high current DMOS universal motor driver

Features

■ Able to drive both windings of a bipolar stepper

motor or two DC motors

■ Output current up to 1.3A each winding

■ Wide voltage range: 12V to 40V

■ Four quadrant current control, ideal for

microstepping and DC motor control

■ Precision PWM control

■ No need for recirculation diodes

■ TTL/CMOS compatible inputs

■ Cross conduction protection

■ Thermal shutdow

Description

L6258EP is a dual full bridge for motor control

applications realized in BCD technology, with the

capability of driving both windings of a bipolar

stepper motor or bidirectionally control two DC

motors.

L6258EP

PWM controlled

PowerSSO36

The power stage is a dual DMOS full bridge

capable of sustaining up to 40V, and includes the

diodes for current recirculation. The output current

capability is 1.3A per winding in continuous mode,

with peak start-up current up to 2A. A thermal

protection circuitry disables the outputs if the chip

temperature exceeds the safe limits.

L6258EP and a few external components form a

complete control and drive circuit. It has high

efficiency phase shift chopping that allows a very

low current ripple at the lowest current control

levels, and makes this device ideal for steppers as

well as for DC motors.

Table 1. Device summary

Order code Package Packing

E-L6258EP PowerSSO36 Tube

December 2007 Rev 4 1/32

www.st.com

1

Contents L6258EP

Contents

1 Block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2 Functional description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.1 Reference voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.2 Input logic (I0 - I1 - I2 - I3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.3 Phase input ( PH ) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.4 Triangular generator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.5 Charge pump circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.6 Current control loop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.7 Current control loop compensation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3 PWM current control loop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.1 Open loop transfer function analysis . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.2 Power amplifier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.3 Load attenuation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.4 Error amplifier and sense amplifier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.5 Effect of the Bemf on the current control loop stability . . . . . . . . . . . . . . . 22

4 Application information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4.1 Interference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4.2 Motor selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.3 Unused inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.4 Notes on PCB design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

5 Operation mode time diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

6 Package information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

7 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

2/32

L6258EP List of tables

List of tables

Table 1. Device summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Table 2. Absolute maximum rating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Table 3. Pin functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Table 4. Electrical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Table 5. Current levels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Table 6. Charge pump capacitor's values. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Table 7. Document revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

3/32

List of figures L6258EP

List of figures

Figure 1. Block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Figure 2. Pin connection (top view) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Figure 3. Power bridge configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Figure 4. Current control loop block diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Figure 5. Output comparator waveforms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Figure 6. Ax bode plot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 7. Aloop bode plot (uncompensated) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 8. Aloop bode plot (compensated) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Figure 9. Electrical model of the load. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Figure 10. Typical application circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Figure 11. Full step operation mode timing diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Figure 12. Half step operation mode timing diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Figure 13. 4 bit microstep operation mode timing diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Figure 14. PowerSSO36 mechanical data & package dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4/32

