Page 1

Introduction

AM10219V1

AN4016

Application note

2 kW PPA for ISM applications

STMicoelectronics has recently introduced a new generation of high voltage DMOS

products housed in STAC

up to 1.2 kW for industrial, scientific, and medical applications such as 1.5 T and 3 T

magnetic resonance imaging (MRI). This new air-cavity technology now enables lower

thermal resistance, lower weight, and reduced cost compared to devices in ceramic

packages.

In this application note we report on the design of a 2 kW-100 V, 123 MHz Class AB peak

power amplifier (PPA) for 3 Tesla MRI applications. It almost doubles the output power of

previous amplifiers using MOSFET transistors in standard ceramic packages. The design

techniques and construction practices are described in enough detail to permit duplication

of the amplifier. The devices used in this amplifier are two STAC4932B N-channel

MOSFETs in a push-pull configuration capable of 1.2 kW each, under pulse conditions, and

housed in the STAC244B, a bolt-down air cavity package.

The design goals for the amplifier are:

■ Frequency: 123 MHz

■ Supply voltage: 100 V

■ Pulse conditions: 1 msec – 10%

■ Output power: > 2 kW

■ Gain: > 19 dB

■ Efficiency: > 60%

Figure 1. STEVAL-IMR002V1

®

air cavity packages and capable of delivering an output power of

December 2011 Doc ID 022523 Rev 1 1/17

www.st.com

Page 2

Contents AN4016

Contents

1 Design choices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2 Circuit description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3 Layout, parts list, and design considerations . . . . . . . . . . . . . . . . . . . . 7

4 MRI board performance and application . . . . . . . . . . . . . . . . . . . . . . . . 14

5 Conclusion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

6 References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

7 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2/17 Doc ID 022523 Rev 1

Page 3

AN4016 Design choices

P1_RF INPUT

SMA_Female

P2_RF OUTPUT

N_Female

GND

GND

Q3

Q4

Q2

Q1

GND

GND

C31

C32

GND

R13

C9C14

GNDGND

+

C6

GND

C21

C40

R4

C18

R6

R8

R10

R12

R14

R15

C41

GND

R19

R20

R21

R25

R26

R27

GND

VCC

+

C13+C12

GNDGND

C23

C28

C30

GND

R17

R22

R3

Vg1

C34

C16

GND

+

C3

GNDGND

L2

C7

C10

GNDGND

+

C15

GND

R7

C8

C11

GNDGND

C17

STAC4932B

STAC4932B

T1

T2

L14

L3

R30

R1

C57

GND

GND

C58

L5

R24

Vg2

C48+C47

GNDGND

L13

C49

C52

GNDGND

+

C51

GND

R29

C50C53

GNDGND

L15

GND

L10

L8

L16

L12

L4

GND

C2

GND

R11

R16C24

GND

C20

C36

C45

R31

C55

GND

GND

GND

GND

GND

R28

R5

R9 GND

GND

C33

C37

C26C25

Rm

(~5 V typ)

(~5 V typ.)

(+100 V)

D1

LED

R32

GND

R33

GND

R34

R35

GND

C60

C59

C61

C63

C62

C64

VBIAS_1

VBIAS_1

VBIAS_1

VBIAS_2

VBIAS_2

VBIAS_2

GND

GND

Rm

GND

GND

C29

GND

GND

C42

J1

J2

J3

GND

Line_Bridge

GND

GND

1

2

3

CON3

1

2

3

CON3

Vg1

GND

GND

Vg2

1

CON11CON1

GND

Input Board 3 layer

Output Board 2 layer

C4

AM10220V1

1 Design choices

The main objectives of the 2 kW power amplifier design are board compactness (100 x 150

mm), full SMT technology, and to avoid the use of ferromagnetic components and coaxial

transmission line transformers.

