High-voltage high and low side driver

Features

■ High voltage rail up to 600 V

■ dV/dt immunity ± 50 V/nsec in full temperature

range

■ Driver current capability:

– 290 mA source,

– 430 mA sink

■ Switching times 75/35 nsec rise/fall with 1 nF

load

■ 3.3 V, 5 V TTL/CMOS inputs with hysteresis

■ Integrated bootstrap diode

■ Comparator for fault protections

■ Smart shut-down function

■ Adjustable dead-time

■ Interlocking function

■ Compact and simplified layout

■ Bill of material reduction

■ Effective fault protection

■ Flexible, easy and fast design

L6391

Description

The L6391 is a high-voltage device manufactured

with the BCD “OFF-LINE” technology. It is a single

chip half-bridge gate driver for N-channel power

MOSFET or IGBT.

The high side (floating) section is designed to

stand a voltage rail up to 600 V. The logic inputs

are CMOS/TTL compatible down to 3.3 V for easy

interfacing microcontroller/DSP.

An integrated comparator is available for

protections against overcurrent, overtemperature,

etc.

Applications

■ Motor driver for home appliances, factory

automation, industrial drives and fans.

■ HID ballasts, power supply units.

Table 1. Device summary

Order codes Package Packaging

L6391N DIP-14 Tube

L6391D SO-14 Tube

L6391DTR SO-14 Tape and reel

December 2010 Doc ID 17892 Rev 1 1/21

www.st.com

21

Contents L6391

Contents

1 Block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2 Pin connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3 Truth table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

4 Electrical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4.1 Absolute maximum ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4.2 Thermal data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4.3 Recommended operating conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

5 Electrical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

5.1 AC operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

5.2 DC operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

6 Waveforms definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

7 Smart shut down function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

8 Typical application diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

9 Bootstrap driver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

9.1 CBOOT selection and charging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

10 Package mechanical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

11 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2/21 Doc ID 17892 Rev 1

L6391 Block diagram

1 Block diagram

Figure 1. Block diagram

6##

().

,).

3$/$

$4

'.$

56

$%

4%#4)/.

6

"//4342! 0$2)6%2

FROM,6'

3-!24

3$

,/')#

3(//4

4(2/5'(

02%6%.4)/.

$%!$

4)-%

&,/!4).'3425#452%

56

$%4%#4)/.

,%6%,

3()&4%2

6

#/-0!2!4/2

"//4

(6'

3

2

$2)6%2

6

##

,6'

$2)6%2

(6'

/54

,6 '

