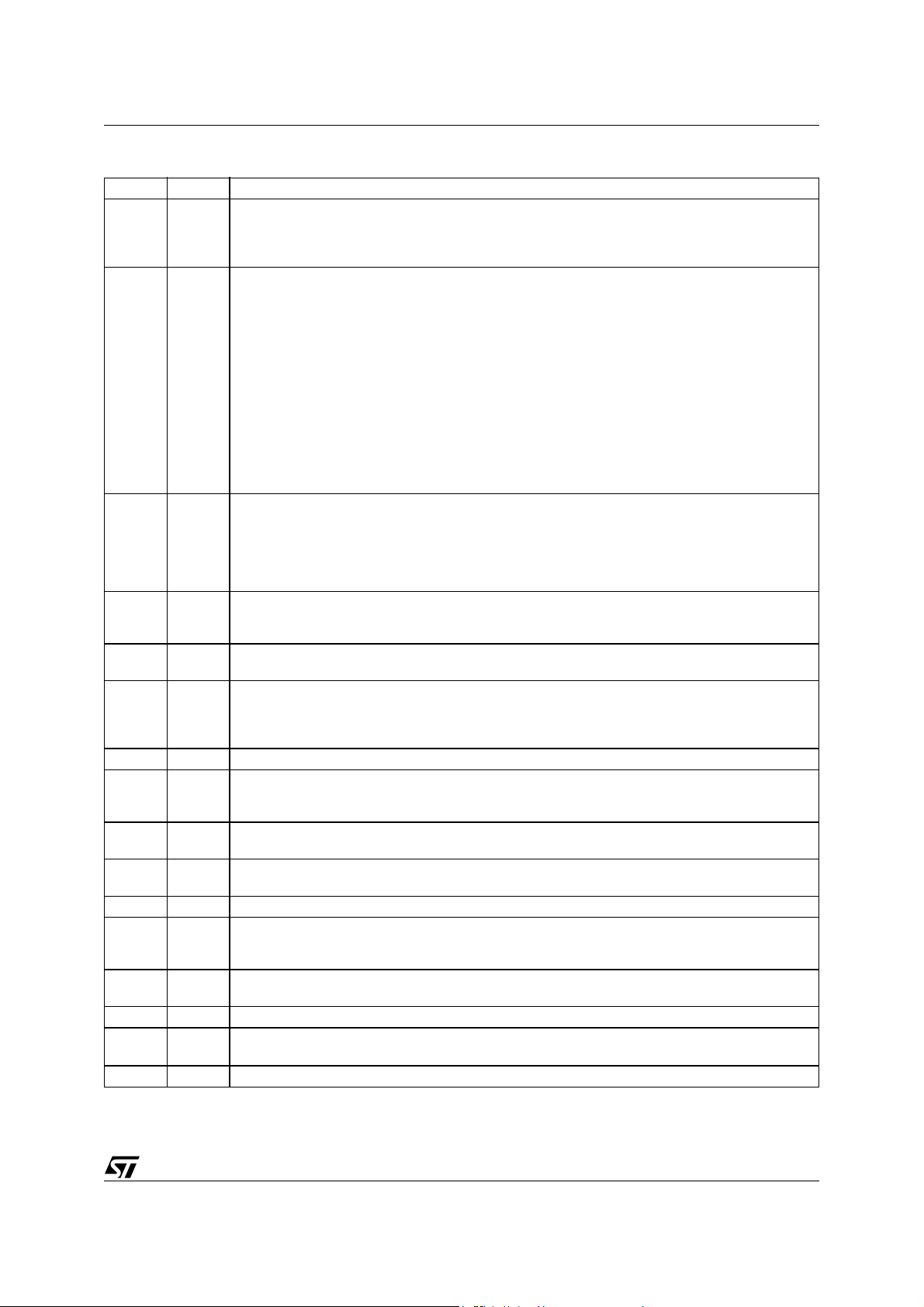

Table 4. Pins Function

Pin Name Description

1 VREF Internal 0.9V ±1.5% reference is available for external regulators or for the internal error amplifier

2 OSC Oscillator switching frequency pin. Connecting an external resistor (R

3 OCSET A resistor connected from this pin and the upper Mos Drain sets the current limit protection.

4 SS/INH The soft start time is programmed connecting an external capacitor from this pin and GND. The

5 COMP This pin is connected to the error amplifier output and is used to compensate the voltage control

6 FB This pin is connected to the error amplifier inverting input and is used to compensate the voltage

7 GND All the internal references are referred to this pin. Connect it to the PCB signal ground.

8 EAREF Error amplifier non-inverting input. Connect to this pin an external reference (from 0.9V to 3V) for

9

PGOOD

10 PHASE

11 HGATE High side gate driver output.

12 BOOT Bootstrap capacitor pin. Through this pin is supplied the high side driver and the upper mosfet.

13 PGND Power ground pin. This pin has to be connected closely to the low side mosfet source in order to

14 LGATE This pin is the lower mosfet gate driver output

15 VCC Device supply voltage. The operative supply voltage ranges is from 5V to 12V.

16 N.C. This pin is not internally bonded. It may be left floating or connected to GND.

(connecting this pin to EAREF) if external reference is not available.

A minimum 1nF capacitor is required.

If the pin is forced to a voltage lower than 70%, the device enters the hiccup mode.

) from this pin to GND, the

T

external frequency is increased according to the equation:

6

⋅

4.94 10

f

OSC,RT

200K H z

-------------------------+=

R

KΩ()

T

Connecting a resistor (RT) from this pin to Vcc (12V), the switching frequency is reduced according to

the equation:

7

⋅

4.306 10

f

OSC,RT

200K H z

-----------------------------–=

R

T

KΩ()

If the pin is not connected, the switching frequency is 200KHz.

The voltage at this pin is fixed at 1.23V. Forcing a 50µA current into this pin, the built in oscillator

stops to switch.

In Over Voltage condition this pin goes over 3V until that conditon is removed.

The internal 200µA current generator sinks a constant current through the external resistor. The

Over-Current threshold is due to the following equation:

I

I

----------------------------------------------=

P

⋅

OCSETROCSET

R

DSon

internal current generator forces through the capacitor 10µA.

This pin can be used to disable the device forcing a voltage lower than 0.4V

feedback loop.

control feedback loop.

Connected to the output resistor divider, if used, or directly to Vout, it manages also over-voltage

conditions and the PGOOD signal

the PWM regulation or short it to VREF pin to use the internal reference.

If this pin goes under 650mV (typ), the device shuts down.

This pin is an open collector output and it is pulled low if the output voltage is not within the above

specified thresholds. If not used it may be left floating.

This pin is connected to the source of the upper mosfet and provides the return path for the high side

driver. This pin monitors the drop across the upper mosfet for the current limit together with OCSET.

Connect through a capacitor to the PHASE pin and through a diode to Vcc (cathode vs. boot).

VBOOT limited to VOCSET -10V(typ.) when all other pins are connected to GND.

reduce the noise injection into the device

DO NOT CONNECT V

TO A VOLTAGE GREATER THAN VCC.

