Page 1

Application note

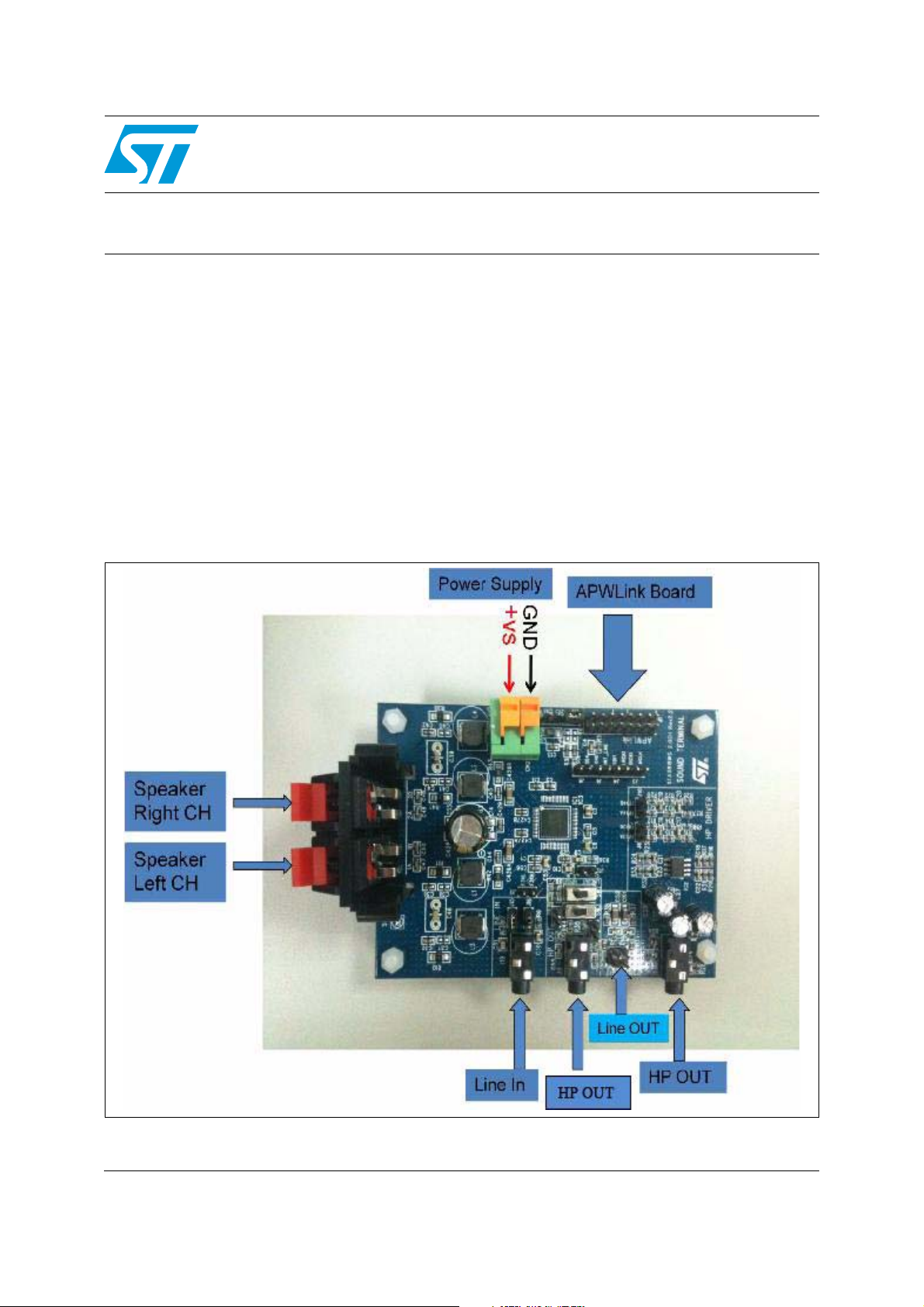

2.0-channel demonstration board

based on the STA381BW and STA381BWS

Introduction

The purpose of this application note is to describe:

■ how to connect the STA381BW/STA381BWS 2.0-channel demonstration board

■ how to evaluate the performance of the demonstration board with significant electrical

curves

■ how to avoid critical issues in the PCB schematic and layout of the

STA381BW/STA381BWS

The STA381BW/STA381BWS demonstration board is configured for 2.0 BTL channels,

releasing up to 2 x 20 W into 8 ohm of power output at 18 V of supply voltage in the VQFN48

package. It represents a total solution for the digital audio power amplifier.

Figure 1. STA381BW/STA381BWS 2.0-channel demonstration board

AN3959

December 2011 Doc ID 022081 Rev 3 1/65

www.st.com

Page 2

Contents AN3959

Contents

1 Functional description of the demonstration board . . . . . . . . . . . . . . . 6

1.1 Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.2 Output configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.3 Schematic and block diagrams, bill of material, PCB layout . . . . . . . . . . . . 7

2 STA381BWS power section test results . . . . . . . . . . . . . . . . . . . . . . . . 16

3 STA381BW power section test results . . . . . . . . . . . . . . . . . . . . . . . . . 20

4 Analog section test results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5 Thermal performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

5.1 Thermal results - test 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

5.2 Thermal results - test 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

6 Design guidelines for schematic and PCB layout . . . . . . . . . . . . . . . . 28

6.1 Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

6.1.1 Criteria for selection of components . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

6.1.2 Decoupling capacitors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

6.1.3 Output filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

6.1.4 Snubber filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

6.1.5 Main filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6.1.6 Dumping network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6.1.7 Recommended power-up and power-down sequence . . . . . . . . . . . . . 31

6.2 Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

7 Software setup to use the STA381BW/STA381BWS devices (ST Map)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

7.1 Processing configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

7.2 STCompressor

TM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

7.2.1 STCompressor settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

7.2.2 Configuring and enabling the STCompressor . . . . . . . . . . . . . . . . . . . . 41

7.2.3 Example settings of the STCompressor . . . . . . . . . . . . . . . . . . . . . . . . 42

7.2.4 Test results with APWorkbench . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

2/65 Doc ID 022081 Rev 3

Page 3

AN3959 Contents

7.3 CRC computation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

7.3.1 Biquad CRC computation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

7.3.2 Crossover CRC computation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

7.3.3 STCompressor

TM

CRC computation . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

7.4 Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

7.5 Short-circuit protection for the STA381BW/STA381BWS . . . . . . . . . . . . . 49

7.6 Settings for bridge power-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

8 Examples of code (TV SoC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

8.1 FFX381X_Sample.h . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

8.2 FFX381X_Sample.C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

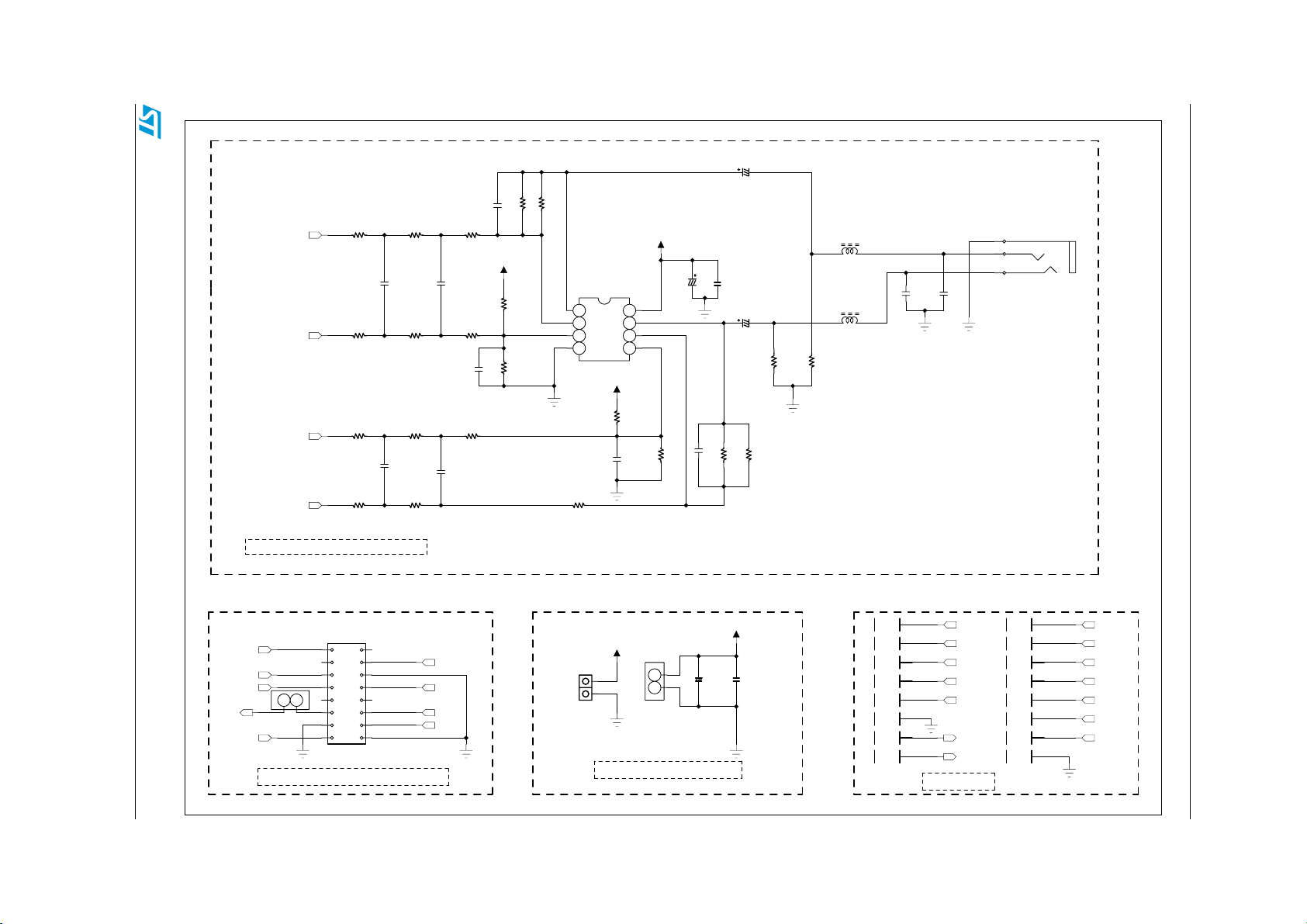

Appendix A Mono BTL schematic. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

9 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Doc ID 022081 Rev 3 3/65

Page 4

List of figures AN3959

List of figures

Figure 1. STA381BW/STA381BWS 2.0-channel demonstration board . . . . . . . . . . . . . . . . . . . . . . . . 1

