Page 1

DMOS DUAL FULL BRIDGE DRIVER

■

SUPPLY VOLTAGE UP TO 48V

■

R

■

CROSS CONDUCTION PROTECTION

■

THERMAL SHUTDOWN

■

0.5A DC CURRENT

■

TTL/CMOS COMPATIBLE DRIVER

■

HIGH EFFICIENCY CHOPPING

■

MULTIPOWER BCD TECHNOLOGY

DESCRIPTION

The L6204 is a dual full bridge driver for motor

control applications realized in BCD technology

which combines isolated DMOS power transistors

with CMOS and Bipolar circuits on the same chip.

By using mixed technology it has been possible to

optimize the logic circuitry and the powe r stage to

achieve the best possible performance.

The logic inputs are TTL/CMOS compatible. Both

channels are controlled by a separate Enable.

1.2Ω L6204 (25°C)

DS(ON)

L6204

MULTOPOWER BCD TECHNOLOGY

Powerdip 16+2+2 SO 24+2+2

ORDERING NUMBERS:

L6204 L6204D

Each bridge has a sense resistor to control the

currenrt lev e l.

The L6204 is mounted in an 20-lead Powerdip and

SO 24+2+2 packages and the four center pins are

used to conduct heat to t he PC B. A t normal operating temperatures no external heatsink is required.

