ST L6229 User Manual

L6229

Fi

DMOS DRIVER FOR

THREE-PHASE BRUSHLESS DC MOTOR

1FEATURES

■ OPERATING SUPPLY VOLTAGE FROM 8 TO

52V

■ 2.8A OUTPUT PEAK CURRENT (1.4A DC)

■ R

■ OPERATING FREQUENCY UP TO 100KHz

■ NON DISSIPATIVE OVERCURRENT

0.73Ω TYP. VALUE @ Tj = 25 °C

DS(ON)

DETECTION AND PROTECTION

■ DIAGNOSTIC OUTPUT

■ CONSTANT t

PWM CURRENT

OFF

CONTROLLER

■ SLOW DECAY SYNCHR. RECTIFICATION

■ 60° & 120° HALL EFFECT DECODING LOGIC

■ BRAKE FUNCTION

■ TACHO OUTPUT FOR SPEED LOOP

■ CROSS CONDUCTION PROTECTION

■ THERMAL SHUTDOWN

■ UNDERVOLTAGE LOCKOUT

■ INTEGRATED FAST FREEWEELING DIODES

2 DESCRIPTION

The L6229 is a DMOS Fully Integrated Three-Phase

Motor Driver with Overcurrent Protection.

Realized in MultiPower-BCD technology, the device

combines isolated DMOS Power Transistors with

CMOS and bipolar circuits on the same chip.

The device includes all the circuitry needed to drive a

three-phase BLDC motor including: a three-phase

DMOS Bridge, a constant off time PWM Current Controller and the decoding logic for single ended hall

sensors that generates the required sequence for the

power stage.

Available in PowerDIP24 (20+2+2), PowerSO36 and

SO24 (20+2+2) packages, the L6229 features a non-

gure 1. Package

PowerDIP24

(20+2+2)

PowerSO36

SO24

(20+2+2)

Table 1. Order Codes

Part Number Package

L6229N PowerDIP24

L6229PD PowerSO36

L6229PDTR PowerSO36 in Tape & Reel

L6229D SO24

L6229DTR SO24 in Tape & Reel

dissipative overcurrent protection on the high side

Power MOSFETs and thermal shutdown.

