AN3973

Application note

Electronic ballast with active PFC using

STD3N62K3 power MOSFET and STD845DN40 BJT device

Introduction

In the most recent developments regarding energy saving, optimization and correct

selection of design components are considered a must in order to have improved electric

efficiency. An increasing sensitivity regarding energy problems has made companies and

consumers more demanding. In this context, cooperation and support between silicon

makers and customers is paramount: an exchange of experience leads to a better and

quicker way to realize new projects. In this article, we present an electronic ballast project

designed thanks to customer input. This application note describes the demonstration board

for 2X28 W electronic lamp ballast with active PFC. The ballast is formed by a part of the

PFC section and a self-oscillating half bridge converter. The circuit has been designed for a

nominal input voltage of 230 Vrms±15% and 50-60 Hz. The key components are the power

bipolar transistor (STD845DN40), the MOSFET device (STD3N62K3), and an ST power

switching driver for the PFC section. The purpose of this application note is to show a simple

and cheap lighting application optimized in terms of power factor (PFC), THD harmonic

distortion, and electric efficiency. The DC-AC converter section presents a layout solution

that offers the customer the possibility of using a bipolar transistor, or DIP 8 or SOT-82

package.

November 2011 Doc ID 022164 Rev 1 1/24

www.st.com

Contents AN3973

Contents

1 System description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2 Power factor section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.1 PFC section design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.1.1 Input capacitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1.2 Output capacitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1.3 Boost inductor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1.4 Power MOSFET selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1.5 L6562A biasing circuitry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3 DC-AC converter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.1 System description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.1.1 Preheating phase . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.1.2 Ignition phase . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.1.3 Steady-state phase . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4 Driving optimization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.1 MOSFET circuit optimization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.2 BJT circuit optimization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5 Experimental results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

6 Conclusions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

7 Layout layers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

8 Bill of material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

9 Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

10 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2/24 Doc ID 022164 Rev 1

AN3973 List of figures

List of figures

Figure 1. Ballast model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Figure 2. PFC section, boost converter diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Figure 3. Inductor and input current waveform. MOSFET timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Figure 4. PFC section, relevant elements for THD and PFC factor . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Figure 5. DC-AC converter section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Figure 6. Voltage and current lamp waveforms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Figure 7. Zoom of the highlighted section (in Figure 6) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Figure 8. Voltage and current lamp waveforms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Figure 9. Zoom of the highlighted section (in Figure 8) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Figure 10. Voltage and current lamp waveforms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Figure 11. Zoom of the highlighted section (in Figure 10) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Figure 12. Snubber and driving circuit of MOSFET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Figure 13. MOSFET turn-off without snubber circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 14. MOSFET turn-off with snubber circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 15. MOSFET turn-on @ R7=10 W . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 16. MOSFET turn-on R7=47 W . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 17. BJT in low side. Snubber and driving circuit of BJT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 18. Steady-state operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 19. Zoom of the highlighted section 1 (in Figure 18) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 20. Zoom of the highlighted section 2 (in Figure 18) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 21. Bottom layout layer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 22. Top layout layer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 23. Silkscreen top . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 24. Silkscreen bottom . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Doc ID 022164 Rev 1 3/24