#0

#0

!-V

Doc ID 17892 Rev 1 3/21

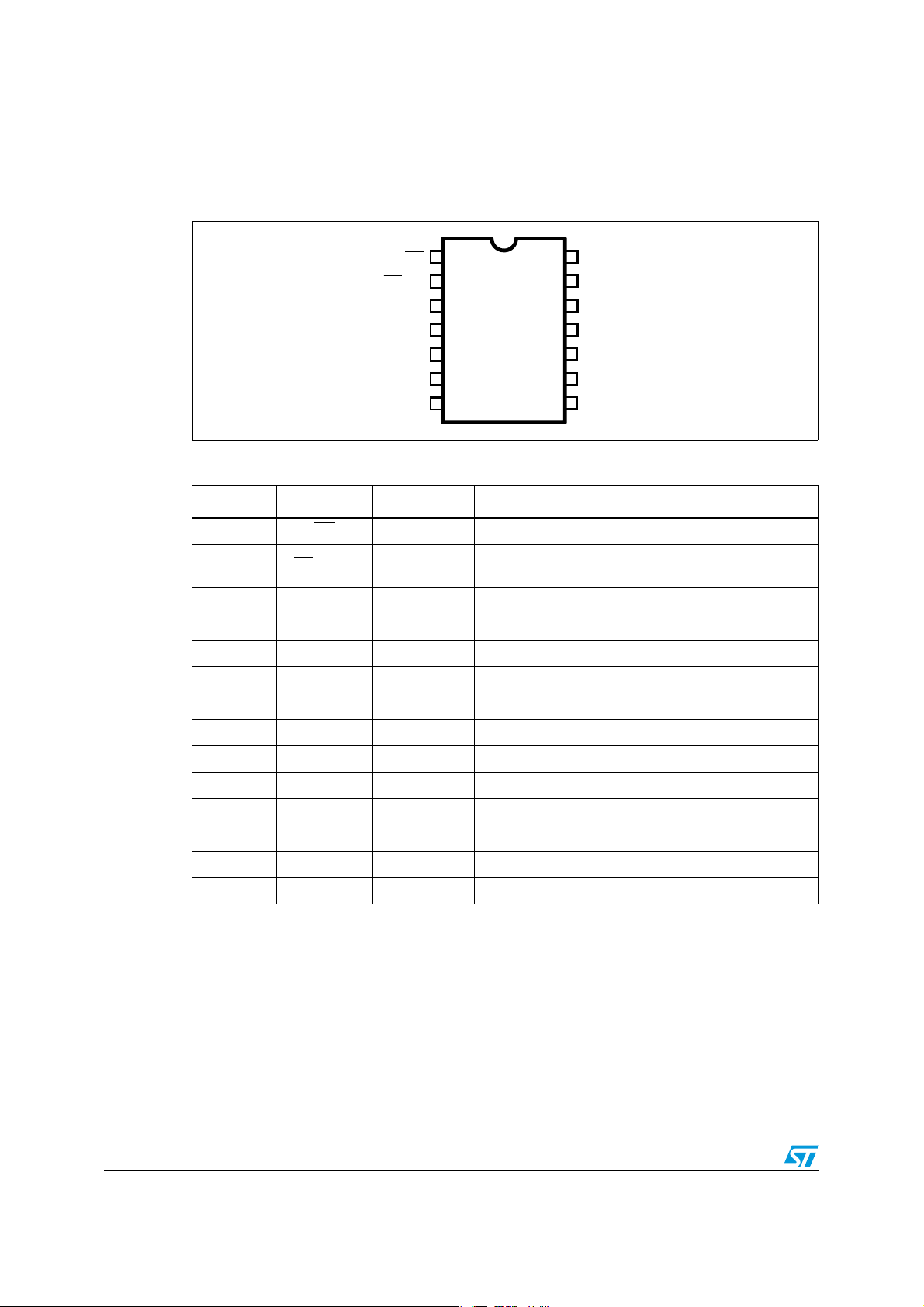

Pin connection L6391

2 Pin connection

Figure 2. Pin connection (top view)

-*/

4%0%

)*/

7$$

%5

/$

(/%

#005

)7(

065

/$

-7(

$1

$1

Table 2. Pin description

Pin n # Pin name Type Function

1 LIN

2 SD/OD

3 HIN I High side driver logic input (active high)

4 VCC P Lower section supply voltage

5 DT I Dead time setting

6 NC Not connected

7 GND P Ground

8 CP- I Comparator negative input

I Low side driver logic input (active low)

(1)

I/O

Shut down logic input (active low)/open drain

comparator output

!-V

9 CP+ I Comparator positive input

10 LVG

(1)

O Low side driver output

11 NC Not connected

12 OUT P High side (floating) common voltage

(1)

13 HVG

O High side driver output

14 BOOT P Bootstrapped supply voltage

1. The circuit guarantees less than 1 V on the LVG and HVG pins (@ Isink = 10 mA), with VCC > 3 V. This

allows omitting the “bleeder” resistor connected between the gate and the source of the external MOSFET

normally used to hold the pin low; the gate driver assures low impedance also in SD condition.

