Page 1

AN3995

Application note

Getting started tutorial

for SPC564Bxx and SPC56ECxx family

Introduction

The SPC564Bxx and SPC56ECxx is a family of Power Architecture® based microcontrollers

that target automotive vehicle body and gateway applications such as Central body

controller, Smart junction boxes, Front modules, High end gateway, Combined Body

controller and gateway.

These dual core architecture devices contain an e200z4d and e200z0h core, compliant with

the Power Architecture standard.

It provides the scalability needed to implement platform approaches and delivers the

performance required by increasingly sophisticated software architectures.

These devices feature up to 3 MB of internal Flash and up to 256 KB of internal SRAM

memory.

It operates at speeds of up to 120 MHz and offers high performance processing optimized

for low power consumption.

The SPC564Bxx and SPC56ECxx family expands the range of the SPC560B/C

microcontroller family but differs from it by being the first device to feature the e200z4d core

and the e200z0h in a dual core configuration.

The differences between this family and the previous one (SPC560B/C) mean that the

initialization and configuration are different.

This application note details the steps required to properly initialize the SPC564Bxx and

SPC56ECxx from reset as well as how to control the second core. An example code is

described throughout the application note to explain the steps.

It is intended that this application note is read along with the SPC564Bxx and SPC56ECxx

Reference Manual, RM0070 that can be obtained from the STMicroelectronics

http://www.st.com (see Section C.1: Reference document).

®

website at

November 2011 Doc ID 022384 Rev 1 1/49

www.st.com

Page 2

Contents AN3995

Contents

1 Application example description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2 Microcontroller boot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1 Boot mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1.1 Bootable sectors and RCHW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3 e200z4d initialization and example code . . . . . . . . . . . . . . . . . . . . . . . 10

3.1 Creating e200z4d Flash boot file . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.1.1 MMU remarks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.1.2 Configure MMU for SRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.1.3 Initialize the SRAM ECC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.1.4 Configure MMU for Flash . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.1.5 Configure MMU for Peripheral Bridge . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.1.6 Memory initialization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.1.7 Performance Hints Initialization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.2 e200z4d device configuration from C code . . . . . . . . . . . . . . . . . . . . . . . 24

3.2.1 Disable watchdog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3.2.2 Mode configuration and clocking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.2.3 Clock & PLL configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

3.2.4 Configure Cache . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

3.2.5 Starting the e200z0h core . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

3.3 The e200z4d example code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4 e200z0h Initializations and example code . . . . . . . . . . . . . . . . . . . . . . 32

4.1 e200z0h startup code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Appendix A Application code example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

A.1 main.c file . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

A.2 crt0_corez4_Flash.s . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Appendix B Linker file . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Appendix C Further information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

C.1 Reference document . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

2/49 Doc ID 022384 Rev 1

Page 3

AN3995 Contents

C.2 Acronyms and abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Doc ID 022384 Rev 1 3/49

Page 4

List of tables AN3995

List of tables

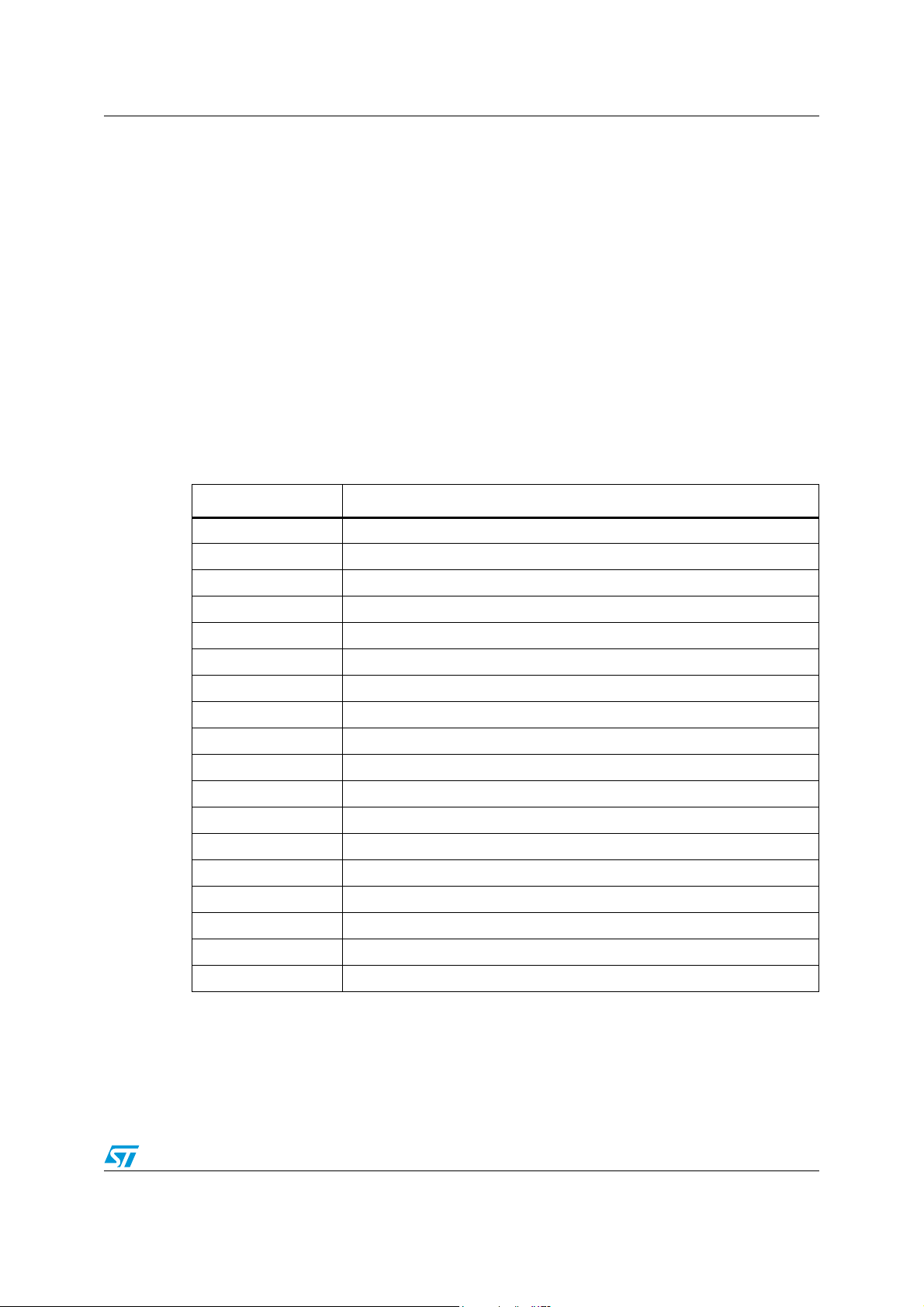

Table 1. Boot mode selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Table 2. RCHW field description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Table 3. Example of MMU configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Table 4. Memory partition schema . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Table 5. Acronyms and abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Table 6. Document revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

4/49 Doc ID 022384 Rev 1

Page 5

AN3995 List of figures

List of figures

Figure 1. Boot sector structure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

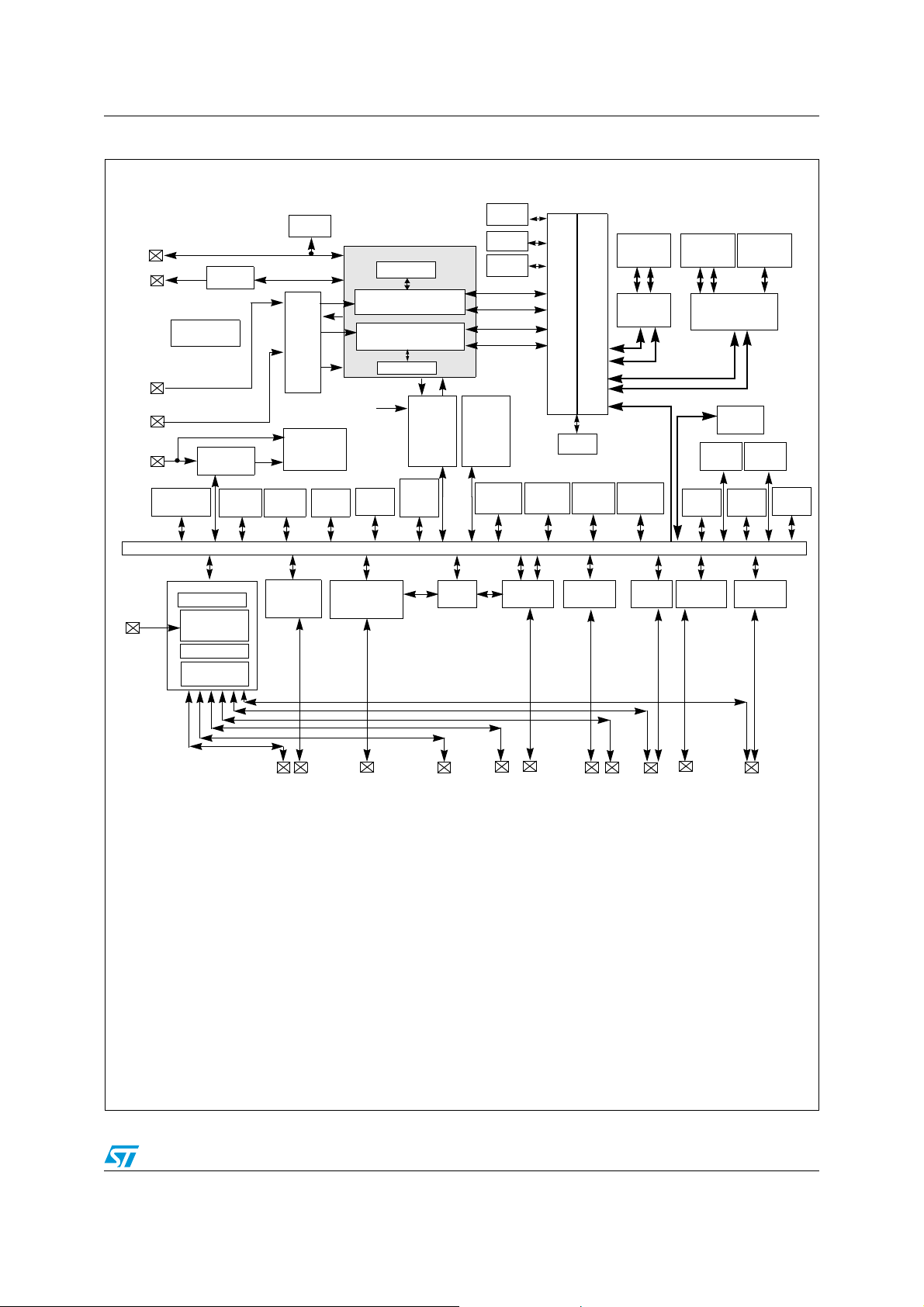

Figure 2. SPC564Bxx/SPC56ECxx block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Figure 3. MMU configuration code for SRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Figure 4. SRAM ECC initialization code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Figure 5. MMU configuration code for Flash . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 6. Code to copy configuration code from Flash to SRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 7. MMU configuration code for peripherals area. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 8. Booting flow using GHS startup libraries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 9. Startup file: __ghs_board_memory_init . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Figure 10. Startup file: branch to GHS startup libraries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Figure 11. Startup file: enable BTB and SPE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 12. Startup file: Flash Configuration code. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 13. Startup file: SRAM wait states configuration code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 14. Startup file: XBAR register configuration values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 15. Startup file: XBAR configuration code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Figure 16. Cache Configuration Code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Figure 17. Environment configurations code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Figure 18. SWT disabling code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Figure 19. Mode entry diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Figure 20. Mode Initialization Code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Figure 21. Peripheral Control Registers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Figure 22. Run peripheral control registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Figure 23. System clock dividers configuration code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Figure 24. PLL configuration code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Figure 25. Application code: the main function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Figure 26. e200z0h startup code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Doc ID 022384 Rev 1 5/49

Page 6

Application example description AN3995

1 Application example description

This application note describes the necessary steps to configure the device in order to run

two independent codes on the two cores.