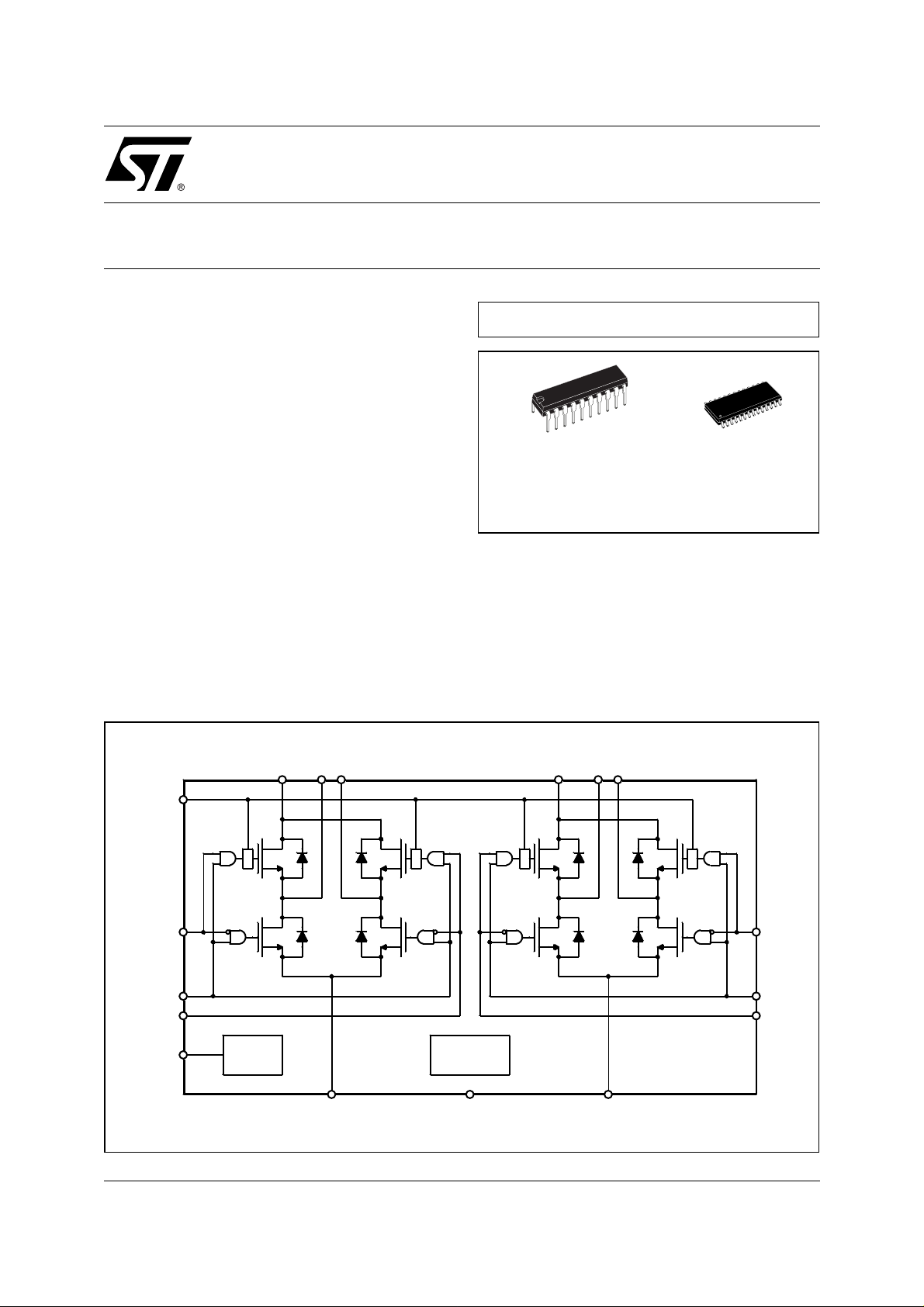

BLOCK DIAGRAM

VBOOT

IN1

ENABLE 1

IN2

BOOTSTRAP

OSCILLATOR

CHARGE

PUMP

Vs1

OUT 1

SENSE 1

OUT 2

THERMAL

SHUT DOWN

GND

Vs2

OUT 3

OUT 4

IN4

ENABLE 2

IN3

SENSE 2

July 2003

1/12

Page 2

L6204

PIN CONNECTIONS

SENS1

IN1

ENABLE1

OUT1

GND GND

GND

OUT3

ENABLE2

IN3

SENSE2

1

2

3

4

5

6

7

8

9

10 11

20

19

18

17

16

15

14

13

12

DIP20

DIP16+2+2

VBOOT

IN2

OUT2

Vs1

GND

Vs2

OUT4

IN4

VCP

SENSE1

IN1

ENABLE1

N.C.

N.C.

OUT1

GND

GND

OUT3 VS2

N.C. N.C.

N.C.

ENABLE2

IN3 IN4

2

3

4

5

6

7

8

9

10

12

13

SO24+2+2

28

27

26

25

24

23

22

21

20

19

18

17

16

1514SENSE2 VCP

VBOOT1

IN2

OUT2

N.C.

N.C.

VS1

GND

GND

N.C.11

OUT4

SO24+2+2

PIN DESCRIPTION

SO

(*)

DIP

Pin

Symbols Functions

1 1 SENSE 1 Sense resistor to provide the feedback for motor current control of the bridge

A

2 2 IN1 Digital input from the motor controller (bridge A)

3 3 ENABLE 1 A logic level low on this pin disable the bridge A

6 4 OUT 1 Output of one half bridge of the bridge A

7 5 GND Common Power Ground

8 6 GND Common Power Ground

9 7 OUT 3 Ouput of one half bridge of the bridge B

12 8 ENABLE 2 A logic level low on this pin disable the bridge B

13 9 IN 3 Digital input from the motor controller (bridge B)

14 10 SENSE 2

Sense resistor to provide the feedback for motor current control of the bridge B

15 11 BOOSTRAP OSC. VCP Oscillator output for the external charge pump

16 12 IN 4 Digital input from the motor controller (bridge B)

17 13 OUT 4 Output of one half bridge of the bridge B

20 14

VS2

Supply voltage bridge B

21 15 GND Common Power Ground

22 16 GND Common Power Ground

23 17

VS1

Supply Voltage bridge A

26 18 OUT 2 Output of one half bridge of the bridge A

27 19 IN 2 Digital input from the motor controller (bridge A)

28 20 VBOOT Overvoltage input for driving of the upper DMOS

Pin

(*) For SO pac kage the pins 4, 5, 10, 11, 18, 19, 24 and 25 are not connected.

