Page 1

CURRENTCONTROLLERFOR STEPPING MOTORS

DESCRI P TI ON

The L6506/Dis a linearintegratedcircuit designed

to senseand controlthecurrentinsteppingmotors

and similardevices.Whenusedin conjunctionwith

the L293, L298, L7150,L6114/L6115,the chip set

formsa constantcurrentdrive foran inductiveload

andperformsalltheinterfacefunctionfromthe control logic thruthe powerstage.

Two or more devices may be synchronized using

thesyncpin.In thismodeof operationtheoscillator

in themasterchipsetstheoperatingfrequencyinall

chips.

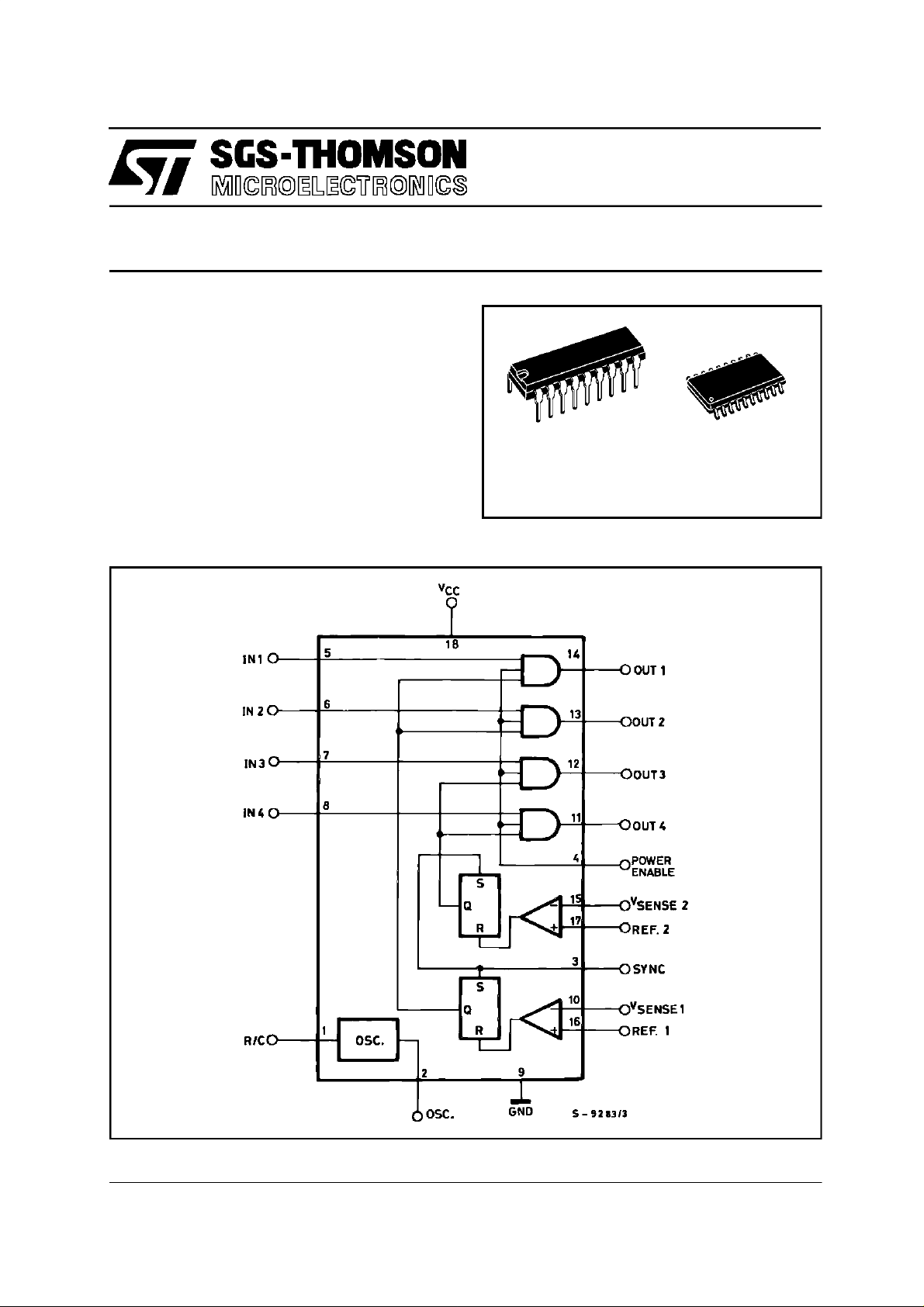

BLOCK DIAGRAM (pin’s number referred to DIP-18)