IN

3/26

L6910G

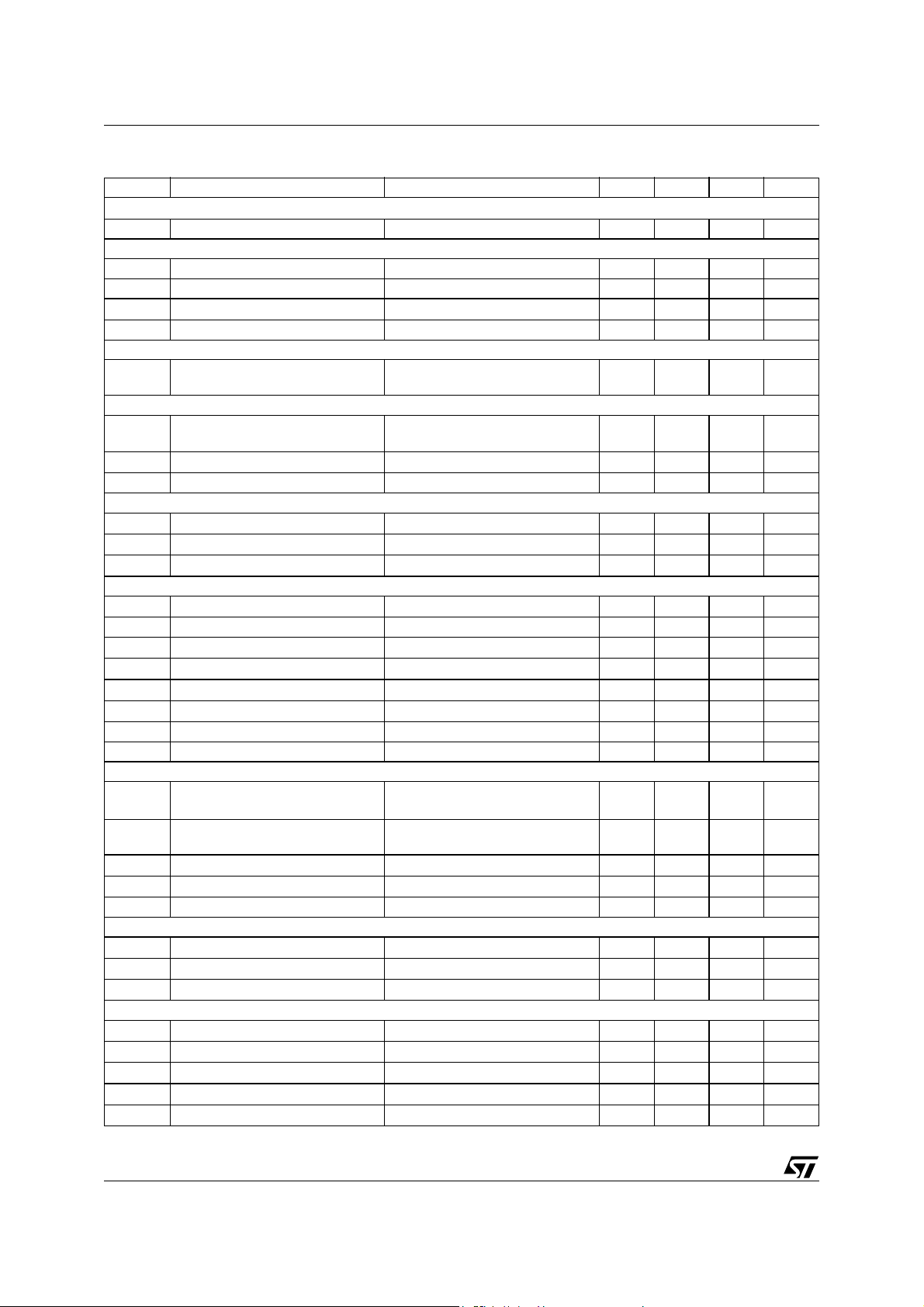

Table 5. Electrical Characteristics (Vcc = 12V, TJ =25°C unless otherwise specified)

Symbol Parameter Test Condition Min Typ Max Unit

SUPPLY CURRENT

V

cc

Icc Vcc Supply current OSC = open; SS to GND 4 7 9 mA

POWER-ON

Turn-On Vcc threshold VOCSET = 4V 4.0 4.3 4.6 V

Turn-Off Vcc threshold VOCSET = 4V 3.8 4.1 4.4 V

Rising V

Turn On EAREF threshold VOCSET = 4V 650 750 mV

SOFT START AND INHIBIT

Iss Soft start Current

S.S. current in INH condition

OSCILLATOR

f

OSC

f

OSC,RT

Initial Accuracy OSC = OPEN

Total Accuracy 16 KΩ < RT to GND < 200 KΩ -15 15 %

∆Vosc Ramp amplitude 1.9 V

REFERENCE

V

V

V

Output Voltage Accuracy V

OUT

Reference Voltage C

REF

Reference Voltage C

REF

ERROR AMPLIFIER

I

EAREF

N.I. bias current V

EAREF Input Resistance Vs. GND 300 kΩ

I

V

V

COMP

G

I.I. bias current VFB = 0V to 3V 0.01 0.5 µA

FB

Common Mode Voltage 0.8 3 V

CM

Output Voltage 0.5 4 V

Open Loop Voltage Gain 70 85 dB

V

GBWP Gain-Bandwidth Product 10 MHz

SR Slew-Rate COMP = 10pF 10 V/µs

GATE DRIVERS

I

HGATE

High Side

Source Current

R

HGATE

High Side

Sink Resistance

I

LGATE

R

LGATE

Low Side Source Current Vcc = 12V; V

Low Side Sink Resistance Vcc = 12V 1.5 3 Ω

Output Driver Dead Time PHASE connected to GND 90 210 ns

PROTECTIONS

I

OCSET

OCSET Current Source V

Over Voltage Trip (V

I

OSC

OSC Sourcing Current V

POWER GOOD

Upper Threshold (V

Lower Threshold (V

Hysteresis (V

V

PGOOD

I

PGOOD

PGOOD Voltage Low I

Output Leakage Current V

threshold 1.24 1.4 V

OCSET

SS = 2V

6103514

SS = 0 to 0.4V

FB

/ V

180

OSC = OPEN; T

= VFB; V

OUT

= 1nF; I

REF

= 1nF; TJ = 0 to 125°C-2 +2%

REF

= 3V 10 µA

EAREF

V

- V

BOOT

- V

V

HGATE

V

- V

BOOT

= 4V 170 200 230 µA

OCSET

/ V

FB

/ V

FB

/ V

FB

EAREF

)VFB Rising 117 120 %

EAREF

> OVP Trip 15 30 mA

FB

)VFB Rising 108 110 112 %

EAREF

)VFB Falling 88 90 92 %

EAREF

) Upper and Lower threshold 2 %

= -4mA 0.4 V

PGOOD

= 6V 0.2 1 µA

PGOOD

= 0° to 125°

j

= V

EAREF

REF

PHASE

PHASE

= 12V 2 4 Ω

PHASE

LGATE

REF

= 0 to 100µA 0.886 0.900 0.913 V

= 12V

= 6V

= 6V 0.9 1.1 A

170

0.886 0.900 0.913 V

11.3 A

200 220

60

230

µA

µA

KHz

kHz

4/26

L6910G

4 DEVICE DESCRIPTION

The device is an integrated circuit realized in BCD technology. The controller provides complete control logic and protection for a high performance step-down DC-DC converter. It is designed to drive N

Channel Mosfets in a synchronous-rectified buck topology. The output voltage of the converter can be

precisely regulated down to 900mV with a maximum tolerance of ±1.5% when the internal reference is

used (simply connecting together EAREF and VREF pins). The device allows also using an external

reference (0.9V to 3V) for the regulation. The device provides voltage-mode control with fast transient

response. It includes a 200kHz free-running oscillator that is adjustable from 50kHz to 1MHz. The error amplifier features a 10MHz gain-bandwidth product and 10V

high converter bandwidth for fast transient performance. The PWM duty cycle can range from 0% to

100%. The device protects against over-current conditions entering in HICCUP mode. The device

monitors the current by using the

r

DS(ON)

of the upper MOSFET(s) that eliminates the need for a cur-

rent sensing resistor. The device is available in SO16 narrow package.

4.1 Oscillator

The switching frequency is internally fixed to 200kHz. The internal oscillator generates the triangular waveform

for the PWM charging and discharging with a constant current an internal capacitor. The current delivered to the

oscillator is typically 50

OSC pin and GND or V

µ

A (Fsw = 200KHz) and may be varied using an external resistor (RT) connected between

. Since the OSC pin is maintained at fixed voltage (typ. 1.235V), the frequency is var-

CC

ied proportionally to the current sunk (forced) from (into) the pin.

In particular connecting R

vs. GND the frequency is increased (current is sunk from the pin), according to the

T

following relationship:

4.94 10

-------------------------+=

R

Connecting R

f

OSC,RT

to VCC = 12V or to VCC = 5V the frequency is reduced (current is forced into the pin), according

T

200KHz

to the following relationships:

f

OSC,RT

200KHz

4.306 10

-----------------------------–=

R

⋅

KΩ()

T

7

/µs

slew rate that permits to realize

6

⋅

K

Ω()