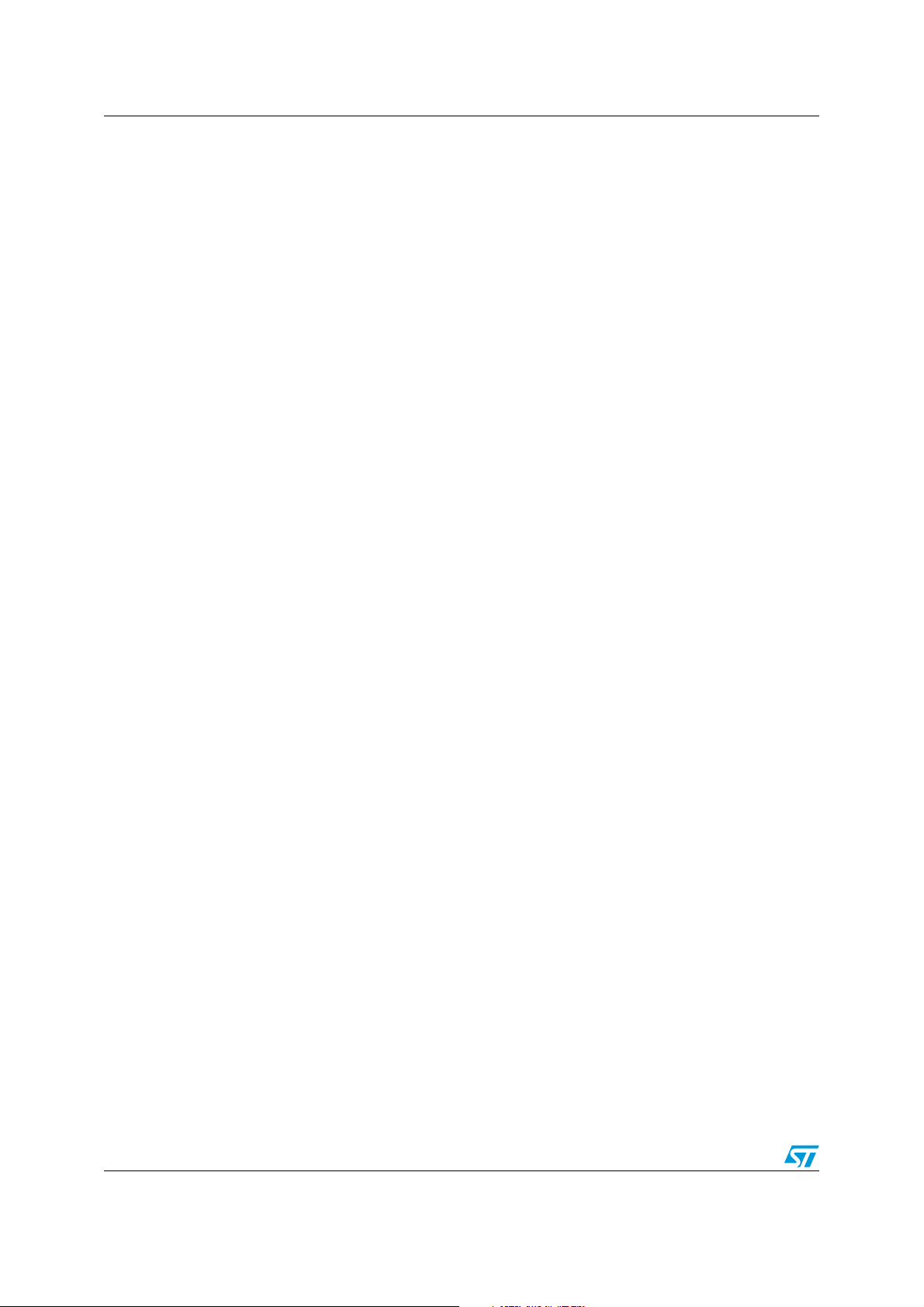

Figure 2. Schematic-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

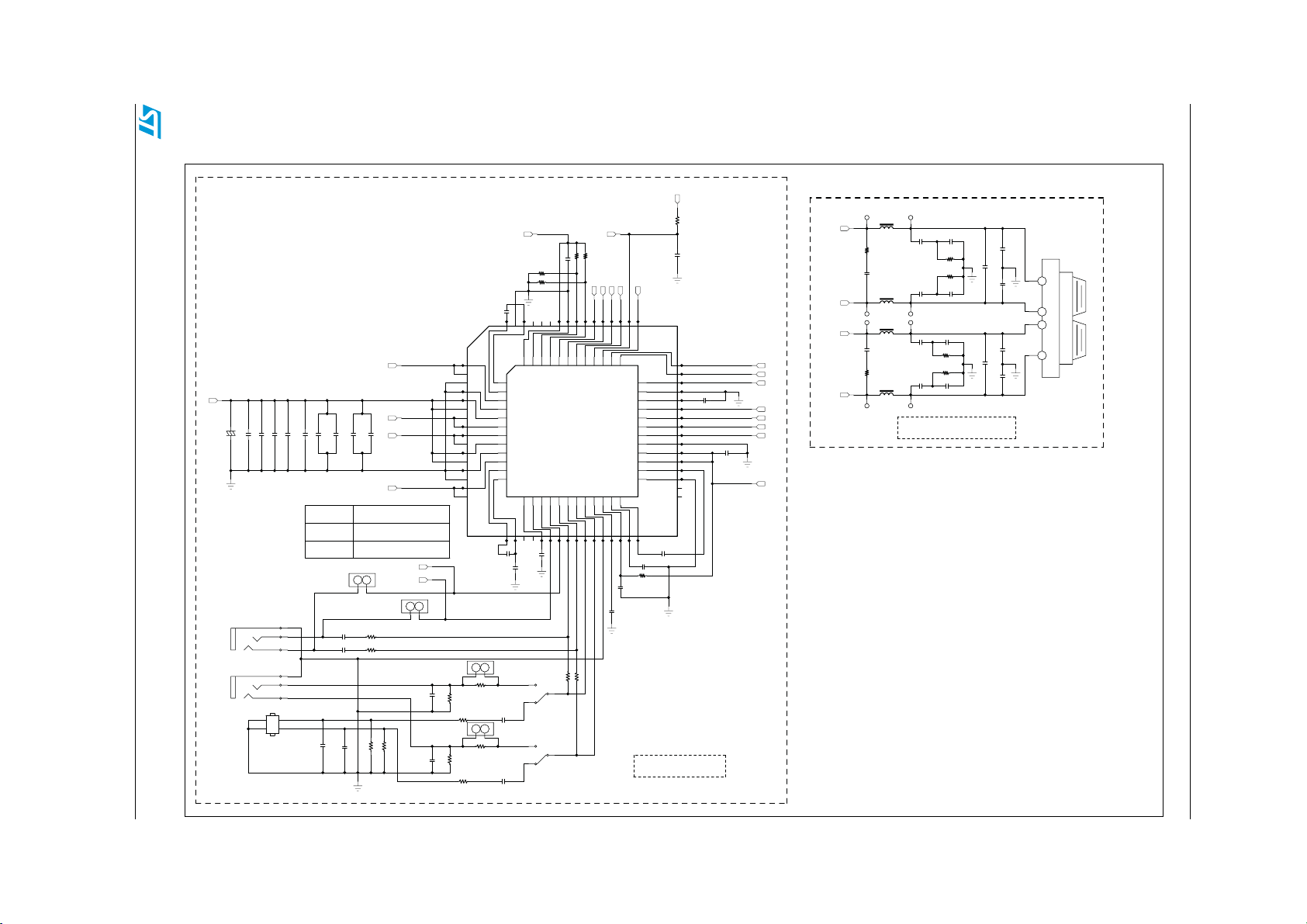

Figure 3. Schematic-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

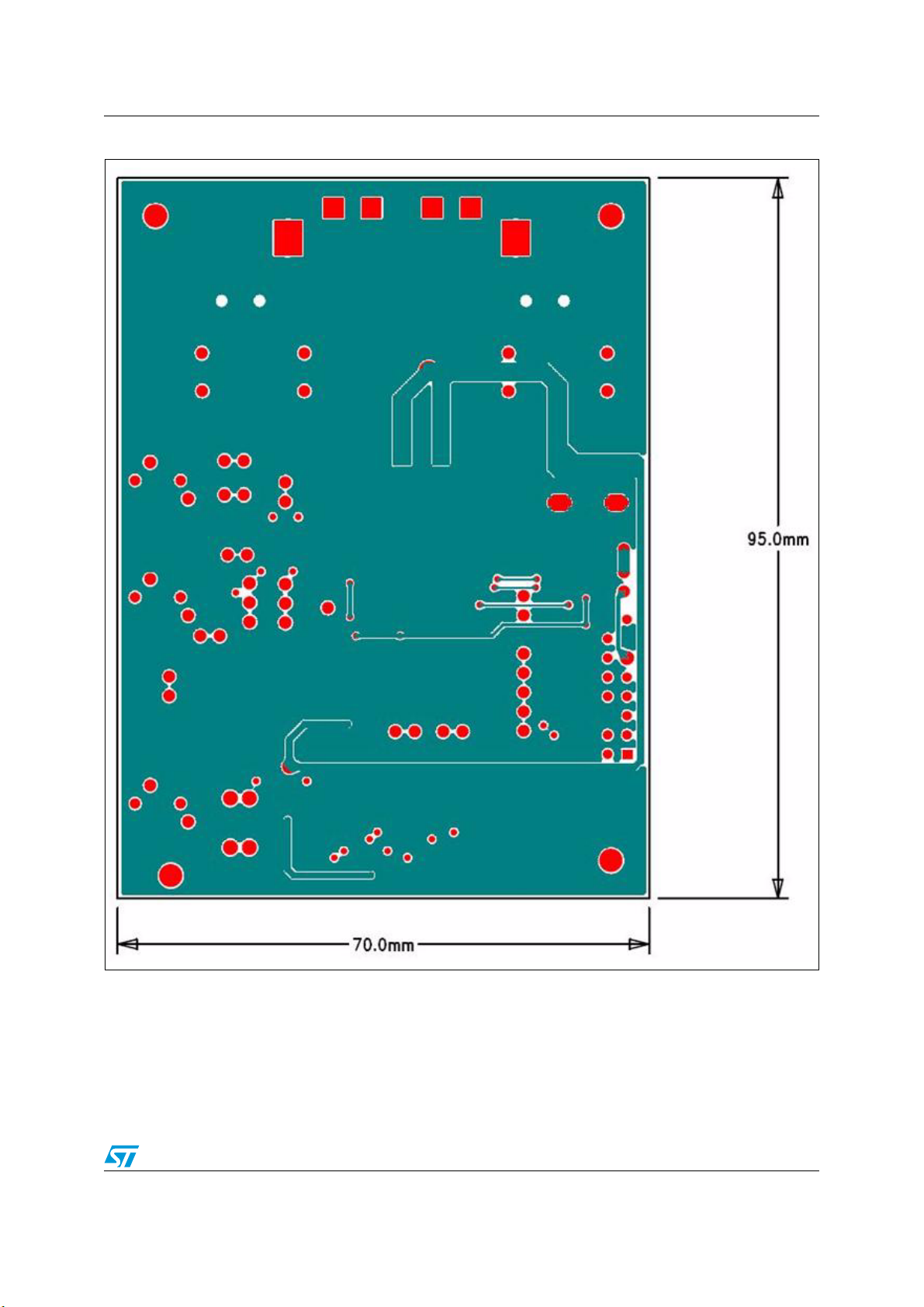

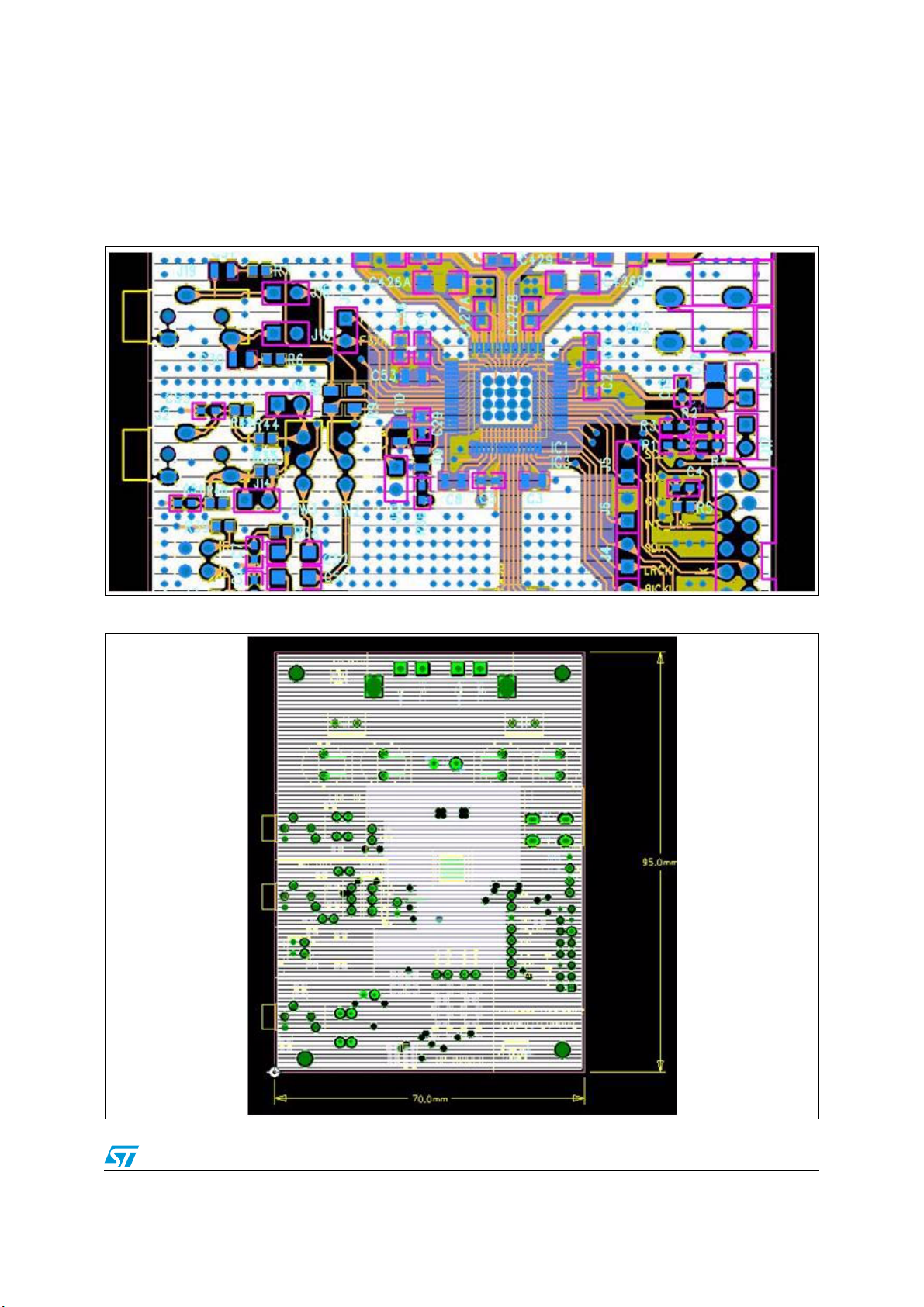

Figure 4. Top view of PCB layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Figure 5. Inner layer2 view of PCB layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Figure 6. Inner layer3 view of PCB layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

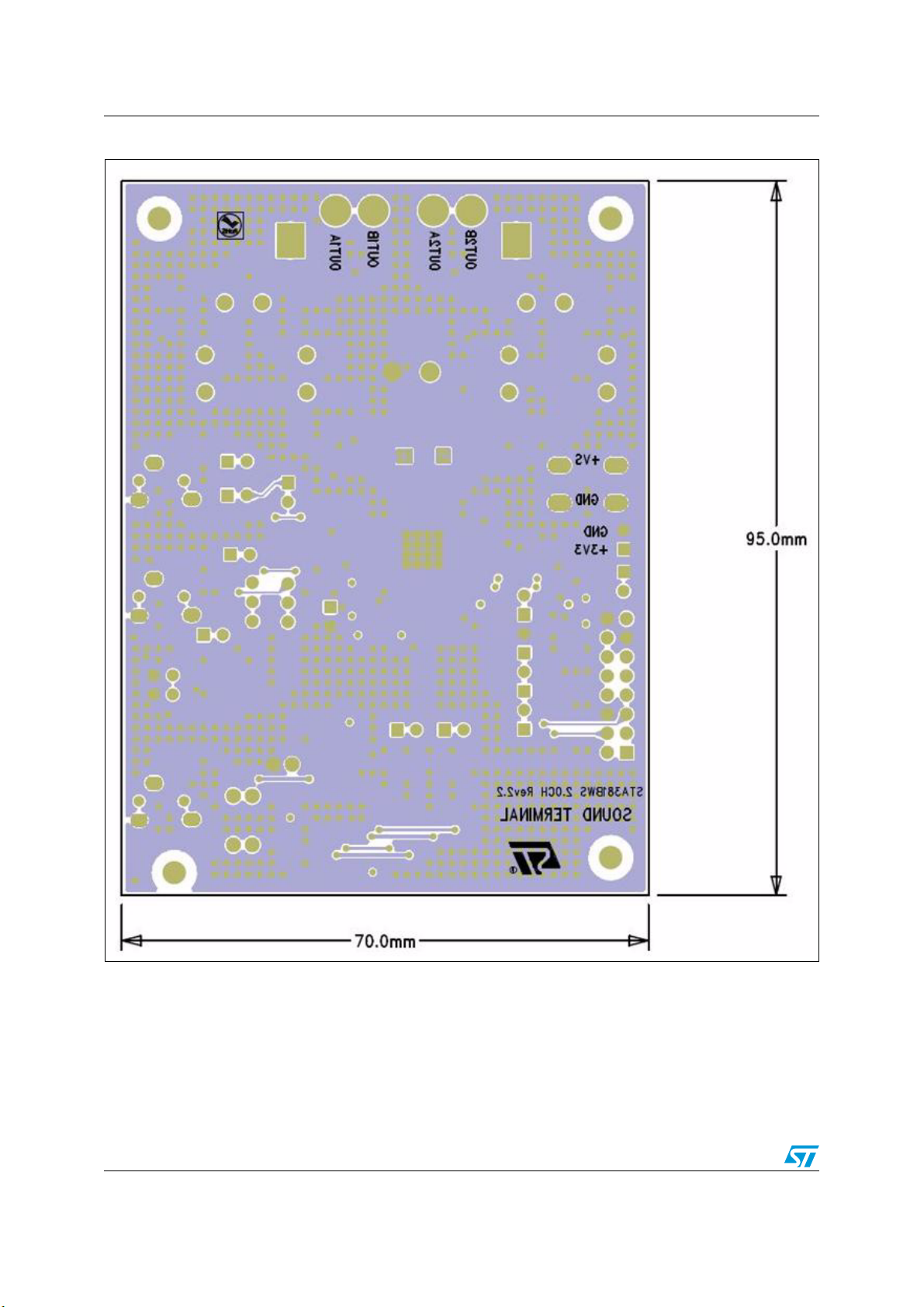

Figure 7. Bottom view of PCB layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

