Highly integrated ballast controller for TL and CFL

Features

■ Half bridge circuit able to drive both BJT and

MOSFET transistors

■ Very accurate oscillator precision in wide

operating temperature range

■ BJTs' storage time compensation

■ Preheated start and instant start

■ Hard switching protection

■ Overcurrent / voltage protection

■ Choke saturation control

■ End-of-life protection

■ Programmable without capacitors

L6520

L6521

SO8

Applications

■ Electronic ballasts (TL, Industrial CFL)

■ Integrated CFLs

Table 1. Device summary

Order codes Package Packaging

L6520

Tube

Figure 1. Block diagram

3:0BGHW

9

9

(2/

)35(

9

9FF

X$

L6520TR Tape and reel

SO8

L6521 Tube

L6521TR Tape and reel

9&&

9FF

6WDUW8S 89/2

9

,1

9

$'&

9

,QWHUQDO9

/2*,&

9

9

5HJ

&25(

&&&%ORFN

9FF

7[0 7[/7[+

7KUHVKROG08;

+6'

/6'

+%&6

*1'

March 2011 Doc ID 16998 Rev 3 1/19

www.st.com

19

Contents L6520, L6521

Contents

1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2 Pin connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3 Maximum ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

4 Electrical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

5 Functions description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

5.1 Start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

5.2 Preheating and instant start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

5.3 Ignition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

5.4 Run mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

5.5 Storage time compensation network . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

5.6 Current control circuit (CCC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

5.6.1 Hard switching protection (HSP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

5.6.2 Overcurrent protection (OCPH) during ignition mode . . . . . . . . . . . . . . 11

5.6.3 Overcurrent protection (OCPL) during run mode . . . . . . . . . . . . . . . . . . 11

5.6.4 Choke saturation control (CSC) during ignition and run mode . . . . . . . 12

5.7 End of life (EOL) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5.8 Summary of protections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

6 Typical electrical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

7 Application examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

8 Package mechanical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

9 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2/19 Doc ID 16998 Rev 3

L6520, L6521 Description

1 Description

The L6520/1 is the first highly integrated ballast controller in the market able to drive both

BJTs and MOSFETs, providing all the necessary protections to ensure the maximum

reliability of the application in compliance with major safety and power consumption

regulations.

By adopting BJTs switches in the application, the IC allows to replace more expensive

MOSFETs, strongly reducing the system cost without compromises.

The IC represents also the best and cost effective solution to replace self oscillating

solutions when the key requirement is the reliability of the ballast. The benefits are an

increased MTBF and a reduction of the costs due to the return from the field.

The higher level of flexibility and integration provided allows the possibility to quickly design

ballast with any kind of lamp topology/size/power, without limitations. Depending on the

power of the lamp, the IC can work without PFC, with passive PFC or with active PFC. In the

latter case the L6562A from STMicroelectronics is the suggested IC for the most cost

effective solution.

The IC is fully programmable using only resistors and offers over current protections, choke

saturation control and hard switching protection thanks to a sophisticated current control

circuit (CCC). In ignition, the CCC limits both the maximum lamp voltage in case of old or

broken lamp, and also the lamp current in case of inductor saturation.

When the IC is driving bipolar transistors, a variable dead time ensures the correct base

discharge time avoiding cross conduction phenomena. Moreover, the IC prevents the failure

due to the lamp's end of life (EOL).

Doc ID 16998 Rev 3 3/19

Pin connection L6520, L6521

2 Pin connection

Figure 2. Pin connection

)35(

(2/

+%&6

3:0BGHW

9&&

+6'

/6'

*1'

Table 2. Pin description

Symbol Pin Description

FPRE 1 Preheating frequency programming and ignition modes selection

EOL 2 Window comparator input

HBCS 3 Current sensing input

PWM_det 4 Half bridge middle point monitor

GND 5 IC power and signal ground

LSD 6 Low side driver output

HSD 7 High side driver output

VCC 8 Power supply

4/19 Doc ID 16998 Rev 3

L6520, L6521 Maximum ratings

3 Maximum ratings

Table 3. Absolute maximum ratings

Symbol Pin Parameter Conditions Value Unit

Active clamp protection must not be supplied

by a low impedance voltage source

V

V

OD1

OD2

= VCC – V

= V

OUT –

OUT

GND

(1)