T

V

CC

= 12V

15 10

f

OSC,RT

200KHz

---------------------–=

R

T

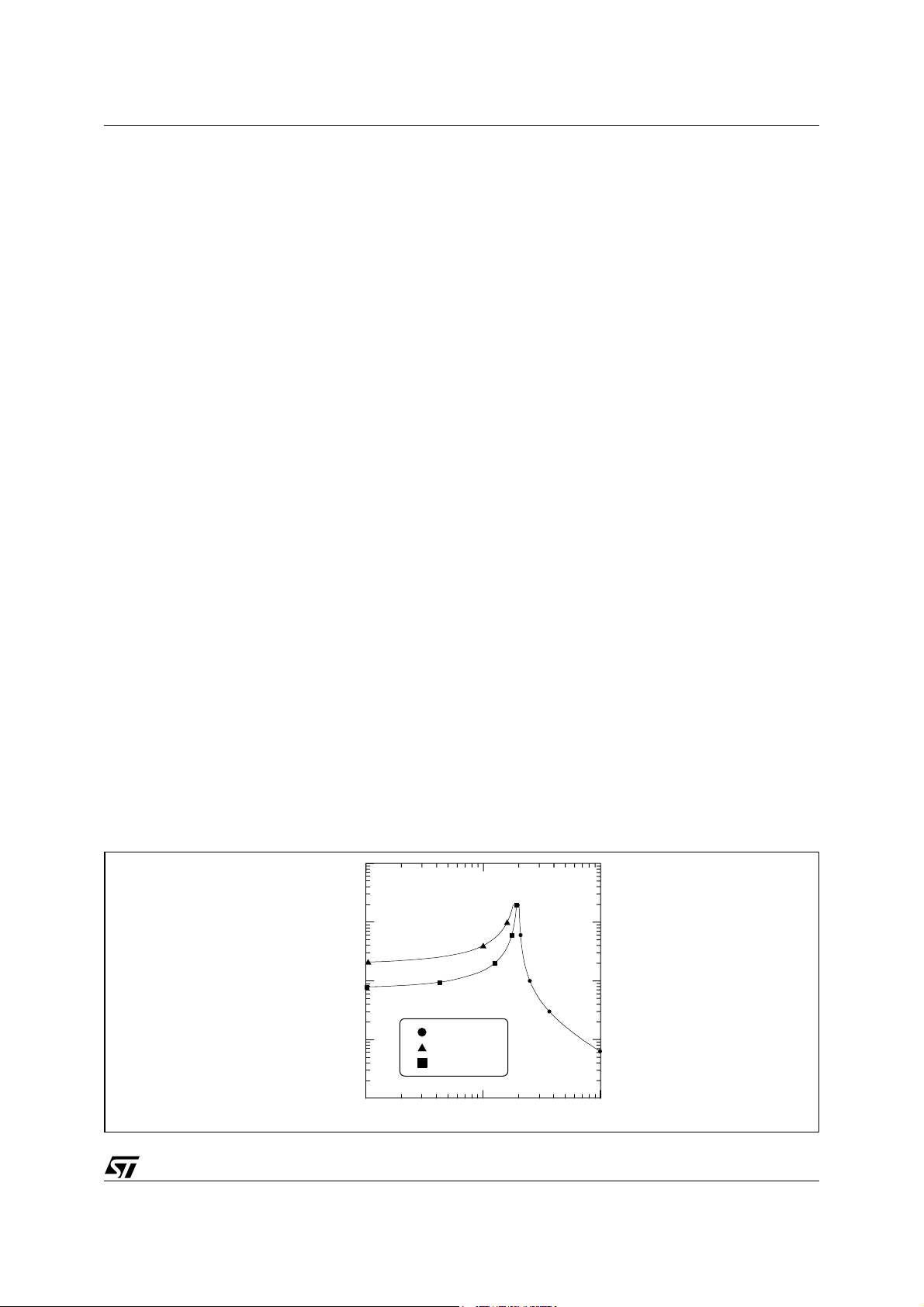

Switching frequency variation vs. RT are repeated in Fig. 4.

Note that forcing a 50

µ

A current into this pin, the device stops switching because no current is delivered to the

oscillator.

Figure 4.

10000

1000

100

Resistance [kOhm]

10

10 100 1000

RT to GND

RT to VCC=12V

RT to VCC=5V

Frequency [kHz]

6

⋅

KΩ()

= 5V

V

CC

5/26

L6910G

4.2 Reference

A precise ±1.5% 0.9V reference is available. This reference must be filtered with 1nF ceramic capacitor to avoid

instability in the internal linear regulator. It is able to deliver up to 100

device regulation and also for other devices. If forced under 70% of its nominal value, the device enters in Hiccup mode until this condition is removed.

Through the EAREF pin the reference for the regulation is taken. This pin directly connects the non-inverting

input of the error amplifier. An external reference (or the internal 0.9V ±1.5%) may be used. The input for this

pin can range from 0.9V to 3V. It has an internal pull-down (300k

no reference is connected (pin floating). However the device is shut down if the voltage on the EAREF pin is

lower than 650mV (typ).

4.3 Soft Start

At start-up a ramp is generated charging the external capacitor CSS with an internal current generator. The initial

value for this current is of 35

10

µ

A until the final charge value of approximatively 4V.

When the voltage across the soft start capacitor (V

charge the output capacitor. As V

µ

A and speeds-up the charge of the capacitor up to 0.5V. After that it becames

) reaches 0.5V the lower power MOS is turned on to dis-

reaches 1.1V (i.e. the oscillator triangular wave inferior limit) also the upper

SS

SS

MOS begins to switch and the output voltage starts to increase.

No switching activity is observable if SS is kept lower than 0.5V and both mosfets are off.

If VCC and OCSET pins are not above their own turn-on thresholds and V

Start will not take place, and the relative pin is internally shorted to GND. During normal operation, if any undervoltage is detected on one of the two supplies, the SS pin is internally shorted to GND and so the SS capacitor

is rapidly discharged.

µ

A and may be used as reference for the

Ω

resistor) that forces the device shutdown if

is not above 650mV, the Soft-

EAREF

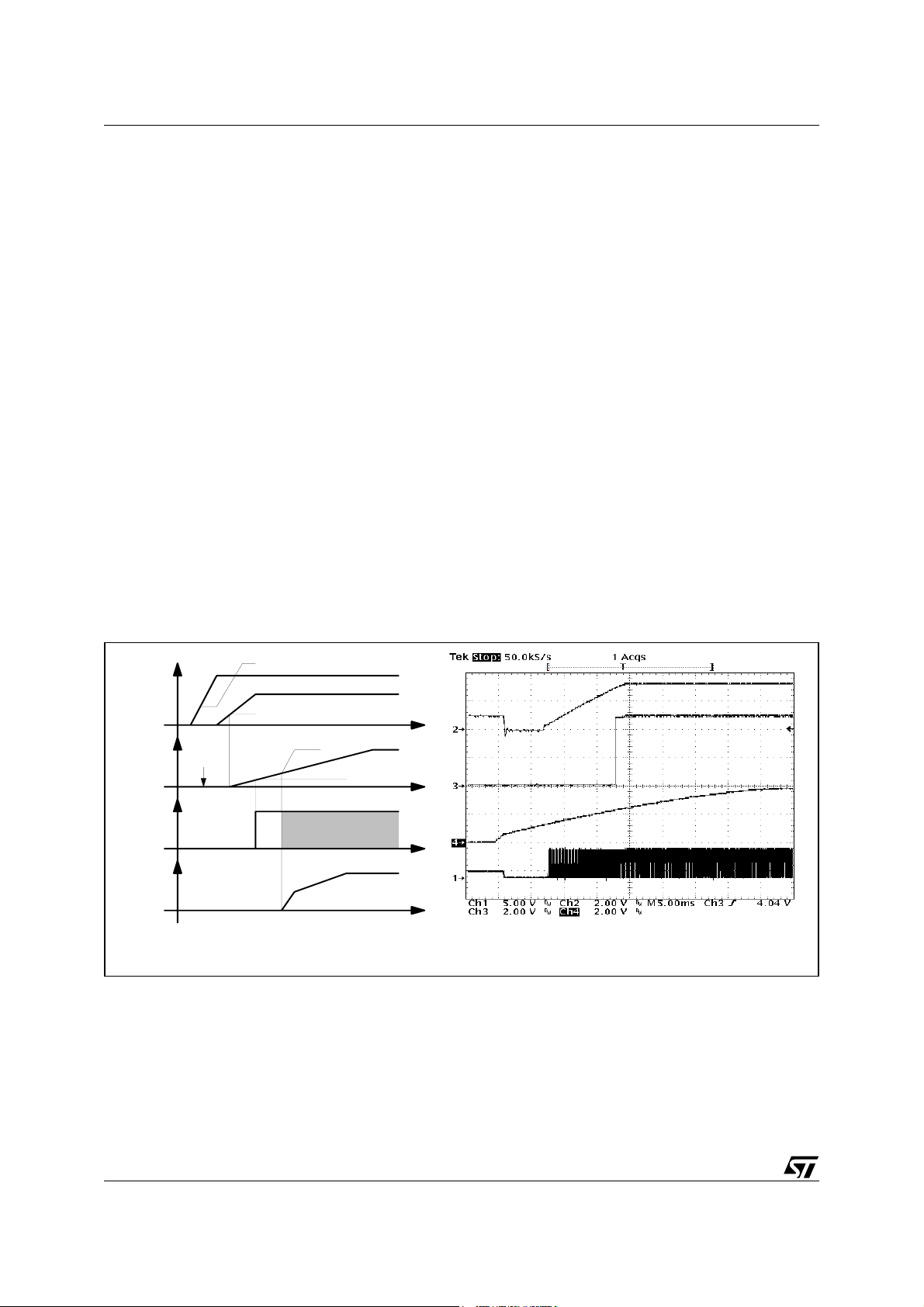

Figure 5. Soft Start (with Reference Present)

Vcc

Vin

Vss

LGATE

Vout

to GND

Vcc Turn-on threshold

Vin Turn-on threshold

1V

Timing Diagram

0.5V

Acquisition: CH1 = PHASE; CH2 = V

CH3 = PGOOD; CH4 = V

ss

out

;

4.4 Driver Section

The driver capability on the high and low side drivers allows using different types of power MOS (also multiple

MOS to reduce the R

), maintaining fast switching transition.

DSON

The low-side mos driver is supplied directly by Vcc while the high-side driver is supplied by the BOOT pin.

Adaptative dead time control is implemented to prevent cross-conduction and allow to use several kinds of mos-

fets. The upper mos turn-on is avoided if the lower gate is over about 200mV while the lower mos turn-on is

6/26

L6910G

avoided if the PHASE pin is over about 500mV. The lower mos is in any case turned-on after 200ns from the

high side turn-off.