October 2004

Rev. 3

1/25

L6229

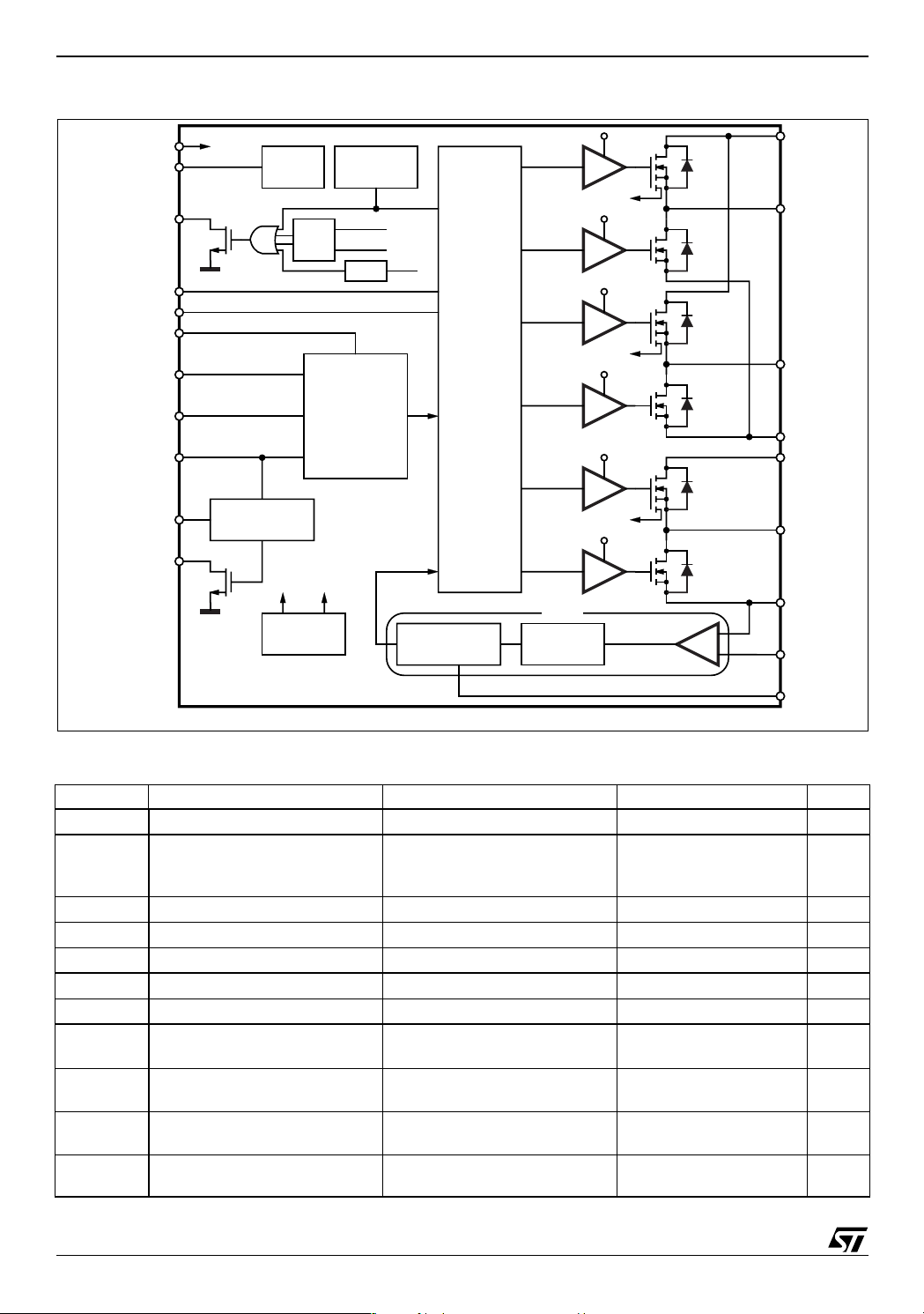

Figure 2. Block Diagram

VBOOT V

VCP

DIAG

EN

BRAKE

FWD/REV

H

3

H

2

H

1

RCPULSE

TACHO

BOOT

CHARGE

PUMP

TACHO

MONOSTABLE

10V

VOLTAGE

REGULATOR

THERMAL

PROTECTION

OCD1

OCD

OCD2

HALL-EFFECT

SENSORS

DECODING

LOGIC

5V

OCD

OCD3

ONE SHOT

MONOSTABLE

GATE

LOGIC

PWM

MASKING

TIME

V

BOOT

OCD1

10V

V

BOOT

OCD2

10V

V

BOOT

OCD3

10V

COMPARATOR

SENSE

VS

A

OUT

1

OUT

2

SENSE

A

VS

B

OUT

3

SENSE

B

+

-

VREF

RCOFF

D99IN1095B

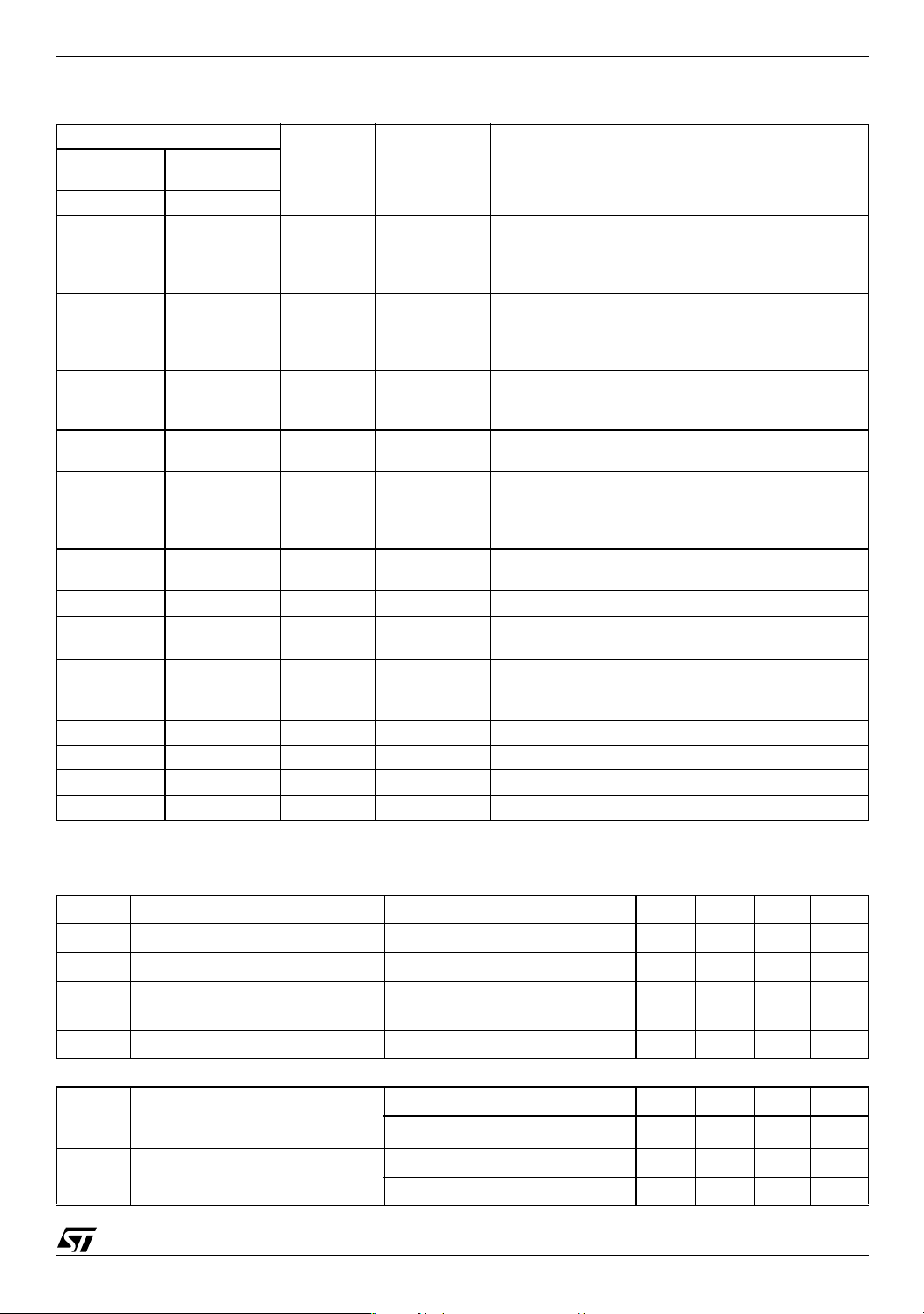

Table 2. Absolute Maximum Ratings

Symbol Parameter Test conditions Value Unit

V

V

V

RCPULSE

V

I

T

2/25

V

V

OD

V

BOOT

, V

IN

V

REF

RCOFF

SENSE

S(peak)

I

S

, T

stg

Supply Voltage VSA = VSB = V

S

Differential Voltage between:

VS

, OUT1, OUT2, SENSEA

A

and VS

, OUT3, SENSE

B

B

VSA = VSB = VS = 60V;