(1)

18.5 V

18.5 V

18.5 V

V

V

V

V

1. V

V

Z

I

VCC

V

OD1

V

OD2

V

FPRE

V

FPRE

PWM_det

PWM_det

V

HBCS

V

HBCS

EOL,max

EOL,min

OUT

8 Active clamp protection voltage

8 Active clamp protection current During low consumption state 2 mA

Differential voltage between

6,7

driver output and V

Differential voltage between

6,7

driver output and GND

CC

1 FPRE positive voltage 5 V

1 FPRE negative voltage -0.3 V

4 PWM_det pin positive voltage PWM_det input current < 5mA 5.1 V

4 PWM_det pin negative voltage PWM_det output current < 0.1mA -0.3 V

3 HBCS positive voltage 5 V

3 HBCS negative voltage HBCS output current < 2mA -5 V

2 EOL positive voltage EOL input current < 5mA 5 V

2 EOL negative voltage EOL output current < 0.1mA -0.3 V

refers to the voltage at either LVG pin or HVG pin

Table 4. Thermal data

Symbol Description Value Unit

thJA Max. thermal resistance junction to ambient 150 °C/W

R

T

J Junction operating temperature range -40 to 150 °C

STG Storage temperature -55 to 150 °C

T

Doc ID 16998 Rev 3 5/19

Electrical characteristics L6520, L6521

4 Electrical characteristics

(a)

VCC = 16 V, TA = -25 °C to 85 °C, unless otherwise specified

Table 5. Electrical characteristics

Symbol Pin Parameter Test condition Min. Typ. Max. Unit

Supply voltage

(2)

(1)

10.5 V

150 220 µA

Z

V

V

CC(ON)

V

CC(OFF)

V

CC

Z

VCC Operating range After turn-on

VCC Turn-on threshold 13.5 15 16.5 V

VCC Turn-off threshold 10.5 11.5 12.5 V

VCC Zener voltage IZ = 2 mA 16.5 17.5 18.5 V

Supply current

I

ST-UP

I

CC

I

Q

VCC Start-up current Before turn-on, (VCC = 13 V) 130 200 µA

VCC Operating supply current No load 8 10 mA

VCC Quiescent current IDLE mode,

Timing and oscillator

V

D Output duty cycle Run mode 49.5 50 50.5 %

t

DEAD

f

RUN

f

PRE

t

PRE

f

df

IGN

df

CCC

I

FPRE

t

ON,min

INS

Fixed dead time

HB run frequency

Max programmable

preheating frequency

Preheating time

HB instant start initial

frequency

/dt

/dt

Ignition time frequency sweep

rate

Frequency sweep rate after

overcurrent

FPRE FPRE current reference

HSD LSD Minimum half bridge on time T

(3)

T

= 25° C 46 46.6 47.2 kHz

AMB

1.24 1.42 1.6 µs

43.2 47.8 kHz

R

= 24.9 kΩ 96 100 104 kHz

FPRE

R

≥ 196 Ω,

FPRE

≥ 196 Ω,

R

FPRE

FPRE connected to GND,

(4)

, T

AMB

(4)

, T

AMB

T

= 25 °C 200 202 204

AMB

(1), (4)

, L6520 1.5 s

(2), (4)

, L6521 0.8

(2)

85 kHz

= 25 °C -2.75 kHz/ms

= 25 °C -500 Hz/ms

192 204

= 25 °C 1 µs

AMB

Half bridge drivers

V

HSD LSD Output low voltage Iload = 300 mA 3 V

OL

µA

a. This is a preliminary version: all the parameters are subject to change

6/19 Doc ID 16998 Rev 3

L6520, L6521 Electrical characteristics

Table 5. Electrical characteristics (continued)

Symbol Pin Parameter Test condition Min. Typ. Max. Unit

V

I

I

T

T

SRC

SNK

RISE

FAL L

I

HSD LSD Output high voltage Iload = 300 mA 13 V

OH

HSD LSD Peak source current 300 mA

HSD LSD Peak sink current 300 mA

HSD LSD Rise time Cload = 1 nF 120 ns

HSD LSD Fall time Cload = 1 nF 120 ns

HSD LSD Pull down current

PD

Before turn-on, (VCC = 13V)

