easySPIN – fully integrated microstepping motor driver

Features

■ Operating voltage: 8 - 45 V

■ 7.0 A output peak current (3.0 A r.m.s.)

■ Low R

■ Programmable power MOS slew-rate

■ Up to 1/16 microstepping

■ Current control with adaptive decay

■ Non dissipative current sensing

■ SPI interface

■ Low quiescent and standby currents

■ Programmable non dissipative overcurrent

protection on all power MOS

■ Two-level overtemperature protection

Application

■ Bipolar stepper motor

power MOSFETS

DSon

L6474

POWERSO36

an adaptive decay mode which outperforms

traditional implementations.

All data registers, including those used to set

analogue values (i.e. current control value,

current protection trip point, dead time, etc.) are

sent through a standard 5 Mbit/s SPI.

A very rich set of protections (thermal, low bus

voltage, overcurrent) makes the L6474 “bullet

proof” as required by the most demanding motor

control applications.

HTSSOP28

Description

The L6474, realized in analog mixed signal

technology, integrates a dual low R

full bridge with all power switches equipped with

an accurate on-chip current sensing circuitry

suitable for non dissipative current control and

overcurrent protections. Thanks to a new current

control, a 1/16 microstepping is achieved through

Table 1. Device summary

Order codes Package Packing

L6474H HTSSOP28 Tube

L6474HTR HTSSOP28 Tape and reel

L6474PD POWERSO36 Tube

L6474PDTR POWERSO36 Tape and reel

December 2011 Doc ID 022529 Rev 2 1/51

DSon

DMOS

www.st.com

51

Contents L6474

Contents

1 Block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2 Electrical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1 Absolute maximum ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.2 Recommended operating conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.3 Thermal data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3 Electrical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

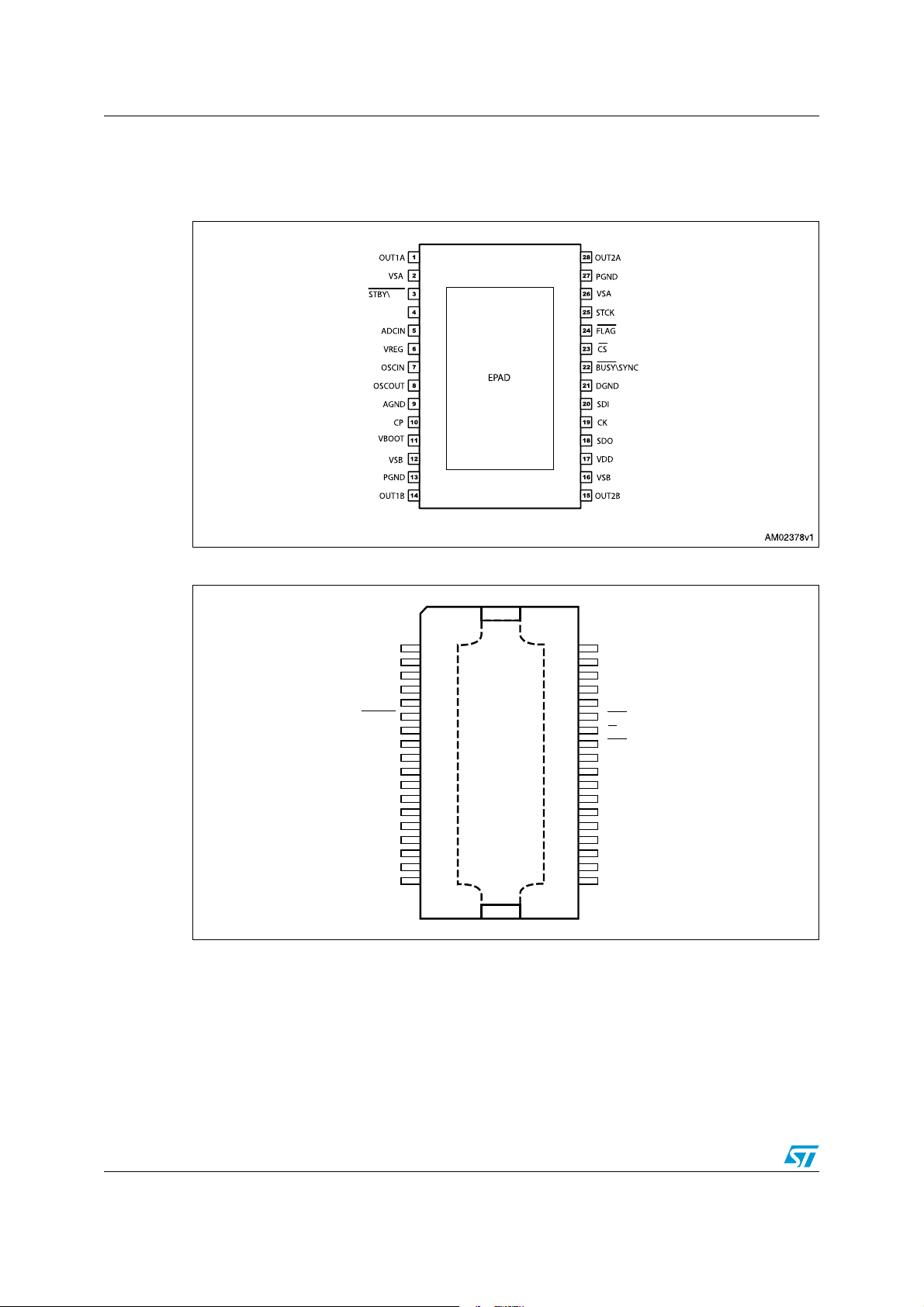

4 Pin connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.1 Pin list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5 Typical applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

6 Functional description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

6.1 Device power-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

6.2 Logic I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

6.3 Charge pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

6.4 Microstepping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6.5 Absolute position counter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

6.6 Step sequence control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

6.7 Enable and disable commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

6.8 Internal oscillator and oscillator driver . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.8.1 Internal oscillator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.8.2 External clock source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.9 Overcurrent detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

6.10 Undervoltage lock-out (UVLO) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

6.11 Thermal warning and thermal shutdown . . . . . . . . . . . . . . . . . . . . . . . . . 23

6.12 Reset and standby . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

6.13 Programmable DMOS slew-rate, dead-time and blanking-time . . . . . . . . 24

6.14 Integrated analog to digital converter . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

6.15 Internal voltage regulator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2/51 Doc ID 022529 Rev 2

L6474 Contents

6.16 SYNC pin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6.17 FLAG pin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

7 Phase current control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

7.1 Peak current control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

7.2 Auto-adjusted decay mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

7.3 Auto-adjusted fast decay during the falling steps . . . . . . . . . . . . . . . . . . . 28

7.4 Torque regulation (output current amplitude regulation) . . . . . . . . . . . . . . 29

8 Serial interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

9 Programming manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

9.1 Registers and flags description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

9.1.1 ABS_POS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

9.1.2 EL_POS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

9.1.3 MARK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

9.1.4 TVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

9.1.5 T_FAST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

9.1.6 TON_MIN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

9.1.7 TOFF_MIN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

9.1.8 ADC_OUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

9.1.9 OCD_TH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

9.1.10 STEP_MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

9.1.11 ALARM_EN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

9.1.12 CONFIG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

9.1.13 STATUS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

9.2 Application commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

9.2.1 Command management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

9.2.2 Nop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

9.2.3 SetParam (PARAM, VALUE) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

9.2.4 GetParam (PARAM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

9.2.5 Enable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

9.2.6 Disable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

9.2.7 GetStatus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

10 Package mechanical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

11 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Doc ID 022529 Rev 2 3/51

List of tables L6474

List of tables

Table 1. Device summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Table 2. Absolute maximum ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Table 3. Recommended operating conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Table 4. Thermal data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

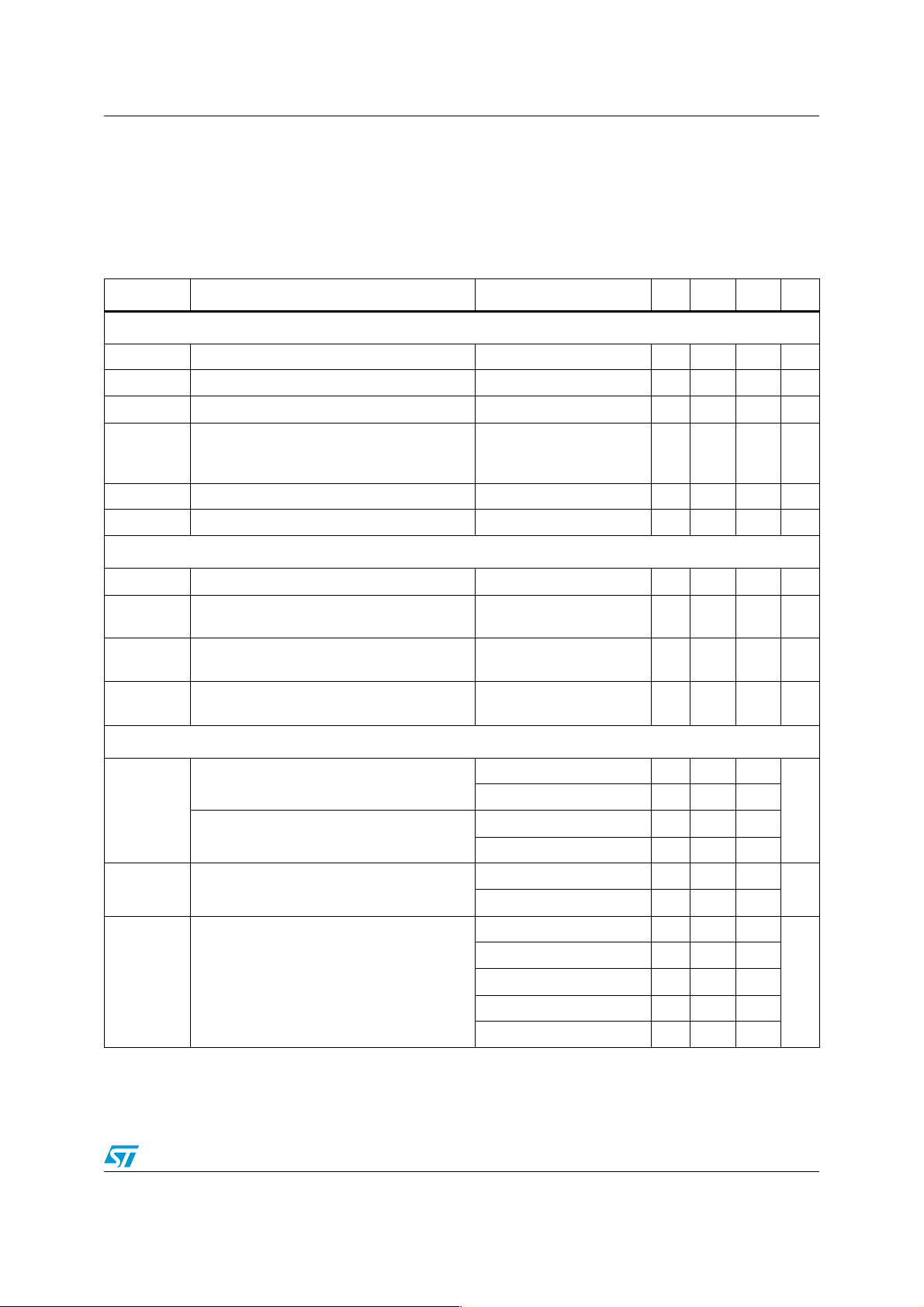

Table 5. Electrical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Table 6. Pin description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Table 7. Typical application values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Table 8. CL values according to external oscillator frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Table 9. Registers map. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Table 10. EL_POS register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Table 11. Torque regulation by TVAL_HOLD, TVAL_ACC, TVAL_DEC and TVAL_RUN registers . 34