V

SENSEA

Bootstrap Peak Voltage VSA = VSB = V

Logic Inputs Voltage Range -0.3 to 7 V

EN

= V

S

SENSEB

S

= GND

60 V

60 V

VS + 10 V

Voltage Range at pin VREF -0.3 to 7 V

Voltage Range at pin RCOFF -0.3 to 7 V

Voltage Range at pin RCPULSE -0.3 to 7 V

Voltage Range at pins SENSEA

and SENSE

B

Pulsed Supply Current (for each

VS

and VSB pin)

A

DC Supply Current (for each

VS

and VSB pin)

A

Storage and Operating

OP

= VSB = VS; T

V

SA

= VSB = V

V

SA

S

< 1ms 3.55 A

PULSE

-1 to 4 V

1.4 A

-40 to 150 °C

Temperature Range

Table 3. Recommended Operating Condition

Symbol Parameter Test Conditions MIN MAX Unit

L6229

V

V

V

SENSE

I

OUT

f

V

OD

REF

T

SW

Supply Voltage VSA = VSB = V

S

Differential Voltage between:

VS

, OUT1, OUT2, SENSEA and

A

, OUT3, SENSE

VS

B

VSA = VSB = VS;

V

SENSEA

B

= V

S

SENSEB

Voltage Range at pin VREF -0.1 5 V

Voltage Range at pins SENSEA

and SENSE

B

DC Output Current VSA = VSB = V

Operating Junction Temperature -25 125 °C

J

(pulsed tW < trr)

(DC)

S

Switching Frequency 100 KHz

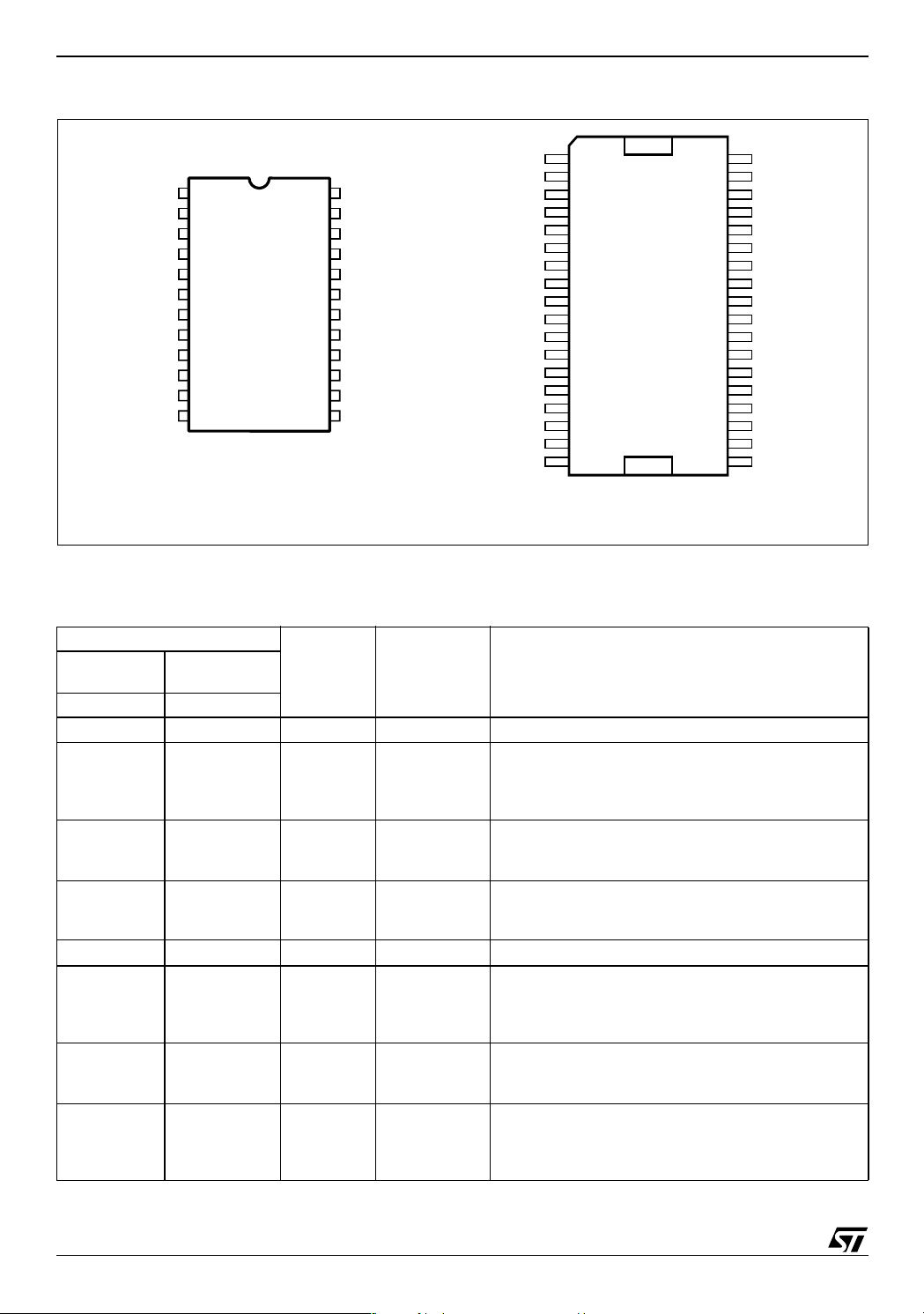

Table 4. Thermal Data

Symbol Description PDIP24 SO24

R

th(j-pins)

R

th(j-case)

R

th(j-amb)1

Maximum Thermal Resistance Junction-Pins 19 15 °C/W

Maximum Thermal Resistance Junction-Case 2 °C/W

MaximumThermal Resistance Junction-Ambient

(1)

44 55 - °C/W

12 52 V

52 V

-6

-1

6

1

1.4 A

PowerSO36

Unit

V

V

(3)

(2)

(4)

--36°C/W

--16°C/W

59 78 63 °C/W

R

th(j-amb)1

R

th(j-amb)1

R

th(j-amb)2

(1) Mounted on a multi-layer FR4 PCB with a dissipating copper surface on the bottom side of 6 cm2 (with a thickness of 35 µm).