4/21 Doc ID 17892 Rev 1

L6391 Truth table

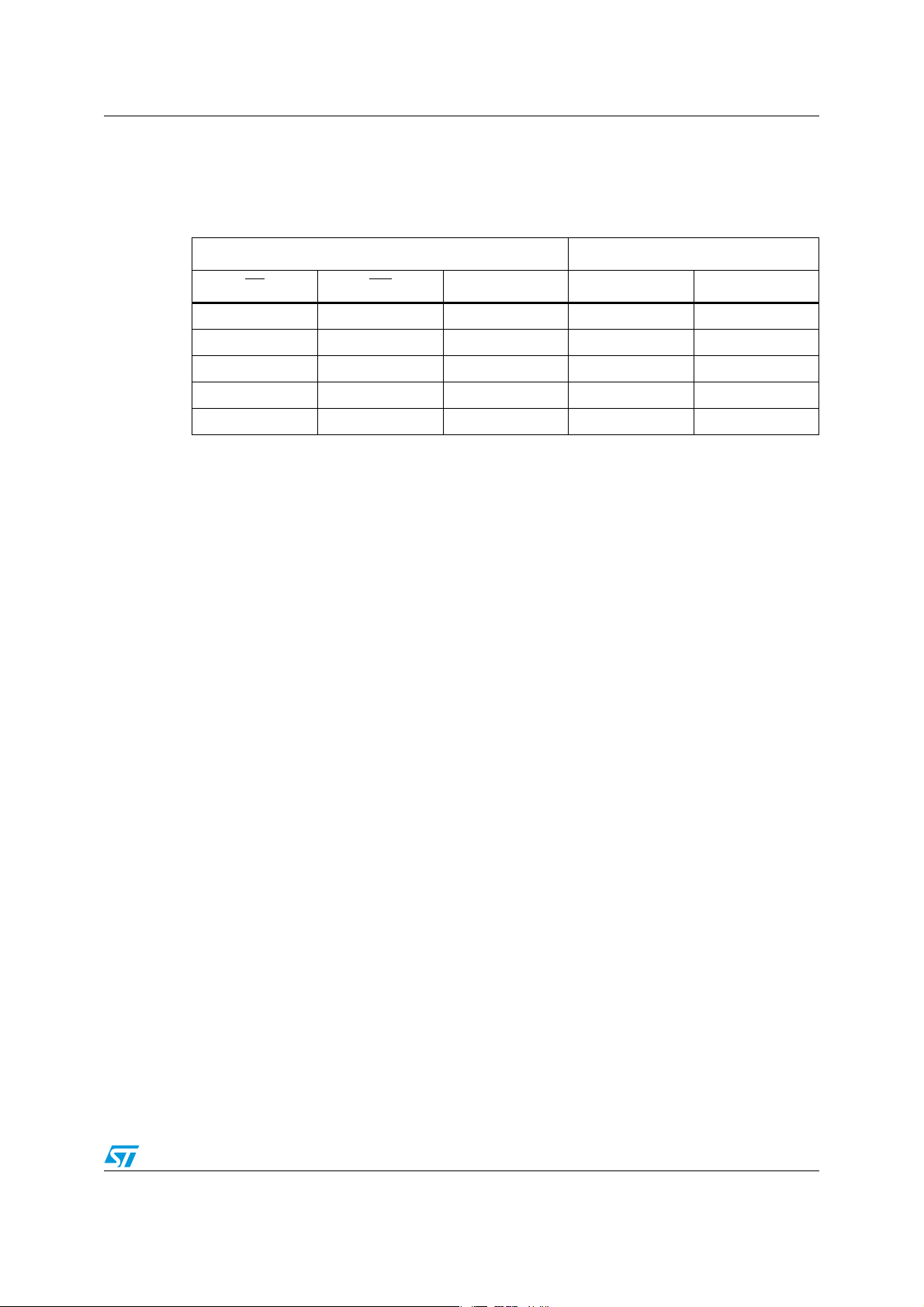

3 Truth table

Table 3. Truth table

Input Output

SD

LXXLL

HHLL L

HLHLL

HLLHL

HHHL H

Note: X: don't care

LIN HIN LVG HVG

Doc ID 17892 Rev 1 5/21

Electrical data L6391

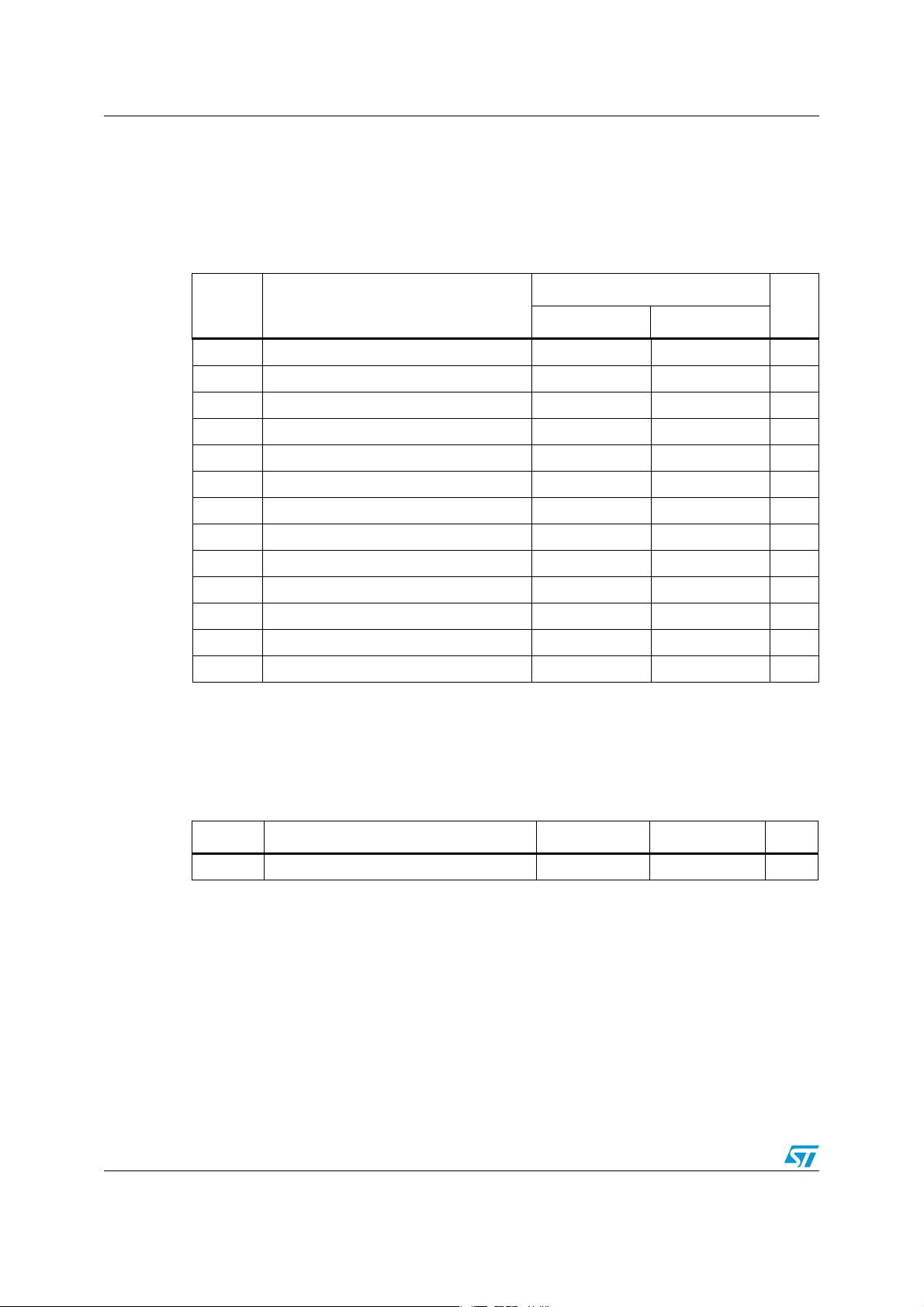

4 Electrical data

4.1 Absolute maximum ratings

Table 4. Absolute maximum rating

Val ue

Symbol Parameter

Min Max

Vcc Supply voltage -0.3 21 V

Output voltage V

out

Bootstrap voltage -0.3 620 V

boot

High side gate output voltage V

hvg

Low side gate output voltage -0.3 Vcc + 0.3 V

lvg

Comparator negative input voltage -0.3 Vcc + 0.3 V

cp-

Comparator positive input voltage -0.3 Vcc + 0.3 V

cp+

V

Logic input voltage -0.3 15 V

i

Open drain voltage -0.3 15 V

OD

/dt Allowed output slew rate 50 V/ns

Total power dissipation (TA = 25 °C) 800 mW

tot

Junction temperature 150 °C

J

Storage temperature -50 150 °C

stg

dV

V

V

V

V

V

V

V

out

P

T

T

- 21 V

boot

- 0.3 V

out

