ST L6382D User Manual

Features

■ Integrated high-voltage start-up

■ 4 drivers for PFC, half-bridge & pre-heating

MOSFETs

■ 3.3V microcontroller compatible

■ Fully integrate power management for all

operating modes

■ Internal two point V

■ Over-current protection with digital output

signal

■ Cross-conduction protection (interlocking)

■ Under voltage lock-out

■ Integrated bootstrap diode

regulator

CC

L6382D

Power management unit

for microcontrolled ballast

SO-20

Description

The L6382D is suitable for microcontrolled

electronic ballasts embedding a PFC stage and a

half-bridge stage. The L6382D includes 4

MOSFET driving stages (for the PFC, for the half

bridge, for the preheating MOSFET) plus a power

management unit (PMU) featuring also a

reference able to supply the microcontroller in any

condition.

Applications

■ Dimmable / non-dimmable ballast

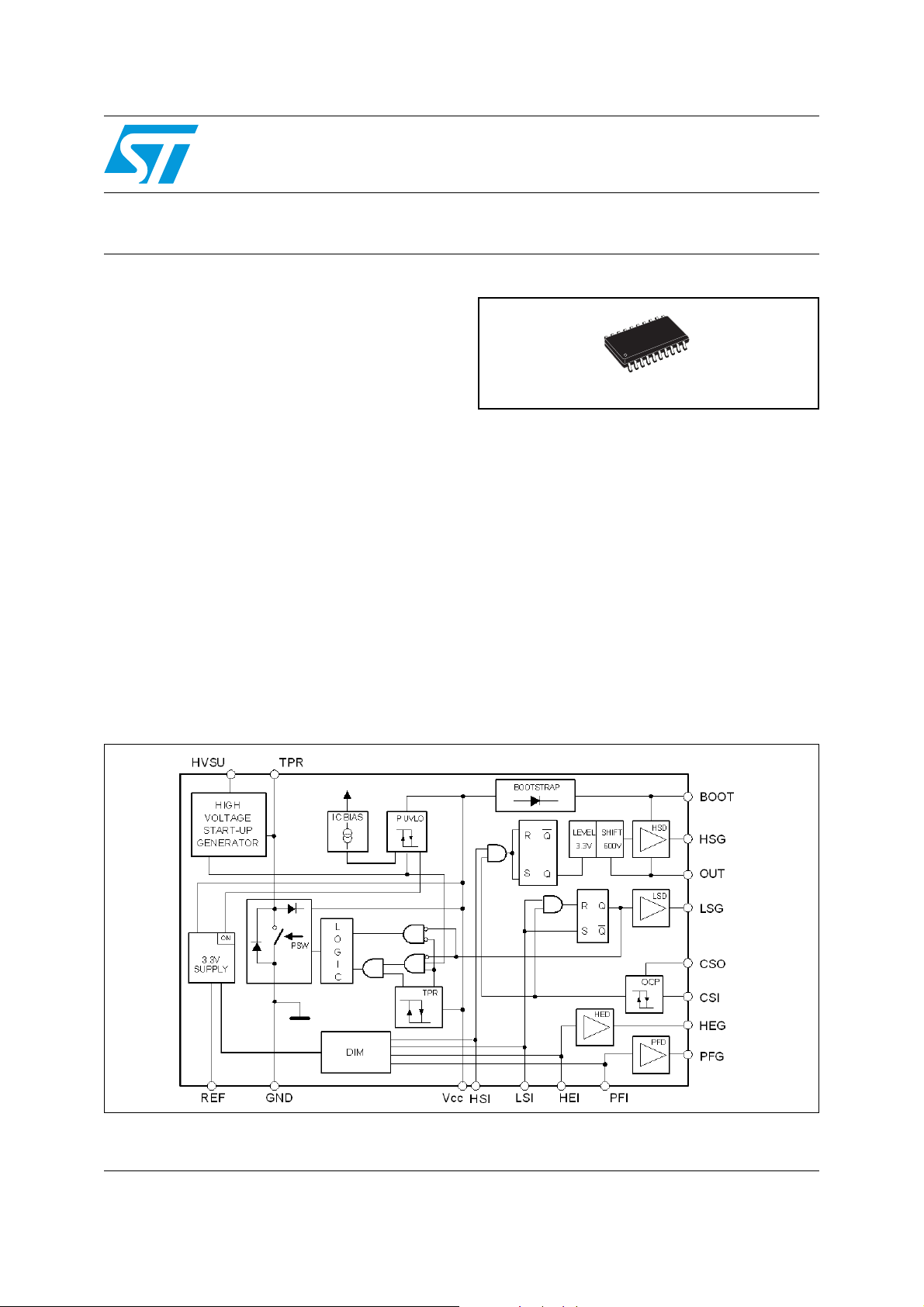

Figure 1. Block diagram

Besides increasing the application efficiency, the

L6382D reduces the bill of materials because

different tasks (regarding drivers and power

management) are performed by a single IC, which

improves the application reliability.