2/12

Page 3

ABSOLUTE MAXIMUM RATINGS

Symbol Parameter Value Unit

V

IN

V

V

T

V

, V

I

o

SENSE

BOOT

P

tot

stg

Supply Voltage 50 V

S

Input or Enable Voltage Range -0.3 to +7 V

EN

Pulsed Output Current 3 A

Sensing Voltage -1 to 4 V

Bootstrap Supply 60 V

Total power dissipation: ( T

= 80°C)

pins

(T

= 70°C no copper area on PCB)

amb

(T

= 70°C 8cm2 copper area on PCB)

amb

5

1.23

2

, TjStorage and Junction Temperature -40 to 150 °C

THERMA L D ATA

Symbol Parameter SO DIP Unit

R

th j-pins

R

th j-amb

Thermal Resistance Junction-pins Max 16 14 °C/W

Thermal Resistance Junction-ambient Max 73 65 °C/W

L6204

W

W

W

ELECTRICAL CHARACTERISTCS

Symbol Parameter Test Condition Min. Typ. Max. Unit

V

S

I

S

f

C

T

J

T

d

TRANSISTORS

I

DSS

R

DS

LOGIC LEVELS

V

, V

INL

V

, V

INH

, I

I

INL

I

, I

INH

Supply Voltage 12 48 V

Total Quiescent Current EN1=EN2=H; IN1=IN2=IN3=IN4=L

EN1 = EN2 = L

Commutation Frequency 20 KHz

Thermal Shutdown 150 °C

Dead Time Protection 500 ns

Leakage Current OFF 1 mA

On Resistance ON 1.2 Ω

Input Low Voltage -0.3 0.8 V

ENL

Input High Voltage 2 7 V

ENH

Input Low Current IN1 = IN2 = IN3 = IN4 = EN1 = EN2

ENL

= L

Input High Current IN1 = IN2 = IN3 = IN4 = EN1 = EN2

ENH

50 µA

= H

10

10

-10 µA

mA

mA

3/12

Page 4

L6204

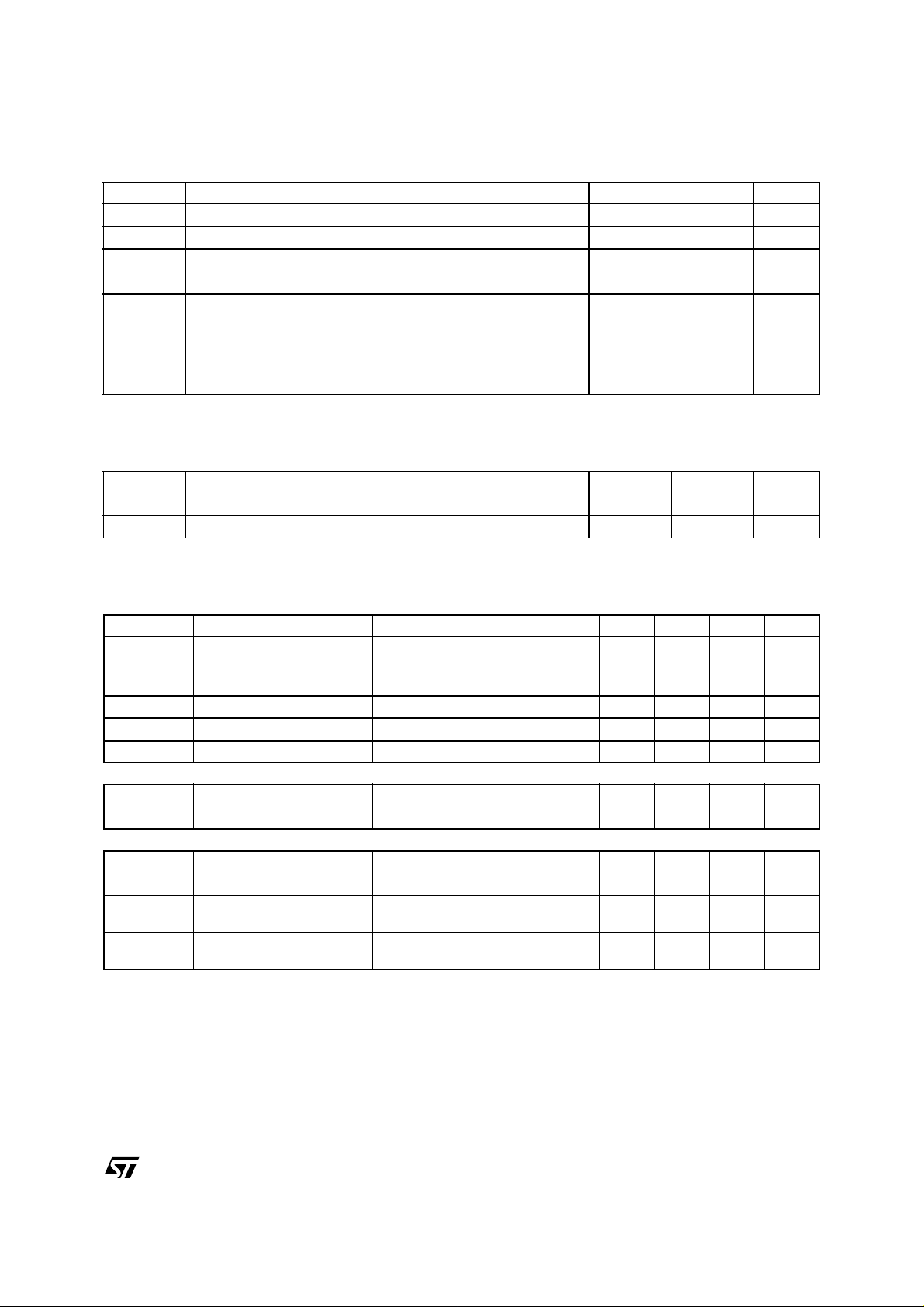

APPLICATION DIAGRAM

Vs

D1

C1

VBOOT

Vs1

OUT1

OUT2

A

STEPPER MOTOR

B

Vs2

OUT3

OUT4

IN1

ENABLE1

IN2

CHARGE

PUMP

BOOTSTRAP

OSCILLATOR

D2

C2

SENSE1

SENSE1