System description AN3973

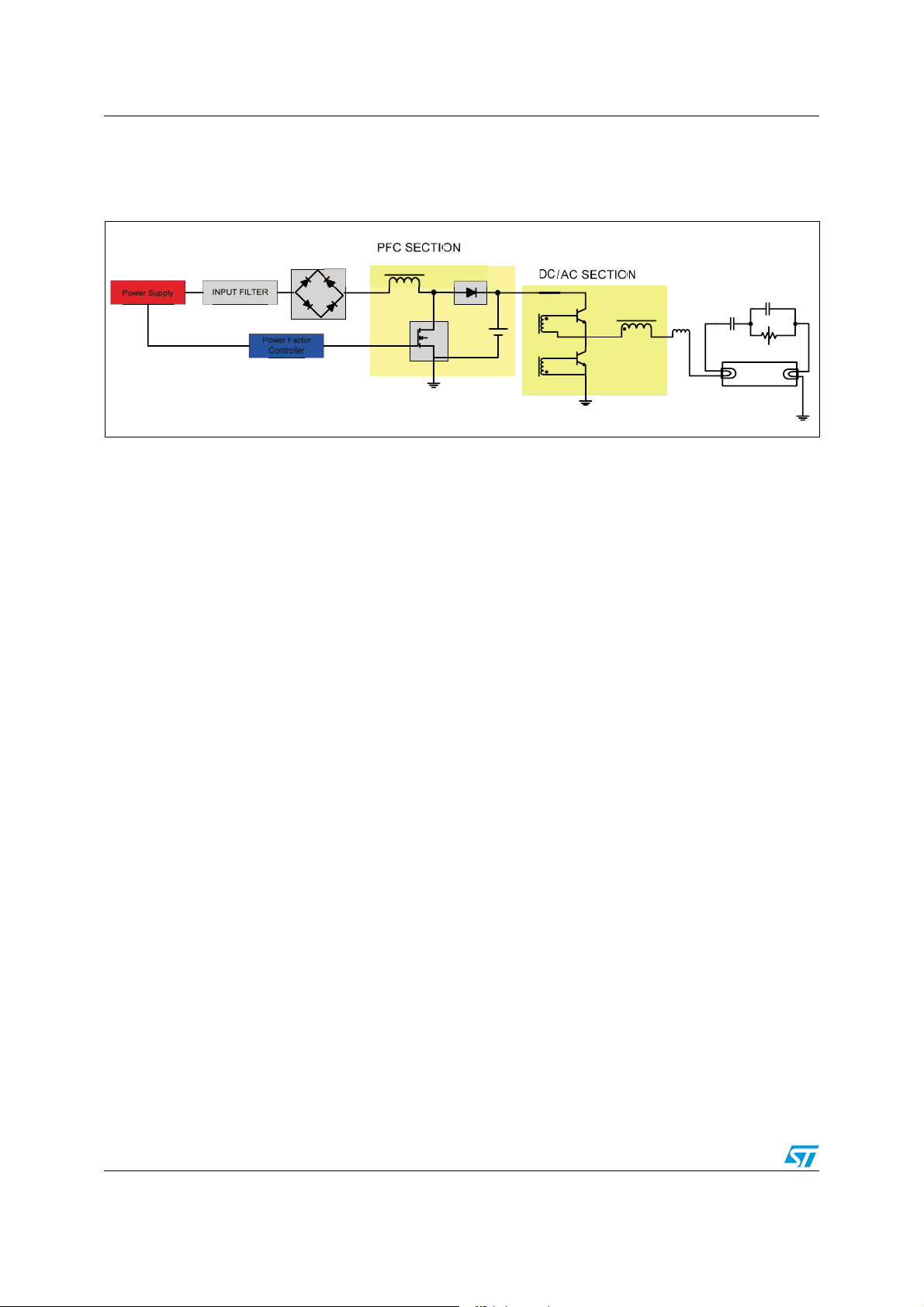

1 System description

Figure 1. Ballast model

!-V

The system description is subdivided into two main sections, namely the PFC boost section

and half bridge converter. The system description starts with the PFC section and then

continues with the DC-AC converter. In the PFC section the method and the electrical

elements concerning the optimization of PFC and THD parameters are pointed out. In the

DC-AC converter section, the focus is the optimization of transistor bipolar driving.