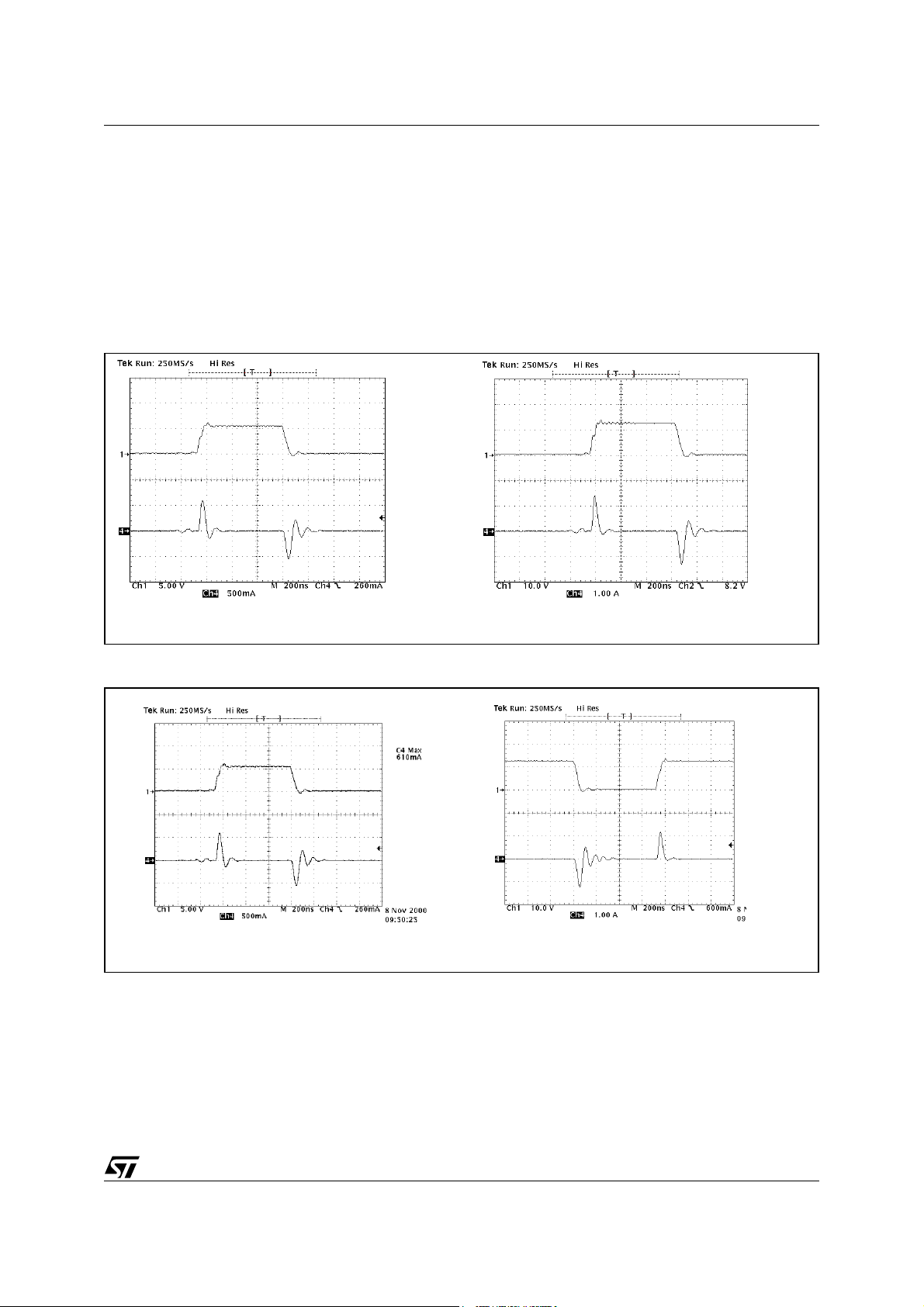

The peak current is shown for both the upper (fig. 6) and the lower (fig. 7) driver at 5V and 12V. A 3.3nF capacitive load has been used in these measurements.

For the lower driver, the source peak current is 1.1A @ V

current is 1.3A @ V

= 12V and 500mA @ VCC = 5V.

CC

Similarly, for the upper driver, the source peak current is 1.3A @ Vboot-Vphase = 12V and 600mA @ VbootVphase = 5V, and the sink peak current is 1.3A @ Vboot-Vphase =12V and 550mA @ Vboot-Vphase = 5V.

Figure 6. High Side Driver Peak Current. Vboot-Vphase = 12V (right) Vboot-Vphase = 5V (left)

= 12V and 500mA @ VCC = 5V, and the sink peak

CC

CH1 = High Side Gate CH4 = Gate Current

Figure 7. Low Side Driver Peak Current. VCC = 12V (right) VCC = 5V (left)

CH1 = Low Side Gate CH4 = Gate Current

4.5 Monitoring and Protections

The output voltage is monitored by means of pin FB. If it is not within ±10% (typ.) of the programmed value, the

powergood output is forced low.

The device provides overvoltage protection, when the voltage sensed on pin FB reaches a value 17% (typ.)

greater than the reference the OSC pin is forced high (3V typ.) and the lower driver is turned on as long as the

over-voltage is detected.

7/26

L6910G

µ

µ

µ

Overcurrent protection is performed by the device comparing the drop across the high side MOS, due to the

R

, with the voltage across the external resistor (R

DSON

upper MOS. Thus the overcurrent threshold (I

Where the typical value of I

R

(also the variation with temperature) and the minimum value of I

dsON

is 200µA. To calculate the R

OCS

) can be calculated with the following relationship:

P

I

P

overcurrent protection this relationship must be satisfied:

I

PIOUTMAX

∆

Where

I is the inductance ripple current and I

OUTMAX

In case of over current detectionthe soft start capacitor is discharged with constant current (10

the SS pin reaches 0.5V the soft start phase is restarted. During the soft start the over-current protection is always active and if such kind of event occurs, the device turns off both mosfets, and the SS capacitor is discharged again (after reaching the upper threshold of about 4V). The system is now working in HICCUP mode,

as shown in figure 8. After removing the cause of the over-current, the device restart working normally without

power supplies turn off and on.

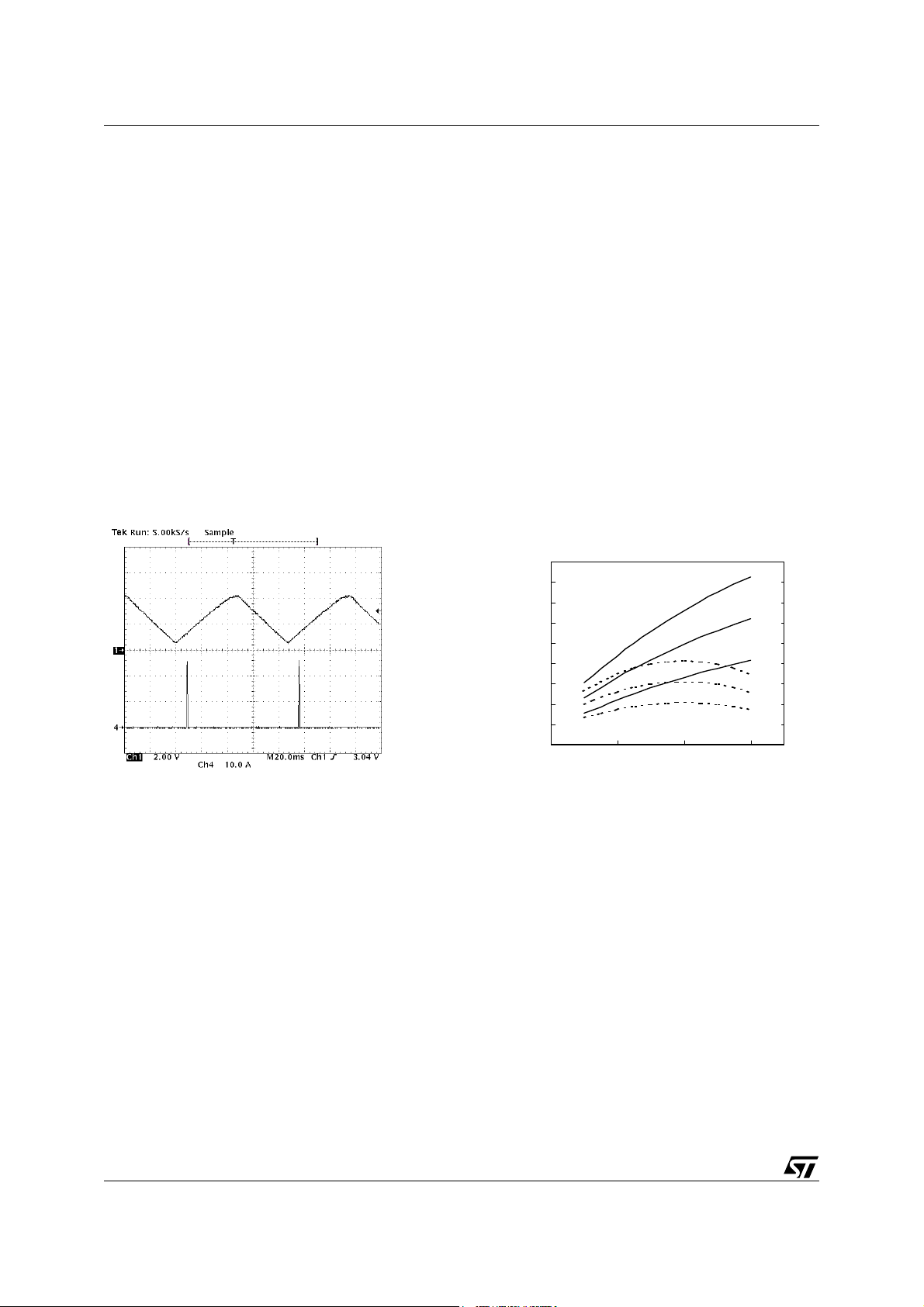

Figure 8. Hiccup Mode Figure 9. Inductor Ripple Current vs. Vout

) connected between the OCSET pin and drain of the

OCS

R

⋅

OCSIOCS

---------------------------------=

R

dsON

value it must be considered the maximum

I∆

=

-----+≥ I

2

OCS

PEAK

. To avoid undesirable trigger of

OCS

is the maximum output current.