V

LSD

Storage time compensation and hard switching detection

V

OUTup

V

HSW

V

P_dclamp

t

HSW

PWM_det PWM detector threshold Positive going HB middle point 2.65 3 V

PWM_det

PWM_det Clamping voltage I

PWM_det

Hard switching detector

threshold

Max. time of hard switching

operation

Negative going HB middle point 2 2.35 V

PWM_det

(4)

, T

AMB

Half bridge current control circuit (CCC)

THL HBCS

THM HBCS

First threshold in ignition

mode

Second threshold in ignition

mode

or V

HSD

= 1V

20 mA

= 2 mA 4.5 5 5.5 V

= 25 °C 200 ms

0.96 1 1.04 V

1.21 1.26 1.31 V

THH HBCS

Third threshold in ignition

mode

2.4 2.5 2.6 V

TLL HBCS First threshold in run mode 0.67 0.7 0.73 V

TLM HBCS Second threshold in run mode 0.87 0.9 0.93 V

TLH HBCS Third threshold in run mode 1.7 1.8 1.9 V

T

PROT

t1 HBCS

Maximum current control time

Minimum interval between two

consecutive threshold

(4)

(4)

, T

= 25 °C 200 ms

AMB

, T

= 25 °C 510 ns

AMB

crossing for slow events

Minimum interval between two

t2 HBCS

consecutive threshold

crossing for fast events (not

(4)

, T

= 25 °C 255 ns

AMB

saturating)

∆f

∆f

∆f

TxL

slow

fast

HBCS

HBCS

HBCS

Frequency increase in case of

lower threshold crossing

Frequency increase in case of

slow event

Frequency increase in case of

fast event

(4)

(4)

(4)

, T

= 25 °C 1 kHz

AMB

, T

= 25 °C 1 kHz

AMB

, T

= 25 °C 2 kHz

AMB

Doc ID 16998 Rev 3 7/19

Electrical characteristics L6520, L6521

Table 5. Electrical characteristics (continued)

Symbol Pin Parameter Test condition Min. Typ. Max. Unit

t

LEB

HBCS

Leading edge time after LSD

turn on

(4)

, T

= 25 °C 255 ns

AMB

End of life

V

EOL

V

EOL_H

V

EOL_l

I

EOL

t

EOL

1. During the operation at Vcc ≥ Vz the maximum supply current must be limited to 2mA.

2. Guaranteed by characterization.

3. t

DEAD

4. Guaranteed by testing logic verification.

EOL

EOL EOL upper threshold 3.84 4 4.16 V

EOL EOL lower threshold 0.96 1 1.04 V

EOL Sink/source capability

EOL Protection delay time

is the sum of a fixed time, generated by internal logic and the propagation delay of PWM_det comparator.

EOL pin biasing voltage

reference

V

= 1.5V (source)

EOL

= 3.5V (sink)

V

EOL

(4)

, T

= 25 °C 1.5 s

AMB

2.43 2.5 2.57 V

8.2 9.1 10 µA

8/19 Doc ID 16998 Rev 3

L6520, L6521 Functions description

5 Functions description

5.1 Start-up

During the first start-up ramp of the supply voltage (VCC) both driver outputs, LSD and HSD,

are low impedance to ground (Isink 20 mA min). Once the V

voltage V

the IC starts its operation. During the first 100 µs the IC senses the status

CC(ON)

of FPRE pin to detect the programmed preheating frequency and the selected ignition mode

(instant or preheated start). When all the IC internal functions are ready, the driver-outputs

are released.

If the preheated start is selected, the half-bridge oscillates at the programmed preheating

frequency, otherwise it starts from 85 kHz (typ.).

5.2 Preheating and instant start

The preheating time is 1.5 s (typ.) in the L6520 and 0.8 s (typ.) in the L6521. The FPRE pin

embeds a precise current reference: the voltage read by this pin sets the preheating

frequency or enables the instant start. If the FPRE pin is connected to ground, the instant

start is active and the IC runs immediately into ignition sequence from the starting frequency

of 85 kHz. If the pin FPRE is connected to a resistor equal or higher than 196 Ω, the

preheating frequency can be programmed from 55 kHz upwards till 100 kHz (1.5 kHz/step)

accordingly to Table 6. For the best precision the resistor tolerance should be less or equal

to 1%. After the preheating sequence, the IC runs into ignition mode.