L6258EP Block diagram

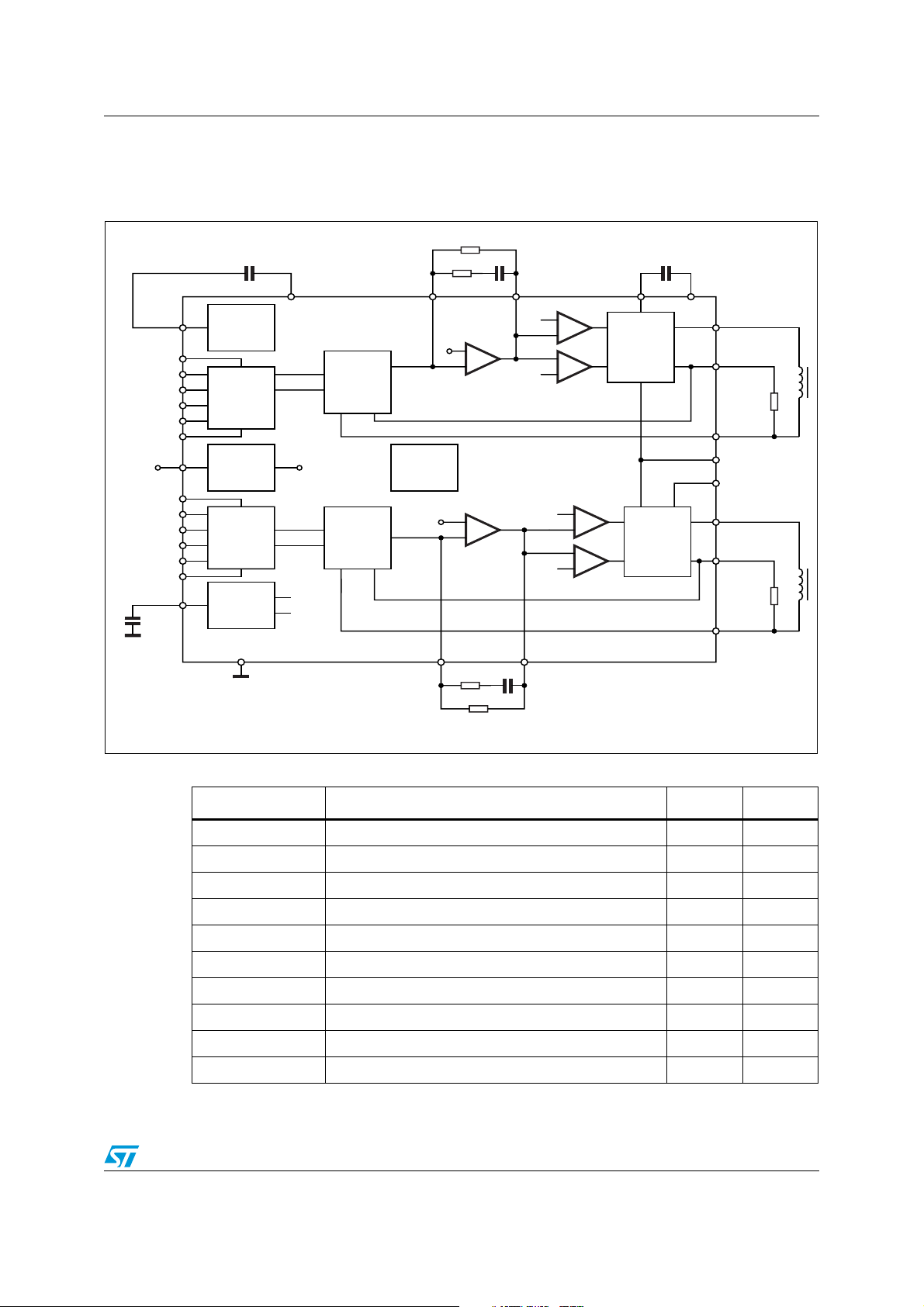

1 Block diagram

Figure 1. Block diagram

R

1M

VDD(5V)

TRI_CAP

VCP1

VREF1

I3_1

I2_1

I1_1

I0_1

PH_1

VREF1

I3_2

I2_2

I1_2

I0_2

PH_2

C

FREF

C

P

CHARGE

PUMP

DAC

VR GEN

DAC

TRIANGLE

GENERATOR

VR (VDD/2)

TRI_0

TRI_180

INPUT

&

SENSE

AMP

INPUT

&

SENSE

AMP

EA_IN1 EA_OUT1VCP2

THERMAL

PROT.