4/24 Doc ID 022164 Rev 1

AN3973 Power factor section

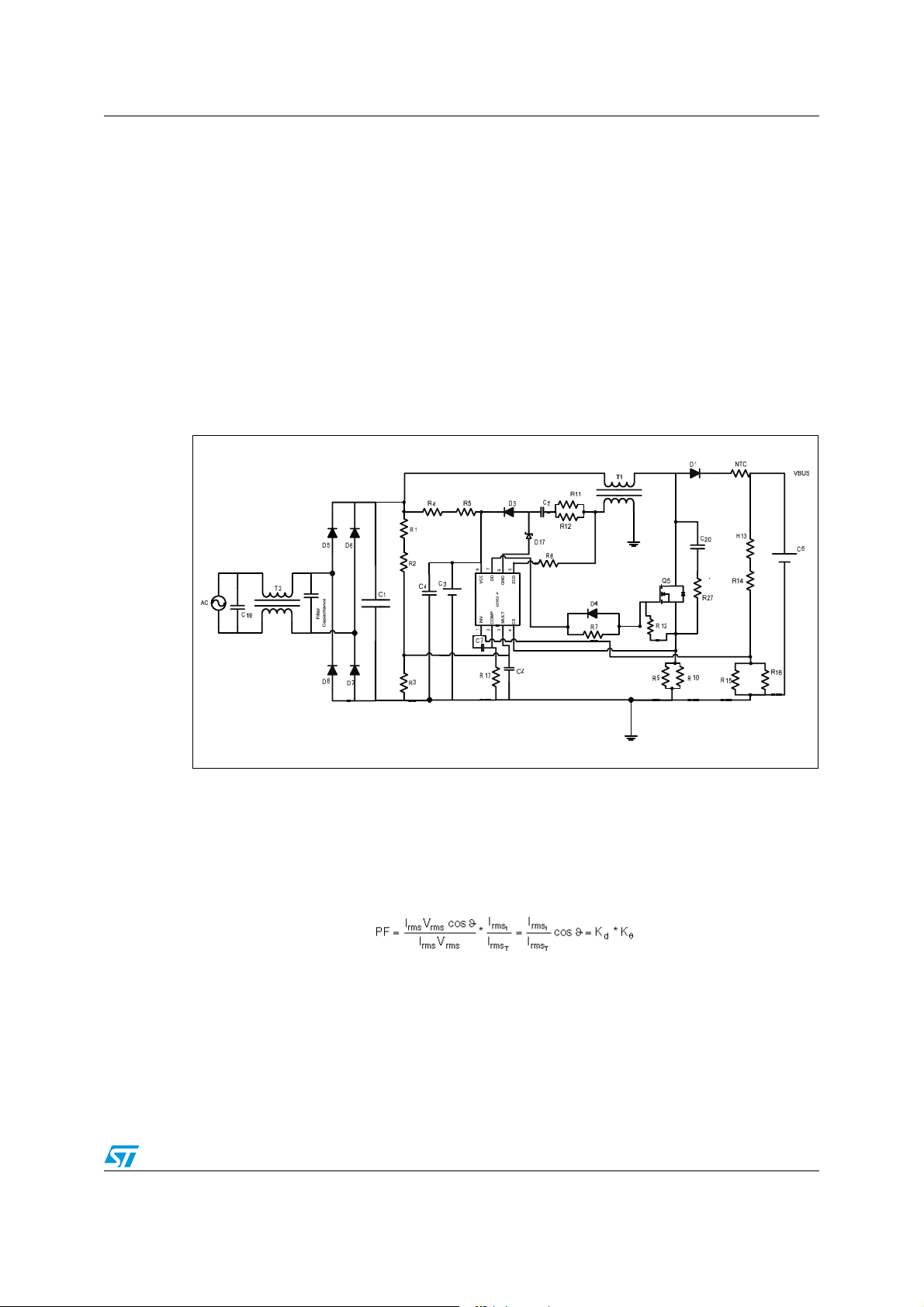

2 Power factor section

The PFC section (boost converter) mainly consists of STD3N62K3 MOSFET SuperMESH3

technology and the L6562A power switching driver. The new SuperMESH3 technology is

obtained through the combination of fine tuning between standard SuperMESH and

MDMESH technology. This has resulted in the development of a new technology that

represents the optimization of the basic standard SuperMESH in terms of R

dynamic features. SuperMesh has integrated Zener diodes gate-to-source in order to

protect its gate-oxide from voltage spikes. The L6562A is a current-mode PFC controller

operating in transition mode. It has an improved performance compared to its predecessor,

the L6561.

Figure 2 shows the PFC section schematic plus the component values.

Figure 2. PFC section, boost converter diagram

DS(on)

* area and

!-V

The power factor consists of the displacement factor related to phase angle and the

distortion factor related to wave shape. The displacement factor is the ratio between the real

power (transferred to the output) and the apparent power (RMS line voltage times RMS line

current) drawn from the main, while the distortion factor is the ratio between the

fundamental component of the current and the total current:

Equation 1

Therefore, the section is designed in order to minimize input current distortion and forces the

input current to be in phase with the input voltage.

This system operates in transition mode, the boundary between continuous and

discontinuous current mode. The control simplicity and the inductor size, due to the low

inductance value needed, are the main advantages of this conduction current mode.

