Page 1

AN3960

Application note

ESD considerations for touch sensing applications

Introduction

Electrostatic discharge (ESD) is not a new phenomenon. It is often used to describe high

voltage that may produce permanent damage. ESD can be destructive and may leave a

sytem in an unknown state from which recovery is impossible. Fortunately, it can be

prevented by several methods. Some of these methods are cheap whilst some modify the

behavior of the equipment. The ideal situation is to balance both of these factors to obtain a

robust application which is not too expensive and which is unlikely to behave erratically.

This document describes ESD, its causes and risks. Several models and standards relating

to ESD simulation are outlined. Typical ESD protection techniques are explained. Test

results are presented for the STM8T142-EVAL evaluation board which was tested against

ESD events using some of the protection methods detailed in this application note.

October 2011 Doc ID 022082 Rev 1 1/21

www.st.com

Page 2

Contents AN3960

Contents

1 What is ESD ? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.1 Causes of ESD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2 Risks of ESD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.1 Simulation and testing of electronic devices using models . . . . . . . . . . . . 6

2.1.1 Human body model (HBM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.1.2 Machine model (MM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.2 Standards overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.2.1 JS-001-2010 international standard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.2.2 SP723 EIAJ IC121 standard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.2.3 IEC61000-4-2 international standard . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.2.4 MIL-STD-883H . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.2.5 ESD standard summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.2.6 Test results of ESD standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3 Protecting against ESD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.1 Dielectric overlays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.2 Spark gaps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.3 Ground rings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.4 Adding resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.5 Adding diodes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.6 ESD protection devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.7 Firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4 STM8T142-EVAL evaluation board: ESD tests . . . . . . . . . . . . . . . . . . . 16

4.1 Test setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.2 Test results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5 Conclusion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2/21 Doc ID 022082 Rev 1

Page 3

AN3960 List of tables

List of tables

Table 1. Test conditions for ESD standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Table 2. Dielectric overlay materials and their dielectric strength. . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Table 3. ESD protection devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Table 4. ESD discharges for tested STM8T142-EVAL evaluation board . . . . . . . . . . . . . . . . . . . . . 18

Table 5. Document revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Doc ID 022082 Rev 1 3/21

Page 4

List of figures AN3960

List of figures

Figure 1. Electrostatic discharge test (ESD generator and DUT) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Figure 2. IEC61000-4-2 ESD current waveform (R

Figure 3. PCB with spark gap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Figure 4. Ground ring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Figure 5. Test set up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 6. STM8T142-EVAL evaluation board modifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

= 330 W/CD = 150 pF). . . . . . . . . . . . . . . . . . . . 8

D

4/21 Doc ID 022082 Rev 1

Page 5

AN3960 What is ESD ?

1 What is ESD ?

ESD is the sudden and momentary electric current that flows between two objects at

different electrical potentials.

ESD immunity is a category of electromagnetic compatibility (EMC) - the branch of electrical

sciences which studies the unintentional generation, propagation and reception of

electromagnetic energy with reference to its unwanted effects.

EMC describes the ability of a piece of equipment or a system to function satisfactorily in its

electromagnetic environment without introducing intolerable electromagnetic disturbances

to anything in that environment.

1.1 Causes of ESD

One of the causes of ESD events is static electricity. Static electricity is often generated

through the separation of electric charges when two materials are brought into contact and

then separated, for example, rubbing a plastic comb against dry hair, removing some types

of plastic packaging. In these cases, the friction between two materials creates a difference

of electrical potential that can lead to an ESD stress.

Another cause of ESD damage is through electrostatic induction. This occurs when an

electrically charged object is placed near a conductive object isolated from ground. The

presence of the charged object creates an electrostatic field that causes electrical charges

on the surface of the other object to redistribute. Even though the net electrostatic charge of

the object has not changed, it now has regions of excess positive and negative charges. An

ESD stress may occur when the object comes into contact with a conductive path. For

example, charged regions on the surfaces of styrofoam cups or plastic bags can induce

potential on nearby ESD sensitive components via electrostatic induction and an ESD

stress may occur if the component is touched with a metallic tool.