1

C

C1

R

C1

TRI_0

+

C

TRI_0

TRI_180

-

+

C

-

+

C

-

+

C

-

ERROR

V

R

AMP

+

TRI_180

-

ERROR

V

R

AMP

+

-

VS

POWER

BRIDGE

C

1

POWER

BRIDGE

2

BOOT

VBOOT

OUT1A

OUT1B

SENSE1B

SENSE1A

DISABLE

VS

OUT2A

OUT2B

SENSE2B

SENSE2A

R

s

R

s

EA_IN2 EA_OUT2GND

R

R

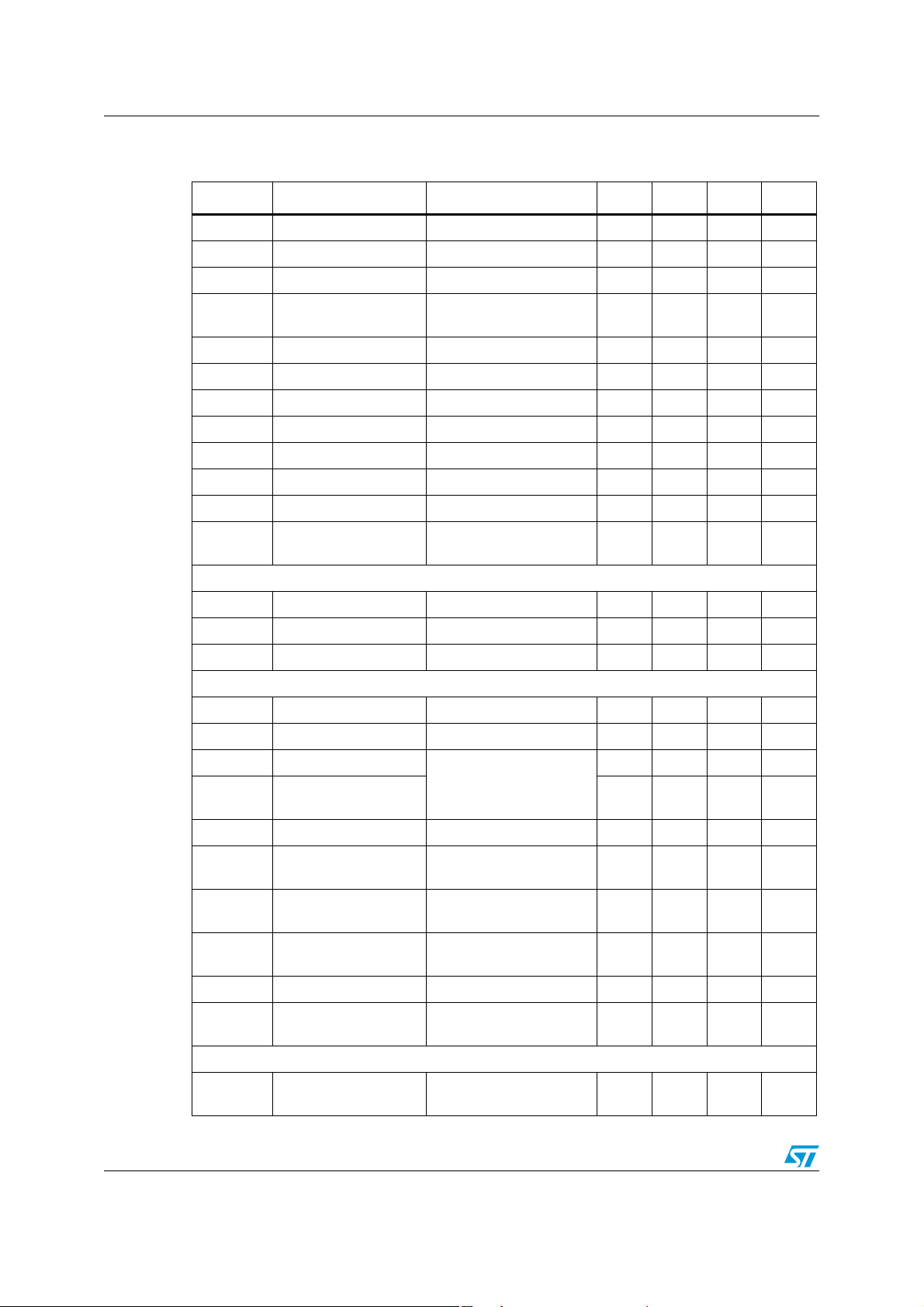

Table 2. Absolute maximum rating

C2

C

C2

1M

2

D96IN430D

Parameter Description Value Unit

V

s

V

DD

V

ref1/Vref2

I

O

I

O

V

in

V

boot

- V

V

boot

s

T

j

T

stg

1. This current is intended as not repetitive current for max. 1 second.

Supply voltage 45 V

Logic supply voltage 7 V

Reference voltage 2.5 V

Output current (peak)

(1)