Doc ID 022164 Rev 1 5/24

Power factor section AN3973

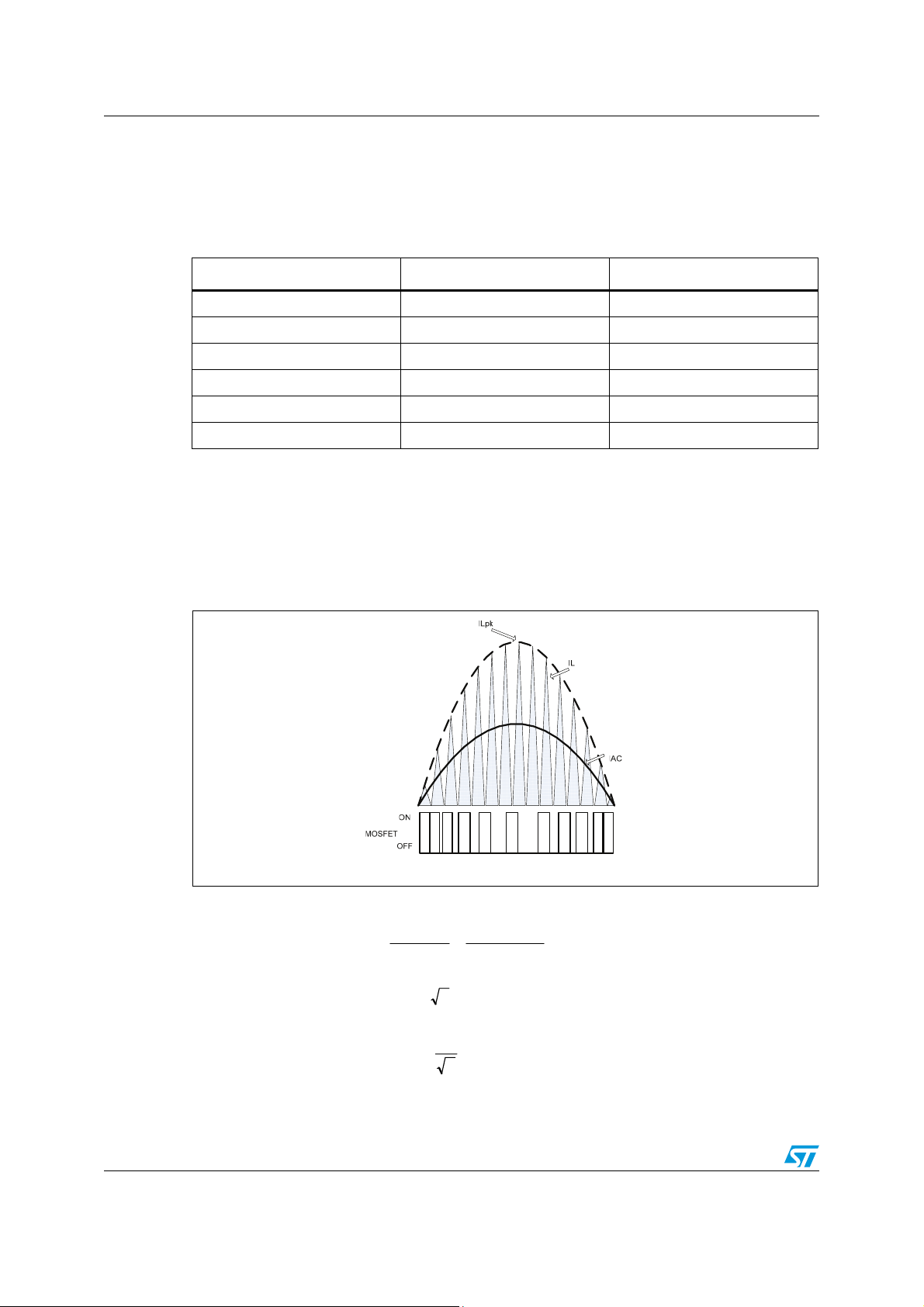

2.1 PFC section design

The first step is to define the converter specifications that the user must set for the new PFC

boost topology project.

Table 1. Converter specification data and fixed parameters

Name Symbol Value

Input voltage range V

Nominal output voltage V

Nominal output power P

INmin-VINmax

out

out

Target efficiency n ∼

Minimum switching frequency f

s

180 Vac to 264 Vac

400 V

60 W

90%

35 kHz

Expected power factor PF 0.99

At switching frequency, the inductor current is a triangle shape and the average value is half

of the peak of triangle. The resulting inductor current is shown in Figure 3, where it is also

shown that, by geometric relationships, the average value is the peak of sinewave input

current. The system operates the boundary between continuous and discontinuous

(transition mode current):

Figure 3. Inductor and input current waveform. MOSFET timing

Therefore the main operating conditions are:

● RMS input current

● Peak inductor current

● RMS inductor current

6/24 Doc ID 022164 Rev 1

I

in

P

IL =

P

in

==

PFV

minAC

I22IL =

inpk

2

3

out

η

minAC

I

inRMS

AM10586v1

A374.0

=

PFV*

AN3973 Power factor section

2.1.1 Input capacitor

The input filter capacitor (Cin) must reduce the high frequency voltage ripple across Cin and

the switching noise due to the high frequency inductor current ripple. The input capacitor

depends on the voltage ripple (r) and it is usually between 5% and 20% of the minimum

input voltage:

● Ripple voltage coefficient (%):

● Input capacitor

=

C

IN

π

1.0r =

I

in

r*V*f2

minACminSW

nF100

≈

In the applicative conditions, a polyester capacitor was chosen. It offers benefits in terms of

voltage stability and power factor (PF).

