4 A continuous (more than 5 A pulsed) step-down switching

regulator with synchronous rectification

Features

■ 4 A output current (more than 5 pulsed)

■ Operating input voltage from 2.9 V to 18 V

■ External 1.8 V ± 2% reference voltage

■ Output voltage from 0.6 to input voltage

■ MLCC compatible

■ 200 ns T

■

Programmable UVLO matches 3.3 V, 5 V and

12 V bus

■ F

SW

■ Voltage feed-forward

■ Zero load current operation

■ Programmable current limit on both switches

■ Programmable sink current capability

■ Pre-bias start up capability

■ Thermal shutdown

ON

programmable up to 1 MHz

L5989D

HTSSOP 16

Applications

■ Consumer: STB, DVD, LCD TV, VCR, car

radio, LCD monitors

■ Networking: XDSL, modems, routers and

switches

■ Computer and peripherals: printers, audio /

graphic cards, optical storage, hard disk drive

■ Industrial: DC-DC modules, factory automation

■ HC LED driving

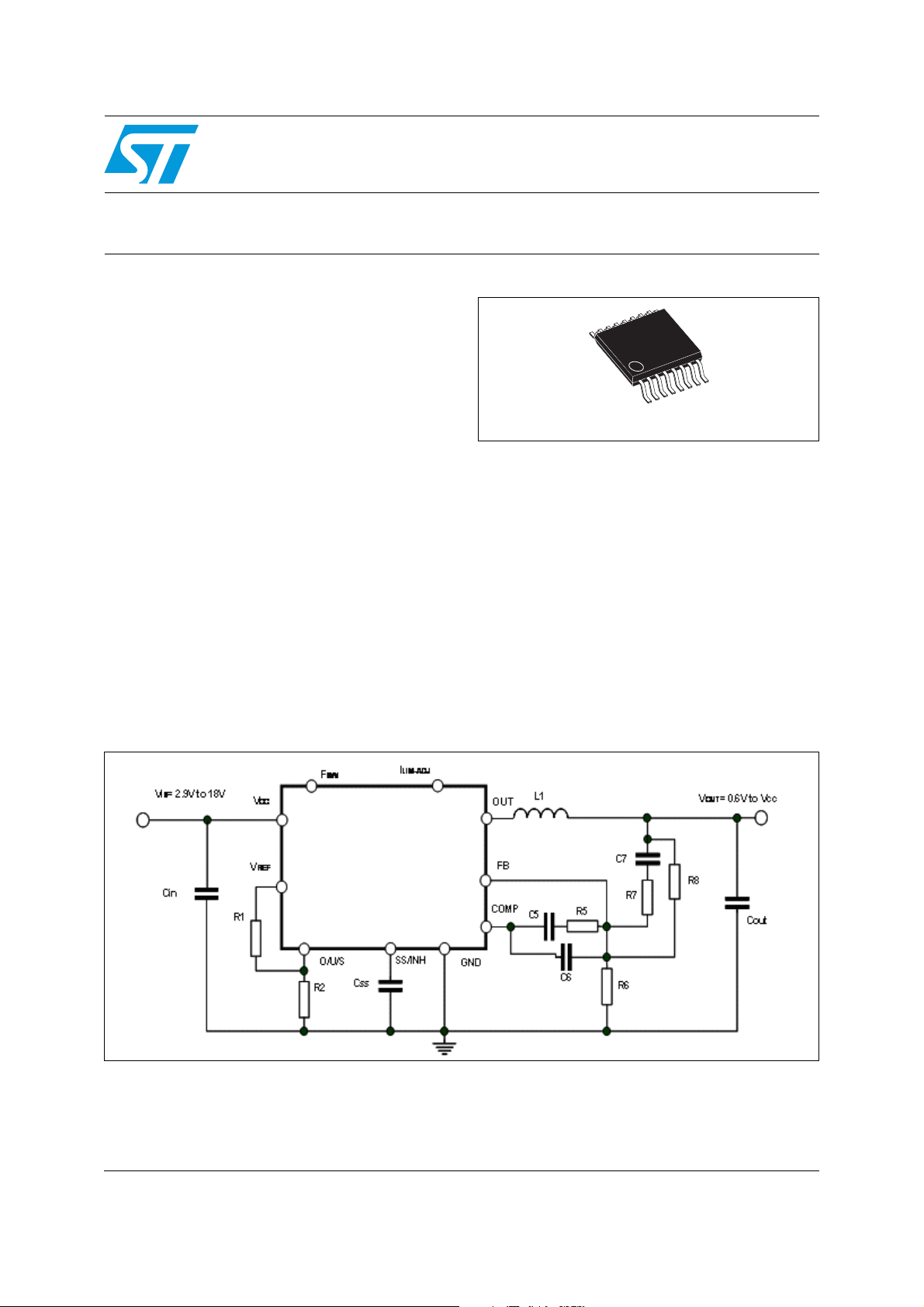

Figure 1. Test application circuit

L5989D

January 2010 Doc ID 15778 Rev 3 1/51

www.st.com

51

Contents L5989D

Contents

1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2 Pin function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3 Maximum ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4 Electrical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

5 Functional description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5.1 Multifunction pin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5.2 Oscillator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.3 External voltage reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.4 Soft-start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.5 Monitoring and protections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.5.1 Overvoltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.5.2 Current limiting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5.5.3 UVLO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.5.4 Thermal shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.6 Power Good . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.7 Minimum on time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.8 Error amplifier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

6 Application information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

6.1 Input capacitor selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

6.2 Inductor selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6.3 Output capacitor selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