Table 6. Preheating and instant start

voltage reaches the turn-on

CC

F

(kHz) R

PRE

Instant start 0 77.5 5490

55 196 79 6190

56.5 383 80.5 6980

58 576 82 7870

59.5 806 83.5 8660

61 1050 85 9530

62.5 1300 86.5 10500

64. 1580 88 11500

65.5 1870 89.5 12700

67 2210 91 14000

68.5 2550 92.5 15400

70 2940 94 16900

71.5 3400 95.5 18700

73 3830 97 20500

74.5 4320 98.5 22600

76 4870 100 24900

(Ω) F

FPRE

(kHz) R

PRE

FPRE

(Ω)

Doc ID 16998 Rev 3 9/19

Functions description L6520, L6521

5.3 Ignition

During the ignition sequence the output frequency ramps down from the programmed

preheating frequency to the fixed run frequency with a fixed rate df

the instant start is selected, the frequency ramps down from 85 kHz to 46.6 kHz (typ.) with

the same rate.

The current control circuit limits the maximum lamp voltage (OCPH) in case of old or broken

lamp and it is able to control the lamp current in case of inductor saturation (CSC).

The ignition phase lasts for maximum 200 ms. If the Run frequency is not reached during

ignition phase, the IC is turned off (latched).

/dt of - 2.75 kHz/ms. If

IGN

5.4 Run mode

The run frequency is internally set to 46.6 kHz.

The HSD and LSD pins drive respectively the high side and the low side switches. The

potential isolation to the high side switch is realized by a pulse transformer. The HSD and

LSD drivers are able to manage the inductive load represented by the primary side of the

pulse transformer.

Between the turn-off of one driver and turn-on of the other one there is a dead time

automatically optimized accordingly to the kind of the half bridge switches (MOS or BJT) to

ensure the maximum reliability. The CCC protects the circuit against over currents, choke

saturation and hard switching events.

5.5 Storage time compensation network

In all the operating states (preheating, ignition and run mode), the storage time

compensation ensures the application of the fixed dead time (t

BJT's collector current is effectively reduced to zero. The t

generated by internal logic and the propagation delay of PWM_det comparator.

The voltage level of the middle point of the half bridge is monitored through the PWM_det

pin: the high side switch is turned on after a fixed dead time from the instant when the

voltage on the PWM_det pin is above 2.65 V. The time between the falling edge of pin LSD

and the rising edge of HSD is recorded in order to set the same dead time between the

falling edge of pin HSD and the rising edge of pin LSD.

The minimum duration of the resulting ON time is internally limited to 1 µs. This condition

can last for a maximum time equal to 200 ms. After this time the IC is shut down (latched).

The PWM_det pin embeds a 5 V (typ.) clamping zener, allowing the connection between the

half bridge middle point and the pin itself by means of a limiting resistor.

When driving MOSFET no storage time is present, therefore the resulting dead time is equal

to (1.42 µs).

, 1.42 us typ.) once the

DEAD

is the sum of a fixed time,

DEAD

10/19 Doc ID 16998 Rev 3

L6520, L6521 Functions description

5.6 Current control circuit (CCC)

The current control circuit (CCC) is a sophisticated circuit able to protect the ballast against

any possible failure. It limits the maximum lamp voltage during ignition (OCPH), overcurrent

protection (OCPL) during run mode, chokes saturation control (CSC) and hard switching

protection (HSP). The control circuit senses the voltage on HBCS pin and PWM_det pin.

Figure 3 on page 13 shows the CCC protections active in each operating mode (preheating,

ignition and run):

5.6.1 Hard switching protection (HSP)

If the voltage on PWM_det pin is higher than 2.35 V at the moment the LS driver turns on,

an up-down event counter is increased and an internal timer is started. Without hard

switching events, the counter decreases at every cycle and the timer is reset when 0 is

reached. If the events counter value is higher than 0 after 200 ms from the detection of the

first event, then the IC is turned off (latched).

5.6.2 Overcurrent protection (OCPH) during ignition mode

The protection results in lamp voltage limitation during ignition. In this phase three

thresholds are active (THL, THM and THH):

If the first threshold is crossed the frequency is increased by 1 kHz during the next cycle.