2A

Output current (continuous) 1.3 A

Logic input voltage range -0.3 to 7 V

Bootstrap supply 60 V

Maximum Vgate applicable 15 V

Junction temperature 150 °C

Storage temperature range -55 to 150 °C

5/32

Block diagram L6258EP

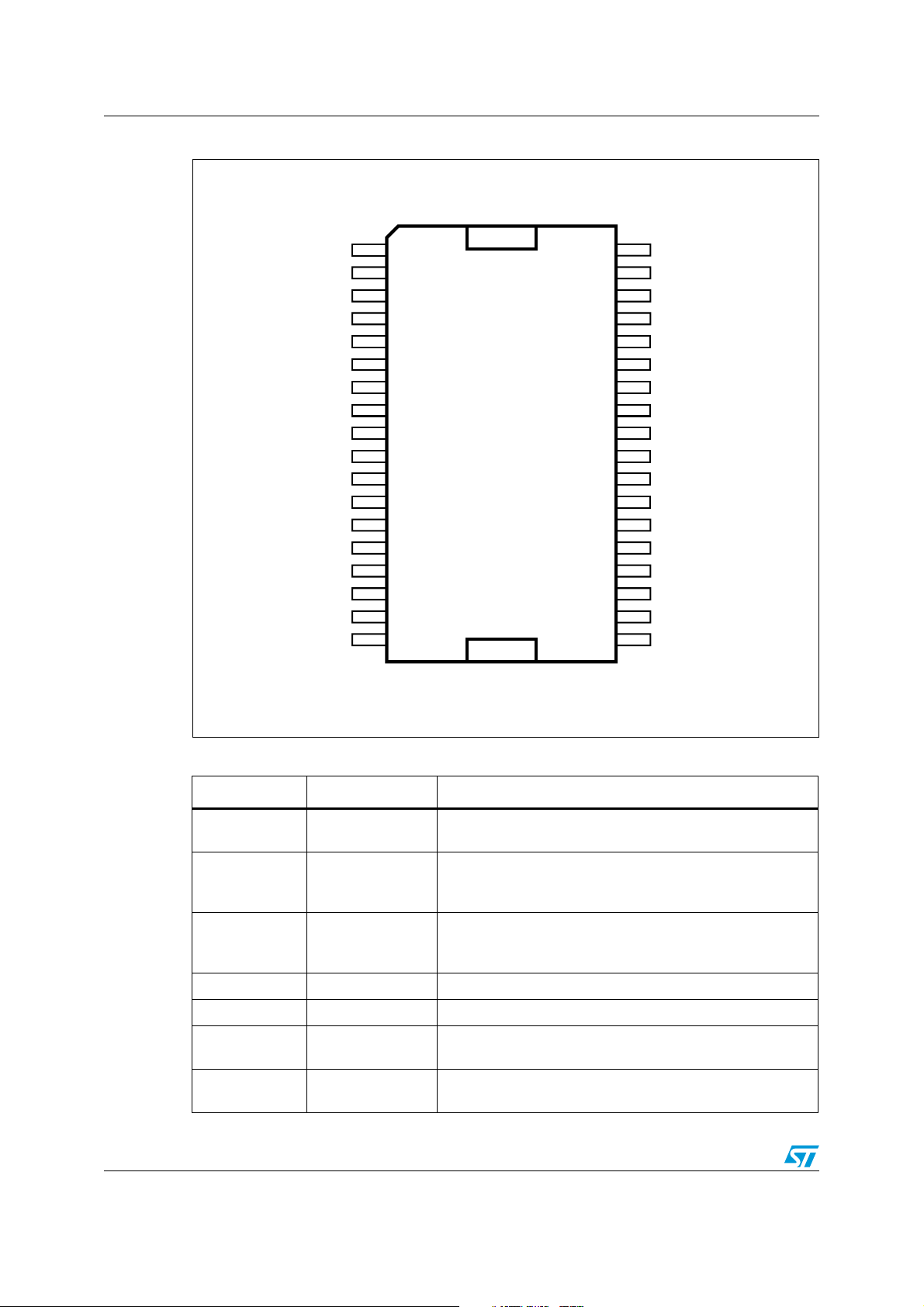

Figure 2. Pin connection (top view)

