Page 1

AN4030

Application note

Gate to cathode capacitor, impact on Triac immunity and reliability

Introduction

Triacs and SCRs are power semiconductors which are usually directly connected to the grid

line. As is well known, the AC grid voltage can be highly perturbed by important voltage

variation during very short times, for example, mechanical relay contact bounce, universal

motor disturbances. Several electromagnetic standards describe how appliances have to be

tested to check their immunity to such events. For example, the IEC 61000-4-4 standard

gives the test procedures and immunity requirements respectively for fast transient voltages.

To increase power-semiconductor device immunity, most designers add a capacitor across

the power device control terminal (the gate for SCRs or Triacs) and its reference terminal (K

or A1 respectively for SCRs and Triacs). This capacitor helps stabilize the control terminal

potential and so is believed to help increase resistance to fast voltage rises (dV/dt). As this

capacitor is also placed between the power device and the control circuit, which could be a

logic gate or a microcontroller unit (MCU), it acts as a filter on the path from the line to the

sensitive control circuit, and helps filter the noise coming from line disturbances.

This paper demonstrates why a gate to cathode capacitor is not efficient to improve Triac

immunity to fast voltage transients, especially for non-sensitive devices. This Application

note demonstrates that such capacitors can increase the risk of failure for repetitive or

accidentally high dI/dt.

The results presented in this Application note have been produced over a considerable

period of time. Some products, which are used as examples to present these results, may

no longer be available. However, the results presented apply to classes and types of

product, and thus are equally applicable to similar products available in the market.

March 2012 Doc ID 022635 Rev 1 1/15

www.st.com

Page 2

Contents AN4030

Contents

1 Gate to cathode capacitor, impact on dV/dt immunity . . . . . . . . . . . . . 3

1.1 dV/dt test method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.2 dV/dt improvement for SCR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.3 Behavior of Triacs regarding dV/dt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.4 Behavior of Triacs to EFT (electrical fast transient) . . . . . . . . . . . . . . . . . . 8

2 Gate to cathode capacitor, impact on dI/dt capability . . . . . . . . . . . . . 11

3 Conclusion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2/15 Doc ID 022635 Rev 1

Page 3

AN4030 Gate to cathode capacitor, impact on dV/dt immunity

1 Gate to cathode capacitor, impact on dV/dt immunity

1.1 dV/dt test method

To characterize device immunity, semiconductor companies give the maximum dV/dt rate

which can be applied across a device without a risk of triggering it.