Table 12. T_FAST register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Table 13. Maximum fast decay times . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Table 14. Minimum ON time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Table 15. Minimum OFF time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Table 16. ADC_OUT value and torque regulation feature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Table 17. Overcurrent detection threshold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Table 18. STEP_MODE register. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Table 19. Step mode selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Table 20. SYNC signal source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Table 21. ALARM_EN register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Table 22. CONFIG register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Table 23. Oscillator management. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Table 24. Overcurrent event . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Table 25. Programmable power bridge output slew-rate values. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Table 26. External torque regulation enable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Table 27. Switching period . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Table 28. STATUS register. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Table 29. STATUS register DIR bit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Table 30. Application commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Table 31. Nop command structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Table 32. SetParam command structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Table 33. GetParam command structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Table 34. HardStop command structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Table 35. Disable command structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Table 36. GetStatus command structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Table 37. HTSSOP28 mechanical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Table 38. POWERSO36 mechanical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Table 39. Document revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

4/51 Doc ID 022529 Rev 2

L6474 List of figures

List of figures

Figure 1. Block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Figure 2. HTSSOP28 pin connection (top view) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Figure 3. POWERSO36 pin connection (top view) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Figure 4. Bipolar stepper motor control application using L6474 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 5. Charge pump circuitry. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 6. Normal mode and microstepping (16 microsteps) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 7. OSCIN and OSCOUT pin configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Figure 8. Internal 3 V linear regulator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Figure 9. Peak current control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Figure 10. Adaptive decay - fast decay tuning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Figure 11. Adaptive decay - switch from normal to slow+fast decay mode and vice versa . . . . . . . . . 28

Figure 12. Fast decay tuning during the falling steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Figure 13. SPI timings diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Figure 14. Daisy-chain configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Figure 15. Command with three-byte argument . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Figure 16. Command with three-byte response . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Figure 17. Command response aborted . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Figure 18. HTSSOP28 mechanical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Figure 19. POWERSO36 drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Doc ID 022529 Rev 2 5/51

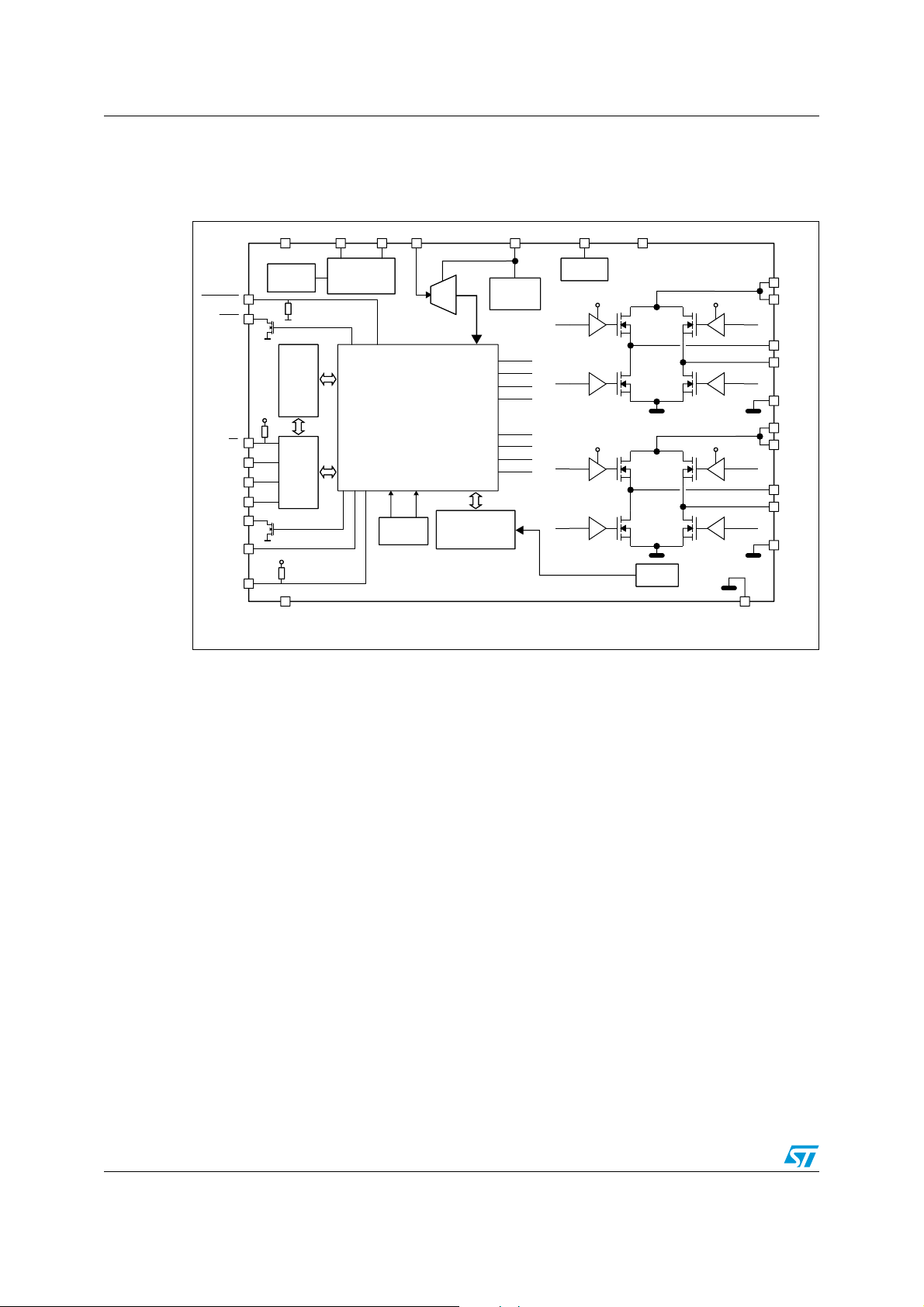

Block diagram L6474

1 Block diagram

Figure 1. Block diagram

9'' 26&,1 26&287 $'&,1 95(* &3 9%227

67%<5(6

)/$*

6'2

6<1&

67&.

6',

',5

0+]

2VFLOODWRU

9''

&6

&.

([W2VFGULYHU

5HJLVWHUV

&ORFNJHQ

$'&

&RQWURO

/RJLF

9

9ROWDJH5HJ

+6 $

/6$

+6 $

/6$

+6 %

/6%

+6 %

/6%

63,

&XUUHQW'$&V

&RPSDUDWRUV

9''

'*1'

7HPSHUDWXUH

VHQVLQJ

&KDUJH

SXPS

9ERRW 9ERRW

+6 $

/6$

9ERRW 9ERRW

+6 %

/6%

&XUUHQW

VHQVLQJ

96$

96$

+6 $

287$

287$

/6$

3*1'

96%

96%

+6 %

287%

287%

/6%

3*1'

$*1'

!-V

6/51 Doc ID 022529 Rev 2

L6474 Electrical data

2 Electrical data

2.1 Absolute maximum ratings

Table 2. Absolute maximum ratings

Symbol Parameter Test condition Value Unit

VDD Logic interface supply voltage 5.5 V

VS Motor supply voltage VSA = VSB = VS 48 V

Differential voltage between AGND,

V

V

V

V

I

out_peak

1. Maximum output current limit is related to metal connection and bonding characteristics. Actual limit must satisfy maximum

thermal dissipation constraints.

2. TBD.

GND, diff

V

boot

V

REG

ADCIN

V

OSC

out_diff

LOGIC

I

out

T

OP

T

P

tot

PGND and DGND

Bootstrap peak voltage 55 V

Internal voltage regulator output pin

and logic supply voltage

Integrated ADC input voltage range

(ADCIN pin)

OSCIN and OSCOUT pin voltage

range

Differential voltage between V

, OUT2A, PGND and VSB,

OUT1

A

OUT1

, OUT2B, PGND pins

B

SA

,

= VSB = VS 48 V

V

SA

Logic inputs voltage range -0.3 to +5.5 V

(1)

R.m.s. output current 3 A

(1)

Pulsed output current T

< 1 ms 7 A

PULSE

Operating junction temperature 150 °C

Storage temperature range -55 to 150 °C

s

Total power dissipation (TA = 25 ºC)

(2)

±0.3 V

3.6 V

-0.3 to +3.6 V

-0.3 to +3.6 V

TBD W

Doc ID 022529 Rev 2 7/51

Electrical data L6474

2.2 Recommended operating conditions

Table 3. Recommended operating conditions

Symbol Parameter Test condition Value Unit

V

Logic interface supply voltage

DD

V

Motor supply voltage VSA = VSB = VS 8 45 V

S

Differential voltage between

, OUT1A, OUT2A, PGND

V

V

out_diff

SA

and V

, OUT1B, OUT2B,

SB

PGND pins

V

Logic supply voltage

REG,in

Integrated ADC input voltage

V

ADC

(ADCIN pin)

Operating junction temperature -25 125 °C

T

j

2.3 Thermal data

Table 4. Thermal data

Symbol Parameter Package Typ Unit

R

thJA

1. TBD.

2. TBD.

Thermal resistance junction-ambient

3.3 V logic outputs 3.3 V

5 V logic outputs 5

V

= V

SA

V

REG

external source

= VS 45 V

SB

voltage imposed by

HTSSOP28

POWERSO36

3.2 3.3 V

TBD

TBD

REG

V

°C/W

0 V

(1)

(2)

8/51 Doc ID 022529 Rev 2

L6474 Electrical characteristics

3 Electrical characteristics

VSA = VSB = 36 V; VDD = 3.3 V; internal 3 V regulator; TJ = 25 °C, unless otherwise

specified.

Table 5. Electrical characteristics

Symbol Parameter Test condition Min. Typ. Max. Unit

General

V

SthOn

V

SthOff

V

SthHyst VS

I

q

T

j(WRN)

T

j(SD)

VS UVLO turn-on threshold 7.5 8.2 8.9 V

VS UVLO turn-off threshold 6.6 7.2 7.8 V

UVLO threshold hysteresis 0.7 1 1.3 V

Quiescent motor supply current

Thermal warning temperature 130 °C

Thermal shutdown temperature 160 °C

Charge pump

Voltage swing for charge pump oscillator 10 V

V

pump

f

pump,min

f

pump,max

I

boot

Minimum charge pump oscillator frequency

(1)

Maximum charge pump oscillator frequency

(1)

Average boot current

Output DMOS transistor

High side switch ON resistance

R

DS(on)

Low side switch ON resistance

I

DSS

t

Leakage current

Rise time

r

(3)

Internal oscillator selected;

V

= 3.3 V ext; CP

REG

floating

= f

f

sw,A

= 15.6 kHz

sw,B

POW_SR = ‘10’

= 25 °C, I

T

j

T

= 125 °C,

j

T

= 25 °C, I

j

= 125 °C,

T

j

OUT = V

= 3A 0.37

out

(2)

I

= 3A 0.51

out

= 3A 0.18

out

(2)