This family is quite different from the previous one, indeed apart from the memories size

now it has been introduced the dual core concept: in the SPC564Bxx and SPC56ECxx

family the primary core is an e200z4d while the second one is a e200z0h.

While the second core (e200z0h) is thought only as performance core (only to speed up the

execution), the introduction of the e200z4d implies that the user has a more powerful

architecture to cope with the application tasks.

The availability of MMU, ICache and Signal Processing instructions enhance the

performance, but require the correct configuration.

The example code described herein toggles two LEDs with each core running the

application independent of the other.

It has been chosen to treat the two applications separately to better understand the dual

core concept even for compiler projects: of course each project produces one executable

image. The user then has to program the device with both executable images (the

instruction codes are located in different places).

Following this strategy the device is perceived as two separate MCUs each with proprietary

Flash and SRAM.

In this application note, it has been decided to split (in equal parts) the Flash and the SRAM

for both cores.

The memory partition and the XBAR (crossbar architecture) have been optimized for dual

core operations and in particular to give priority to e200z4d core (see Section 3.1.7:

Performance Hints Initialization):

● The SRAM is split over 2 slave ports, 0x4000_0000 to 0x4001_FFFF on slave port 2

(used by e200z4d) and 0x4002_0000 to 0x4003_FFFF on slave port 3 (used by

e200z0h);

● There are 2 Flash ports, z4 instruction port on slave port 0 and a second Flash port for

everything else on slave port 1.

By splitting the SRAM in the linker file(s) so that the e200z4d has access to one block and

the e200z0h has access to the other block, crossbar contentions are generally avoided

between the cores for SRAM access

(a)

(see Appendix B: Linker file).

a. When, for example, there are large amounts of DMA transfers to/from SRAM it could be useful to use the

SRAM allocated to the processor which allows fewer accesses to SRAM. User has to take care that none of

this prevents either core from writing the full SRAM array so care has to be taken in software (using

semaphores and / or software interrupts) to ensure memory coherency.

6/49 Doc ID 022384 Rev 1

Page 7

AN3995 Microcontroller boot

2 Microcontroller boot

This chapter describes the configuration required by the user, and the steps performed by

the microcontroller

(b)

and in particular, by the SSCM (System Status and Configuration

Module), in order to achieve a successful boot from Flash memory.

For further information, look at SPC564Bxx and SPC56ECxx Reference Manual (see

Section C.1: Reference document).

2.1 Boot mechanism

SPC564Bxx and SPC56ECxx family (as other SPC56xx devices), has two hardware boot

configuration pins, FAB (Force Alternate Boot mode) and ABS (Alternate Boot Select).

These 2 external pins on the microcontroller are latched during reset and used by the SSCM

to determine whether the microcontroller boots from Flash memory or attempts a serial

download via FlexCAN or LINFlex (RS232) (see Tab l e 1 ).

In this application note, the focus is on the default operating mode: the Flash boot mode.

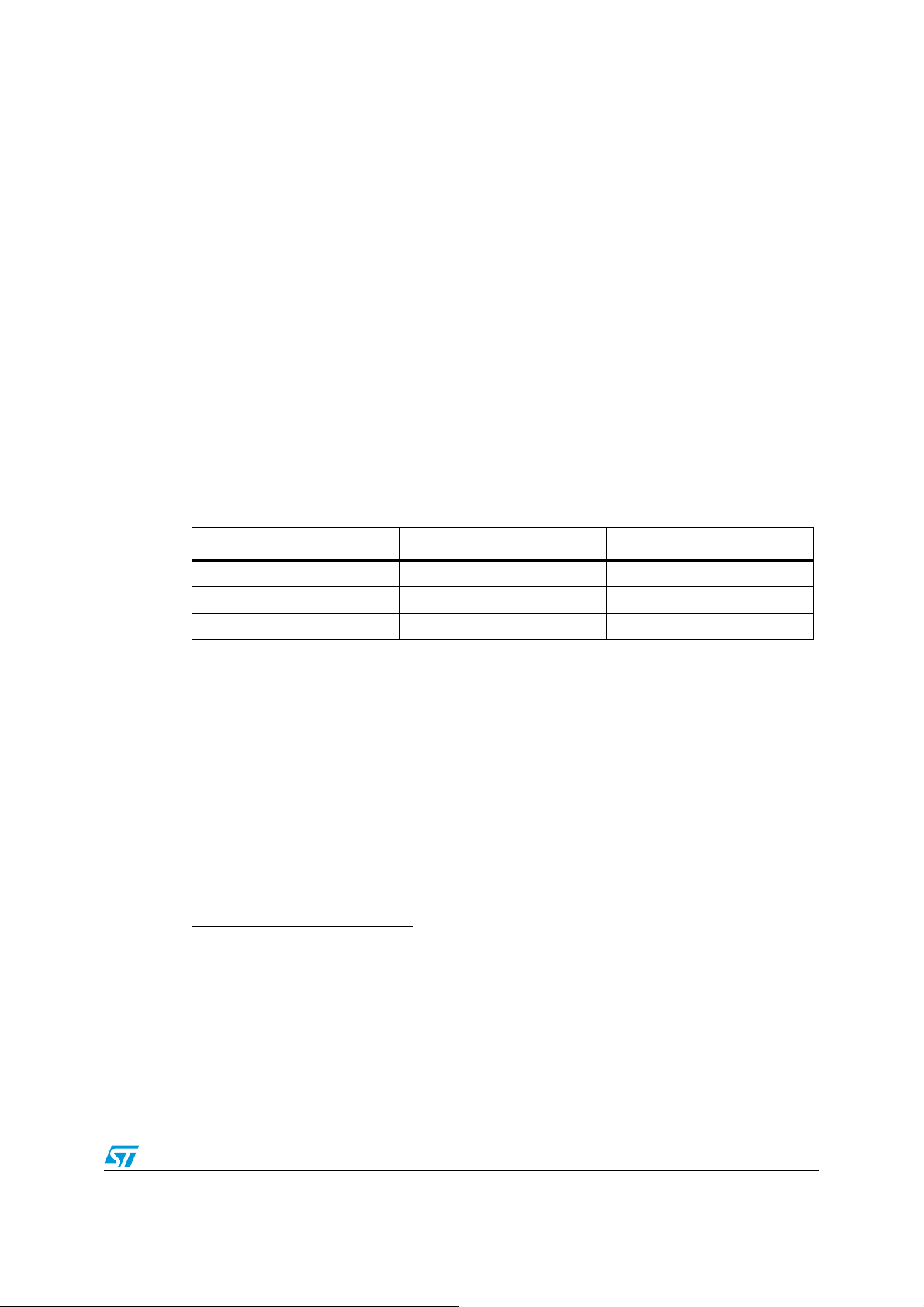

Table 1. Boot mode selection

Mode FAB pin (PA[9]) ABS pin (PA[8])

Flash Boot (Default Mode) 0 –

Serial Boot (LINFlex) 1 0

Serial Boot (FlexCAN) 1 1

When the device is powered on, the SSCM (System Status Configuration Module) searches

the pre-determined locations in Flash for a valid RCHW (Reset Configuration Half Word)

(see Section 2.1.1: Bootable sectors and RCHW).

● If a valid BOOT_ID is found, the SSCM reads the VLE bit and the boot vector address

(as well as the CSE block size).

● If a valid BOOT_ID is not found, the SSCM starts the process of putting the

microcontroller (e200z4d) into static mode

(c)

. See SPC564Bxx and SPC56ECxx family

Reference Manual for detailed information (see Section C.1: Reference document).

Note: The static mode differs from safe mode. Static mode is a non-operational mode which can

only be entered via the BAM (Boot Assist Module).

b. The booting mechanism has an impact only on the e200z4d core.

c. Static Mode Sequence:

1. The SSCM creates a 4 KB MMU page at the start of the BAM with the VLE bit set (the BAM is VLE code).

2. The SSCM then sets the CPU core (e200z4d) instruction pointer to the BAM address and the core starts to

execute the code to enter static mode as follows:

- the Software Watchdog Timer (SWT) is enabled;

- the core executes the "wait" instruction which halts the core.

After the microcontroller enters static mode, the SWT periodically resets the core (approximately every 10 ms)

to re-attempt a boot from Flash memory.

Doc ID 022384 Rev 1 7/49

Page 8

Microcontroller boot AN3995

In all these conditions, the e200z0h core remains held in reset: for further information please

refer to SPC564Bxx and SPC56ECxx Reference Manual, RM0070 (see Section C.1:

Reference document).

In order to access memory (for the e200z4d core), a valid MMU TLB entry has to be

created. The SSCM does this automatically by reading the reset vector and modifying TLB

entry 0 to create a 4 KB page containing the reset vector address.

The MMU VLE bit is set depending on the status of the VLE bit within the RCHW. The 4 KB

MMU page

(d)

must be 4 KB aligned. This means that the most efficient place to put the

application code is immediately after the boot sector (see Section 2.1.1: Bootable sectors

and RCHW). So in order to maximize the available space inside the 4 KB block, the reset

vector should be set close to the start of a 4 KB boundary.

Note: For example, if the reset vector is set to address 0x0000_0020, then the SSCM aligns the 4

KB MMU page to the start of the 4 KB aligned block containing address 0x0000_0020 – an

MMU page starting at address 0x0000_0000.