µ

March 2007 Rev 6 1/22

www.st.com

22

Contents L6382D

Contents

1 Device description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2 Pin settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.1 Pin connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.2 Pin description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3 Maximum ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.1 Absolute maximum ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.2 Thermal data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4 Electrical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

5 Typical electrical performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

6 Application information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

6.1 Power management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

6.1.1 START-UP mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

6.1.2 SAVE Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

6.1.3 OPERATING Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

6.1.4 Shut down . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

7 Block description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

7.1 Supply section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

7.2 3.3V reference voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

7.3 Drivers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

7.4 Internal logic, over current protection (OCP) and interlocking function . . 17

8 Package mechanical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

9 Order codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

10 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2/22

L6382D Device description

1 Device description

Designed in High-voltage BCD Off-line technology, the L6382D is a PFC and ballast

controller provided with 4 inputs pin and a high voltage start-up generator conceived for

applications managed by a microcontroller providing the maximum flexibility. It allows the

designer to use the same ballast circuit for different lamp wattage/type by simply changing

the µC software.

The digital input pins - able to receive signals up to 400KHz - are connected to level shifters

that provide the control signals to their relevant drivers; in particular the L6382D embeds

one driver for the PFC pre-regulator stage, two drivers for the ballast half-bridge stage (High

Voltage, including also the bootstrap function) and the last one to provide supplementary

features like preheating of filaments supplied through isolated windings in dimmable

applications.

A precise reference voltage (+3.3V ±1%) able to provide up to 30mA is available to supply

the µC: this current is obtained thanks to the on-chip high voltage start-up generator that,

moreover, keeps the consumption before start-up below 150µA.

The chip has been designed with advanced power management logic to minimize power

losses and increase the application reliability.

In the half-bridge section, a patented integrated bootstrap section replaces the external

bootstrap diode.

The L6382D integrates also a function that regulates the IC supply voltage (without the need

of any external charge pump) and optimizes the current consumption.