+ 0.3 V

boot

+ 0.3 V

boot

Unit

Note: ESD immunity for pins 12, 13 and 14 is guaranteed up to 1 kV (human body model)

4.2 Thermal data

Table 5. Thermal data

Symbol Parameter SO-14 DIP-14 Unit

R

th(JA)

Thermal resistance junction to ambient 165 100 °C/W

6/21 Doc ID 17892 Rev 1

L6391 Electrical data

4.3 Recommended operating conditions

Table 6. Recommended operating conditions

Symbol Pin Parameter Test condition Min Max Unit

V

cc

(1)

V

BO

V

out

V

CP-

V

CP+

f

sw

T

J

1. VBO = V

2. LVG off. Vcc = 12.5 V

Logic is operational if V

3. At least one of the comparator's input must be lower than 2.5 V to guarantee proper operation.

4 Supply voltage 12.5 20 V

14-12 Floating supply voltage 12.4 20 V

12 DC output voltage - 9

Comparator negative

8

input voltage

Comparator positive

9

input voltage

[ 2.5 V V

V

CP+

V

[ 2.5 V V

CP-

(2)

Switching frequency HVG, LVG load CL = 1 nF 800 kHz

Junction temperature -40 125 °C

- V

boot

out

> 5 V

boot

580 V

(3)

CC

(3)