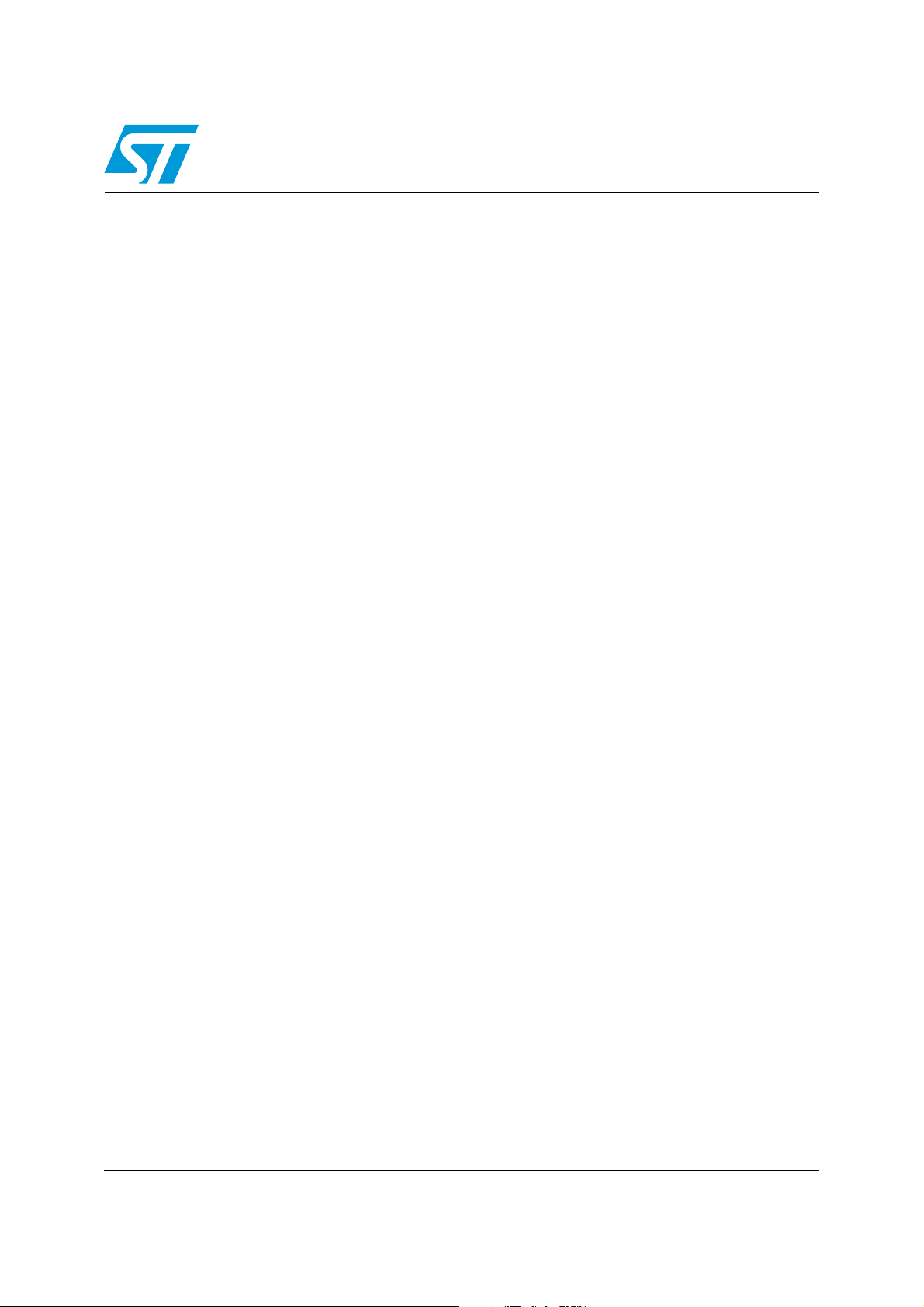

The test schematic features a dV/dt generator which applies a voltage-versus-time linear

slope (see Figure 1). The test equipment detects if the voltage across the DUT (device

under test) decreases below a given threshold. For a given dV/dt level, if the device voltage

drops below this threshold, this means that the device has switched on. The DUT capability

is then lower than this dV/dt rate. The dV/dt parameter specified in the device datasheet is

then the minimum rate that all devices were able to withstand during the tests.

Figure 1. dV/dt test simplified schematic

20 Ω

dV/dt generator

(LEMSYS 50)

V

+

V

(Fixed value: usually 67% x V

dV/dt

peak

t

<V

DRM

V

DRM

T

Device

under test

I

T

Triac

or

SCR

Gate to

cathode

capacitor

The dV/dt parameter is usually measured under the following conditions:

● Peak applied voltage = 67% of V

●

Maximum junction temperature (125 °C most of the time)

● Gate open

DRM

These test conditions are the worst case, as the dV/dt immunity decreases if both the

junction temperature and the impedance between G and K increase.