6.4 Compensation network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

6.4.1 Type III compensation network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

6.4.2 Type II compensation network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

6.5 R.M.S. current of the embedded power MOSFETs . . . . . . . . . . . . . . . . . 35

6.6 Thermal considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

6.7 Layout considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

6.8 Application circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

2/51 Doc ID 15778 Rev 3

L5989D Contents

7 Typical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

8 Package mechanical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

9 Order codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

10 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Doc ID 15778 Rev 3 3/51

List of table L5989D

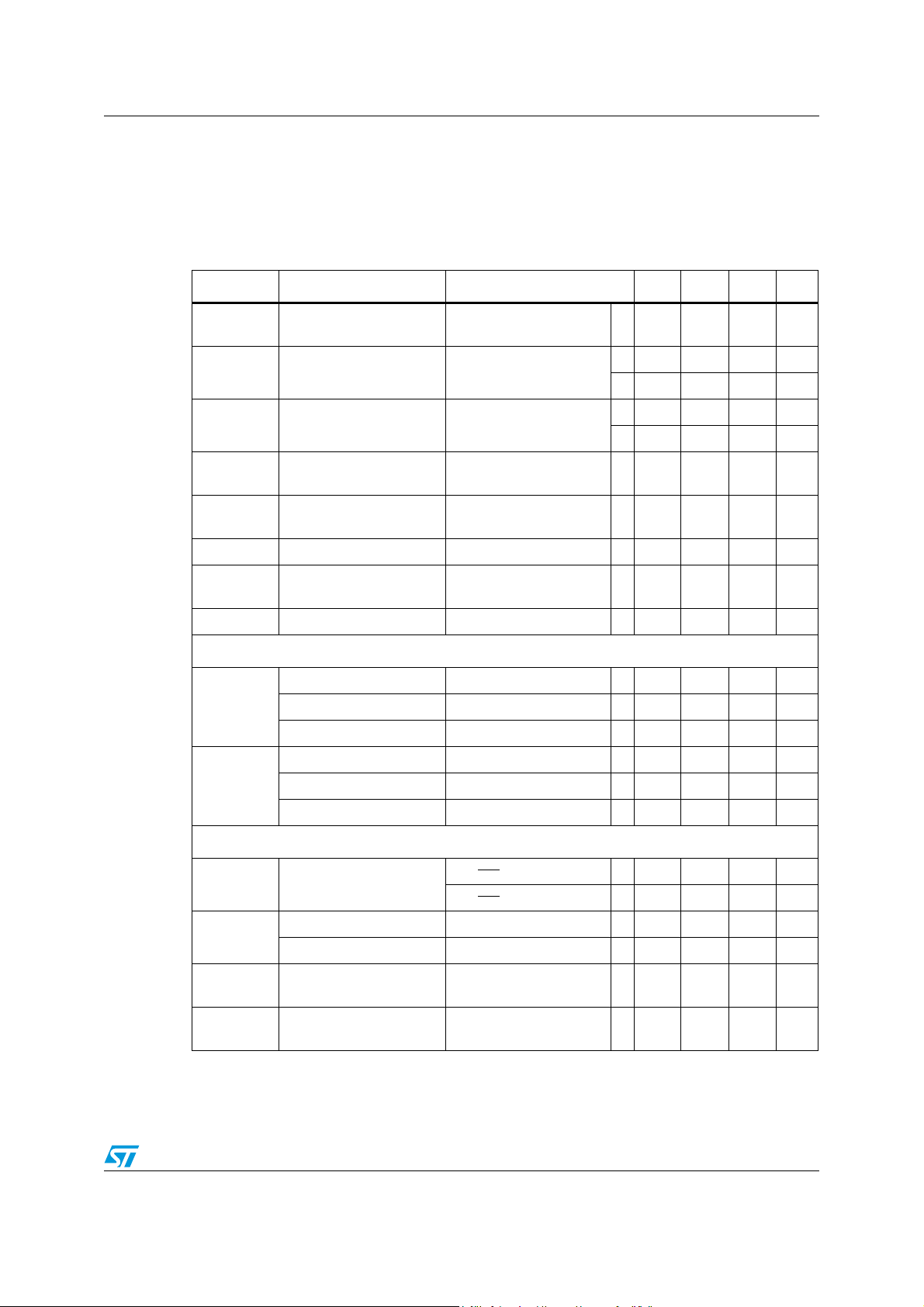

List of table

Table 1. Pinout description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Table 2. Absolute maximum ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Table 3. Thermal data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Table 4. Electrical characteristic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Table 5. A/D voltage windows . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Table 6. UOS voltage biasing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Table 7. FSW resistor examples. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Table 8. ILIM-ADJ resistor examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Table 10. Input capacitors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Table 11. Inductors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Table 12. Output capacitors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Table 13. Component list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Table 14. Component list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Table 15. HTSSOP16 mechanical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Table 16. Order codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Table 17. Document revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

4/51 Doc ID 15778 Rev 3

L5989D List of figures

List of figures

Figure 1. Test application circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

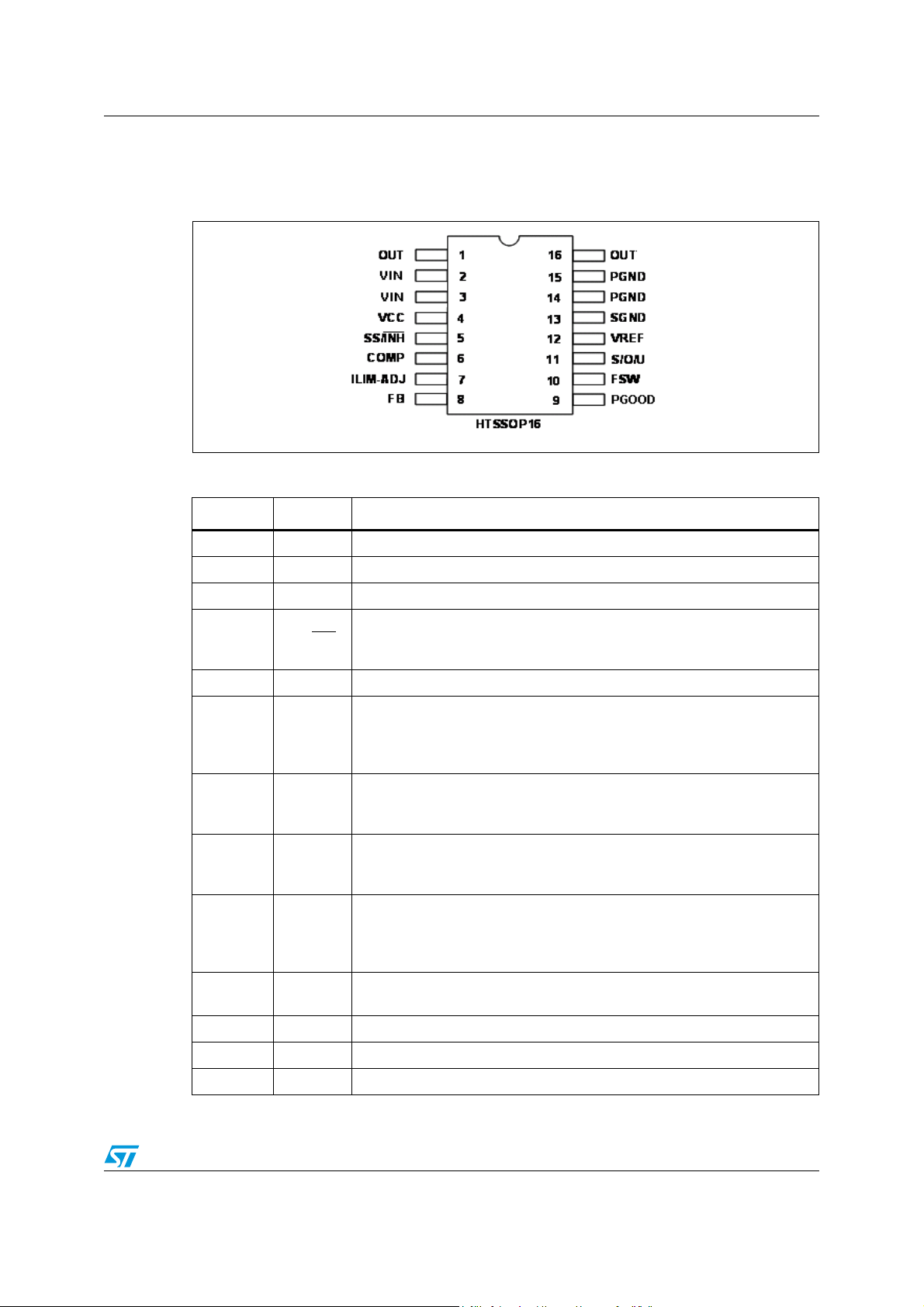

Figure 2. Pin connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Figure 3. Voltage mode control loop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Figure 4. Internal block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Figure 5. Oscillator circuit block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 6. Sawtooth: voltage feed forward . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 7. Sawtooth: frequency adjust . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 8. OVP not latched . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Figure 9. OVP latched . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 10. Constant current protection at extreme duty cycles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 11. Minimum TON. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Figure 12. Type III compensation network. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Figure 13. Open loop gain: module bode diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Figure 14. Open loop gain bode diagram with ceramic output capacitor . . . . . . . . . . . . . . . . . . . . . . . 31