2.1.2 Output capacitor

The output capacitor is a function of voltage ripple (ΔV

ΔV

is usually selected at around 1.5% of the output voltage capacitor:

out

● Output capacitor

An electrolytic capacitor has been selected because it has low impedance (ESR) and

therefore provides good energy storage and improves the transient performance.

2.1.3 Boost inductor

The inductor boost depends on the several parameters and different approaches which can

be used. First, the inductor value is usually calculated so that the minimum switching

frequency is greater than the maximum frequency of the L6562A internal starter. Assuming

unity PF, it is possible to write:

● Instantaneous switching frequency

Therefore, the inductor value is determined at the top of the sinusoid ( ) where the

switching frequency is the minimum:

● Inductor value

The optimum dynamic performances of the MOSFET device, selected for this application,

have allowed higher operation minimum frequency and consequently lower boost

inductance. In this case a 1.8 mH boost inductance was selected.

) and of the capacitor impedance.

out

C

=

Out

)V(L

=

AC

2

AC

P

out

−

VV*f4

Δπ

fθ−=

sw

outoutmain

P*Vf2

uF47

≈

2

1

AC

LP2

IN

)V2V(V

ACOut

INoutminSW

ACOut

V

out

))sin(V2V(V

π

=θ

2

2.1.4 Power MOSFET selection

MOSFET SuperMESH3 technology perfectly matches boost converter characteristics. In

fact, this technology has got a dynamic performance better than that of the standard

SuperMESH but not as good as MDMESH. That translates into having low switching power

losses and commutation which is not so fast that it implies ringing phenomenon such as

decreased PF and THD factors. MOSFET selection is based mainly on maximum voltage

rating, total power losses, and maximum operating temperature. In this case a MOSFET

device with minimum voltage rating 500 V (1.2*V

Doc ID 022164 Rev 1 7/24

=480 V) must be selected: 20% of V

BUS

BUS

Power factor section AN3973

indicates the safe margin. In the end, the MOSFET selection depended on power losses

and maximum operating temperature. MOSFET total power losses depend on conduction

and switching losses. The conduction losses at minimum input voltage are calculated by:

● Conduction losses

● RMS switch current

Pc R

DS on()

2

I

⋅=

SWrms

senV2V

min

θ−

*senII

θ=

LpkSWrms

V3

inBUS

BUS

The switching losses in the MOSFET occur only during turn-off, because this boost topology

works in transition mode. Basically they can be expressed by:

● Switching power losses

Psw

where Qgd is the gate drain charge, I

f

s(ILRMS

) is switch frequency calculated for value.

=

is RMS inductor current, Ig is the gate current and

LRMS

I*V*Q

LBUSgd

RMS

I*2

g

)I(f

Ls

RMS

Based on the information above, the MOSFET choice was the STD3N62K3 device. The final

results show that STD3N62K3 ensures good performance in terms of electrical and thermal

behavior.

2.1.5 L6562A biasing circuitry

The dimensioning of biasing circuitry of the L6562A driver is reported for only a few

elements. In particular, the dimensioning is shown for those components that have been

relevant in terms of THD harmonic distortion and power factor (PF).

Figure 4. PFC section, relevant elements for THD and PFC factor

!-V

Pin2 (COMP). A feedback compensation network is put between this pin and INV in order to

fix narrow bandwidth and avoid high distortion of the input current waveform. In this way a

8/24 Doc ID 022164 Rev 1

AN3973 Power factor section

voltage value (VCOMP) is determined, it is the reference (in the multiplier characteristic

graph) for the “MULT” and “CS” signal. Taking this into account, the procedure to set the

operation point of the multiplier Pin3 (MULT) is suggested. First, the maximum peak value is

selected. This value, which occurs at maximum mains voltage, should be less 3 V in case of

single mains. Therefore:

● Minimum peak value:

● This value is then multiplied by the minimum guaranteed and it gives

the maximum output voltage of multiplier: .

● In this way the divider resistor is: .

● Subsequently thanks to these relationships:

V

minCS

R <

S

IL

.

peak

VV =

MULTpk xminMU LTpk

R

3

V

V

=

RRR

++

321

V

MULTpkx

V*2

minINRMS

maxINRMS

V

Δ

CS

V

Δ

MULT

V*1.1V =

maxINRMS

1.1

=

minMULTpkxCSpk

V)V5.2V(kV −=

MULTCOMPCS

The divider resistor R3=15 kΩ and R1/R2=2.7 MΩ and the sense resistors R9=0.39 Ω and

R10=1 Ω have been fixed.

In particular:

– the reference for the current sense.

– the typical multiplier gain

– the voltage on the Pin2

– the voltage on the Pin3

This experimental fine tuning guarantees a high value of both PF and THD.