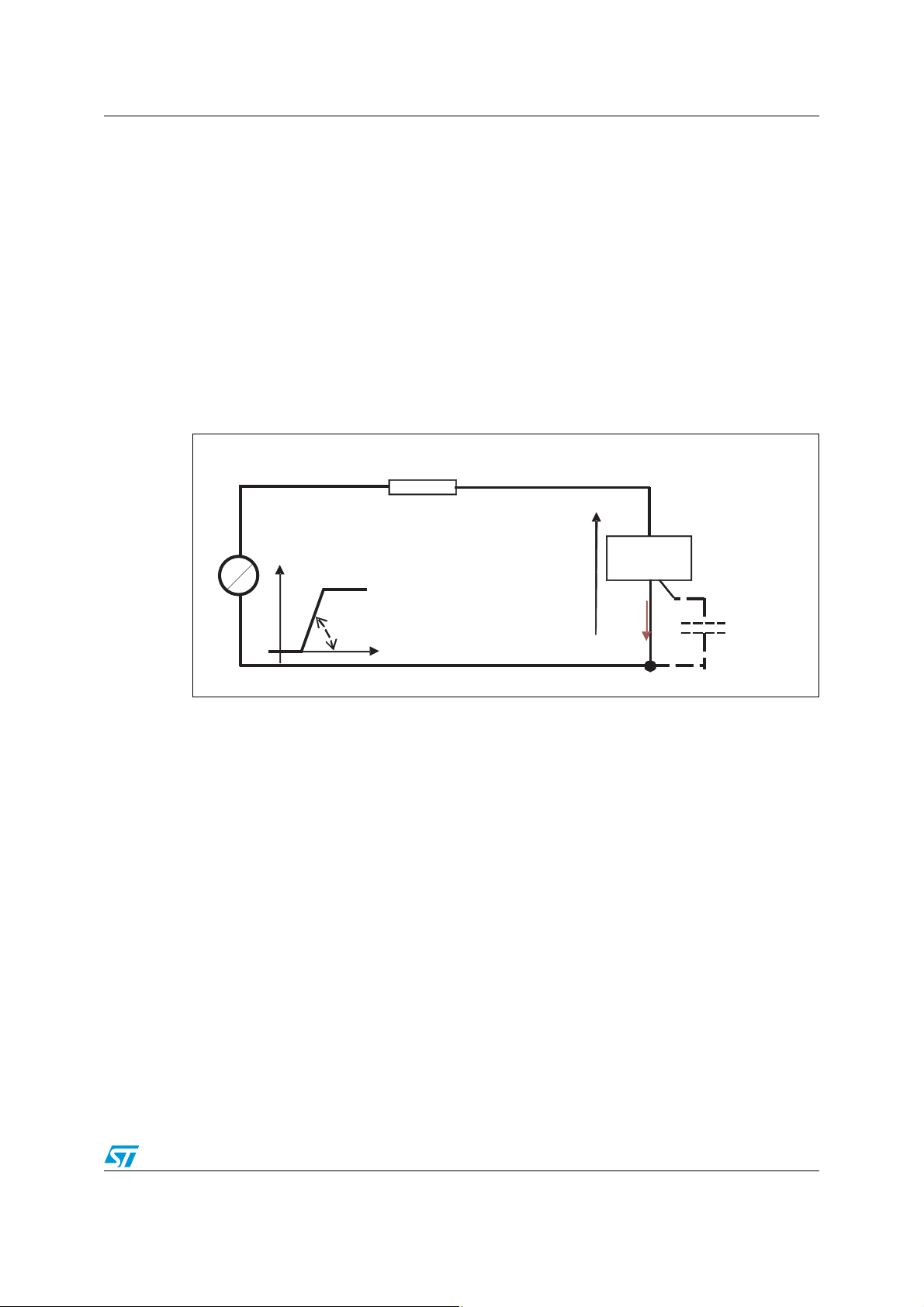

The following figures give an example of a 600 V SCR dV/dt measurement. A 402 V peak

voltage is applied, as it represents 67% of the specified V

. In Figure 2, the device

DRM

remains off. There is no current increase. In Figure 3, the same device switches on

approximately 2 µs after the voltage reaches its peak and stable level. According to these

two results, it could be said that the tested SCR is able to withstand a 150 V/µs rate.

Doc ID 022635 Rev 1 3/15

Page 4

Gate to cathode capacitor, impact on dV/dt immunity AN4030

Figure 2. c test with a 150 V/µs slope

V

T

402 V

I

T

Figure 3. 600 V SCR test with a 160 V/µs slope

V

402 V

1.2 dV/dt improvement for SCR

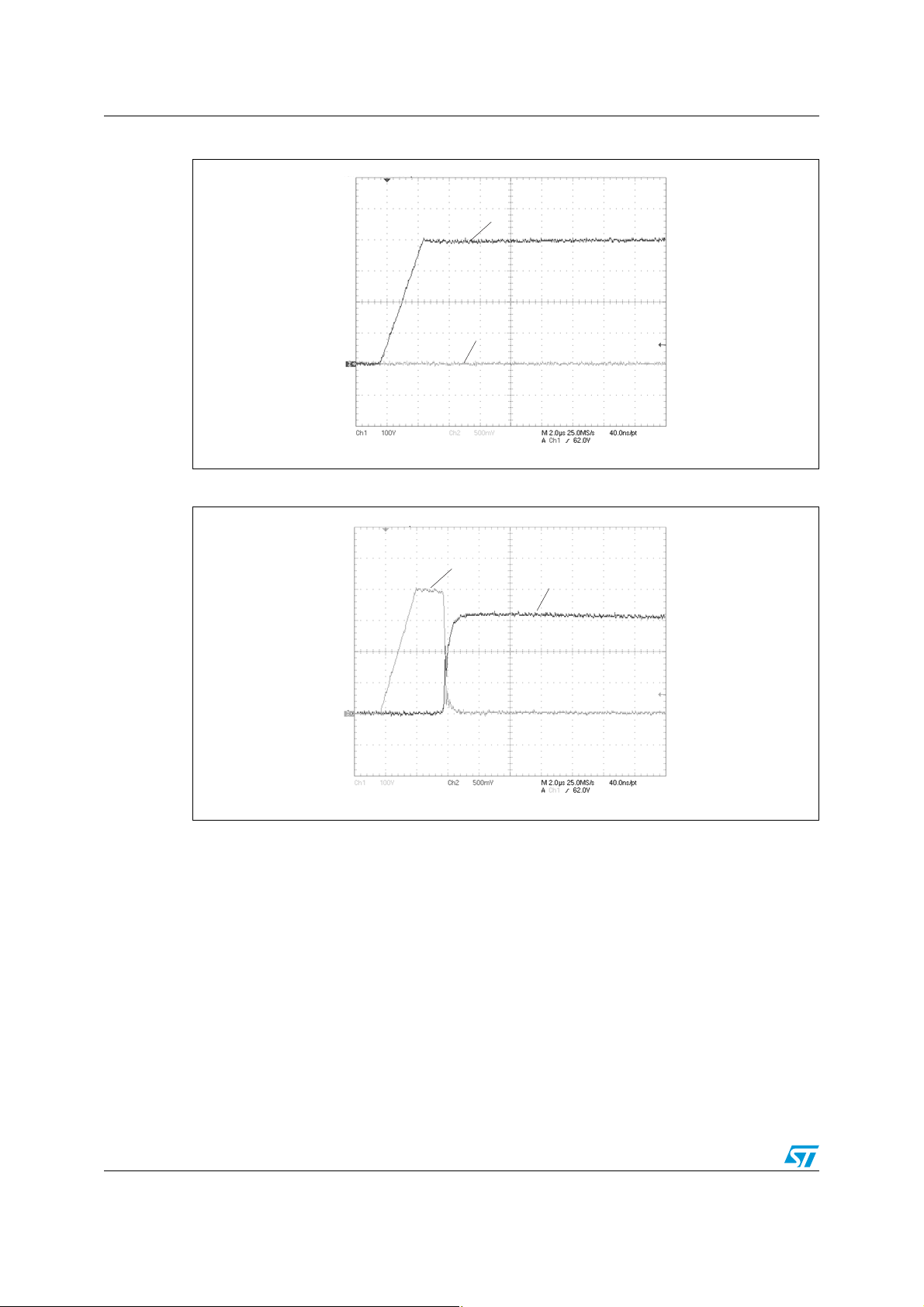

To understand why a semiconductor can be triggered by a dV/dt slope applied across its

terminals, it should be kept in mind that semiconductor devices are composed of several

silicon layers. An SCR features four layers, alternatively doped by holes (P area) or by

electrons (N area). Each PN junction presents a spurious capacitance (see Figure 4). When

a voltage slope is applied, a spurious capacitive current (I

capacitances. This current can then flow to the cathode through the P1-N1 junction and

cause device switch-on. To solve this issue, an impedance, for example a resistor (refer to

gate to cathode resistor in Figure 4), could be added between the gate and cathode

terminals. The spurious capacitive current is then shunted and avoids the device being

triggered.