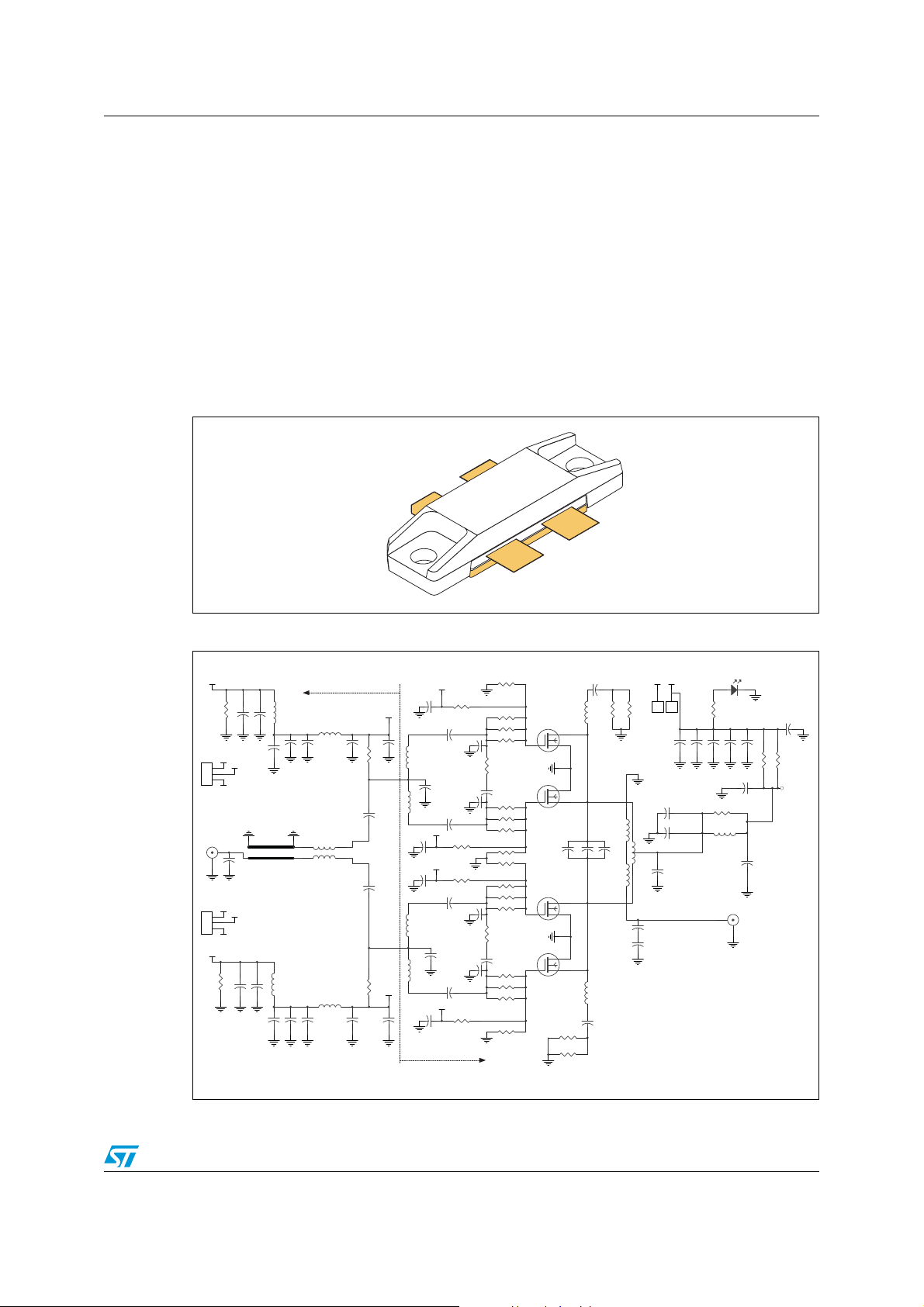

In summary, see circuit diagram in Figure 3, the power amplifier uses double push-pull boltdown devices, 2 x STAC4932B (see Figure 2) operate in Class AB. The two STACs are

driven in push-pull through the transformer T1 together with two in-phase power splitters:

this choice seems to be the best topology layout in terms of circuit size and mechanical

compactness. Moreover, as the temperature coefficient of MOSFET channel resistance is

positive, this makes a short-circuit possible in each pair of STAC4932B drains.

