L4972A

Fi

2A SWITCHING REGULATOR

1 Features

■ 2A OUTPUT CURRENT

■ 5.1V TO 40V OUTPUT VOLTAGE RANGE

■ 0 TO 90% DUTY CYCLE RANGE

■ INTERNAL FEED-FORWARD LINE REG.

■ INTERNAL CURRENT LIMITING

■

PRECISE 5.1V ± 2% ON CHIP REFERENCE

■ RESET AND POWER FAIL FUNCTIONS

■ INPUT/OUTPUT SYNC PIN

■ UNDER VOLTAGE LOCK OUT WITH

HYSTERETIC TURN-ON

■ PWM LATCH FOR SINGLE PULSE PER

PERIOD

■ VERY HIGH EFFICIENCY

■ SWITCHING FREQUENCY UP TO 200KHz

■ THERMAL SHUTDOWN

■ CONTINUOUS MODE OPERATION

2 Description

The L4972A is a stepdown monolithic power

switching regulator delivering 2A at a voltage variable from 5.1 to 40V.

Realized with BCD mixed technology, the device

gure 1. Packages

PowerDIP20 (16+2+2) SO20

Table 1. Order Codes

Part Number Package

L4972A DIP20 (16+2+20)

L4972AD SO20

L4972AD013TR SO20 in Tape & Reel

uses a DMOS output transistor to obtain very high

efficiency and very fast switching times. Features

of the L4972 include reset and power fail for microprocessors, feed forward line regulation, soft start,

limiting current and thermal protection. The device

is mounted in a Powerdip 16 + 2 + 2 and SO20

large plastic packages and requires few external

components. Efficient operation at switching frequencies up to 200KHz allows reduction in the

size and cost of external filter component.

Figure 2. Block Diagram

May 2005

Rev. 3

1/22

L4972A

Table 2. Pin Description

N° Pin Function

1 BOOTSTRAP A C

2 RESET DELAY A C

3 RESET OUT Open Collector Reset/power Failand the output voltages are safe. Signal Output.

4 RESET INPUT Input of Power Fail Circuit. The threshold is 5.1V. It may be connected via a divider

5, 6 15,

16

7 FREQUENCY

8 SOFT START Soft Start Time Constant. A capacitor is connected between the sterminal and

9 FEEDBACK INPUT The Feedback Terminal of the Regulation Loop. The output is connected directly to

10 SYNC INPUT Multiple L4972A’s are synchronized by connecting pin 10 inputs together or via an

11 SUPPLY VOLTAGE Unregulated Input Voltage.

12, 19 N.C. Not Connected.

13 V

14 V

17 OSCILLATOR R

18 OSCILLATOR C

20 OUTPUT Regulator Output.

GROUND Common Ground Terminal

COMPENSATION

ref

start

capacitor connected between this terminal and the output allows to drive

boot

properly the internal D-MOS transistor.

capacitor connected between this terminal and ground determines the reset

d

signal delay time.

This output is high when the supply

to the input for power fail function. It must be connected to the pin 14 an external

30KΩ resistor when power fail signal not required.

A series RC network connected between this terminal and ground determines the

regulation loop gain characteristics.

ground to define the soft start time constant.

this terminal for 5.1V operation; It is connected via a divider for higher voltages.

external syncr. pulse.

5.1V V

Internal Start-up Circuit to Drive the Power Stage.

current of C

frequency.

Device Reference Voltage.

ref

. External resistor connected to ground determines the constant charging

osc

. External capacitor connected to ground determines (with R

osc

osc

.

) the switching

osc

Figure 3. Pin Connection (Top view)

BOOTSTRAP

RESET DELAY

RESET OUT

P. FAIL INPUT

FREQ. COMP.

SOFT START

FEEDBACK IN.

SYNC INPUT

2/22

1

2

3

4

GND GND

GND

5

6

7

8

9

10 11

DIP20

20

19

18

17

16

15

14

13

12

OUTPUT

N.C.