CC

V

V

Doc ID 17892 Rev 1 7/21

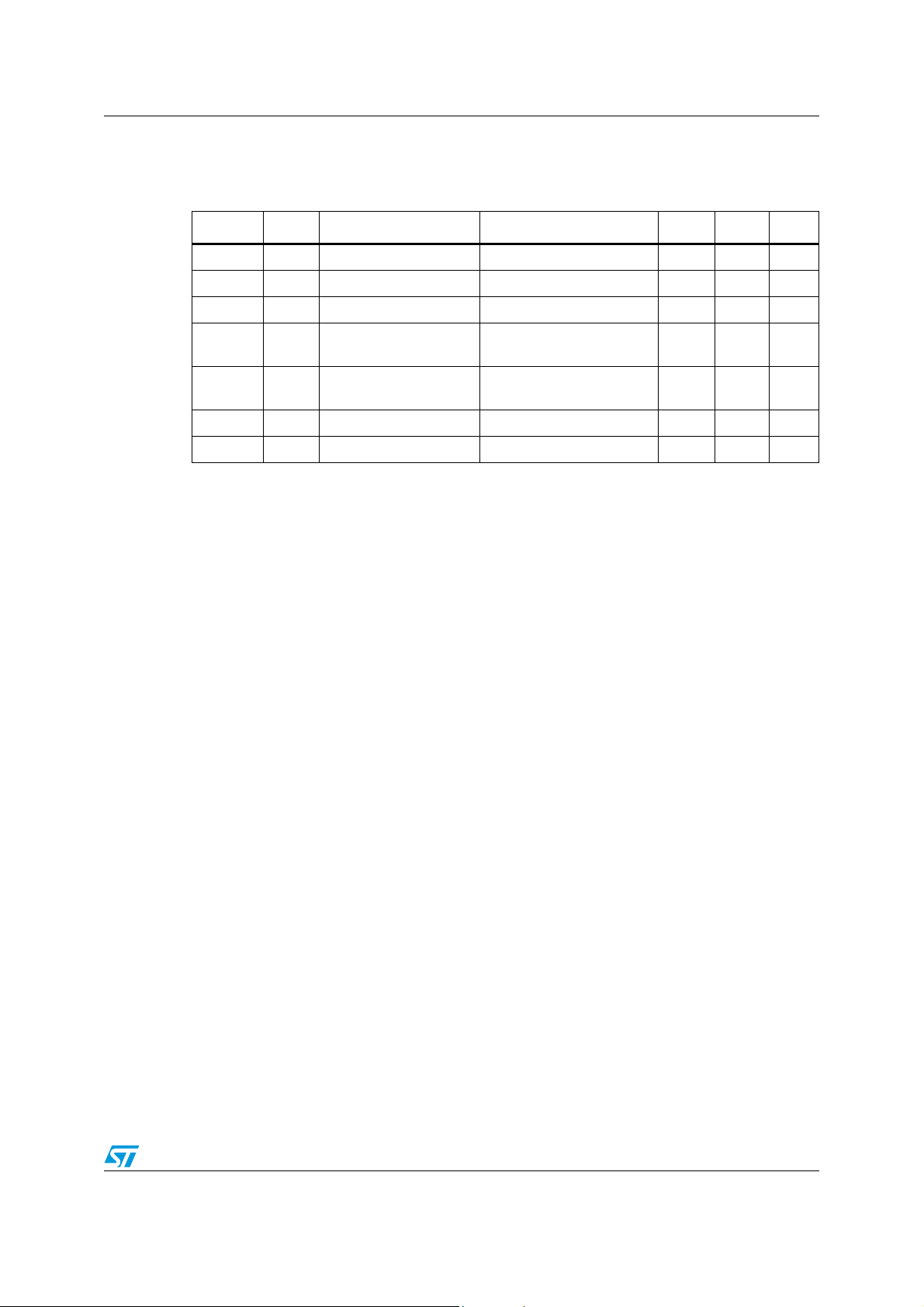

Electrical characteristics L6391

5 Electrical characteristics

5.1 AC operation

Table 7. AC operation electrical characteristics (VCC = 15 V; TJ = +25 °C)

Symbol Pin Parameter Test condition Min Typ Max Unit

ton

t

off

t

sd

t

isd

MT

1 vs 10

3 vs 13

10, 13

High/low side driver turn-on

propagation delay

High/low side driver turn-off

propagation delay

2 vs

Shutdown to high/low side

driver propagation delay

Comparator triggering to

high/low side driver turn-off

propagation delay

Delay matching, HS and LS

turn-on/off

= 0 V

V

out

V

= Vcc

boot

= 1 nF

C

L

= 0 to 3.3 V

V

i

See Figure 3.

Measured applying a voltage step from 0

V to 3.3 V to pin CP+; CP-=0.5 V

50 125 200 ns

50 125 200 ns

50 125 200 ns

200 250 ns

30 ns

RDT = 0Ω, CL = 1 nF 0.1 0.18 0.25 µs

= 37kΩ, CL = 1 nF, CDT = 100 nF 0.48 0.6 0.72 µs

R

DT

(2)

(1)

= 136kΩ, CL = 1 nF, CDT = 100 nF 1.35 1.6 1.85 µs

R

DT

R

= 260kΩ, CL = 1 nF, CDT = 100 nF 2.6 3.0 3.4 µs

DT

= 0Ω, CL = 1 nF 80 ns

R

DT

= 37kΩ, CL = 1 nF, CDT = 100 nF 120 ns

R

DT

R

= 136kΩ, CL = 1 nF, CDT = 100 nF 250 ns

DT

= 260kΩ, CL = 1 nF, CDT = 100 nF 400 ns

R

DT

= 1 nF 75 120 ns

L

DT 5 Dead time setting range

MDT Matching dead time

t

r

t

1. See Figure 4 on page 9

2. MDT = | DT

10,13

f

Rise time C

Fall time CL = 1 nF 35 70 ns

- DTHL | see Figure 5 on page 12

LH

8/21 Doc ID 17892 Rev 1

L6391 Electrical characteristics

Figure 3. Timing

LIN

LVG

HIN

HVG

50%

50%

50%

tr tf

90%

10%

ton toff

50%

tr tf

90%

10%

ton toff

90%

10%

90%

10%

SD

50%

tf

90%

LVG/HVG

tsd

Figure 4. Typical dead time vs. DT resistor value

'7XV

$SSUR[LPDWHGIRUPXODIRU

5GWFDOFXODWLRQW\S

5GW>Nȍ@ Â'7>V@

5GWN2KP

10%

Doc ID 17892 Rev 1 9/21

Electrical characteristics L6391

5.2 DC operation

Table 8. DC operation electrical characteristics (VCC = 15 V; TJ = + 25 °C)