I

= 3A 0.23

out

S

OUT = GND -0.3

POW_SR = '00', I

POW_SR = '00', I

POW_SR = ‘11’, I

POW_SR = ‘10’, I

POW_SR = ‘01’, I

= +1A 100

out

= -1A 80

out

= ±1A 100

out

= ±1A 200

out

= ±1A 300

out

0.5 0.65 mA

660 kHz

800 kHz

1.1 1.4 mA

Ω

3.1

mA

ns

Doc ID 022529 Rev 2 9/51

Electrical characteristics L6474

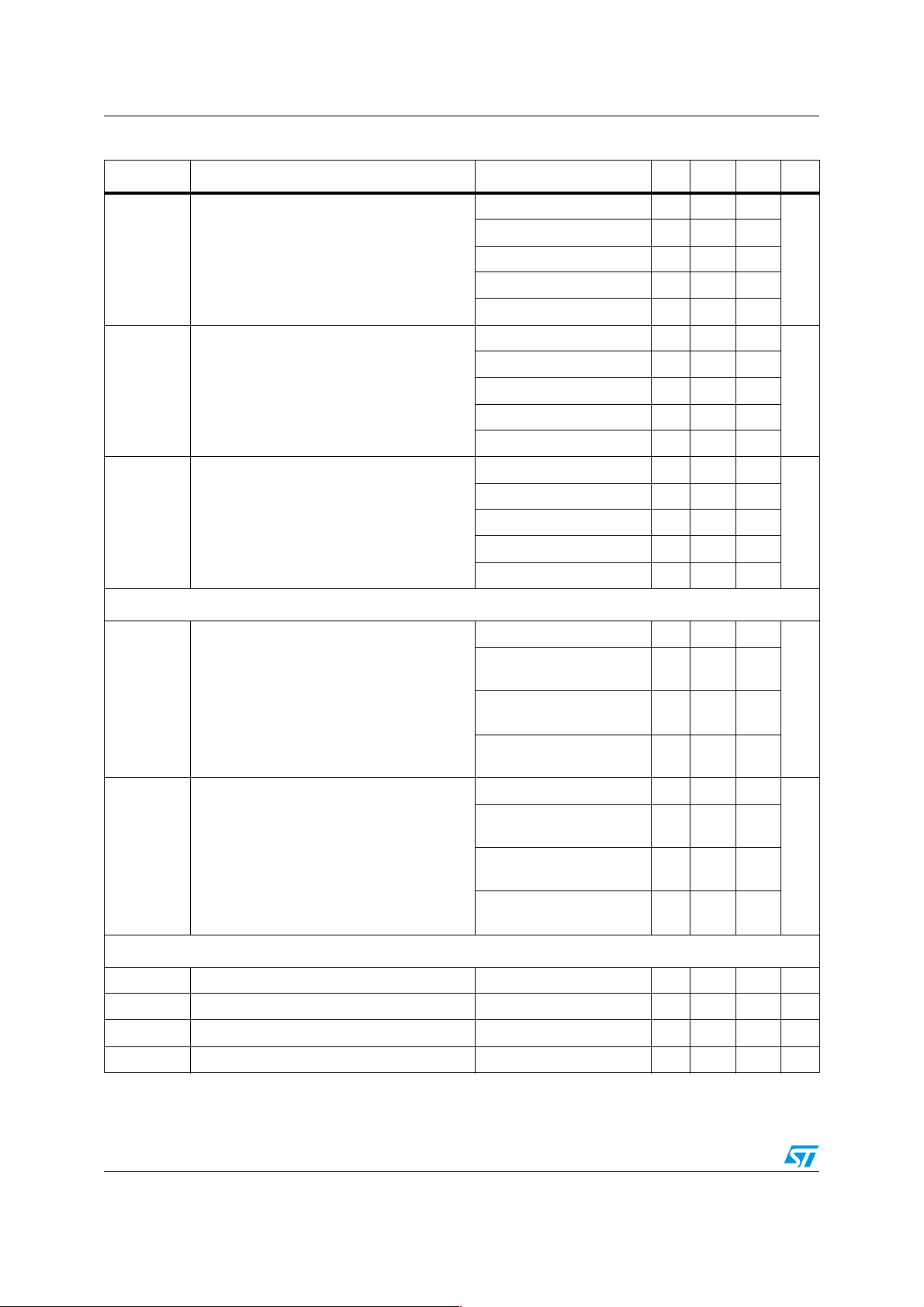

Table 5. Electrical characteristics (continued)

Symbol Parameter Test condition Min. Typ. Max. Unit

(3)

SR

SR

t

f

out_r

out_f

Fall time

Output rising slew-rate

Output falling slew-rate

Dead time and blanking

POW_SR = '00'; I

POW_SR = '00'; I

POW_SR = ‘11’, I

POW_SR = ‘10’, I

POW_SR = ‘01’, I

POW_SR = '00', I

POW_SR = '00', I

POW_SR = ‘11’, I

POW_SR = ‘10’, I

POW_SR = ‘01’, I

POW_SR = '00', I

POW_SR = '00', I

POW_SR = ‘11’, I

POW_SR = ‘10’, I

POW_SR = ‘01’, I

= +1A 90

out

= -1A 110

out

= ±1A 110

out

= ±1A 260

out

= ±1A 375

load

= +1A 285

out

= -1A 360

out

= ±1A 285

out

= ±1A 150

out

= ±1A 95

out

= +1A 320

out

= -1A 260

out

= ±1A 260

out

= ±1A 110

out

= ±1A 75

out

POW_SR = '00' 250

ns

V/µs

V/µs

t

DT

t

blank Blanking time

Dead time

Source-drain diodes

High side diode forward ON voltage I

V

SD,HS

V

Low side diode forward ON voltage I

SD,LS

t

rrHS

t

rrLS

High side diode reverse recovery time I

Low side diode reverse recovery time I

(1)

(1)

POW_SR = ‘11’,

= 16 MHz

f

OSC

POW_SR = ‘10’,

f

= 16 MHz

OSC

POW_SR = ‘01’,

= 16 MHz

f

OSC

375

625

875

POW_SR = '00' 250

POW_SR = ‘11’,

= 16 MHz

f

OSC

POW_SR = ‘10’,

= 16 MHz

f

OSC

POW_SR = ‘01’,

f

= 16 MHz

OSC

= 1 A 1 1.1 V

out

= 1 A 1 1.1 V

out

= 1 A 30 ns

out

= 1 A 100 ns

out

375

625

875

ns

ns

10/51 Doc ID 022529 Rev 2

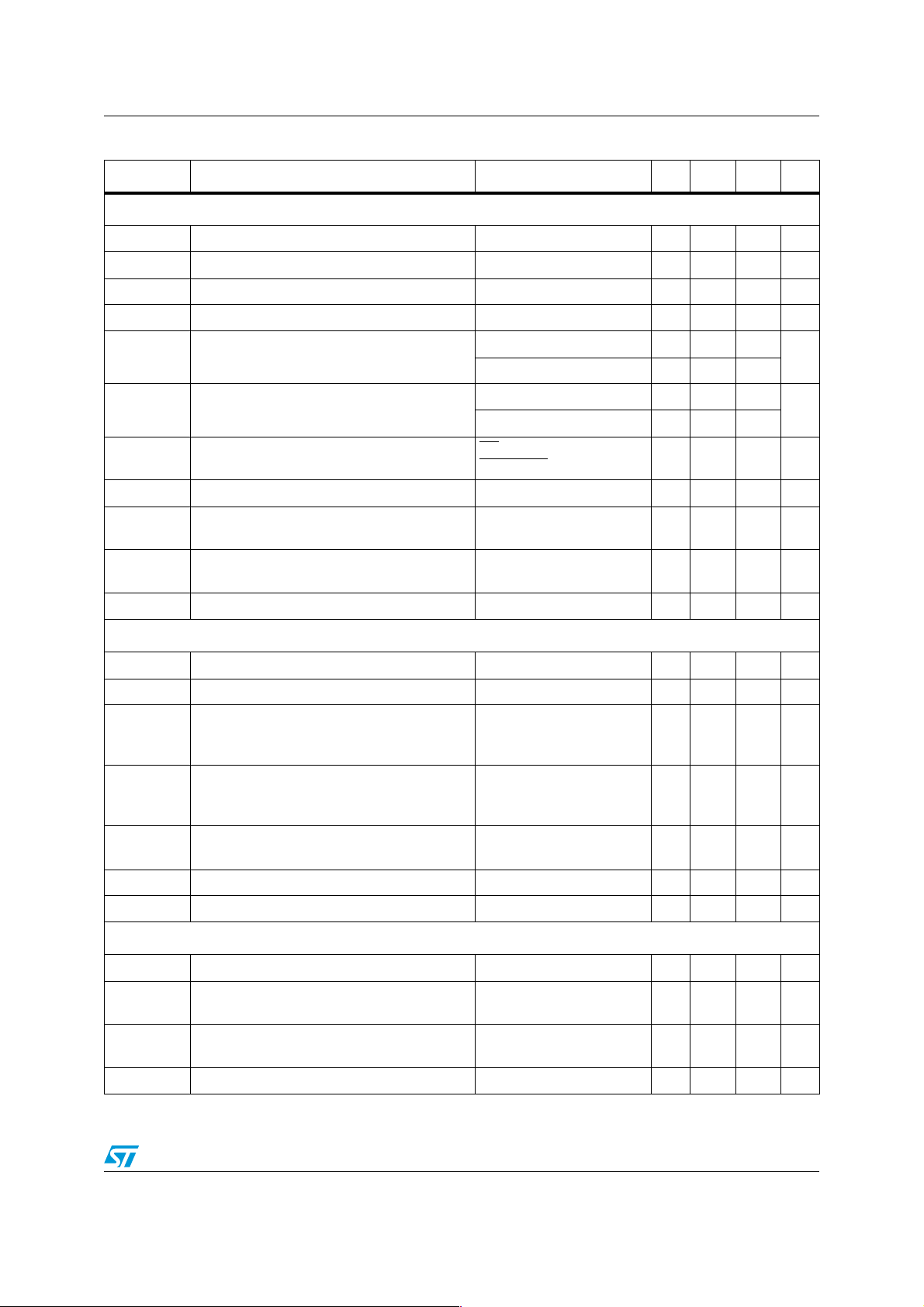

L6474 Electrical characteristics

Table 5. Electrical characteristics (continued)

Symbol Parameter Test condition Min. Typ. Max. Unit

Logic inputs and outputs

V

Low logic level input voltage 0.8 V

IL

V

High logic level input voltage 2 V

IH

I

IH

I

IL

V

OL

High logic level input current

Low logic level input current

Low logic level output voltage

VOH High logic level output voltage

RPU

R

R

PUDIR

I

logic

PD

CS pull-up and STBY pull-down resistors

DIR input pull-up resistance DIR = GND 60 85 110 kΩ

Internal logic supply current

(4)

V

(5)

(6)

= 5 V 1 µA

IN

V

= 0 V -1 µA

IN

VDD = 3.3 V, IOL = 4 mA 0.3

VDD = 5 V, IOL = 4 mA 0.3

V

= 3.3 V, IOH = 4 mA 2.4

DD

= 5 V, IOH = 4 mA 4.7

V

DD

= GND;

CS

STBY/RST

3.3 V V

= 5 V

externally

REG

supplied, internal oscillator

335 430 565 kΩ

3.7 4.3 mA

V

V

I

logic,STBY

f

Standby mode internal logic supply current

Step clock input frequency 2 MHz

STCK

Internal oscillator and external oscillator driver

Internal oscillator frequency T

f

osc,i

f

Programmable external oscillator frequency 8 32 MHz

osc,e

V

OSCOUTH

V

OSCOUTL

t

rOSCOUT

t

fOSCOUT

t

t

OSCOUT clock source high level voltage

OSCOUT clock source low level voltage

OSCOUT clock source rise and fall time Internal oscillator 20 ns

Internal to external oscillator switching delay 3 ms

extosc

intosc

External to internal oscillator switching delay 1.5 µs

SPI

f

Maximum SPI clock frequency

CK,MAX

t

rCK

t

fCK

t

hCK

t

lCK

t

setCS

SPI clock rise and fall time

SPI clock high and low time

Chip select set-up time

(7)

(7)

(7)

(7)

3.3 V V

supplied

= 25 °C, V

j

externally

REG

REG

2 2.5 µA

= 3.3 V -3% 16 +3% MHz

Internal oscillator 3.3 V

V

externally supplied;

REG

I

OSCOUT

= 4 mA

2.4 V

Internal oscillator 3.3 V

V

externally supplied;