Figure 15. Type II compensation network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Figure 16. Open loop gain: module bode diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Figure 17. Open loop gain bode diagram with high ESR output capacitor . . . . . . . . . . . . . . . . . . . . . 34

Figure 18. Maximum continuos output current vs. duty cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Figure 19. Switching losses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Figure 20. Estimation of the internal power losses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Figure 21. Estimation of the internal power losses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Figure 22. Measurement of the thermal impedance of the evaluation board. . . . . . . . . . . . . . . . . . . . 39

Figure 23. Top board layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Figure 24. Bottom board layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Figure 25. Demonstration board application circuit (fSW = 400 kHz) . . . . . . . . . . . . . . . . . . . . . . . . . 41

Figure 26. Demonstration board application circuit (fSW = 600 kHz) . . . . . . . . . . . . . . . . . . . . . . . . . 43

Figure 27. Junction temperature vs. fSW. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Figure 28. Junction temperature vs. fSW. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Figure 29. Junction temperature vs. fSW. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Figure 30. Junction temperature vs. VOUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Figure 31. Junction temperature vs. VOUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Figure 32. Junction temperature vs. VOUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Figure 33. Efficiency vs. output current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Figure 34. Efficiency vs. output current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Figure 35. Efficiency vs. output current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Figure 36. Load regulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Figure 37. Line regulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Figure 38. Load transient from 0 to 3 A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Figure 39. Soft-start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Figure 40. Mechanical drawing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Doc ID 15778 Rev 3 5/51

Description L5989D

1 Description

The L5989D is a monolithic step down power switching regulator able to deliver a continuos

output current of 4 A to the load in most of the application conditions limited only by the

thermal performance (see Chapter 6.5 for details). The device is able to deliver more than

5 A to the load for a maximum time which is dependent on the thermal impedance of the

system and the specific operating conditions (see Chapter 6.6).

The input voltage can range from 2.9 V to 18 V. The device is capable of 100% duty cycle

operation thanks to the embedded high side PMOS switch which doesn’t need external

bootstrap capacitor to be driven.

The internal switching frequency is adjustable by external resistor and can be set

continuously from 100 kHz to 1 MHz.

The multifunction UOS pin allows to set-up properly the additional embedded features

depending on the value of the voltage level.

● U (UVLO): two UVLO thresholds can be selected to match the 3.3 V and 5 V or 12 V

input buses

● O (OVP): latched or not latched OVP protection selectable. In latched mode the

switching activity is interrupted until an UVLO or INH event happens

● S (SINK): the sink capability is always disabled during soft-start time to support pre-

biased output voltage. Afterwards the sink capability can be enabled or not depending

on the voltage set on the multifunction pin.

During soft-start phase a constant current protection is active to deliver extra current

necessary to load the output capacitor. The current limit protection is achieved by sensing

the current flowing in both embedded switches to assure an effective protection even at

extreme duty cycle operations. Finished the soft-start phase the current protection feature

triggers the “HICCUP” mode forcing the soft-start capacitor to be discharged and recharged.

The current thresholds of both switches can be adjusted in tracking by using an external

resistor to dimension the current protection accordingly to the local application.

The soft-start time is based on a constant current charge of an external capacitor. As a

consequence the time can be set accordingly to the value of the output capacitor.

The latest smart power technology BCD6 (Bipolar-CMOS-DMOS version 6) features a low

resistance of the embedded switches (35 mΩ typical for a NMOS, 50 mΩ typical for a

PMOS), achieving high efficiency levels.

The HTSSOP16 package with exposed pad accomplishes low R

(40°C/W), useful in

thJA

dissipating power internally generated during high output current / high frequency

operations.

6/51 Doc ID 15778 Rev 3

L5989D Pin function

2 Pin function

Figure 2. Pin connection

Table 1. Pinout description

N. Name Description

1, 16 OUT Regulator output

2, 3 VIN Unregulated DC input voltage

4 VCC Unregulated DC signal input voltage

An external logic signal (active LOW) disables the device. In case the pin is

5 SS/INH

floating the device deliver a constant current (22 μA typ.) to charge the

soft-start capacitor (see Chapter 5.4)

6 COMP Error amplifier output for frequency compensation

Connecting a pull-up resistor to VREF or a pull-down resistor to GND the

7 ILIM-ADJ

internal current limit thresholds can be tuned to match the local application.