2 Risks of ESD

ESD is a serious issue in solid state electronics, such as integrated circuits (ICs). ICs are

made from semiconductor materials such as silicon and insulating materials like silicon

dioxide. Either of these materials can suffer permanent damage when subjected to high

voltages.

The damaging effects of ESD poses unacceptable risks in many areas of technology and it

is necessary to control such interference and reduce the risks to acceptable levels through

the:

● Simulation and testing of electronic devices using models

● Definition of standards

Doc ID 022082 Rev 1 5/21

Page 6

Risks of ESD AN3960

#

$

2

2

$

(6SUPPLY6

$

#HARGESWITCH $ISCHARGESWITCH

$54

AI

).054

2.1 Simulation and testing of electronic devices using models

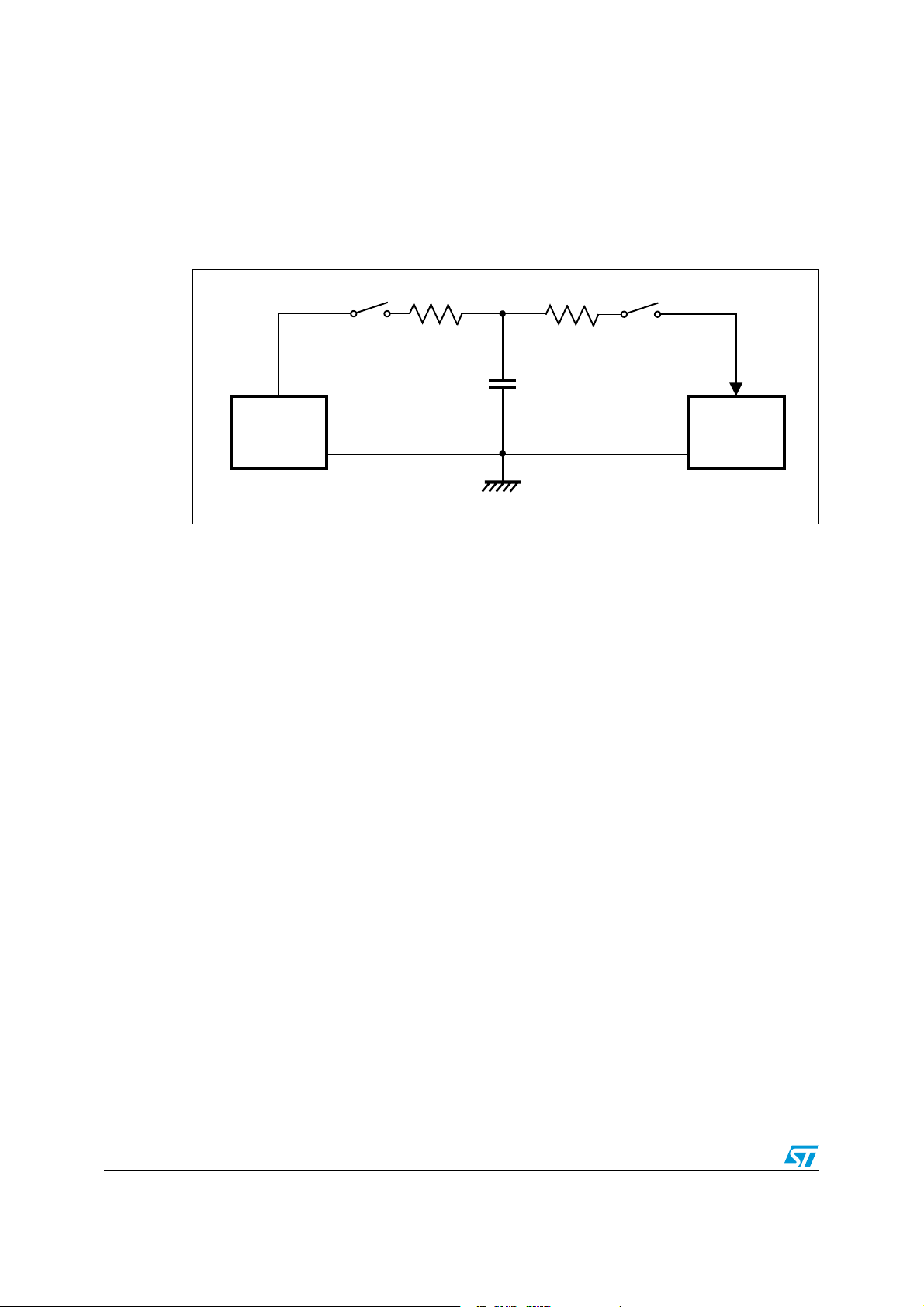

Several models describe how to simulate an ESD stress. The schematic circuit of Figure 1,

shows how to generate an ESD event to a device under test (DUT). It is the basis of these

models.

Figure 1. Electrostatic discharge test (ESD generator and DUT)

1. Legend: R1 = resistor 1, RD = discharge resistor, CD = discharge capacitor, HV = high voltage, and VD =

discharge voltage. R

2. The charge and discharge switches are not closed simultaneously.

, RD, and CD are defined according to a standard.

1

2.1.1 Human body model (HBM)

For testing the susceptibility of electronic devices to ESD stress from human contact, an

ESD simulator with a special output circuit called the human body model (HBM) is often

used.

This model simulates the discharge which might occur when a human touches an electronic

device (either a system or a component).

The HBM consists of a capacitor in series with a resistor (see Figure 1). The capacitor is

charged to a specified voltage from an external source, and then suddenly discharged

through the resistor into an electronic terminal of the DUT.

2.1.2 Machine model (MM)

This model simulates what happens when a machine becomes electrostatically charged

and subsequently discharges into an electronic device when it comes in contact with it.

The MM test circuit consists of charging up a 200 pF capacitor to a certain voltage and then

discharging this capacitor directly into the DUT.