C OSC

R OSC

GND

Vstart

Vref

N.C.

Vi

Table 3. Absolute Maximum Ratings

Symbol Parameter Value Unit

V

Input Voltage 55 V

11

Input Operating Voltage 50 V

V

11

Output DC Voltage

V

20

Output Peak Voltage at t = 0.1µs f = 200kHz

I

Maximum Output Current Internally Limited

20

Boostrap Voltage

V

I

Boostrap Operating Voltage

V

4

V

, V7, V9,

V

2

V

P

, V

I

3

10

I

2

I

7

I

8

tot

Input Voltage at Pins 4, 12 12 V

8

Reset Output Voltage 50 V

3

Reset Output Sink Current 50 mA

Input Voltage at Pin 2, 7, 9, 10 7 V

Reset Delay Sink Current 30 mA

Error Amplifier Output Sink Current 1 A

Soft Start Sink Current 30 mA

Total Power Dissipation at T

PINS

≤ 90°C

at Tamb = 70°C (No copper area on PCB)

, T

Junction and Storage Temperature -40 to 150 °C

T

J

stg

(*) SO-20

-1

-5

65

V

+ 15

11

5 / 3.75(*)

1.3/1 (*)

L4972A

V

V

V

V

W

W

Table 4. Thermal Data

Symbol Parameter PowerDIP SO20 Unit

R

th j-pins

R

th j-amb

Thermal Resistance Junction-Pins max, 12 16 °C/W

Thermal Resistance Junction-ambient max, 60 80 °C/W

3 Circuit Operation

The L4972A is a 2A monolithic stepdown switching regulator working in continuous mode realized in the

new BCD Technology. This technology allows the integration of isolated vertical DMOS power transistors

plus mixed CMOS/Bipolar transistors.

The device can deliver 2A at an output voltage adjustable from 5.1V to 40V and contains diagnostic and

control functions that make it particularly suitable for microprocessor based systems.

3.1 BLOCK DIAGRAM

The block diagram shows the DMOS power transistors and the PWM control loop. Integrated functions

include a reference voltage trimmed to 5.1V ± 2%, soft start, undervoltage lockout, oscillator with feedforward control, pulse by pulse current limit, thermal shutdown and finally the reset and power fail circuit. The

reset and power fail circuit provides an output signal for a microprocessor indicating the status of the system.

Device turn on is around 11V with a typical 1V hysterysis, this threshold porvides a correct voltage for the

driving stage of the DMOS gate and the hysterysis prevents instabilities.

An external bootstrap capacitor charge to 12V by an internal voltage reference is needed to provide correct gate drive to the power DMOS. The driving circuit is able to source and sink peak currents of around

0.5A to the gate of the DMOS transistor. A typical switching time of the current in the DMOS transistor is

50ns. Due to the fast commutation switching frequencies up to 200kHz are possible.

The PWM control loop consists of a sawtooth oscillator, error amplifier, comparator, latch and the output

3/22

L4972A

stage. An error signal is produced by comparing the output voltage with the precise 5.1V ± 2% on chip

reference. This error signal is then compared with the sawtooth oscillator in order to generate frixed frequency pulse width modulated drive for the output stage. A PWM latch is included to eliminate multiple

pulsing within a period even in noisy environments.

The gain and stability of the loop can be adjusted by an external RC network connected to the output of

the error amplifier. A voltage feedforward control has been added to the oscillator, this maintains superior

line regulation over a wide input voltage range. Closing the loop directly gives an output vol-tage of 5.1V,

higher voltages are obtained by inserting a voltage divider.