L6506

L6506D

DIP18 SO20

ORDERING NUMBERS:

L6506 L6506D

June 1997

1/8

Page 2

L6506 -L6506D

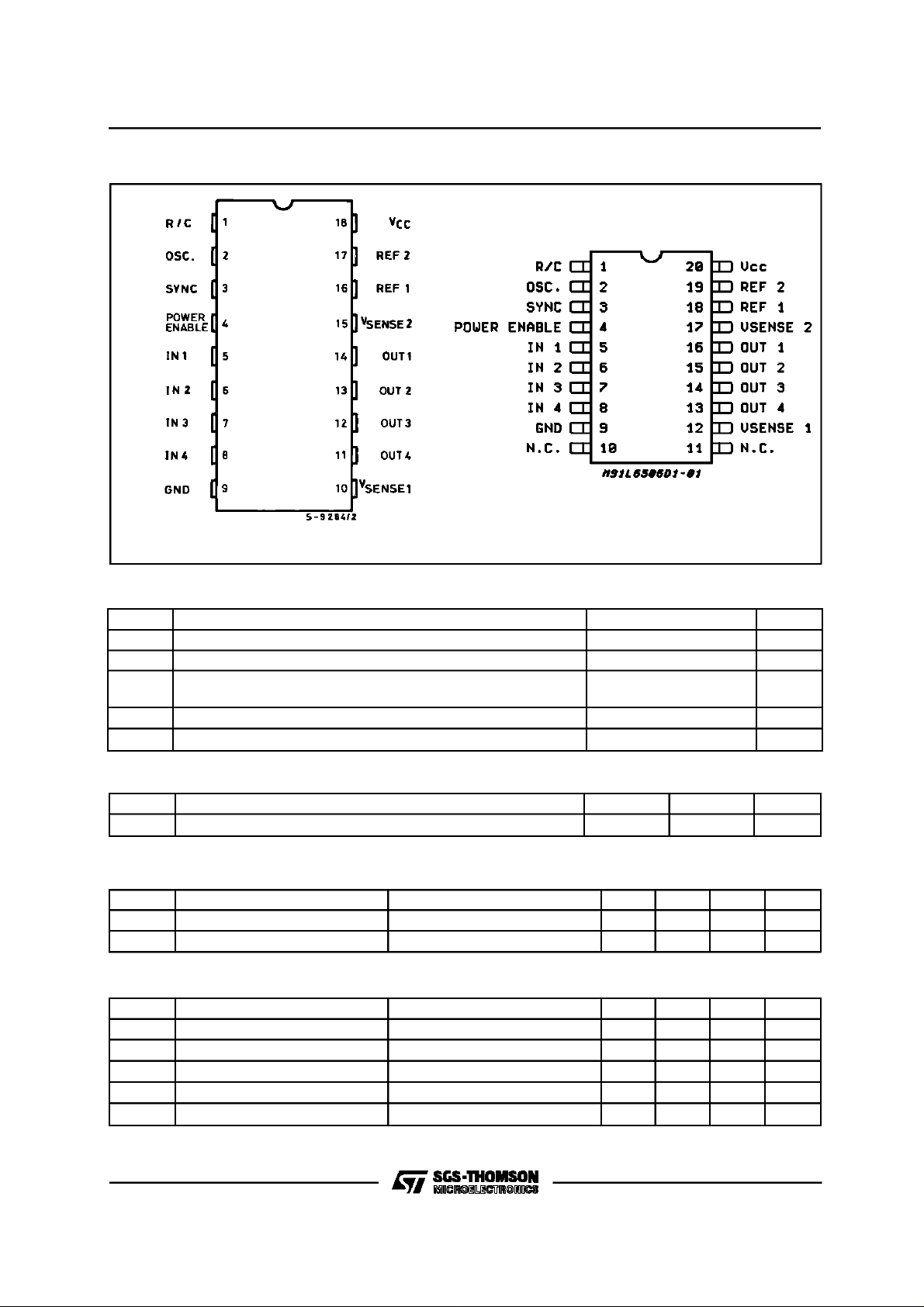

PI N CONNE CTI ONS (top view)