6/21 Doc ID 022082 Rev 1

Page 7

AN3960 Risks of ESD

2.2 Standards overview

Standards exist for the following reasons:

● To reproduce well-defined tests in terms of their setup (bench size, type of isolating

area) and conditions (such as temperature and pressure)

● To eliminate misunderstandings between manufacturers and purchasers

● To facilitate interchangeability and improvement of products

● To assist the purchaser in selecting and obtaining the appropriate product for his

particular needs.

None of these reasons are paramount. Each depends on the needs of the customer who

must also discuss with his purchaser.

The subsections below provide an overview of the more important ESD standards.

2.2.1 JS-001-2010 international standard

The ESD association and JEDEC solid state technology association have established a joint

standard procedure for testing, evaluating, and classifying components and microcircuits

according to their susceptibility to damage or degradation by exposure to a defined HBM

ESD (1.5 k

Ω, 100 pF and 8 kV).

2.2.2 SP723 EIAJ IC121 standard

The SP723 EIAJ IC121 MM standard is for ensuring that the ESD capability is typically

greater than 2 kV (from 200 pF) with no serial resistor. For this standard, R

Figure 1 are respectively 0 Ω and 200 pF.

2.2.3 IEC61000-4-2 international standard

The IEC61000-4-2 standard for ESD protection is ±15 kV for air and ±8 kV for contact. The

typical waveform of the output current of the ESD generator is described in

standard, RD and CD of Figure 1 are respectively 330 Ω and 150 pF. This standard is more

accurate for performing tests at system level rather than at electronic device level.

and CD of

D

Figure 2. For this

Doc ID 022082 Rev 1 7/21

Page 8

Risks of ESD AN3960

120

100

80

60

53

40

27

20

0

Discharge current I

ESD

(%)

-10 0 10 20 3040 50607080 90 100

Time (ns)

Rise time = 0.7 ns to 1 ns

ai18793

Figure 2. IEC61000-4-2 ESD current waveform (RD = 330 Ω/CD = 150 pF)

2.2.4 MIL-STD-883H

This standard method classifies microcircuits according to their susceptibility to damage or

degradation by exposure to ESD. For this standard R

suited for electronic device tests as ESD stress can be applied directly onto its pins.