T

I

T

) is induced by these

CAP

4/15 Doc ID 022635 Rev 1

Page 5

AN4030 Gate to cathode capacitor, impact on dV/dt immunity

Figure 4. SCR simplified silicon structure and spurious capacitive current

I

CAP

Cathode (K)

N1

P1

N2

P2

C

N1/P1

C

P1/N2

C

N2/P2

Anode (A)

R

GK

Gate (G)

A better solution could be found if a capacitor is used instead of a resistor. A high-voltage

gate to cathode capacitor is not necessary because only a low voltage (V

is around 1 V

GK

typically) is applied across this capacitor.

Figure 5 shows the typical relative dV/dt increase versus gate-cathode capacitance for an

8 A sensitive SCR series (I

max = 0.2 mA). The SCR dV/dt could be improved more than

GT

ten times with a 100 nF gate to cathode capacitor.

It should be noted that a gate to cathode resistor is still used in parallel with the gate to

cathode capacitor to discharge it after gate current removal.

For non–sensitive SCRs (I

above around 5 mA), a gate to cathode capacitor does not

GT

improve dV/dt immunity a lot. Indeed, these devices already feature a very low internal gate

to cathode resistor. So adding any external component is not very efficient to shunt the

spurious capacitive current.

Doc ID 022635 Rev 1 5/15

Page 6

Gate to cathode capacitor, impact on dV/dt immunity AN4030

Figure 5. SCR dV/dt increase versus added gate to cathode capacitor

dV/dt [CGK] / dV/dt [RGK= 220 ]Ω

15.0

12.5

10.0

7.5

5.0

VD= 0.67 x V

RGK=220 Ω

Tj=125

°C

DRM

2.5

0.0

0 20 100 160 200

40 60 80 120 140 180

CGK(nF)

1.3 Behavior of Triacs regarding dV/dt

A Triac silicon structure differs from an SCR structure. First, Triacs can conduct current in

both directions. A Triac is equivalent to 2 SCRs back-to-back with a common gate. The real

gate area of the reverse SCR is on the opposite side of the gate terminal connection (see

Figure 6).

Figure 6. Triac simplified silicon structure

A1

G

N4

G

SCR1

K

N1

P1

N2

P1

N2

A

SCR2

A

P2

A2

This device can turn on with dV/dt slope in direct or in reverse. When a positive dV/dt static

is applied on A2, the device SCR1 can improve its immunity with a gate to cathode capacitor

or gate to cathode resistor. With this polarity the device is equivalent to an SCR. It’s really

efficient for a sensitive Triac which has a high value internal R1

external gate to cathode capacitor or gate to cathode resistor is then in parallel and

improves immunity. When the positive dV/dt slope is applied on A1, there is no possibility to

reinforce this immunity. The gate electrode is on opposite side and there is no possibility to

add an external component in parallel with internal R2

6/15 Doc ID 022635 Rev 1

GK

P2

N3

K

(see Figure 7). The

GK

.

Page 7

AN4030 Gate to cathode capacitor, impact on dV/dt immunity

Figure 7. Triac simplified silicon structure with internal gate to cathode resistor

shown

A1

G

N1

Internal R1

N2

P2

GK

N4

A2

P1

N2

Internal R2

N3

GK

The gate to cathode capacitor thus has a totally different impact according to the bias

voltage. Ta bl e 1 and Ta bl e 2 give, for example, some dV/dt characterization results

respectively for one Triac (16 A, 600 V, 10 mA I

35 mA I

For the more sensitive device (I

device).

GT

= 10 mA), a 100 nF gate to cathode capacitor improves

GT

device) and for another Triac (16 A, 600 V,

GT

the dV/dt capability by a factor of 10, but only for positive voltage bias. For the other devices

(I

= 35 mA), the 100 nF gate to cathode capacitor does not have any impact on the dV/dt

GT

capability.

So a gate to cathode capacitor could be useful only for sensitive devices, but only for half the

time for appliances working on AC voltage. Experiments have shown that a gate to cathode

capacitor could improve the immunity level during IEC 61000-4-4 standard tests for the

more sensitive device (I

= 10 mA) but not for the 35 mA IGT device, as shown in

GT

Section 1.4.