In case the pin is left floating no changes are applied to the default current

limit thresholds

Feedback input. Connecting the output voltage directly to this pin results in

8FB

a regulation voltage of 600 mV. An external resistive divider is required for

higher output voltages

Open collector output; low impedance if the feedback voltage is lower than

9 PGOOD

0.85 times the internal reference of the error amplifier. An hysteresis is

provided

Connecting a pull-up resistor to VREF or a pull-down resistor to GND the

10 FSW

internal oscillator frequency will be increased or decreased respectively. In

case the pin is left floating the predefined oscillator frequency

(400 kHz ± 10%) is active

11 U/O/S

12 VREF 1.8 V voltage reference

Multifunction pin used to program additional features: UVLO thresholds,

OVP latched/not latched, SINK enabled/disabled

13 SGND Signal ground

14, 15 PGND Power ground

Doc ID 15778 Rev 3 7/51

Maximum ratings L5989D

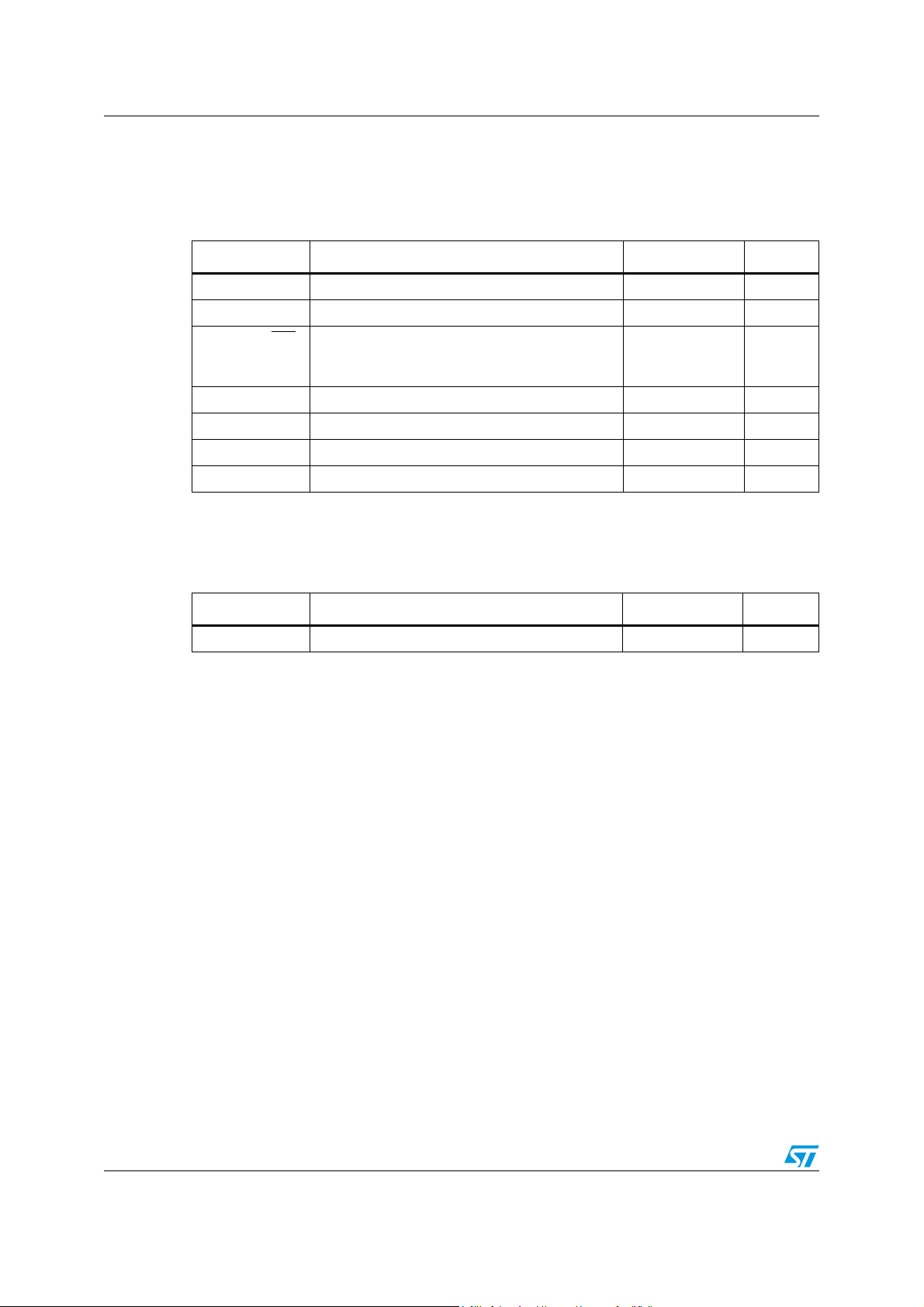

3 Maximum ratings

Table 2. Absolute maximum ratings

Symbol Parameter Value Unit

VCC Input voltage 20 V

VOUT Output DC voltage -0.3

(1)

to VCC

V

U/O/S, SS/INH

COMP, PGOOD,

,

Analog pins -0.3 to 4 V

Fsw, ILIM-ADJ

FB Feedback voltage 1.5 V

P

tot

T

J

T

STG

1. During the switching activity the negative peak voltage could reach -1.5 V without any damage for the

device

Power dissipation at TA < 60 °C 2.25 W

Junction temperature range -40 to 150 °C

Storage temperature range -55 to 150 °C

Table 3. Thermal data

Symbol Parameter Value Unit

R

thJA

Thermal resistance junction to ambient max 40

1. HTSSOP16 package mounted on ST demonstration board

(1)

°C/W

8/51 Doc ID 15778 Rev 3

L5989D Electrical characteristics

4 Electrical characteristics

VCC = 12 V, TJ = 25 °C unless otherwise specified.

Table 4. Electrical characteristic

Symbol Parameter Test condition Min Typ Max Unit

Vcc

Rdson HS

Rdson LS

I

L HIGH SIDE

I

L LOW SIDE

f

SW

f

SW ADJ

Operating input voltage

range

High side MOSFET on

resistance

Low side MOSFET on

resistance

Maximum peak limiting

current

Maximum valley limiting

current

Vout = 0.6 V; Iout = 3 A 2.9 18 V

75 85 95 mΩ

Iout = 1.0 A

(1)

111 120 132 mΩ

62 67 72 mΩ

Iout = 1.0 A

I

I

= float 3.6 4 4.4 A

LIM-ADJ

= float 4.14 4.6 5.06 A

LIM-ADJ

(1)

92 100 106 mΩ

Switching frequency FSW = floating 360 400 440 kHz

Adjusted switching

frequency

R

FSW PULL DWN

= 27 kΩ 1000 kHz

D Duty cycle 0 100 %

Selectable undervoltage lock-out (UVLO)

Turn ON Vcc threshold 2.7 2.8 V

3.3 V BUS

Turn OFF Vcc threshold 2.4 2.5 V

Hysteresis 200 mV

Turn ON Vcc threshold 8 8.6 V

12 V BUS

Turn OFF Vcc threshold 6.8 7 V

Hysteresis 1 V

DC characteristic

I

SS

Soft-start current

V

V

= 2 V 22 μA

SS/INH

= 0 5 μA

SS/INH

Device ON level 0.8 V

INH

Device OFF level 0.3 V

I

q

I

q st-by

Quiescent current

Total stand-by quiescent

current

Duty Cycle = 0;

= 1 V

V

FB

3mA

35 μA

Doc ID 15778 Rev 3 9/51

Electrical characteristics L5989D

Table 4. Electrical characteristic (continued)

Symbol Parameter Test condition Min Typ Max Unit

Dynamic characteristic (see figure 1)

V

FB

Voltage feedback in

regulation

Error amplifier

V

OH

V

OL

I

O SOURCE

I

O SRCE LIM

I

O SINK

A

V0

High level output voltage VFB = 0.2 V; SS floating 3.1 V

Low level output voltage VFB = 1.0 V 0.1 V

Source output current VFB = 0.2 V

Source current limitation VFB = 0.2 V, V

Sink output current VFB = 1.0 V, V

DC open loop gain

PGOOD

Up threshold

(V

V

FB_PGOOD

FB_PGOOD

Low threshold

(V

FB_PGOOD

V

PGOOD

Reference section

V

REF

Reference voltage Vcc = 2.9 V to 18 V

/ VFB)

/ VFB)

2.9 V < VCC < 18 V

COMP

COMP

rising 81 85 90

V

FB

V

falling 77 82 86

FB

I

= -1 mA 0.4 V

PGOOD

(1)

0.592 0.6 0.609

(2)

25 mA

=3 V 2 mA

=0.5 V 30 mA

(2)

100 dB

1.756 1.8 1.837 V

(1)

1.754 1.8 1.852 V

0.595 0.6 0.605

V

%

V

FB

Line regulation

Load regulation I

Short circuit current 12 18 24 mA

Protections

V

FB_OVP

Overvoltage trip

FB_OVP

- VFB) / V

(V

FB

Bus thresholds

- UVLO 3.3 V bus

TH1

- OVP not latched

- No sink

- UVLO 3.3 V bus

TH2

- OVP not latched

- Sink

- UVLO 3.3 V bus

TH3

- OVP latched

- No sink

10/51 Doc ID 15778 Rev 3

Vcc = 2.9 V to 18 V

I

= 0 mA

REF

= 0 to 5 mA 7.5 15 mV

REF

V

rising 15 20 24 %

FB

(3)

00.2V

(3)

0.26 0.425 V

(3)