2.2.5 ESD standard summary

An application has to align with one or more standards as agreed with the customer. Tab l e 1

summarizes the test conditions for the ESD standards.

Table 1. Test conditions for ESD standards

Standard Model R

JS-001-2010 HBM 1.5 kΩ 100 pF 8 kV

SP723 EIAJ IC121 MM 0 Ω 200 pF 2 kV

IEC61000-4-2

(level 4)

MIL-STD-883H (class 3B)

1. Level 4 = maximum level of test voltage in the IEC61000-4-2 standard.

2. Class 3B = maximum level of test voltage in the MIL-STD-883H standard.

When an ESD event occurs, the standards outlined in Section 2.2 describe four test results

which can occur in a real application.

(1)

(2)

is 1.5 Ω and CD is 100 pF. It is well

D

D

C

D

±V

D

HBM and air discharge 330 Ω 150 pF 15 kV

HBM, and direct discharge 330 Ω 150 pF 8 kV

HBM 1.5 kΩ 100 pF 8 kV

8/21 Doc ID 022082 Rev 1

Page 9

AN3960 Risks of ESD

2.2.6 Test results of ESD standards

The test results are as follows:

● Normal performance continues within the specification limits

● Temporary degradation or loss of function or performance which is self-recoverable

● Temporary degradation or loss of function or performance which requires operator

intervention or system reset (the operator can be the end user)

● Degradation or loss of function which is not recoverable due to damage of equipment

(components) or software, or loss of data.

The risks of failure are the same for touch sensing application as for other applications.

When a touch occurs, the system or equipment can fail if it is not sufficiently robust.

Doc ID 022082 Rev 1 9/21

Page 10

Protecting against ESD AN3960

3 Protecting against ESD

An effective approach for protecting any electronic system against ESD is to mechanically

minimize the pathways by which high voltages enter the system from the outside

environment. This can be especially difficult if the user needs to touch the application or if

there is a void or other opening in the packaging.

Mechanical switches and control potentiometers are classic system entry points for ESD

stress. Changing from mechanical controls to capacitive touch controls eliminates the voids

for these traditional ESD entry paths.

Some methods which protect against ESD stress include:

● Dielectric overlays (see Section 3.1)

● Spark gaps (see Section 3.2)

● Ground rings (see Section 3.3)

● Adding resistance (see Section 3.4)

● Adding diodes (see Section 3.5)

● ESD protection devices (see Section 3.6)

● Firmware (see Section 3.7)

3.1 Dielectric overlays

In the touch sensing application domain, a protective layer of "dielectric" material (any

insulating material that can intrinsically withstand high voltages without breaking down) can

be placed between the ESD source and the touch sensing application. For example, one

layer of 5 mil Kapton® tape withstands 18 kV. Other dielectric overlay materials are listed

in

Ta bl e 2 together with their dielectric strengths.

10/21 Doc ID 022082 Rev 1

Page 11

AN3960 Protecting against ESD

Table 2. Dielectric overlay materials and their dielectric strength

Material

Air 1200–2800 10

Dry wood 3900 3

Common glass 7900 1.5

Borosilicate glass, e.g. Pyrex® 13000 0.9

Polymethyl methacrylate

(PMMA) plastic, e.g. Plexiglas®

Acrylonitrile butadiene styrene

(ABS) plastic

Polycarbonate, e.g. Lexan® 16000 0.8

Formica plastic 18000 0.7

(2)

FR-4

Breakdown voltage

(V/mm)

13000 0.9

16000 0.8

28000 0.4

(1)

Min. overlay thickness at 12 kV

(mm)

Polyethylene terephthalate

(PET) film, e.g. Mylar®

Polymide film, e.g. Kapton® 280000 0.04

1. The breakdown voltage of an insulating material is the minimum voltage that causes a portion of the

insulator to become electrically conductive.

2. FR-4 is a widely accepted international grade deignation for fiberglass reinforced epoxy laminates that are

flame retardant.