µ

A typ.) and when

CH1 = SS; CH4 = Inductor current

9

8

7

6

5

4

3

2

Inductor Ripple [A]

1

0

0.5 1.5 2.5 3.5

Output V oltage [V]

L=1.5

H, Vin=12V

H, Vin=5V

L=3

L=2µH,

Vin=12V

L=3µH,

Vin=12V

L=1.5

Vin=5V

L=2µH,

Vin=5V

H,

4.6 Inductor Design

The inductance value is defined by a compromise between the transient response time, the efficiency, the cost

and the size. The inductor has to be calculated to sustain the output and the input voltage variation to maintain

the ripple current

∆

IL between 20% and 30% of the maximum output current. The inductance value can be cal-

culated with this relationship:

V

–

INVOUT

L

------------------------------

f

swIL

Where f

is the switching frequency, VIN is the input voltage and V

SW

the ripple current vs. the output voltage for different values of the inductor, with V

V

OUT

---------------⋅=

∆⋅

V

IN

is the output voltage. Figure 9 shows

OUT

= 5V and VIN = 12V.

IN

Increasing the value of the inductance reduces the ripple current but, at the same time, reduces the converter

response time to a load transient. If the compensation network is well designed, the device is able to open or

close the duty cycle up to 100% or down to 0%. The response time is now the time required by the inductor to

change its current from initial to final value. Since the inductor has not finished its charging time, the output current is supplied by the output capacitors. Minimizing the response time can minimize the output capacitance

required.

8/26

L6910G

The response time to a load transient is different for the application or the removal of the load: if during the application of the load the inductor is charged by a voltage equal to the difference between the input and the output

voltage, during the removal it is discharged only by the output voltage. The following expressions give approximate response time for

The worst condition depends on the input voltage available and the output voltage selected. Anyway the worst

case is the response time after removal of the load with the minimum output voltage programmed and the maximum input voltage available.

4.7 Output Capacitor

The output capacitor is a basic component for the fast response of the power supply. In fact, during load transient, for first few microseconds they supply the current to the load. The controller recognizes immediately the

load transient and sets the duty cycle at 100%, but the current slope is limited by the inductor value. The output

voltage has a first drop due to the current variation inside the capacitor (neglecting the effect of the ESL):

∆

I load transient in case of enough fast compensation network response:

t

application

LI∆⋅

------------------------------ t

V

–

INVOUT

removal

LI∆⋅

---------------==

V

OUT

∆ I

V

OUT

∆ ESR⋅=

OUT

A minimum capacitor value is required to sustain the current during the load transient without discharge it. The

voltage drop due to the output capacitor discharge is given by the following equation:

2

I

OUT

L

⋅

–⋅()⋅⋅

Where D

∆

OUT

is the maximum duty cycle value that is 100%. The lower is the ESR, the lower is the output drop

MAX

---------------------------------------------------------------------------------------------=

2C

OUTVINMINDMAXVOUT

V

∆

during load transient and the lower is the output voltage static ripple.

4.8 Input Capacitor

The input capacitor has to sustain the ripple current produced during the on time of the upper MOS, so it must

have a low ESR to minimize the losses. The rms value of this ripple is:

I

rmsIOUT

D1D–()⋅=

Where D is the duty cycle. The equation reaches its maximum value with D = 0.5. The losses in worst case are:

P ESR I

2

⋅=

rms

4.9 Compensation Network Design

The control loop is a voltage mode (figure 10). The output voltage is regulated to the input Reference voltage

level (EAREF). The error amplifier output V

a pulse-width modulated (PWM) wave with an amplitude of V

output filter. The modulator transfer function is the small-signal transfer function of V

has a double pole at frequency F

depending on the L-C

LC

output capacitor ESR. The DC Gain of the modulator is simply the input voltage V

oscillator voltage

∆

V

.

OSC

is then compared with the oscillator triangular wave to provide

COMP

at the PHASE node. This wave is filtered by the

IN

resonance and a zero at F

out

IN

OUT/VCOMP

ESR

divided by the peak-to-peak

. This function

depending on the

9/26

L6910G

Figure 10. Compensation Network

V

IN

∆V

OSC

PWM

COMPARATOR

C18

C19

R5

EAREF

V

COMP

-

The compensation network consists in the internal error amplifier and the impedance networks ZIN (R3, R4 and

C20) and Z

(R5, C18 and C19). The compensation network has to provide a closed loop transfer function with

FB

the highest 0dB crossing frequency to have fast response (but always lower than fsw/10) and the highest gain

in DC conditions to minimize the load regulation.

A stable control loop has a gain crossing with -20dB/decade slope and a phase margin greater than 45°. Include

worst-case component variations when determining phase margin.

To locate poles and zeroes of the compensation networks, the following suggestions may be used:

Modulator singularity frequencies:

ω

LC

1

--------------------------- ω

LC

⋅

OUT

ESR

L

V

OUT

ESR

C

OUT

R3

C20

R4

D03IN1512

1

---------------------------------==

ESR C

⋅

OUT

Compensation network singularity frequency:

ω

----------------------------------------------- ω

P1

R5

ω

------------------------ ω

Z1

R5 C19⋅

1

C18 C19⋅

⋅

-----------------------------

C18 C19+

1

Z2

P2

-------------------------------------------==

R3 R4+()C20⋅

– Put the gain R5/R3 in order to obtain the desired converter bandwidth;

– Place ω

– Place ω

– Place ω

– Place ω

before the output filter resonance ωLC;

Z1

at the output filter resonance ωLC;

Z2

at the output capacitor ESR zero ω

P1

at one half of the switching frequency;

P2

ESR

;

– Check the loop gain considering the error amplifier open loop gain.

1

------------------------==

R4 C20⋅

1

10/26

Figure 11. Asymptotic Bode Plot of Converter's Gain

ω

ω

ω

ω

ω

ω

ω

dB

Error Amplifier

R5/R3

L6910G

Ζ1

LC

Modulator Gain

Compensation Network Gain

Error Amplifier Closed Loop Gain

Ζ2

ESR

P1

P2

5 15A DEMO BOARD DESCRIPTION

The demo board shows the operation of the device in a general purpose application. This evaluation board allows voltage adjustability from 0.9V to 5V through the switches S2-S5 according to the reported table when the

internal 0.9V reference is used (G1 closed). Output current in excess of 20A can be reached dependently on

the kind of mosfet used: up to three SO8 mosfet may be used for both High side and Low side switches. External

reference may be used for the regulation simply leaving open G1 and the switches S2-S5. The device may also

be disabled with the switch S1. The V

the V

input rail. The device is also able to operate with a single supply voltage; in this case the jumper G2 has

IN

to be closed and a 5V to 12V input can be directly connected to the V

copper thickness is of 70

µ

m in order to minimize conduction losses considering the high current that the circuit

is able to deliver.The PGOOD signal is used as a logic level and it's been pulled up to V

other appropriate voltage available on the demo board.

Maximum Absolute Rating) a 5V reference is required.

Figure 12. 15A Demo Board Schematic

F1

VIN

GNDIN

VCC

GNDCC

REFIN

GNDREFIN

+VREF

GNDREF

G2

R6

C17

EAREF

C16

G1

C12

C21

R1

S1

S2

S3

S4

S5

R10

R11

SR12

SR13

input rail supplies the device while the power conversion starts from

CC

input. The four layers demo board's

IN

because there's no

IN

In case of input voltage higher than 7V (PGOOD Pin

Figure 12 shows the demo board's schematic circuit

L1

C1-C3

D2

R8

R9

C22

V

S2

OUT

Open Open OpenOpen

0.9

ON Open Open Open

1.2

1.5

1.8

ON ON Open Open

2.5

Open Open ON Open

3.3

Open Open Open ON

5.0

Open Open ON ON

L2

ONOpen

C4-

11

S3 S4 S5

Open Open

R2

V

OUT

GNDOUT

PWRGD

V

C15

GND

VREF

OSC

R7

D1

BOOT

OCSET

CC

SS

15

7

8

1

4

2

COMP

12

5

C19

R5

C18

D03IN1513

VFB

C14

C13

Q1-3

UGATE

3

11

PHASE

10

14

13

9

6

LGATE

PGND

PGOOD

R3

R4

Q4-6

C20

11/26

L6910G

Table 6. Part List

Reference Description Manufacturer

R1 N.C NEOHM

R2 10K 5% 125mW NEOHM SMD 0805

R3 4.7K 5% 125mW NEOHM SMD 0805

R4 1KOhm 5% 125mW NEOHM SMD 0805

R5 2.7K 5% 125mW NEOHM SMD 0805

R6 10Ohm 5% 125mW NEOHM SMD 0805

R7 510Ohm 5% 125mW NEOHM SMD 0805

R8 N.C

R9 0 Ohm SMD 0805

R10 14K 5% 125mW NEOHM SMD 0805

R11 6.98K 5% 125mW NEOHM SMD 0805

R12 2.61K 5% 125mW NEOHM SMD 0805

R13 1.74K 5 5% 125mW NEOHM SMD 0805

C1, C3 100µF - 20V OSCON 20SA100M RADIAL 10X10.5

C9, C10 330µF - 6.3V POSCAP 6TPB330M SMD7343

C12, C13,

C15, C21

C14 1nF KEMET SMD0805

C16 100nF KEMET

C17 4.7µF - 16V AUX SMA6032

C18 1.5nF KEMET SMD0805

C19 15nF KEMET SMD0805

C20 47nF KEMET SMD0805

C22 N.C

L1 Short

L2 3µH (T50-52B Core, 7T AWG15) MICROMETALS

Q2,Q3,Q4,Q6 STS11NF30L ST SO8

D1 1N4148 SOT23

D2 STPS2L25U ST SMB

U1 Device L6910G ST SO16Narrow

F1 Short

SWITCH DIP SWITCH 6 POS.