(2) Mounted on a multi-layer FR4 PCB with a dissipating copper surface on the top side of 6 cm2 (with a thickness of 35 µm).

(3) Mounted on a multi-layer FR4 PCB with a dissipating copper surface on the top side of 6 cm2 (with a thickness of 35 µm),

(4) Mounted on a multi-layer FR4 PCB without any heat-sinking surface on the board.

Maximum Thermal Resistance Junction-Ambient

MaximumThermal Resistance Junction-Ambient

Maximum Thermal Resistance Junction-Ambient

16 via holes and a ground layer.

3/25

L6229

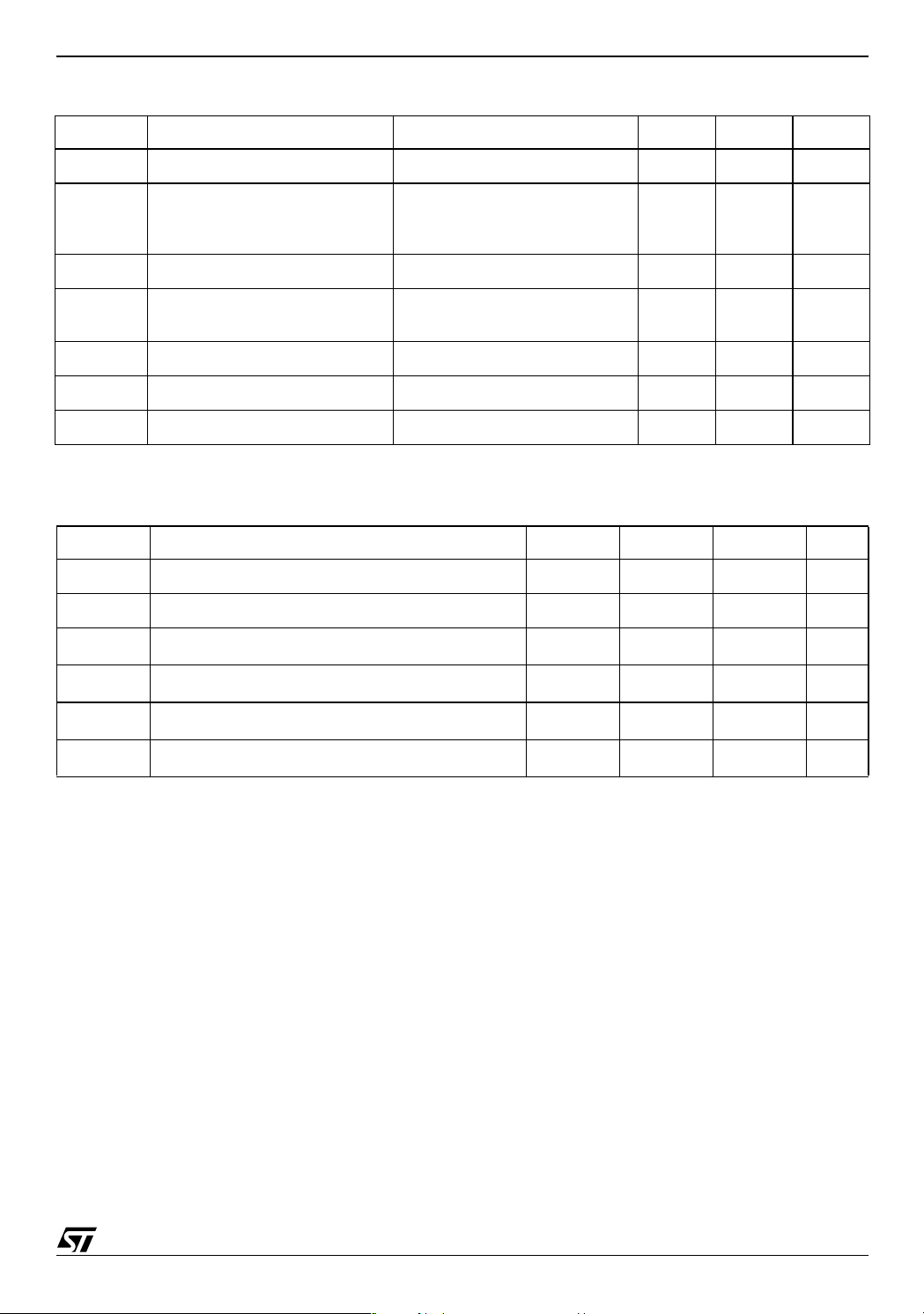

Figure 3. Pin Connections (Top view)

DIAG

SENSE

RCOFF

OUT

GND

GND

TACHO

RCPULSE

SENSE

FWD/REV

EN

1

H

1

2

3

A

4

5

1

6

7

8

9

10

B

11

12

PowerDIP24/SO24

D01IN1194A

GND

N.C.

24

H

3

23

H

2

22

VCP

21

OUT

2

VS

20

18

17

16

15

14

13

A

GND19

GND

VS

B

OUT

3

VBOOT

BRAKE

VREF

N.C.

VS

OUT

N.C.

VCP

DIAG

SENSE

RCOFF

N.C.

OUT

N.C.

N.C.

GND

1

2

3

4

A

5

2

7

H

8

2

H

3

H

10

1

11

12

A

13

14

15

1

16

17

18

D01IN1195A

PowerSO36

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

21

20

19

(5)

(5) The slug is internally connected to pins 1, 18, 19 and 36 (GND pins).