Similarly, if the reset vector is set to address 0x0000_0FF0 which is towards the end of an

aligned 4 KB block, the MMU page still has to start at 0x0000_0000 leaving very little room

in the 4 KB MMU page for code execution.

Finally, the SSCM sets the e200z4d core instruction pointer to the reset vector address and

starts the core running.

2.1.1 Bootable sectors and RCHW

In order to successfully boot from Flash memory, the user must program two 32-bit fields

into one of the 5 possible boot blocks (see Figure 1).

The entities to program are:

● 16-bit Reset Configuration Half Word (RCHW), which contains:

– A BOOT_ID field that must be correctly set to 0x5A in order to "validate" the boot

sector;

– A VLE bit which configures the initial MMU entry to either Power Architecture Book

VLE or Power Architecture Book III-E as described later on in this chapter;

● 32-bit reset vector (this is the start address of the user code)

The boot sector also contains a 32-bit field containing the size of the block of data to be

checked by the CSE (Cryptographic Security Engine) during a secure boot. See

SPC564Bxx and SPC56ECxx family Reference Manual, RM0070 for detailed information

(Section C.1: Reference document).

Note: Application code can then be programmed from offset address 0x000C.

d. The 4 KB block provides sufficient space to the user to:

1. Add MMU entries for SRAM and peripherals

2. Perform standard system initialization tasks (initialize the SRAM, setup stack, copy constant data)

3. Transfer execution to RAM, re-define the Flash memory MMU entry and transfer execution back to Flash

memory.

8/49 Doc ID 022384 Rev 1

Page 9

AN3995 Microcontroller boot

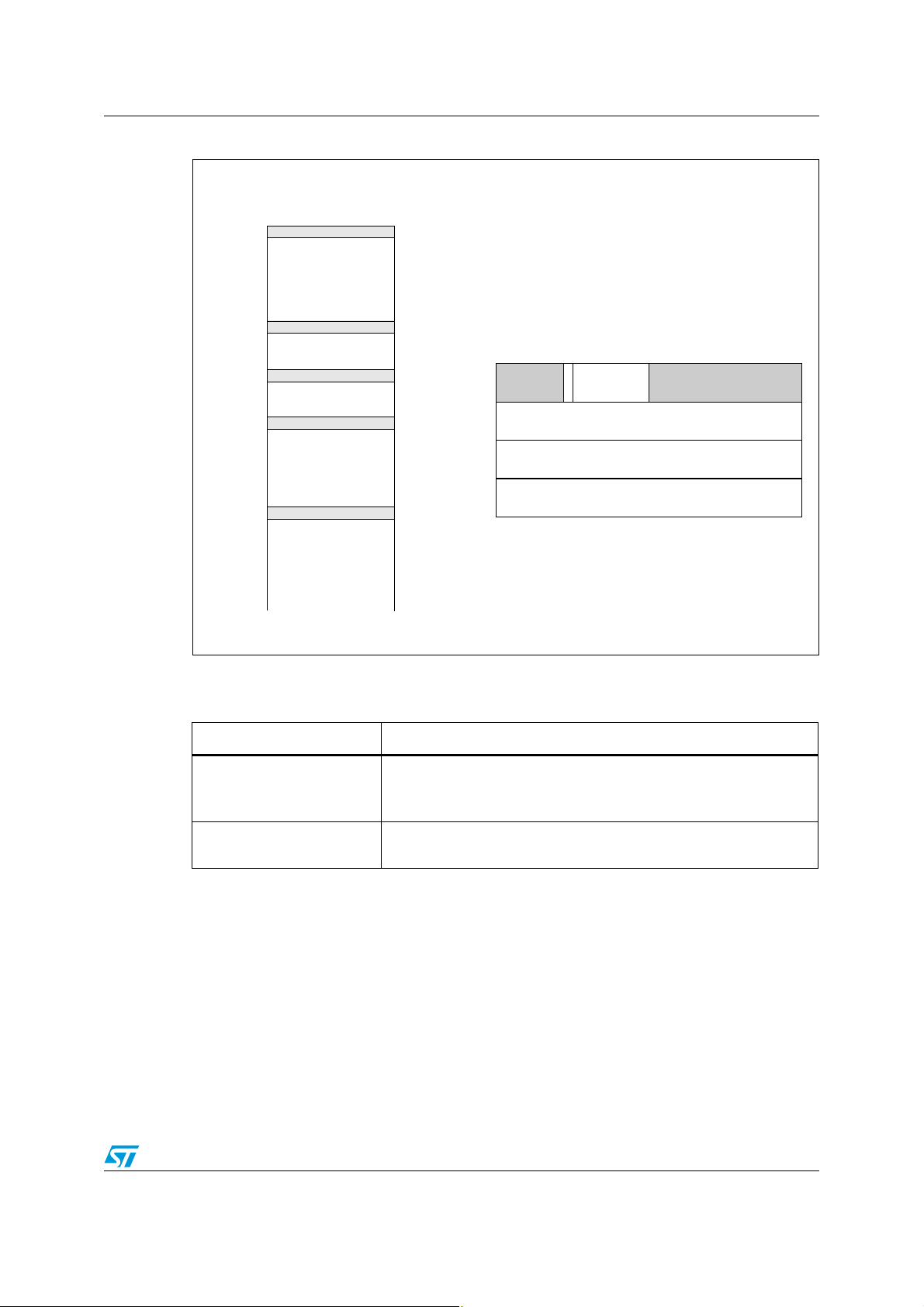

Figure 1. Boot sector structure

0x0000_0000

0x0000_8000

0x0000_C000

0x0001_0000

0x0001_8000

Boot sector 0

32 KB

Boot sector 1

16 KB

Boot sector 2

16 KB

Boot sector 3

32 KB

Boot sector 4

32 KB

Bit 0 Bit 31

0x0

(RCHW)

0x4

0x8

0xC

Code Flash memory

The structure of RCHW is described in Ta bl e 2 :

Table 2. RCHW field description

Boot sector structure

678 1516

Reserved Reserved

32-bit reset vector (points to star t address of application code)

BOOT_ID

(0x5A)

VLE

Size of Flash memory array to be verified by CSE

(see the CSE chapter)

Application code (from offset 0xC and onward)

Field Description

VLE Bit

VLE

0 MMU TLB Entry 0 is configured for Power Architecture Book III-E.

1 MMU TLB Entry 0 is configured for Power Architecture Book VLE.

BOOT_ID

Boot identifier.

If BOOT_ID = 0x5A, the boot sector is considered valid and bootable.

Doc ID 022384 Rev 1 9/49

Page 10

e200z4d initialization and example code AN3995

3 e200z4d initialization and example code

3.1 Creating e200z4d Flash boot file

In order to run an application from Flash memory, the user code must perform a series of

mandatory actions for proper execution:

● Provide reset vector in the location after the RCHW (Section 2.1: Boot mechanism);

● Configure MMU;

● Initialize SRAM (ECC) (see Section 3.1.3: Initialize the SRAM ECC);

● Configure wait states for Flash and SRAM (see Section 3.1.7: Performance Hints

Initialization);

● Configure XBAR (see Section 3.1.7: Performance Hints Initialization);

● Enable SPE (Signal Processing Extension) instructions if needed by the application

● Enable BTB

Initialization).

3.1.1 MMU remarks

The e200z4d core has a Memory Management Unit (MMU)

the e200z4d core to the XBAR (Crossbar) unless a valid MMU entry is configured for that

access.

(e)

(Branch Prediction Buffers) (see Section 3.1.7: Performance Hints

(f)

which prohibits access from

The user has to take care that the MMU only protects access from the e200z4d core to the

crossbar so that, it does not affect any of the other crossbar masters such as the e200z0h

core, FlexRay or the eDMA (see Figure 2).

e. See section e200z4 core in RM0070 (Section C.1: Reference document)

f. MMU is not present on e200z0h core

10/49 Doc ID 022384 Rev 1

Page 11

AN3995 e200z4d initialization and example code

Figure 2. SPC564Bxx/SPC56ECxx block diagram

JTAG Port

Nexus Port

NMI0

NMI1

Clocks

Interrupt

Request

Voltage

regulator

16 x

Semaphores

Reset Control

Pad Control

Nexus

FMPLL

SIUL

External

Interrupt

Request

IMUX

GPIO &

RTC/A PI

NMI0

NMI1

4×STM

10 ch

1×12-bit

ADC

JTAGC

Interrupt requests

from peripheral

blocks

CMU

ECSM

SWT

(1)

27 ch or 33 ch

1×10-bit

ADC

Nexus 3+

e200z0h

e200z4d

Nexus 3+

8

PIT RTI

(2)

INTC

×

FlexRay

Instructions

Instructions

MPU

registers

Peripheral Bridge

CTU

FEC

CSE

(Master)

Data

(Master)

(Master)

Data

(Master)

2

32 ch

×

eMIOS

64-bit 8 x 5 crossbar switch

eDMA

(Master)

10

LINFlexD

MPU

×

SRAM

×

128 KB

2

2

×

SRAM

controller

MC_PCUMC_MEMC_CGMMC_RGM

8

DSPI

×

(Slave)

(Slave)

Code Flash

×

1.5 MB

2

Flash memory

controller

DMAMUX

CAN

Sampler

BAM

I2C

Data Flash

64 KB

(Slave)

STCU

SSCM

6

FlexCAN

WKPU

×

Legend:

Notes:

I/O

ADC Analog-to-Digital Converter

BAM Boot Assist Module

CSE Cryptographic Services Engine

CAN Controller Area Network (FlexCAN)

CMU Clock Monitor Unit

CTU Cross Triggering Unit

DMAMUX DMA Channel Multiplexer

DSPI Deserial Serial Peripheral Interface

eDMA enhanced Direct Memory Access

FlexCAN Controller Area Network controller modules

FEC Fast Ethenet Controller

eMIOS Enhanced Modular Input Output System

ECSM Error Correction Status Module

FMPLL Frequency-Modulated Phase-Locked Loop

FlexRay FlexRay Communication Controller

I2C Inter-integrated Circuit Bus

IMUX Internal Multiplexer

INTC Interrupt Controller

(3)

(3)

JTAGC JTAG controller

LINFlexD Local Interconnect Network Flexible with DMA support

MC_ME Mode Entry Module

MC_CGM Clock Generation Module

MC_PCU Power Control Unit

MC_RGM Reset Generation Module

MPU Memory Protection Unit

Nexus Nexus Development Interface

NMI Non-Maskable Interrupt

PIT_RTI Periodic Interrupt Timer with Real-Time Interrupt

RTC/API Real-Time Clock/ Autonomous Periodic Interrupt

SIUL System Integration Unit Lite

SRAM Static Random-Access Memory

SSCM System Status Configuration Module

STM System Timer Module

SWT Software Watchdog Timer

STCU Self Test Control Unit

WKPU Wakeup Unit

1) 10 dedicated channels plus up to 19 shared channels. See the device-comparison table.