100nF KEMET SMD0805

Table 7. Other Inductor Manufacturer

Manufacturer Series Inductor Value (µH) Saturation Current (A)

WÜRTH ELEKTRONIK 744318 1.8 to 2.7 16 to 20

PANASONIC ETQP6F1R8FA 1.8 20

SUMIDA CDEP134-2R7MC-H 2.7 15

12/26

Figure 13. PCB and Components Layouts

Component Side Internal Signal GND Layer

Figure 14. PCB and Components Layouts

L6910G

Internal Power GND Layer Solder Side

Figure 15. Efficiency vs Output Current

100

100

95

95

90

90

85

85

Efficiency (%)

Efficiency (%)

Vin=Vcc=5V

80

80

75

75

1357 911131517

1357 911131517

Vin=Vcc=5V

Fsw=200KHz

Fsw=200KHz

Output Current (A)

Vo=3.3V

Vo=3.3V

Vo=2.5V

Vo=2.5V

Vo=1.8V

Vo=1.8V

Vo=1.5V

Vo=1.5V

Vo=1.2V

Vo=1.2V

Vo=0.9V

Vo=0.9V

13/26

L6910G

Figure 16. Efficiency vs Output Current

100

95

90

85

80

75

Efficiency (%)

70

65

60

55

50

1357911131517

Vin=Vcc=12V

Vin=Vcc=12V

Fsw.=200KHZ

Fsw.=200KHZ

Output Current (A)

Output Current (A)

Vo=5V

Vo=5V

Vo=3.3V

Vo=3.3V

Vo=1.5V

Vo=1.5V

Vo=1.8V

Vo=1.8V

Vo=2.5V

Vo=2.5V

Vo=1.2V

Vo=1.2V

Vo=0.9V

Vo=0.9V

6 COMPONENTS SELECTION

6.1 Inductor Selection

To select the right inductor value, the application conditions must be fixed. For example we can consider:

Vin=12V Vout =3.3V Iout=15A

Considering a ripple of approximately 25% to 30% of Iout, the inductor value will be L=3

An iron powder core (TO50-52B) with 7 windings has been chosen.

µ

H.

6.2 Output Capacitors

2 POSCAP capacitors, model 6TPB330M, have been chosen, with a maximum ERS equal to 40mΩ each.

Therefore, the resultant ESR is of 20m

Ω

. Considering a current ripple of 4A, the output voltage ripple is:

∆

Vout = 4 · 0.02 = 80mV

6.3 Input Capacitors

For I

= 15A and D = 0.5 (worst case for input current ripple), the RMS current of the input capacitor is equal

OUT

to 7.5A.

Two OSCON electrolytic capacitors 6SP680M, with a maximum ESR equal to 13m

tain the ripple. Therefore, the resultant ESR is equal to 13m

P = ESR · I

Ω

/2 = 6.5mΩ. The losses, in worst case, are:

2

rms = 366mW

Ω

, have been chosen to sus-

6.4 Over-Current Protection

The current limit can be set to approximately 20A. Substituting the demo board parameters in the relationship reported in the relative section, (I

that R

OCS

= 510Ω

OSCMIN

=170µA; IP = 20A; R

DSONMAX

= 9mΩ / 2=4.5mΩ) it results

14/26

L6910G

6.5 APPLICATION SUGGESTIONS FOR HIGHER CURRENTS

For higher output currents, up to 20A, the following configuration can be used (with reference to the demo board

schematic):

Q1,Q2,Q3: STS11NF30L

Q4,Q5,Q6: STS17NF3LL

L: 2.5

µ

H Magnetic 77121A7 Core 7T 2x AWG16

In these conditions, the following performance have been achieved:

Table 8.

V

(V) V

IN

5 1.2 20 81 12 1.2 20 80

5 1.5 20 83 12 1.5 20 83

5 1.8 20 85 12 1.8 20 85

5 2.5 20 89 12 2.5 20 88

5 3.3 20 91 12 3.3 20 91

For currents higher than 20A, bigger mosfets should be selected (e.g. STS25NH3LL) both for the high side and

low side (depending on the duty cycle and input voltage).

OUT

(V) I

OUT

(A)

η (%)

V

(V) V

IN

OUT

(V) I

OUT

(A)

12 5 20 93

η (%)

7 6A DEMO BOARD DESCRIPTION

A compact demo board has been realized to manage currents in the range of 5A-6A .

The external power mosfets are included in a single SO8 package to save space and increase power density.

Two separate rails are provided, for V

The PGOOD signal is used as a logic level and it's been pulled up to V

voltage available on the demo board.

solute Rating) a 5V reference is required.

Figure 17. 6A Demo Board Schematic

VIN

VIN

GNDIN

GNDINGNDIN

VCC

VCC

GNDCC

GNDCC

J1

J1

R6

R6

C5

C5

C9

C9C9

C8

C8

R10

R10

and VIN. They can be connected together by shorting the jumper J1.

CC

because there's no other appropriate

IN

In case of input voltage higher than 7V (PGOOD Pin Maximum Ab-

R7

R7

C7

C7

D1

D1

VCC

VCC

GND

GND

OSC

OSC

EAREF

EAREF

OCSET

OCSET

BOOT

BOOT

12

12

3

U1

U1

L6910

L6910

5

5

C19

C19

C18

C18

3

R5

R5

15

15

7

7

SS

SS

4

4

2

2

8

8

COMP

COMP

C6

C6

R8

R8

UGATE

UGATE

11

11

PHASE

PHASE

10

10

LGATE

LGATE

14

14

PGND

PGND

13

13

PGOOD

PGOOD

9

9

VREF

VREF

1

1

6

6

VFB

VFB

Q1/Q1

Q1/Q1

R9

R9

Q2/Q1

Q2/Q1

R3

R3

C20

C20C20

R4

R4R4

R11

R11

D2

D2

C10

C10

C1- C2

C1- C2

L1

L1

C3-4

C3-4

VOUT

VOUT

R2

R2

GNDOUT

GNDOUT

PWRGD

PWRGD

R1

R1

15/26

L6910G

Table 9. Part List

Reference Description Manufacturer

Resistor

R1 2K7 Ohm 0805 5% 125mW NEOHM (Vout = 2.5V)

1K8 Ohm 0805 5% 125mW NEOHM (Vout = 3.3V)

1K Ohm 0805 5% 125mW NEOHM (Vout = 5V)

R2 10K 5% 125mW NEOHM SMD 0805

R3 4K7 5% 125mW NEOHM SMD 0805

R4 4K7 5% 125mW NEOHM SMD 0805

R5 2K7 5% 125mW NEOHM SMD 0805

R6 10 Ohm 5% 125mW NEOHM SMD 0805

R7 680 Ohm 5% 125mW NEOHM SMD 0805

R8 R9 2.2 Ohm 5% 125mW NEOHM SMD 0805

R10 N.C

R11 N.C

Capacitors

C1,C2 10µF 25V TOKIN C34Y5U1E106ZTE12

C3,C4 100µF - 6.3V POSCAP 6TPB100M SMD7343

C5,C6,C9 100nF KEMET SMD0805

C7,C8 1nF KEMET SMD0805

C10 N.C

C18 1.5nF KEMET SMD0805

C19 15nF KEMET SMD0805

C20 47nF KEMET SMD0805

Magnetics

L1 7µH (T50-52B Core, 12T AWG 21) MICROMETALS

Transistor

Q1 STS8DNF3LL ST

Diodes

D1 1N4148 SOT23

D2 STPS2L25U ST SMB

Device

U1 Device L6910G ST SO16Narrow

Table 10. Other inductor manufacturer

Manufacturer Series Inductor Value (µH) Saturation Current (A)

WÜRTH ELEKTRONIK 744 382 4.8 to 5.8 7.5 to 8

PANASONIC ETQP6F 4.6 to 6.4 9.3 to 7.9

SUMIDA CDEP134-H 6 to 8 7.2 to 9.6

COILCRAFT DO3316P-472HC 4.7 5.4

DO3340P 10 to 22 8 to 5.5

COILTRONICS DR125-8R2 8.2 7.8

16/26

L6910G

Figure 18. PCB and Components Layouts

Component Side Solder Side

7.1 Compact Demo Board Performances

Figures 19, 20 show the measured efficiency versus load current for different values of output voltage. The measure has been done at 5V and 12V input. Output voltage has been changed modifying the value of R1 in the

demo board as reported in the part list.

Figure 19. Efficiency vs. Output Current

100

100

95

95

90

90

85

85

80

80

Efficiency (%)

Efficiency (%)

Vin=Vcc=5V

Vin=Vcc=5V

75

75

Fsw=200KHz

Fsw=200KHz

70

70

12345678

12345678

Figure 20. Efficiency vs. Output Current

95

95

90

90

85

85

80

80

Efficiency (%)

Efficiency (%)

Vin=Vcc=12V

75

75

70

70

Vin=Vcc=12V

Fsw=200KHz

Fsw=200KHz

12345678

12345678

Output Current (A)

Output Current (A)

Output Current (A)

Output Current (A)

Vo=5V

Vo=5V

Vo=3.3V

Vo=3.3V

Vo=2.5V

Vo=2.5V

Vo=1.8V

Vo=1.8V

Vo=1.5V

Vo=1.5V

Vo=1.2V

Vo=1.2V

Vo=3.3V

Vo=3.3V

Vo=2.5V

Vo=2.5V

Vo=1.8V

Vo=1.8V

Vo=1.5V

Vo=1.5V

Vo=1.2V

Vo=1.2V

17/26

L6910G

8 APPLICATION IDEA 1: DDR MEMORY AND TERMINATION SUPPLY

Double Data Rate (DDR) Memories require a particular Power Management Architecture. This is due to the fact

that the trace between the driving chipset and the memory input must be terminated with resistors.