Table 5. Pin Description

PACKAGE

SO24/

PowerDIP24

PowerSO36

PIN # PIN #

110H

2 11 DIAG Open Drain

3 12 SENSE

4 13 RCOFF RC Pin RC Network Pin. A parallel RC network connected

515OUT

6, 7,

18, 19

1, 18,

19, 36

8 22 TACHO Open Drain

9 24 RCPULSE RC Pin RC Network Pin. A parallel RC network connected

Name Type Function

1

Sensor Input Single Ended Hall Effect Sensor Input 1.

Overcurrent Detection and Thermal Protection pin. An

Output

internal open drain transistor pulls to GND when an

overcurrent on one of the High Side MOSFETs is

detected or during Thermal Protection.

Power Supply Half Bridge 1 and Half Bridge 2 Source Pin. This pin

A

must be connected together with pin SENSE

Power Ground through a sensing power resistor.

between this pin and ground sets the Current

Controller OFF-Time.

Power Output Output 1

1

GND GND Ground terminals. On PowerDIP24 and SO24

packages, these pins are also used for heat

dissipation toward the PCB. On PowerSO36 package

the slug is connected on these pins.

Frequency-to-Voltage open drain output. Every pulse

Output

from pin H

is shaped as a fixed and adjustable length

1

pulse.

between this pin and ground sets the duration of the

Monostable Pulse used for the Frequency-to-Voltage

converter.

GND

N.C.

N.C.

VS

B

OUT

3

N.C.6

VBOOT

BRAKE

VREF9

EN

FWD/REV

SENSE

B

RCPULSE

N.C.

TACHO

N.C.

N.C.

GND

B

to

4/25

Table 5. Pin Description (continued)

PACKAGE

SO24/

PowerDIP24

PowerSO36

PIN # PIN #

10 25 SENSE

11 26 FWD/REV Logic Input Selects the direction of the rotation. HIGH logic level

12 27 EN Logic Input Chip Enable. LOW logic level switches OFF all Power

13 28 VREF Logic Input Current Controller Reference Voltage.

14 29 BRAKE Logic Input Brake Input pin. LOW logic level switches ON all High

15 30 VBOOT Supply Voltage Bootstrap Voltage needed for driving the upper Power

16 32 OUT

17 33 VS

20 4 VS

21 5 OUT

22 7 VCP Output Charge Pump Oscillator Output.

23 8 H

24 9 H

Name Type Function

Power Supply Half Bridge 3 Source Pin. This pin must be connected

B

together with pin SENSE

to Power Ground through a

A

sensing power resistor. At this pin also the Inverting

Input of the Sense Comparator is connected.

sets Forward Operation, whereas LOW logic level sets

Reverse Operation.

If not used, it has to be connected to GND or +5V..

MOSFETs.

If not used, it has to be connected to +5V.

Do not leave this pin open or connect to GND.

Side Power MOSFETs, implementing the Brake

Function.

If not used, it has to be connected to +5V.

MOSFETs.

Power Output Output 3.

3

Power Supply Half Bridge 3 Power Supply Voltage. It must be

B

connected to the supply voltage together with pin VS

Power Supply Half Bridge 1 and Half Bridge 2 Power Supply Voltage.

A

It must be connected to the supply voltage together

with pin VS

Power Output Output 2.

2

2

3

Sensor Input Single Ended Hall Effect Sensor Input 2.

Sensor Input Single Ended Hall Effect Sensor Input 3.

.

B

L6229

A

.