0.48 0.65 V

612mV

L5989D Electrical characteristics

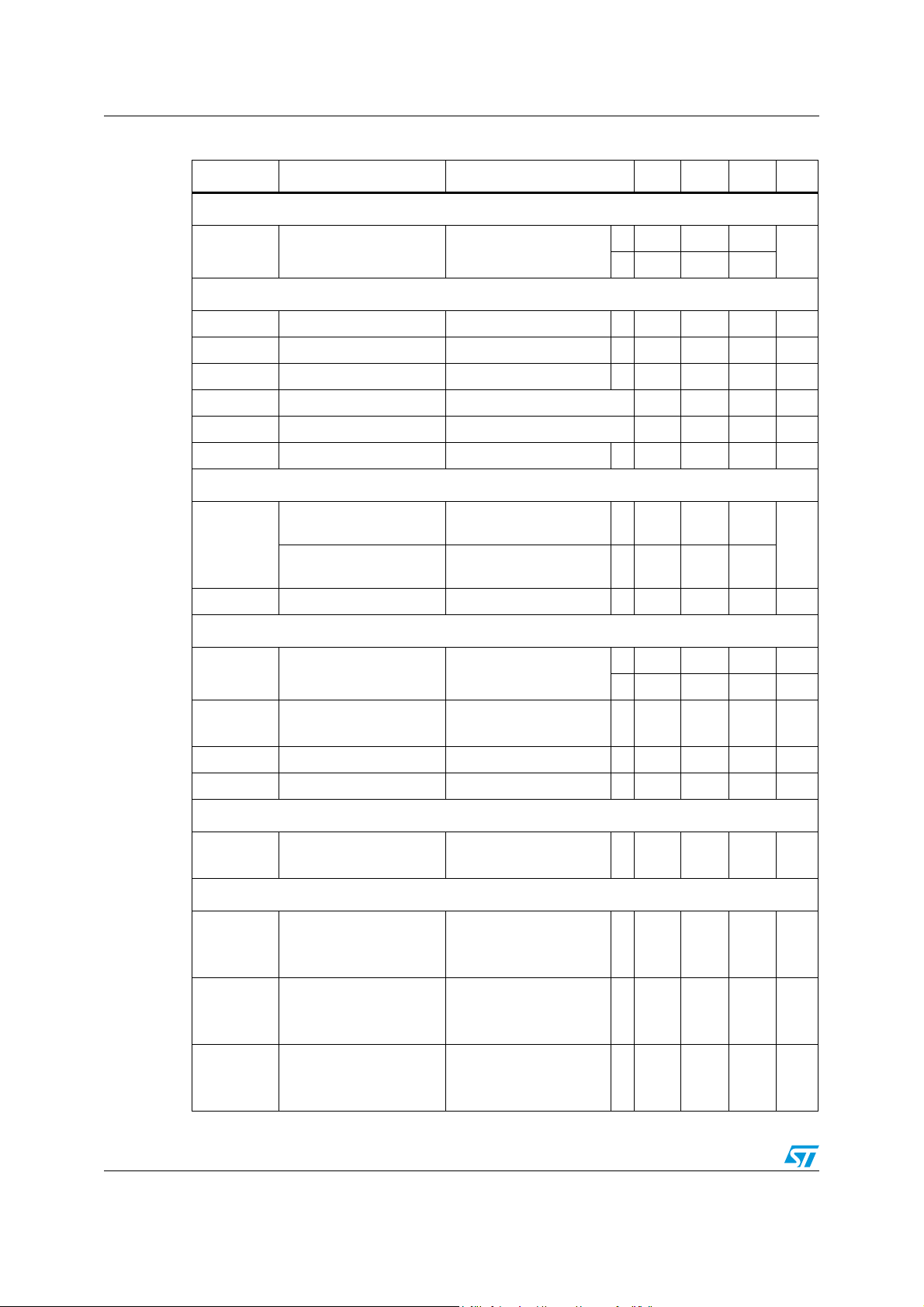

Table 4. Electrical characteristic (continued)

Symbol Parameter Test condition Min Typ Max Unit

- UVLO 3.3 V bus

TH4

- OVP latched

(3)

0.71 0.875 V

- Sink

- UVLO 12 V bus

TH5

- OVP not latched

(3)

0.93 1.085 V

- No sink

- UVLO 12 V bus

TH6

- OVP not latched

(3)

1.16 1.31 V

- Sink

- UVLO 12 V bus

TH7

- OVP latched

(3)

1.385 1.525 V

- No sink

- UVLO 12 V bus

TH8

- OVP latched

(3)

1.615 VREF V

- Sink

1. Specification over the junction temperature range (TJ) of -40 to +125 °C are guaranteed by design,

characterization and statistical correlation

2. Guaranteed by design

= 4 V

3. V

CC

Doc ID 15778 Rev 3 11/51

Functional description L5989D

5 Functional description

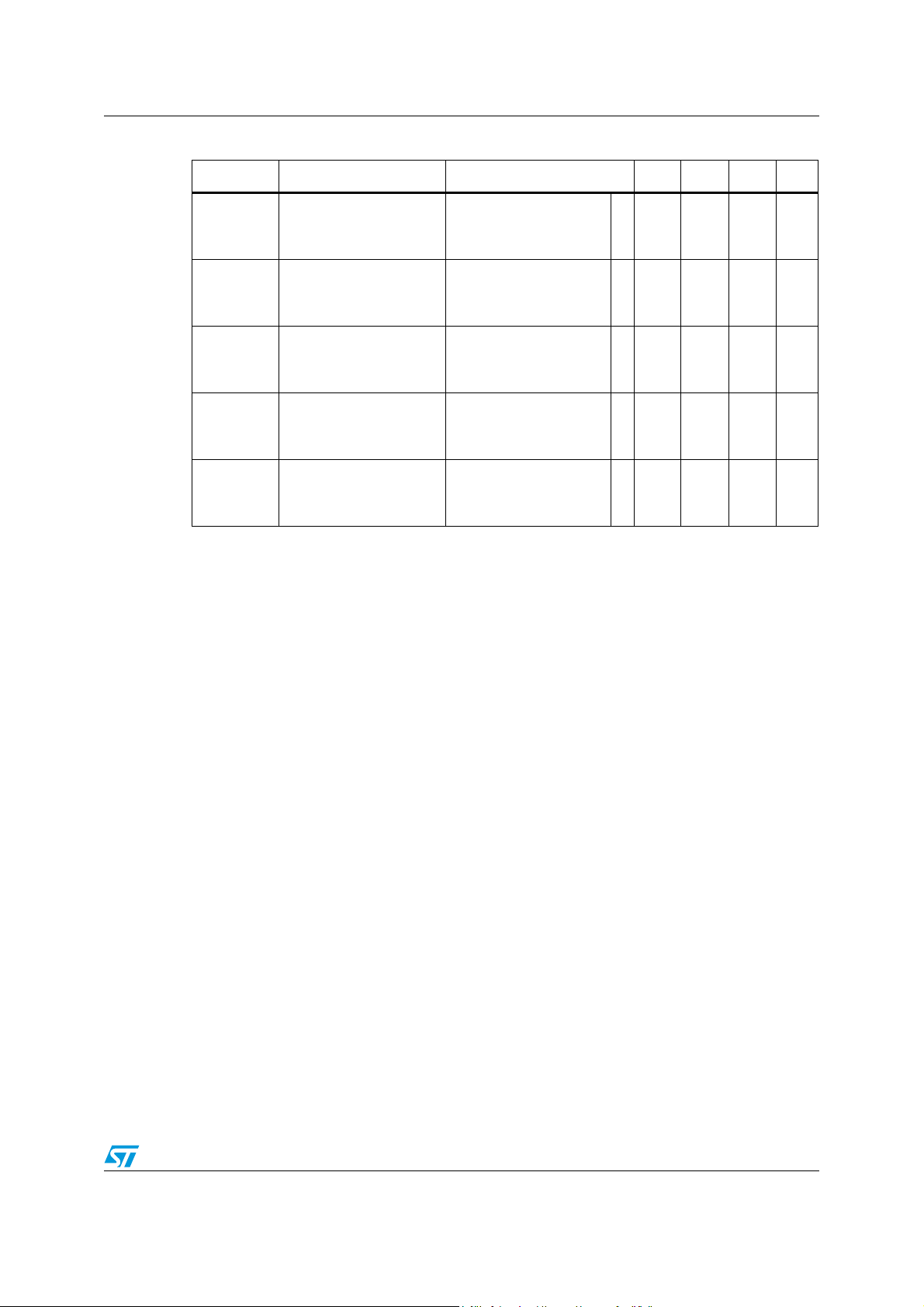

The L5989D is based on a voltage mode control loop. Therefore the duty ratio of the internal

switch is obtained through a comparison between a saw-tooth waveform (generated by an

oscillator) and the output voltage of the error amplifier as shown in Figure 3. The advantage

of this technique is the very short conduction time of the power elements thanks to the

proper operation of the control loop without a precise current sense, which instead is

required in current mode regulators. Thanks to this architecture the L5989D supports

extremely low conversion ratio (D = V

OUT/VIN

(up to 1 MHz).