Symbol Pin Parameter Test condition Min Typ Max Unit

V

cc_hys

V

cc_thON

V

cc_thOFF

I

qccu

I

qcc

4

UV hysteresis 1.2 1.5 1.8 V

V

cc

Vcc UV turn ON threshold 11.5 12 12.5 V

Vcc UV turn OFF threshold 10 10.5 11 V

Undervoltage quiescent

supply current

Quiescent current

Bootstrapped supply voltage section

V

BO_hys

V

BO_thON

V

BO_thOFF

I

QBOU

I

QBO

V

V

14-12

UV hysteresis 1.2 1.5 1.8 V

V

BO

UV turn ON threshold 10.6 11.5 12.4 V

BO

UV turn OFF threshold 9.1 10 10.9 V

BO

Undervoltage VBO quiescent

current

VBO quiescent current

(1)

V

= 9.5 V

cc

SD = 5 V; LIN = 5 V;

HIN = GND;

= 0 Ω;

R

DT

CP+=GND; CP-=5 V

Vcc = 15 V

= 5 V; LIN = 5 V;

SD

HIN = GND;

= 0 Ω;

R

DT

CP+=GND; CP-=5 V

= 9 V

V

BO

= 5 V; LIN and

SD

HIN = 5 V;

= 0 Ω;

R

DT

CP+=GND; CP-=5 V

V

= 15 V

BO

= 5 V; LIN and

SD

HIN = 5 V;

= 0 Ω;

R

DT

CP+=GND; CP-=5 V

100 150 μA

500 1000 μA

70 110 μA

200 μA

I

R

DS(on)

LK

High voltage leakage current V

Bootstrap driver on

resistance

(2)

= V

out

= V

hvg

LVG ON 120 Ω

Driving buffers section

I

so

I

si

High/low side source short

circuit current

10,

13

High/low side sink short

circuit current

= V

V

IN

= V

V

IN

< 10 μs) 200 290 mA

ih (tp

< 10 μs) 250 430 mA

il (tp

10/21 Doc ID 17892 Rev 1

= 600 V 10 μA

boot

L6391 Electrical characteristics

Table 8. DC operation electrical characteristics (VCC = 15 V; TJ = + 25 °C) (continued)

Symbol Pin Parameter Test condition Min Typ Max Unit

Logic inputs

V

V

I

HINh

V

il_S

il

1, 2, 3

ih

Low logic level voltage 0.8 V

High logic level voltage 2.25 V

1, 3

Single input voltage

HIN logic “1” input bias

current

LIN and HIN connected

together and floating

HIN = 15 V 110 175 260 μA

3

I

HINl

I

LINl

HIN logic “0” input bias

current

LIN

logic “0” input bias

current

HIN = 0 V 1 μA

LIN

= 0 V 3 6 20 μA

1

I

LINh

I

SDh

LIN logic “1” input bias

current

SD

logic “1” input bias

current

= 15 V 1 μA

LIN

= 15 V 10 40 100 μA

SD

2

I

SDl

1. V

BO = Vboot

2. R

DSON

R

DSON

where I1 is pin 14 current when V

- V

is tested in the following way:

= [(VCC - V

SD logic “0” input bias

current

out

) - (VCC - V

CBOOT1

CBOOT2

CBOOT

)] / [I1(VCC,V

= V

CBOOT1, I2

= 0 V 1 μA

SD

) - I2(VCC,V

CBOOT1

when V

CBOOT

Table 9. Sense comparator (VCC = 15 V, TJ = +25 °C)

= V

CBOOT2

CBOOT2

0.8 V

)]

.

Symbol Pin Parameter Test conditions Min Typ Max Unit

V

io

I

ib

V

ol

t

d_comp

8, 9 Input offset voltage -15 15 mV

8, 9 Input bias current V

Open drain low level output

2

voltage

Comparator delay

= 1 V, V

CP+

= - 3 mA VCP+=1V;

I

od

= 0.5 V 1 μA

CP-

VCP-=0.5V;

=100 kΩ to 5 V on

R

pull

SD

/OD pin; VCP-=0.5V;

voltage step on CP+ = 0 ÷

0.5 V

90 130 ns

3.3V,

SR 2 Slew rate C

= 180 pF; Rpu = 5 kΩ 60 V/μs

L

Doc ID 17892 Rev 1 11/21

Waveforms definitions L6391

6 Waveforms definitions

Figure 5. Dead time and interlocking waveforms definitions

LIN

CONTROL SIGNAL EDGES

OVERLAPPED:

INTERLOCKING + DEAD TIME

CONTROL SIGNALS EDGES

SYNCHRONOUS (*):

DEAD TIME

CONTROL SIGNALS EDGES

NOT OVERLAPPED,

BUT INSIDE THE DEAD TIME:

DEAD TIME

CONTROL SIGNALS EDGES

NOT OVERLAPPED,

OUTSIDE THE DEAD TIME:

DIRECT DRIVING

HIN

LVG

HVG

gate driver outputs OFF

(HALF-BRIDGE TRI-STATE)

LIN

HIN

LVG

HVG

gate driver outputs OFF

(HALF-BRIDGE TRI-STATE)

LIN

HIN

LVG

HVG

gate driver outputs OFF

(HALF-BRIDGE TRI-STATE)

LIN

HIN

LVG

HVG

gate driver outputs OFF

(HALF-BRIDGE TRI-STATE)

INTERLOCKING

DTLH

gate driver outputs OFF

(HALF-BRIDGE TRI-STATE)

DTLH DTHL

gate driver outputs OFF

(HALF-BRIDGE TRI-STATE)

DTLH DTHL

gate driver outputs OFF

(HALF-BRIDGE TRI-STATE)

DTLH

gate driver outputs OFF

(HALF-BRIDGE TRI-STATE)

INTERLOCKING

DTHL

DTHL

(*) HIN and LIN can be connected togheter and driven by just one control signal

12/21 Doc ID 17892 Rev 1

L6391 Smart shut down function

7 Smart shut down function

L6391 integrates a comparator committed to the fault sensing function. The comparator

input can be connected to an external shunt resistor in order to implement a simple overcurrent detection function.

The output signal of the comparator is fed to an integrated MOSFET with the open drain

output available on pin 2, shared with the SD

device is set in shut down state and both its outputs are set to low level leaving the halfbridge in tri-state.

Figure 6. Smart shut down timing waveforms

CP-

CP+

input. When the comparator triggers, the

PROTECTION

HIN/LIN

HVG/LVG

SD/OD

upper

threshold

lower

threshold

open drain gate

(internal)

the driver outputs are set in SD state

immediately after the comparator

triggering even if the SD signal

Fast shut down:

has not yet reach

the lower input threshold

FROM/TO

CONTROLLER

1

real disable time

SHUT DOWN CIRCUIT

V

BIAS

SD

R

SD/OD

SD

C

2

TIME CONSTANTS

ON_OD

R

1

2

ON_OD

= (R

= R

SDCSD

SMART

LOGIC

// RSD)

SD

SD

C

Doc ID 17892 Rev 1 13/21

Smart shut down function L6391

In common over-current protection architectures the comparator output is usually connected

to the SD

input and an RC network is connected to this SD/OD line in order to provide a

mono-stable circuit, which implements a protection time that follows the fault condition.

Differently from the common fault detection systems, L6391 Smart shut down architecture

allows to immediately turn-off the outputs gate driver in case of fault, by minimizing the

propagation delay between the fault detection event and the actual outputs switch-off. In fact

the time delay between the fault and the outputs turn off is no more dependent on the RC

value of the external network connected to the pin. In the smart shut down circuitry, the fault

signal has a preferential path which directly switches off the outputs after the comparator

triggering. At the same time the internal logic turns on the open drain output and holds it on

until the SD

voltage goes below the SD logic input lower threshold. The Smart shut down

system provides the possibility to increase the time constant of the external RC network

(that is the disable time after the fault event) up to very large values without increasing the

delay time of the protection. Any external signal provided to the SD

pin is not latched and

can be used as control signal in order to perform, for instance, PWM chopping through this

pin. In fact when a PWM signal is applied to the SD

input and the logic inputs of the gate

driver are stable, the outputs switch from the low level to the state defined by the logic inputs

and vice versa.

14/21 Doc ID 17892 Rev 1

L6391 Typical application diagram

8 Typical application diagram

Figure 7. Application diagram

$CPPU

)7

#005

67

'-0"5*/(4536$563&

)7(

)7(

%3*7&3

4

3

%&5&$5*0/

-&7&-

4)*'5&3

50-0 "%

#*"4

7

$1

065

-7(

-7(

%3*7&3

$$

7

$1

7

$0.1"3"503

5*.&

-0( *$

4)005

5)306()

13&7&/5*0/

#005453"1%3*7&3

GSPN-7(

67

%&5&$5*0/

7$$

$$

7

)*/

'30.$0/530--&3

7

-*/

#*"4

7

'30.$0/530--&3

'30.50

4%0%

$0/530--&3

4%

4."35

%&"%

%5

(/%

!-V

Doc ID 17892 Rev 1 15/21

Bootstrap driver L6391

9 Bootstrap driver

A bootstrap circuitry is needed to supply the high voltage section. This function is normally

accomplished by a high voltage fast recovery diode (Figure 8). In the L6391 a patented

integrated structure replaces the external diode. It is realized by a high voltage DMOS,

driven synchronously with the low side driver (LVG), with diode in series, as shown in

Figure 9. An internal charge pump (Figure 9) provides the DMOS driving voltage.