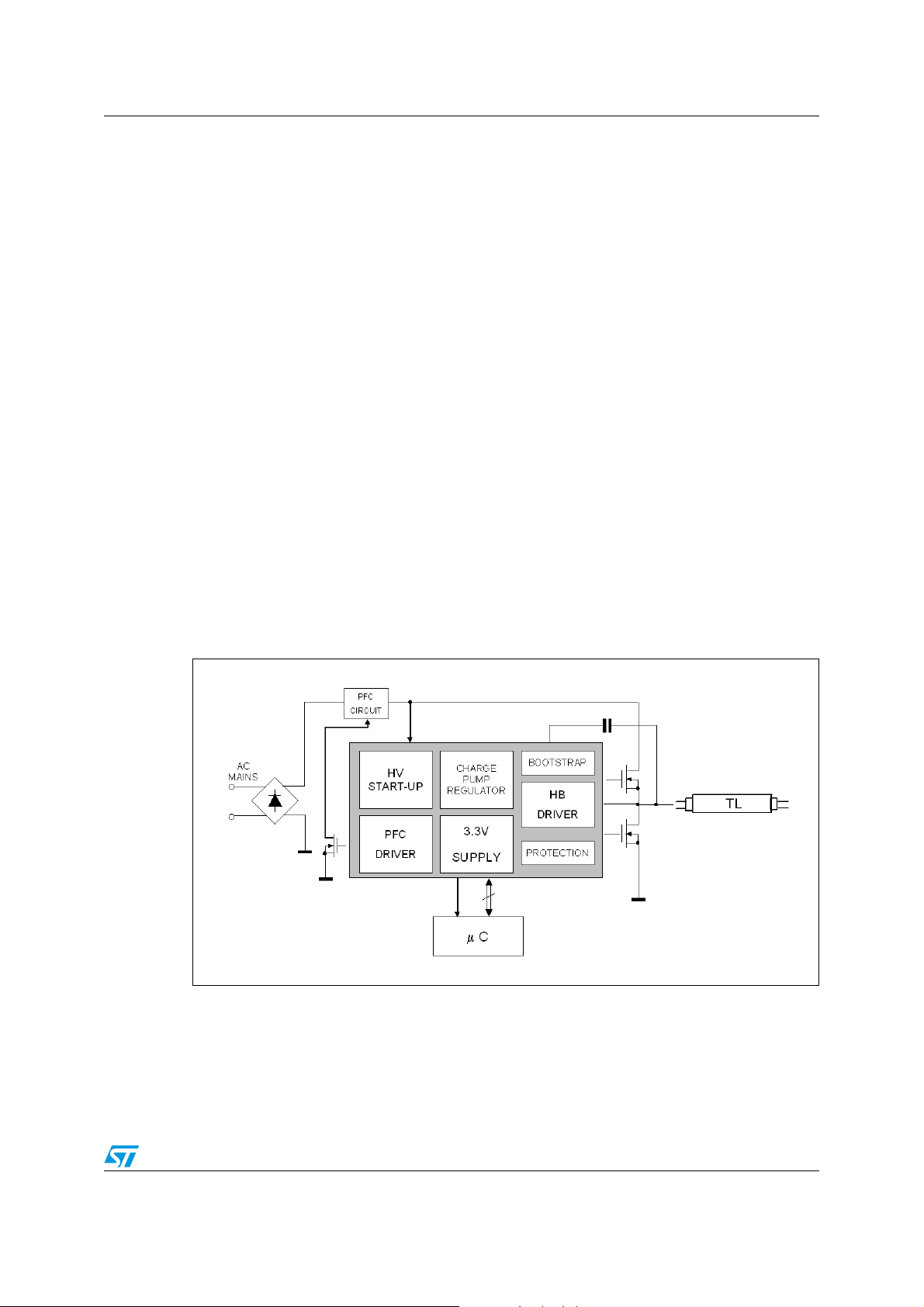

Figure 2. Typical system block diagram

3/22

Pin settings L6382D

2 Pin settings

2.1 Pin connection

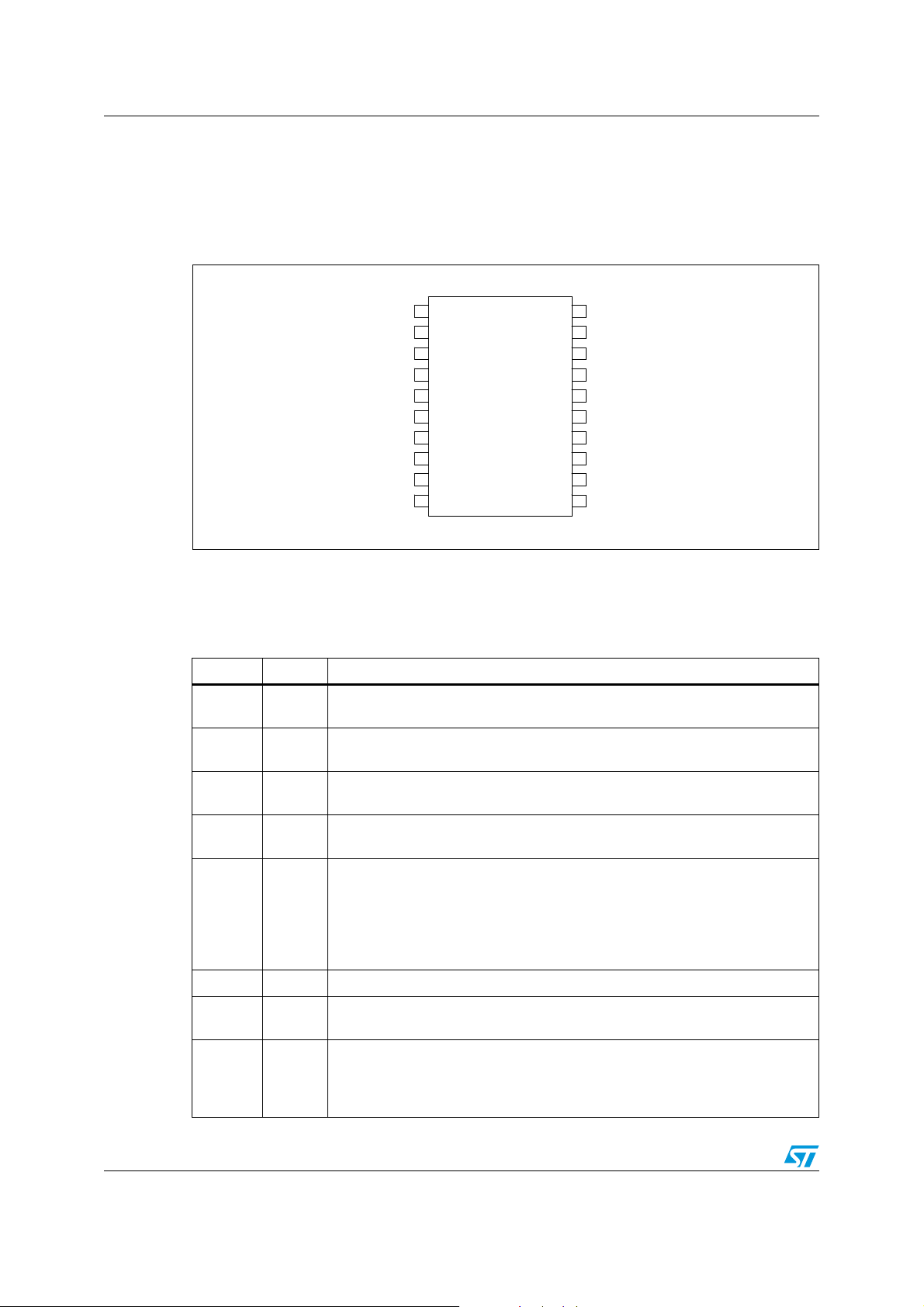

Figure 3. Pin connection (top view)

2.2 Pin description

Table 1. Pin description

Name Pin N° Description

1PFI

2LSI

3HSI

Digital input signal to control the PFC gate driver. This pin has to be connected

to a TTL compatible signal.

Digital input signal to control the half-bridge low side driver. This pin has to be

connected to a TTL compatible signal.

Digital input signal to control the half-bridge high side driver. This pin has to be

connected to a TTL compatible signal.

PFI

PFI

LSI

LSI

HSI

HSI

HEI

HEI

PFG

PFG

N.C.

N.C.

TPR

TPR

GND

GND

LSG

LSG

VCC

VCC

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

9

9

10

10

20

20

19

19

18

18

17

17

16

16

15

15

14

14

13

13

12

12

11

11

VREF

VREF

CSI

CSI

CSO

CSO

HEG

HEG

N.C.

N.C.

HVSU

HVSU

N.C.

N.C.

OUT

OUT

HSG

HSG

BOOT

BOOT

4HEI

5PFG

6 N.C. Not connected

7TPR

8GND

4/22

Digital input signal to control the HEG output. This pin has to be connected to a

TTL compatible signal.

PFC Driver Output. This pin is intended to be connected to the PFC power

MOSFET gate. A resistor connected between this pin and the power MOS gate

can be used to reduce the peak current. An internal 10KΩ resistor toward

ground avoids spurious and undesired MOSFET turn-on. The totem pole

output stage is able to drive the power MOS with a peak current of 120mA