Table 1. dV/dt characterization @ 125 °C and V

device (I

dV/dt

(V/µs)

= 10 mA)

GT

Without gate to cathode

Sample 1 Sample 2 Sample 1 Sample 2

Direct 360 450 2260 1900

Reverse 800 760 800 760

Doc ID 022635 Rev 1 7/15

capacitor

= 402 V for sensitive Triac

peak

With gate to cathode

capacitor (100 nF)

Page 8

Gate to cathode capacitor, impact on dV/dt immunity AN4030

Table 2. dV/dt characterization @ 125 °C and V

device (I

dV/dt

(V/µs)

= 35 mA)

GT

Without gate to cathode

capacitor

Sample 1 Sample 2 Sample 1 Sample 2

Direct 2350 1850 2350 1850

Reverse 2750 1950 2750 1950

= 402 V for less sensitive Triac

peak

With gate to cathode

capacitor (100 nF)

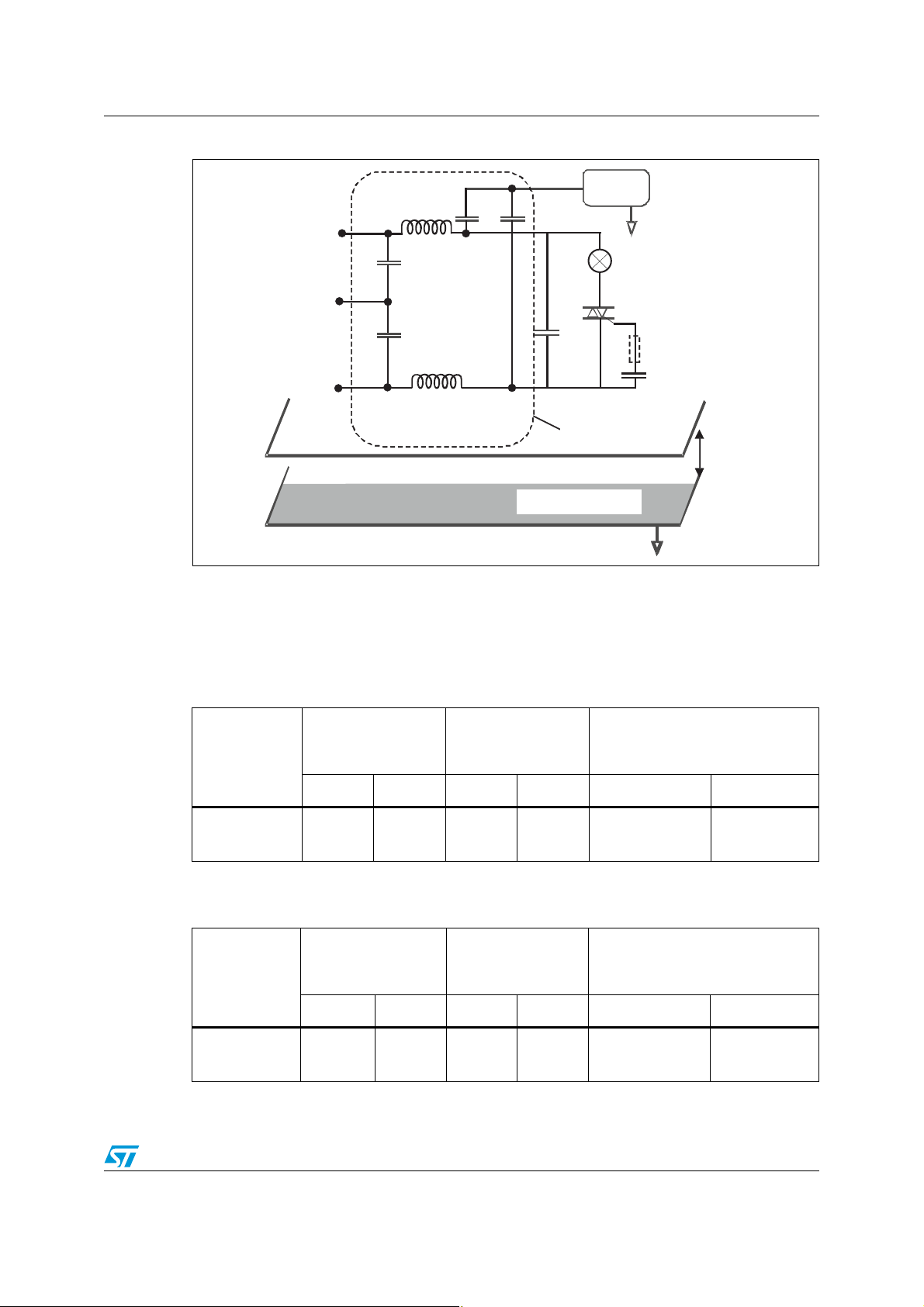

1.4 Behavior of Triacs to EFT (electrical fast transient)

To compare immunity between several Triacs (snubberless and logic level) with and without

gate to cathode capacitor, tests have been carried out in the following conditions (see

Figure 8):

● An X2 1nF capacitor is connected at line input.

● The PCB is 10 cm above the reference plane.

● The Triac A2 terminal is linked to a 25 W light bulb (resistive loads are chosen in order

to reduce dI/dt rates in case of firing).

● The gate could be left open, or connected to A1 terminal through an external gate to

cathode capacitor or connected to A1 through a 100 Ω R

cathode capacitor.

● No snubber circuits are added across the Triacs.

● Ambient temperature: 25 °C.