2) Package dependent. 27 or 33 dedicated channels plus up to 19 shared channels. See the device-comparison table.

3)

16 x precision channels (ANP) are mapped on input only I/O cells.

Doc ID 022384 Rev 1 11/49

Page 12

e200z4d initialization and example code AN3995

As previously described in the Section 2.1: Boot mechanism the MMU is not automatically

configured

(g)

apart from a small 4 KB page containing the reset vector address in the TLB

entry 0.

This means that the MMU must be configured by the user, before any access outside to the

block mapped by the SSCM.

In a typical application, the e200z4d core accesses Flash, SRAM and the peripheral blocks

and therefore MMU access needs to be granted.

An example of configuration is showed in Ta bl e 3 .

This configuration is quite similar to the ones implemented in this application note with the

exception of the SRAM 2 memory area (second row of the table). The relative TLB was not

configured because this area is used by the performance core (e200z0h).

Note: The e200z4d core has 16 MMU TLB entries and these allow the user to increase if needed

the protection granularity by splitting the memory in several blocks.

For further information see Memory Protection Unit section in the Reference Manual (see

Section C.1: Reference document).

Table 3. Example of MMU configuration

Memory area Memory address Size Closest MMU size

SRAM 1 0x4000_0000 - 0x4001_FFFF 128KB 128KB

SRAM 2 0x4002_0000 - 0x4003_FFFF 128KB 128KB

Flash including shadow

sector

Peripherals 0xC000_0000 - 0xFFFF_FFFF 1GB 1GB

0x0000_0000 - 0x00FF_FFFF 16MB 16MB

The user has to take into account setting up the stack (see Section 3.1.3: Initialize the

SRAM ECC), prior to performing any RAM accesses like executing the mandatory ECC

initialization, or before any peripheral register writes, the memory spaces have to be

configured through the MMU entries.

These considerations both with small block (4KB) mapped by SSCM on TLB entry 0 by

default (see Section 2.1: Boot mechanism) imply that all MMU regions have to be mapped at

the start of the boot code.

MMU pages must not overlap and must also be configured on a boundary matching their

size (for example, 4 KB MMU page must sit on a 4 KB boundary).

Moreover, it is strongly recommended that the user doesn’t change the MMU configuration

of a memory location currently being accessed, otherwise there is potential for errors.

The suggested order of MMU configuration could be defined as follows:

g. In this device family the Boot Assist Module (BAM) does not run when the device performs a normal Flash boot

then the MMU configurations must be done by the user.

12/49 Doc ID 022384 Rev 1

Page 13

AN3995 e200z4d initialization and example code

1. Configure the MMU TLB entry for RAM. In this manner, the user code can initialize the

SRAM ECC (see Section 3.1.3: Initialize the SRAM ECC).

2. Configure the MMU TLB entry for Flash

(h)

(see Section 3.1.4: Configure MMU for

Flash)

– Copy configuration code to SRAM

(i)

– Jump to first instruction of this code in SRAM and execute it

– Transfer execution back to the Flash

3. Configure the MMU TLB entry for the IPBridge (peripherals space) (see Section 3.1.5:

Configure MMU for Peripheral Bridge)

3.1.2 Configure MMU for SRAM

In order to configure MMU TLB entries, there are four MMU Assist registers (MAS) which

are written with the TLB entry number, start address and size of the MMU entry and other

information such as whether the page is VLE or BookE instructions.

In Figure 3 is showed a scratch code of MMU configuration

Figure 3. MMU configuration code for SRAM

#/*************************************************************************/

#/* MMU configuration code for SRAM */

#/* TLB1, Entry 1 128KB 0x4000_0000 to 0x4001_FFFF */

#/*************************************************************************/

e_lis r3, 0x1001

mtmas0 r3 #/* MAS0 */

(j)

for RAM using TLB entry 1:

e_lis r3, 0xC000

e_or2i r3, 0x0380

mtmas1 r3 #/* MAS1 = 0xC0000380 (128Kb) */

e_lis r3, 0x4000

e_or2i r3, 0x0028

mtmas2 r3 #/* MAS2 = 0x40000028 */

e_lis r3, 0x4000

e_or2i r3, 0x003F

mtmas3 r3 #/* MAS3 = 0x4000003F */

tlbwe #/* Write the entry to the TLB */

The SRAM space mapped through the TLB 1 is half of the space available on the device

(k)

and it corresponds to the bank placed at the lower addresses.

The example shown here is using this as the upper bank is reserved for the e200z0h core.

h. In this application note the strategy suggested is to re-uses the TLB 0 to map all Flash memory space.

i. User can use this mechanism at this time (the execution from SRAM) to configure the wait states for Flash (see

Section 3.1.7: Performance Hints Initialization): to avoid executing code from Flash while wait states are

changing. This means that should copy also this configuration code to SRAM at this time and execute it with

the MMU ones.

j. After the MAS registers are written, the TLB is validated with a single “tlbwe” (TLB Write Entry) instruction

k. This device family has two 128KB contiguous banks start at 0x4000_0000

Doc ID 022384 Rev 1 13/49

Page 14

e200z4d initialization and example code AN3995

This means that the e200z4d core doesn’t need to have any mapping on this memory space

(see Section 1: Application example description).

3.1.3 Initialize the SRAM ECC

The SRAM in the SPC564Bxx and SPC56ECxx family (as other SPC56xx devices) has the

ECC (Error Correction Code) protection.

ECC checks are performed during the read portion of an SRAM ECC read/write (R/W)

operation, and ECC calculations are performed during the write portion of a R/W operation.

Because the ECC bits can contain random data after the device is powered on, the SRAM

must be initialized by executing 32-bit write operations prior to any read accesses

ECC error and therefore an exception being raised.

Figure 4 shows a scratch code of SRAM initialization.

Figure 4. SRAM ECC initialization code

#/**************************************************************************/

#/* Initialize all SRAM space by copying all 32GPR's to RAM (fast) */

#/* Counter defines number of 32 x 32-bit words needed to write to RAM*/

#/**************************************************************************/

e_lis r5, _SRAM_ADDR_Z4@h #/* SRAM start address defined in the linker file */

e_or2i r5, _SRAM_ADDR_Z4@l

(l)

to avoid

e_lis r6, _SRAM_SIZE_Z4@h #/* SRAM size defined in the linker file */

e_or2i r6, _SRAM_SIZE_Z4@l

e_srwi r6, r6, 0x7 #/* Divide SRAM size by 128 bytes */

mtctr r6 #/* Move to counter for use with "bdnz" */

sram_loop:

e_stmw r0,0x0(r5) #/* Write all 32 registers to SRAM */

e_addi r5,r5,128 #/* Increment the RAM pointer to next */

e_bdnz sram_loop #/* Loop for all of SRAM */

3.1.4 Configure MMU for Flash

It is strongly recommended (see Section 3.1.1: MMU remarks), not to re-configure an MMU

entry for memory that is currently being used because doing so that can cause stability

issues at the point when the MMU TLB region is re-validated.

From the user point of view this means that it should be fine to configure additional TLB

entries while executing from an existing entry.

Of course users could use the same TLB 0 to map all the Flash but the MMU configuration

code must be executed by the SRAM: the code has to be copied to SRAM and then the

execution flow is transferred to SRAM so that the Flash MMU entry can be safely reconfigured (in this Application Note was described this strategy).

#/* 128byte(4bytes*32 registers) */

Figure 5 shows a scratch code of MMU configuration for Flash using TLB entry 0.

l. This is also true for implicit read accesses caused by any write accesses of less than 32 bits

14/49 Doc ID 022384 Rev 1

Page 15

AN3995 e200z4d initialization and example code

When the code is executed from Flash, all the code between the labels

“conf_sram_code_begin” and “conf_sram_code_end” is copied

(m)

to and executed from the

SRAM.

Figure 6 shows a scratch code of copy code from Flash to SRAM.

Figure 5. MMU configuration code for Flash

#/**************************************************************************/

#/* MMU configuration code for Flash (TLB1 entry 0) -> copy to RAM */

#/* TLB1 entry 0, 0x0000_0000 to 0x00FF_FFFF overwriting existing TLB */

#/* infact MMU have configured the small 4 KB block at the reset vector. */

#/* NOTE: this configuration allows access to all device Flash */

#/**************************************************************************/

#/* ---- MMU configuration (TLB1, Entry 0) for Code Flash:this block will be

copied to RAM */

e_lis r3, 0x1000 #/* MAS0, Configure TLB1, Entry 0 */

mtmas0 r3

e_lis r3, 0xC000 #/* MAS1 = 0xC0000700 (16MB) */

e_or2i r3, 0x0700

mtmas1 r3

e_lis r3, 0x0000 #/* MAS2 = 0x00000020 */

e_or2i r3, 0x0020

mtmas2 r3

e_lis r3, 0x0000 #/* MAS3 = 0x0000003F */

e_or2i r3, 0x003F

mtmas3 r3

tlbwe #/* Write the entry to the TLB */

Figure 6. Code to copy configuration code from Flash to SRAM

conf_sram:

#/* Calculate number of bytes to copy (data between labels) */

e_lis r3, conf_sram_code_begin@h

e_or2i r3, conf_sram_code_begin@l

e_lis r4, conf_sram_code_end@h

e_or2i r4, conf_sram_code_end@l

subf r4, r3, r4

mtctr r4 #/* Move to counter register the number of bytes to copy */

e_lis r5, _SRAM_ADDR_Z4@h #/* SRAM start address defined in the linker file */

e_or2i r5, _SRAM_ADDR_Z4@l

copy_configuration_code: #/* Copy configuration code from Flash to RAM */

e_lbz r6, 0(r3)

e_stb r6, 0(r5)

e_addi r3, r3, 1

e_addi r5, r5, 1

e_bdnz copy_configuration_code#/* Loop is based on the value of counter */

e_lis r24, _SRAM_ADDR_Z4@h #/* SRAM start address defined in the linker file*/

e_or2i r24, _SRAM_ADDR_Z4@l

se_mtctr r24

se_bctr #/* Jump to the SRAM Start address */

m. As mentioned previously, at this time, user can use this mechanism to configure also the Flash wait states (see

Section 3.1.7: Performance Hints Initialization): he has to put the code between the labels.