Use of the dielectric overlay is effective and is almost mandatory for many applications

however, there are some drawbacks, namely that the overlay does not surround the whole

application and that an ESD event can bypass the overlay. If the user can avoid accessing

the application through the front panel (example, by accessing it from the back or

elsewhere) or if the ESD event can bypass the front panel, one of the other methods which

protect the device against an ESD event should be considered.

3.2 Spark gaps

Physical techniques, such as the addition of spark gaps, can give supplementary protection

to the input/output lines of a circuit board which are susceptible to extraneous voltage such

as ESD. For example, printed circuit board (PCB) spark gaps can be used to route ESD to

earth in products using capacitive sensing electrodes (see

A spark gap consists of an arrangement of two conducting electrodes separated by a gap

usually filled with a gas such as air which is designed to allow an electric spark to pass

between the conductors. When the voltage difference between the conductors exceeds the

gap's breakdown voltage, a spark forms, ionizing the gas and drastically reducing its

electrical resistance.

280000 0.04

Figure 3: PCB with spark gap).

The spark gap shown in Figure 3 is an 8 mm gap which is a common PCB tolerance. The

approximate breakdown of such a small spark gap is given in Equation 1.

Doc ID 022082 Rev 1 11/21

Page 12

Protecting against ESD AN3960

V 3000 p× d×()1350+=

3PARKGAPTOEARTH

4OUCHSENSINGELECTRODE

-36

Equation 1

Where p is the pressure in atmospheres and d is the distance in millimetres.

This spark gap can be expected to have a peak voltage of about 2000-2500 V.

Figure 3. PCB with spark gap

1. The contact area of this spark gap needs to be free of solder resist, in order to function as a spark gap.

3.3 Ground rings

To protect against ESD stress on the touch sensing surface, a low impedance path to

ground must exist through the device. The touch sensor can be protected using a ground

ring (also called a guard ring) which is a ring around all the system electrodes (see

Figure 4:

Ground ring). It is placed in the border area. The ground ring can be a simple metal foil. It is

necessary to ensure that there is a firm connection between the ground ring and the device

system ground.

If the product is densely packed, it may not be possible to prevent an ESD stress.

Consequently, the touch sensing device can be protected by controlling where the discharge

occurs. This can be achieved through a combination of the:

● PCB layout

● Mechanical layout of the system

● Conductive tape or other shielding material

These three items avoid an ESD stress reaching the electrodes (and therefore the MCU)

because they form a sufficient shield. For example, an ESD stress goes directly to ground if

it occurs in the ground ring.

As recommended in “PCB Layout Guidelines”, providing a hatched ground plane around the

touchkey or rotary or linear sensors (other types of electrode with different shapes) can

redirect the ESD stress away from the electrodes and touch sensing device.

12/21 Doc ID 022082 Rev 1

Page 13

AN3960 Protecting against ESD

%LECTRODE

%LECTRODE

'UARDRINGTOTHEGROUND

-36

4HE%3$GOESTHROUGHTHISWAY

PROTECTINGTHEELECTRODEAND

THEDEVICE

Figure 4. Ground ring

3.4 Adding resistance

The most common method of external ESD protection is to add a small serial resistor in-line

between the ESD energy source and the touch sensing device pin to be protected. A

resistor as small as 50

protection is somewhat proportional to increased serial resistance so, higher immunity is

possible.

This method works for two reasons. First, the serial resistor works with the parasitic pin

capacitance (typically 5 to 10 pF) of the device to create a single-pole low pass filter with a

cutoff frequency below 1 GHz. This causes the serial resistor to attenuate most of an ESD

event's high-frequency energy (as much as 90 % of the rising-edge power in an HBM

discharge). Second, when the protection circuits of the device are operating normally, their

impedance is very low (in the order of tens of ohms or less). This low impedance works with

the serial resistor to create a voltage divider, so that the high voltage from an ESD stress

can only bias the built-in protection circuits of the device with a portion of the total ESD

voltage. This attenuation is in addition to rising-edge filtering. The sum of these effects from

a simple external serial resistor dramatically improves ESD performance in a demanding

application.