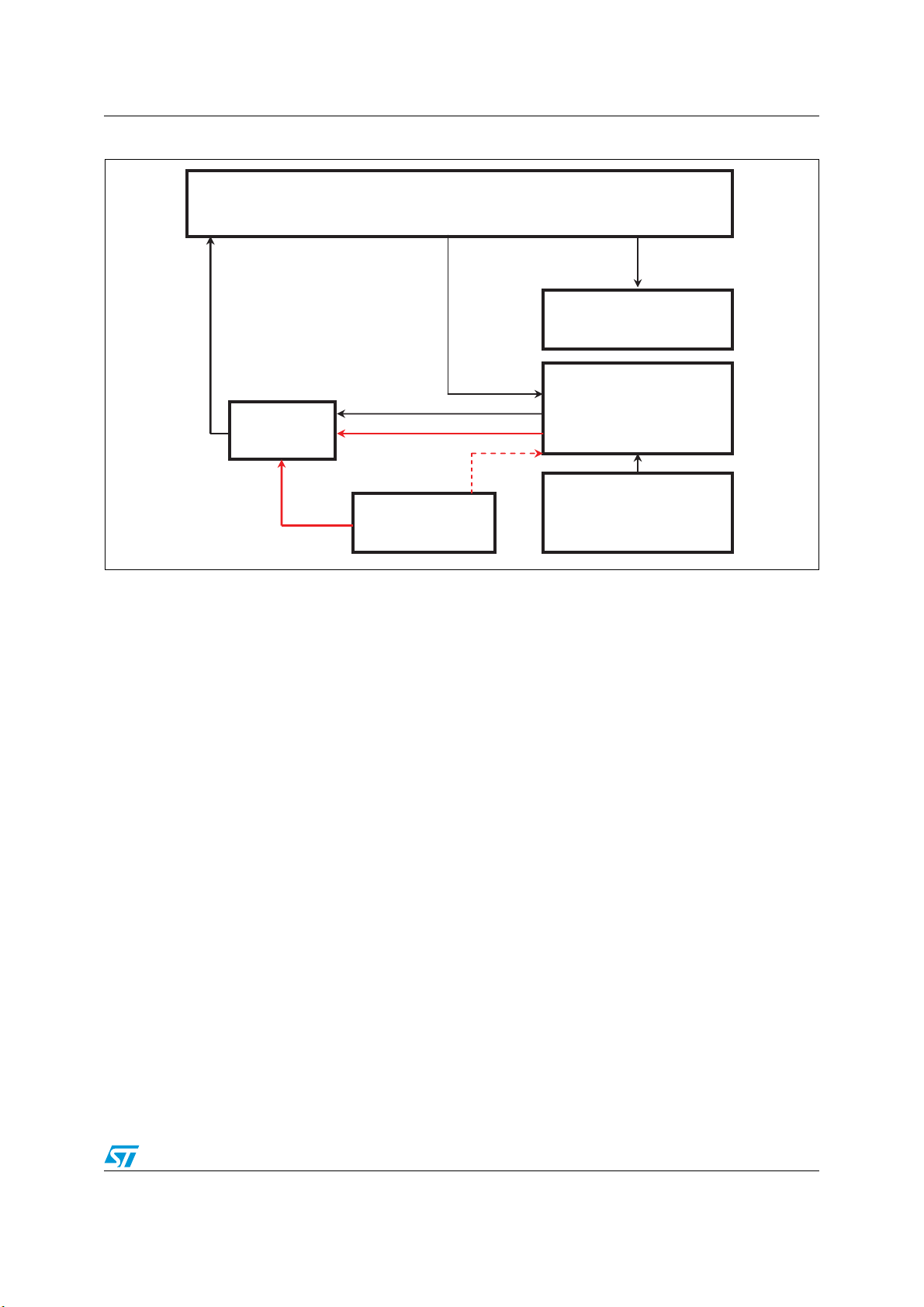

Figure 8. Block diagram of test connections with equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 9. Frequency response, V

Figure 10. Crosstalk, V

Figure 11. SNR, V

CC

= 18 V, RL = 8 ohm, 0 dB (Pout = 1 W) . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

CC

= 18 V, RL = 8 ohm, 0 dB (Pout = 1 W) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 12. THD vs. frequency, V

Figure 13. FFT (0 dBFS), V

Figure 14. FFT (-60 dBFS), V

= 18 V, RL = 8 ohm, 0 dBFS (Pout = 1 W) . . . . . . . . . . . . . . . . . . . . . 18

CC

CC

Figure 15. THD vs. output power, V

Figure 16. THD vs. output power at different power supplies, R

Figure 17. Frequency response, V

Figure 18. Crosstalk, V

Figure 19. SNR, V

CC

= 24 V, RL = 8 ohm, 0 dB (Pout = 1 W) . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

CC

= 24 V, RL = 8 ohm, 0 dB (Pout = 1 W) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 20. THD vs. frequency, V

Figure 21. FFT (0 dBFS), V

Figure 22. FFT (-60 dBFS), V

= 24 V, RL = 8 ohm, 0 dBFS (Pout = 1 W) . . . . . . . . . . . . . . . . . . . . . 22

CC

CC

Figure 23. THD vs. output power, V

Figure 24. THD vs. output power at different power supplies, R

Figure 25. Temperature test 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Figure 26. Temperature test 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Figure 27. Output filter (BTL) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Figure 28. Differential-mode snubber circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Figure 29. Common-mode snubber circuit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Figure 30. Main filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Figure 31. Dumping network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Figure 32. Recommended power-up and power-down sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Figure 33. Snubber network soldered as close as possible to the respective IC pin . . . . . . . . . . . . . . 31

Figure 34. Electrolytic capacitor used first to separate the V

Figure 35. Path between V

and ground pin minimized in order to avoid inductive paths . . . . . . . . 32

CC

Figure 36. Large ground plane on the top side . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Figure 37. Large ground plane on inner layer2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Figure 38. Large ground plane on inner layer3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Figure 39. Large ground plane on bottom side . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Figure 40. Symmetrical paths created for output stage, for differential applications . . . . . . . . . . . . . . 35

Figure 41. Coils separated in order to avoid crosstalk . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Figure 42. V

filter for high frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

CC

Figure 43. Thermal layout with large ground . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Figure 44. Processing path . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Figure 45. 2.1-channel with STCompressor

Figure 46. STCompressor - overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Figure 47. STCompressor - mapper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Figure 48. STCompressor - compression ratio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

= 18 V, RL = 8 ohm, 0 dB (Pout = 1 W) . . . . . . . . . . . . . . . . . . 16

CC

= 18 V, RL = 8 ohm, Pout = 1 W . . . . . . . . . . . . . . . . . . . . . . . . . 17

CC

= 18 V, RL = 8 ohm, 0 dBFS (Pout = 1 W) . . . . . . . . . . . . . . . . . . . . 18

= 18 V, RL = 8 ohm, f = 1 kHz . . . . . . . . . . . . . . . . . . . . . . . . 19

CC

= 24 V, RL = 8 ohm, 0 dB (Pout = 1 W) . . . . . . . . . . . . . . . . . . 20

CC

= 24 V, RL = 8 ohm, Pout = 1 W . . . . . . . . . . . . . . . . . . . . . . . . . 21

CC

= 8 ohm, f = 1 kHz . . . . . . . . . . . . . 19

L

= 24 V, RL = 8 ohm, 0 dBFS (Pout = 1 W) . . . . . . . . . . . . . . . . . . . . 22

= 24 V, RL = 8 ohm, f = 1 kHz . . . . . . . . . . . . . . . . . . . . . . . . 23

CC

TM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

= 8 ohm, f = 1 kHz . . . . . . . . . . . . . 23

L

branches . . . . . . . . . . . . . . . . . . . . . . 32

CC

4/65 Doc ID 022081 Rev 3

Page 5

AN3959 List of figures

Figure 49. STCompressor - limiter threshold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Figure 50. STCompressor - offset control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Figure 51. APWorkbench results for STC example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Figure 52. F3X output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Figure 53. F3X for HPout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Figure 54. Mono BTL schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Doc ID 022081 Rev 3 5/65

Page 6

Functional description of the demonstration board AN3959

1 Functional description of the demonstration board

The following terms used in this application note are defined as follows:

● THD+N vs. Freq: Total harmonic distortion (THD) plus noise versus frequency curve

● THD+N vs. Pout: Total harmonic distortion (THD) plus noise versus output power

● S/N ratio: Signal-to-noise ratio

● FFT: Fast Fourier Transform algorithm (method)

● CT: Channel separation L to R, or R to L channel crosstalk

The equipment used includes the following:

● Audio Precision (System 2700) by AP Co., USA

● DC power supply (4.5 V to 25.5 V operating range)

● Digital oscilloscope (TDS3034B by Tektronix)

● MS Windows-based PC with APWorkbench GUI control software installed. For the

APWorkbench software setup, please refer to the APW UserManualR1.0.pdf

Reference documents include:

● STA381BW and STA381BWS datasheets

● Demonstration board schematic, PCB layout and test curves

1.1 Connections

Power supply and interface connection

1. Connect the positive voltage of the 18 V DC power supply to the +VS pin and negative

to GND (note that the operating voltage range of the DC power supply is from 4.5 V to

25.5 V).

2. Connect the APWLink board to the J1 connector of the STA380BWS demonstration

board.

3. Connect the S/PDIF signal cable to the RCA jack on the APWLink board, the other side

connects to the signal source such as Audio Precision or a DVD player.

1.2 Output configuration

The STA381BW/STA381BWS demonstration board is specifically configured in 2 BTL

channels.

6/65 Doc ID 022081 Rev 3

Page 7

1.3 Schematic and block diagrams, bill of material, PCB layout

Figure 2. Schematic-1

+3V3

R5

10K

C4

1nF

SDI1

49

48

47

36

46

35

45

34

33

32

31

30

29

28

27

26

25

32

C9

1uF/10V

0ohm

C3

2u2/10V

44

43

42

41

40

39

38

37

36

35

34

33

C8

1uF/10V

STA381BWS

LRCKI

BICKI

MCLK

FFX4B

FFX4A

FFX3B

FFX3A

C5

100nF

+3V3

Doc ID 022081 Rev 3 7/65

+3V3

R3

0 ohm

R1

0 ohm

C11

100nF

63

64

606162

47

OUT2B

+VS

C428

470U/35V

+

C35

100nF

C33NSC14

1uF/50V

C429

C426A

C34

NS

NS

NS

OUT2A

100nF

100nF

1uF/50V

OUT1B

C427B

C427A

C426B

OUT1A

NOTE:

NS

C30

1uF/10V

C31

1uF/10V

C7

3.3nF/10V

CONFIGURATION

2.0CH & 2.1CH

MONO BT L

J15

1

2

J16

R6

11K

R7

11K

47K

47K

3.3nF/10V

R40

R39

F3XR

F3XL

1

HPJCKX3.5-06

Line in

J2

HPJCKX3.5-06

HEADER2X2

2

Line out

C56

100nF

J19

1

2

3

1

2

3

J7

1

34

C6

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

2

1

J14

R35

1K

C54

100nF

R46

470R

R37

1

J18

R44

1K

C55

100nF

R45

470R

R38

48

1

VDDDIG2

GNDDIG2

VCC_REG

TESTMODE

2

VSS_REG

3

OUT2B

4

GND2

5

VCC2

6

OUT2A

7

OUT1B

8

VCC1

9

GND1

10

OUT1A

11

VDD_REG

12

GND_REG

HALFVDD14F3XL15F3XR16HPIN_L17HPIN_R18LINEHPOUT_L19LINEHPOUT_R20GNDA21SOFTMUTE22VDD3V323CPVSS24CPM

13

171819202122232425262728293031

C1

1uF/10V

100nF

NS

C56

*

2

47R

2

47R

1

3

10uF/10V

C51

1

3

10uF/10V

C52

59

C53

2

SW2

2

SW3

58

44

45SA46

SCL

STA381BWS

STA381BWS_NEW

R8

27K

RESET

NS

NS

100nF

R4

R2

C2

SDA

SCL

INT_LINE

PWRDN

53

54

505152

555657

37

38

39

40

41

42

43

SDI

SDA

IC1

IC3

BICKI

LRCKI

PWDN

RESET

INTLINE

R9

27K

1uF/10V

SOFTMUTE

AGNDPLL

VREGFILT

GNDDIG1

VDDDIG1

VDD3V3CHP

GNDPSUB

C29

100nF

C10

MCLK

FFX4B

FFX4A

FFX3B

FFX3A

CPP

R36

OUT1A

R42

20(S)

C44

330P(S)

L1

SWPA6045S220MT

OUT1B

OUT2A

OUT2B

C45

330P(S)

R43

20(S)

SWPA6045S220MT

L2

SWPA6045S220MT

L4

C37

C32

NS

220nF

R10

0R

0R

R11

220nF

NS

C36

C38

NS

C41

C43

0R

220nF

R41

0R

R30

220nF

NS

C40

C42

C47

1N(S)

C46

220nF

220nF

4

C50

1N(S)

3

2

C48

1N(S)

1

C39

C49

1N(S)

SPEAKJA CK2X2

J9

L3

SWPA6045S220MT

OUTPUT FILTER

Note 1:

The output filter for the line/HP output

path is optional (not required for the STA381BW/S).

If the 2x 47 ohm resistors (R35 and R44) are

bypassed through J14 and J18, the 2x 100 nF

capacitors (C54 and C55) must also be removed.

Note 2:

C56 is not soldered when the STA 381BW/S

is configured in 2.0 or 2.1 channels; C56 is 100 nF

when the STA 381BW/S is configured in mono BTL.