Doc ID 022384 Rev 1 15/49

Page 16

e200z4d initialization and example code AN3995

3.1.5 Configure MMU for Peripheral Bridge

As mentioned user has to create a valid MMU entry before addressing any of the

peripherals (including the SWT).

Figure 7 shows a scratch code of MMU configuration

Figure 7. MMU configuration code for peripherals area

#/**************************************************************************/

#/* MMU configuration code for Peripheral Area (IPBridge) */

#/* TLB1, entry 2 1GB 0xC000_0000 to 0xFFFF_FFFF */

#/**************************************************************************/

e_lis r3, 0x1002 #/* MAS0, Configure TLB1, Entry 2 */

mtmas0 r3

e_lis r3, 0xC000 #/* MAS1 = 0xC0000A00 */

e_or2i r3, 0x0A00

mtmas1 r3

e_lis r3, 0xC000 #/* MAS2 = 0xC000002A */

e_or2i r3, 0x002A

mtmas2 r3

e_lis r3, 0xC000 #/* MAS3 = 0xC000003F */

e_or2i r3, 0x003F

mtmas3 r3

tlbwe #/* Write the entry to the TLB */

(n)

for peripheral area TLB entry 2:

3.1.6 Memory initialization

The Stack/Heap memory sections must be initialized as well as constants and pre-initialized

variables being copied from Flash to RAM.

These initialization steps can be done by user by scratch or left to pre-built compiler

initialization script (often hidden from user).

In any case these initialization steps are tightly coupled to the linker file and are compiler

specific so it is not detailed in this document: GHS (GreenHills) compiler suite was used for

this document (see Figure 8).

For this reason in the startup files described in these paragraphs (see Appendix A:

Application code example) the label “_start” was substituted by “__ghs_board_memory_init”

(see Figure 9) and at the end of the startup file the execution flow doesn’t branch to the

application code (for example “e_bl main”) (see Figure 10) but instead it is redirected to

GHS startup library which completes the memory initialization (for example, handle the SDA

(Small Data Area) optimization).

n. After the MAS registers are written, the TLB is validated with a single “tlbwe” (TLB Write Entry) instruction

16/49 Doc ID 022384 Rev 1

Page 17

AN3995 e200z4d initialization and example code

Figure 8. Booting flow using GHS startup libraries

&RPSLOHU

6HFWLRQ

*+6VWDUWXSVFULSW

,QLWLDOL]DWLRQ6WDUW

FRQWDLQBVWDUWODEHO

*+6VWDUWXSVFULSW

,QWLDOL]DWLRQ(QG

FRS\RIGDWDWR65$0

,QLWLDOL]DWLRQVWDFNKHDS

RSWLPL]DWLRQVKDQGOLQJ

8VHU

6HFWLRQ

BJKVBERDUGBPHPRU\BLQLW

3ODWIRUPGHSHQGHQW

LQLWLDOL]DWLRQFRGHLV

ORFDWHGKHUH

«

«

«

«

VHBEOU-XPSWR&DOOHU

0DLQF

XVHUDSSOLFDWLRQ

Doc ID 022384 Rev 1 17/49

Page 18

e200z4d initialization and example code AN3995

Figure 9. Startup file: __ghs_board_memory_init

#/**************************************************************************/

#/* RCHW Configuration (and referencing of start label for linker) */

#/**************************************************************************/

.section .rchw

.LONG 0x015A0000 #/* RCHW: VLE bit, Valid Bood Identifier 0x5A */

.LONG _start

.file "crt0_corez4_Flash.s"

.section .vletext_boot, "vax"

.vle

#.global _start

.global__ghs_board_memory_init

.global asm_init_cache

.equ MPR0ADDR, 0xFFF04000

.equ MPR0VALUE, 0x76543210 #/* Flash PORT1: Priority to corez4(instruct.)*/

.equ SGPCR0VALUE, 0x0

.equ MPR1ADDR, 0xFFF04100

.equ MPR1VALUE, 0x76543201 #/* Flash PORT1: Priority to corez4(data)*/

.equ SGPCR1VALUE, 0x1

.equ MPR2ADDR, 0xFFF04200

.equ MPR2VALUE, 0x54376201 #/* PRAM0: Priority to corez4(data)*/

.equ SGPCR2VALUE, 0x1

.equ MPR3ADDR, 0xFFF04300

.equ MPR3VALUE, 0x54301276 #/* PRAM1: Priority to corez0(data)*/

.equ SGPCR3VALUE, 0x4

.equ MPR7ADDR, 0xFFF04700

.equ MPR7VALUE, 0x54327106 #/* PBRIDGE: Priority to corez4(data)*/

.equ SGPCR7VALUE, 0x1

#/*_start: */ #/* uncomment this line and comment the following one */

__ghs_board_memory_init:

#/* you don't use GHS libraries (take care to */

#/* configure SDA/Stack/..pointers */

Figure 10. Startup file: branch to GHS startup libraries

se_blr #/* Jump to Caller */

#e_bl main #/* Use this Branch and comment the previous if you not

#/* use GHS crt0.ppc */

.type __ghs_board_memory_init,@function

.size __ghs_board_memory_init,$-__ghs_board_memory_init

18/49 Doc ID 022384 Rev 1

Page 19

AN3995 e200z4d initialization and example code

3.1.7 Performance Hints Initialization

The device performance can be addressed by customizing several system level

configurations that of course need to be changed on user's application basis.

Below is a list of actions that user can done to speed up the device performances:

● Signal Processing Extension (SPE) for fixed point and single precision calculations

(see Figure 11);

● Branch Target Buffer (BTB) providing target address pre-fetching (see Figure 11): This

enables operation beyond a conditional branch without waiting for the branch to be

decoded and resolved;

● Flash Port Configuration. The user can choose to set the minimum wait states (with

regard to device operating frequency) as well as configure the line buffer allocation and

pre-fetch behavior.

In this application note the minimum allowed wait states for a device frequency equal to

120MHz, when prefetching enabled has been selected.(see Figure 12);

● SRAM wait states: User has to setup an additional wait states over the SRAM (see

Figure 13) if the system clock is above 64MHz.

In this application note it is preferred to insert this initialization (just to have all wait

states configurations together) here even if this configuration is only strictly linked to

system clock frequency (see Section 3.2.3: Clock & PLL configuration).

● The highly configurable crossbar (XBAR) architecture allows tailored priorities and

arbitration schemes on a per slave port basis. For detailed information please refer to

the XBAR chapter in the Reference Manual (see Section C.1: Reference document).

In this application note it has been selected to configure the XBAR so that the e200z4d

core execution can have the maximum priority over all other slaves (Figure 14).

All the configurations related to XBAR (for example: all the masters) are done inside the

startup file of the e200z4d core even if no special constraints are present. This

implementation has been chosen to have all XBAR configurations together.

Note how the slave 3 (the slave port related to PRAM controller one) is configured to

give priority to e200Z0h (see Section 1: Application example description);

● Configure the ICache. The e200z4d processor supports a 4 Kbyte, 2 or 4-way set-

associative, instruction cache (ICache) with a 32-byte line size.

The ICache improves system performance by providing low-latency data to the

instruction pipeline. In this application note the 4-way configuration, which generally

allows the best performance versus the 2-way ones, has been chosen (see Figure 16).

Note that this code is located in the startup file (as an assembly function) but isn’t

executed at this time (see Section 3.2.4: Configure Cache).

Figure 11. Startup file: enable BTB and SPE

#/**************************************************************************/

#/* Enable Signal Processing extension (SPE) in Machine State Register */

#/**************************************************************************/

mfMSR r3

e_or2isr3, 0x0200

mtMSR r3

#/**************************************************************************/

#/* Enable Branch Target Buffers BTB */

#/**************************************************************************/

e_li r0, 0x201

mtspr1013, r0

Doc ID 022384 Rev 1 19/49

Page 20

e200z4d initialization and example code AN3995

Figure 12. Startup file: Flash Configuration code

#/**************************************************************************/

#/* Configure the Flash wait states and the prefetch buffers -> copy to RAM*/

#/* Code is copied to RAM first, then executed, to avoid executing code */

#/* from Flash while wait states are changing. */

#/**************************************************************************/

#/* PFCR0 = 0x294BFDFD (settings for 120MHz) */

#/* APC and RWSC = 0b101 (5 additional hold cycles) */

#/* WWSC = 0b101 (5 wait) */

#/* B02_P0_DPFE = 0b1 (enabled) */

#/* B02_P0_IPFE = 0b1 (enabled) */

#/* B02_P0_PFLIM = 0b1x (prefetch on miss or hit) */

#/* B02_P0_BFE = 0b1 (enabled) */

e_lis r3, 0x294B

e_or2i r3,0xFDFD #/* NOTE: 0xaDaD = 0xaFaF */

e_lis r4, 0xC3F8 #/* PFCR0 ADDRESS HIGH */

e_or2i r4, 0x801C #/* PFCR0 ADDRESS LOW */

e_stw r3, 0(r4)

se_isync

msync

#/* PFAPR = 0x0300FFFF */

e_lis r3, 0xFF00 #/* Round-robin arbitration-Prefetching enabled. */

e_or2i r3, 0xFFFF #/* Both read and write accesses */

e_lis r4, 0xC3F8 #/* PFAPR ADDRESS HIGH */

e_or2i r4, 0x8024 #/* PFAPR ADDRESS LOW */

e_stw r3, 0(r4)

se_isync

msync

Figure 13. Startup file: SRAM wait states configuration code

#/**************************************************************************/

#/* Configure SRAM wait states to 1 */

#/* RAM needs an additional wait state if the system clock is above 64 Mhz */

#/**************************************************************************/

e_lis r3, 0x4000 #/* 1-wait state for RAM access */

e_or2i r3, 0x0

e_lis r4, 0xFFF4 #/* ECSM */

e_or2i r4, 0x0024

e_stw r3, 0(r4)