Pin5 (ZCD).This pin is the zero current detector circuit. In this case (PFC in transition mode)

the ZCD pin is connected, through a resistor, to the auxiliary winding of the boost inductor.

In particular, the resistance value (R6=47 kΩ) was tuned in order to minimize the switching

power losses at turn-on. In fact, this fine tuning allows the MOSFET to switch on when the

resonant phenomenon between boost inductor and drain-source capacitance occurs on the

valley of the drain voltage. In this way, the MOSFET device turns on with lower voltage

across drain source, this implies a reduced current peak and lower switch-on losses.

Doc ID 022164 Rev 1 9/24

DC-AC converter AN3973

3 DC-AC converter

The electronic ballast consists of a self-oscillating voltage-fed half bridge inverter, which has

been developed to drive two lamps of 28 W. One of the key components is the

STD845DN40 power bipolar transistor. It is a dual NPN high voltage power transistor and is

housed in dual-island DIP-8 package. This package solution allows to save layout area and

its driving circuit has been optimized so that the thermal performance is not too different to

that of a single transistor. The second of the key components is the possibility to use, for

bipolar transistors, a DIP-8 or SOT-82 package solution.

Figure 5. DC-AC converter section

!-V

The DC-AC converter section has been realized according to customer indications. The

ballast coil L3/L5 (3.7 mH) and the saturable core transformer L4 (20 µH) were given by the

customer and in relation to this, all the other passive and active elements have been

selected. In particular, the design has been realized so that the lamp voltage is 180 V and

the lamp current about 0.15 A. The following design procedure is suggested for resonant

components and for proper operation of the self-oscillating inverter.

Considering first the given set of specifications: V

=400 V, output current I

BUS

OUT

=0.15 A,

ballast coil L3/L5=3.7 mH, core saturable transformer L4=20 µH and, more specifically, the

lamp resistance (R ≈1160 Ω).

The RMS input voltage can be calculated from:

Equation 2

=2VV

BUSRMS_IN

π

The value of the desired characteristic impedance is extracted:

10/24 Doc ID 022164 Rev 1

AN3973 DC-AC converter

Equation 3

Z ==

r

L

C

I

OUT

RMS_IN

V

Given the resonance inductance, the switching frequency is calculated:

Equation 4

Z

f

s

r

=

3L2

π

Then the resonant capacitor is given by:

Equation 5

Cπ=

r

1

Z*f2

rs

where .

r

11C10CC

+=

For proper operation resonant, the network must be , in this way the

drop across the serially connected lamps is higher than the bus voltage and the current is

sinusoidal. This is the preferred operation mode.

3.1 System description

The system description is subdivided into three main sections, preheating, ignition and

steady-state phase.

3.1.1 Preheating phase

To obtain a long lamp life, it is important that the electrodes are preheated by a certain

current. A PTC RT1 (for the single lamp) put in parallel with the lamp guarantees the

electrode preheating as it ensures that the current is flowing via the lamp electrodes. During

this period the voltage across the lamp is maintained sufficiently low to avoid the lamp

igniting too early and the operating frequency is determined by L3 and C11 (C10 is partially

inhibited by PTC).

R

1

Q

>=

Z

r

Doc ID 022164 Rev 1 11/24

DC-AC converter AN3973

Figure 6. Voltage and current lamp

waveforms

The preheating time depends on the setting of the circuit parallel to the lamp (time

constant). In particular, it is the PTC value that determines this duration of preheating as

well as the ignition of the lamp. In fact, as long as it does not increase its impedance, it does

not allow the resonant circuit (L3, C11, and C10) to generate the overvoltage on the lamp

and so on the ignition itself.

3.1.2 Ignition phase

Figure 7. Zoom of the highlighted section (in

Figure 6)

As soon as the electrodes are preheated, the impedance of the PTC rapidly increases and

the series resonance of L3, C11, and C10 results in an increasing lamp voltage. The lamp

voltage increases until it ignites.

Figure 8. Voltage and current lamp

waveforms

The resonant circuit operates in order to ignite the lamp. In the ignition phase, the voltage

shape of the lamp depends on the rise time of the PTC impedance.

Figure 9. Zoom of the highlighted section (in

Figure 8)

12/24 Doc ID 022164 Rev 1

AN3973 DC-AC converter

Resonant circuit frequency:

Equation 6

f

=

r

1

)CC(L2

+π

10103

3.1.3 Steady-state phase

Once the tubes are ionized, it is effectively a short-circuit across C10 + C11. The inverter

system sets the voltage and current shape so that the lamp correctly operates.