Refer to the s

for an example of a mono BTL application.

chematic in Appendix A on page 63

AN3959 Functional description of the demonstration board

Page 8

Figure 3. Schematic-2

Doc ID 022081 Rev 3 8/65

R12

FFX3B

FFX3A

FFX4B

FFX4A

4K7

C16

470PF

R13

4K7

R20

4K7

C19

470PF

R21

4K7

STEREO HEA DPHONE DRIVER

AN3959 Functional description of the demonstration board

C15

100uF

35V

10K

10K

C22

220PF

R29

R31

+VS

+VS

IC2

R27

4K7

LM833

1

2

3

4

OUTA

INA1

OUTB

INA2

VSS5INB2

VDD

INB1

+VS

R24

10K

220PF

C21

10K

R16

10K

R17

220PF

C28

47uF

8

7

6

10K

R25

C27

100nF

50V

C25

100uF

35V

10K

R34

220PF

C23

10K

10K

R33

R32

BD3

BEAD or 33R

C26

C24

100PF

100PF

BD4

BEAD o r 33R

10K

R28

1

2

3

HEADPHONE O/P

J13

C17

150PF

C20

150PF

R18

4K7

R19

4K7

C18

R26

4K7

R14

4K7

R15

4K7

R22

4K7

R23

4K7

+3V3

SDI1

BICKI

J17

MCLK

12

1

2

11 12

13 14

15 16

TO AP INTERFACE

AP INTERFACE CONNECTOR

J1

HEADER8X2

34

56

78

910

LRCKI

SDASCL

RESET

PWRDN

+VS

CN1

CN2

CN-5-02P

1

2

+

1

2

C12

10uF/10V

The r ange of +Vs is f rom +5V t o +24V

POWER SUPPLY INPUT

+3V3

C13

100nF

J3-1

J4-1

J3-2

J4-2

J6-1

J6-2

SDA

J5-1

SCL

J5-2

MCLK

LRCKI

BICKI

SDI1

INT_LINE

SDA

SCL

J8-1

J8-2

J10-1

J10-2

J11-1

J11-2

J12-1

J12-2

FFX3A

FFX3B

FFX4A

FFX4B

F3XL

F3XR

SOFTMUTE

TEST PINS

Page 9

AN3959 Functional description of the demonstration board

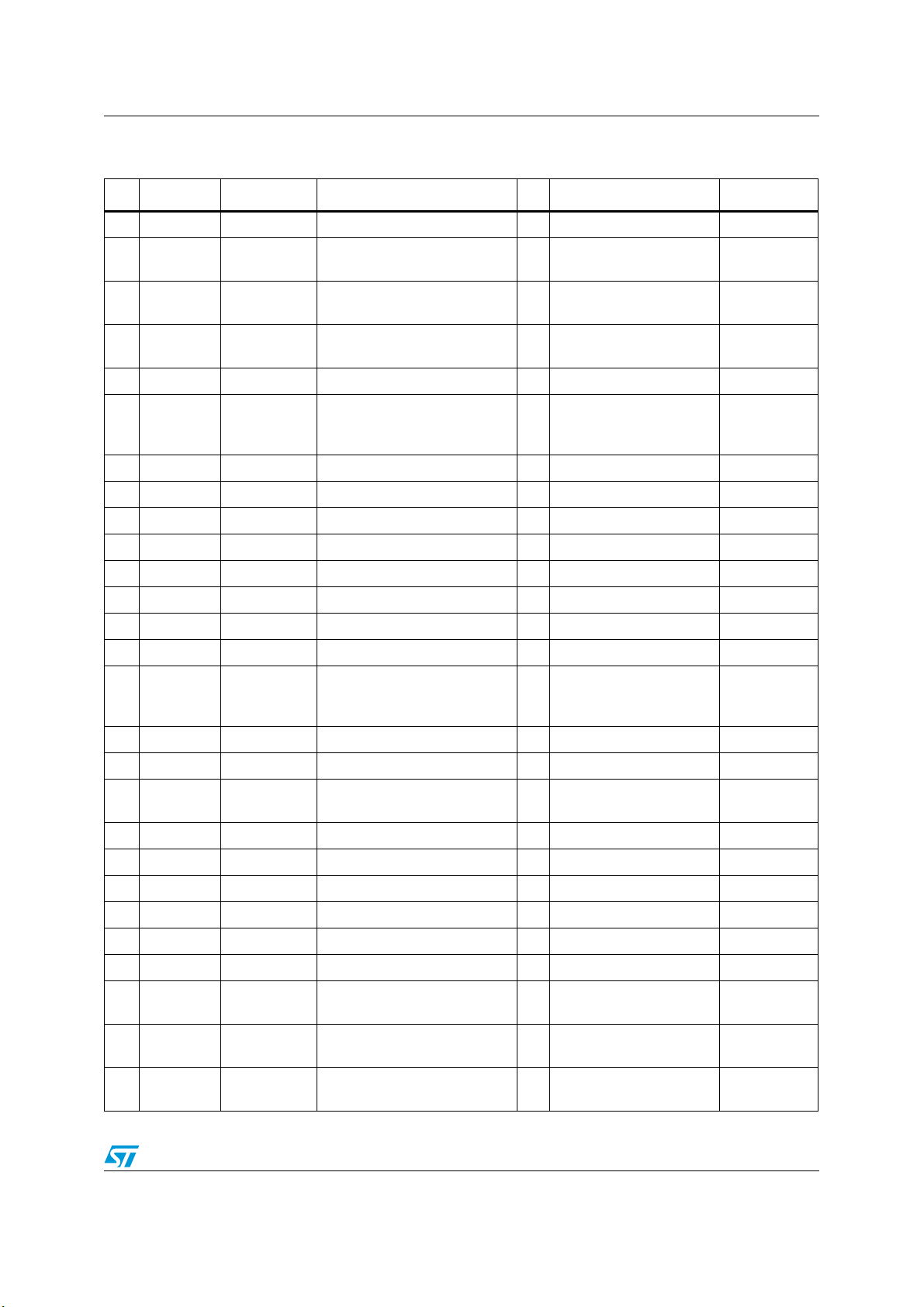

Table 1. Bill of material

No. Type Footprint Description Qty Reference Manufacturer

1 Jack Speaker jack MP4-16 1 J9 Songchen

Headphone

2

3Switch

4 Terminal Through-hole

5 Header Through-hole 4P (2x2 row) 2.54 mm header 1 J7 Any source

6 Header Through-hole 2P (2x1 row) 2.54 mm header 14

7 Header Through-hole 16P (8x2 row) 2.54 mm header 1 J1 Any source

8 CCAP CAP0603 50 Volt NPO 100 pF +/-10% 2 C24, C26 Murata

9 CCAP CAP0603 50 Volt NPO 150 pF +/-10% 2 C17, C20 Murata

10 CCAP CAP0603 50 Volt NPO 220 pF +/-10% 4 C18, C21, C22, C23 Murata

11 CCAP CAP0603 50 Volt NPO 330 pF +/-10% 2 C44, C45 Murata

12 CCAP CAP0603 50 Volt NPO 470 pF +/-10% 2 C16, C19 Murata

13 CCAP CAP0603 50 Volt 1 nF +/-10% 5 C4, C47, C48, C49, C50 Murata

14 CCAP CAP0603 50 Volt 3.3 nF +/-10% 2 C6, C7 Murata

15 CCAP CAP0603 50 Volt 100 nF +/-10% 12

16 CCAP CAP0603 50 Volt 220 nF +/-10% 4 C32, C36, C42, C43 Murata

17 CCAP CAP0603 NS 5 C37, C38, C40, C41, C56 Murata

jack

Phone jack

Deviator

switch

SONGCHEN CKX-3.5-06

3-pin

Deviator switch 2 SW2, SW3 Any source

2P pitch: 5mm connector

terminal

3 J2, J13, J19 Songchen

1 CN2

J3, J4, J5, J6, J8, J10,

J11, J12, J14, J15, J16,

J17, CN1, J18

C1, C2, C5, C11, C13,

C27, C29, C54, C55,

C429, C427A, C427B

Phoenix

Contact

Any source

Murata

18 CCAP CAP0805 10 Volt 1 µF +/-10% 5

19 CCAP CAP0805 10 Volt 2.2U +/-10% 1 C3 Murata

20 CCAP CAP1206 50 Volt 220 nF +/-10% 2 C39, C46 Murata

21 CCAP CAP1206 50 Volt 1U +/-10% 2 C426A, C426B Murata

22 CCAP CAP1206 10 Volt 10 µF +/-10% 2 C51, C52 Murata

23 CCAP CAP1206 NS 4 C14, C33, C34, C35 Murata

24 ECAP CAP1206 10µF/10V 1 C12 Samsung

25 ECAP Through-hole 47µF/35V 105 Centigrade 1 C28

26 ECAP Through-hole 100µF/35V 105 Centigrade 2 C15, C25

27 ECAP Through-hole

470µF/25V, pitch = 5 mm,

φ 10 mm

Doc ID 022081 Rev 3 9/65

C8, C9, C10, C30,

C31, C53

1C428

Murata

Rubycon/

Panasonic

Rubycon/

Panasonic

Rubycon/

Panasonic

Page 10

Functional description of the demonstration board AN3959

Table 1. Bill of material (continued)

No. Type Footprint Description Qty Reference Manufacturer

28 RES R1206 0R 4 R10, R11, R30, R41 Murata

29 RES R1206 20 +/-5% 1/8W 2 R42, R43 Murata

30 RES R0603 0 ohm 1/16W R1, R3, R36 Murata

31 RES R0603 47R +/-5% 1/16W 2 R35, R44 Murata

32 RES R0603 470R +/-5% 1/16W 2 R37, R38 Murata

33 RES R0603 1K +/-5% 1/16W 2 R45, R46 Murata

R5, R16, R17, R24, R25,

34 RES R0603 10K +/-5% 1/16W 11

35 RES R0603 11K +/-5% 1/16W 2 R6, R7 Murata

36 RES R0603 4.7K +/-5% 1/16W 12

37 RES R0603 47K +/-5% 1/16W 2 R39, R40 Murata

38 RES R0603 NS R2, R4 Murata

R28, R29, R31, R32,

R33, R34

R12, R13, R14, R15,

R18, R19, R20, R21,

R22, R23, R26, R27

Murata

Murata

39 RES R0805 27K +/-5% 1/16W 2 R8, R9 Murata

40 Bead L0805

41 Plastic rod

42 Plastic rod

43 IC

44 IC SOP8 LM833D (SOP8) 1 IC2 ST

45 Coil SMD SWPA6045S220MT, 22 µH 4 L1, L2, L3, L4 Sunlord

46 PCB STA381BWS 2.0CH REV2.2 1 Fastprint

QFN48 or

QFP64

Bead 600 ohm at 100 MHz or

33R

Hexagonal rod 15 mm length,

male type

Hexagonal rod 8 mm length,

female type

STA381BWS (QFN48 or

QFP64)