se_isync

msync

20/49 Doc ID 022384 Rev 1

Page 21

AN3995 e200z4d initialization and example code

Figure 14. Startup file: XBAR register configuration values

.equ MPR0ADDR, 0xFFF04000

.equ MPR0VALUE, 0x76543210 #/* Flash PORT1: Priority to corez4(instruct.)*/

.equ SGPCR0VALUE, 0x0

.equ MPR1ADDR, 0xFFF04100

.equ MPR1VALUE, 0x76543201 #/* Flash PORT1: Priority to corez4(data)*/

.equ SGPCR1VALUE, 0x1

.equ MPR2ADDR, 0xFFF04200

.equ MPR2VALUE, 0x54376201 #/* PRAM0: Priority to corez4(data)*/

.equ SGPCR2VALUE, 0x1

.equ MPR3ADDR, 0xFFF04300

.equ MPR3VALUE, 0x54301276 #/* PRAM1: Priority to corez0(data)*/

.equ SGPCR3VALUE, 0x4

.equ MPR7ADDR, 0xFFF04700

.equ MPR7VALUE, 0x54327106 #/* PBRIDGE: Priority to corez4(data)*/

.equ SGPCR7VALUE, 0x1

Doc ID 022384 Rev 1 21/49

Page 22

e200z4d initialization and example code AN3995

Figure 15. Startup file: XBAR configuration code

#/**************************************************************************/

#/* Configure XBAR */

#/**************************************************************************/

#/* Configure Master Priority Register 0 */

e_lis r4, MPR0VALUE@h #/* MPR0 Conf. High Value */

e_or2i r4, MPR0VALUE@l #/* MPR0 Conf. Low Value */

e_lis r5, MPR0ADDR@h #/* MPR0 Address High Value */

e_or2i r5, MPR0ADDR@l #/* MPR0 Address Low Value */

se_stw r4,0x0(r5) #/* Store Value */

#/* Configure Slave General Purpose Control Register 0 */

e_lis r4, SGPCR0VALUE@h #/* SGPCR0 High Value High Value */

e_or2i r4, SGPCR0VALUE@l #/* SGPCR0 Low Value */

se_stw r4,0x10(r5) #/* Store Value (SGPCR0 address is 0x10 bytes after MPR0)*/

#/* Configure Master Priority Register 1 */

e_lis r4, MPR1VALUE@h #/* MPR1 Conf. High Value */

e_or2i r4, MPR1VALUE@l #/* MPR1 Conf. Low Value */

e_lis r5, MPR1ADDR@h #/* MPR1 Address High Value */

e_or2i r5, MPR1ADDR@l #/* MPR1 Address Low Value */

se_stw r4,0x0(r5) #/* Store Value */

#/* Configure Slave General Purpose Control Register 1 */

e_lis r4, SGPCR1VALUE@h #/* SGPCR1 High Value High Value */

e_or2i r4, SGPCR1VALUE@l #/* SGPCR1 Low Value */

(o)

se_stw r4,0x10(r5) #/* Store Value (SGPCR1 address is 0x10 bytes after MPR1)*/

#/* Configure Master Priority Register 2 */

e_lis r4, MPR2VALUE@h #/* MPR2 Conf. High Value */

e_or2i r4, MPR2VALUE@l #/* MPR2 Conf. Low Value */

e_lis r5, MPR2ADDR@h #/* MPR2 Address High Value */

e_or2i r5, MPR2ADDR@l #/* MPR2 Address Low Value */

se_stw r4,0x0(r5) #/* Store Value */

#/* Configure Slave General Purpose Control Register 2 */

e_lis r4, SGPCR2VALUE@h #/* SGPCR2 High Value High Value */

e_or2i r4, SGPCR2VALUE@l #/* SGPCR2 Low Value */

se_stw r4,0x10(r5) #/* Store Value (SGPCR2 address is 0x10 bytes after MPR1)*/

o. XBAR configuration not fully showed in this picture.

22/49 Doc ID 022384 Rev 1

Page 23

AN3995 e200z4d initialization and example code

Figure 16. Cache Configuration Code

#************************************************************

# invalidate and enable the instruction cache (4WAY)

#************************************************************

asm_init_cache:

e_lis r3, 0x0

e_or2i r3,0x0002

mtl1csr1 r3

loop_invalid_cache:

msync

mfl1csr1 r3

e_and2i.r3,2

se_bne loop_invalid_cache

# inst cache enable (4way)

e_lis r3, 0x0

e_or2i r3, 0x0011 #(use 0x0001 for 2way)

mtl1csr1 r3

se_blr

Doc ID 022384 Rev 1 23/49

Page 24

e200z4d initialization and example code AN3995

3.2 e200z4d device configuration from C code

Before the execution of the application code, user has to complete the device initialization by

performing the following steps (see Figure 17):

1. Disable the SWT (Software Watchdog Timer) (see Section 3.2.1: Disable watchdog);

2. Configure device modes (see Section 3.2.2: Mode configuration and clocking);

3. Configure system dividers (see Section 3.2.3: Clock & PLL configuration);

4. Configure PLL (Phase Looked Loop) (see Section 3.2.3: Clock & PLL configuration);

5. Enable Instruction cache (see Section 3.2.4: Configure Cache);

6. Start e200z0h core (see Section 3.2.5: Starting the e200z0h core);

Figure 17. Environment configurations code

void Environment_Init(void){

SWT_Disable(); /* Disable Software Watchdog Timer (Can */

/* also be disabled in Shadow row) */

MODE_Init(); /* Configure modes and activate all clocks */

/* for all peripherals */

CGM.Z0_DCR.B.DIV = 0x1; /* Z0 clock divider to divide by 2 */

CGM.Flash_DCR.B.DIV = 0x1; /* Flash register interface /2 (default) */

PLL_Init(); /* Set system clock to 120MHz */

asm_init_cache(); /* Enable Cache 4WAY */

/* Start Z0 Core */

SSCM.DPMBOOT.R = 0x00180000; /* Start address of Z0 (2nd Flash block) */

SSCM.DPMKEY.R = 0x00005AF0; /* Write key 1 */

SSCM.DPMKEY.R = 0x0000A50F; /* Write key 2 */

}

3.2.1 Disable watchdog

The Software Watchdog Timer (SWT)

lockup in situations such as software getting trapped in a loop or if a bus transaction fails to

terminate.

When enabled, the SWT requires periodic execution of a watchdog servicing operation: in

order to prevent a system reset, the watchdog must be serviced or disabled prior to the

initial expiry of the timer.

In a real application it is expected that the SWT would be serviced (before it expires) and reconfigured to match application timing rather than being disabled.

Look at Reference Manual (Section C.1: Reference document) for more information on

configuring and using the SWT.

In this document, the watchdog is disabled to avoid any servicing.

/* based on 40Mhz XTAL */

(p)

is a peripheral module that can prevent system

p. The SWT is clocked from the Slow Internal Reference Clock (SIRC) with a nominal frequency of 128 KHz. The

default SWT timeout is set to approximately 10 ms: this timeout period is determined by the actual SIRC

frequency which varies over temperature according to the device specification.

24/49 Doc ID 022384 Rev 1

Page 25

AN3995 e200z4d initialization and example code

The simplest way to disable the SWT is to do it at the start of the main program once all of

the initialization code has been executed. The user has to take care that there is enough

time (versus the SWT time period) between the start of initialization code (startup code) and

the main function.

If there is any doubt over the time taken to run the initialization code, the watchdog can be

addressed as soon as the MMU page is defined for the peripherals.

In order to disable the watchdog in software the user needs to:

● Write the sequence of 0xC520 followed by 0xD928 to the service register. This clears

the soft lock bit enabling the next step in the process;

● Clear the WEN bit in the Control register;

Figure 18. SWT disabling code

void SWT_Disable(void)

{

SWT.SR.R = 0xC520; /* Clear Soft lock bit in CR by writing */

SWT.SR.R = 0xD928; /* 0xC520 followed by 0xD928 to WSC field */

SWT.CR.B.WEN = 0x0; /* Clear Watchdog Enable Bit */

}

Note: When user is connecting to the device using a debugger, it is likely that the debugger itself

disables the watchdog to allow debug to be carried out.

This can result in a fairly common problem when attempting to run the code in a standalone

configuration where a periodic device reset is observed, caused by the SWT time-out.

It’s possible to use an additional way to disable the SWT at device reset by writing to the

Non Volatile User Options (NVUSRO) register located in the shadow row at address

0x00FF_FE18.

By disabling the watchdog

(q)

in this manner it can then be re-enabled at a later stage if

desired.

● If bit-0 (MSB) of NVUSRO is set, as with an erased shadow Flash, then the SWT is

enabled

● If bit-0 of NVUSRO is cleared, then the SWT is disabled

3.2.2 Mode configuration and clocking

The SPC564Bxx and SPC56ECxx device family (as other SPC56xx devices) has several

operating modes (see Section C.1: Reference document). Out of reset the device leaves the

Reset mode and enters DRUN mode (see Figure 19).

q. If no valid RCHW is found by the SSCM, the watchdog is re-enabled (even if the SWT is disabled in the

NVUSRO register) before the device enters Static mode (see Section 2.1: Boot mechanism)

Doc ID 022384 Rev 1 25/49

.

Page 26

e200z4d initialization and example code AN3995

Figure 19. Mode entry diagram

In order to use all of the available modes, they must be enabled in the Mode Enable register

(see Figure 20).

Figure 20. Mode Initialization Code

void MODE_Init(void)

{

ME.MER.R = 0x000025FF; /* Enable all modes */

ME.RUNPC[0].R = 0x000000FE; /* Enable all peripherals in all modes */

/* Enable system clock for all peripherals assuming 120MHz system clock */

CGM.SC_DC[0].R = 0x83; /* Max 32MHz. Closest is 30MHz, Div+1=3 */

CGM.SC_DC[1].R = 0x81; /* Max 64MHz. Closest is 60MHz, Div+1=2 */

CGM.SC_DC[2].R = 0x81; /* Max 64MHz. Closest is 60MHz, Div+1=2 */

/* Re-enter DRUN mode to update the clock configuration */

ME.MCTL.R = 0x30005AF0; /* DRUN Mode & Key */

ME.MCTL.R = 0x3000A50F; /* DRUN Mode & Key */

while (ME.GS.B.S_MTRANS == 1); /* Wait for mode transition complete */

}

26/49 Doc ID 022384 Rev 1

Page 27

AN3995 e200z4d initialization and example code

Every peripheral (see Figure 21) has an associated control register which has 3 fields to

determine what happens when the MCU is in the following modes:

● Debug mode (DBG_F)

● Low Power mode (LP_CFG)

● Run Mode (RUN_CFG)

For Low Power and Run modes there are 8 sets of configuration registers that are

referenced by the LP_CFG and RUN_CFG fields from the peripheral control registers.

Each of these configuration registers have a bit for each Run or Low Power mode which

determines whether the peripherals referencing this register are clock gated or available in

that mode: this allows up to 8 different power schemes to be created with a different mix of

peripherals to be available in each Low Power or Run mode.

Figure 21. Peripheral Control Registers

Out of reset, all of the peripheral control registers have value 0x0 which means they are

associated with ME_RUN_PC0 for Run modes (and ME_LP_PC0 for Low Power modes).

Setting ME_RUN_PC0 to 0x0000_00FE (see Figure 22), enables all peripherals in all Run

modes which is the baseline configuration used in this example (see Figure 20).