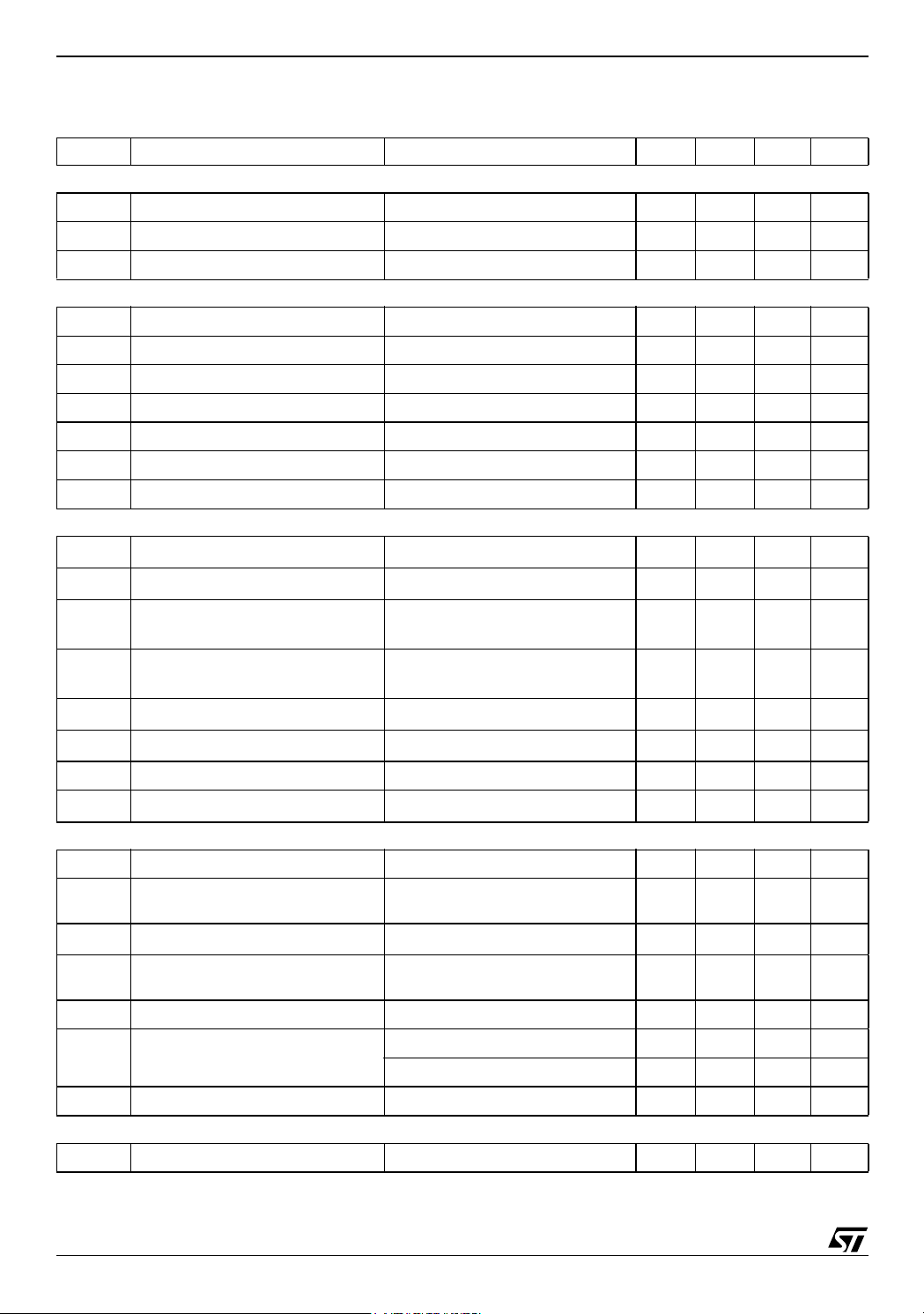

Table 6. Electrical Characteristics

(V

= 48V , T

S

Symbol Parameter Test Conditions Min Typ Max Unit

V

Sth(ON)

V

Sth(OFF)

T

J(OFF)

Turn ON threshold 5.8 6.3 6.8 V

Turn OFF threshold 5 5.5 6 V

Quiescent Supply Current All Bridges OFF;

I

S

Thermal Shutdown Temperature 165 °C

Output DMOS Transistors

R

DS(ON)

High-Side + Low-Side Switch ON

Resistance

I

Leakage Current EN = Low; OUT = V

DSS

= 25 °C , unless otherwise specified)

amb

Tj = -25 to 125°C

Tj = 25 °C 1.47 1.69 Ω

T

=125 °C

j

EN = Low; OUT = GND -0.3 mA

(7)

(6)

CC

510mA

2.35 2.70 Ω

2mA

5/25

L6229

Table 6. Electrical Characteristics (continued)

(V

= 48V , T

S

Symbol Parameter Test Conditions Min Typ Max Unit

Source Drain Diodes

V

Forward ON Voltage ISD = 1.4A, EN = LOW 1.15 1.3 V

SD

t

Reverse Recovery Time If = 1.4A 300 ns

rr

t

Forward Recovery Time 200 ns

fr

Logic Input (H1, H2, H3, EN, FWD/REV, BRAKE)

Low level logic input voltage -0.3 0.8 V

V

IL

V

High level logic input voltage 2 7 V

IH

I

Low level logic input current GND Logic Input Voltage -10 µA

IL

High level logic input current 7V Logic Input Voltage 10 µA

I

IH

V

th(ON)

V

th(OFF)

V

thHYS

Turn-ON Input Threshold 1.8 2.0 V

Turn-OFF Input Threshold 0.8 1.3 V

Input Thresholds Hysteresys 0.25 0.5 V

Switching Characteristics

t

D(on)EN

t

D(off)EN

t

D(on)IN

Enable to out turn-ON delay time

Enable to out turn-OFF delay time

Other Logic Inputs to Output TurnON delay Time

t

D(off)IN

Other Logic Inputs to out Turn-OFF

delay Time

t

RISE

t

FAL L

Output Rise Time

Output Fall Time

Dead Time 0.5 1 µs

t

DT

Charge Pump Frequency

f

CP

PWM Comparator and Monostable

I

RCOFF

V

OFFSET

Source current at pin RC

Offset Voltage on Sense

Comparator

t

prop

Turn OFF Propagation delay

t

blank

Internal Blanking Time on Sense

Comparator

t

ON(min)

t

I

BIAS

Minimum on Time

PWM RecirculationTime R

OFF

Input Bias Current at pin VREF 10 µA

Tacho Monostable

I

RCPULSE

Source Current at pin RCPULSE V

= 25 °C , unless otherwise specified)

amb

(7)

I

LOAD

(7

)

I

LOAD

I

LOAD

I

LOAD

(7)

(7)

I

LOAD

I

LOAD

Tj = -25 to 125°C

V

OFF

(8)

RCOFF

V

ref

V

ref

OFF

R

OFF

RCPULSE

= 1.4 A, Resistive Load 500 650 800 ns

= 1.4 A, Resistive Load 500 1000 ns

= 1.4 A, Resistive Load 1.6 µs

= 1.4 A, Resistive Load 800 ns

= 1.4 A, Resistive Load 40 250 ns

= 1.4 A, Resistive Load 40 250 ns

(6)

0.6 1 MHz

= 2.5 V 3.5 5.5 mA

= 0.5 V ±5 mV

= 0.5 V 500 ns

1µs

2.5 3 µs

= 20kΩ ; C

= 100kΩ ; C

OFF

OFF

=1nF

=1nF

13

61

= 2.5V 3.5 5.5 mA

µs

µs

6/25

L6229

Table 6. Electrical Characteristics (continued)

(V

= 48V , T

S

Symbol Parameter Test Conditions Min Typ Max Unit

t

PULSE

R

TACHO

Monostable of Time R

Open Drain ON Resistance 40 60 Ω

Over Current Detection & Protection

I

SOVER

Supply Overcurrent Protection

Threshold

R

OPDR

t

OCD(ON)

t

OCD(OFF)

(6) Tested at 25°C in a restricted range and guaranteed by characterization.