2BD3, BD4 Murata

4 Four corners Any source

4 Four corners Any source

1 IC1 or IC3 ST

10/65 Doc ID 022081 Rev 3

Page 11

AN3959 Functional description of the demonstration board

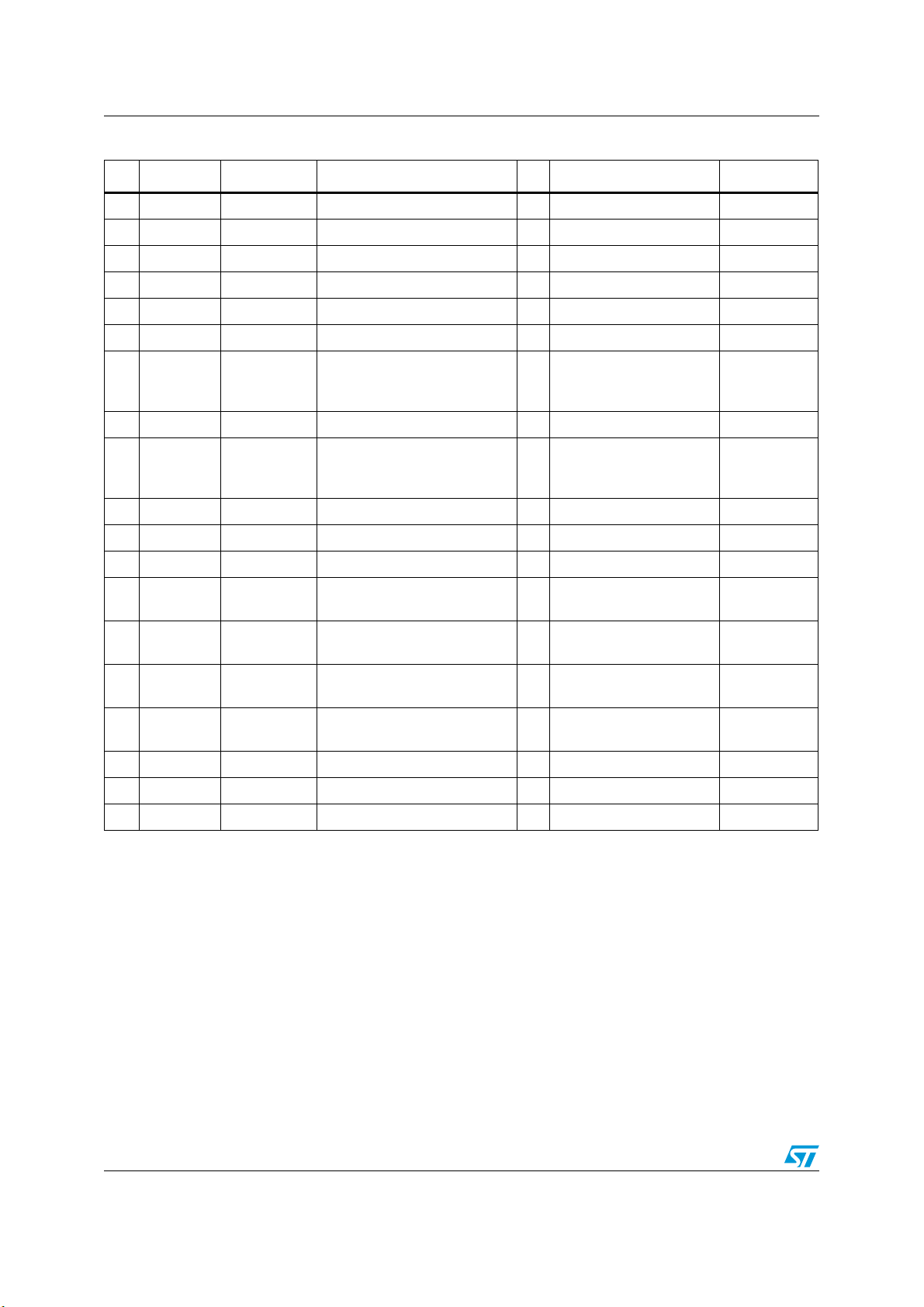

Figure 4. Top view of PCB layout

Doc ID 022081 Rev 3 11/65

Page 12

Functional description of the demonstration board AN3959

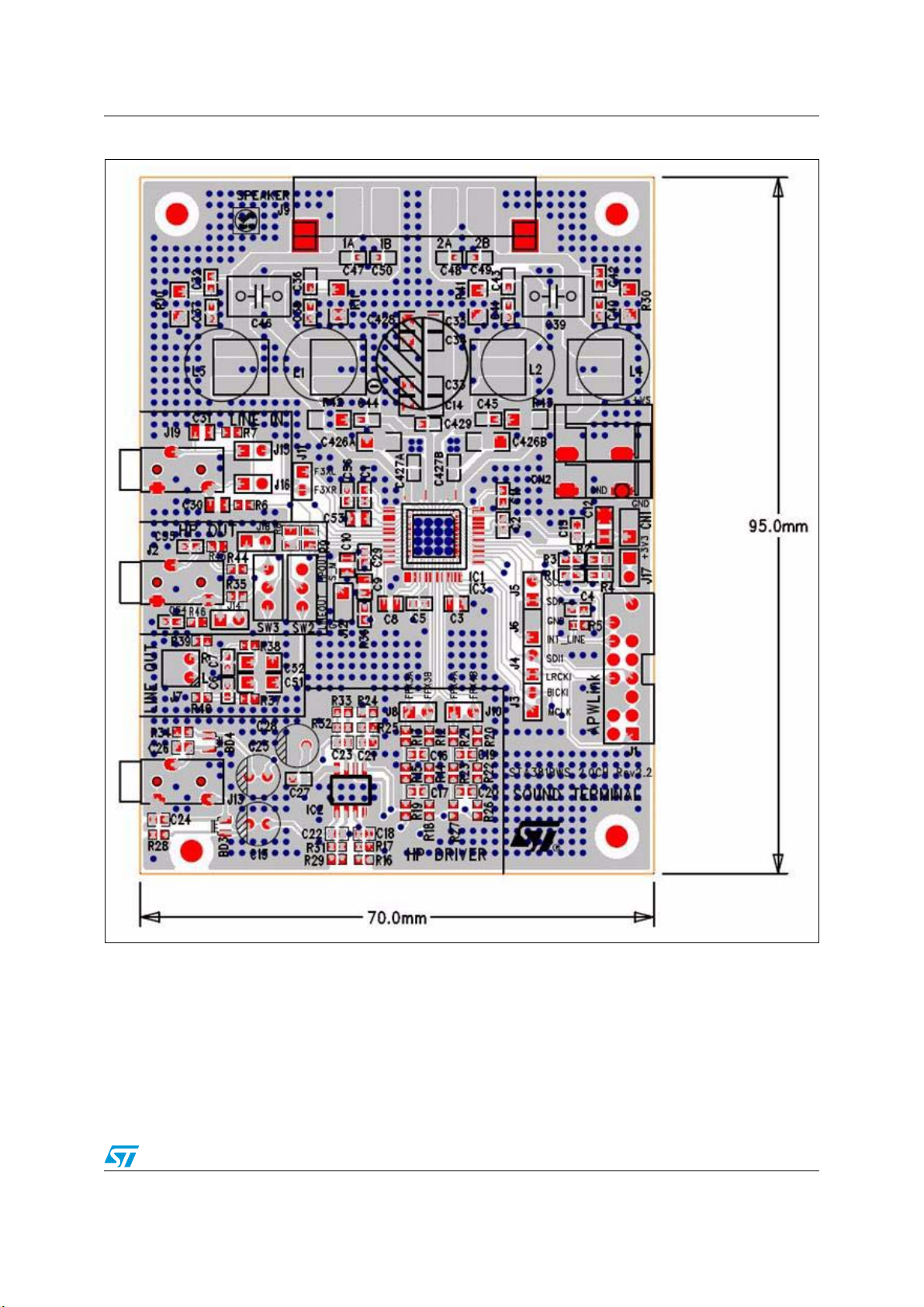

Figure 5. Inner layer2 view of PCB layout

12/65 Doc ID 022081 Rev 3

Page 13

AN3959 Functional description of the demonstration board

Figure 6. Inner layer3 view of PCB layout

Doc ID 022081 Rev 3 13/65

Page 14

Functional description of the demonstration board AN3959

Figure 7. Bottom view of PCB layout

14/65 Doc ID 022081 Rev 3

Page 15

AN3959 Functional description of the demonstration board

g

(

(

Figure 8. Block diagram of test connections with equipment

Output

to AP

STA380BWS

2.0CH

Demo

Board

From 4.5V to24V

Audio Precision Equipment

S/PDIF

nal

Si

I2S Input

DC3V3)

DC7V)

DC Power Supply

Monitor

Digital Oscilloscope

TDS3034B Tektronix

APWLink Board

PC with GUI to control the

chipset

Doc ID 022081 Rev 3 15/65

Page 16

STA381BWS power section test results AN3959

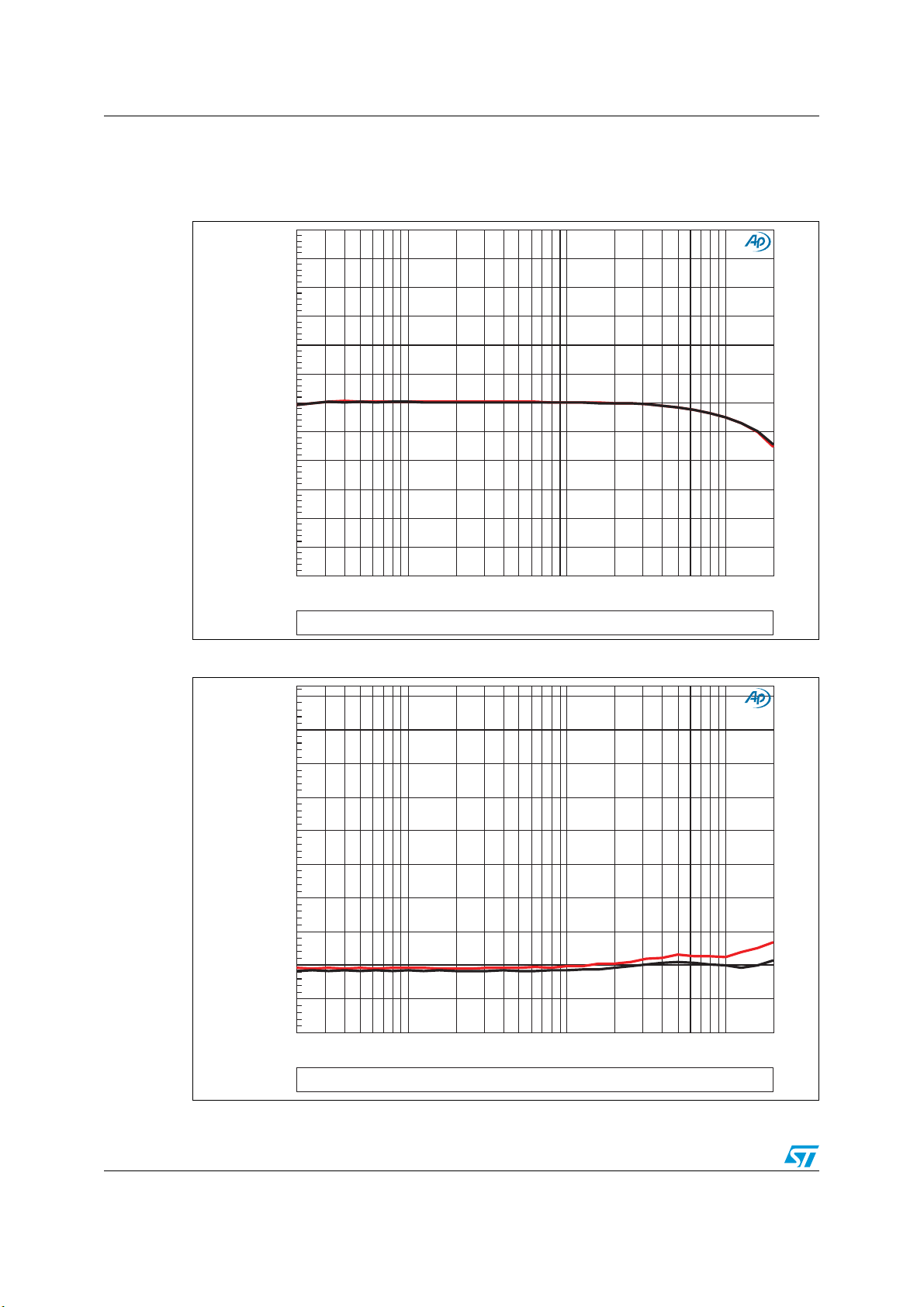

2 STA381BWS power section test results

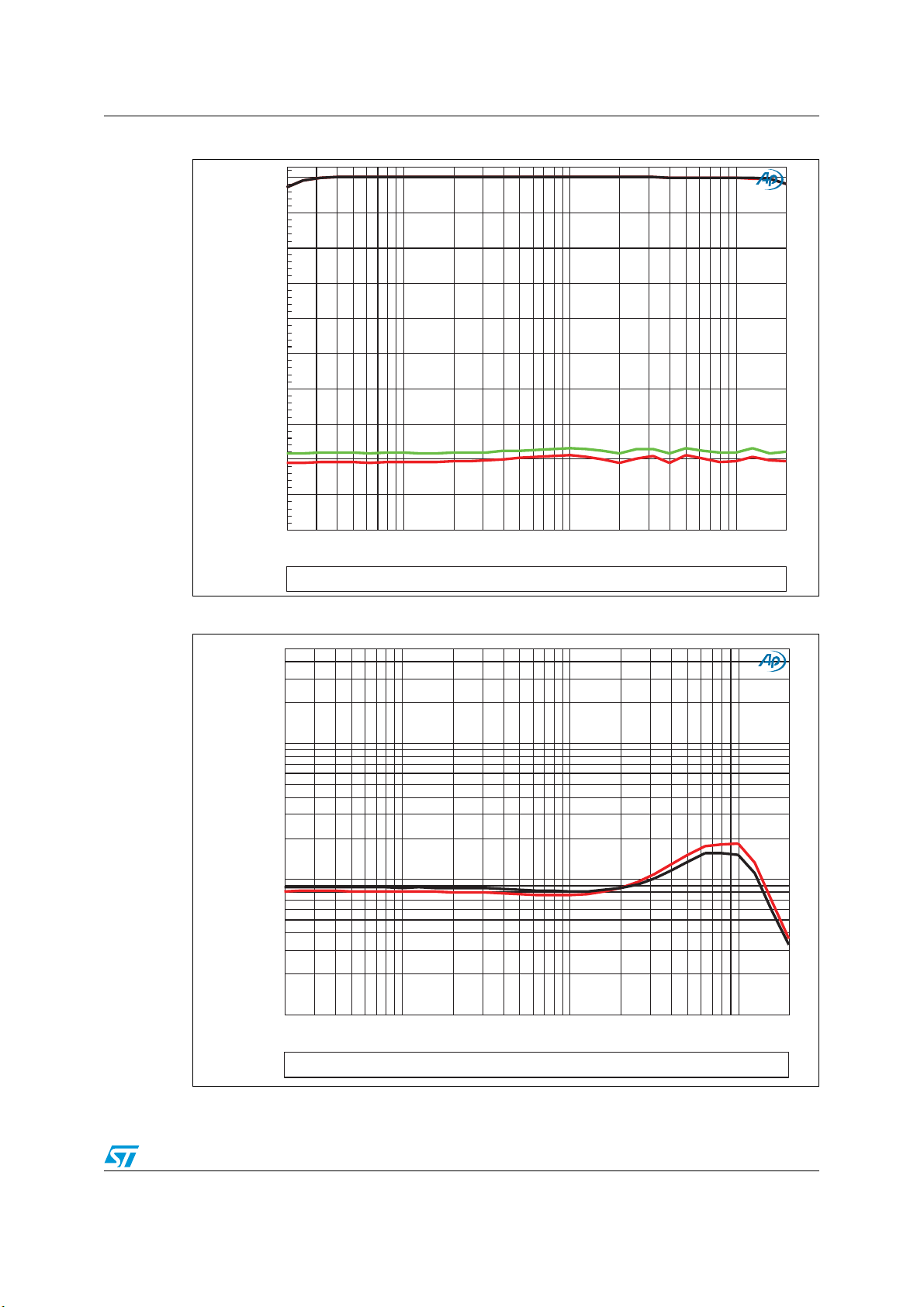

Figure 9. Frequency response, VCC = 18 V, RL = 8 ohm, 0 dB (Pout = 1 W)

+3

+2.5

+2

+1.5

+1

+0.5

d

B

+0

r

A

-0.5

-1

-1.5

-2

-2.5

-3

20 20k50 100 200 500 1k 2k 5k 10k

Test Conditions: VCC=18V, Rl=8ohm, Dual BTL, Input Signal=-14dBFS, Pout=1W, Volum e: +3dB

Figure 10. Crosstalk, V

+0

-10

-20

-30

-40

d

B

r

-50

A

-60

-70

-80

-90

Hz

= 18 V, RL = 8 ohm, 0 dB (Pout = 1 W)

CC

-100

20 20k50 100 200 500 1k 2k 5k 10k

Test Conditions: VCC=18V, Rl=8ohm, Dual BTL, Pout=1W, Volum e: +3dB

16/65 Doc ID 022081 Rev 3

Hz

Page 17

AN3959 STA381BWS power section test results

Figure 11. SNR, VCC = 18 V, RL = 8 ohm, 0 dB (Pout = 1 W)