Figure 2. STAC244B bolt-down package

Figure 3. STEVAL-IMR002V1 circuit diagram

Doc ID 022523 Rev 1 3/17

Page 4

Design choices AN4016

Therefore, a compact design can be realized: only one RF output matching network, with

one impedance transformer T2, and an RF input matching network that supports the phase

and amplitude signals on each of the two gates STAC4932B (electrical symmetry).

The schematic incorporates the necessary input / output biasing networks for proper feed

biasing on the gates and drains.

Finally, planar microstrip technology was the main choice for the design of RF circuits: in

particular, the design of transformers T1 and T2 is fully embedded into the substrate (PCB)

itself as RF planar structures, and allows easy assembly of the design.

4/17 Doc ID 022523 Rev 1

Page 5

AN4016 Circuit description

2 Circuit description

The Input RF network must be carefully designed respecting the correct electrical symmetry,

because it is affected by driving high level signals (Pin ~ 20 W), and is made up of:

1. Balun transformer T1, λ / 4-25 Ohm transmission line type @ 123 MHz, needed to

lower the 50 Ohm RF input impedance to 12.5 Ohm, and is realized in a stripline

technique on a 2-layer substrate (Roger 4350B, with a thickness of 20 +20 mils: see

Figure 5) and is fed by a suspended microstrip line ('line bridge' in Figure 3). Moreover,

T1, being a quasi one-dimensional RF structure, can be mapped on the PCB without

compromising the electrical symmetry. T1, finally, is loaded from R7 and R29 in order to

dampen reflected waves from the gates and for stability purposes.

2. Two in-phase power splitters (L4, L8, C16, C18, C20) and (L12, L16, C36, C41, C45)

simply decrease the impedance level (2 Ohm), and more importantly, allow the gates of

each STAC4932 to be kept isolated.

3. RF decoupling filters, fed through the VG1 and VG2 connectors (Figure 3) need to bias

each STAC4932B gate. They are essentially LC multi-section filters with capacitors of

several technologies (tantalum, ceramic) to improve effective broadband RF isolation.

Independent voltage dividers act on the 4 gates (R4, R32, R16, R33, R17, R34, R31, R35)

to assure broadband RF stability, while the lower value series resistors (R6, R8, R10, ...)

need to dampen mismatching reflections on the gate impedance and then mitigate any

asymmetries on the gate impedance value.

The output RF network acts on the DMOS drains, in order to achieve optimal impedance by

means of the RF transformer T2, and also to properly feed high DC current filtered at

Vd=100 V, through the output biasing network directly via the primary winding of T2.

The transformer T2 (ratio 4:1) is designed on the top/bottom layers (see Figure 7) using

substrate Roger 4350B of 60 mils thickness in suspended broadside coupled strips and acts

as a composite transmission line transformer in balanced to unbalanced mode. The RF

output (type N-female connector) is directly connected to the winding output strip of T2 (see

top view in Figure 7) through an air suspended microstrip-line (50 Ohm): in this way, the

current (differential) generated on the primary winding strip (on the top layer) between the

two STACs is moved from T2 versus unbalanced RF output by the ground of the plate

copper carrier (see Figure 8) without further wave discontinuity, therefore avoiding losses

and creating a reliable design to support very high RF output power.

The transformer T2 has been designed using commercially available SW (ADS, HFSS) and

continues the refinement between electromagnetic and circuit simulation: T2, in fact, uses a

lamped capacitor (C25, C26, C23 caps group on winding top strip, and C37, C42 caps

group on the bottom side strip) to tune the proper impedance for DMOS drains.