Figure 3. Voltage mode control loop

) even at very high switching frequency

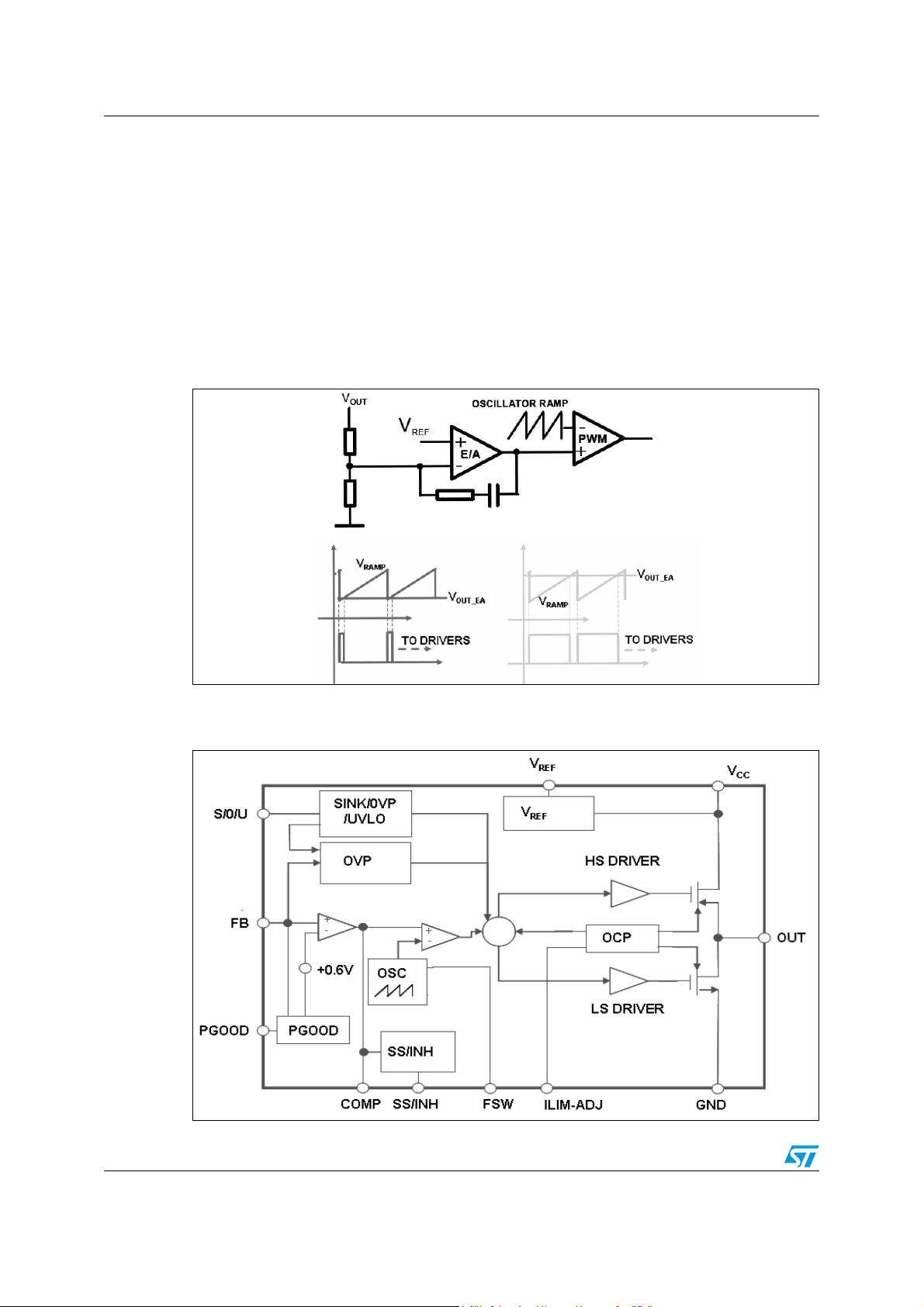

The main internal blocks are represented in Figure 4.

Figure 4. Internal block diagram

12/51 Doc ID 15778 Rev 3

L5989D Functional description

Below follows a brief description of the main blocks:

● A voltage pre-regulator supplies the internal circuitry. The external 1.8 V voltage

reference is supplied by this regulator.

● A voltage monitor circuit that checks the input and internal voltages

● A fully integrated sawtooth oscillator whose frequency is 400 kHz ± 10% when the Fsw

pin is floating. Its frequency can be increased/decreased connecting a proper resistor

to GND or VREF

● The internal current limitation circuitry monitors the current flowing in both embedded

switches to guarantee an effective protection even in extreme duty cycle conditions

● The over voltage protection (OVP) monitors the feedback voltage. If the voltage of this

pin overcomes the 20% of the internal reference value (600 mV ± 1%) it will force the

conduction of the low side switch until the overshoot is present

● A voltage mode amplifier. The inverting input and the output are externally available for

compensation

● A pulse width modulator (PWM) comparator and the relative logic to drive the

embedded switches

● The soft-start circuit charges an external capacitor with a constant current equal to

20 µA (typ.). The soft-start feature is realized clamping the output of the error amplifier

until the voltage across the capacitor is below 2.7 V

● The PGOOD is an open collector output: low impedance if the feedback voltage is

lower than 0.85 times the internal reference of the error amplifier. An hysteresis is

provided

● The circuitry related to the UOS multifunction pin is composed of a 3 bit A/D converter

and the decoding logic. It recognizes eight different voltage windows of a VREF voltage

magnitude for selecting additional features.

● An inhibit block for stand-by operation

● A circuit to realize the thermal protection function

5.1 Multifunction pin

The UOS pin is used to configure the device additional features accordingly to the voltage

bias imposed through VREF voltage partitioning.

The selectable options are:

● UVLO level: two pre-defined the under voltage lock out thresholds can be selected to

match the 3.3 V and 5 V or 12 V power bus

● SINK capability: this feature is always disabled during the soft-start period to be

compatible with pre-biased output voltages. After the soft-start phase, the synchronous

rectification can be enabled or not depending on the status of the UOS pin. Anyway, in

case an overvoltage is detected, the sink capability is always enabled to bring the FB

back to regulation as fast as possible

● OVP management: in case the latched mode is selected and an overvoltage event

recurs, the switching activity will be suspended until VCC is reapplied or the SS/INH

is toggled. Otherwise when the overvoltage transient is ended the regulator will work

accordingly to the load request without regulation discontinuity

The circuitry related to the UOS multifunction pin is composed of a 3 bit A/D converter and

the decoding logic. Table 5 shows the internal thresholds of each voltage window

pin

Doc ID 15778 Rev 3 13/51

Functional description L5989D

composing the VREF magnitude. The voltage biasing of the multifunction can be set

accordingly to table Table 6 .