The interval between the crossings of the two lower thresholds (THL and THM) is used as

an indication of the slope of the half bridge current: if this interval is longer than t1 = 510 ns

the event is considered “slow” and the frequency is increased by another 1 kHz/cycle during

the next cycle. If the interval is shorter than t1 = 510 ns but longer than t2 = 255 ns, the

event is considered “fast” and the frequency is increased by another 2 kHz/cycle during the

next cycle.

If no further threshold crossing is detected, the frequency is decreased with a fixed rate

equal to df

crossed firstly is reached; then, the decreasing ratio becomes again df

If the run frequency has not been reached within 200 ms after the lower threshold was

crossed the first time, the IC is turned off (latched).

A leading edge blanking of 255 ns is active.

/dt = - 500 Hz/ms, until the frequency at which the lowest threshold was

CCC

5.6.3 Overcurrent protection (OCPL) during run mode

The behavior of the OCPL is similar to the OCPH but with reduced thresholds (TLL, TLM

and TLH) since the current involved in this phase is smaller. If no further threshold crossing

is detected, the frequency is decreased with a fixed rate equal to d

until the run frequency is reached.

If the run frequency has not been reached after 200 ms from when the lower threshold was

crossed the first time, the IC is turned off (latched).

IGN

fCCC/dt

/dt.

= - 500 Hz/ms,

A leading edge blanking of 255 ns is active.

Doc ID 16998 Rev 3 11/19

Functions description L6520, L6521

5.6.4 Choke saturation control (CSC) during ignition and run mode

The same thresholds used to detect OCPH and OCPL are active.

The control is still based on the time between two consecutive thresholds but its behavior is

different with respect to the OCPH/OCPL detection to take into account the increase of dI/dt

when the inductor is saturating. When either the two lower thresholds are crossed in a time

shorter than 255 ns or the higher threshold is crossed, the LS driver is immediately turned

off and the time between the LS turn on and the instant when the second threshold (THM or

TLM) is crossed is used to calculate the new (higher) frequency.

If this new frequency is higher than 100 kHz then the new frequency will be set at 100 kHz.

The frequency is then decreased with a fixed df/dt equal to df

frequency at which the first threshold was crossed is reached. Then, the decreasing ratio

becomes again df

/dt during ignition whereas, during run mode, the df

IGN

ratio is maintained until run frequency is reached.

If the run frequency has not been reached after 200 ms from when the lower threshold was

crossed the first time, the IC is turned off (latched).

A leading edge blanking of 255 ns is active.

5.7 End of life (EOL)

An embedded window comparator can be used to detect the end of life (EOL) when the

lamp is directly connected to ground (lamp to ground configuration).

After the ignition sequence, the EOL window comparator becomes active. When the voltage

at EOL pin goes outside the limits of this comparator a 1.5 s timer is started. If the EOL pin

voltage does not return inside the allowed range before the end of the timer, the IC is shut

down (latched).

The EOL pin is biased to the center of the window comparator by means of an OTA (2.5 V

typ. with +/- 1.5 V typ. window), having a current capability equal to 9.1 µA (typ.).

/dt = - 500 Hz/ms, until the

CCC

/dt decreasing

CCC

12/19 Doc ID 16998 Rev 3

L6520, L6521 Functions description

5.8 Summary of protections

Figure 3. Summary of protections

IN+]

N+]

N+]

N+]

Table 7. Table of faults

Active during

Fault

PH Ign Run

Minimum

driving pulse

duration

Inductor

saturation

Hard switching

Overcurrent

End Of Life 9

9 Driving pulses shorter than 1 µs

99

9

99

VRUV

35(+($7,1*

LIHQDEOHG

Condition Ic behaviour

HBCS TxL and TxM thresholds

crossed in less than 255 ns

OR

Higher threshold crossing

PWM_det higher than 2.35 V at

LSD turn on

HBCS TxL and TxM thresholds

crossing (different values during

ignition or run mode)

EOL voltage outside the limits of

the window comparator

GW N+]PV

GI

,*1

PV

,*1,7,21 58102'(

2&3+

&6&

2&3/

&6&

+63

(2/

0LQ3XOVH3URWHFWLRQ

- The drivers are stopped after

200 ms of minimum pulse

duration events

- The IC is shut down in low

consumption mode

LS driver turned off and a new

frequency is calculated.

If the situation is not recovered

after 200 ms, the IC is shut down

in low consumption mode

IC is shut down in low

consumption mode after 200 ms

of HSW events

Frequency increase proportional

to the failure.