In particular, the output biasing network (acts through the center tap of the winding top strip

of T2) uses several multilayer ceramic capacitors, and also adds the following electrical

functions:

1. Dampens voltage overshoot generated by each transient effected by pulsed RF

modulation: that is the group L10, R13, C29, C30, C33.

2. Two test points can be inserted between two calibrated Rm resistors for current /

voltage monitoring.

3. Lamp LED D1, for safety purposes.

Doc ID 022523 Rev 1 5/17

Page 6

Circuit description AN4016

Finally, the two bipole groups, consisting of L3-C37-R1/R5 and L14-C58-R28/R30, are

inserted in the drain side of the amplifier and give more flexibility to the impedence, for

example, it is used to improve low frequency stability, or to dominate harmonic impedance,

or as broadband internal RF loads.

6/17 Doc ID 022523 Rev 1

Page 7

AN4016 Layout, parts list, and design considerations

3 Layout, parts list, and design considerations

As mentioned previously (see Figure 3), the amplifier is built with separated input-output

PCB cards:

a) The input PCB, as shown in Figure 5, integrates the RF balun transformer, T1,

together with the RF decoupling networks.

b) The output PCB, see Figure 7, however, relates to the design of the RF

transformer, T2, with the remaining biasing/filtering networks for the gates and

drains of STAC4932B.

An image of the assembled board is shown in Figure 1, while Tabl e 1 gives the part list.