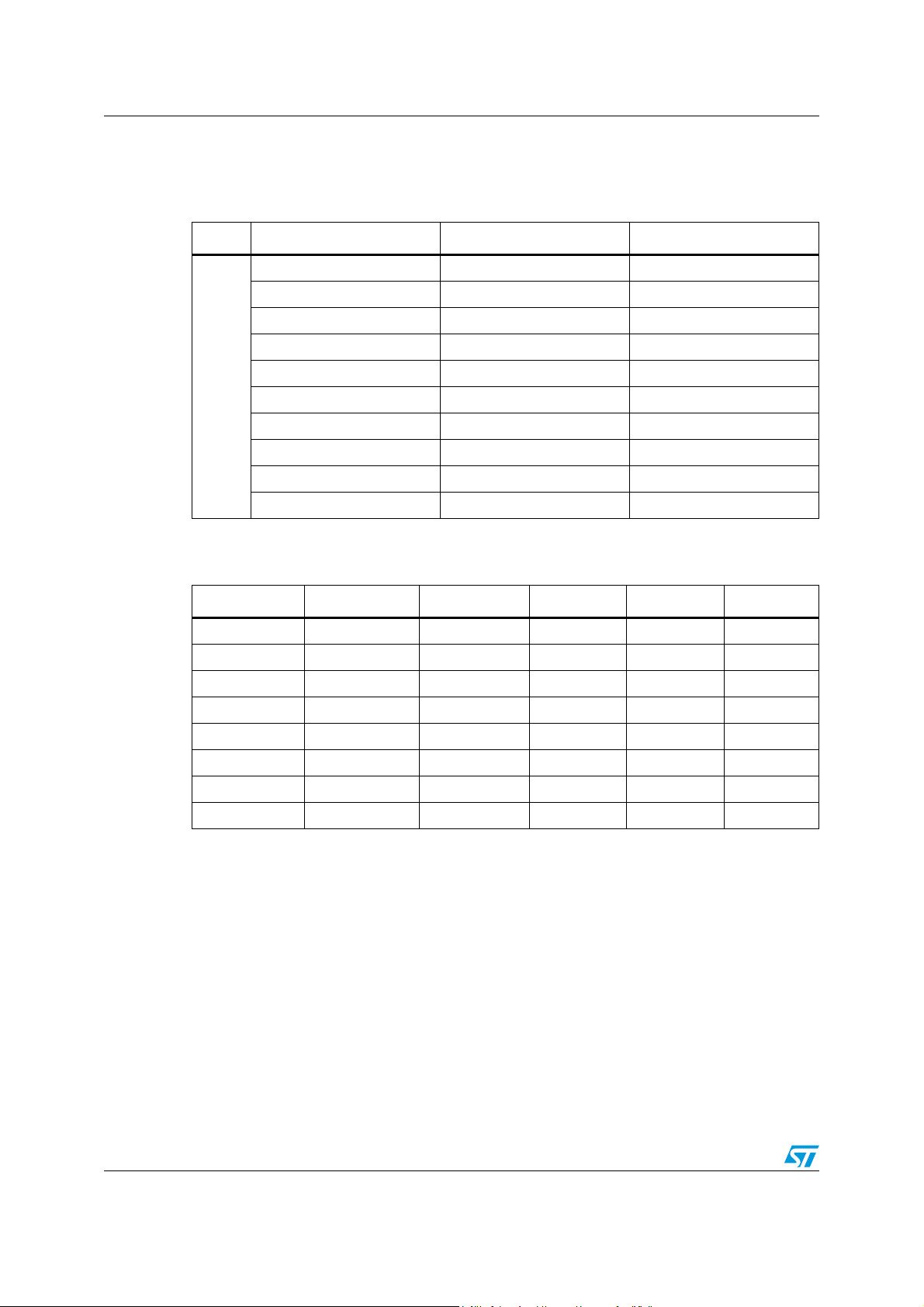

Table 5. A/D voltage windows

UVLO OVP SINK

1.8 V

1.575 V

1.35 V

1.125 V

0.9 V

12 V BUS Latch Sink

12 V BUS Latch No sink

12 V BUS No latch Sink

12 V BUS No latch No sink

3.3 V BUS Latch Sink

0.675 V

3.3 V BUS Latch No sink

0.45 V

3.3 V BUS No latch Sink

0.225 V

3.3 V BUS No latch No sink

0 V

Table 6. UOS voltage biasing

R1 (kΩ)R2 (kΩ)V

0 N.C. 1.8 12 V bus Latch Sink

0.68 2.7 1.438 12 V bus Latch No sink

1.2 2.7 1.246 12 V bus No latch Sink

2 2.7 1.034 12 V bus No latch No sink

(V) UVLO OVP SINK

OUS

3.3 2.7 0.810 3.3 V bus Latch Sink

6.2 2.7 0.546 3.3 V bus Latch No sink

11 2.7 0.355 3.3 V bus No latch Sink

N.C. 0 0 3.3 V bus No latch No sink

14/51 Doc ID 15778 Rev 3

L5989D Functional description

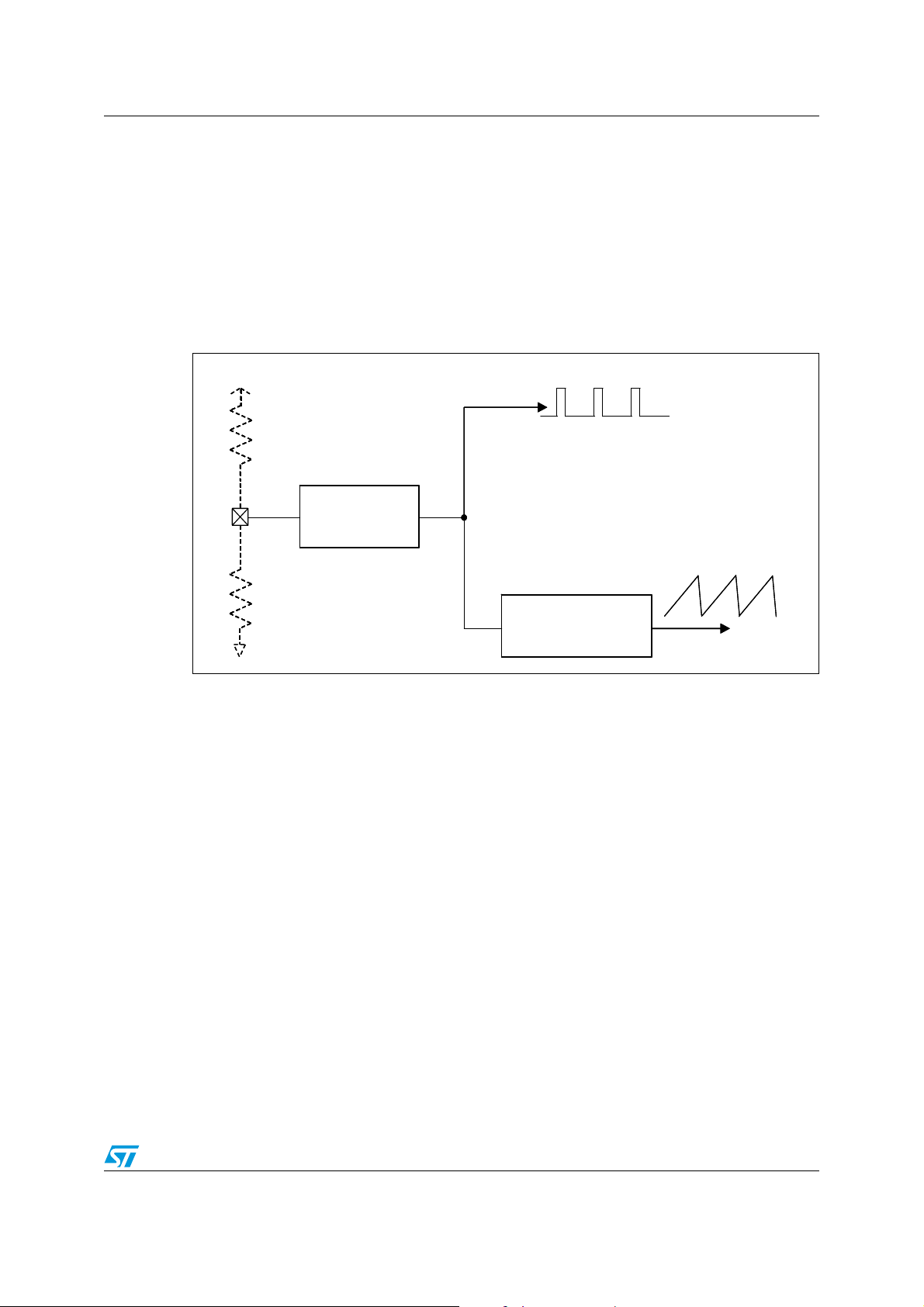

5.2 Oscillator

The generation of the internal saw-tooth waveform is based on the constant current charge /

discharge of an internal capacitor. The current generator is designed to get a switching

frequency of 400 kHz ± 10% in case the FSW pin is left floating.

The current mirror connected to FSW (see Figure 5) pin acts increasing / decreasing the

value of the internal charging current to adjust the oscillator frequency. Since the internal

circuitry forces the FSW voltage bias at 1.235 V, the user can easily source / sink current in

this pin connecting a pull up resistor to VREF or a pull down to GND respectively.

Figure 5. Oscillator circuit block diagram

VREF

VREF

Clock

ClockClock

Clock

Clock