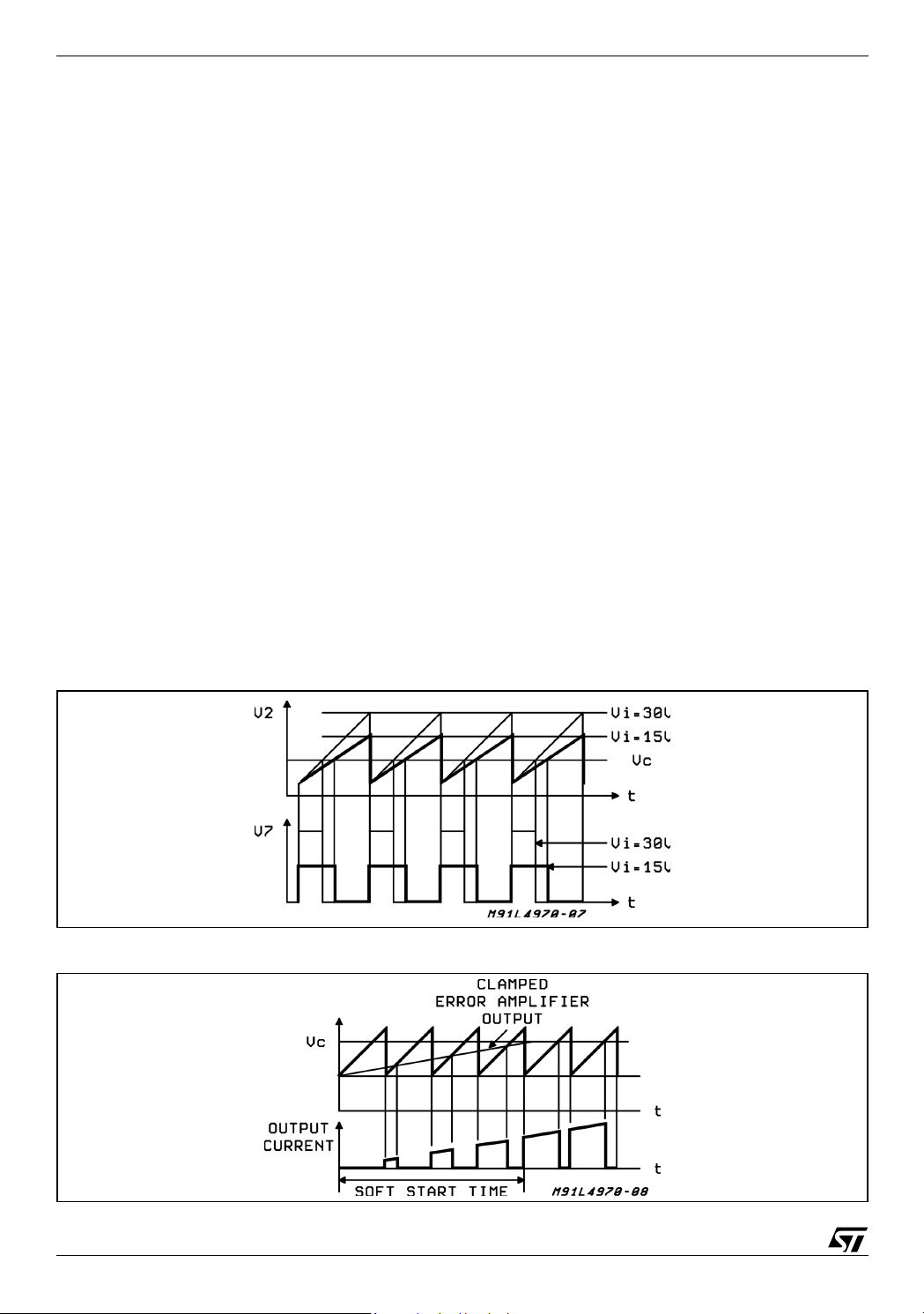

At turn on, output overcurrents are prevented by the soft start function (fig. 5). The error amplifier is initially

clamped by an external capacitor, Css, and allowed to rise linearly under the charge of an internal constant

current source.