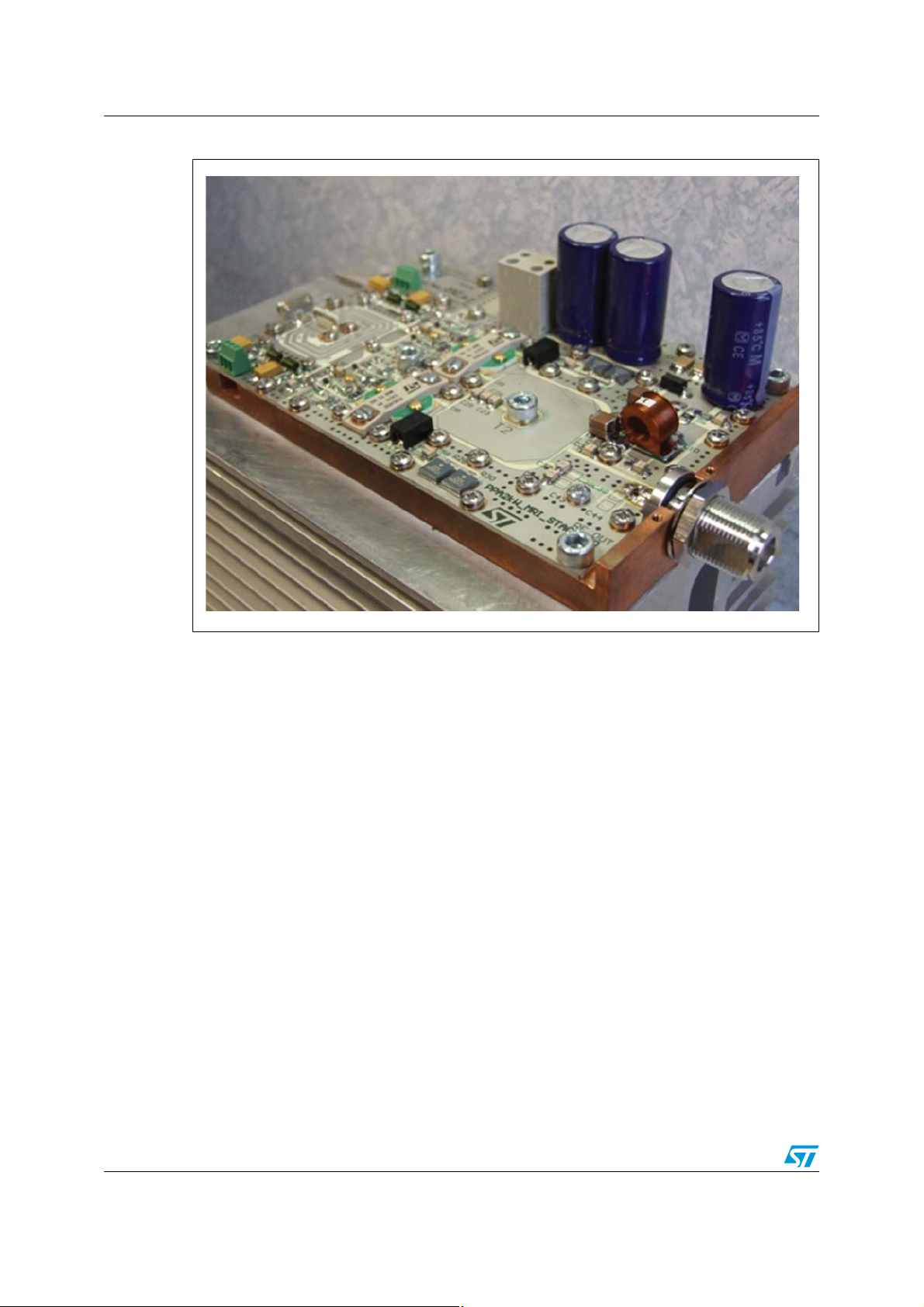

Figure 4, shows the final assembled board on the copper carrier and heatsink: board

robustness is an important factor in order to ensure electrical stability to manage very high

RF power.

The PCB cards are built in substrate Roger 4350B, in order to reduce dielectric losses

through the Joule effect (50 to 100 W less when compared to FR4 @ 2 kW), and in

particular to maintain thermal expansion compatibility with the copper carrier. Another

aspect of this rigid thermoset laminate allows the creation of a PCB with very good surface

finish, planarity and roughness, which are compatible with copper carrier surfaces that

support it. In fact, a carefully finished PCB surface is recommended: HAL LF with tinned

chemical deposition.

Moreover, accurate mounting procedures need to avoid bending/dirt that can compromise

the planarity of PCB cards.