Generator

Generator

Ramp

Ramp

Sawtooth

Generator

Generator

Sawtooth

The value of the pull up resistor versus VREF to decrease the oscillator frequency follows

the formula:

8.5 103⋅

R1KΩ()

-------------------------------------------- - 0.95+=

400 F

SW

KHz()–

In the same way to increase the switching frequency the pull down resistor is selected using

the formula:

R

2

KΩ()

18 103⋅

-------------------------------------------- - 2.1–=

KHz()400–

F

SW

Ta bl e 1 0 shows some resistor values to adjust the oscillator frequency

Doc ID 15778 Rev 3 15/51

Functional description L5989D

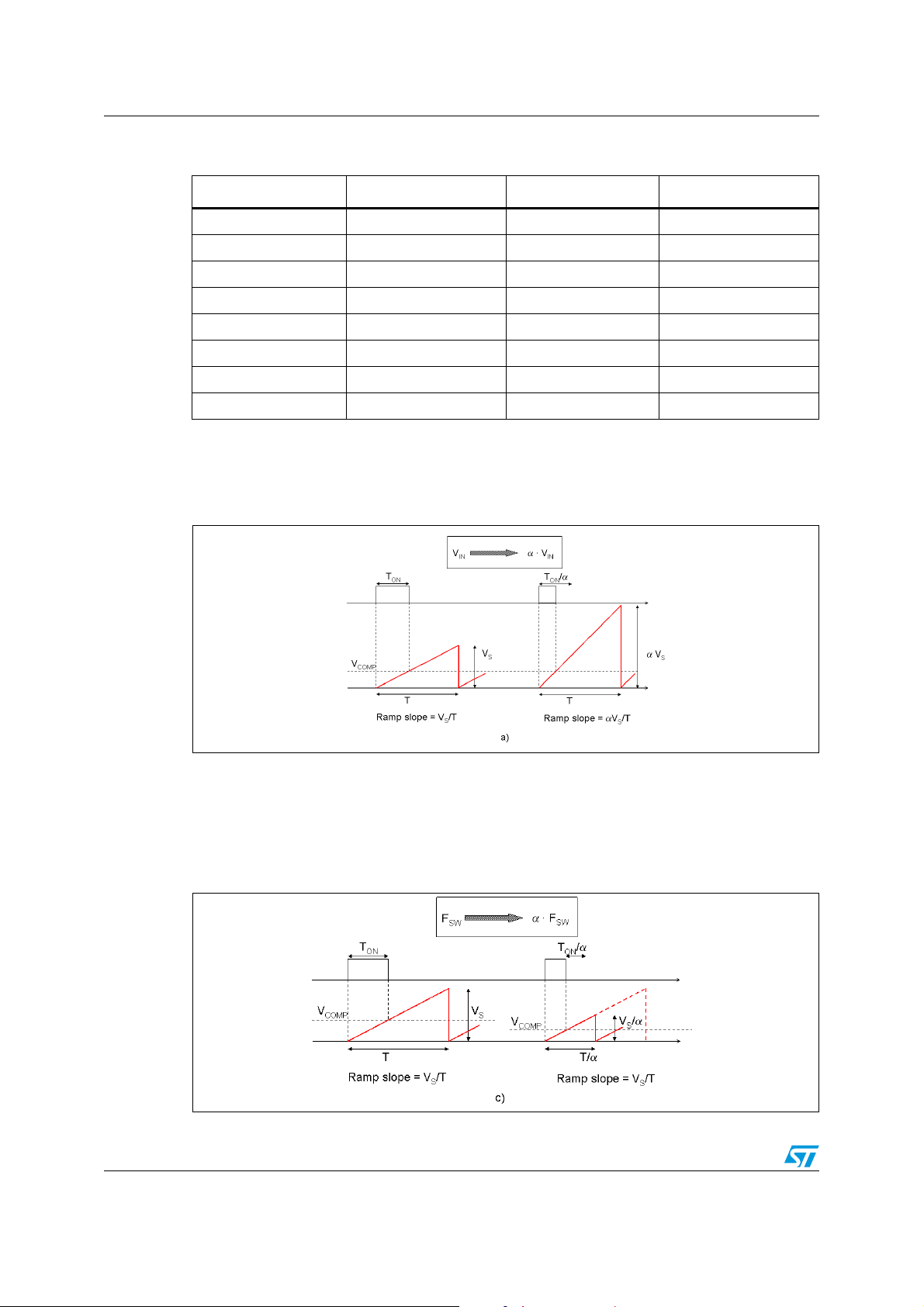

Table 7. FSW resistor examples

R1 (kΩ)f

(kHz) R2 (kΩ)f

SW

SW

(kHz)

43 198 360 450

47 215 180 499

56 245 120 548

62 261 91 594

82 295 56 711

110 322 43 801

150 343 33 915

220 361 27 1022

To improve the line transient performance, the voltage feed forward is implemented by

changing the slope of the sawtooth according to the input voltage change (see Figure 6 a).

Figure 6. Sawtooth: voltage feed forward

The slope of the sawtooth does not change if the oscillator frequency is increased by an

external signal or adjusted by the external resistor (see Figure 7). As a consequence the

gain of the PWM stage is a function of the switching frequency and its contribution must be

taken in account when performing the calculations of the compensation network (see

Chapter 6.4.1 and Chapter 6.4.2).

Figure 7. Sawtooth: frequency adjust

16/51 Doc ID 15778 Rev 3

Loading...

Loading...