DIP18 SO20

ABSOLUTEMAXIMUM RATINGS

Symbol Parameter Val u e Uni t

V

V

P

T

T

Supply Voltage 10 V

CC

Input Signals 7 V

i

Total Power Dissipation(T

tot

=70°C) for DIP18

amb

Total Power Dissipation(Tamb =70ÉC) for SO20

JunctionTemperature 150

j

Storage Temperature -40 to 150

stg

1

0.8

THERMAL DATA

Symb o l Parameter DIP 18 SO 20 Uni t

R

thj-amb

ELECTRICAL CHARACTERESTICS (VCC= 5.0V,T

Thermal ResistanceJunction-ambient Max. 80 100

=25°C; unlessotherwisenoted)

amb

C/W

°

Symb o l Parameter Test Cond itions Mi n . Typ . Max. Unit

V

I

SupplyVoltage 4.5 7 V

CC

QuiescentSupplyCurrent VCC=7V 25 mA

CC

COMPARATOR SECTION

Symb o l Parameter Test Cond itions Mi n . Typ . Max. Unit

V

V

I

I

Input Voltage Range V

IN

Input Offset Voltage VIN= 1.4V

IO

Input Offset Current

IO

Input Bias Current 1 µ

IB

Response time V

Inputs –0.3 3 V

sense

±5.0

±200

REF

= 1.4V V

= 0 to 5V 0.8 1.5

SENS

W

W

C

°

°C

mV

nA

µ

A

s

2/8

Page 3

L65 06 - L6506D

ELECTRICAL CHARACTERISTICS(continued)

COMPARATOR SECTIONPERFORMANCE(OverOperatingTemperatureRange)

Symbol Parameter Test Condtions Min. Typ. Max. Unit

V

Input Offset Voltage VIN= 1.4V

IO

Input Offset Curent

I

IO

±

±

500

20

mV

nA

LOGICSECTION

Symbol Parameter Test Condtions Min. Typ. Max. Unit

V

V

V

Input High Voltage 2 V

IH

Input Low Voltage 0.8 V

V

IL

Output High Voltage VCC= 4.75V

OH

Ouptut Low Voltage VCC= 4.75V

OL

Ouput Source Current - Outputs

I

OH

1-4

(OverOperatingTemperatureRange -TTL compatibleinputs& outputs)

2 3.5 V

= 400µA

I

OH

0.25 0.4 V

= 4mA

I

OH

VCC= 4.75V 2.75 mA

s

OSCILLATOR

Symbol Parameter Test Condtions Min. Typ. Max. Unit

f

V

V

Frequency Range 5 70 KHz

osc

Lower Threshold Voltage 0.33 V

thL

Higher Threshold Voltage 0.66 V

thH

Internal Discharge Resistor 0.7 1 1.3

R

i

CC

CC

CIRCUIT OP ERATION

TheL6506isintendedfor use withdual bridgedrivers,suchasthe L298,quaddarlingtonarrays,such

as the L7150, quad DMOS array such as L6114L6115,ordiscretepowertransistorstodrivestepper

motorsandothersimilarloads.Themainfunctionof

thedeviceistosenseandcontrolthecurrentineach

of theload windings.

Acommonon-chiposcillatordrivesthedualchopper

andsetsthe operatingfrequencyforthepulsewidth

modulateddrive.The RCnetworkon pin1 setsthe

operatingfrequencywhichis givenby the equation

:

f = forR > 10 K

1

0.69 RC

The oscillator provides pulses to set the two flipflopswhichin turncausethe outputsto activatethe

drive.Whenthecurrentintheloadwindingreaches

theprogrammedpeakvalue,thevoltageacrossthe

senseresistor (R

) is equal to V

sense

and the cor-

ref

respondingcomparatorresetsits flip-flopinterruptingthedrivecurrentuntilthenextoscillatorpulseoccurs. The peak current in each winding is programmedby selectingthe valueofthe senseresis-

tor and V

. Sinceseparateinputsare providedfor

ref

each chopper, each of the loads may be programmed independentlyallowing the device to be

used to implement microstepping of the motor.

LowerthresholdofL6506’soscillatoris 1/3V

per thresholdis 2/3 V

sistoris 1 KΩ ±

30%.

and internal dischargere-

CC

CC

Ground noise problems in multiple configurations

can be avoided by synchronizing the oscillators.

This may be done by connecting the sync pins of

eachof the deviceswith the oscillatoroutput of the

masterdeviceandconnectingtheR/Cpinoftheunusedoscillatorsto ground.