RS1

THERMAL

SHUT DOWN

GND

SENSE2

SENSE2

RS2

IN4

ENABLE 2

IN3

CIRCUIT DESCRIPTION

L6204 is a dual full bridge IC designed to drive DC motors, stepper motors and other inductive loads. Each

bridge has 4 power DMOS transistor with R

= 1.2Ω and the relative protection and control circuitry.

DSon

(see fig. 3)

The 4 half bridges can be controlled independen tly by means of the 4 inputs I N!, IN2, IN3 , IN4 and 2 en-

able inputs ENABLE1 and ENABLE2.

External connections are provided so that sensing resistors can be added for c onstant current chopper

applications.

LOGIC DRIVE (*)

INPUTS

IN1 IN2

OUTPUT MOSFETS

IN3 IN4

L L Sink 1, Sink 2

EN1=EN2=H

L H Sink 1, Source 2

H L Source 1, Sink 2

H H Source 1, Source 2

EN1=EN2=L X X All transistor turned OFF

L = Low H = High X = Don’ t care

(*) True table for the two ful l bri dges

4/12

Page 5

L6204

CROSS CONDUCTION

Although the device guarantees the absence of cross-conduction, the presence of the intrinsic diodes in

the POWER DMOS structure causes the generation of current spikes on the sensing terminals.

This is due to charge-discharge phenomena in the capacitors C1 & C2 associated with the drain source

junctions (fig. 1). When the output switches from high to low, a current spike is generated associated with

the capacitor C1. On the low-to-high transition a spike of the same polarity is generated by C2, preceded

by a spike of t he o ppos ite p olarity due to the charging o f the in put capac ity of the lower POWER DM OS

transistor (see fig. 2).