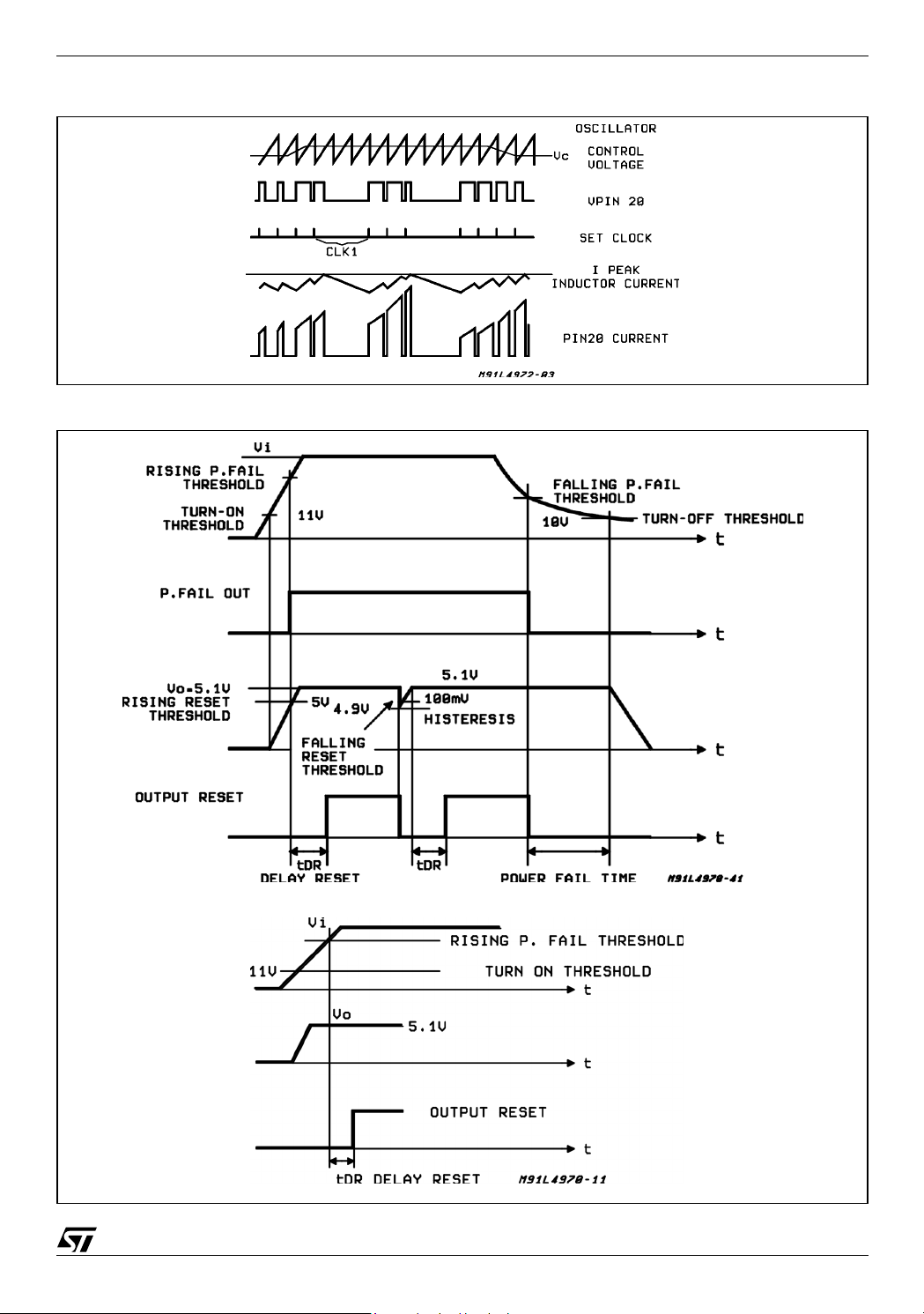

Output overload protection is provided by a current limit circuit. The load current is sensed by a internal

metal resistor connected to a comparator. When the load current exceeds a preset threshold, the output

of the comparator sets a flip flop which turns off the power DMOS. The next clock pulse, from an internal

40kHz oscillator, will reset the flip flop and the power DMOS will again conduct. This current protection

method, ensures a constant current output when the system is overloaded or short circuited and limits the