Doc ID 022523 Rev 1 7/17

Page 8

Layout, parts list, and design considerations AN4016

AM10221V1

Figure 4. 2 kW MRI final assembled board

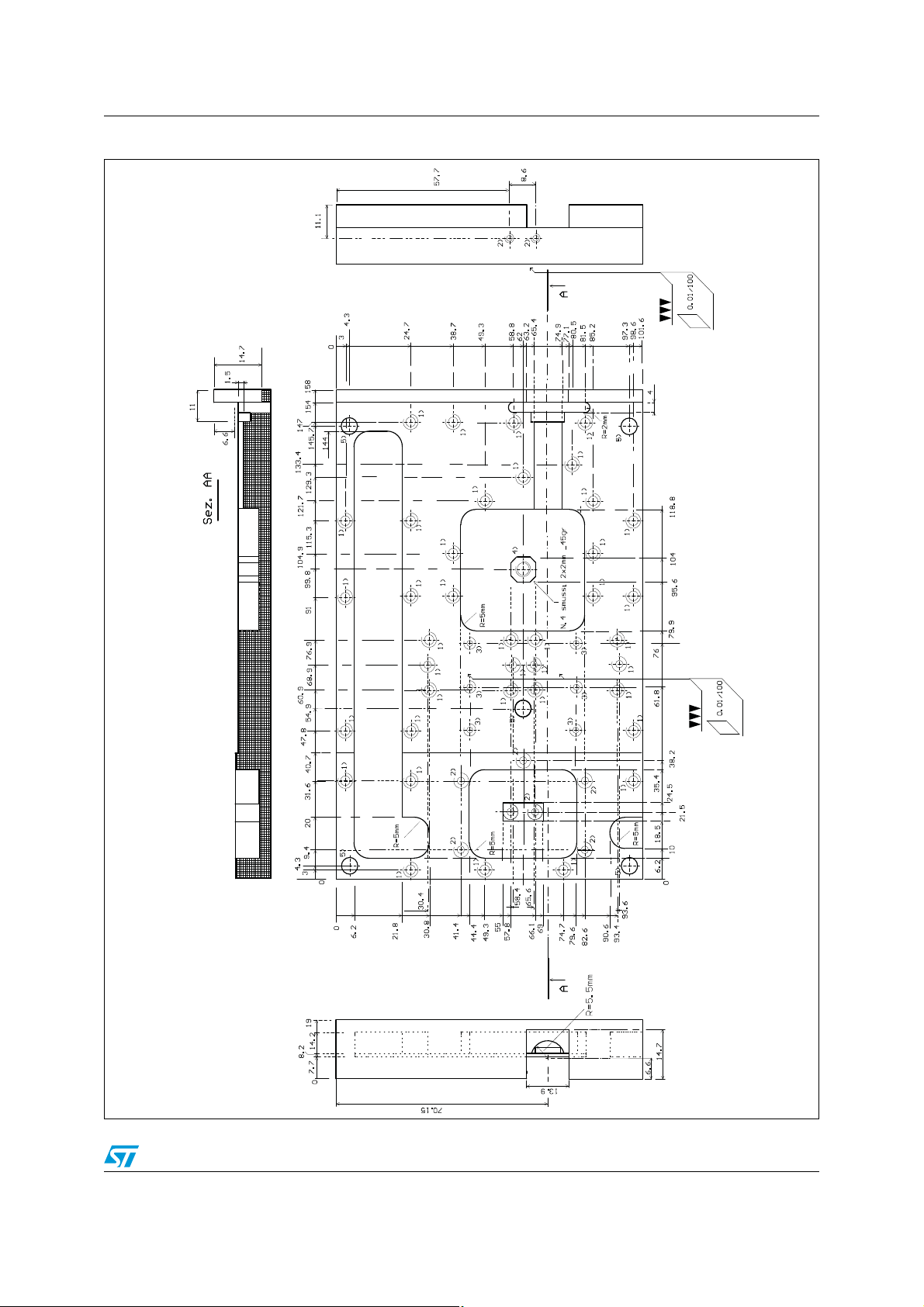

Figure 5 and Figure 7 show the input and output PCB cards, top and bottom-side. A

mechanical drawing of the base-plate is shown in Figure 8: in particular, the two

counterbores housing the transformers T1 and T2, are designed to control the unwanted

parasitic impedance (leakage) to ground.

8/17 Doc ID 022523 Rev 1

Page 9

AN4016 Layout, parts list, and design considerations

AM10222V1

Figure 5. Input PCB, and top and bottom view

The new package technology (STAC

®

) allows very low thermal impedance to be achieved,

Rtjc = 0.075 K / W (with T = 1 msec pulsed RF/Duty = 10%), so that, in combination with a

suitable heatsink (heatsink @ Rca <0.2 K / W max.), it permits the junction temperature to

be lower than the rating (Tjmax = 200 degC): in fact, considering a 60% efficiency @ 2200

W, a DeltaTjc = 56 ° C, and DeltaTca <15 ° C, a Tj=95 ° C max. junction temperature can be

expected.

The ability of STAC

®

to dissipate a high power pulse (see AN3232) allows the possibility to

reduce board dimension and external heatsinks; so that, using the flangeless package

STAC 244F (see Figure 6), you can design a new board with the same electrical

characteristics but with a dimension target of 80 x 100 mm.