PWR_GND

PH_1

I1_1

I0_1

OUT1A

DISABLE

TRI_CAP

V

CC

GND

VCP1

VCP2

VBOOT

VS

OUT2A

I0_2

I1_2

PH_2

PWR_GND

1

2

3

4

5

6

7

8

9

10 27

11

12

13 24

14

15

16

17

18

D96IN432E

36

35

34

33

32

31

30

29

28

26

25

23

22

21

20

19

PWR_GND

SENSE1

OUT1B

I3_1

I2_1

VS

EA_OUT1

EA_IN1

VREF1

SIG_GND

VREF2

EA_IN2

EA_OUT2

I2_2

I3_2

OUT2B

SENSE2

PWR_GND

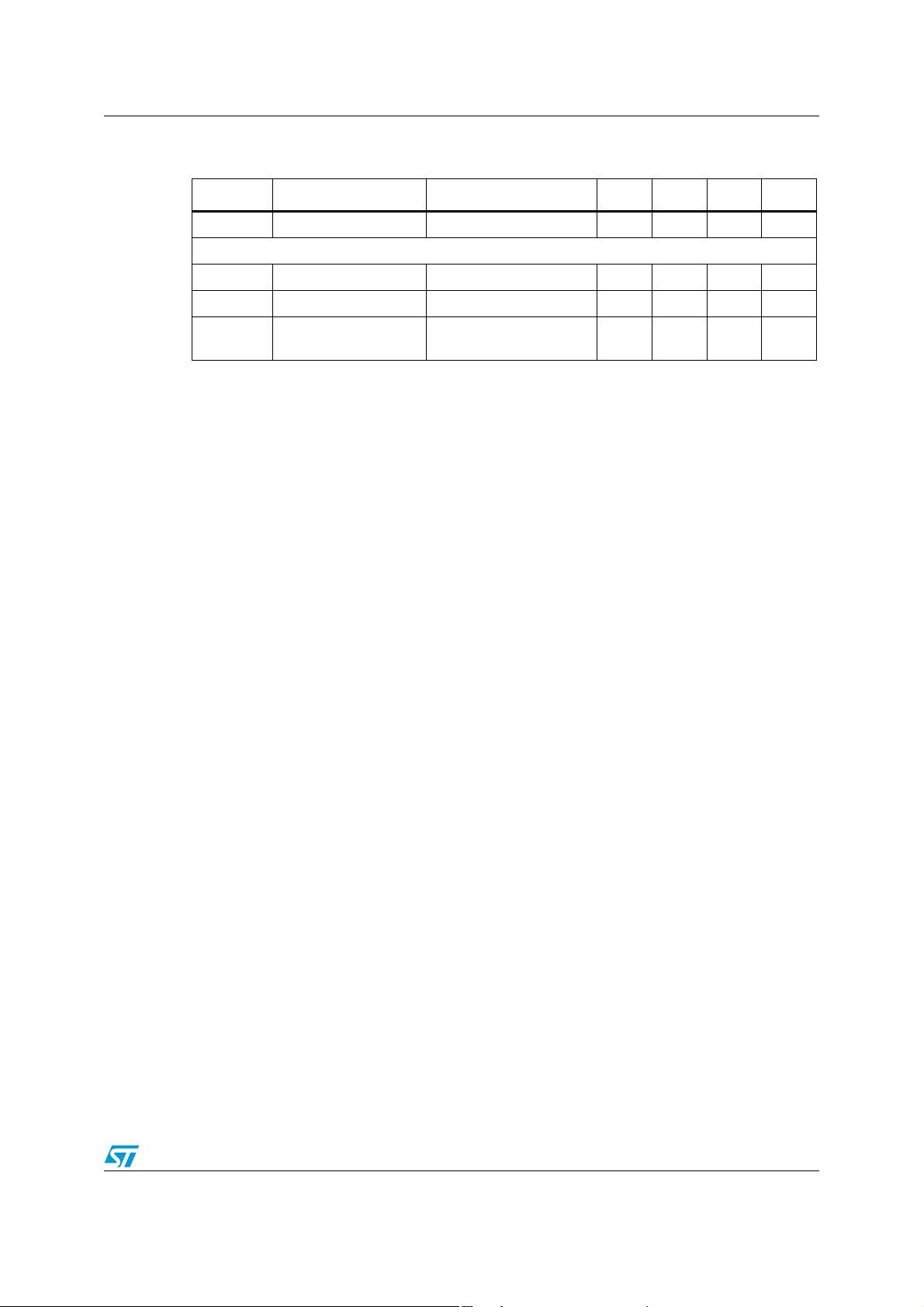

Table 3. Pin functions

Pin # Name Description

1, 36 PWR_GND

Ground connection (1). They also conduct heat from die to

printed circuit copper.

These TTL compatible logic inputs set the direction of

2, 17 PH_1, PH_2

current flow through the load. A high level causes current to

flow from OUTPUT A to OUTPUT B.

Logic input of the internal DAC (1). The output voltage of the

3I

1_1

DAC is a percentage of the Vref voltage applied according to

the thruth Table 5 on page 12.

4I

0_1

See pin 3

5 OUT1A Bridge output connection (1)

6 DISABLE

7TRI_cap

Disables the bridges for additional safety during switching.

When not connected the bridges are enabled

Triangular wave generation circuit capacitor. The value of

this capacitor defines the output switching frequency

6/32

L6258EP Block diagram

Table 3. Pin functions (continued)

Pin # Name Description

8V

(5V) Supply voltage input for logic circuitry

DD

9 GND Power ground connection of the internal charge pump circuit

10 V