source and 250mA sink.

Input for two point regulator; by coupling the pin with a capacitor to a switching

circuit, it is possible to implement a charge circuit for the Vcc.

Chip ground. Current return for both the low-side gate-drive currents and the

bias current of the IC. All of the ground connections of the bias components

should be tied to a trace going to this pin and kept separate from any pulsed

current return.

L6382D Pin settings

Table 1. Pin description

Name Pin N° Description

Low Side Driver Output. This pin must be connected to the gate of the halfbridge low side power MOSFET. A resistor connected between this pin and the

power MOS gate can be used to reduce the peak current.

9LSG

10 Vcc Supply Voltage for the signal part of the IC and for the drivers.

11 BOOT

12 HSG

13 OUT

14 N.C. Not connected

An internal 20KΩ resistor toward ground avoids spurious and undesired

MOSFET turn-on.

The totem pole output stage is able to drive power with a peak current of

120mA source and 120mA sink.

High-side gate-drive floating supply Voltage. The bootstrap capacitor

connected between this pin and pin 13 (OUT) is fed by an internal

synchronous bootstrap diode driven in phase with the low-side gate-drive. This

patented structure normally replaces the external diode.

High Side Driver Output. This pin must be connected to the gate of the half

bridge high side power MOSFET . A resistor connected between this pin and

the power MOS gate can be used to reduce the peak current.