REG

I

OSCOUT

= 4 mA

0.3 V

5 MHz

CL = 30 pF 25 ns

75 ns

350 ns

Doc ID 022529 Rev 2 11/51

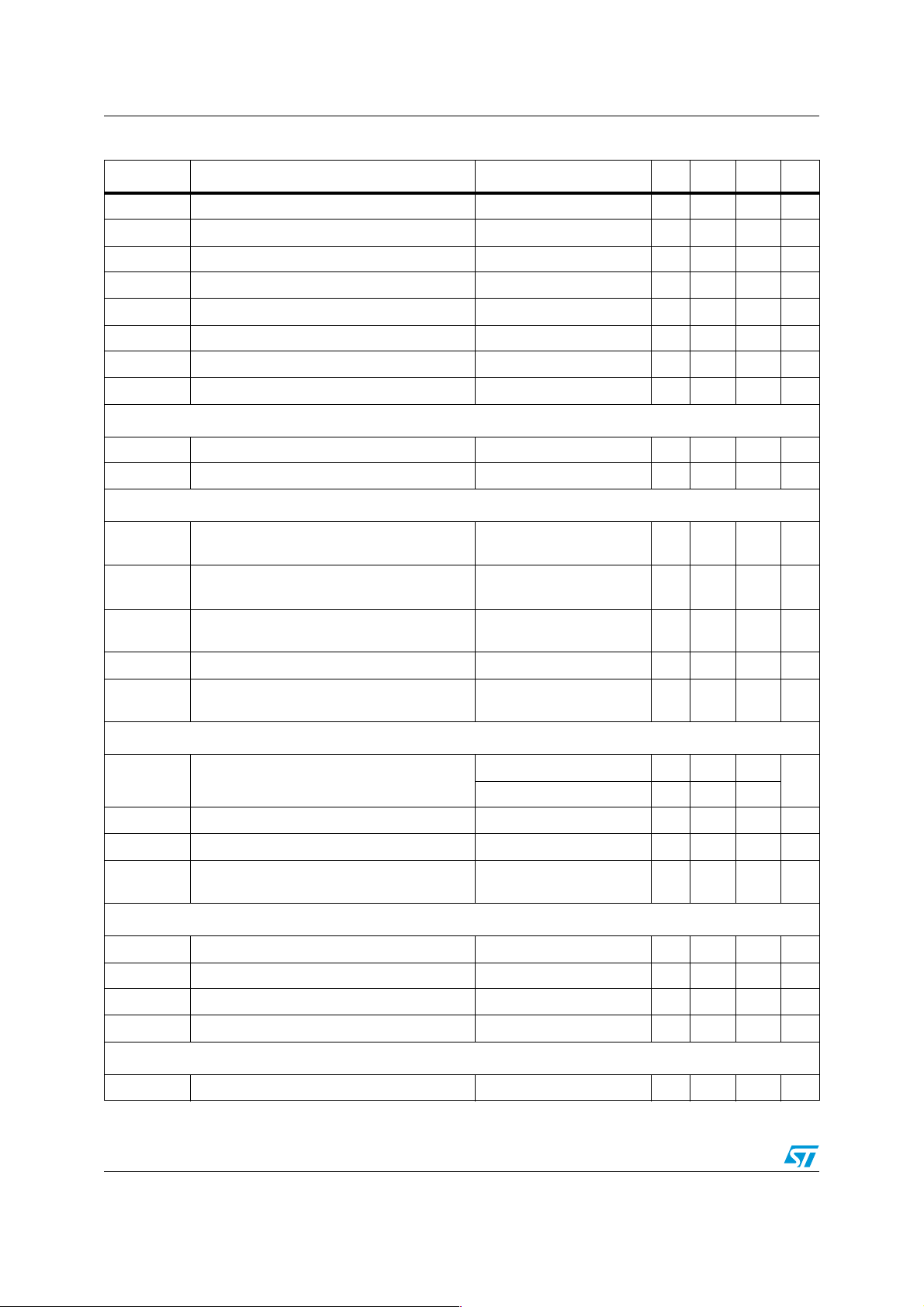

Electrical characteristics L6474

Table 5. Electrical characteristics (continued)

Symbol Parameter Test condition Min. Typ. Max. Unit

(7)

(7)

10 ns

800 ns

(7)

(7)

(7)

(7)

(7)

(7)

37 ns

25 ns

20 ns

38 ns

47 ns

57 ns

t

Chip select hold time

holCS

t

Deselect time

disCS

t

setSDI

t

holSDI

t

enSDO

t

disSDO

t

vSDO

t

holSDO

Data input set-up time

Data input hold time

Data output enable time

Data output disable time

Data output valid time

Data output hold time

Current control

I

STEP,max

I

STEP,m in

Max. programmable reference current 4 A

Min. programmable reference current 31 mA

Overcurrent protection

I

OCD,MAX

I

OCD,MIN

I

OCD,RES

t

OCD,Flag

t

OCD,SD

Maximum programmable overcurrent

detection threshold

Minimum programmable overcurrent

detection threshold

Programmable overcurrent detection

threshold resolution

OCD to flag signal delay time dI

OCD to shut down delay time

Standby

qSTBY

t

STBY,min

t

logicwu

t

cpwu

conditions

Minimum standby time 10 µs

Logic power-on and wake-up time 38 45 µs

Charge pump power-on and wake-up time

Quiescent motor supply current in standby

I

Internal voltage regulator

OCD_TH = ‘1111’ 6 A

OCD_TH = ‘0000’ 0.375 A

0.375 A

= 350A/µs 650 1000 ns

out/dt

= 350A/µs

dI

out/dt

POW_SR = '10'

V

= 8 V 26 34

S

S = 36 V 30 36

V

Power bridges disabled, C

= 10 nF, C

= 220 nF

boot

p

600 µs

µA

650 µs

Voltage regulator output voltage 2.9 3 3.2 V

V

REG

I

Voltage regulator output current 40 mA

REG

V

REG, drop

I

REG,STBY

Voltage regulator output voltage drop I

= 40 mA 50 mV

REG

Voltage regulator standby output current 10 mA

Integrated analog to digital converter

Analog to digital converter resolution 5 bit

N

ADC

12/51 Doc ID 022529 Rev 2

L6474 Electrical characteristics

Table 5. Electrical characteristics (continued)

Symbol Parameter Test condition Min. Typ. Max. Unit

V

1. Accuracy depends on oscillator frequency accuracy.

2. Tested at 25 °C in a restricted range and guaranteed by characterization.

3. Rise and fall time depends on motor supply voltage value. Refer to SR

4. Not valid for STBY/RST

5. Not valid for SW and CS pins which have internal pull-up resistor.

6. FLAG

7. See Figure 13– SPI timings diagram for details.

Analog to digital converter reference voltage V

ADC,ref

f

S

rise and fall time.

Analog to digital converter sampling

frequency

out

pins which have internal pull-down resistor.

and SYNC open drain outputs included.

V

REG

f

/

OSC

512

values (Table 5) in order to evaluate the actual

kHz

Doc ID 022529 Rev 2 13/51

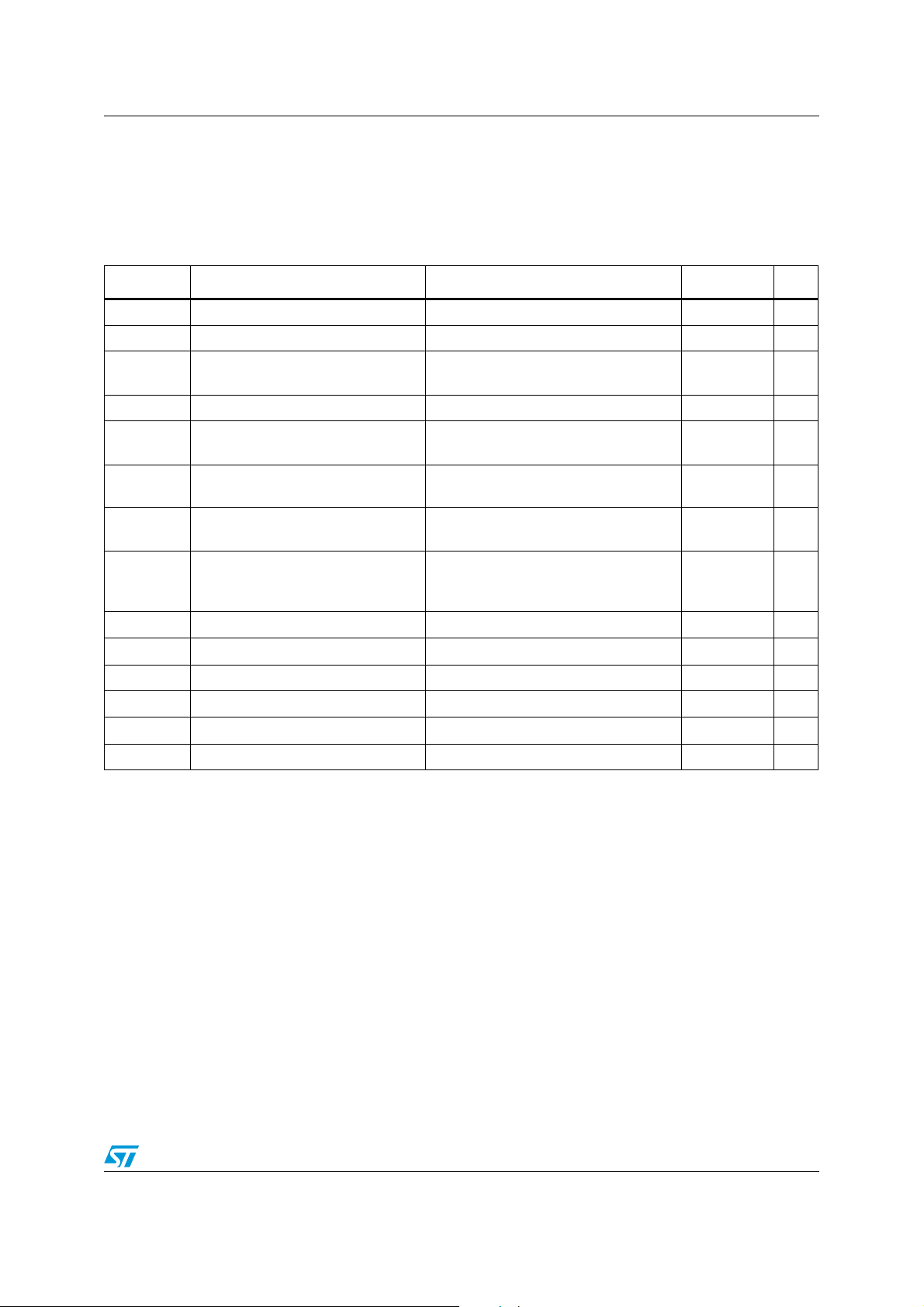

Pin connection L6474

4 Pin connection

Figure 2. HTSSOP28 pin connection (top view)

RST

DIR

Figure 3. POWERSO36 pin connection (top view)

74"

74"

74#

74#

48

&1"%

$1

1(/%

065"

065"

45#:345

"%$*/

73&(

04$*/

04$065

"(/%

7#005

065#

065#

065"

065"

74"

74"

45$,

'-"(

$4

#64:=4:/$

%(/%

4%*

$,

4%0

7%%

74#

74#

065#

065#

1(/%

14/51 Doc ID 022529 Rev 2

L6474 Pin connection

4.1 Pin list

Table 6. Pin description

N. Name Type Function

17 VDD Power Logic outputs supply voltage (pull-up reference)

6 VREG Power

7 OSCIN Analog input

Internal 3 V voltage regulator output and 3.3 V external logic

supply

Oscillator pin 1. To connect an external oscillator or clock source.

If this pin is unused, it should be left floating.

Oscillator pin 2. To connect an external oscillator. When the

8 OSCOUT Analog output

internal oscillator is used this pin can supply 2/4/8/16 MHz. If this

pin is unused, it should be left floating.