If the situation is not recovered

after 200 ms the IC is shut down

in low consumption mode

- Delay time started

- If EOL voltage is outside the

limits of the window comparator at

the end of the timer count than

the IC is shut down (latched)

W

Required

action

cycle

V

CC

cycle

V

CC

cycle

V

CC

cycle

V

CC

cycle

V

CC

Doc ID 16998 Rev 3 13/19

Typical electrical characteristics L6520, L6521

6 Typical electrical characteristics

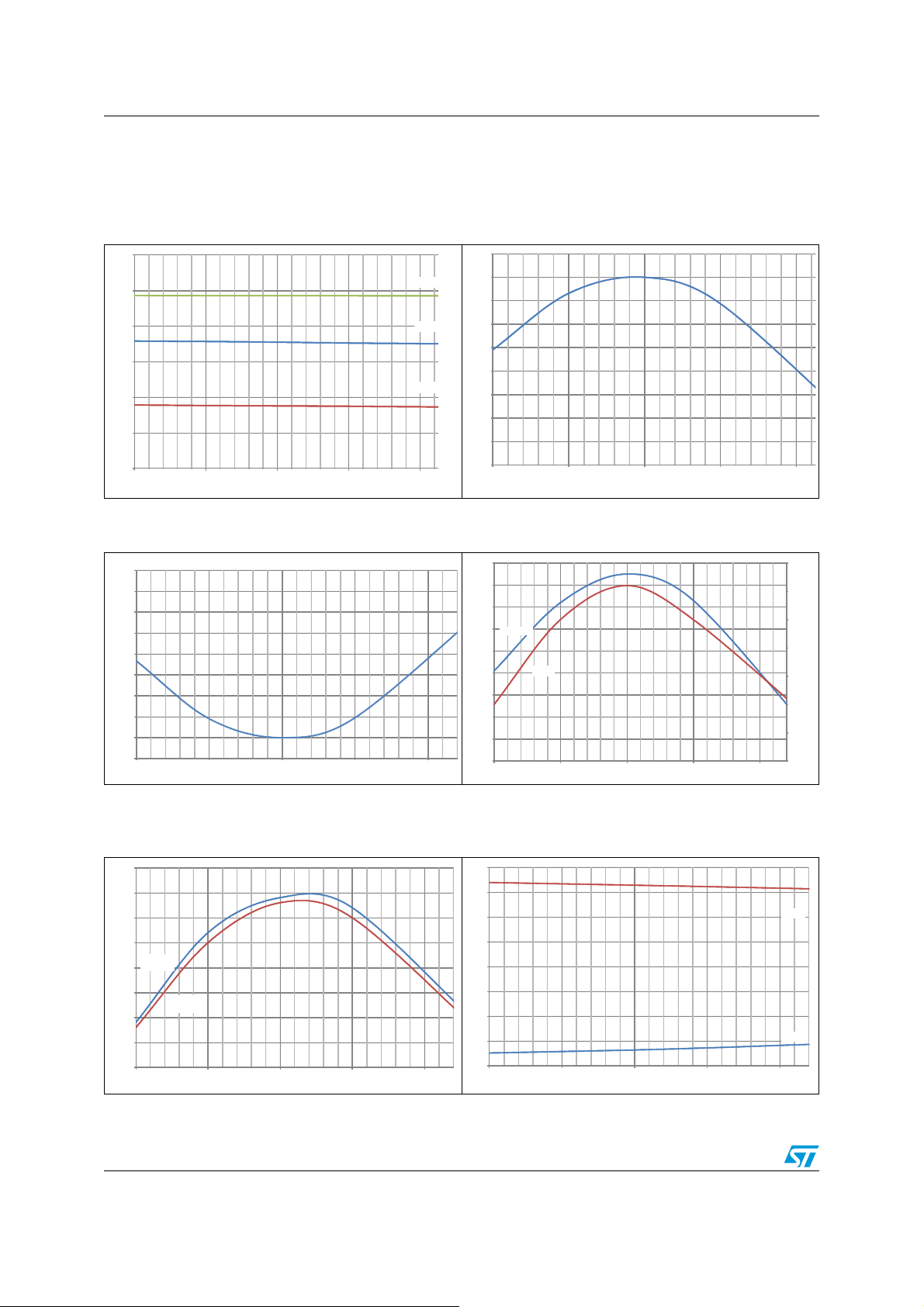

Figure 4. VCC thresholds vs temperature Figure 5. Frequencies vs temperature

20

18

16

14

VCC Voltage

12

10

8

-25 0 25 50 75

Temperature [ C]