Theequationsfor the activetime of thesync pulse

(T2),the inactivetimeof thesyncsignal(T1)andthe

dutycyclecanbefoundbylookingatthefigure1 and

are:

R1R

T2 = 0.69C1 (1)

R1 + R

IN

IN

T1 = 0.69 R1C1 (2)

DC= (3)

T2

T1 + T2

V

V

V

kΩ

.Up-

3/8

Page 4

L6506 -L6506D

By substituting equations1 and 2 into equation 3

and solving for the value of R1 the followingequationsfor theexternal componentscan bederived :

R1 = ( –2) R

1

DC

C1 = (5)

0.69R1

IN

T1

(4)

Figure1 : OscillatorCircuitandWaveforms.

Lookingat equation1 itcan easilybe seen thatthe

minimumpulsewidthof T2willoccurwhenthevalue

of R1 is at its minimum and the valueof R1 at its

maximum. Therefore, when evaluatingequation 4

the minimum value for R1 of 700Ω (1KΩ –30%)

should be used to guarantee the required pulse

width.

APPL ICATI ONS INFO RMATION

Thecircuits shown infigure2 use theL6506 toimplementconstantcurrentdrivesforsteppermotors.

Figure 2 shows the L6506 used with the L298 to

drivea 2 phasebipolarmotor. Thepeakcurrentcan

be calculatedusingthe equation:

V

I

peak

ref

=

R

sense

The circuit of Fig.2 can be used in applicationsrequiring different peak and hold current values by

modifyingthe referencevoltage.

TheL6506maybeusedtoimplementeitherfullstep

or half step drives. In the case of 2 phase bipolar

stepper motor applications, if a half step drive is

used,thebridge requiresan additionalinput todisablethe power stageduringthe half step.Ifusedin

conjunctionwith the L298the enableinputsmaybe

usedfor this purpose.

Forquad darlingtonarrayin 4 phaseunipolarmotor

applications half step may be implemented using

the 4 phaseinputs.

The L6506 may also be used to implement microsteppingof either bipolaror unipolarmotors.

4/8

Page 5

L65 06 - L6506D

Figure2 : ApplicationCircuit BipolarStepperMotorDriver.(pin’s numberreferredto DIP18)

5/8

Page 6

L6506 -L6506D

DIP18PACKAGE MECHANICAL DATA

DIM.

MIN. TYP. MAX. MIN. TYP. MAX.

a1 0.254 0.010

B 1.39 1.65 0.055 0.065

b 0.46 0.018

b1 0.25 0.010

D 23.24 0.915

E 8.5 0.335

e 2.54 0.100

e3 20.32 0.800

F 7.1 0.280

I 3.93 0.155

L 3.3 0.130

Z 1.27 1.59 0.050 0.063

mm inch

6/8

Page 7

SO20PACKAGEMECHANICAL DATA

L65 06 - L6506D

DIM.

MIN. TYP. MAX. MIN. TYP. MAX.

A 2.65 0.104

a1 0.1 0.3 0.004 0.012

a2 2.45 0.096

b 0.35 0.49 0.014 0.019

b1 0.23 0.32 0.009 0.013

C 0.5 0.020

c1 45 (typ.)

D 12.6 13.0 0.496 0.512

E 10 10.65 0.394 0.419

e 1.27 0.050

e3 11.43 0.450

F 7.4 7.6 0.291 0.299

L 0.5 1.27 0.020 0.050

M 0.75 0.030

S 8 (max.)

mm inch

7/8

Page 8

L6506 -L6506D

Information furnished is believed to be accurate and reliable. However, SGS-THOMSON Microelectronics assumes no responsibility for

the consequences of use of such information nor for any infringement of patents or other rights of third parties which may result from its

use. No license is granted by implication or otherwise under any patent or patent rights of SGS-THOMSON Microelectronics. Specification

mentioned in this publication are subject to change without notice. This publication supersedes and replaces all information previously

supplied. SGS-THOMSON Microelectronics products are not authorized for use as critical components in life support devices or systems

withoutexpress written approval of SGS-THOMSON Microelectronics.

Australia - Brazil - Canada - China - France - Germany - Hong Kong - Italy - Japan - Korea - Malaysia - Malta - Morocco -

The Netherlands - Singapore - Spain - Sweden - Switzerland - Taiwan - Thailand - United Kingdom - U.S.A.

1997 SGS-THOMSON Microelectronics – Printed in Italy – All Rights Reserved

SGS-THOMSON Microelectronics GROUP OF COMPANIES

8/8

Loading...

Loading...