11 V

12 V

13, 31 V

CP1

CP2

BOOT

S

Charge pump oscillator output

Input for external charge pump capacitor

Overvoltage input for driving of the upper DMOS

Supply voltage input for output stage. They are shorted

internally

14 OUT2A Bridge output connection (2)

Logic input of the internal DAC (2). The output voltage of the

15 I

0_2

DAC is a percentage of the VRef voltage applied according

to the truth Table 5 on page 12

16 I

1_2

18, 19 PWR_GND

See pin 15

Ground connection. They also conduct heat from die to

printed circuit copper

20, 35 SENSE2, SENSE1 Negative input of the transconductance input amplifier (2, 1)

21 OUT2B

22 I

23 I

3_2

2_2

Bridge output connection and positive input of the

tranconductance (2)

See pin 15

See pin 15

24 EA_OUT_2 Error amplifier output (2)

25 EA_IN_2 Negative input of error amplifier (2)

Reference voltages for the internal DACs, determining the

26, 28 V

REF2

, V

REF1

output current value. Output current also depends on the

logic inputs of the DAC and on the sensing resistor value

27 SIG_GND Signal ground connection

29 EA_IN_1 Negative input of error amplifier (1)

30 EA_OUT_1 Error amplifier output (1)

32 I

33 I

2_1

3_1

34 OUT1B

See pin 3

See pin 3

Bridge output connection and positive input of the

tranconductance (1)

Note: The number in parenthesis shows the relevant Power Bridge of the circuit. Pins 18, 19, 1

and 36 are connected together.