An internal 20KΩ resistor toward OUT pin avoids spurious and undesired

MOSFET turn-on

The totem pole output stage is able to drive the power MOS with a peak

current of 120mA source and 120mA sink.

High-side gate-drive floating ground. Current return for the high-side gate-drive

current. Layout carefully the connection of this pin to avoid too large spikes

below ground.

15 HVSU

16 N.C.

17 HEG

18 CSO

19 CSI

20 VREF

High-voltage start-up. The current flowing into this pin charges the capacitor

connected between pin Vcc and GND to start up the IC. Whilst the chip is in

mode, the generator is cycled on-off between turn-on and save mode

save

voltages. When the chip works in operating

and it is re-enabled when the Vcc voltage falls below the UVLO threshold.

According to the required V

rectified mains voltage either directly or through a resistor.

High-voltage spacer. The pin is not connected internally to isolate the highvoltage pin and comply with safety regulations (creepage distance) on the

PCB.

Output for the HEI block; this driver can be used to drive the MOS employed in

isolated filaments preheating. An internal 20KΩ resistor toward ground avoids

spurious and undesired MOSFET turn-on.

Output of current sense comparator, compatible with TTL logic signal; during

operating

triggered (CSI> 0.5V typ.) the pin latches high.

Input of current sense comparator, it is enabled only during operating mode;

when the pin voltage exceeds the internal threshold, the CSO pin is forced

high and the half bridge drivers are disabled. It exits from this condition by

either cycling the Vcc below the UVLO or with LGI=HGI=low simultaneously.

Voltage reference. During normal mode an internal generator provides an

accurate voltage reference that can be used to supply up to 30mA (during

operating mode) to an external circuit. A small film capacitor (0.22µF min.),

connected between this pin and GND is recommended to ensure the stability

of the generator and to prevent noise from affecting the reference.