10 CP Output Charge pump oscillator output

11 VBOOT Supply voltage

Bootstrap voltage needed for driving the high side power DMOS of

both bridges (A and B)

5 ADCIN Analog input Internal analog to digital converter input

2

VSA Power supply Full bridge A power supply pin. It must be connected to VSB

26

12

VSB Power supply Full bridge B power supply pin. It must be connected to VSA

16

27

PGND Ground Power ground pin

13

1 OUT1A Power output Full bridge A output 1

28 OUT2A Power output Full bridge A output 2

14 OUT1B Power output Full bridge B output 1

15 OUT2B Power output Full bridge B output 2

9 AGND Ground Analog ground

4 DIR Logical input Direction input

21 DGND Ground Digital ground

22 SYNC Open drain output Synchronization signal.

18 SDO Logic output Data output pin for serial interface

20 SDI Logic input Data input pin for serial interface

19 CK Logic input Serial interface clock

23 CS Logic input Chip select input pin for serial interface

Status flag pin. An internal open drain transistor can pull the pin to

24 FLAG Open drain output

GND when a programmed alarm condition occurs (step loss,

OCD, thermal pre-warning or shutdown, UVLO, wrong command,

non performable command)

Standby and reset pin. LOW logic level resets the logic and puts

3 STBY\RST

Logic input

the device into standby mode. If not used, should be connected to

VDD

Doc ID 022529 Rev 2 15/51

Pin connection L6474

Table 6. Pin description (continued)

N. Name Type Function

25 STCK Logic input Step clock input

EPAD Exposed pad Ground Internally connected to PGND, AGND and DGND pins

16/51 Doc ID 022529 Rev 2

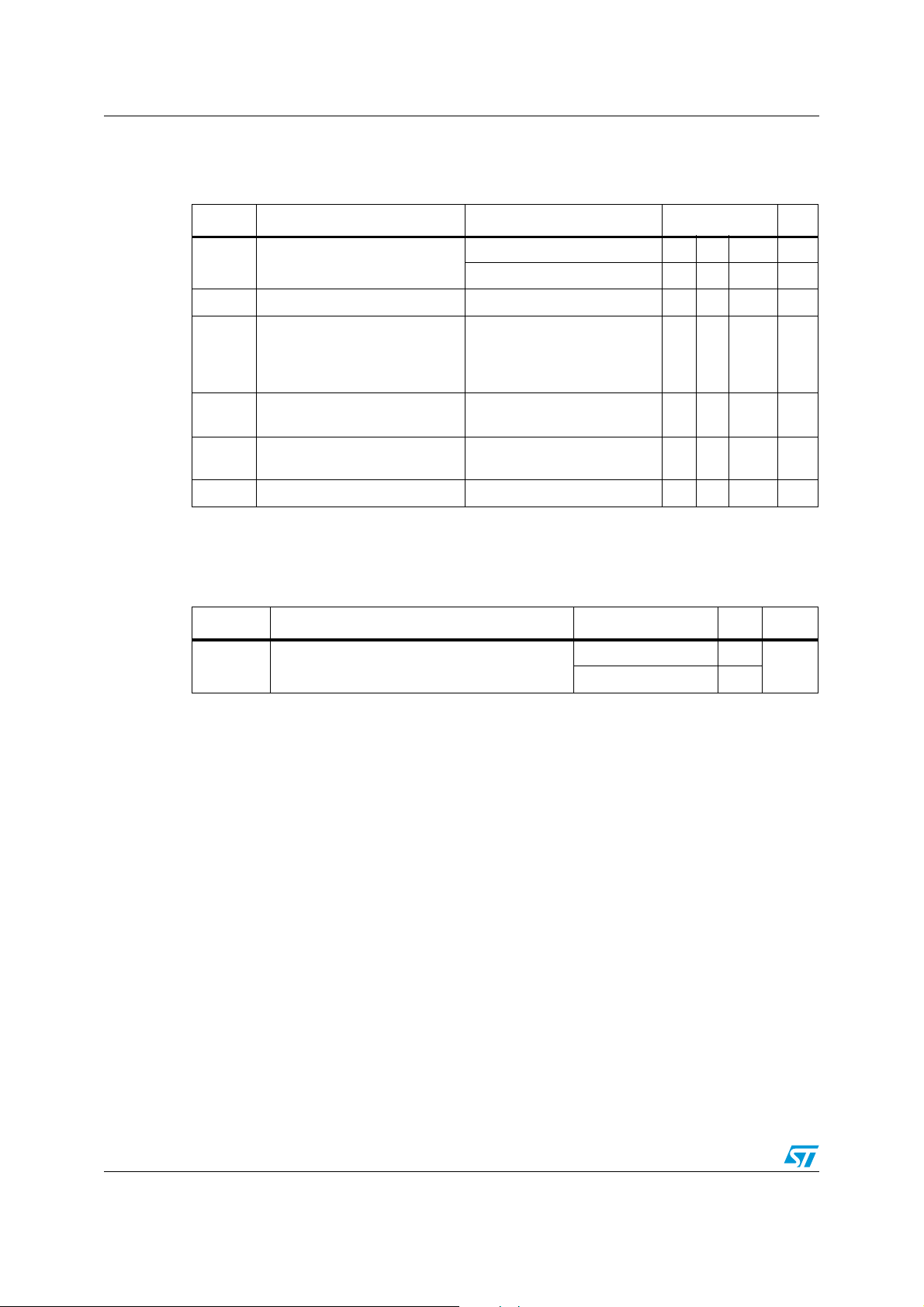

L6474 Typical applications

5 Typical applications

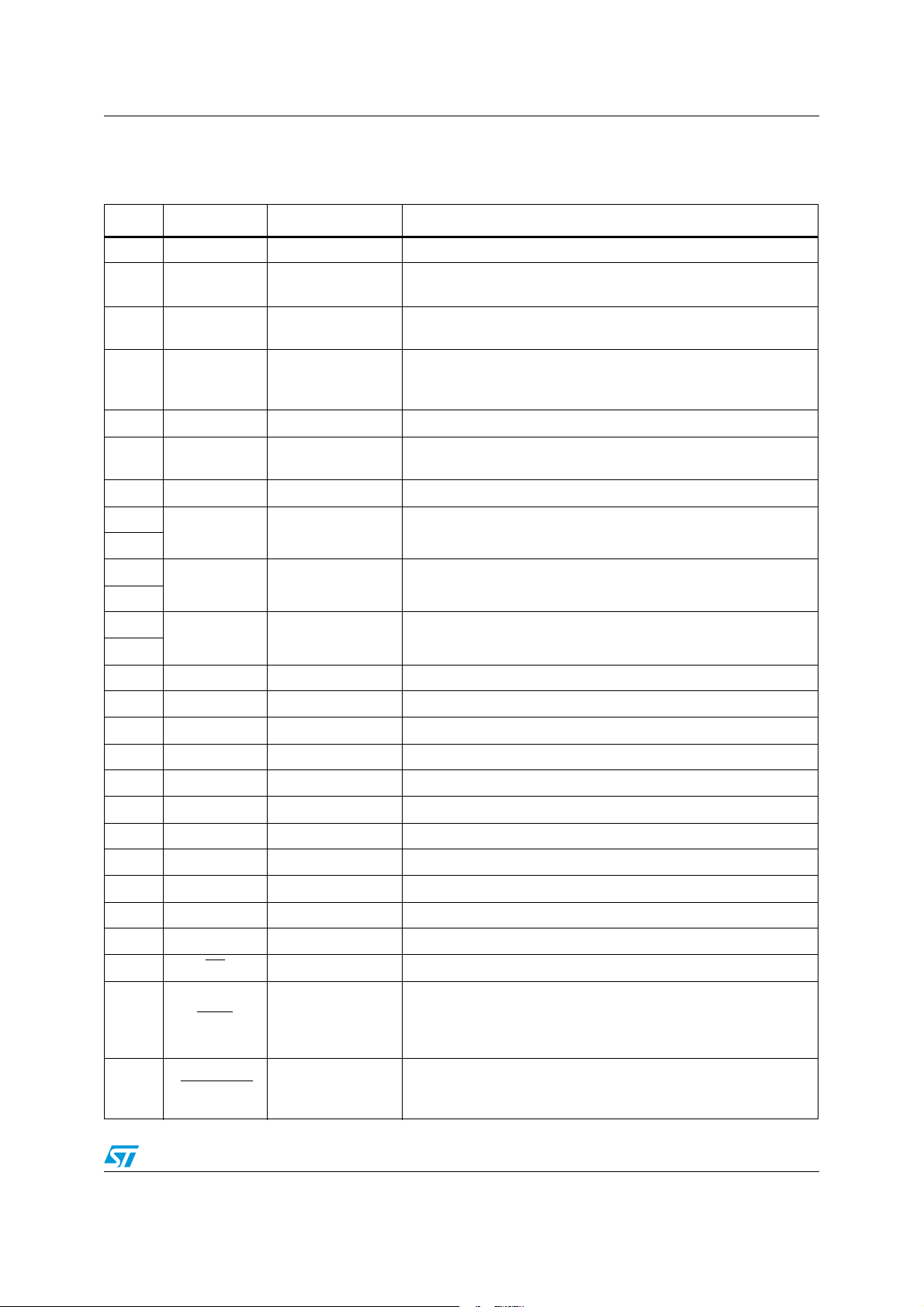

Table 7. Typical application values

Name Value

220 nF

C

VS

C

C

C

100 µF

VSPOL

C

100 nF

REG

47 µF

REGPOL

C

100 nF

DD

10 µF

DDPOL

D1 Charge pump diodes

C

220 nF

BOOT

C

10 nF

FLY

R

39 kΩ

PU

R

100 Ω

SW

CSW 10 nF

Figure 4. Bipolar stepper motor control application using L6474

#

"//4

$

(/34

'0)/

30)

#

$$0/,

2

2

05

05

&,!'

39.#

34#+

34"9

$)2

#3

#+

3$/

3$)

/3#).

/3#/54

#

$$

,

#

63

#

&,9

6"//4 #0 63" 63!6$$62%'

!$#).

/54!

/54!

/54"

/54"

0'.$!'.$$'.$

63

66

#

-OTOR

630/,

Doc ID 022529 Rev 2 17/51

Functional description L6474

6 Functional description

6.1 Device power-up

At power-up end, the device state is the following:

● Registers are set to default

● Internal logic is driven by internal oscillator and a 2 MHz clock is provided by the

OSCOUT pin

● Bridges are disabled (High Z)

● UVLO bit in STATUS register is forced low (fail condition)

● FLAG output is forced low.

During power-up the device is under reset (all logic IO disabled and power bridges in high

impedance state) until the following conditions are satisfied:

● V

●

● Internal oscillator is operative.

is greater than V

S

V

is greater than V

REG

SthOn

REGth

= 2.8 V typical

6.2 Logic I/O

Pins CS, CK, SDI, STCK, DIR and STBY\RST are TTL/CMOS 3.3 V-5 V compatible logic

inputs.

Pin SDO is a TTL/CMOS compatible logic output. VDD pin voltage sets the logic output pin

voltage range; when it is connected to VREG or 3.3 V external supply voltage, the output is

3.3 V compatible. When VDD is connected to a 5 V supply voltage, SDO is 5 V compatible.

VDD is not internally connected to V

A 10 µF capacitor should be connected to the VDD pin in order to obtain a proper operation.

Pins FLAG

and SYNC are open drain outputs.

6.3 Charge pump

To ensure the correct driving of the high side integrated MOSFETs, a voltage higher than

the motor power supply voltage needs to be applied to the VBOOT pin. The high side gate

driver supply voltage VBOOT is obtained through an oscillator and a few external

components realizing a charge pump (see Figure 5).

, an external connection is always needed.

REG

18/51 Doc ID 022529 Rev 2

L6474 Functional description

Figure 5. Charge pump circuitry

6.4 Microstepping

The driver is able to divide the single step into up to 16 microsteps. Stepping mode can be

programmed by STEP_SEL parameter in STEP_MODE register (see Ta bl e 1 9 ).

Step mode can only be changed when bridges are disabled. Every time the step mode is

changed, the electrical position (i.e. the point of microstepping sinewave that is generated)

is reset to the first microstep and the absolute position counter value (see Section 6.5)

becomes meaningless.

Figure 6. Normal mode and microstepping (16 microsteps)

Doc ID 022529 Rev 2 19/51

Functional description L6474

6.5 Absolute position counter

An internal 22 bit register (ABS_POS) takes memory of motor motion according to the

selected step mode; the stored value unit is equal to the selected step mode (full, half,

quarter, etc.). The position range is from -2

21

to +221-1 (µ) steps (see Section 9.1.1).

6.6 Step sequence control

The motor movement is defined by the step clock signal applied to the STCK pin. At each

step clock rising edge, the motor is moved by one microstep in the direction selected by DIR

input (high for forward direction and low for reverse direction) and absolute position is

consequently updated.