Figure 22. Run peripheral control registers

0123456789101112131415

R000000000000000 0

W

Reset000000000000000 0

16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31

R00000000

RESET

TEST

RUN3

RUN2

RUN1

W

RUN0

Reset000000000000000 0

Doc ID 022384 Rev 1 27/49

SAFE

DRUN

Page 28

e200z4d initialization and example code AN3995

There are 3 peripheral clock groups on the SPC564Bxx and SPC56ECxx device family with

associated clock dividers. These allow all 3 peripheral clock groups independent clock

control so groups can be slowed down or even clock gated which helps with power saving.

For more details and for peripheral assignments, refer to the device Reference Manual (see

Section C.1: Reference document).

Peripheral group 1 can be clocked at a maximum of 32 kHz, peripheral groups 2 and 3 can

run at a maximum of 64 kHz. Care needs to be taken not to exceed these limits (see

Figure 20).

Note: A peripheral clock group has to be specifically enabled or the peripherals is not accessible.

For the purpose of this example, all of the peripheral clock groups are enabled by writing to

the associated system clock divider registers even though all are not required.

Finally, in line with all clock and mode configuration, a mode transition must be made for all

the above changes to take effect.

For further information look at Mode Entry Module chapter in the device Reference Manual

(see Section C.1: Reference document).

In this case, DRUN mode is re-entered by writing a mode and key command sequence (see

Figure 20).

3.2.3 Clock & PLL configuration

The SPC564Bxx and SPC56ECxx device family is clocked by default from the 16 MHz IRC.

In order to attain the maximum performance of the device, the system clock speed needs to

be increased, up to 120 Mhz for the maximum system clock.

The device has several functional blocks that run at different frequency and for this reason

before the system clock is changed the user has to take some constraints into account (the

individual clock dividers must be set accordingly) to allow the device to run up to the

maximum of 120 MHz:

● The e200z0h core has a maximum clock speed of 80 Mhz;

● The FEC (Fast Ethernet Controller) requires its clock divider to be /2 if system clock is >

80 MHz;

● The Flash register interface has a maximum operating frequency of 80 Mhz;

● The RAM needs an additional wait state if the system clock is above 64 Mhz;

Note: The FEC is not used so in this case the divider is left at its default value.

Figure 23. System clock dividers configuration code

CGM.Z0_DCR.B.DIV = 0x1; /* Z0 clock divider to divide by 2 */

CGM.Flash_DCR.B.DIV = 0x1; /* Flash register interface /2 (default) */

(r)

At this time the PLL can be used to change the system clock to the desired level (see

Figure 24).

Note: All of the clock and PLL re-configuration can be achieved with a single mode re-entry but

there is also an option to effect a mode re-entry for each critical step in the process. It allows

an easy debug if the steps fail, in this way the problem can be identified easily.

r. In this application note the SRAM wait states configuration is done in the initialization code at startup (see

Section 3.1.7: Performance Hints Initialization)

28/49 Doc ID 022384 Rev 1

Page 29

AN3995 e200z4d initialization and example code

Figure 24. PLL configuration code

void PLL_Init(void){

ME.DRUN.B.FXOSC0ON = 1; /* Switch on external oscillator in DRUN mode */

/* Re-Enter DRUN mode (mode=0x3) to activate change */

ME.MCTL.R = 0x30005AF0; /* Mode & Key */

ME.MCTL.R = 0x3000A50F; /* Mode & Key inverted */

while(ME.GS.B.S_MTRANS == 1); /* Wait for mode transition complete */

while(ME.GS.B.S_CURRENTMODE != 3); /* Error trap - if current mode is not */

/* DRUN(eg in safe mode), then loop */

while(ME.GS.B.S_FXOSC != 1); /* Wait for external OSC to stabilize */

/* Select External OSC as the FMPLL Reference Clock Source */

CGM.AC0_SC.B.SELCTL = 0x0;

/* Configure PLL for 120MHz with 40MHz xtal: */

/* PLL frequency = (40 * NDIV)/(IDF * ODF) */

/* NOTE: VCO (PLL * ODF) must be between 256 and 512MHz */

CGM.FMPLL_CR.B.IDF = 0x4; /* Divide by 5 */

CGM.FMPLL_CR.B.ODF = 0x1; /* Divide by 4 */

CGM.FMPLL_CR.B.NDIV = 60; /* Divide by 60 */

/* Enable PLL in DRUN mode. */

ME.DRUN.B.FMPLLON = 1;

/* Re-Enter DRUN mode (mode=0x3) to activate change */

ME.MCTL.R = 0x30005AF0; /* Mode & Key */

ME.MCTL.R = 0x3000A50F; /* Mode & Key inverted */

while(ME.GS.B.S_MTRANS == 1); /* Wait for mode transition complete */

while(ME.GS.B.S_CURRENTMODE != 3); /* Error trap - if current mode is not */

while(CGM.FMPLL_CR.B.S_LOCK == 0); /* wait for PLL to lock (will not lock */

/* Finally set system clock to be PLL in DRUN mode */

ME.DRUN.B.SYSCLK = 0x4;

/* Re-Enter DRUN mode (mode=0x3) to activate change */

ME.MCTL.R = 0x30005AF0; /* Mode & Key */

ME.MCTL.R = 0x3000A50F; /* Mode & Key inverted */

while(ME.GS.B.S_MTRANS == 1); /* Wait for mode transition complete */

while(ME.GS.B.S_CURRENTMODE != 3); /* Error trap - if current mode is not */

while(ME.GS.B.S_SYSCLK != 4){}; /* Final check - ensure ME_GS reports clk */

/* Enable CLKOUT pin so clock frequency can be verified */

CGM.OC_EN.B.EN = 1; /* Enable Output clock */

CGM.OCDS_SC.R = 0x23000000; /* And seclect output as system clock / 4 */

SIU.PCR[0].R = 0x0A04; /* PA0 ALT2 function (Clkout), MAX SRC */

}

3.2.4 Configure Cache

The e200z4d processor supports a 4 Kbyte, 2 or 4-way set-associative, instruction cache

(ICache) with a 32-byte line size. The cache, as it is easy to understand, speeds up the

device performances because it decouples processor performance from system memory

performance (see Section 3.1.7: Performance Hints Initialization).

/* DRUN(eg safe mode), then loop */

/* until re-enter DRUN mode */

/* DRUN (eg safe mode), then loop */

/* as system PLL(0x4) - fail if stuck here */

Doc ID 022384 Rev 1 29/49

Page 30

e200z4d initialization and example code AN3995

In this application note, the 4-way mode has been chosen because it allows better

performance with respect to the 2-way mode.

Even if this initialization is strictly linked to performance increase, it’s recommended to

enable it after the clocks because there is no telling what the Cache Controller or the

Tag/Data arrays do if their clock is changed. Look at section e200z4d Core in RM0070 for

details (see Section C.1: Reference document).

3.2.5 Starting the e200z0h core

After a reset, the e200z0h core is held in reset until it is released by writing a sequence of

registers from the e200z4d core:

● Write the e200z0h boot (start) address

● Write 0x0000_5AF0 to the SSCM DPM Boot Key register

● Write 0x0000_A50F to the SSCM DPM Boot Key register

After the execution of the sequence (see Figure 17), the e200z0h executes code from the

start address defined in the DPM Boot register.

Any subsequent reset of the MCU results in the e200z0h being held in reset until the

sequence is carried out again by the e200z4d core.

Note: If the e200z0h starting sequence is not performed well the device works (as single core)

only with e200z4d core.

(s)

to the SSCM DPM Boot.

s. This address has to be 4 byte aligned as the lower 2 bits in the BPM boot register are reserved and set to 0b00

30/49 Doc ID 022384 Rev 1

Page 31

AN3995 e200z4d initialization and example code

3.3 The e200z4d example code

After the basics initialization (see Section 3.2: e200z4d device configuration from C code),

the user configures the output pin (PE[4]) on which is connected a led (see e200z4d Core in

RM0070, see Section C.1: Reference document), the e200z4d core toggles the pin and then

loops forever (see Figure 25).

In the meantime, the e200z0h core executes a similar code to toggle a led through a

contiguous port pin.

Figure 25. Application code: the main function

int main(int argc, char *argv[]){

Environment_Init(); /* Basic device Initilaizations */

/* Example Code start here */

/* Loop forever Flashing an LED connected to Port PE[4] */

/* (core Z0 code blink contiguous led) */

SIU.PCR[PIN_NUMBER].R = 0x0200; /* PE[4] to GPIO mode, output */

while(1){

/* Invert LED output */

SIU.GPDO[PIN_NUMBER].R = (~(SIU.GPDO[PIN_NUMBER].R) & 0x01);

for (count=0; count<1000000; count++); /* wait a while */

};

return 0;

} /* End Of Main */

/* (Modes,Pll,Start core 1,...) */

Doc ID 022384 Rev 1 31/49

Page 32

e200z0h Initializations and example code AN3995

4 e200z0h Initializations and example code

The e200z0h core executes code from the start address defined in the DPM boot register

after the execution of the three write sequences over the SSCM registers (see Section 3.2.5:

Starting the e200z0h core).

As previously mentioned in this application note, with the exception of XBAR (see

Section 3.1.7: Performance Hints Initialization), the initialization code for the cores are

executed separately

Section 4.1: e200z0h startup code).

4.1 e200z0h startup code

The startup code for the e200z0h is very simple because the user has to configure only few

topics.

The e200z0h is activated by the e200z4d core and for this reason the microcontroller

doesn’t follow the normal boot sequence as for the primary core (see section e200z4d Core

in RM0070 see Section 2.1: Boot mechanism): this implies that there is no RCHW section in

the code (see Figure 26).

(t)

and it means that the e200z0h has its own startup file (see

Whereas the e200z0h core doesn’t have either MMU, nor cache and considering the device

initializations done by e200z4d core (see Section 3: e200z4d initialization and example

code), the initialization code has to perform only two actions (see Figure 26):

1. Initialize SRAM ECC (second block) (see Section 3.1.3: Initialize the SRAM ECC);

2. Enable BTB (Branch Target Buffer) for the e200z0h core (see Section 3.1.7:

Performance Hints Initialization).

t. In order to simplify the work to the user it was suggested to have two separate projects for the two cores.