Figure 10. Voltage and current lamp

waveforms

Therefore, the frequency is defined by C15 and so is lower than the ignition phase. At this

frequency, the overvoltage generated is also lower, but enough to keep the tube lit. During

steady-state, when the transistor is first turned on, the current in the transformer L4

increases until its core saturates. At this point, after the storage time of the transistor has

passed, it turns off. In this way, the operating frequency also depends on the size and

maximum flux density of the core of L4 and the storage times of the transistor.

Figure 11. Zoom of the highlighted section (in

Figure 10)

Doc ID 022164 Rev 1 13/24

Driving optimization AN3973

4 Driving optimization

The driving circuit optimization has been done in order to have the best performance of the

lighting system. Basically, this circuit concerns MOSFET and BJT transistors and it has

been realized in order to have thermal and electrical behavior of devices compliant to the

system features.

4.1 MOSFET circuit optimization

The elements of circuit optimization are shown below.

Figure 12. Snubber and driving circuit of MOSFET

&

4

'

5

5

5

5 5

!-V

A small RC snubber circuit (C=680 pF and R=180 Ω) has been used to prevent voltage

spikes and voltage oscillation across the MOSFET during device turn-off. This means

limiting the rate of rise (ΔV

/Δt) of the MOSFET, to reduce the cross between voltage and

DS

current and to have less switching losses during turn-off. The driving circuit (R7=47 Ω and

diode) allows the MOSFET to not turn on too quickly in order to reduce the discharge of

snubber circuit capacitance and consequently to guarantee negligible switch-on losses and,

thanks to the diode, it allows the fastest discharge of parasitic capacitance of the MOSFET

and therefore speeds up switch-off.

14/24 Doc ID 022164 Rev 1

AN3973 Driving optimization

The waveforms show the advantages of the driving solution and the snubber circuit.

Figure 13. MOSFET turn-off without snubber

circuit

Figure 14. MOSFET turn-off with snubber

circuit

The comparison between these waveforms shows that the insertion of the RC snubber

circuit reduces voltage spikes and Vds slope and in particular it decreases switching losses

during turn-off.

Figure 15. MOSFET turn-on @ R7=10 Ω Figure 16. MOSFET turn-on R7=47 Ω

As the figures show, the resistor R7=47 Ω in the driving circuit provides a slower switch-on

of the MOSFET, reduces the discharge of snubber circuit capacitance and consequently it

guarantees negligible power losses during turn-on.

Doc ID 022164 Rev 1 15/24

Driving optimization AN3973

4.2 BJT circuit optimization

The snubber and the driving circuit of BJT is the same as low side and high side. In

particular,

Figure 17. BJT in low side. Snubber and driving circuit of BJT

Figure 6 shows the elements of low side BJT driving circuit which are highlighted.

'

5

4

5

&

&

5

!-V

A small C9 snubber circuit has been used in order to decrease the cross between voltage

(VCE) and current (ICE) and, consequently, to have less switching losses during turn-off.

The capacitance C9 allows to limit, in the middle point (2), the rate of rise of VCE. This

snubber capacitance is put in the low side in order to ensure the discharge to ground and

therefore to avoid a current too high spike during the startup phase. The choice of the C9

capacitance was made in order to balance the power switching losses, in fact, the value

C9=680 pF, obtained in experimental results, guaranteed the lowest switch-off losses and

negligible switch-on losses due to the discharge of capacitance during the turn-on of the

transistor. The driving circuit (R23=5.6 Ω, R24=33 Ω and diode) provided the best

commutation of the bipolar transistor. The R24 value was able to reduce current spike due to

the discharge of snubber circuit capacitance and to ensure the charge quantity so that the

IC current was sufficient to power the lamp. R23||R24 put in parallel determined the

commutation time, the storage time of the bipolar transistor, and consequently the operating

frequency of the ballast system.

The waveforms in

Figure 18 show the behavior of BJT during steady-state operation.

Figure 18. Steady-state operation

1

16/24 Doc ID 022164 Rev 1

2

AN3973 Driving optimization

Figure 19. Zoom of the highlighted section 1

(in Figure 18)

The turn-on of the bipolar transistor had a spike of Ibe current due to C18 capacitance, it

assisted the charge phenomenon of the bipolar junction. The fall time value during the

turn-off was very low and this implied shorter commutation time and lower switching losses.

Figure 20. Zoom of the highlighted section 2

(in Figure 18)

Doc ID 022164 Rev 1 17/24

Experimental results AN3973

5 Experimental results

The experimental results have been measured for different input voltage levels and leaving

the application in free air: all electrical components were in the original position. The test

equipment list has been given in order to check the measurements repeatability.