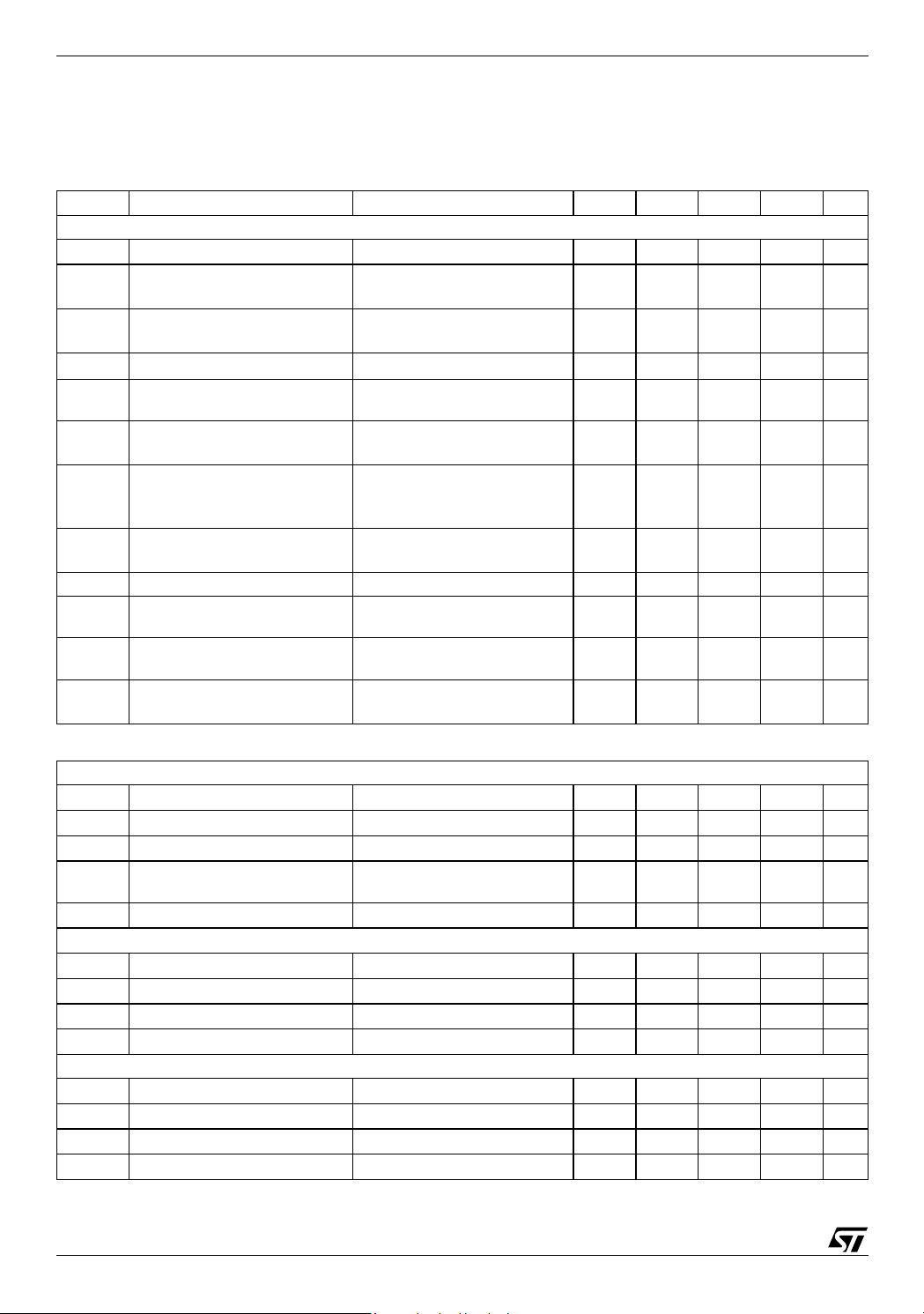

switching frequency, in this condition, to 40kHz. The Reset and Power fail diagram (fig. 7), generates an

output signal when the supply voltage exceeds a threshold programmed by an external voltage divider.