● The burst generator is programmed as required in the IEC 61000-4-4 standard (15 ms

burst duration, 3 Hz burst frequency, 5 kHz spike frequency, one second test duration).

in series with a gate to

G

8/15 Doc ID 022635 Rev 1

Page 9

AN4030 Gate to cathode capacitor, impact on dV/dt immunity

Figure 8. IEC 61000-4-4 test configuration

Burst

generator

L

PE

1 nF

X2

N

Coupling

network

Reference plane

R

G

C

GK

10 cm

PE

Ta bl e 3 and Ta bl e 4 give the test results for the two previous sample Triacs (logic level and

snubberless) with and without gate to cathode capacitor. A burst test is carried out for each

coupling mode (to line, to neutral, and to line and neutral). Only the minimum burst level

before turn-on, for all coupling modes, is recorded in these two tables.

Table 3. IEC 61000-4-4 tests results with logic level Triac - sensitive device

(I

= 10 mA)

GT

Without gate to

cathode capacitor

Sample 1 Sample 2 Sample 1 Sample 2 Sample 1 Sample 2

Minimum held

burst level (kV)

Table 4. IEC 61000-4-4 test results with snubberless Triac - less sensitive device

(I

1.3 1.3 3.6 3.5 3.3 3.2

= 35 mA)

GT

Without gate to

cathode capacitor

Sample 1 Sample 2 Sample 1 Sample 2 Sample 1 Sample 2

With gate to

cathode capacitor

(100 nF)

With gate to

cathode capacitor

(100 nF)

With R

With R

(100 Ω) and CGK (100 nF)

G

(100 Ω) and CGK (100 nF)

G

Minimum held

burst level (kV)

> 4.5 > 4.5 > 4.5 > 4.5 > 4.5 > 4.5

Doc ID 022635 Rev 1 9/15

Page 10

Gate to cathode capacitor, impact on dV/dt immunity AN4030

These experimental results show that there is no immunity improvement if a gate to cathode

capacitor is added to snubberless Triacs. Indeed, the immunity level is very high and above

our burst generator capability (4.5 kV).

On the other hand, logic level Triacs withstand a lower immunity level compared to

snubberless devices. This level is lower without gate to cathode capacitor. A 100 nF gate to

cathode capacitor improves almost by 3 the Triac immunity. But gate to cathode capacitor

lowers Triac reliability (refer to Section 2: Gate to cathode capacitor, impact on dI/dt

capability).

To keep the gate to cathode capacitor benefits without lowering system reliability, one

solution is then to add a resistor (R

) in series with gate to cathode capacitor. The immunity

G

level is then similar to that with the single gate to cathode capacitor. Such a resistor comes

for free, since the gate resistor, used to limit the control circuit output current, can be used

as R

.

G

Usually, logic level Triacs are driven directly by a microprocessor. MCU 4-4 immunity

behavior is improved by adding an RCR filter. A comparison with and without filter has been

performed with an ACST (I

max = 10 mA, 6 A on-state rms current) and an ST MCU. A

GT

capacitor is connected between 2 resistors and A1. One of these resistors (240 Ω) is

connected to the output of the MCU and the other one (50 Ω) to the ACST gate. This can

improve the level of immunity up to 600 V according to coupling, polarity and MCU output

configuration. For instance, with an MCU open drain output configuration, negative voltage

applied on Line, 4-4 immunity is 3.9 kV with a filter compared to 3.3 kV without a filter.

10/15 Doc ID 022635 Rev 1

Page 11

AN4030 Gate to cathode capacitor, impact on dI/dt capability

2 Gate to cathode capacitor, impact on dI/dt capability

As well as being almost ineffective in improving Triac immunity, a gate to cathode capacitor

has a major drawback when operating with Triacs. A gate to cathode capacitor significantly

decreases the Triac dI/dt capability. For example, Ta bl e 5 gives the experimental results

obtained in repetitive operation for a standard Triac (1 A, 600 V, 5 mA I

shows that the lifetime of the device is drastically reduced when a 100 nF or 10 nF gate to

cathode capacitor is added. On the other hand, the Triac dI/dt capability remains if a resistor

is added in series with a gate to cathode capacitor.

Table 5. Repetitive dI/dt tests results with a standard 1 A Triac

). Ta bl e 5 clearly

GT

Without gate to

cathode capacitor

dI/dt (A/µs) 30 30 30

I

(A) 3.5 3.5 3.5

peak

Number of cycles

(million of cycles)

Results 0 failed / 20 8 failed / 10 0 failed / 10

50 0.1 50

With gate to cathode

capacitor (100 nF)

With RG (50 Ω) and

(100 nF)

C

G

The high density current during charge and discharge of the capacitor explained the poor

life time with a gate to cathode capacitor. In case of an R

circuit, the resistor in series

G-CG

limited this density of current. Triac dV/dt immunity is improved with this circuit and dI/dt

capability is not decreased.