32/49 Doc ID 022384 Rev 1

Page 33

AN3995 e200z0h Initializations and example code

Figure 26. e200z0h startup code

.LONG _start

.file "crt0_corez0_Flash.s"

.section .vletext_boot, "vax"

.vle

#.global _start

.global__ghs_board_memory_init

__ghs_board_memory_init:

#/**************************************************************************/

#/* Initialize all SRAM space by copying all 32GPR's to RAM (fast) */

#/* Counter defines number of 32 x 32-bit words needed to write to RAM */

#/**************************************************************************/

e_lis r5, _SRAM_ADDR_Z0@h #/* SRAM start address defined in the Locator */

e_or2i r5, _SRAM_ADDR_Z0@l

e_lis r6, _SRAM_SIZE_Z0@h #/* SRAM size defined in the Locator */

e_or2i r6, _SRAM_SIZE_Z0@l

e_srwi r6, r6, 0x7 #/* Divide SRAM size by 128 bytes */

mtctr r6 #/* Move to counter for use with "bdnz" */

sram_loop:

e_stmw r0,0x0(r5) #/* Write all 32 registers to SRAM */

e_addi r5,r5,128 #/* Increment the RAM pointer to next 128byte */

#/* (4bytes*32 registers) */

e_bdnz sram_loop #/* Loop for all of SRAM */

#/**************************************************************************/

#/* Enable Branch Target Buffers BTB */

#/**************************************************************************/

e_lir0, 0x201

mtspr1013, r0

se_blr #/* Jump to Caller */

#e_bl main #/* Use this Branch and comment the previous */

.type __ghs_board_memory_init,@function

.size __ghs_board_memory_init,$-__ghs_board_memory_init

##----------------------------------------------------------------------

#/* if you not use GHS crt0.ppc */

Doc ID 022384 Rev 1 33/49

Page 34

Application code example AN3995

Appendix A Application code example

The example application code for e200z4d core discussed in this application note is

available for the user to use directly from the following pages.

Note that the formatting and alignment is configured for a normal text editor so the

formatting should be correctly aligned when pasted into a standard text editor with normal

spacing.

A.1 main.c file

#include "typedefs.h"

#include "MPC5646x.h"

#ifdef __cplusplus

extern "C" {

#endif

/*******************************************************************

| external declarations

|------------------------------------------------------------------*/

extern asm_init_cache(void);

/*******************************************************************

| defines and macros (scope: module-local)

|------------------------------------------------------------------*/

/*******************************************************************

| typedefs and structures (scope: module-local)

|------------------------------------------------------------------*/

/*******************************************************************

| global variable definitions (scope: module-exported)

|------------------------------------------------------------------*/

/*******************************************************************

| global variable definitions (scope: module-local)

|------------------------------------------------------------------*/

uint32_t count; /* counter used in delay loop */

const int PIN_NUMBER = 68; /* PE4 */

/*******************************************************************

| function prototypes (scope: module-local)

|-----------------------------------------------------------------*/

static void SWT_Disable(void);

static void MODE_Init(void);

static void PLL_Init(void);

static void Environment_Init(void);

/*******************************************************************

| function implementations (scope: module-local)

|------------------------------------------------------------------*/

/******** void SWT_Disable(void) *********/

//! This function disable the software watchdog

/*!

\brief Disable Software Watchdog Timer

\return No return value.

\retval void

\note Can also be disabled in Shadow row

*/

void SWT_Disable(void)

{

34/49 Doc ID 022384 Rev 1

Page 35

AN3995 Application code example

SWT.SR.R = 0xC520; /* Clear Soft lock bit in CR by writing */

SWT.SR.R = 0xD928; /* 0xC520 followed by 0xD928 to WSC field */

SWT.CR.B.WEN = 0x0; /* Clear Watchdog Enable Bit */

}

/******** void MODE_Init(void) *********/

//! This function initialize the modes

/*!

\brief Enable system clock for all peripherals assuming 120MHz system cloc

\return No return value.

\retval void

\note None

*/

void MODE_Init(void)

{

ME.MER.R = 0x000025FF; /* Enable all modes */

ME.RUNPC[0].R = 0x000000FE; /* Enable all peripherals in all modes */

/* Enable system clock for all peripherals assuming 120MHz system clock */

CGM.SC_DC[0].R = 0x83; /* Max 32MHz. Closest is 30MHz, Div+1=3 */

CGM.SC_DC[1].R = 0x81; /* Max 64MHz. Closest is 60MHz, Div+1=2 */

CGM.SC_DC[2].R = 0x81; /* Max 64MHz. Closest is 60MHz, Div+1=2 */

/* Re-enter DRUN mode to update the clock configuration */

ME.MCTL.R = 0x30005AF0; /* DRUN Mode & Key */

ME.MCTL.R = 0x3000A50F; /* DRUN Mode & Key */

while (ME.GS.B.S_MTRANS == 1); /* Wait for mode transition complete */

}

/******** void PLL_Init(void) *********/

//! This function configure the PLL

/*!

\brief This function configure the PLL

\return No return value.

\retval void

\note Switch on osc, change mode and wait for osc ON

Configure and enable PLL, change mode and wait for PLL to lock

Set clock source as PLL, change mode and check clock is PLL

*/

void PLL_Init(void){

ME.DRUN.B.FXOSC0ON = 1;/* Switch on external oscillator in DRUN mode */

/* Re-Enter DRUN mode (mode=0x3) to activate change */

ME.MCTL.R = 0x30005AF0; /* Mode & Key */

ME.MCTL.R = 0x3000A50F; /* Mode & Key inverted */

while(ME.GS.B.S_MTRANS == 1); /* Wait for mode transition complete */

while(ME.GS.B.S_CURRENTMODE != 3);/* Error trap - if current mode is not DRUN (eg

in safe mode), then loop */

while(ME.GS.B.S_FXOSC != 1);/* Wait for external OSC to stabilize */

/* Select External OSC as the FMPLL Reference Clock Source */

CGM.AC0_SC.B.SELCTL = 0x0;

/* Configure PLL for 120MHz with 40MHz xtal: PLL frequency = (40 * NDIV) / (IDF *

ODF) */

/* NOTE: VCO (PLL * ODF) must be between 256 and 512MHz */

CGM.FMPLL_CR.B.IDF = 0x4; /* Divide by 5 */

CGM.FMPLL_CR.B.ODF = 0x1; /* Divide by 4 */

CGM.FMPLL_CR.B.NDIV = 60; /* Divide by 60 */

/* Enable PLL in DRUN mode. */

Doc ID 022384 Rev 1 35/49

Page 36

Application code example AN3995

ME.DRUN.B.FMPLLON = 1;

/* Re-Enter DRUN mode (mode=0x3) to activate change */

ME.MCTL.R = 0x30005AF0; /* Mode & Key */

ME.MCTL.R = 0x3000A50F; /* Mode & Key inverted */

while(ME.GS.B.S_MTRANS == 1); /* Wait for mode transition complete */

while(ME.GS.B.S_CURRENTMODE != 3);/* Error trap - if current mode is not DRUN (eg

safe mode), then loop */

while(CGM.FMPLL_CR.B.S_LOCK == 0);/* wait for PLL to lock (will not lock until reenter DRUN mode */

/* Finally set system clock to be PLL in DRUN mode */

ME.DRUN.B.SYSCLK = 0x4;

/* Re-Enter DRUN mode (mode=0x3) to activate change */

ME.MCTL.R = 0x30005AF0; /* Mode & Key */

ME.MCTL.R = 0x3000A50F; /* Mode & Key inverted */

while(ME.GS.B.S_MTRANS == 1); /* Wait for mode transition complete */

while(ME.GS.B.S_CURRENTMODE != 3);/* Error trap - if current mode is not DRUN (eg

safe mode), then loop */

while(ME.GS.B.S_SYSCLK != 4){}; /* Final check - ensure ME_GS reports clock as

system PLL (0x4) -- fail if stuck here */

/* Enable CLKOUT pin so clock frequency can be verified */

CGM.OC_EN.B.EN = 1; /* Enable Output clock */

CGM.OCDS_SC.R = 0x23000000; /* And seclect output as system clock / 4 */

SIU.PCR[0].R = 0x0A04; /* PA0 ALT2 function (Clkout), MAX SRC */

}

/******** void Environment_Init(void) *********/

//! This function initialize the device

/*!

Called functions:

- SWT_Disable();

- MODE_Init();

- PLL_Init();

- asm_init_cache();

\brief This function configure the PLL

\return No return value.

\retval void

\note Start also the core 1

Set clock source as PLL, change mode and check clock is PLL

*/

void Environment_Init(void){

SWT_Disable(); /* Disable Software Watchdog Timer (Can also be disabled in Shadow

row) */

MODE_Init();/* Configure modes and activate all clocks for all peripherals */

CGM.Z0_DCR.B.DIV = 0x1; /* Z0 clock divider to divide by 2 */

CGM.Flash_DCR.B.DIV = 0x1; /* Flash register interface /2 (default) */

PLL_Init(); /* Set system clock to 120MHz based on 40Mhz XTAL */

asm_init_cache(); /* Enable Cache 4WAY */

/* Start Z0 Core */

SSCM.DPMBOOT.R = 0x00180000; /* Start address of Z0 (2nd Flash block) */

SSCM.DPMKEY.R = 0x00005AF0; /* Write key 1 */

SSCM.DPMKEY.R = 0x0000A50F; /* Write key 2 */

}

/*******************************************************************

36/49 Doc ID 022384 Rev 1

Page 37

AN3995 Application code example

| function implementations (scope: module-exported)

|------------------------------------------------------------------*/

/******** int main(int argc, char *argv[]) *********/

//! This is the main function

/*!

Called functions:

- Environment_Init()

\param[in] argc (argument) see type definition

\param[in] *argv[] (list) type definition

\brief This code is a blink led example

\return function result.

\retval integer

\note

*/

int main(int argc, char *argv[]){

Environment_Init();/* Basic device Initilaizations (Modes,Pll,Start core 1,...)

*/

/* Example Code start here */

/* Loop forever Flashing an LED connected to Port PE[4] (core Z0 code blink

contiguous led) */

SIU.PCR[PIN_NUMBER].R = 0x0200; /* PE[4] to GPIO mode, output */

while(1){

SIU.GPDO[PIN_NUMBER].R = (~(SIU.GPDO[PIN_NUMBER].R) & 0x01); /* Invert LED

output */

for (count=0; count<1000000; count++); /* wait a while */

};

return 0;

} /* End Of Main */

#ifdef __cplusplus

}

#endif

Doc ID 022384 Rev 1 37/49

Page 38

Application code example AN3995

A.2 crt0_corez4_Flash.s

#/***********************************************************************/

#/* DESCRIPTION: */

#/* This is the initialization (crt0) file for SPC5646X devices running*/

#/* from Flash in VLE mode */

#/* */

#/* CONFIGURATIONS: */

#/* (1) Configures the Reset Config Half word for VLE */

#/* (2) Configures MMU TLB entry 1 for 128KB RAM at 0x4000_0000 */

#/* (3) Configures peripherals space (IPBridge) on MMU TLB entry 2 */