The reset signal, is generated with a delay time programmed by a external capacitor on the delay pin.

When the supply voltage falls below the threshold or the output voltage goes below 5V, the reset output

goes low immediately. The reset output is an open drain.

Fig. 7A shows the case when the supply voltage is higher than the threshold, but the output voltage is not

yet 5V.

Fig. 7B shows the case when the output is 5.1V, but the supply voltage is not yet higher than the fixed

threshold. The thermal protection disables circuit operation when the junction temperature reaches about

150°C and has a hysterysis to prevent unstable conditions.

Figure 4. Feedforward Waveform.

Figure 5. Soft Start Function.

4/22

Figure 6. Limiting Current Function.

Figure 7. Reset and Power Fail Functions

L4972A

A

B

5/22

L4972A

4 Electrical Characteristcs

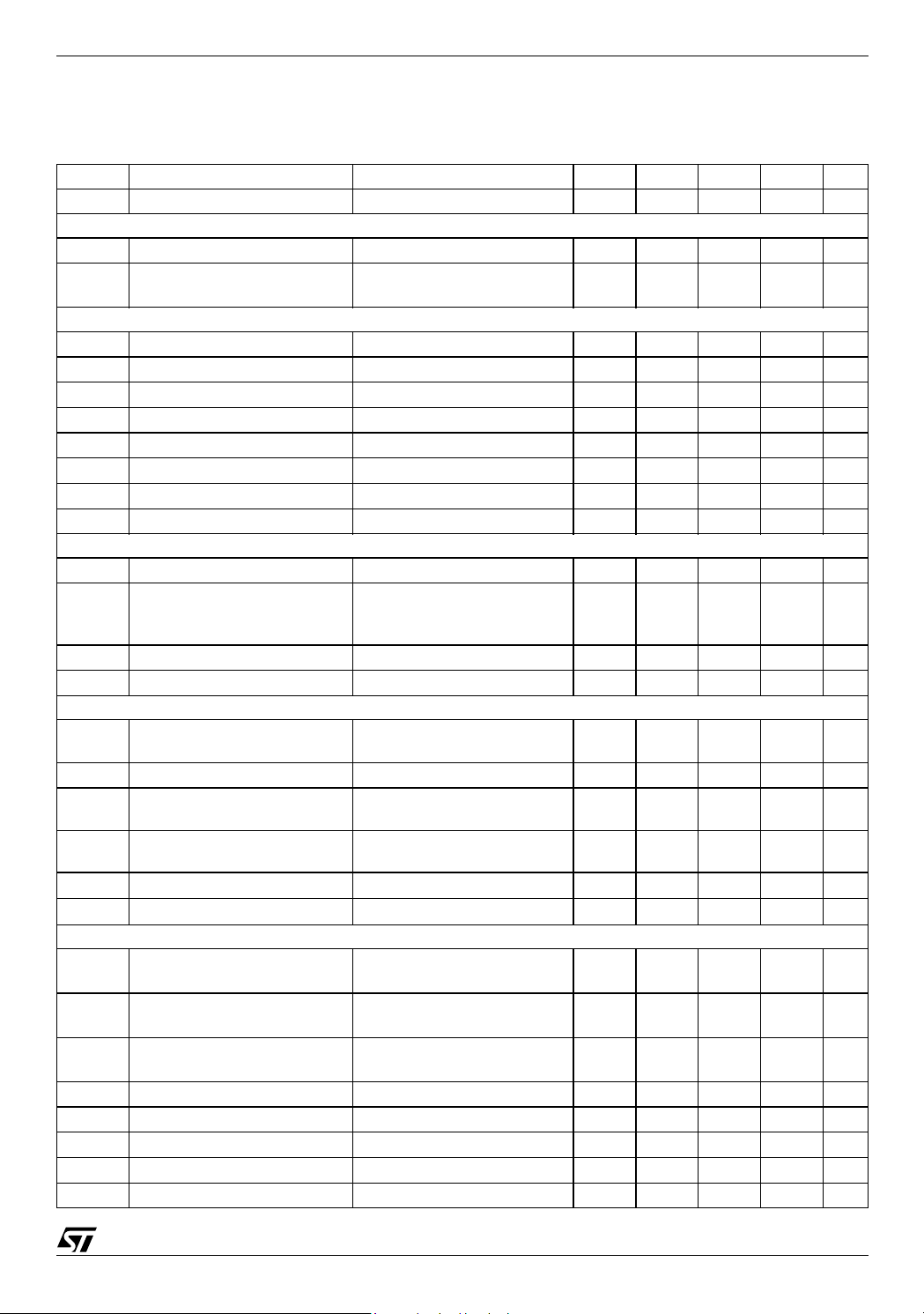

Table 5. Electrical Characteristcs

Refer to the test circuit, T

specified.

Symbol Parameter Test Condition Min. Typ. Max. Unit Fig.

DYNAMIC CHARACTERISTICS

V

Input Volt. Range (pin 11) Vo = V

i

Output Voltage Vi =15V to 50V Io= 1A;

V

o

∆Vo

∆Vo

SVR Supply Voltage Ripple Rejection V

∆f/∆Vi

∆f/T

f

(*) Only for DIP version (**) Pulse testing with a low duty cycle

Line Regulation Vi =15V to 50V

Load Regulation Vo = V

V

Dropout Voltage between Pin

d

11 and 20

I

Max Limiting Current Vi = 15V to 50V

20L

η Efficiency (*) I

f Switching Frequency 90 100 110 KHz 8

Voltage Stability of Switching