(7) See Fig. 4.

(8) Measured applying a voltage of 1V to pin SENSE and a voltage drop from 2V to 0V to pin VREF.

(9) See Fig. 5.

Open Drain ON Resistance I

OCD high level leakage current V

I

OH

OCD Turn-ON Delay Time

OCD Turn-OFF Delay Time

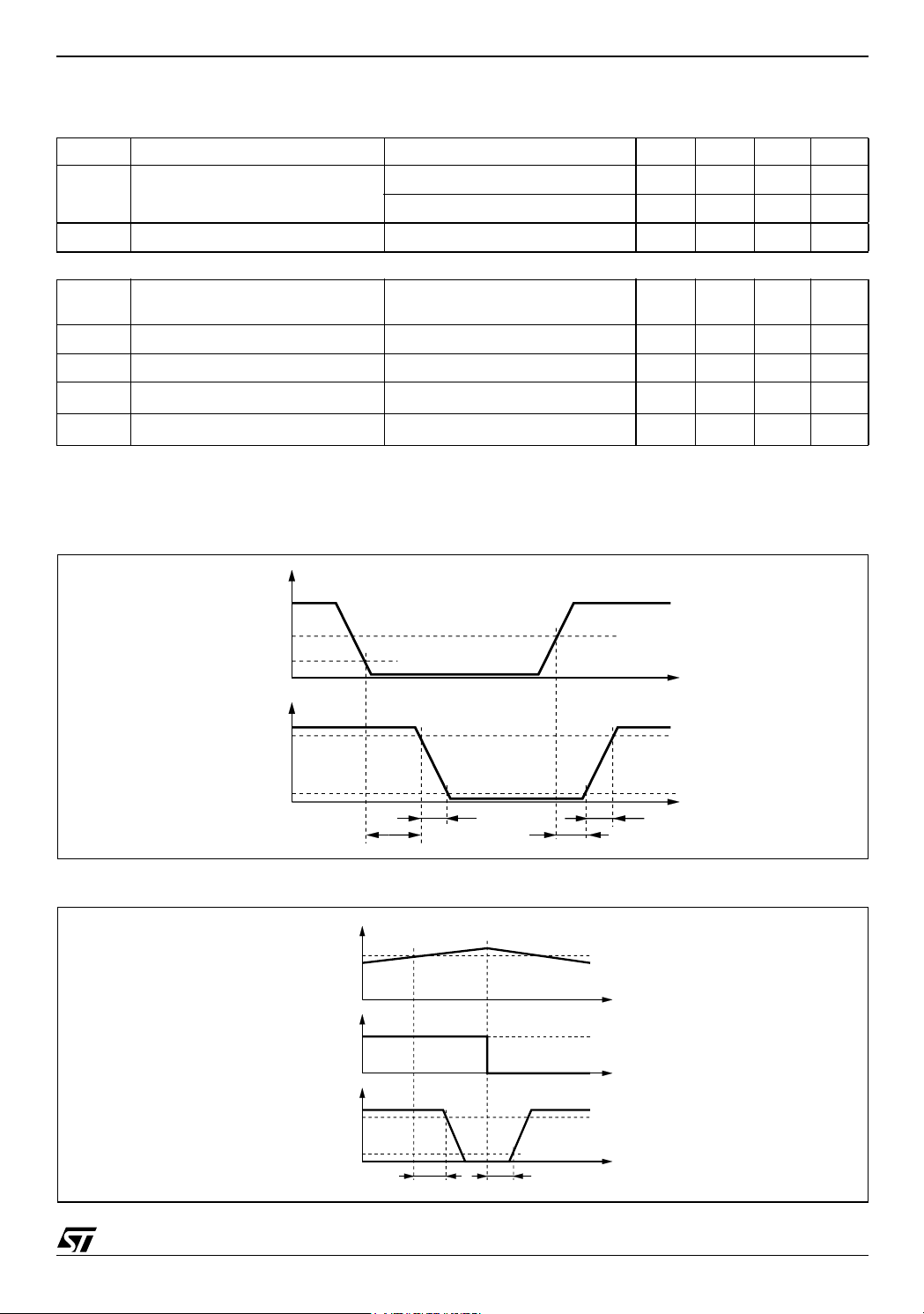

Figure 4. Switching Characteristic Definition

= 25 °C , unless otherwise specified)

amb

PUL

R

PUL

= -25 to 125°C

T

J

DIAG

DIAG

(9)

(9)

I

DIAG

I

DIAG

= 20kΩ ; C

= 100kΩ ; C

PUL

PUL

(6)

=1nF

=1nF

12

60

2 2.8 3.55 A

= 4mA 40 60 Ω

= 5V 1 µA

= 4mA; C

= 4mA; C

< 100pF 200 ns

DIAG

< 100pF 100 ns

DIAG

µs

µs

EN

V

th(ON)

V

th(OFF)

I

OUT

90%

10%

D01IN1316

t

D(OFF)EN

Figure 5. Overcurrent Detection Timing Definition

I

OUT

I

SOVER

ON

BRIDGE

OFF

V

DIAG

90%

t

FALL

t

D(ON)EN

t

RISE

t

t

10%

t

OCD(ON)

t

OCD(OFF)