7/32

Block diagram L6258EP

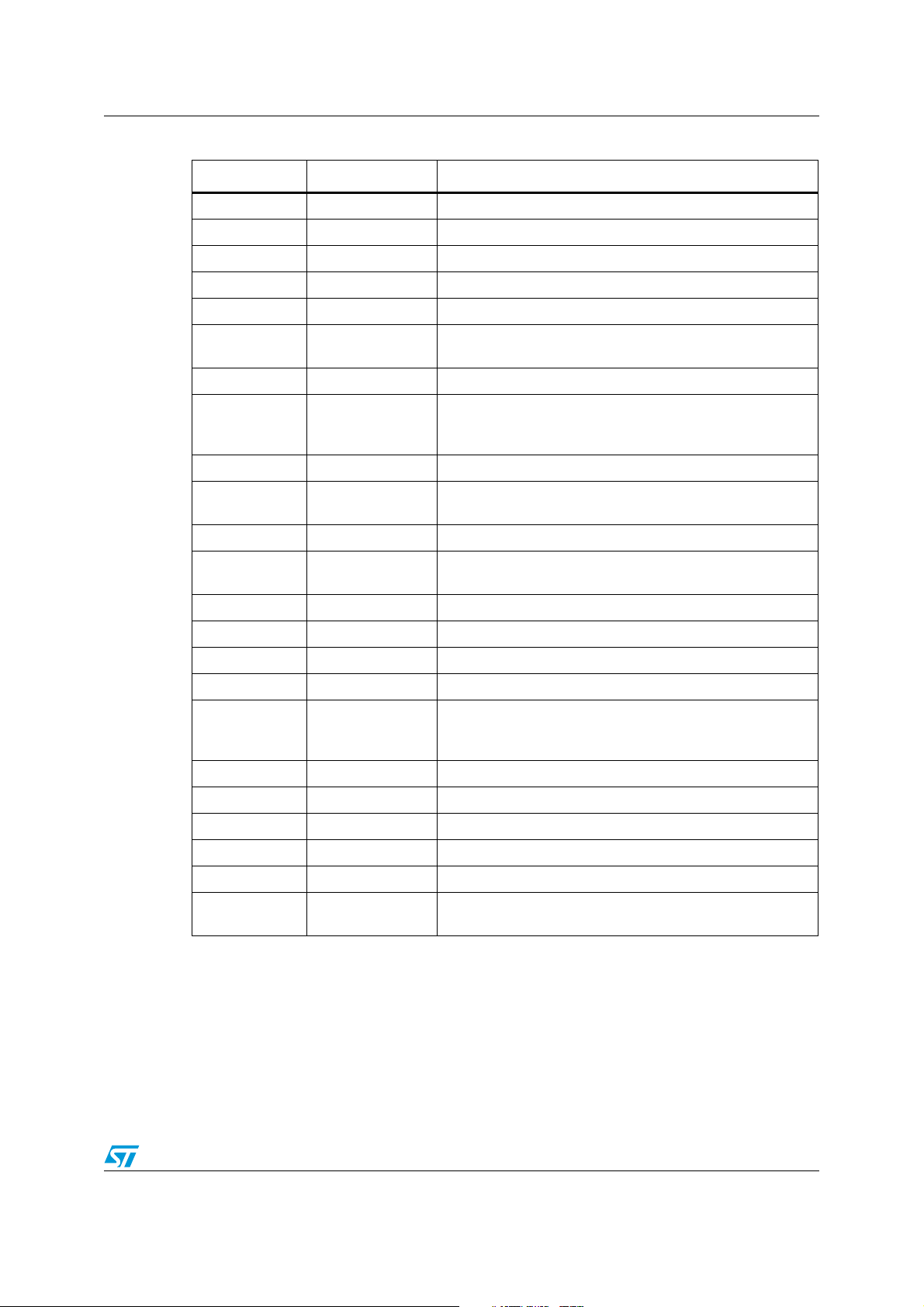

Table 4. Electrical characteristics

(V

= 40V; VDD = 5V; Tj = 25°; unless otherwise specified.)

S

Parameter Description Test condition Min. Typ. Max. Unit

V

V

V

BOOT

V

Sense

V

S(off)

V

DD(off)

I

S(on)

I

S(off)

I

ΔT

T

f

DD

DD

SD-H

SD

osc

Supply voltage 12 40 V

S

Logic supply voltage 4.75 5.25 V

Storage voltage VS = 12 to 40V VS+6 VS+12 V

Max drop across sense

resistor

Power off reset Off threshold 6 7.2 V

Power off reset Off threshold 3.3 4.1 V

VS quiescent current Both bridges ON, no load 15 mA

VS quiescent current Both bridges OFF 7 mA

VDD operative current 15 mA

Shut down hysteresis 25 °C

Thermal shutdown 150 °C

Triangular oscillator

frequency

TRANSISTORS

I

R

DSS

ds(on)

V

Leakage current OFF State 500 μA

On resistance ON state 0.6 0.75 W

Flywheel diode voltage If =1.0A 1 1.4 V

f

CONTROL LOGIC

V

in(H)

V

in(L)