Figure 6. STAC244B

Doc ID 022523 Rev 1 9/17

Page 10

Layout, parts list, and design considerations AN4016

AM10223v1

Figure 7. Output PCB, top and bottom view

Table 1. 2 kW MRI part list

Component ID Value Manufacturer Part code

C12, C13, C6 1000 µF, 100 V Panasonic ECA2AM102

C10, C11, C52, C53 100 nF Murata GCM188R71E104KA57D

C28 4.7 µF, 100 V TDK CKG57NX7R1E226M

C29 15 µF, 100 V Murata KRM552R72A156M

C15, C51 10 µF, 35 V KEMET T494D106K035AT

C3,C47 100 µF, 20 V KEMET T491X107K020AT

C4, C7, C48, C49 22 µF, 25 V Murata GRM32ER61E226ME15

C18, C41 300 pF ATC ATC100B301FWN200XC

C16, C20, C36, C45 68 pF ATC ATC800A680JTN250X

10/17 Doc ID 022523 Rev 1

Page 11

AN4016 Layout, parts list, and design considerations

Table 1. 2 kW MRI part list (continued)

Component ID Value Manufacturer Part code

C30 1000 pF ATC ATC100B102FWN300XC

C57, C58 3.3 pF ATC ATC100B3R3BW1500XT

C8, C31, C32, C50 470 pF ATC ATC 100B 471FWN200XC

C2, C17, C24, C34, C40, C55,

C59, C60, C61, C62, C63, C64

C9, C14 1 µF, 100 V AVX 22201C105KAT2A

C33 1 µF, 100 V AVX 12101C105K4Z2A

C21 18 pF ATC ATC100B180FWN1500XT

C25 75 pF ATC ATC100B750FWN1500XC

C26, C23 100 pF ATC ATC100B101FWN1500XC

C37, C42 56 pF ATC ATC100B560FWN1500XC

L10 700 nH Coilcraft CP-K0376-A

L2, L5, L13, L15 82 nH Coilcraft 1515SQ-82NJEB

L3, L14 110 nH Coilcraft 132-10SMJ

L4, L8, L12, L16 5.4 nH Coilcraft 0906-5JLB

R1, R5, R28, R30 50 Ω, 100 W Anaren C100N50Z4

R9 5600 Ω Tyco Electronics SMF25K6JT

R13 22 Ω Tyco Electronics SMW222RJT

R7, R29 100 Ω Panasonic ERJP14J101U

R11, R22 4.7 Ω Vishay 4.7 Ohm -1206

R3, R24 43 Ω Panasonic ERJP14J430U

2000 pF ATC ATC 200A202KTN50C

R32, R33, R34, R35 27 Ω Panasonic ERJP14J270U

R4, R16, R17, R31 20 Ω Panasonic ERJP14J200U

R6, R8, R10, R12, R14, R15, R19,

R20, R21,R25,R26, R27

Rm x 2 0.001 mΩ Tyco Electronics TL3A R001 1%

1P_J3 1 double pole Wieland 25.700.0153.0

Spacer_J3 Spacer Wieland 07.300.2753.0

3P_J1,J2 3 poles PHOENIX CONTACT 1725669

P2 N_Female Telegartner J01021A1084

P1 SMA_Female RADIALL R124.510.000W

(Q1-Q2)/(Q3-Q4) STAC4932B STMicroelectronics STAC4932B

D1 LED Kingbright KP-1608SURC

1 Ω Phycomp 232271111108

Doc ID 022523 Rev 1 11/17

Page 12

Layout, parts list, and design considerations AN4016

Table 2. Materials part list

Component Description

Line bridge

Board input

Fin fixing

Board output

Mechanical

plate

Roger 4350B, three layers, 20+20 mils, 1 OZ Cu on top-mid-bottom layers, Finit. metal HAL LF;

total Tk=1.2 mm max., top screen printing component, tin chemical surface deposition.

Roger 4350B, three layers, 20+20 mils, 1 OZ Cu on top-mid-bottom layers, Finit. metal HAL LF;

total Tk=1.2 mm max., top screen printing comp., tin chemical surface deposition.

Roger 4350B, two layers, Tk=60 mils, 1 OZ Cu on top- bottom layers, Finit. metal HAL LF; total

Tk=1.6 mm max., top screen printing comp., tin chemical surface deposition.