Figure 1. Intrinsic Structures in the POWER MOS Transistors

Figure 2. Current Typical Spikes on the Sensing Pin

5/12

Page 6

L6204

TRANSISTOR OPERATION

ON STATE

When one of the POWER DMOS transistors is ON it can be considered as a resistor R

a junction temperature of 25°C.

In this condition the dissipated power is given by :

· I

DS

2

The low R

PON = R

of the Multipower-BCD process can provide high currents with low power dissipation.

DS(ON)

DS(ON)

OFF STATE

When one of the POWER DMOS transistor is OFF the VDS voltage is equal to the supply voltage and only

the leakage current IDSS flows. The power dissipation during this period is given by :

P

= VS · I

OFF

DSS

TRANSITIONS

Like all MOS power transistors the DMOS POWER transistors have as intrinsic diode between their

source and drain that can operate as a fast freewheeling diode in switched mode applications.

During recirculation with the ENABLE input high, the voltage drop across the transistor is RDS(ON) . ID

and when the voltage reaches the diode voltage it is clamped to its characteristic.

When the ENABLE input is low, the POW ER MOS is OFF and the diode carries a ll of the recirculation

current. The power dissipated in the transitional times in the cycle depends upon the voltage and current

waveforms in the application.

P

= IDS(t) × VDS(t)

trans

DS(ON)

= 1.2Ω at

BOOTSTRAP CAPA CI TO RS

To ensure the correct driving of high side drivers a voltage higher than V

is supplied on pin 20 (V

S

boot

This bootstrap voltage is not needed for the lower power DMOS transistor because their sources are

grounded. To produce this v oltage a charge pump method is used and mAde by two ext ernal capa citors

and two diodes. It can supply the 4 driving blocks of the high side drivers. Using an external capacitor the

turn-on speed of the high s ide d river is very hi gh; furtherm ore wi th differen t capac itance values it is possible to adapt the device to different switching frequencies. It is also possible to operate two or more

L6204s using only 2 diodes and 2 capacitance for all the ICs; all the Vboot pins are connected to the Cstore capacitance while the pin 11 (VCP) of just one L6204 is connect to C

have to be connected to the same V

. (see fig. 6)