6.7 Enable and disable commands

The power stage of the device can be enabled and disabled through the respective SPI

commands.

The enable command turns on the power outputs and starts the current control algorithm.

The phase currents are controlled according to present EL_POS value. If a fault condition

requires the power stage to be disabled, the command is ignored.

The disable command immediately forces the power outputs in a high impedance condition.

20/51 Doc ID 022529 Rev 2

L6474 Functional description

6.8 Internal oscillator and oscillator driver

The control logic clock can be supplied by the internal 16 MHz oscillator, an external

oscillator (crystal or ceramic resonator) or a direct clock signal.

These working modes can be selected by EXT_CLK and OSC_SEL parameters in the

CONFIG register (see Ta b le 2 3 ).

At power-up the device starts using the internal oscillator and provides a 2 MHz clock signal

on the OSCOUT pin.

Attention: In any case, before changing clock source configuration, a

hardware reset is mandatory. Switching to different clock

configurations during operation could cause unexpected

behavior.

6.8.1 Internal oscillator

In this mode the internal oscillator is activated and OSCIN is unused. If OSCOUT clock

source is enabled, the OSCOUT pin provides a 2, 4, 8 or 16 MHz clock signal (according to

OSC_SEL value); otherwise it is unused (see Figure 7).

6.8.2 External clock source

Two types of external clock source can be selected: crystal/ceramic resonator or direct clock

source. Four programmable clock frequencies are available for each external clock source:

8, 16, 24 and 32 MHz.

When an external crystal/resonator is selected, the OSCIN and OSCOUT pins are used to

drive the crystal/resonator (see Figure 7). The crystal/resonator and load capacitors (CL)

must be placed as close as possible to the pins. Refer to Ta bl e 8 for the choice of the load

capacitor value according to the external oscillator frequency.

Table 8. CL values according to external oscillator frequency

Crystal/resonator freq.

8 MHz 25 pF (ESR

16 MHz 18 pF (ESR

24 MHz 15 pF (ESR

32 MHz 10 pF (ESR

1. First harmonic resonance frequency.

2. Lower ESR value allows driving greater load capacitors.

If a direct clock source is used, it must be connected to the OSCIN pin and the OSCOUT pin

supplies the inverted OSCIN signal (see Figure 7).

(1)

CL

(2)

max

max

max

max

= 80 Ω)

= 50 Ω)

= 40 Ω)

= 40 Ω)

Doc ID 022529 Rev 2 21/51

Functional description L6474

Figure 7. OSCIN and OSCOUT pin configurations

Note: When OSCIN is UNUSED, it should be left floating.

When OSCOUT is UNUSED it should be left floating.

6.9 Overcurrent detection

When the current in any of the power MOSFETs exceeds a programmed overcurrent

threshold, the STATUS register OCD flag is forced low until the overcurrent event has

expired and a GetStatus command is sent to the IC (see paragraphs 9.1.13 and 9.1.9).

Overcurrent event expires when all the power MOSFET currents fall below the programmed

overcurrent threshold.

The overcurrent threshold can be programmed through the OCD_TH register in one of 16

available values ranging from 375 mA to 6 A with steps of 375 mA (see Ta bl e 9 , paragraph

9.1.9).

It is possible to set whether or not an overcurrent event causes the MOSFET turn-off

(bridges in high impedance status) acting on the OC_SD bit in the CONFIG register (see

paragraph 9.1.12). The OCD flag in the STATUS register is raised anyway (see Ta bl e 2 8 ,

paragraph 9.1.13).

When the IC outputs are turned off by an OCD event, they cannot be turned on until the

OCD flag is released by a GetStatus command.

22/51 Doc ID 022529 Rev 2

L6474 Functional description

Attention: The overcurrent shutdown is a critical protection feature. It is

not recommended to disable it.

6.10 Undervoltage lock-out (UVLO)

The L6474 provides a motor supply UVLO protection. When the motor supply voltage falls

below the VSthOff threshold voltage, the STATUS register UVLO flag is forced low. When a

GetStatus command is sent to the IC, and the undervoltage condition has expired, the

UVLO flag is released (see paragraphs 9.1.13 and 9.2.7). Undervoltage condition expires

when the motor supply voltage goes over the VSthOn threshold voltage. When the device is

in undervoltage condition no motion can be performed. The UVLO flag is forced low by logic

reset (power-up included) even if no UVLO condition is present.

6.11 Thermal warning and thermal shutdown

An internal sensor allows the L6474 to detect when the device internal temperature exceeds

a thermal warning or an overtemperature threshold.

When the thermal warning threshold (T

register is forced low (see paragraph 9.1.13) until the temperature decreases below T

and a GetStatus command is sent to the IC (see paragraphs 9.1.13 and 9.2.7).

When the thermal shutdown threshold (T

shutdown condition: the TH_SD bit in the STATUS register is forced low, the power bridges

are disabled, bridges in high impedance state and the HiZ bit in the STATUS register are

raised (see paragraph 9.1.13).

Thermal shutdown condition only expires when the temperature goes below the thermal

warning threshold (T

On exiting thermal shutdown condition, the bridges are still disabled (HiZ flag high).

j(WRN)

6.12 Reset and standby

The device can be reset and put into standby mode through a dedicated pin. When the

STBY

\RST pin is driven low, the bridges are left open (High Z state), the internal charge

pump is stopped, the SPI interface and control logic are disabled, and the internal 3 V

voltage regulator maximum output current is reduced to I

heavily reduces the power consumption. At the same time the register values are reset to

default and all protection functions are disabled. STBY\RST

least for tSTBY, min. in order to ensure the complete switch to standby mode.

On exiting standby mode, as well as for IC power-up, a delay of up to tlogicwu must be given

before applying a new command to allow proper oscillator and logic startup and a delay of

up to tcpwu must be given to allow the charge pump startup.

) is reached, the TH_WRN bit in the STATUS

j(WRN)

) is reached, the device goes into thermal

j(OFF)

).

REG,STBY

; as a result the L6474

input must be forced low at

j(WRN)

On exiting standby mode the bridges are disabled (HiZ flag high).

Doc ID 022529 Rev 2 23/51

Functional description L6474

Attention: It is not recommended to reset the device when outputs are

active. The device should be switched to high impedance

state before being reset.

6.13 Programmable DMOS slew-rate, dead-time and blanking-time

Using the POW_SR parameter in the CONFIG register, it is possible to set the commutation

speed of the power bridges output (see Ta bl e 2 5, paragraph 9.1.17).

6.14 Integrated analog to digital converter

The L6474 integrates a NADC bit ramp-compare analog to digital converter with a reference

voltage equal to VREG. The analog to digital converter input is available through the ADCIN

pin and the conversion result is available in the ADC_OUT register (see paragraph 9.1.13).

Sampling frequency is equal to the clock frequency divided by 512.

The ADC_OUT value can be used for the torque regulation or is at the user’s disposal.

6.15 Internal voltage regulator

The L6474 integrates a voltage regulator which generates a 3 V voltage starting from the

motor power supply (VSA and VSB). In order to make the voltage regulator stable, at least

22 µF should be connected between the VREG pin and ground (suggested value is 47 µF).

The internal voltage regulator can be used to supply the VDD pin in order to make the

device digital output range 3.3 V compatible (Figure 8). A digital output range 5 V

compatible can be obtained connecting the VDD pin to an external 5 V voltage source. In

both cases, a 10 µF capacitance should be connected to the VDD pin in order to obtain a

correct operation.

The internal voltage regulator is able to supply a current up to I

consumption included (I

can be supplied is I

REG, STBY

If an external 3.3 V regulated voltage is available, it can be applied to the VREG pin in order

to supply all the internal logic and avoid power dissipation of the internal 3 V voltage

regulator (Figure 8). The external voltage regulator should never sink current from the

VREG pin.

). When the device is in standby mode the maximum current that

logic

, internal consumption included (I

REG,MAX, internal logic

logic, STBY

).

24/51 Doc ID 022529 Rev 2

L6474 Functional description

Figure 8. Internal 3 V linear regulator

6"!4

6S

6

$$

6

62%' 6$$ 63! 63"

6

2%'

62%' 6$$ 63! 63"

6

S

M#

6.16 SYNC pin

This pin works as a synchronization signal: the output status is an echo of one of the bits of

the EL_POS register according to a SYNC_SEL and STEP_SEL parameter combination

(see paragraph 9.1.10).

6.17 FLAG pin

By default, an internal open drain transistor pulls the FLAG pin to ground when at least one

of the following conditions occurs:

● Power-up or standby/reset exit

● Overcurrent detection

● Thermal warning

● Thermal shutdown

● UVLO

● Switch turn-on event

● Wrong command

● Non performable command.

,OGIGSUPPLIEDBY

).4%2.!,VOLTAGEREGULATOR

)#

)#

!'.$$'.$

,OGIGSUPPLIEDBY

%84%2.!,VOLTAGEREGULATOR

!'.$$'.$

It is possible to mask one or more alarm conditions by programming the ALARM_EN

register (see paragraph 9.1.11, Ta b le 2 1 ). If the corresponding bit of the ALARM_EN

register is low, the alarm condition is masked and it does not cause a FLAG pin transition; all

other actions imposed by alarm conditions are performed anyway. In case of daisy-chain

configuration, FLAG pins of different ICs can be or-wired to save host controller GPIOs.

Doc ID 022529 Rev 2 25/51

Phase current control L6474

7 Phase current control

The L6474 performs a peak current control technique described in detail in Section 7.1.

Furthermore, the L6474 automatically selects the best decay mode in order to follow the

current profile.

Current control algorithm parameters can be programmed by T_FAST, TON_MIN,

TOFF_MIN and CONFIG registers (see paragraphs 9.1.5, 9.1.6, 9.1.7 and 9.1.12 for

details).

The current amplitude can be set through the TVAL register (see paragraph 9.1.4). The

output current amplitude can also be regulated by ADCIN voltage value (see paragraph

6.14).

Each bridge is driven by an independent control system that shares with the other bridge the

control parameters only.

7.1 Peak current control

The L6474 implements a peak current control algorithm with fixed OFF time. The control

cycle begins in the ON state: the opposite high side DMOS low side DMOS of the power

bridges are turned on according to the required current direction. In this way, the phase

current is increased according to the electrical model of the motor.

When the target current value is reached (this value is internally generated according to the

present value of the EL_POS register), the device switches to the OFF state in order to

make the phase current decay. During the OFF state both slow and fast decay can be

performed; the better decay combination is automatically selected by L6472 as described in

section 7.2.

The t

the TOFF_MIN register. If TOFF is greater than TOFF_MIN, it defines the OFF time of the

system. Otherwise the TOFF_MIN value is used.

Figure 9. Peak current control

value sets through the TOFF parameter of the CONFIG register and the value of

OFF

26/51 Doc ID 022529 Rev 2

L6474 Phase current control

7.2 Auto-adjusted decay mode

During the current control, the device automatically selects the best decay mode in order to

follow the current profile reducing the current ripple.

At reset, the OFF time is performed by turning on both the low side MOS of the power stage

and the current recirculates in the lower half of the bridge (slow decay).

If, during a PWM cycle, the target current threshold is reached in a time shorter than the

TON_MIN value, a fast decay of TOFF_FAST/8 (T_FAST register) is immediately

performed, turning on the opposite MOS of both half bridges and the current recirculates

back to the supply bus.

After this time, the bridge returns to the ON state: if the time needed to reach the target

current value is still less than TON_MIN, a new fast decay is performed with a period twice

the previous one. Otherwise, the normal control sequence is followed as described in

section 7.1. The maximum fast decay duration is set by TOFF_FAST value.

Figure 10. Adaptive decay - fast decay tuning

STFASTDECAY

4FAST4/&&?&!34

RDFASTDECAY

4FAST4/&&?&!34

4ON4/.?-).