● Input voltage: ∼180 - 230 - 265 Vac

● Test equipment:

– Agilent AC power supply 6813B

– Digital power meter WT210

– Flir systems thermal camera

● Ambient temperature:

– ∼25 °C

Table 2. Main electrical and thermal results @ 25 °C ambient temperature

Input voltage [V] PFC THD Pin [W] MOSFET temperature [°C]

180 V 0.998 3.5 66.4 52 78

230 V 0.993 4.1 65.4 43 78

264 V 0.983 13.9 65.8 42 78

BJT temperature [°C] @

DIP-8

Exchanging input voltage, the main electrical parameters of the PFC factor and THD

suggest that the application performances were very good. Everything the energy soaked

up by the system was converted into useful power. The temperatures of transistor devices

respect the datasheet specifications. In particular the temperature of BJT transistors was

not too high considering that the DIP-8 package had a dual NPN high voltage power

transistor housed in dual-island.

Tab l e 3 , the thermal performance between the DIP-8 and SOT-82 package were

In

compared.

Table 3. Thermal results @ 25 °C ambient temperature

Input voltage [V] BJT temperature [°C] @ DIP-8 BJT temperature [°C] @ SOT-82

230 V 78 61

The temperature of the two package solutions was not too different, for both cases the

transistors worked in safety condition. The temperature value of the bipolar transistor didn't

depend on the input voltage because the PFC active section allows to fix, at 400Vdc, the

voltage of the DC-AC section. For this reason the temperature of the bipolar (both

packages), was only measured at 230 Vac (nominal input voltage).

18/24 Doc ID 022164 Rev 1

AN3973 Conclusions

6 Conclusions

The proposed design of electrical ballast with active PFC and self-oscillating inverter

showed the capability of driving 2X28 W fluorescent lamps with very good electrical and

thermal performance. The component choice and the optimization of the transistors driving

circuit guarantee the highest PFC factor and lowest THD. For each work condition the

ballast drove the lamps safely.

This power source offers the customer the double package solution: bipolar transistors in

DIP-8 or SOT-82 package. For both solutions the temperature of power devices is fully

compliant with the absolute maximum rating limit in the datasheet specification.

In addition, the design layout was designed using the double layer solution. Anyway,

according to customer needs, the PCB layout of the application can be realized both in

double layer and in single, using the jumpers instead of the net in the top layer.

Doc ID 022164 Rev 1 19/24

Layout layers AN3973

7 Layout layers

Figure 21. Bottom layout layer

Figure 22. Top layout layer

Figure 23. Silkscreen top

Figure 24. Silkscreen bottom

20/24 Doc ID 022164 Rev 1

AN3973 Bill of material

8 Bill of material

Table 4. Bill of material

Quantity Reference Part/value

2 R1/R2 2.7 MΩ

1R315 kΩ

2 R4/R5 270 kΩ

1R647 kΩ

1 R7 10 Ω

1 R12 47 kΩ

1R90.39 Ω

1R101 Ω

2 R11/R12 220 Ω

2 R13/R14 1 MΩ

1 R15 15 kΩ

1 R16 82 kΩ

1 R17 10 kΩ

3 R18/R19/R20 180 kΩ

2 R21/R23 5.6 Ω

2 R22/R24 33 Ω

2 R25/R26 0.82 Ω

1 R27 180 Ω

1C1150 nF

4 C2/C5/C17/C18 10 nF

1 C3 10 µF

2 C4/C8 100 nF

1 C6 33 µF

1C71 µF

1 C21 680 pF

2 C10/C12 4.7 nF

2 C11/C13 10 nF

2 C14/C15 100 nF

1 C20 27 pF

1 C19 330 nF

1 Filter capacitance 2.2 nF

1 D1 STTH1L06A

Doc ID 022164 Rev 1 21/24

Reference AN3973

Table 4. Bill of material (continued)

Quantity Reference Part/value

4 D3/D4/D12/D13 1N4148

5 D5/D6/D7/D8/D11 1N4007

1D16Zener

2RT1/RT2PTC

1 NTC 2.5

1 T2 18 mH filter inductance

1 T1 1.8 mH 0.5 A

1 L4 20 µH

2 L3/L5 3.7 mH

1 U3 L6562A

1 Q1 STD3N62K3

1 Q8 1-2 bipolar STD845DN40

9 Reference

1. AN2761 application note

22/24 Doc ID 022164 Rev 1

AN3973 Revision history

10 Revision history

Table 5. Document revision history

Date Revision Changes

11-Nov-2011 1 Initial release.

Doc ID 022164 Rev 1 23/24

AN3973

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY TWO AUTHORIZED ST REPRESENTATIVES, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2011 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Philippines - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

24/24 Doc ID 022164 Rev 1

Loading...

Loading...