S

, obviously all the L6204 ICs

pump

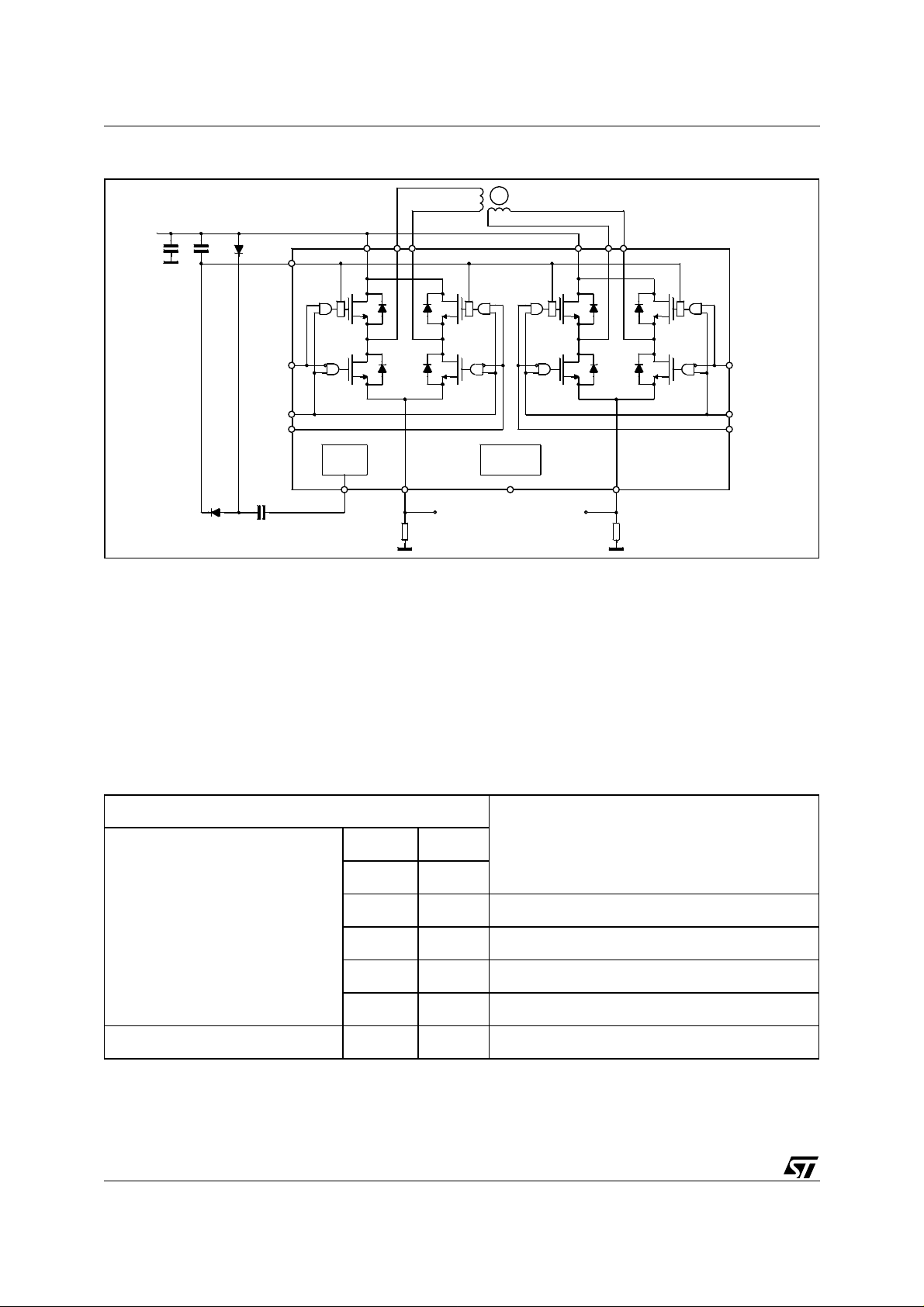

Figure 3. Two Phase Chopping

IN1 = H

IN2 = L

EN1 = H

IN1 = L

IN2 = H

EN1 = H

).

6/12

Page 7

Figure 4. One Phase Chopping

L6204

IN1 = H

IN2 = L

EN1 = H

Figure 5. Enable Chop ping

IN1 = H

IN2 = L

EN1 = H

Figure 6.

IN1 = H

IN2 = H

EN1 = H

IN1 = X

IN2 = X

EN1 = L

DEAD TIME

To protect the device against simultaneous conduction in both arms of the bridge and the resulting rail-to-

rail short, the logic circuits provide a dead time.

THERMAL PROTEC T I O N

A thermal protection circuit has been included that will disable the device if the junction temperature reach-

es 150 °C. When the temperat ure has fallen to a safe l evel the device restart s under the control of the

input and enable signals.

7/12

Page 8

L6204

APPLICATION INFORMATION

RECIRCULATION

During recirculation with the ENABLE input high, the voltage drop across the transistor is R

voltages less than 0.7 V and is clamped at a voltage depending on the characteristics of the source-drain

diode for greater voltages. Although the device is protected against cross conduction, current spikes can

appear on the current sense pin due to charge/discharge phenomena in the intrinsic source drain capacitances. In the application this does not cause any problems because the voltage created across the sense

resistor is usually much less than the peak value, although a small RC filter can be added if necessary.

POWER DISSIPATION (each bridge)

In order to achieve the high performa nce provided by the L6204 some attention m ust be paid to ensure

that it has an adequate PCB area to dissipate the heat. The first stage of any thermal design is to calculate

the dissipated power in the appl ication, for this example the half step operation shown in figure 7 is considered.

DS(ON)

. IL for

RISE TIME T

r

When an arm of the half bridge is turned on current begins to flow in the inductive load until the maximum

current I

The dissipated energy E

is reached after a time Tr.