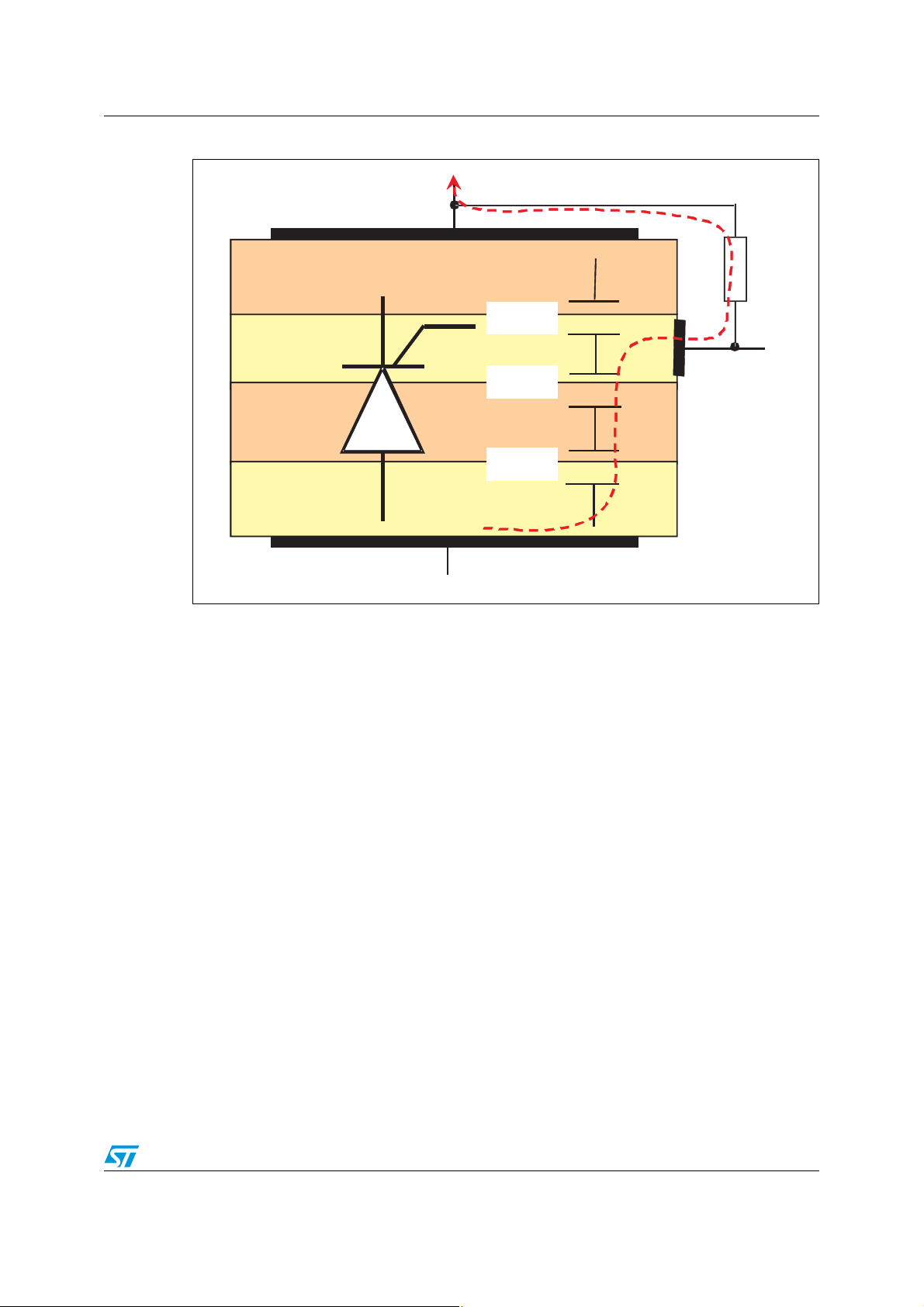

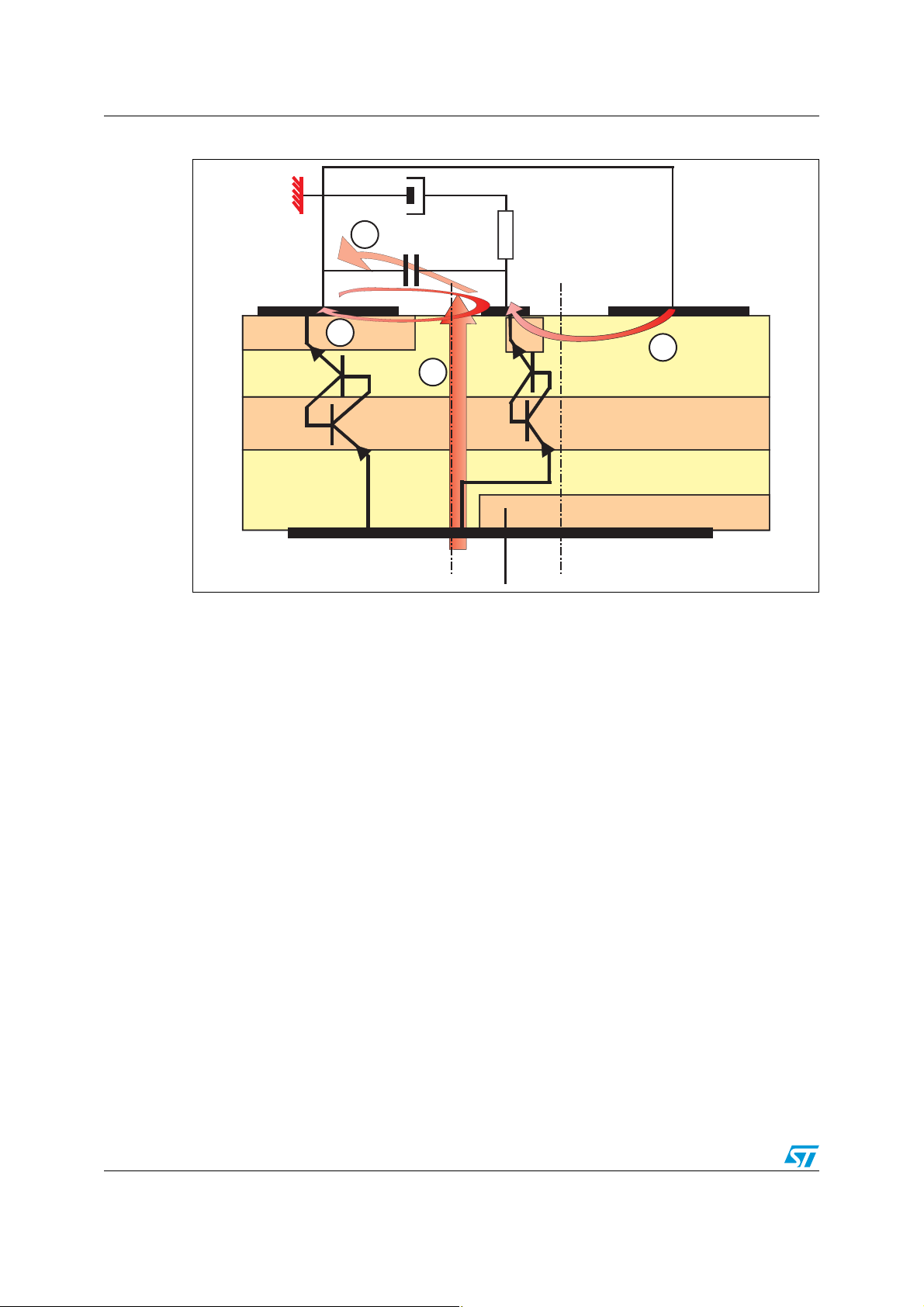

Figure 9 gives the different operating steps when a Triac is switched on in quadrant 2

(V

> 0 and IG < 0) with a gate to cathode capacitor.

T

The event sequence is as follows.

1. The triggering current is first sunk from the gate by the control circuit.

2. The pilot SCR is turned on. This pilot SCR is implemented by the P2-N2-P1-N4 layers.

It is not the same SCR that is on at the end of this switching-on process.

3. A high inrush current circulates through the gate to cathode capacitor due to the pilot

SCR turn-on (without gate to cathode capacitor, the gate current would be limited by

the gate resistor R

).

G

4. The gate to cathode capacitor is discharged after the main SCR turn-on. This SCR is

implemented by the P2-N2-P1-N1 layers. This causes a high peak gate current and

can damage the Triac.

Doc ID 022635 Rev 1 11/15

Page 12

Gate to cathode capacitor, impact on dI/dt capability AN4030

Figure 9. Sequence of events during Triac switch-on in quadrant 2

N1

P1

N2

P2

A1

3

I

C

C

GK

4

2

I

T

++

R

G

G

I

N4

A2

G

1

P1

N2

P2

N3

Even if the Triac is driven in zero voltage switch mode, a spurious turn-on could appear and

a high dI/dt could run through pilot SCR. A gate to cathode capacitor could increase the

failure rate as explained above. For example, for the sensitive logic level Triac described in

Section 1.4, non repetitive dI/dt capability robustness in Q2 is divided by around 2 with a

gate to cathode capacitor: 360 A/µS with C

= 200 nF and 670 A/µs without gate to

GK

cathode capacitor.

This behavior is not linked to the Triac technology but directly linked to the internal device.