Vz

VCC(on)

VCC(off)

Figure 6. Times vs temperature Figure 7. FPRE resistance converter

1.04

1.035

1.03

1.025

1.02

1.015

1.01

Time intervals [normalized ]

1.005

1

0.995

-25 0 25 50 75

Temperature [ C]

1.005

1

0.995

0.99

0.985

0.98

Normalized Frequency

0.975

0.97

0.965

0.96

-25 0 25 50 75

Temper at ur e [ C]

temperature behavior

203

202

201

200

IFPRE

199

198

IFPRE [uA]

197

196

195

194

Vref

-25 0 25 50 75

Temperature [ C]

5.01

5.005

5

4.995

4.99

4.985

4.98

4.975

Vref (V)

Figure 8. IEOL vs temperature Figure 9. LSG and HSG output voltage vs

temperature (driver's current:

9.45

9.4

9.35

9.3

IEOL

9.25

(source)

9.2

IEOL (absolute value) [uA]

9.15

9.1

9.05

IEOL

(sink )

-25 0 25 50 75

Temperature [ C]

16

14

12

10

8

Vout_driver [V]

6

4

2

0

-25 0 25 50 75

14/19 Doc ID 16998 Rev 3

300mA)

Temperature [ C]

VOH

VOL

L6520, L6521 Application examples

7 Application examples

Figure 10. BJT application example

&YFF

5SUH

)35(

(2/

+%&6

3:0BGHW

9&&

+6'

/6'

*1'

5

287

Figure 11. MOSFET application example

&YFF

5VWXS

5

5VWXS

287

+9

&FS

+6

&

%/2&.

/

/6

5

(

'='=

5

+%&6

5

(

5(6

&

5(6

+9

5SUH

)35(

(2/

+%&6

3:0BGHW

&FS

+6

9&&

+6'

/6'

*1'

5

287

5

287

/6

5

(

'='=

5

+%&6

5

(

Doc ID 16998 Rev 3 15/19

&

%/2&.

/

5(6

&

5(6

Package mechanical data L6520, L6521

8 Package mechanical data

In order to meet environmental requirements, ST offers these devices in different grades of

ECOPACK

®

packages, depending on their level of environmental compliance. ECOPACK®

specifications, grade definitions and product status are available at: www.st.com.

ECOPACK is an ST trademark.

Table 8. SO-8 mechanical data

Dim.

Min Typ Max Min Typ Max

A 1.35 1.75 0.053 0.069

A1 0.10 0.25 0.004 0.010

A2 1.10 1.65 0.043 0.065

B 0.33 0.51 0.013 0.020

C 0.19 0.25 0.007 0.010

(1)

D

4.80 5.00 0.189 0.197

E 3.80 4.00 0.15 0.157

e 1.27 0.050

H 5.80 6.20 0.228 0.244

h 0.25 0.50 0.010 0.020

L 0.40 1.27 0.016 0.050

k 0° (min.), 8° (max.)

ddd 0.10 0.004

1. Dimensions D does not include mold flash, protrusions or gate burrs. Mold flash, potrusions or gate burrs

shall not exceed 0.15mm (.006inch) in total (both side).

mm. inch

16/19 Doc ID 16998 Rev 3

L6520, L6521 Package mechanical data

Figure 12. Package dimensions

Doc ID 16998 Rev 3 17/19

Revision history L6520, L6521

9 Revision history

Table 9. Document revision history

Date Revision Changes

19-Jan-2010 1 Initial release

Added: L6521 option, Section 6: Typical electrical characteristics

08-Feb-2011 2

09-Mar-2011 3 Datasheet updated from preliminary data to final datasheet

Updated: Coverpage, Figure 1, Table 4, Table 5, Section 1, Figure 3,

Table 7, Figure 10, Figure 11

18/19 Doc ID 16998 Rev 3

L6520, L6521

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZED ST REPRESENTATIVE, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2011 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Philippines - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

Doc ID 16998 Rev 3 19/19

Loading...

Loading...