I

in

I

dis

V

ref1/ref2

I

ref

FI =

V

ref/Vsense

V

FS

V

offset

lnput voltage All Inputs 2 V

Input voltage All inputs 0 0.8 V

Input current

Disable pin input

current

Reference voltage Operating 0 2.5 V

V

terminal input

ref

current

PWM loop transfer

ratio

DAC full scale

precision

Current loop offset V

DAC factor ratio

SENSE AMPLIFIER

(1)

(2)

1.25 V

C

= 1nF 12.5 15 18.5 KHz

FREF

DD

-150 +10 μA

0 < Vin < 5V

-10 +150 μA

= 1.25 -2 5 μA

V

ref

2

= 2.5V I0/I1/I2/I3 = L 1.23 1.34 V

V

ref

= 2.5V I0/I1/I2/I3 = H -40 +40 mV

ref

Normalized @ full scale

value

-2 +2 %

V

V

cm

lnput common mode

voltage range

8/32

-0.7 V

+0.7 V

S

L6258EP Block diagram

Table 4. Electrical characteristics (continued)

(V

= 40V; VDD = 5V; Tj = 25°; unless otherwise specified.)

S

Parameter Description Test condition Min. Typ. Max. Unit

I

inp

Input bias sense1/sense2 -200 0 μA

ERROR AMPLIFIER

G

Open loop voltage gain 70 dB

V

SR Output slew rate Open loop 0.2 V/μs

GBW

1. Chopping frequency is twice fosc value.

2. This is true for all the logic inputs except the disable input.

Gain bandwidth

product

400 kHz

9/32

Functional description L6258EP

2 Functional description

The circuit is intended to drive both windings of a bipolar stepper motor or two DC motors.

The current control is generated through a switch mode regulation.

With this system the direction and the amplitude of the load current are depending on the

relation of phase and duty cycle between the two outputs of the current control loop.

The L6258EP power stage is composed by power DMOS in bridge configuration as it is

shown in Figure 3, where the bridge outputs OUT_A and OUT_B are driven to V

high level at the inputs IN_A and IN_B while are driven to ground with a low level at the

same inputs.

The zero current condition is obtained by driving the two half bridge using signals IN_A and

IN_B with the same phase and 50% of duty cycle.

In this case the outputs of the two half bridges are continuously switched between power

supply (V

) and ground, but keeping the differential voltage across the load equal to zero.

s

In Figure 3 is shown the timing diagram of the two outputs and the load current for this

working condition.

Following we consider positive the current flowing into the load with a direction from OUT_A

to OUT_B, while we consider negative the current flowing into load with a direction from

OUT_B to OUT_A.

with an

s

Now just increasing the duty cycle of the IN_A signal and decreasing the duty cycle of IN_B

signal we drive positive current into the load.

In this way the two outputs are not in phase, and the current can flow into the load trough the

diagonal bridge formed by T1 and T4 when the output OUT_A is driven to V

and the output

s

OUT_B is driven to ground, while there will be a current recirculation into the higher side of

the bridge, through T1 and T2, when both the outputs are at Vs and a current recirculation

into the lower side of the bridge, through T3 and T4, when both the outputs are connected to

ground.

Since the voltage applied to the load for recirculation is low, the resulting current discharge

time constant is higher than the current charging time constant during the period in which

the current flows into the load through the diagonal bridge formed by T1 and T4. In this way

the load current will be positive with an average amplitude depending on the difference in

duty cycle of the two driving signals.

In Figure 3 is shown the timing diagram in the case of positive load current

On the contrary, if we want to drive negative current into the load is necessary to decrease

the duty cycle of the IN_A signal and increase the duty cycle of the IN_B signal. In this way

we obtain a phase shift between the two outputs such to have current flowing into the

diagonal bridge formed by T2 and T3 when the output OUT_A is driven to ground and

output OUT_B is driven to Vs, while we will have the same current recirculation conditions of

the previous case when both the outputs are driven to Vs or to ground.

So, in this case the load current will be negative with an average amplitude always

depending by the difference in duty cycle of the two driving signals.

In Figure 3 is shown the timing diagram in the case of negative load current.

Figure 4 shows the device block diagram of the complete current control loop.

10/32

Loading...

Loading...