Since the Chipset driving the Memory has a push pull output buffer, the Termination voltage must be capable

of sourcing and sinking current.

Moreover, the Termination voltage must be equal to one half of the memory supply (the input of the memory is

a differential stage requiring a reference bias midpoint) and in tracking with it. For DDRI the Memory Supply is

2.5V and the Termination voltage is 1.25V while, for DDRII, the Memory Supply is 1.8V and the Termination

voltage is 0.9V. Fig. 23 shows a complete DDRI Memory and Termination Power Supply realized by using 2 x

L6910G. The 2.5V section is powering the memory while the 1.25V section is providing the termination voltage.

The tracking between the two sections is realized by providing the EAREF voltage of the 1.25V section through

a resistor divider connected to the 2.5V.

Figure 21. Application idea : DDR Memory Supply

VIN

VIN

VIN

12V

12V

12V

BOOT

BOOT

BOOT

OCSET

OCSET

OCSET

12

12

12

3

3

VCC

VCC

VCC

GND

GND

GND

OSC

OSC

OSC

EAREF

EAREF

EAREF

3

UGATE

UGATE

UGATE

11

11

11

15

15

15

PHASE

PHASE

PHASE

10

10

10

7

7

7

SS

SS

SS

4

4

4

2

2

2

8

8

8

5

5

5

COMP

COMP

COMP

U1

U1

U1

L6910

L6910

L6910

VFB

VFB

VFB

LGATE

LGATE

LGATE

14

14

14

13

13

13

PGOOD

PGOOD

PGOOD

9

9

9

VREF

VREF

VREF

1

1

1

6

6

6

STS11NF3LL

STS11NF3LL

STS11NF3LL

PGND

PGND

PGND

STS11NF3LL

STS11NF3LL

STS11NF3LL

V

V

V

DDQ

DDQ

DDQ

2.5V@15A

2.5V@15A

2.5V@15A

PWRGD

PWRGD

PWRGD

MEMORY

MEMORY

MEMORY

TERMIN ATION

TERMIN ATION

TERMIN ATION

NETWORK

NETWORK

NETWORK

DDR

DDR

DDR

VREF

VREF

VREF

BUS

BUS

BUS

VIN

VIN

VIN

12V

12V

12V

STS8DNF3LL

STS8DNF3LL

BOOT

BOOT

BOOT

OCSET

OCSET

OCSET

3

3

3

12

12

12

VCC

VCC

VCC

15

15

15

GND

GND

GND

7

7

7

SS

SS

SS

4

4

EAREF

EAREF

EAREF

4

OSC

OSC

OSC

2

2

2

8

8

8

5

5

5

COMP

COMP

COMP

-

-

+

+

+

R

R

R

R

R

R

U2

U2

U2

L6910

L6910

L6910

UGATE

UGATE

UGATE

11

11

11

PHASE

PHASE

PHASE

10

10

10

LGATE

LGATE

LGATE

14

14

14

PGND

PGND

PGND

13

13

13

PGOOD

PGOOD

PGOOD

9

9

9

VREF

VREF

VREF

1

1

1

6

6

6

VFB

VFB

VFB

STS8DNF3LL

V

V

V

TT

TT

TT

1.25V@ - 5A

1.25V@ - 5A

1.25V@ - 5A

PWRGD

PWRGD

PWRGD

CHIPSET

CHIPSET

CHIPSET

+

+

+

The current required by the memory and the termination supply, depends on the memory type and size.

The figure 22, 23 shows the efficiency of the L6910G for the termination section of the application shown in fig.

21, in sink and source mode. The figures show the efficiency values also when the input voltage is coming directly from the 12V rail.

18/26

L6910G

Figure 22. Efficiency vs Output Current Source

Mode

95

95

95

90

90

90

85

85

85

80

80

80

75

75

75

Efficiency (%)

Efficiency (%)

Vcc=12V

Vcc=12V

70

70

70

Vout=1.25V

Vout=1.25V

Fsw=200KHz

Fsw=200KHz

65

65

65

60

60

60

1234567

1234567

1234567

Output Current (A)

Output Current (A)

Vin=12V

Vin=12V

Vin=2.5V

Vin=2.5V

8

8

8

Figure 23. Efficiency vs Output Current Sink

Mode

95

95

90

90

85

85

Vin=2.5V

Vin=2.5V

Vin=12V

Vin=12V

Vin=12V

Vin=2.5V

80

80

75

75

Efficiency (%)

Efficiency (%)

Efficiency (%)

70

70

Vcc=12V

Vcc=12V

Vcc=12V

Vout=1.25V

Vout=1.25V

Vout=1.25V

65

65

Fsw=200KHz

Fsw=200KHz

Fsw=200KHz

60

60

12345678

12345678

Output Current (A)

Output Current (A)

Output Current (A)

For very big systems (e.g. servers), the DDR memory

termination can require much higher currents, in the

range of 10A-15A and more.

Figures 24, 25 and 26, 27 show the efficiency of the

L6910G in sink and source mode, up to 17A both for

DDRI and DDRII memories.The measurements have

been realized with the 15A demo board. (See pag.11 )

Figure 24. Efficiency vs Output Current Sink

Mode

100

100

100

90

90

90

80

80

80

70

70

70

Efficiency (%)

Efficiency (%)

Efficiency (%)

Efficiency (%)

60

60

60

50

50

50

1 3 5 7 9 11 13 15 17

1 3 5 7 9 11 13 15 17

1 3 5 7 9 11 13 15 17

Vin=12V

Vin=12V

Vin=12V

Vin=12V

Vin=12V

Vin=12V

Vcc=12V

Vcc=12V

Vcc=12V

Vcc=12V

Vout=1.25V

Vout=1.25V

Vout=1.25V

Vout=1.25V

Fsw=200KHz

Fsw=200KHz

Fsw=200KHz

Fsw=200KHz

Output Current (A)

Output Current (A)

Output Current (A)

Output Current (A)

Vin=2.5V

Vin=2.5V

Vin=2.5V

Vin=2.5V

Figure 25. Efficiency vs Output Current Sink

Mode

100

100

100

100

90

90

90

90

Vin=1.8V

Vin=1.8V

Vin=12V

Vin=12V

Vin=12V

Vin=1.8V

80

80

80

80

70

70

70

70

60

60

60

60

Efficiency (%)

Efficiency (%)

Vcc=12V

Vcc=12V

Vcc=12V

Vout=0.9V

Vout=0.9V

Vout=0.9V

50

50

50

50

Fsw=200KHz

Fsw=200KHz

Fsw=200KHz

40

40

40

40

1357911131517

1357911131517

1357911131517

1357911131517

Output Current (A)

Output Current (A)

Figure 26. Efficiency vs Output Current Source

Mode

100

100

Vout=2.5V

90

90

80

80

70

70

Efficiency (%)

Efficiency (%)

Vcc=12V

Vcc=12V

Vout=1.25V

Vout=1.25V

60

60

Fsw=200KHz

Fsw=200KHz

50

50

1 3 5 7 9 11 13 15 17

1 3 5 7 9 11 13 15 17

Output Current (A)

Output Current (A)

Vout=2.5V

Vout=12V

Vout=12V

Figure 27. Efficiency vs Output Current Source

Mode

100

100

100

90

90

90

80

80

80

70

70

70

Efficiency (%)

Efficiency (%)

Vin=12V

Vin=12V

Vin=12V

60

60

60

Vout=0.9V

Vout=0.9V

Vout=0.9V

Fsw=200KHz

Fsw=200KHz

Fsw=200KHz

50

50

50

1357911131517

1357911131517

1357911131517

Output Current (A)

Output Current (A)

Vin=1.8V

Vin=1.8V

Vin=1.8V

Vin=12V

Vin=12V

Vin=12V

19/26

L6910G

9 APPLICATION IDEA 2: POSITIVE BUCK-BOOST REGULATOR 3V TO 13.2V

INPUT / 5V 2.5A OUTPUT

In some applications the input voltage changes in a very wide range while the output must be regulated to a

fixed value. In this case a Buck-Boost topology can be required in order to keep the output voltage in regulation.

The schematic below shows how to implement a Buck-Boost regulating 5V at the output from both 3.3V and 5V

and 12V input buses.

In a Buck-Boost topology the current is delivered to the output during the OFF phase only. So, for a given current

limit, the maximum output current depends strongly on the duty cycle. Assuming a 100% efficiency and neglecting the current ripple across the inductor, the relationship betweent the current limit and the maximum output

current is the following:

Where I

is the current limit and D is the duty cycle of the application.

LIM

The worst case is with D

The worst case is with V

I

OMAXILIM

. Since, in a Buck-Boost application, D is given by the following formula:

MAX

D

.