Ω can double the ESD immunity of a CMOS device. A higher level of

Doc ID 022082 Rev 1 13/21

Page 14

Protecting against ESD AN3960

3.5 Adding diodes

Input/output lines that are susceptible to ESD stress are sometimes protected by adding

‘external’ diodes which shunt the high energy of the ESD stress before it can reach the

device input pin. These diodes may either pass the current to the power supply rails or they

may internally dissipate the unwanted power. External diodes are similar to the diodes built

into a device (internal diodes) for protection but, they are designed differently. External

diodes have two significant advantages:

● They can switch faster and at a lower excursion voltage than the internal diodes of the

device.

● They can have much better connections to the supply rails and can carry more power.

The effects of external diodes on circuit operation are different from internal diodes,

because the connections used internally cannot be achieved with external devices.

Two types of protection diode are typically used against ESD stress. Zener diodes or

transient voltage suppression (TVS) avalanche diodes can be placed between an input

signal and ground. In this configuration, the diode protects the CMOS input by reverse

conduction whenever its voltage rises above the specified diode breakdown voltage.

Negative ESD excursions are shunted to ground through normal diode action. In another

configuration, diode pairs (typically Schottky diodes due to their lower forward voltage drop)

are placed between the input line and the power and ground rails. These devices protect the

CMOS input by normal diode conduction whenever the input line voltage moves outside the

range of the power supply rails.

Diodes placed on capacitive sensed lines present the same problems to capacitive sensing

circuits as they do with any analog circuit input: they can be highly capacitive (over 100 pF)

and leaky. Some Schottky pairs leak over 20 µA; some avalanche diodes leak over 1 mA

when operated near their reverse-standoff voltage (generating significant noise voltage as

well). Although these given numbers are for the least suitable devices, the most commonlyused Schottky and TVS diodes have parasitic parameters that make them unacceptable for

use in capacitive sensing applications. If the diode circuit can be designed to add only a very

small amount of additional capacitance, capacitance sensing solutions can be adjusted to

match. This is because compensation mechanisms are usually built into the touch sensing

device for adaptation to the naturally-occurring changes in capacitance that result from

environmental changes. However, leakage and bulk capacitance can create problems for

any sort of capacitive sensing method, some more than others.

External diodes with high reverse leakage make the test capacitance look larger because

their leakage drains test current from the circuit. This disappearing test current (which

should fill the capacitance under test) has no dV/dt effect on the test load. As diode leakage

currents approach the level of the test current, the apparent load capacitance approaches

infinity. Also, the amount of current required to detect a 0.1 pF change in capacitance is less

than 20 pA, many orders of magnitude less than the leakage current for some protection

diodes. For this reason, where external diodes must be used, it is essential to specify

devices with extremely low reverse leakage.

The ESDAULC6 diode from STMicroelectronics was designed to resist multiple ESD

stresses. It has low capacitance (1 pF) and low leakage (less than 100 nA), both of which

reduce the problems encountered when using Schottky protection diodes. The bidirectional

protection ESDAXLC6 diode, with even lower capacitance (0.5 pF), can be used instead of

the ESDAULC6 diode to prevent the occurrence of negative and positive pulses.

Note: Although small and inexpensive, an external diode circuit can be two to four times larger and

four times more expensive than adding a serial resistor.

14/21 Doc ID 022082 Rev 1

Page 15

AN3960 Protecting against ESD

3.6 ESD protection devices

A very effective method to protect input/outputs lines from ESD discharges is to provide

special purpose ESD protection devices on the vulnerable traces. ESD protection devices

for touch sensing devices need to have a low capacitance.

Ta bl e 3 lists the ESD protection devices which are recommended for use with touch sensing

microcontrollers.