Roger 4350B, two layers, Tk=60 mils, 1 OZ Cu on top-bottom layers, Finit. metal HAL LF; total

Tk=1.6 mm max., top screen printing comp., tin chemical surface deposition.

PPAMRI_002-Rev B

12/17 Doc ID 022523 Rev 1

Page 13

AN4016 Layout, parts list, and design considerations

AM10224V2

Figure 8. Base-plate copper carrier

Doc ID 022523 Rev 1 13/17

Page 14

MRI board performance and application AN4016

-20

-18

-16

-14

-12

-10

-8

-6

-4

-2

0

5

7

9

11

13

15

17

19

21

23

25

105 110 115 120 125 130 135

IRL(dB

)

Gain(dB)

Freq(MHz

)

STAC4932B -

Gain & IRL Vs Freq @ Pin=43 dBm

PULSED WIDTH= 1msec, DUTYCYCLE =10%

Vds=100 VDC, Idq=2 x 100 mA

Gain

IRL

STAC244B

AM10225V1

4 MRI board performance and application

The power amplifier has been measured on two different RF scalar test benches: RF Power

Lab. in STM Catania (Italy) and RF Power Lab. in STM Quakertown (USA): the

measurements are in good agreement (+ / -0.15 dB max. error). The test includes a 2

kW/CW attenuator and a pulsed RF generator with high power amplifier driver to manage

large signals at RF input (20 W min.) with good harmonic rejection (-30 dBc).

Figure 9. Gain and IRL frequency response

Figure 9 shows the large signal gain frequency response of the amplifier, as well as the

input return loss, while Figure 10 shows the gain compression curve and the drain efficiency

curve Vs output power at 123 MHz (Idq = 200 mA and Vds = 100 V) and RF pulse width=1

msec, duty cycle=10%. The maximum efficiency is 60% @ 2.2 kW of output power.

14/17 Doc ID 022523 Rev 1

Page 15

AN4016 Conclusion

0

10

20

30

40

50

60

70

80

90

100

5

7

9

11

13

15

17

19

21

23

25

0 500 1000 1500 2000 2500

Drain Eff.(%)

Gain(dB)

Pout(W)

STAC4932B -

Gain & Eff. Vs Pout @ 123 MHz

PULSED WIDTH= 1msec, DUTYCYCLE =10%

Vds=100 VDC, Idq=2 x 100 mA

Gain

Eff.

AM10226V1

Figure 10. Gain and drain efficiency vs. output power

For IMS applications, two or more boards can be embedded to realize high power RF chains

(4 kW or more): e.g., 10 kW RF power can be obtained by linking six RF basic units,

properly using a Gysel power combiner, and integrated with the appropriate λ / 4

transmission lines to improve electrical stability, together with a control/monitoring card to

support global safety.

5 Conclusion

A pulsed RF high power amplifier (> 2 kW) has been described as a guideline-design,

oriented to new high voltage DMOS devices at Vd = 100 V: STAC4932B. In particular, the

amplifier combines excellent high frequency response with an efficient use of DC power and

allows a very compact design and robustness, in conjunction with SMT technology and

joined to the fully planar microstrip design (RF transformers). This amplifier can be

understood as the basic unit for high power RF chains to achieve very high power for an RF

pulse generator in the RF systems for medical magnetic resonance imaging (3T-fMRI).

6 References

● RF and Microwave Power Amplifier Design, by Andrei Grebennikov - Mc Graw Hill,

● Essentials of RF and Microwave Grounding, by Eric Holzman - Artech House, 2006

● AN3232 application note.

2005.

Doc ID 022523 Rev 1 15/17

Page 16

Revision history AN4016

7 Revision history

Table 3. Document revision history

Date Revision Changes

23-Dec-2011 1 Initial release.

16/17 Doc ID 022523 Rev 1

Page 17

AN4016

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY TWO AUTHORIZED ST REPRESENTATIVES, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2011 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Philippines - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

Doc ID 022523 Rev 1 17/17

Loading...

Loading...