4FAST4/&&?&!34

NDFASTDECAY

4FAST4/&&?&!34

REFERENCECURRENT

.OTESTARTINGFROM

FASTANDSLOWDECAYDURINGTHE/&&PHASE

ND

FASTDECAYTHESYSTEMWILLCOMBINE

4IME

When two or more fast decays are performed with present target current, the control system

adds a fast decay at the end of every OFF time, keeping the OFF state duration constant

(t

is split into t

OFF

OFF,SLOW

and t

OFF,FAST

). When the current threshold is increased by a

micro-step change (rising step), the system returns to normal decay mode (slow decay only)

and the t

value is halved.

FAS T

Reaching the current sinewave zero crossing causes the current control system to return to

the reset state.

Doc ID 022529 Rev 2 27/51

Phase current control L6474

Figure 11. Adaptive decay - switch from normal to slow+fast decay mode and vice

versa

reference current

1st fast decay

t

OFF

Target current is increased (raising step)

system returns to slow decay mode and t

nd

fast decay

switch to fast + slow decay mode

2

t

FAST

value is halved

FAST

t

OFF,SLOW

Time

t

OFF

t

OFF,FAST

reference current

7.3 Auto-adjusted fast decay during the falling steps

When the target current is decreased by a micro-step change (falling step), the device

performs a fast decay in order to reach the new value as fast as possible. Anyway,

exceeding the fast duration could cause a strong ripple on the step change. The L6474

automatically adjusts these fast decays reducing the current ripple.

At reset, the fast decay value (t

value is doubled every time, within the same falling step, an extra fast decay is necessary to

obtain an ON time greater than TON_MIN. The maximum t

FALL_STEP.

At the next falling step, the system uses the last t

Stopping the motor or reaching the current sinewave zero crossing causes the current

control system to return to the reset state.

) is set to FALL_STEP/4 (T_FAST register). The t

FAL L

value is equal to

FALL

value of the previous falling step.

FALL

Time

FALL

28/51 Doc ID 022529 Rev 2

L6474 Phase current control

Figure 12. Fast decay tuning during the falling steps

&ALLINGSTEP

REFERENCECURRENT

STFASTDECAY

T

&!,,?34%0

&!,,

ND

FASTDECAY

T

&!,,?34%0

&!,,

&ALLINGSTEP

STFASTDECAY

T

&!,,?34%0

&!,,

4IME

7.4 Torque regulation (output current amplitude regulation)

The output current amplitude can be regulated in two ways: writing the TVAL register or

varying the ADCIN voltage value.

The EN_TQREG bit (CONFIG register) sets the torque regulation method. If this bit is high,

ADC_OUT prevalue is used to regulate output current amplitude (see paragraph 9.1.8).

Otherwise the internal analog to digital converter is at the user’s disposal and the output

current amplitude is managed by the TVAL register (see paragraph 9.1.4).

The voltage applied to the ADCIN pin is sampled at fS frequency and converted in an NADC

bit digital signal. The analog to digital conversion result is available in the ADC_OUT

register.

Doc ID 022529 Rev 2 29/51

Serial interface L6474

8 Serial interface

The integrated 8-bit serial peripheral interface (SPI) is used for a synchronous serial

communication between the host microprocessor (always master) and the L6474 (always

slave).

The SPI uses chip select (CS

output (SDO) pins. When CS

(high-impedance).

The communication starts when CS

data communication.

All commands and data bytes are shifted into the device through the SDI input, most

significant bit first. The SDI is sampled on the rising edges of the CK.

All output data bytes are shifted out of the device through the SDO output, most significant

bit first. The SDO is latched on the falling edges of the CK. When a return value from the

device is not available, an all zero byte is sent.

After each byte transmission, the CS

tdisCS in order to allow the device to decode the received command and put the return

value into the shift register.

All timing requirements are shown in Figure 13 (see respective Section 3: Electrical

characteristics for values).

Multiple devices can be connected in a daisy-chain configuration, as shown in Figure 14.

Figure 13. SPI timings diagram

), serial clock (CK), serial data input (SDI) and serial data

is high, the device is unselected and the SDO line is inactive

is forced low. The CK line is used for synchronization of

input must be raised and be kept high for at least

30/51 Doc ID 022529 Rev 2

L6474 Serial interface

Figure 14. Daisy-chain configuration

Doc ID 022529 Rev 2 31/51

Programming manual L6474

9 Programming manual

9.1 Registers and flags description

The following is a map of the user registers available (detailed description in respective

paragraphs):

Table 9. Registers map

Address

[Hex]

h01 ABS_POS Current position 22 000000 0 R, WR

h02 EL_POS Electrical position 9 000 0 R, WR

h03 MARK Mark position 22 000000 0 R, WR

h04 RESERVED Reserved address 24

h05 RESERVED Reserved address 16

h06 RESERVED Reserved address 16

h07 RESERVED Reserved address 16

h08 RESERVED Reserved address 16

h15 RESERVED Reserved address 16 R, WR

h09 TVAL Reference current 7 29 1.3125 A R, WR

h0A RESERVED Reserved address 8

h0B RESERVED Reserved address 8

h0C RESERVED Reserved address 8

h0D RESERVED Reserved address 16

h0E T_FAST Fast decay/fall step time 8 19 1 µs / 5 µs R, WH

h0F TON_MIN Minimum ON time 7 29 20.5 µs R, WH

h10 TOFF_MIN Minimum OFF time 7 29 20.5 µs R, WH

Register

name

Register function Len. [bit]

Reset

Hex

Reset Value

Remarks

(1)

h11 RESERVED Reserved address 8

h12 ADC_OUT ADC output 5 XX

h13 OCD_TH OCD threshold 4 8 3.38A R, WR

h14 RESERVED Reserved address 8

h16 STEP_MODE Step mode 8 7 16 microsteps, no synch R, WH

h17 ALARM_EN Alarms enables 8 FF All alarms enabled R, WR

h18 CONFIG IC configuration 16 2E88

32/51 Doc ID 022529 Rev 2

(2)

Internal oscillator, 2 MHz

OSCOUT clock, supply

voltage compensation

disabled, overcurrent

shutdown enabled, slewrate = 290 V/µs TOFF = 40

µs

R

R, WH

L6474 Programming manual

Table 9. Registers map (continued)

Address

[Hex]

h19 STATUS Status 16 XXXX

h1A RESERVED Reserved address

h1B RESERVED Reserved address

1. R: Readable, WH: writable only when outputs are in high impedance, WR: always writable.

2. According to startup conditions.

Register

name

Register function Len. [bit]

Reset

Hex

High impedance state,

(2)

UVLO/Reset flag set.

9.1.1 ABS_POS

The ABS_POS register contains the current motor absolute position in agreement to the

selected step mode; the stored value unit is equal to the selected step mode (full, half,

quarter, etc.). The value is in 2's complement format and it ranges from -2

At power-on the register is initialized to “0” (HOME position).

9.1.2 EL_POS

The EL_POS register contains the current electrical position of the motor. The two MSbits

indicate the current step and the other bits indicate the current microstep (expressed in

step/128) within the step.

Table 10. EL_POS register

Reset Value

21

to +221-1.

Remarks

(1)

R

Bit 8 Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

When the EL_POS register is written by the user the new electrical position is instantly

imposed. When the EL_POS register is written its value must be masked in order to match

with the step mode selected in the STEP_MODE register in order to avoid a wrong

microstep value generation (see paragraph 9.1.10); otherwise the resulting microstep

sequence is incorrect.

Any attempt to write the register when the outputs are enabled causes the command to be

ignored and the NOTPERF_CMD flag to rise (see paragraph 9.1.13).

9.1.3 MARK

The MARK register contains an absolute position called MARK, according to the selected

step mode; the stored value unit is equal to the selected step mode (full, half, quarter, etc.).

It is in 2's complement format and it ranges from -2

9.1.4 TVAL

The TVAL register contains the current value that is assigned to the torque regulation DAC.

The available range is from 31.25 mA to 4 A with a resolution of 31.25 mA, as shown in

Ta bl e 2.

STEP MICROSTEP

21

to +221-1.

Doc ID 022529 Rev 2 33/51

Programming manual L6474

Table 11. Torque regulation register

TVAL [6..0] Output current amplitude

0 0 0 0 0 0 0 31.25 mA

0 0 0 0 0 0 1 62.5 mA

…

…

…

…

…

…

…

1 1 1 1 1 1 0 3.969 A

1 1 1 1 1 1 1 4 A

…

9.1.5 T_FAST

The T_FAST register contains the maximum fast decay time (TOFF_FAST) and the

maximum fall step time (FALL_STEP) used by the current control system (see Sections 7.2

and 7.3 for details):

Table 12. T_FAST register

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

TOFF_FAST FAST_STEP

The available range for both parameters is from 0.5 µs to 8 µs.

Table 13. Maximum fast decay times

TOFF_FAST [3..0]

FAST_STEP[3..0]

0 0 0 0 0.5 µs

0 0 0 1 1 µs

…

1 1 1 0 7.5 µs

1 1 1 1 8 µs

Any attempt to write to the register when the outputs are enabled causes the command to

be ignored and the NOTPERF_CMD to rise (see Section 9.1.13).

9.1.6 TON_MIN

The TON_MIN register contains the minimum ON time value used by the current control

system (see Section 7.2).

The available range for both parameters is from 0.5 µs to 64 µs.

…

…

…

Fast decay time

…

34/51 Doc ID 022529 Rev 2

L6474 Programming manual

Table 14. Minimum ON time

Time

0 0 0 0 0 0 0 0.5 µs

0 0 0 0 0 0 1 1 µs

…

…

…

…

…

…

…

…

1 1 1 1 1 1 0 63.5 µs

1 1 1 1 1 1 1 64 µs

Any attempt to write to the register when the outputs are enabled causes the command to

be ignored and the NOTPERF_CMD to rise (see Section 9.1.13).

9.1.7 TOFF_MIN

The TOFF_MIN register contains the minimum OFF time value used by the current control

system (see Section 7.1 for details).This parameter imposes the OFF time of the current

control system only if its value is greater than the TSW one.

The available range for both parameters is from 0.5 µs to 64 µs.

Table 15. Minimum OFF time

Time

0 0 0 0 0 0 0 0.5 µs

0 0 0 0 0 0 1 1 µs

…

…

…

…

…

…

…

…

1 1 1 1 1 1 0 63.5 µs

1 1 1 1 1 1 1 64 µs

Any attempt to write to the register when the outputs are enabled causes the command to

be ignored and the NOTPERF_CMD to rise (see Section 9.1.13).

Doc ID 022529 Rev 2 35/51

Programming manual L6474

9.1.8 ADC_OUT

The ADC_OUT register contains the result of the analog to digital conversion of the ADCIN

pin voltage.

Any attempt to write to the register causes the command to be ignored and the

NOTPERF_CMD flag to rise (see Section 9.1.13).

Table 16. ADC_OUT value and torque regulation feature

VADCIN/ VREG ADC_OUT [4..0] Output current amplitude

0 0 0 0 0 0 125 mA

1/32 0 0 0 0 1 250 mA

…

30/32 1 1 1 1 0 3.875 A

31/32 1 1 1 1 1 4 A

…

…

…

…

…

…

9.1.9 OCD_TH

The OCD_TH register contains the overcurrent threshold value (see Section 6.9 for details).

The available range is from 375 mA to 6 A, steps of 375 mA as shown in Ta bl e 1 7 .

Table 17. Overcurrent detection threshold

OCD_TH [3..0] Overcurrent detection threshold

0 0 0 0 375 mA

0 0 0 1 750 mA

…

1 1 1 0 5.625 A

1 1 1 1 6 A

…

…

…

…

36/51 Doc ID 022529 Rev 2

L6474 Programming manual

9.1.10 STEP_MODE

The STEP_MODE register has the following structure:

Table 18. STEP_MODE register

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

1 SYNC_SEL 1

1. When the register is written this bit should be set to 1.

The STEP_SEL parameter selects one of five possible stepping modes:

Table 19. Step mode selection

STEP_SEL[2..0] Step mode

0 0 0 Full step

0 0 1 Half step

0 1 0 1/4 microstep

0 1 1 1/8 microstep

1 X X 1/16 microstep

(1)

STEP_SEL

Every time the step mode is changed, the electrical position (i.e. the point of microstepping

sinewave that is generated) is reset to the first microstep.