Frequency

Temperature Stability of

j

Switching Frequency

Maximum Operating Switching

max

Frequency

= 25°C, Vi = 35V, R4 = 30KΩ, C9 = 2.7nF, fSW = 100KHz typ, unless otherwise

J

to 40V Io = 2A (**) 15 50 V 8

ref

5 5.1 5.2 V 8

= V

V

o

ref

12 30 mV

= 0.5A; Vo= V

I

o

ref Io

ref

= 0.5A to 2A 7 20 mV

Io = 2A 0.25 0.4 V

2.5 2.8 3.5 A

= Vref to 40V

V

o

= 2A, f = 100KHz

o

= V

V

o

ref

Vo = 12V

= 2V

i

f = 100Hz; V

V

= 15V to 45V 2 6 % 8

i

RMS

; Io= 1A

= V

o

ref

75 85

90

%

%

56 60 dB 8

Tj = 0 to 125°C 1 % 8

Vo= V

= 2A C9= 2.2nF

I

o

ref R4

= 15KΩ

200 KHz 8

Vref SECTION (pin 13)

V

Reference Voltage 5 5.1 5.2 V 10

13

Line Regulation V

∆V

13

Load Regulation I

∆V

13

/∆T Average Temperature

∆V

13

= 15V to 50V 10 25 mV 10

i

= 0 to 1mA 20 40 mV 10

13

Tj = 0°C to 125°C 0.4 mV/°C 10

Coefficient Reference Voltage

I

13 short

V

START

∆V

∆V

I

14 short

Short Circuit Current Limit V13 = 0 70 mA 10

SECTION (pin 15)

Reference Voltage 11.4 12 12.6 V 10

V

14

Line Regulation V

14

Load Regulation I

14

= 15 to 50V 0.6 1.4 V 10

i

= 0 to 1mA 50 200 mV 10

14

Short Circuit Current Limit V15 = 0V 80 mA 10

DC CHARACTERISTICS

V

V

11 Hyst

I

I

11OQ

Turn-on Threshold 10 11 12 V 12

11on

Turn-off Hysteresys 1 V 12

Quiescent Current V8 = 0; S1 = D 13 19 mA 12

11Q

Operating Supply Current V

= 0; S1 = B; S2 = B 16 23 mA 12

8

6/22

L4972A

Table 5. Electrical Characteristcs (continued)

Refer to the test circuit, T

specified.