+0

-10

-20

-30

-40

d

B

r

-50

A

-60

-70

-80

-90

-100

20 20k50 100 200 500 1k 2k 5k 10k

Hz

Test Conditions: VCC=18V, Rl=8ohm, Dual BTL, Pout=1W, Volume: +3dB

Figure 12. THD vs. frequency, V

5

2

1

0.5

%

0.2

0.1

0.05

0.02

0.01

20 20k50 100 200 500 1k 2k 5k 10k

Test Conditions: VCC=18V, Rl=8ohm, Dual BTL, Pout=1W, Volum e: +3dB

= 18 V, RL = 8 ohm, Pout = 1 W

CC

Hz

Doc ID 022081 Rev 3 17/65

Page 18

STA381BWS power section test results AN3959

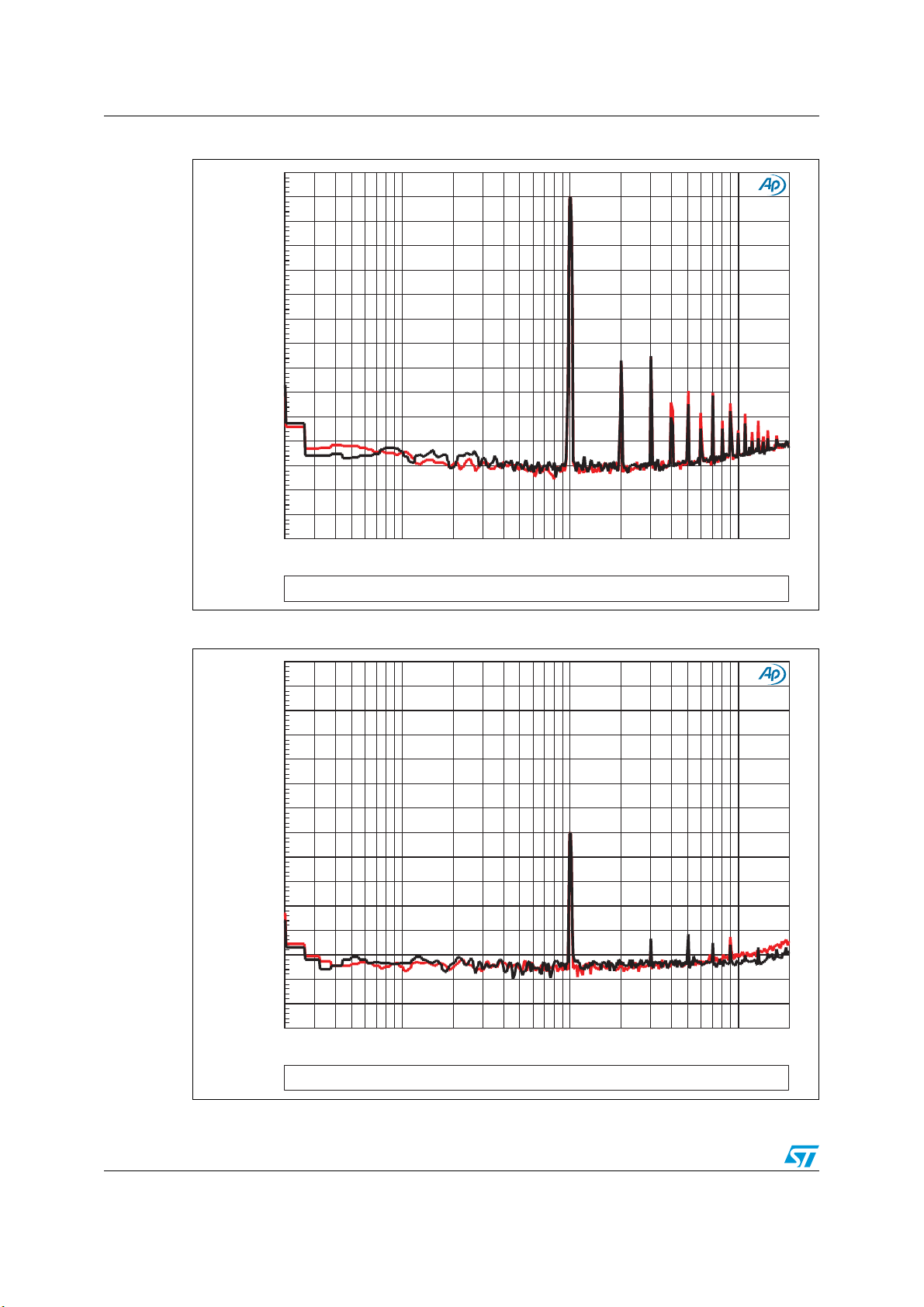

Figure 13. FFT (0 dBFS), VCC = 18 V, RL = 8 ohm, 0 dBFS (Pout = 1 W)

+10

+0

-10

-20

-30

-40

-50

d

B

-60

r

-70

A

-80

-90

-100

-110

-120

-130

-140

20 20k50 100 200 500 1k 2k 5k 10k

Hz

Test Conditions: VCC=18V, Rl=8ohm, f=1KHz, Dual BTL, Input Signal=0dBFS, Pout=1W, Volum e: -11.5dB

Figure 14. FFT (-60 dBFS), V

+10

+0

-10

-20

-30

-40

-50

d

B

-60

r

-70

A

-80

-90

-100

-110

-120

-130

-140

20 20k50 100 200 500 1k 2k 5k 10k

Test Conditions: VCC=18V, Rl=8ohm, f=1KHz, Dual BTL, Input Signal=-60dBFS, Volume: -11.5dB

= 18 V, RL = 8 ohm, 0 dBFS (Pout = 1 W)

CC

Hz

18/65 Doc ID 022081 Rev 3

Page 19

AN3959 STA381BWS power section test results

Figure 15. THD vs. output power, VCC = 18 V, RL = 8 ohm, f = 1 kHz

10

5

2

1

0.5

%

0.2

0.1

0.05

0.02

0.01

10m 2020m 50m 100m 200m 500m 1 2 5 10

W

Test Conditions: VCC=18V, Rl=8ohm, Dual BTL, Volum e: +3dB

Figure 16. THD vs. output power at different power supplies, R

10

5

2

1

0.5

%

0.2

0.1

0.05

0.02

0.01

10m 4020m 50m 100m 200m 500m 1 2 5 10 20

Test Conditions: Rl=8ohm, Dual BTL, Volum e: +3dB

VCC=6V

VCC=9V

VCC=12V

VCC=15V

W

= 8 ohm, f = 1 kHz

L

VCC=24V

VCC=21V

VCC=18V

Doc ID 022081 Rev 3 19/65

Page 20

STA381BW power section test results AN3959

3 STA381BW power section test results

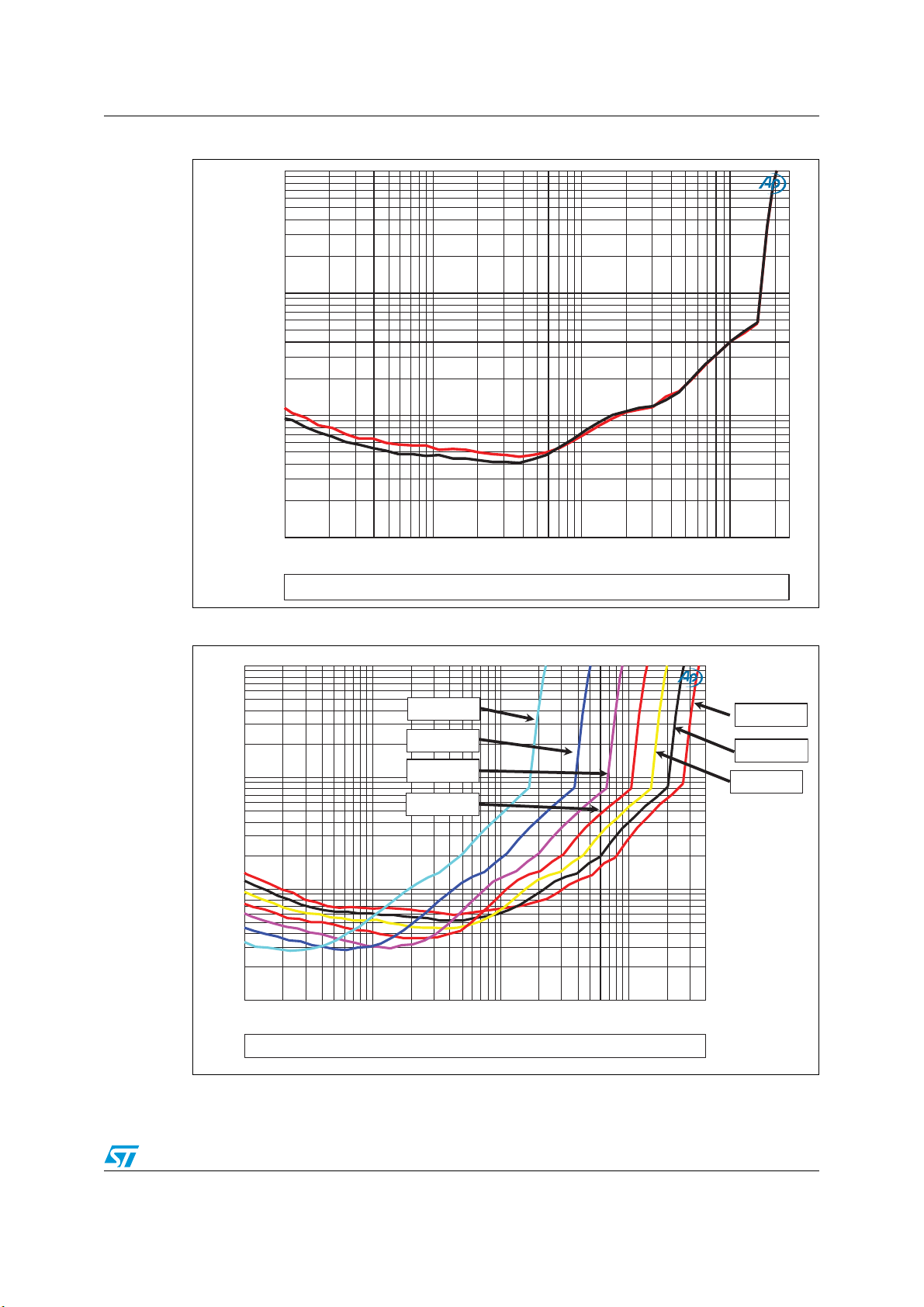

Figure 17. Frequency response, VCC = 24 V, RL = 8 ohm, 0 dB (Pout = 1 W)

+3

+2.5

+2

+1.5

+1

+0.5

d

B

+0

r

A

-0.5

-1

-1.5

-2

-2.5

-3

20 20k50 100 200 500 1k 2k 5k 10k

Test Conditions: VCC=24V, Rl=8ohm, Dual BTL, Input Signal=-17dBFS, Pout=1W, Volume: +3dB

Figure 18. Crosstalk, V

+0

-10

-20

-30

-40

d

B

r

-50

A

-60

-70

-80

Hz

= 24 V, RL = 8 ohm, 0 dB (Pout = 1 W)

CC

-90

-100

20 20k50 100 200 500 1k 2k 5k 10k

Test Conditions: VCC=24V, Rl=8ohm, Dual BTL, Pout=1W, Volum e: +3dB

20/65 Doc ID 022081 Rev 3

Hz

Page 21

AN3959 STA381BW power section test results

Figure 19. SNR, VCC = 24 V, RL = 8 ohm, 0 dB (Pout = 1 W)

+0

-10

-20

-30

-40

d

B

r

-50

A

-60

-70

-80

-90

-100

20 20k50 100 200 500 1k 2k 5k 10k

Hz

Test Conditions: VCC=24V, Rl=8ohm, Dual BTL, Pout=1W, Volum e: +3dB

Figure 20. THD vs. frequency, V

5

2

1

0.5

%

0.2

0.1

0.05

0.02

0.01

20 20k50 100 200 500 1k 2k 5k 10k

Test Conditions: VCC=24V, Rl=8ohm, Dual BTL, Pout=1W, Volum e: +3dB

= 24 V, RL = 8 ohm, Pout = 1 W

CC

Hz

Doc ID 022081 Rev 3 21/65

Page 22

STA381BW power section test results AN3959

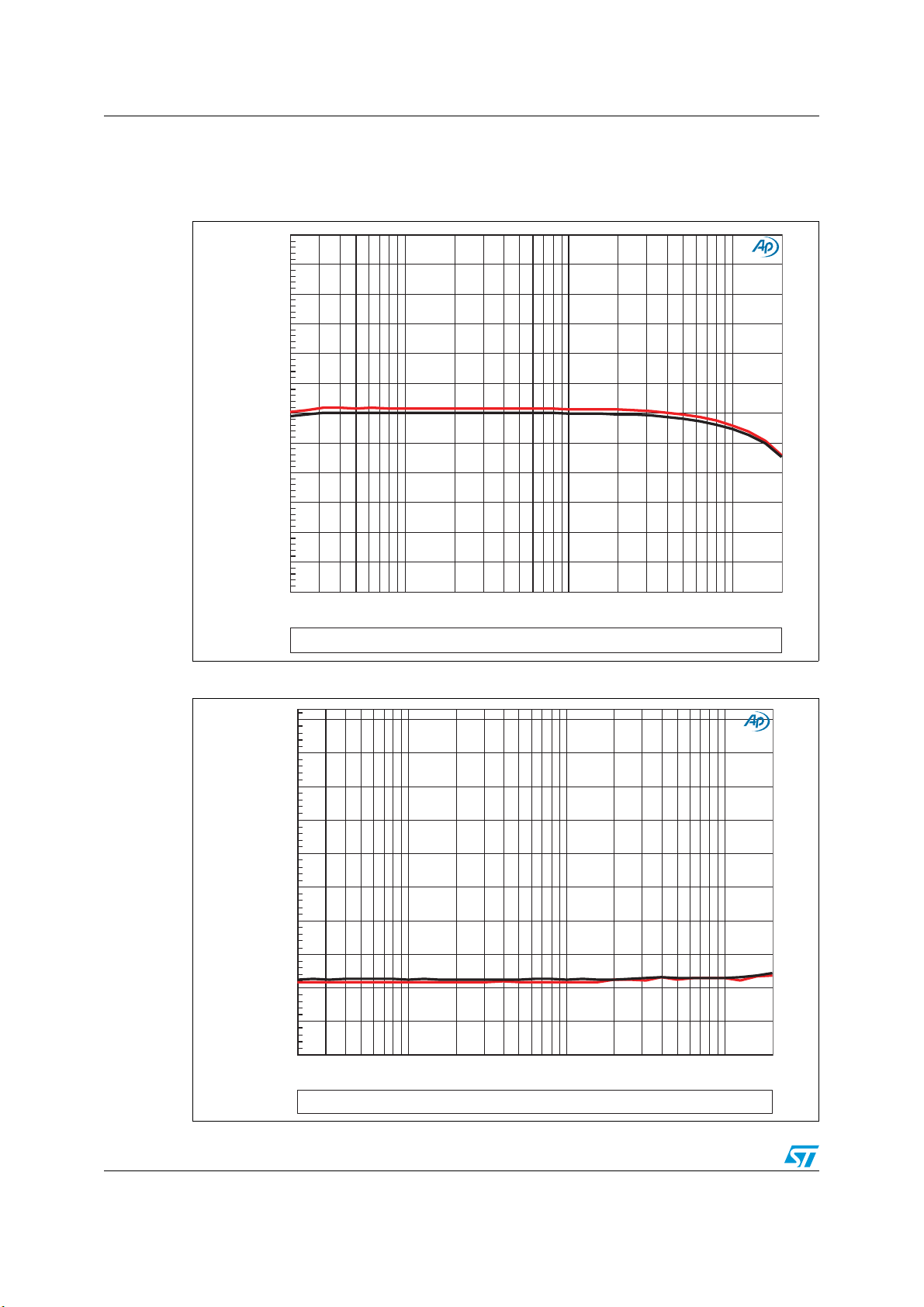

Figure 21. FFT (0 dBFS), VCC = 24 V, RL = 8 ohm, 0 dBFS (Pout = 1 W)