9.1 C

To choose the proper C

capacitor. This capacitor C

Equation 1

The ratio between the capacitors C

It has to be:

Equation 2

e.g.: if Q

300 mV.

If HVG has to be supplied for a long time, the C

the leakage and quiescent losses.

e.g.: HVG steady state consumption is lower than 200 μA, so if HVG T

to supply 1 μC to C

The internal bootstrap driver gives a great advantage: the external fast recovery diode can

be avoided (it usually has great leakage current).

BOOT

selection and charging

value the external MOS can be seen as an equivalent

BOOT

is related to the MOS total gate charge:

EXT

C

EXT

and C

EXT

C

BOOT

is 30 nC and V

gate

. This charge on a 1 μF capacitor means a voltage drop of 1V.

EXT

is 10 V, C

gate

EXT

Q

gate

--------------=

V

gate

is proportional to the cyclical voltage loss.

BOOT

>>> C

EXT

is 3 nF. With C

selection has to take into account also

BOOT

= 100 nF the drop would be

BOOT

is 5 ms, C

ON

BOOT

has

This structure can work only if V

LVG is on. The charging time (T

is close to GND (or lower) and in the meanwhile the

OUT

) of the C

charge

BOOT

fulfilled and it has to be long enough to charge the capacitor.

The bootstrap driver introduces a voltage drop due to the DMOS R

120 Ω). At low frequency this drop can be neglected. Anyway increasing the frequency it

must be taken in to account.

16/21 Doc ID 17892 Rev 1

is the time in which both conditions are

(typical value:

DSon

L6391 Bootstrap driver

The following equation is useful to compute the drop on the bootstrap DMOS:

Equation 3

Q

gate

V

drop

ch eargRdson

I

==

→

V

drop

------------------

T

ch earg

R

dson

where Q

bootstrap DMOS and T

is the gate charge of the external power MOS, R

gate

is the charging time of the bootstrap capacitor.

charge

is the on resistance of the

dson

For example: using a power MOS with a total gate charge of 30nC the drop on the bootstrap

DMOS is about 1 V, if the T

is 5 μs. In fact:

charge

Equation 4

30nC

V

drop

V

has to be taken into account when the voltage drop on C

drop

-------------- -

5μs

120Ω 0.7V∼⋅=

is calculated: if this drop

BOOT

is too high, or the circuit topology doesn’t allow a sufficient charging time, an external diode

can be used.

Figure 8. Bootstrap driver with high voltage fast recovery diode

D

BOOT

V

CC

HVG

LVG

BOOT

OUT

H.V.

C

BOOT

TO LOAD

Figure 9. Bootstrap driver with internal charge pump

V

CC

HVG

LVG

BOOT

H.V.

OUT

b

Doc ID 17892 Rev 1 17/21

C

BOOT

TO LOAD

Package mechanical data L6391

10 Package mechanical data

In order to meet environmental requirements, ST offers these devices in different grades of

ECOPACK® packages, depending on their level of environmental compliance. ECOPACK®

specifications, grade definitions and product status are available at: www.st.com.

ECOPACK® is an ST trademark.

Table 10. DIP-14 mechanical data

mm. inch

Dim.

Min Typ Max Min Typ Max

a1 0.51 0.020

B 1.39 1.65 0.055 0.065

b 0.5 0.020

b1 0.25 0.010

D 20 0.787

E 8.5 0.335

e 2.54 0.100

e3 15.24 0.600

F 7.1 0.280

I 5.1 0.201

L 3.3 0.130

Z 1.27 2.54 0.050 0.100

Figure 10. Package dimensions

18/21 Doc ID 17892 Rev 1

L6391 Package mechanical data

Table 11. SO-14 mechanical data

mm. inch

Dim.

Min Typ Max Min Typ Max

A 1.75 0.068

a1 0.1 0.2 0.003 0.007

a2 1.65 0.064

b 0.35 0.46 0.013 0.018

b1 0.19 0.25 0.007 0.010

C 0.5 0.019

c1 45° (typ.)

D 8.55 8.75 0.336 0.344

E 5.8 6.2 0.228 0.244

e 1.27 0.050

e3 7.62 0.300

F 3.8 4.0 0.149 0.157

G 4.6 5.3 0.181 0.208

L 0.5 1.27 0.019 0.050

M 0.68 0.026

S 8° (max.)

Figure 11. Package dimensions

Doc ID 17892 Rev 1 19/21

Revision history L6391

11 Revision history

Table 12. Document revision history

Date Revision Changes

14-Dec-2010 1 First release

20/21 Doc ID 17892 Rev 1

L6391

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZED ST REPRESENTATIVE, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2010 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Philippines - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

Doc ID 17892 Rev 1 21/21

Loading...

Loading...