Table 3. ESD protection devices

ESD protection device

Manufacturer Part number

Littlefuse SP723 5 5 nA (typ) ±8 kV ±15 kV

NXP NUP1301 0.6 (typ) 30 nA ±8 kV ±15 kV

STMicroelectronics HSP061-8M16 0.6 100 nA ±8 kV ±15 kV

Vishay VBUS05L1-DD1 0.3 < 0.1 µA ±15 kV ±16 kV

Input

capacitance (pF)

Leakage

current

Contact discharge

maximum limit (kV)

Air discharge

maximum limit (kV)

3.7 Firmware

When permanent damage occurs, the firmware is inefficient but, irreversible damage is not

always the only consideration of an ESD stress.

The maximum risk due to an ESD stress is degradation. However, in some less negative

cases (such as temporary degradation or loss of function) when a simple system reset is

needed, a self-recoverable application can be implemented by using the “watchdog timer

on”. The system can restart from a known state and resume normal operations. The final

outcome is a robust application.

The debounce firmware method is used to filter some unwanted signals and therefore helps

reduce ESD stress effects.

Doc ID 022082 Rev 1 15/21

Page 16

STM8T142-EVAL evaluation board: ESD tests AN3960

-36

"ATTERY

%VALUATIONBOARD

3ENSOR

2EGULATORANDITSCAPACITOR

4 STM8T142-EVAL evaluation board: ESD tests

The STM8T142-EVAL evaluation board was tested against ESD stress using some of the

protection methods described in

4.1 Test setup

Two ESD protection methods were tested: spark gaps and adding resistance (by testing a

small serial resistor).

During the test, the STM8T142-EVAL evaluation board was supplied by a small 12 V leadacid battery through an L7805 regulator (see

Figure 5. Test set up

Section 3: Protecting against ESD.

Figure 5).

16/21 Doc ID 022082 Rev 1

The STM8T142-EVAL evaluation board was not originally designed to take ESD stress into

account:

● The onboard serial resistor (size 0603) is voltage undersized.

● The insulation distance between the electrode and the neighbouring PCB tracks is too

small so that discharges can be seen directly on the device.

Page 17

AN3960 STM8T142-EVAL evaluation board: ESD tests

The following design modifications were applied (see Figure 6):

● A good voltage dimensioned serial resistor was used.

● Sufficient isolation distances between the electrode and neighboring PCB tracks was

implemented.

● A spark gap was built to route part of the ESD energy away from the electrode to the

application GND.

Figure 6. STM8T142-EVAL evaluation board modifications

Doc ID 022082 Rev 1 17/21

Page 18

STM8T142-EVAL evaluation board: ESD tests AN3960

4.2 Test results

Table 4. ESD discharges for tested STM8T142-EVAL evaluation board

Test condition

ESD stress through contact

on the electrode

(1)

ESD stress through the air

No protection 8 kV -

With through hole resistor 12 kV -

With through hole resistor

and spark gap

With glass panel

(0.55 mm thickness)

1. The ESD stress corresponds to the limit of normal system operation (detection of touch).

> 25 kV > 25 kV

12kV ‐

18/21 Doc ID 022082 Rev 1

Page 19

AN3960 Conclusion

5 Conclusion

Among the techniques to protect electronic systems against ESD stress, the cheapest and

simplest method is to add a small serial resistor of about 50 Ω. For greater robustness a

diode or an ESD protection device can be added.The drawbacks of these choices are price,

leakage, and input capacitance. In an environment where ESD can strike frequently, the

most effective way is to use a combination of the techniques described in

Protecting against ESD, for example, by simultaneously using a spark gap (with a 10 kΩ

serial resistor), a ground ring and robust firmware. In any touch sensing domain, most of the

protection is provided by a dielectric overlay which is nearly always used. However, an ESD

stress can strike from anywhere so, other methods are recommended in parrallel with a

dielectric overlay.

Section 3:

Doc ID 022082 Rev 1 19/21

Page 20

Revision history AN3960

6 Revision history

Table 5. Document revision history

Date Revision Changes

03-Oct-2011 1 Initial release.

20/21 Doc ID 022082 Rev 1

Page 21

AN3960

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY TWO AUTHORIZED ST REPRESENTATIVES, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2011 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Philippines - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

Doc ID 022082 Rev 1 21/21

Loading...

Loading...