So, whatever the technology, a gate to cathode capacitor will decrease dI/dt capability in

repetitive or in accidental mode.

12/15 Doc ID 022635 Rev 1

Page 13

AN4030 Conclusion

3 Conclusion

To increase power semiconductor device immunity to fast transient voltages it is quite

common to add a capacitor between the control terminal (gate or base) and the drive

reference terminal (source, emitter, cathode or A1 terminal). For SCRs, the drive reference

is the cathode, K. A gate to cathode capacitor is then usually added with very sensitive

devices and could be very useful to increase SCR immunity to dV/dt.

This Application note shows that as well as being almost ineffective in improving Triac

immunity, a gate to cathode capacitor has a major drawback when operating with Triacs.

Such a capacitor increases the failure rate when repetitive dI/dt rates are applied at turn-on

or in case of spurious turn-on with high dI/dt.

Explanations of silicon structure behavior during turn-on show the supplementary stress

due to a gate to cathode capacitor

capacitors should be removed from Triac designs.

irrespective of technology choice. This shows that such

Doc ID 022635 Rev 1 13/15

Page 14

Revision history AN4030

4 Revision history

Table 6. Document revision history

Date Revision Changes

27-Mar-2012 1 Initial release.

14/15 Doc ID 022635 Rev 1

Page 15

AN4030

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY TWO AUTHORIZED ST REPRESENTATIVES, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2012 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Philippines - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

Doc ID 022635 Rev 1 15/15

Loading...

Loading...