INMIN

V

-----------------------=

VINVO+

1D–()⋅=

O

Obviously, since the efficiency is lower than 100% and the ripple is usually not negligible, the maximum output

current is always lower than the value calculated in the above formula

Figure 28. Positive buck-boost regulator 3V to 13.2V input / 5V 2.5A Output Circuit

VIN (3.3V-5V-12V BUSES)

VIN (3.3V-5V-12V BUSES)

C3

C3

R1

GNDIN

GNDINGNDIN

VCC (12V BUS)

VCC (12V BUS)

GNDCC

GNDCCGNDCC

G1

G1

D1

D1

R7

R7

C6

C6

C8

C8

VCC

VCC

C5

C5

GND

GND

SS

SS

OSC

OSC

EAREF

EAREF

C7

C7C7

BOOT

BOOT

12

12

15

15

7

7

U1

U1

4

4

L6910/A

L6910/A

2

2

8

8

5

5

COMP

COMP

C9

C9

C10

C10

R1

C4

C4

OCSET

OCSET

3

3

R5

R5

UGATE

UGATE

11

11

PHASE

PHASE

10

10

LGATE

LGATE

14

14

PGND

PGND

13

13

PGOOD

PGOOD

9

9

VREF

VREF

1

1

6

6

VFB

VFB

C12

C12

Q1

Q1

D2

Q2

Q2Q2

D2

R3

R3

C11

C11

R4

R4

C1- C2

C1- C2

Q4

L1

L1

Q4

Q3

Q3

C13

C13

C13

VOUT ( 5V 2.5A )

VOUT ( 5V 2.5A )

R2

R2

-14

-14

-14

GNDOUT

GNDOUT

20/26

R6

R6

Table 11. Part List

Reference Description Manufacturer

R1 910 Ohm 5% 125mW NEOHM SMD 0805

R2 10K 5% 125mW NEOHM SMD 0805

R3 4.7K 5% 125mW NEOHM SMD 0805

R4 1K 5% 125mW NEOHM SMD 0805

R5 2.7K 5% 125mW NEOHM SMD 0805

R6 1K1 NEOHM SMD 0805

R7 10 Ohm 125mW NEOHM SMD 0805

C1,C2 100µF - 20V OSCON 20SA100M RADIAL 10X10.5

C13,C14 330µF - 6.3V POSCAP 6TPB330M SMD7343

C12,C5,C8 100nF KEMET SMD0805

C3 1nF KEMET SMD0805

C4 470nF KEMET SMD0805

C6 4.7µF - 16V AUX SMA6032

C7 100nF KEMET

C9 15nF KEMET SMD0805

C10 1.5nF KEMET SMD0805

C11 47nF KEMET SMD0805

G1 Open Jumper

L1 2.5µH

(77121A7 Core, Double winding 7 AWG16)

Q1,Q2,Q3 STS11NF30L ST SO8

Q4 STS5P30L ST SO8

D1 1N4148 SOT23

D2 STPS3L25U (STPS340U) ST SMB (D0144)

U1 Device L6910G ST SO16 Narrow

MAGNETICS

L6910G

Figure 29. Efficiency vs. Output Current

90

90

Vin=5V

85

85

80

80

75

75

Efficiency (%)

Efficiency (%)

Vcc=5V

Vcc=5V

70

70

Vout=5V

Vout=5V

Fsw=200KHz

Fsw=200KHz

65

65

11.522.533.5

11.522.533.5

Vin=5V

Vin=3.3V

Vin=3.3V

Output Current (A)

Output Current (A)

Vin=12V

Vin=12V

21/26

L6910G

10 APPLICATION IDEA 3: BUCK-BOOST REGULATOR 3V TO 5.5V INPUT/-5V

3A OUTPUT

In applications where a negative output voltage is required, a standard Buck-Boost topology can be implemented. The considerations related to the maximum output current are the same of the "Positive Buck-Boost" (Application Idea 2).

A particularity of this topology is that the device undergoes a voltage that is the sum of V

verting 5V to -5V, the device undergoes 10V voltage. It must be checked that the sum of the input and output

voltage is lower than the maximum operating input voltage of the device.

Figure 30. buck-boost regulator 3V to 5.5V input / -5V 3A Output Circuit

VIN (3V to 5.5V )

VIN (3V to 5.5V )

VIN (3V to 5.5V )

GNDIN=GNDOUT

GNDIN=GNDOUT

GNDIN=GNDOUT

VCC (5V)

VCC (5V)

VCC (5V)

GNDCC

GNDCC

GNDCC

G1

G1

G1

D1

D1

D1

R7

R7

R7

VCC

VCC

VCC

C5

C5

C6

C6

C6

C8

C8

C8C8

C5

GND

GND

GND

SS

SS

SS

OSC

OSC

OSC

EAREF

EAREF

EAREF

C7

C7

C7C7

BOOT

BOOT

BOOT

12

12

12

15

15

15

7

7

7

U1

U1

U1

4

4

4

L6910/A

L6910/A

L6910/A

2

2

2

8

8

8

5

5

5

COMP

COMP

COMP

C9

C9

C9

C10

C10

C10

R1

R1

R1

C3

C3

C3

C4

C4

C4

OCSET

OCSET

OCSET

3

3

3

R5

R5

R5

UGATE

UGATE

UGATE

11

11

11

PHASE

PHASE

PHASE

10

10

10

LGATE

LGATE

LGATE

14

14

14

PGND

PGND

PGND

13

13

13

PGOOD

PGOOD

PGOOD

9

9

9

VREF

VREF

VREF

1

1

1

6

6

6

VFB

VFB

VFB

C12

C12

C12C12

Q1

Q1

Q1

D2

D2

C11

C11

C11

D2

Q2

Q2

Q2

R3

R3

R3

R4

R4

R4

L1

L1

L1

C1- C2

C1- C2

C1- C2C1- C2

and V

IN

C13-14

C13-14

C13-14

. So, con-

OUT

GNDOUT

GNDOUT

GNDOUTGNDOUT

VOUT (-5V 3A)

VOUT (-5V 3A)

VOUT (-5V 3A)

R6

R6

R6

Table 12. Part List

Reference Description Manufacturer

R1 910 Ohm 5% 125mW NEOHM SMD 0805

R2 10K 5% 125mW NEOHM SMD 0805

R3 4.7K 5% 125mW NEOHM SMD 0805

R4 1K Ohm 5% 125mW NEOHM SMD 0805

R5 2.7K 5% 125mW NEOHM SMD 0805

R6 1K 5% 125mW NEOHM SMD 0805

R7 10 Ohm 5% 125mW NEOHM SMD 0805

C1,C2 100µF - 20V OSCON 20SA100M RADIAL 10X10.5

C13,C14 330µF - 6.3V POSCAP 6TPB330M SMD7343

C12,C4,C5,C8 100nF KEMET SMD0805

C3 1nF KEMET SMD0805

C6 4.7µF - 16V AUX SMA6032

C7 100nF KEMET

22/26

Table 12. Part List (continued)

C9 15nF KEMET SMD0805

C10 1.5nF KEMET SMD0805

Reference Description Manufacturer

C11 47nF KEMET SMD0805

G1 Open Jumper

L1 2.5µH (77121A7 Core, Double winding 7 AWG16) MAGNETICS

Q1,Q2 STS11NF30L ST SO8

D1 1N4148 SOT23

D2 STPS3L25U ( STPS340U) ST SMB (D0144)

U1 Device L6910G ST SO16 Narrow

Figure 31. Efficiency vs. Output Current

94

94

92

92

90

90

Vin=5V

Vin=5V

L6910G

88

88

Vin=3.3V

86

86

Efficiency (%)

Efficiency (%)

Vcc=5V

Vcc=5V

84

84

Vout=

Vout=

-5V

-5V

Fsw=200KHz

Fsw=200KHz

82

82

11.522.53

11.522.53

Output Current (A)

Output Current (A)

Vin=3.3V

23/26

L6910G

Figure 32. SO-16 (Narrow) Mechanical Data & Package Dimensions

DIM.

A 1.75 0.069

a1 0.1 0.25 0.004 0.009

a2 1.6 0.063

b 0.35 0.46 0.014 0.018

b1 0.19 0.25 0.007 0.010

C 0.5 0.020

c1 45° (typ.)

(1)

D

E 5.8 6.2 0.228 0.244

e 1.27 0.050

e3 8.89 0.350

(1)

F

G 4.60 5.30 0.181 0.208

L 0.4 1.27 0.150 0.050

M 0.62 0.024

S8° (max.)

(1) "D" and "F" do not include mold flash or protrusions - Mold

flash or protrusions shall not exceed 0.15mm (.006inc.)

mm inch

MIN. TYP. MAX. MIN. TYP. MAX.

9.8 10 0.386 0.394

3.8 4.0 0.150 0.157

OUTLINE AND

MECHANICAL DATA

SO16 (Narrow)

24/26

0016020 D

Table 1. Revision History

Date Revision Description of Changes

May 2005 1 First Issue

L6910G

25/26

L6910G

Information furnished is believed to be accurate and reliable. However, STMicroelectronics assumes no responsibility for the consequences

of use of such information nor for any infringement of patents or other rights of third parties which may result from its use. No license is granted

by implication or otherwise under any patent or patent rights of STMicroelectronics. Specifications mentioned in this publication are subject

to change without notice. This publication supersedes and replaces all information previously supplied. STMicroelectronics products are not

authorized for use as critical components in life support devices or systems without express written approval of STMicroelectronics.

The ST logo is a registered trademark of STMicroelectronics.

All other names are the property of their respective owners

© 2005 STMicroelectronics - All rights reserved

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

STMicroelectronics group of companies

www.st.com

26/26

Loading...

Loading...