+10

+0

-10

-20

-30

-40

-50

d

B

-60

r

-70

A

-80

-90

-100

-110

-120

-130

-140

20 20k50 100 200 500 1k 2k 5k 10k

Hz

Test Conditions: VCC=24V, Rl=8ohm, f=1KHz, Dual BTL, Input Signal=0dBFS, Pout=1W, Volume: -13.5dB

Figure 22. FFT (-60 dBFS), V

+10

+0

-10

-20

-30

-40

-50

d

B

-60

r

-70

A

-80

-90

-100

-110

-120

-130

-140

20 20k50 100 200 500 1k 2k 5k 10k

Test Conditions: VCC=24V, Rl=8ohm, f=1KHz, Dual BTL, Input Signal=0dBFS, Pout=1W, Volume: -13.5dB

= 24 V, RL = 8 ohm, 0 dBFS (Pout = 1 W)

CC

Hz

22/65 Doc ID 022081 Rev 3

Page 23

AN3959 STA381BW power section test results

Figure 23. THD vs. output power, VCC = 24 V, RL = 8 ohm, f = 1 kHz

10

5

2

1

0.5

%

0.2

0.1

0.05

0.02

0.01

10m 4020m 50m 100m 200m 500m 1 2 5 10 20

W

Test Conditions: VCC=24V, Rl=8ohm, Dual BTL, Volume: +3dB

Figure 24. THD vs. output power at different power supplies, R

10

5

2

1

0.5

%

0.2

0.1

0.05

0.02

0.01

60m 50100m 200m 500m 1 2 5 10 20

Test Conditions: Rl=8ohm, Dual BTL, Volum e: +3dB

VCC=6V

VCC=9V

VCC=12V

VCC=15V

W

= 8 ohm, f = 1 kHz

L

VCC=27V

VCC=24V

VCC=21V

VCC=18V

Doc ID 022081 Rev 3 23/65

Page 24

Analog section test results AN3959

4 Analog section test results

The line/headphone out can be fed either with an external analog source, or with the F3X

output, allowing the audio content to come from the digital interface on both the power

output and on the line/headphone out.

Table 2. Test conditions

Conditions Input Output

J15, J16 short-circuit & SW2, SW3 switch to HPOUT STA381BWS F3X F3X HP OUT

J15, J16 short-circuit & SW2, SW3 switch to LINEOUT STA381BWS F3X LINE OUT

J15, J16 open circuit & SW2, SW3 switch to HPOUT LINE IN F3X HP OUT

J15, J16 open circuit & SW2, SW3 switch to LINEOUT LINE IN LINE OUT

Table 3. Headphone section test results

Filter: 22K LPF Ext. Res: 18K + 43K

Headphone Unit Spec. Test results

Reference mVrms 75 mVrms reference

Maximum output level

Left

Right

H/P frequency response

Right

H/P THD+N vs. frequency

Left

Right

H/P THD+N vs. level

Left

Right

H/P signal-to-noise (20-bit)

Left

Right

mVrms 540 mVrms(10 mW) 542 mV

-3 dB↑, +0.5 dB 30 Hz

~20 kHz

dBr -57 77

dBr -57 77

dBr -60

548 mV

-0.4 ~ -0.28Left

77

77

78

78

24/65 Doc ID 022081 Rev 3

Page 25

AN3959 Analog section test results

Table 4. Line out section test results

Filter: 22K LPF Ext Res: 18K + 43K

Line out Unit Spec. Test results

Reference 200 mV +/-20%

Maximum output level

Left

Right

Frequency response

Left

Right

THD+N vs. frequency

Left

Right

TH+N vs. level

Left

Right

Signal-to-noise (20-bit)

Left

Right

Channel separation

Left

Right

L/R CH phase difference deg 5↓ 0.02

Dynamic range (20-bit)

mVrms 2.0 V↓ 1.86

1.87

-1 dB↑,+0.5dB↓ 20Hz

~20 kHz

dBr -60

dBr -60 -78 dB at 200 mV

dBr -70 79

dBr -70 99

-0.87 dB at 20 Hz

-0.83 dB at 20 Hz

-71 dB at 20 Hz

-71 dB at 20 Hz

-78 dB at 200 mV

79

80

Left

Right

Residual noise mV 7↓ 0.021 mV

dBr -85 100

100

Doc ID 022081 Rev 3 25/65

Page 26

Thermal performance AN3959

5 Thermal performance

5.1 Thermal results - test 1

Figure 25. Temperature test 1

Testing conditions:

● V

● 1 kHz sine wave

● 8 ohm

= 12 V

CC

Output power: 2 x 7 W

Table 5. Thermal results - test 1

Result Tamb = 25 °C Tamb = 40°C

IC temp 39.2 °C 54.2 °C

26/65 Doc ID 022081 Rev 3

Page 27

AN3959 Thermal performance

5.2 Thermal results - test 2

Figure 26. Temperature test 2

Testing conditions:

● V

● 1 kHz sine wave

● 8 ohm

= 24 V

CC

Output power: 2 x 15 W

Table 6. Thermal results - test 2

Result Tamb = 25 °C Tamb = 40°C

IC temp 74.5 °C 89.5 °C

Doc ID 022081 Rev 3 27/65

Page 28

Design guidelines for schematic and PCB layout AN3959

6 Design guidelines for schematic and PCB layout

6.1 Schematic

6.1.1 Criteria for selection of components

● Absolute maximum rating: STA381BWS V

● Bypass capacitor 100 nF in parallel to 1 µF for each power V

dielectric is X7R.

● Coil saturation current compatible with the peak current of application

6.1.2 Decoupling capacitors

For the decoupling capacitor(s), one decoupling system can be used with 2 capacitors per

channel. The decoupling capacitors must be as close as possible to the IC pins, in order to

avoid parasitic inductance with the copper wire on the PC board.

6.1.3 Output filter

Figure 27. Output filter (BTL)

IN xA

C90

330p

R36

20

IN xB

22u

L11

L13 22u

C89

100n

C95

100n

C101

100n

C105

100n

= 27 V

CC

R34

6.2

R37

6.2

C98

470n

branch. Preferable

CC

C91

1000p

C99

1000p

C103

1000p

J7

1

2

CON2

SNUBBER

Main Filter

1. The key function of a snubber network is to absorb energy from the reactance in the

power circuit. The purpose of the snubber RC network is to avoid unnecessary high

pulse energy such as a spike in the power circuit which is dangerous to the system.

The snubber network allows the energy (big spike) to be transferred to and from the

snubber network in order for the system to work safely.

2. The purpose of the main filter is to cut off the frequency above the audible range of

20 kHz, which is mandatory in order to have a clean amplifer response. The main filter

is designed using the Butterworth formula to define the cutoff frequency.

3. The purpose of the damping network is to avoid the high-frequency oscillation issue on

the output circuit. The damping network allows the THD to be improved and also allows

avoiding the inductive copper on the PCB route when the system is working at high

frequency with PWM or PCM.

28/65 Doc ID 022081 Rev 3

Dumping Network

Page 29

AN3959 Design guidelines for schematic and PCB layout

6.1.4 Snubber filter

The snubber circuit must be optimized for the specific application. Starting values are

330 pF in series to 22 ohm. The power on this network is dependent on the power supply,

frequency and capacitor value according to the following formula:

P=C*f*(2*V)

2

This power is dissipated on the series resistance.

Figure 28. Differential-mode snubber circuit

INxA

C126

330p

R44

22

INxB

For the common-mode snubber the formula to evaluate power is:

P=C*f*2*(V

2

)

This power is dissipated on the series resistance.

Figure 29. Common-mode snubber circuit

INxA

C127

330p

R45

22

R46

22

C130

INxB

330p

Doc ID 022081 Rev 3 29/65

Page 30

Design guidelines for schematic and PCB layout AN3959

6.1.5 Main filter

The main filter is an L and C based Butterworth filter. The cutoff frequency must be chosen

between the upper limit of the audio band (≈20 kHz) and the carrier frequency (384 kHz).

Figure 30. Main filter

6.1.6 Dumping network

The C-R-C is a dumping network. It is mainly intended for high inductive loads such as

disconnecting the speaker load.

Figure 31. Dumping network

C dump -S

C dump -P

C dump -P

C dump -S

Table 7. Recommended values

Rload 16 ohm 12 ohm 8 ohm 6 ohm 4 ohm

Lload 47 µH 33 µH 22 µH 15 µH 10 µH

Cload 220 nF 330 nF 470 nF 680 nF 1 µF

R dump

Rdump

C dump-S 100 nF 100 nF 100 nF 100 nF 220 nF

C dump-P 100 nF 100 nF 100 nF 100 nF 220 nF

R dump 10 8.2 6.2 4.7 2.7

30/65 Doc ID 022081 Rev 3

Page 31

AN3959 Design guidelines for schematic and PCB layout

6.1.7 Recommended power-up and power-down sequence

There is no constraint regarding power supply voltages while it is required to release the

reset line (RST) only after the master clock (MCLK) is stable, after the power-down (PWDN)

is already set high and before any I

Figure 32. Recommended power-up and power-down sequence

2

C commands.

6.2 Layout

The following figures illustrate layout recommendations.

Figure 33. Snubber network soldered as close as possible to the respective IC pin

Doc ID 022081 Rev 3 31/65

Page 32

Design guidelines for schematic and PCB layout AN3959

Figure 34. Electrolytic capacitor used first to separate the VCC branches

Figure 35. Path between V

and ground pin minimized in order to avoid inductive paths

CC

32/65 Doc ID 022081 Rev 3

Page 33

AN3959 Design guidelines for schematic and PCB layout

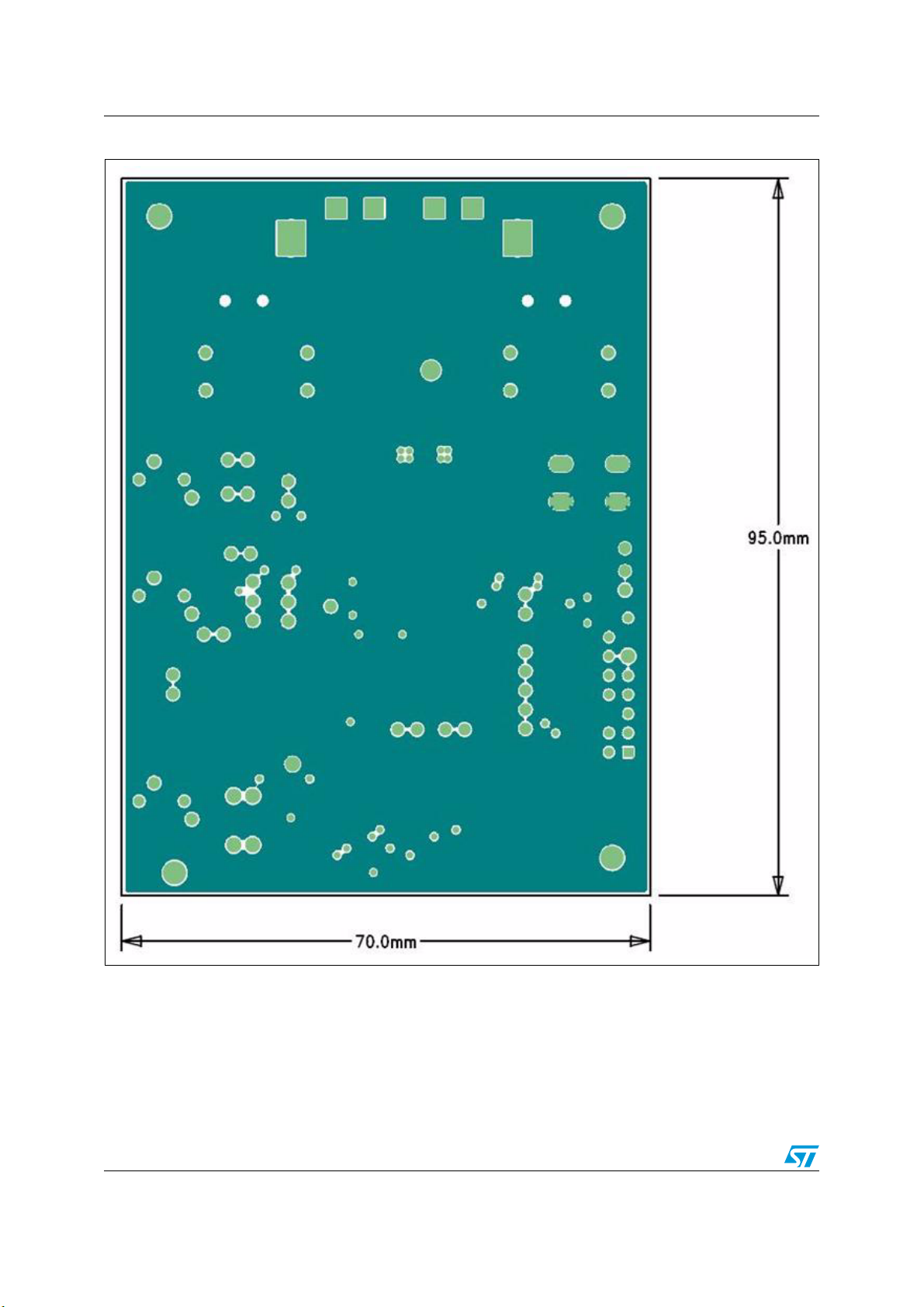

Thermal dissipation

It is mandatory to have a large ground plane on the top layer, inner layer2, inner layer3, and

bottom layer and solder the slug on the PCB.