L

is in this cas e :

OFF/ON

E

OFF/ON

= [R

DS(ON)

· I

L

2

· Tr] · 2/3

Figure 7.

ON TIME T

ON

During this time the energy dissipated is due to the ON resistance of the transistors EON and the commutation E

. As two of the POWER DMOS transistors are ON EON is given by :

COM

EON = I

2

· R

L

DS(ON)

· 2 · T

ON

In the commutation the energy dissipated is :

E

= VS · IL · T

COM

COM

· f

SWITCH

· T

ON

Where :

= Commutation Time and it is assumed that ;

T

COM

T

COM

f

SWITCH

= T

TURN-ON

= Chopper frequency

= T

TURN-OFF

= 100 ns

8/12

Page 9

L6204

FALL TIME T

f

For this example it is assumed that the energ y d is sipa ted in this part of the cycle takes the same form as

that shown for the rise time :

E

ON/OFF

= [R

DS(ON)

· IL · Tf] · 2/3

QUIESCENT ENERG Y

The last contribution to the energy dissipation is due to the quiescent supply current and is given by :

E

QUIESCENT

= I

QUIESCENT

· VS · T

TOTAL ENERGY PER CYCLE

E

TOT

= (E

OFF/ON

+ EON + E

COM

+ E

ON/OFF

) bridge 1 + (E

+ E

QUIESCENT

OFF/ON

+ EON + E

COM

+ E

ON/OFF

)bridge 2 +

The Total Power Dissipation PDIS is simply :

P

DIS

= E

TOT

/T

Tr = Rise time

= ON time

T

ON

= Fall Time

T

f

= Dead time

T

d

T = Period

T = Tr + TON + Tf + T

d

9/12

Page 10

L6204

DIM.

MIN. TYP. MAX. MIN. TYP. MAX.

a1 0.51 0.020

B 0.85 1.40 0.033 0.055

b 0.50 0.020

b1 0.38 0.50 0.015 0.020

D 24.80 0.976

E 8.80 0.346

e 2.54 0.100

e3 22.86 0.900

F 7.10 0.280

I 5.10 0.201

L 3.30 0.130

Z 1.27 0.050

mm inch

OUTLINE AND

MECHANICAL DATA

Powerdip 20

10/12

Page 11

L6204

DIM.

MIN. TYP. MAX. MIN. TYP. MAX.

A 2.65 0.104

a1 0.1 0.3 0.004 0.012

b 0.35 0.49 0.014 0.019

b1 0.23 0.32 0.009 0.013

C 0.5 0.020

c1 45° (typ.)

D 17.7 18.1 0.697 0.713

E 10 10.65 0.394 0.419

e 1.27 0.050

e3 16.51 0.65

F 7.4 7.6 0.291 0.299

L 0.4 1.27 0.016 0.050

S8° (max.)

mm inch

OUTLINE AND

MECHANICAL DATA

SO28

11/12

Page 12

L6204

Information furnished is believed to be accurate and reliable. However, STMicroelectronics assumes no responsibility for the consequences

of use of such information nor for any infringement of patents or other rights of third parties which may result from its use. No license is granted

by implic ation or otherwise under any patent or paten t rights of ST M i croelectroni cs. Specifications mentioned in this publicat ion are subject

to change without notice. This publication supersedes and replaces all information previously supplied. STMicroelectronics products are not

authorized for use as crit i cal component s i n l i f e support devi ces or systems wi t hout express wri t ten approval of STMicroelectronics.

STMicroelectronics acknowledges the trademarks of all comp ani es referred to in this docum ent.

The ST logo is a registered trademark of STMicroelectronics

© 2003 STMic roelectronic s - All Rights R e served

Australia - Brazil - Canada - China - F i nl and - France - Germany - Hong Kong - India - Israel - Italy - J apan -Malay si a - Malta - Morocco -

Singap ore - Spain - Sw eden - Switzerl and - United Ki ngdom - United States.

STMicroelectronics GROUP OF COMPANIES

http://www.s t. com

12/12

Loading...

Loading...