Symbol Parameter Test Condition Min. Typ. Max. Unit Fig.

I

Out Leak Current Vi = 55V; S3 = A; V8= 0 2 mA 12

20L

SOFT START (pin 8)

Soft Start Source Current V8 = 3V; V9= 0V 80 115 150 µA 13

I

8

Output Saturation Voltage I8 = 20mA; V11= 10V

V

8

ERROR AMPLIFIER

V

High Level Out Voltage I7 = 100µA; S1 = C; V9 = 4.7V 6 V 14

7H

Low Level Out Voltage I7 = 100µA; S1 = C; V9= 5.3V 1.2 V 14

V

7L

Source Output Current V7 = 1V; V7 = 4.7V 100 150 µA 14

I

7H

Sink Output Current V7 = 6V; V9 = 5.3V 100 150 µA 14

-I

7L

Input Bias Current S1 = B; RS = 10KΩ 0.4 3 µA 14

I

9

DC Open Loop Gain S1 = A; RS= 10Ω 60 dB 14

G

V

SVR Supply Voltage Rejection 15 < V

Input Offset Voltage RS= 50Ω S1 = A 2 10 mV 14

V

OS

RAMP GENERATOR (pin 18)

Ramp Valley S1 = B; S2 = B 1.2 1.5 V 12

V

18

Ramp Peak S1 = B; S2 = B

V

18

I

Min. Ramp Current S1 = A; I17= 100µA 270 300 µA 12

18

Max. Ramp Current S1 = A; I17= 1mA 2.4 2.7 mA 12

I

18

SYNC FUNCTION (pin 10)

Low Input Voltage Vi = 15V to 50V; V8 = 0;

V

10

V10 High Input voltage V8 = 0; S1 = B; S2 = B; S4 = B 2.5 5.5 V 12

Sync Input Current with Low

I

10L

Input Voltage

I

RESET AND POWER FAIL FUNCTIONS

V

V

I

Input Current with High

10H

Input Voltage

V

Output Amplitude 4 5 V

10

Output Pulse Width V

t

W

Rising Thereshold Voltage (pin 9)

9R

Falling Thereshold Voltage (pin 9)

V

9F

Delay High Threshold Volt. Vi = 15 to 50V

2H

Delay Low Threshold Volt.

V

2L

Delay Source Current V4 = 5.3V; V2 = 3V 30 60 80 µA15

2SO

Delay Source Sink Current V4 = 4.7V; V2 = 3V 10 mA 15

I

2SI

Output Saturation Voltage I3 = 15mA; S1 = B V4 = 4.7V 0.4 V 15

V

3S

Output Leak Current V3 = 50V; S1 = A 100 µA15

I

3

= 25°C, Vi = 35V, R4 = 30KΩ, C9 = 2.7nF, fSW = 100KHz typ, unless otherwise

J

1

= 200µA; V11= 10V

I

8

< 50V 60 80 dB 14

i

V

= 15V

i

= 45V

V

i

2.5

5.5

0.7

V

V

V

V

13

13

12

12

–0.3 0.9 V 12

S1 = B; S2 = B; S4 = B

V10= V18= 0.9V; S4 = B;

0.4 mA 12

S1 = B; S2 = B

V10= 2.5V 1.5 mA 12

= 2.5V 0.3 0.5 0.8 µs

thr

Vi = 15 to 50V

= 5.3V

V

4

Vi = 15 to 50V

= 5.3V

V

4

V

-130

4.77 V

ref

V

ref

-100

ref

-200

V

ref

-80

V

ref

-160

V

mV

V

mV

15

15

4.95 5.1 5.25 V 15

= 5.3V;

V

4

Vi = 15 to 50V;V4 = 4.7V;

V9 = V

13

V9 = V

1

13

1.1 1.2 V 15

–

–

7/22

Loading...

Loading...