mode, the pin is forced low whereas whenever the OC comparator is

pin current, this pin can be connected to the

REF

mode the generator is shut down

5/22

Maximum ratings L6382D

3 Maximum ratings

3.1 Absolute maximum ratings

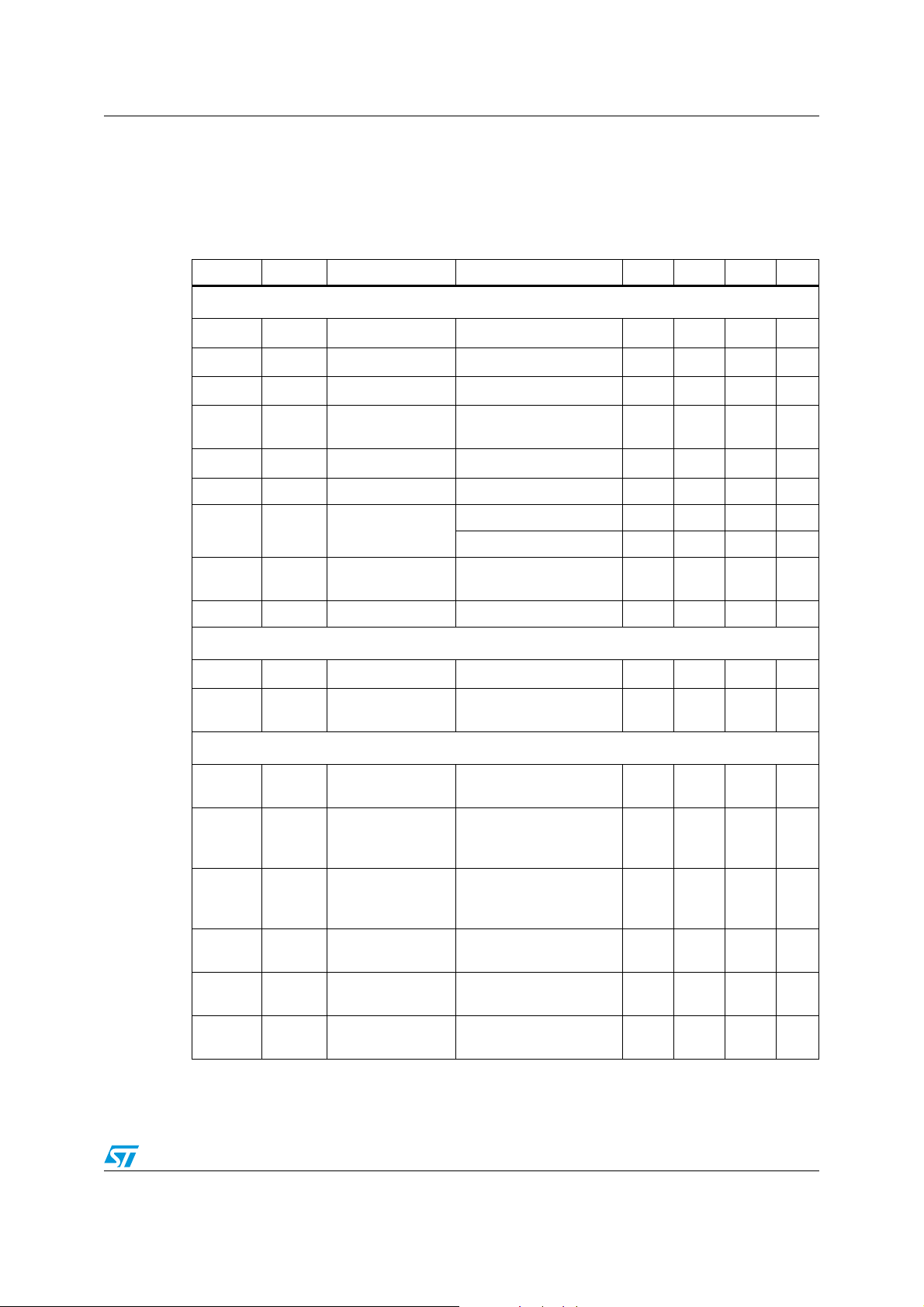

Table 2. Absolute maximum ratings

Symbol Pin Parameter Value Unit

V

CC

V

HVSU

V

BOOT

V

OUT

I

TPR(RMS)

I

TPR(PK)

V

TPR

10 IC supply voltage (ICC = 20mA) Self-limited

15 High voltage start-up generator voltage range -0.3 to 600 V

11 Floating supply voltage

-1 to V

HVSU+VCC

13 Floating ground voltage -1 to 600 V

7 Maximum TPR RMS current ±200 mA

7 Maximum TPR peak current ±600 mA

7

Maximum TPR voltage

(1)

14 V

19 CSI input voltage -0.3 to 7 V

1, 2,

Logic input voltage -0.3 to 7 V

3, 4

9, 12,

Operating frequency 15 to 400 KHz

17

V

5 Operating frequency 15 to 600 KHz

Tstg Storage temperature -40 to +150 °C

T

J

1. Excluding operating mode

3.2 Thermal data

Table 3. Thermal data

Symbol Parameter Value Unit

R

thJA

Maximum thermal resistance junction-ambient 120 °C/W

Ambient temperature operating range -40 to +125 °C

6/22

L6382D Electrical characteristics

4 Electrical characteristics

Table 4. Electrical characteristcs (TJ = 25°C, VCC = 13V, C

unless otherwise specified)

DRIVER

= 1nF

Symbol Pin Parameter Test condition Min Typ Max Unit

Supply voltage

V

CCON

V

CCOFF

V

CCSM

VSMhys 10

V

REF(OFF)

10 Turn-on voltage 13 14 15 V

10 Turn-off voltage 7.5 8.25 9.2 V

10 Save mode voltage 12.75 13.8 14.85 V

Save mode

hysteresys

0.12 0.16 0.2 V

10 Reference turn-off 5.7 6 6.4 V

IvccON 10 Start-up current 150 µA

IvccSM 10

Ivcc 10

Save Mode current

consumption

Quiescent current

in operating mode

(1) 150 230 µA

LGI = HGI = high;

no load on VREF.

190 µA

2mA

Vz 10 Internal Zener 16.5 17 18 V

High voltage start-up

> 50V

IMSS 15 Maximum current

ILSS 15

Leakage current off

state

V

HVSU

V

HVSU

= 600V

20 mA

40 µA

Two point regulator (TPR) protection

T

PR

st

PR

T

(ON)

T

PR

(OFF)

Vcc Protection

10

level

10 Vcc Turn-on level

10 Vcc Turn-off level

Output voltage on

7

state

Forward voltage

7

drop Diode

Leakage current off

7

state

Operating mode 14.0 14.5 15.0 V

Operating mode; after

the first falling edge on

12.5 13 13.5 V

LSG

Operating mode; after

the first falling edge on

12.45 12.95 13.48 V

LSG

= 200mA

I

TPR

@ 600mA forward

current.

V

= 13V

TPR

2V

2.3 V

5µA

7/22

Loading...

Loading...