Warning: Every time STEP_SEL is changed the value in ABS_POS

register loses meaning and should be reset.

Any attempt to write the register when the outputs are enabled causes the command to be

ignored and the NOTPERF_CMD flag to rise (see paragraph 9.1.13).

The SYNC output provides a synchronization signal according to SYNC_SEL parameter.

Doc ID 022529 Rev 2 37/51

Programming manual L6474

The synchronization signal is obtained starting from electrical position information (EL_POS

register) according to Tab l e 1 0:

Table 20. SYNC signal source

SYNC_SEL[2..0] Source

0 0 0 EL_POS[7]

0 0 1 EL_POS[6]

0 1 0 EL_POS[5]

0 1 1 EL_POS[4]

1 0 0 EL_POS[3]

1 0 1 UNUSED

1 1 0 UNUSED

1 1 1 UNUSED

1. When this value is selected the BUSY output is forced low.

(1)

(1)

(1)

38/51 Doc ID 022529 Rev 2

L6474 Programming manual

9.1.11 ALARM_EN

The ALARM_EN register allows to select which alarm signals are used to generate the

FLAG output. If the respective bit of the ALARM_EN register is set high, the alarm condition

forces the FLAG pin output down.

Table 21. ALARM_EN register

ALARM_EN bit Alarm condition

0 (LSB) Overcurrent

1 Thermal shutdown

2 Thermal warning

3 Undervoltage

4 RESERVED

5 RESERVED

6 Switch turn-on event

7 (MSB) Wrong or not performable command

9.1.12 CONFIG

The CONFIG register has the following structure:

Table 22. CONFIG register

Bit 15 Bit 14 Bit 13 Bit 12 Bit 11 Bit 10 Bit 9 Bit 8

0 TOFF POW_SR

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

OC_SD RESERVED EN_TQREG 0 EXT_CLK OSC_SEL

Doc ID 022529 Rev 2 39/51

Programming manual L6474

The OSC_SEL and EXT_CLK bits set the system clock source:

Table 23. Oscillator management

EXT_CLK OSC_SEL[2..0] Clock source OSCIN OSCOUT

0 0 0 0

0 0 0 1

Internal oscillator: 16 MHz Unused Unused

0 0 1 0

0 0 1 1

1 0 0 0 Internal oscillator: 16 MHz Unused

1 0 0 1 Internal oscillator: 16 MHz Unused

1 0 1 0 Internal oscillator: 16 MHz Unused

1 0 1 1 Internal oscillator: 16 MHz Unused

0 1 0 0 External crystal or resonator: 8 MHz Crystal/resonator driving

0 1 0 1

0 1 1 0

0 1 1 1

1 1 0 0

External crystal or resonator: 16

MHz

External crystal or resonator: 24

MHz

External crystal or resonator: 32

MHz

Ext. clock source: 8 MHz

(Crystal/resonator driver disabled)

Crystal/resonator driving

Crystal/resonator driving

Crystal/resonator driving

Clock source

Supplies a 2 MHz

clock

Supplies a 4 MHz

clock

Supplies a 8 MHz

clock

Supplies a 16 MHz

clock

Crystal/resonator

driving

Crystal/resonator

driving

Crystal/resonator

driving

Crystal/resonator

driving

Supplies inverted

OSCIN signal

1 1 0 1

1 1 1 0

1 1 1 1

Ext. clock source: 16 MHz

(Crystal/resonator driver disabled)

Ext. clock source: 24 MHz

(Crystal/resonator driver disabled)

Ext. clock source: 32 MHz

(Crystal/resonator driver disabled)

The OC_SD bit sets whether or not an overcurrent event causes the bridges to turn off; the

OCD flag in the status register is forced low anyway:

Table 24. Overcurrent event

OC_SD Overcurrent event

1 Bridges shut down

0 Bridges do not shut down

The POW_SR bits set the slew rate value of power bridge output:

40/51 Doc ID 022529 Rev 2

Clock source

Clock source

Clock source

Supplies inverted

OSCIN signal

Supplies inverted

OSCIN signal

Supplies inverted

OSCIN signal

L6474 Programming manual

Table 25. Programmable power bridge output slew-rate values

POW_SR [1..0] Output Slew-rate (1) [V/ìs]

(1)

0 0 180

0 1 180

1 0 290

1 1 530

1. See SRout_r and SRout_f parameters in the electrical characteristics Table 5 for details.

The TQREG bit sets if the torque regulation (see Section 7.4) is performed through the

ADCIN voltage (external) or TVAL register (internal):

Table 26. External torque regulation enable

TQREG External torque regulation enable

0 Internal registers

1 ADC input

The TOFF time is used by current control system. If its value is lower than the TOFF_MIN

one, the OFF time is equal to TOFF_MIN.

Table 27. OFF time

0 0 0 0 0 4 µs

0 0 0 0 1 4 µs

0 0 0 1 0 8 µs

…

1 1 1 1 1 124 µs

Any attempt to write the CONFIG register when the outputs are enabled causes the

command to be ignored and the NOTPERF_CMD flag to rise (see Section 9.1.13).

9.1.13 STATUS

Table 28. STATUS register

Bit 15 Bit 14 Bit 13 Bit 12 Bit 11 Bit 10 Bit 9 Bit 8

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

NOTPERF_CMD 0 0 DIR 0 0 1 HiZ

When HiZ flag is high, it indicates that the bridges are in high impedance state. Enable

command makes the device exit from High Z state unless error flags forcing a High Z state

are active.

TOFF [4..0] OFF time

…

…

…

…

…

1 1 1 OCD TH_SD TH_WRN UVLO WRONG_CMD

Doc ID 022529 Rev 2 41/51

Programming manual L6474

The UVLO flag is active low and is set by an undervoltage lock-out or reset events (powerup included). The TH_WRN, TH_SD, OCD flags are active low and indicate, respectively,

thermal warning, thermal shutdown and overcurrent detection events.

The NOTPERF_CMD and WRONG_CMD flags are active high and indicate, respectively,

that the command received by SPI can't be performed or does not exist at all.

The UVLO, TH_WRN, TH_SD, OCD, NOTPERF_CMD and WRONG_CMD flags are

latched: when the respective conditions make them active (low or high), they remain in that

state until a GetStatus command is sent to the IC.

The DIR bit indicates the current motor direction:

Table 29. STATUS register DIR bit

DIR Motor direction

1 Forward

0 Reverse

Any attempt to write to the register causes the command to be ignored and the

NOTPERF_CMD to rise (see paragraph 9.1.13).

9.2 Application commands

The commands summary is given in Ta bl e 3 0.

Table 30. Application commands

Command Mnemonic Command binary code Action

SetParam(PARAM,VALUE) 000 [PARAM] Writes VALUE in PARAM register

9.2.1 Command management

[7..5] [4] [3] [2..1] [0]

NOP 000 0 0 00 0 Nothing

Enable 101 1 1 00 0 Enable the power stage

Disable 101 0 1 00 0

GetStatus 110 1 0 00 0 Returns the status register value

RESERVED 111 0 1 01 1 RESERVED COMMAND

RESERVED 111 1 1 00 0 RESERVED COMMAND

Puts the bridges in High Impedance status

immediately

The host microcontroller can control motor motion and configure the L6474 through a

complete set of commands.

All commands are composed of a single byte. After the command byte, some bytes of

arguments should be needed (see Figure 15). Argument length can vary from 1 to 3 bytes.

42/51 Doc ID 022529 Rev 2

L6474 Programming manual

Figure 15. Command with three-byte argument

By default, the device returns an all zeroes response for any received byte, the only

exceptions are GetParam and GetStatus commands. When one of these commands is

received, the following response bytes represent the related register value (see Figure 16).

Response length can vary from 1 to 3 bytes.

Figure 16. Command with three-byte response

During response transmission, new commands can be sent. If a command requiring a

response is sent before the previous response is completed, the response transmission is

aborted and the new response is loaded into the output communication buffer (see

Figure 17).

Figure 17. Command response aborted

When a byte that does not correspond to a command is sent to the IC it is ignored and the

WRONG_CMD flag in the STATUS register is raised (see Section 9.1.13).

9.2.2 Nop

Table 31. Nop command structure

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Nothing is performed.

0 0 0 0 0 0 0 0 From host

Doc ID 022529 Rev 2 43/51

Programming manual L6474

9.2.3 SetParam (PARAM, VALUE)

Table 32. SetParam command structure

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

0 0 0 PARAM From host

VALUE Byte 2 (if needed)

VALUE Byte 1 (if needed)

VALUE Byte 0

The SetParam command sets the PARAM register value equal to VALUE; PARAM is the

respective register address listed in Ta b le 1 6 .

The command should be followed by the new register VALUE (most significant byte first).

The number of bytes composing the VALUE argument depends on the length of the target

register (see Ta bl e 16 ).

Some registers cannot be written (see Ta b le 1 6 ); any attempt to write one of those registers

causes the command to be ignored and the WRONG_CMD flag to rise at the end of

command byte, the same is true when an unknown command code is sent (see

Section 9.1.13).

Some registers can only be written in particular conditions (see Ta b le 1 6 ); any attempt to

write one of those registers when the conditions are not satisfied causes the command to be

ignored and the NOTPERF_CMD flag to rise at the end of last argument byte (see

Section 9.1.13).

Any attempt to set an inexistent register (wrong address value) causes the command to be

ignored and the WRONG_CMD flag to rise at the end of command byte, the same is true

when an unknown command code is sent.

9.2.4 GetParam (PARAM)

Table 33. GetParam command structure

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

0 0 1 PARAM from host

This command reads the current PARAM register value; PARAM is the respective register

address listed in Ta bl e 1 6 .

The command response is the current value of the register (most significant byte first). The

number of bytes composing the command response depends on the length of the target

register (see Ta bl e 16 ).

ANS Byte 2 (if needed) to host

ANS Byte 1 (if needed) to host

ANS Byte 0 to host

The returned value is the register one at the moment of GetParam command decoding. If

register values change after this moment the response is not accordingly updated.

All registers can be read anytime.

44/51 Doc ID 022529 Rev 2

L6474 Programming manual

Any attempt to read an inexistent register (wrong address value) causes the command to be

ignored and the WRONG_CMD flag to rise at the end of command byte, the same is true

when an unknown command code is sent.

9.2.5 Enable

Table 34. HardStop command structure

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

1 0 1 1 1 0 0 0 from host

The Enable command turns on the power stage of the device.

When the motor is in high-impedance state, an Enable command forces the bridges to exit

from high impedance state.

This command can be given anytime and is immediately executed.

9.2.6 Disable

Table 35. Disable command structure

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

1 0 1 0 1 0 0 0 from host

The Disable command immediately disables the power bridges (high-impedance state) and

raises the HiZ flag.

This command can be given anytime and is immediately executed.

9.2.7 GetStatus

Table 36. GetStatus command structure

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

1 1 0 1 0 0 0 0 from host

The GetStatus command returns the Status register value. The GetStatus command resets

the STATUS register warning flags. The command forces the system to exit from any error

state. The GetStatus command DOES NOT reset the HiZ flag.

STATUS MSByte to host

STATUS LSByte to host

Doc ID 022529 Rev 2 45/51

Package mechanical data L6474

10 Package mechanical data

In order to meet environmental requirements, ST offers these devices in different grades of

®

ECOPACK

packages, depending on their level of environmental compliance. ECOPACK

specifications, grade definitions and product status are available at: www.st.com.

ECOPACK is an ST trademark.

Table 37. HTSSOP28 mechanical data

mm

Dim

Min. Typ. Max.

A 1.2

A1 0.15

A2 0.8 1.0 1.05

b 0.19 0.3

c 0.09 0.2

(1)

D

D1 5.5

E 6.2 6.4 6.6

(2)

E1

E2 2.8

9.6 9.7 9.8

4.3 4.4 4.5

E 0.65

L 0.45 0.6 0.75

L1 1.0

K 0° 8°

Aaa 0.1

1. Dimension “D” does not include mold flash, protrusions or gate burrs. Mold flash, protrusions or gate burrs