D02IN1387

7/25

L6229

3 CIRCUIT DESCRIPTION

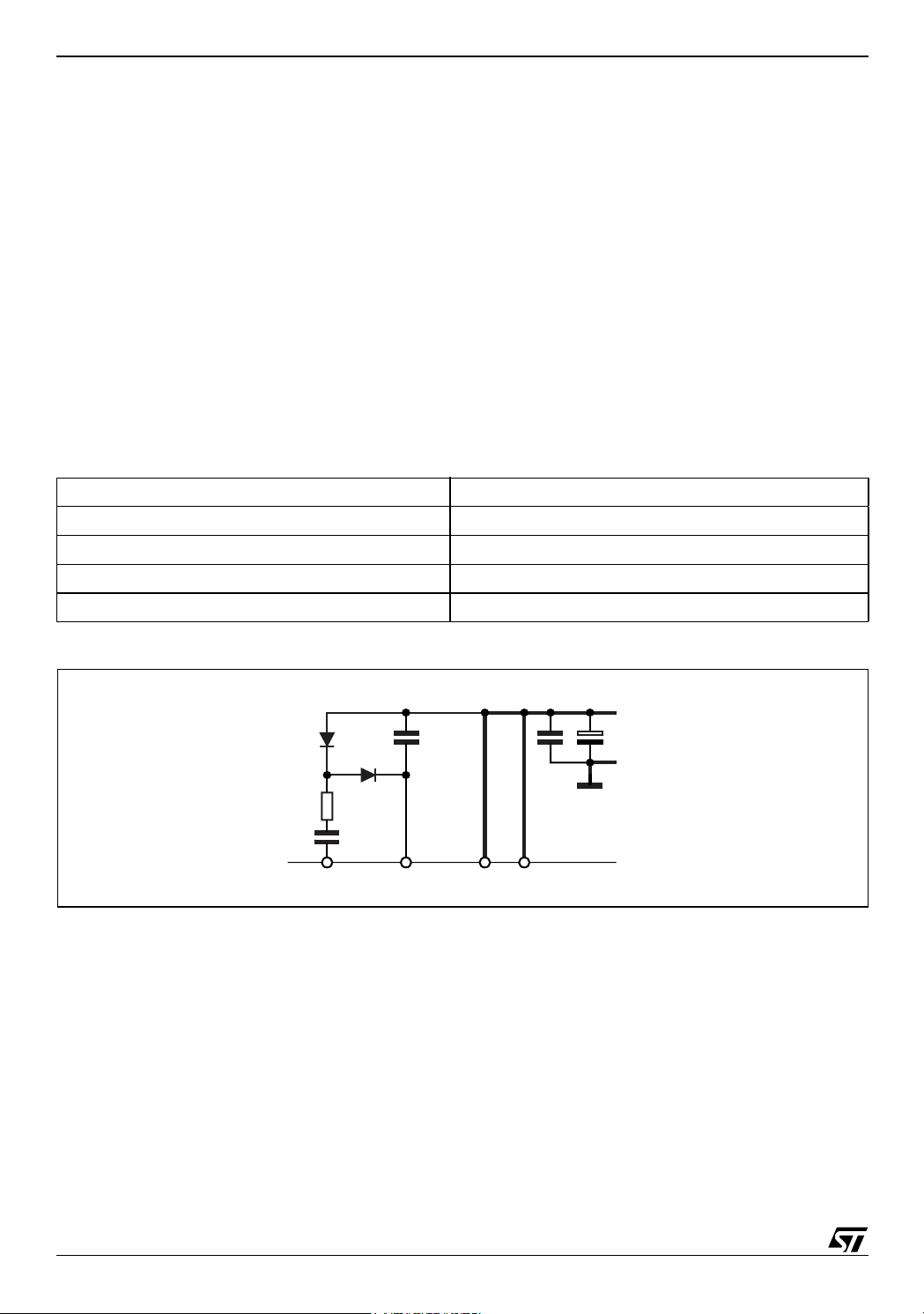

3.1 POWER STAGES and CHARGE PUMP

The L6229 integrates a Three-Phase Bridge, which consists of 6 Power MOSFETs connected as shown on the

Block Diagram. Each Power MOS has an R

diode. Switching patterns are generated by the PWM Current Controller and the Hall Effect Sensor Decoding

Logic (see relative paragraphs). Cross conduction protection is implemented by using a dead time (t

typical value) set by internal timing circuit between the turn off and turn on of two Power MOSFETs in one leg

of a bridge.

Pins VS

and VSB MUST be connected together to the supply voltage (VS).

A

Using N-Channel Power MOS for the upper transistors in the bridge requires a gate drive voltage above the

power supply voltage. The Bootstrapped Supply (V

ternal components to realize a charge pump circuit as shown in Figure 6. The oscillator output (pin VCP) is a

square wave at 600KHz (typically) with 10V amplitude. Recommended values/part numbers for the charge

pump circuit are shown in Table 7.

Table 7. Charge Pump External Component Values.

C

BOOT

C

P

R

P

D

1

D

2

= 0.73Ω (typical value @25°C) with intrinsic fast freewheeling

DS(ON)

) is obtained through an internal oscillator and few ex-

BOOT

220nF

10nF

100Ω

1N4148

1N4148

DT

= 1µs

Figure 6. Charge Pump Circuit

V

S

D1

D2

R

P

C

P

VCP VBOOT VS

C

BOOT

VS

B

D01IN1328

A

3.2 LOGIC INPUTS

Pins FWD/REV, BRAKE, EN, H1, H2 and H3 are TTL/CMOS and µC compatible logic inputs. The internal structure is shown in Figure 4. Typical value for turn-ON and turn-OFF thresholds are respectively V

th(OFF)

= 1.3V.

V

th(ON)

= 1.8V and

Pin EN (enable) may be used to implement Overcurrent and Thermal protection by connecting it to the open collector

DIAG output If the protection and an external disable function are both desired, the appropriate connection must be

implemented. When the external signal is from an open collector output, the circuit in Figure 8 can be used . For external circuits that are push pull outputs the circuit in Figure 9 could be used. The resistor R

Ω

the range from 2.2K

to 180KΩ. Recommended values for REN and CEN are respectively 100KΩ and 5.6nF. More

should be chosen in

EN

information for selecting the values can be found in the Overcurrent Protection section.

8/25

Loading...

Loading...