Figure 36. Large ground plane on the top side

Figure 37. Large ground plane on inner layer2

Doc ID 022081 Rev 3 33/65

Page 34

Design guidelines for schematic and PCB layout AN3959

Figure 38. Large ground plane on inner layer3

34/65 Doc ID 022081 Rev 3

Page 35

AN3959 Design guidelines for schematic and PCB layout

Figure 39. Large ground plane on bottom side

Figure 40. Symmetrical paths created for output stage, for differential applications

Doc ID 022081 Rev 3 35/65

Page 36

Design guidelines for schematic and PCB layout AN3959

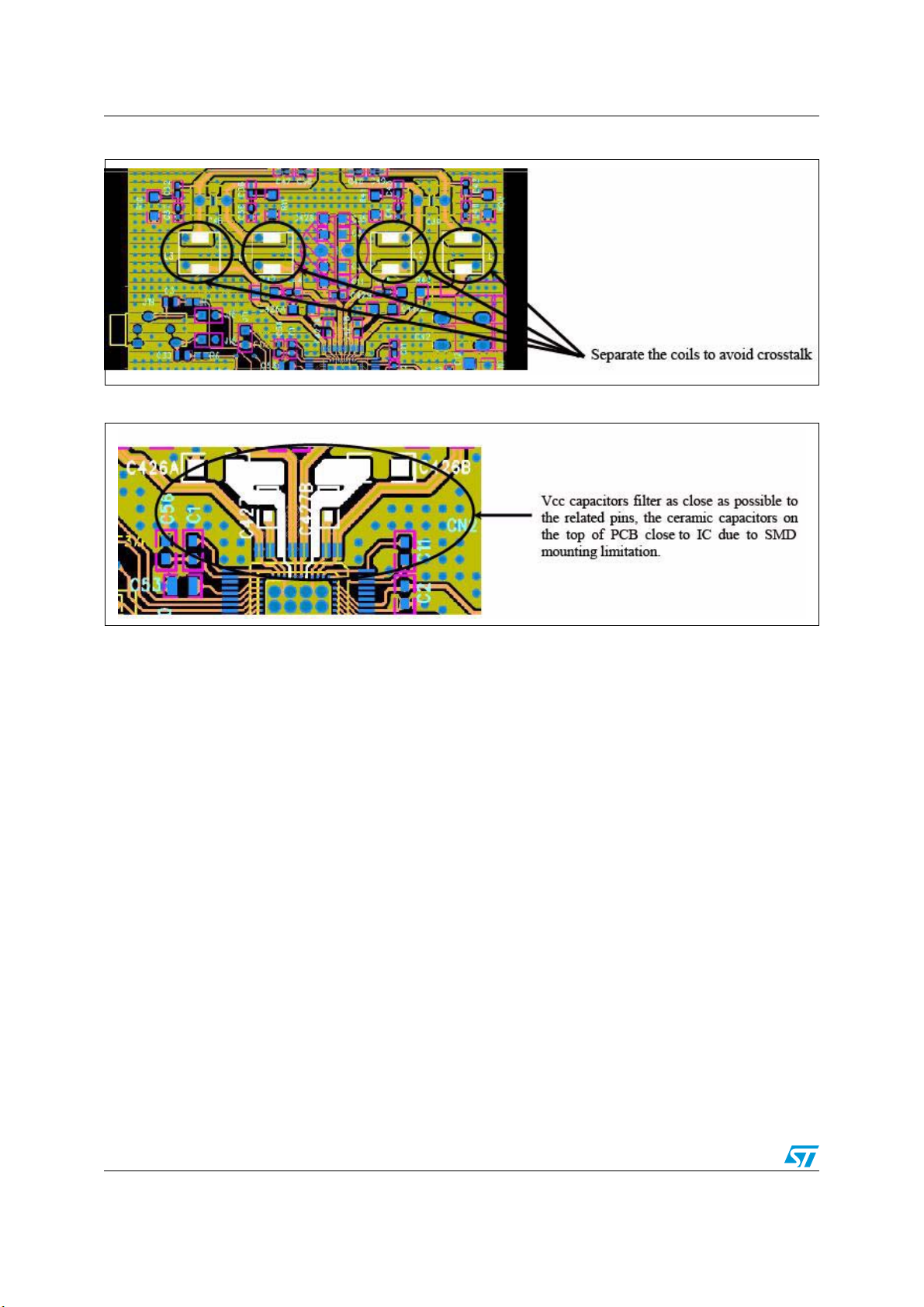

Figure 41. Coils separated in order to avoid crosstalk

Figure 42. V

filter for high frequency

CC

Placing the V

filter capacitors close to the pins avoids an inductive coil generated by the

CC

copper wire, because the system is working in PWM with fast switching (the frequency is

384 kHz with fs = 48 kHz) so the longer copper wire easily becomes an inductor. To improve

this we suggest using the ceramic capacitor to balance the reactance. It's mandatory to put

the ceramic capacitor as close as possible to the related pins. The distance between the

capacitor to the related pins is recommended to be within 5 mm.

36/65 Doc ID 022081 Rev 3

Page 37

AN3959 Design guidelines for schematic and PCB layout

Figure 43. Thermal layout with large ground

The thermal resistance junction in the bottom of the STA381BWS to ambient, obtainable

with a ground copper area of 5.6 x 5.6 mm and with 16 via holes is shown in Figure 43 as an

example.

Doc ID 022081 Rev 3 37/65

Page 38

Software setup to use the STA381BW/STA381BWS devices (ST Map) AN3959

7 Software setup to use the STA381BW/STA381BWS

devices (ST Map)

7.1 Processing configuration

Figure 44. Processing path

Proc essing Frequency = 2xFs

I2S In p ut

Interface

X2Ov er-

-sampling

FIR

X2Ov er-

-sampling

FIR

Proc essing Frequency = 2xFs

Pre-

-scale

Pre-

-scale

Hi-Pass

Filter

By de fault tw o ch an nels

Hi-Pass

Filter

Biquad#1Biquad#2Biquad#3Biquad

are link ed

Biquad#1Biquad#2Biquad#3Biquad

● By default, the post-scale is linked (all channels use the channel-1 coefficient value)

– To use different coefficients, bit D3 register 0x03 must be set to 0

● By default, all 8 biquads are enabled

● By default, all biquads are linked (all channels use the channel-1 coefficient values)

– To use different coefficients, bit D4 register 0x03 must be set to 0

● By default, bass and treble are bypassed

– To use bass, bit D1 register 0x36 must be set to 0

– To use treble, bit D0 register 0x36 must be set to 0

Figure 45. 2.1-channel with STCompressor

L

C1Mx1

+

R

C1Mx2

Channel ½

Biquad #8

--------------

Hi-pass XO

Filter

User D efined Filters

User D efined Filters

TM

STCompressor

#4

#4

Volum e

And

Limiter

Biquad #5

De-emph

By d efault two c han nels

Biquad #5

Or

De-emph

Or

are link ed

Biquad #6

Bass

Biquad #6

Bass

DC Cut

Filter

Or

Tone Control

Or

Tone Control

By d efault the ch annels

Biquad #7

or

Treble

Biquad #7

or

Treble

are link ed

Pos t Scale

L

R

C2Mx1

+

C2Mx2

C3Mx1

+

C3Mx2

User-Defined

Mix Coefficients

Channel ½

Biquad #8

--------------

Hi-pass XO

Filter

Channel 3

Biquad #8

--------------

Low -pass XO

filte r

Crossov er Frequency

Determ ined by XO Setting

(User D efined If

XO=0000)

STCompressor

38/65 Doc ID 022081 Rev 3

Volum e

And

Limiter

Volum e

And

Limiter

DC Cut

Filter

DC Cut

Filter

Pos t Scale

Pos t Scale

Page 39

AN3959 Software setup to use the STA381BW/STA381BWS devices (ST Map)

7.2 STCompressor

TM

Figure 46. STCompressor - overview

BQ0 BQ1

Input

Ch0

BQ0

BQ1

Band Splitter

BQ2 BQ3

Input

Ch1

BQ2

BQ3

Band Splitter

Level

Meter

Level

Meter

Level

Meter

Level

Meter

DRC0

Mapper

Mapper

DRC1

DRC2

Mapper

Mapper

DRC3

Offset

Attenuator

Attenuator

Offset

Offset

Attenuator

Attenuator

Offset

X

Output

Ch0

+

X

X

Output

Ch1

+

X

Figure 47. STCompressor - mapper

● Linear zone

– Standard operation, input and output are linked to volume

● Compression zone

– The signal is compressed with a programmable ratio

● Compression ratio

– The ratio changes the compression slope

● Limiting zone

– The signal is limited to avoid unpredictable effects or damages

Doc ID 022081 Rev 3 39/65

Page 40

Software setup to use the STA381BW/STA381BWS devices (ST Map) AN3959

Figure 48. STCompressor - compression ratio

● The compression ratio is user-programmable

● By default the rate is 1:1 (no variable ratio)

● There are 16 different settings (from 0 to 15) and the ratio varies from 1:1 to 1:16

Figure 49. STCompressor - limiter threshold

● The limiter threshold is user-programmable

● By default the threshold is set to 0 dB

● There are 144 different settings (from -24 to +12 dB) with 0.25 dB/step

40/65 Doc ID 022081 Rev 3

Page 41

AN3959 Software setup to use the STA381BW/STA381BWS devices (ST Map)

Figure 50. STCompressor - offset control

● The offset is a user-programmable gain or volume control

● When the STC is used, it is better to use offset instead of volume for location in the

processing path

There are 192 different settings (from 0 to +48) with 0.25 dB/step

7.2.1 STCompressor settings

● By default the STCompressor is enabled and in pass-through

– Bit D4 of register 0x5A (STC_EN) is set to 1. This means STC is enabled

– Bit D5 of register 0x5A (STC_BYP) is set to 1. This means STC is in pass-through

● By default the STC band recombination is disabled

– Bit D0 register 0x5B (BRC_EN) is set to 0

7.2.2 Configuring and enabling the STCompressor

● Write the STC configuration

– Define the band splitter filtering

– Define the limiter threshold [-24, +12] dB with 0.25 dB/step

– Define the max. linear zone (compression threshold) [-48, 0] dB with 0.25 dB/step

– Define the compression ratio [1:1, 1:16]

– Define the attack rate [0, +16] dB/msec with 0.25 dB/ms step

– Define the release rate [0.0078, 1) dB/msec with 0.0039dB/msec step

– Define the dynamic attack

– Define the offset

● Enable the STC

– Set the STC_BYP bit (register 0x5A bit D1) to 0

Doc ID 022081 Rev 3 41/65

Page 42

Software setup to use the STA381BW/STA381BWS devices (ST Map) AN3959

7.2.3 Example settings of the STCompressor

Band splitter:

● Biquad 0, biquad 1 of band 0: low-pass filter with Fc = 200 Hz

Write in RAM the following values.

BQ0 band 0:

0x40→0x000059

0x41→0x000059

0x42→0x1FB47A

0x43→0xE095A7

0x44→0x000002

BQ1 band0

0x45→0x000059

0x46→0x000059

0x47→0x1FB47A

0x48→0xE095A7

0x49→0x000002

● Biquad 0, biquad 1 of band 1: high pass filter with Fc = 200 Hz

Write in RAM the following values.

BQ0 band 1:

0x4A→0xE04B2D

0x4B→0x1FB4D3

0x4C→0x1FB47A

0x4D→0xE095A7

0x4E→0x0FDA69

BQ1 band 1:

0x4F→0xE04B2D

0x50→0x1FB4D3

0x51→0x1FB47A

0x52→0xE095A7

0x53→0x0FDA69

Limiter threshold = +2 dB

● Coefficient value = HEX (+2/2

● Write in RAM:

0x56→0x040000

0x60→0x040000

Compression threshold= -2 dB

● Coefficient value = HEX [2

● Write in RAM:

0x58→0xFC0000

0x62→0xFC0000

24

- (2/26) * 223] = HEX (16515072) = 0xFC0000

6

*)223 = 0x040000

42/65 Doc ID 022081 Rev 3

Page 43

AN3959 Software setup to use the STA381BW/STA381BWS devices (ST Map)

Compression ratio - 1:2 = 4

● Coefficient value = HEX [(4/2

● Write in RAM:

– 0x57→0x080000

– 0x61→0x080000

6

) * 223] = HEX (524288) = 0x080000

Attack rate: +4 dB/msec

● Coefficient value = HEX [(4/2

● Write in RAM:

0x55→0x080000

0x5F→0x080000

6

) * 223] = HEX (524288) = 0x080000

Release rate: 0.01953 dB/msec

● Coefficient value = HEX (Value * 2

● Write in RAM:

0x54→0x027EF9

0x5E→0x027EF9

23

) = HEX (0.01953*223) = 0x027EF9

Dynamic attack rate: 0.039 dB/msec

● Coefficient value = HEX (Value * 2

● Write in RAM:

0x71→0x04FDF3

23

) = HEX (0.039*223) = 0x04FDF3

Offset: 0.5 dB for all DRC

● Coefficient value = HEX [(0.5/2

● Write in RAM:

0x68→0x010000

0x69→0x010000

0x6A→0x010000

0x6B→0x010000

6

) * 223] = 0x010000

Doc ID 022081 Rev 3 43/65

Page 44

Software setup to use the STA381BW/STA381BWS devices (ST Map) AN3959

7.2.4 Test results with APWorkbench

The following figure shows the APWorkbench results for the example settings given in

Section 7.2.3.

Figure 51. APWorkbench results for STC example

44/65 Doc ID 022081 Rev 3

Page 45

AN3959 Software setup to use the STA381BW/STA381BWS devices (ST Map)

7.3 CRC computation

In the STA381BW/STA381BWS there are three different CRCs:

● Biquad

● Crossover

● STCompressor

7.3.1 Biquad CRC computation

● Download into RAM the biquad filter coefficients (address 0x00-0x27)

● The XOR function calculates bit-to-bit the downloaded coefficients

● Write the calculated coefficients in register BQCHKR (0x66-0x67-0x68)

● Enable the BCGO bit (bit D0 register 0x6C). The checksum XOR of the biquad filter will

be exposed on the BQCHECKE registers (0x60-0x61-0x62)

● Enable the CRC comparison, setting the BCCMP bit (bit D1 register 0x6C). The

comparison will be done on each audio frame and the result is written in BCCRES (bit

D2 register 0x6C)

– BC_RES = 0 means that the checksum is OK, no errors

– BC_RES = 1 means that checksum errors are detected

● It is possible to reset the device if BC_RES = 1, enabling bit D3 of register 0x6C

(BCAUTO). By default, this function is disabled (BCAUTO=0)

7.3.2 Crossover CRC computation

● Download into RAM the Xover filter coefficients (address 0x28-0x31)

● The XOR function calculates bit-to-bit the downloaded coefficients

● Write the calculated coefficients in register XCCKR (0x69-0x6A-0x6B)

● Enable the XCGO bit (bit D4 register 0x6C). The checksum XOR of the Xover filter will

be exposed on the XCCKE registers (0x63-0x64-0x65)

● Enable the CRC comparison, setting the XCCMP bit (bit D5 register 0x6C). The

comparison will be done on each audio frame and the result is written in XCRES (bit D6

register 0x6C).

– XCRES=0 means that the checksum is OK, no errors

– XCRES=1 means that checksum errors are detected

● It is possible to reset the device if XCRES = 1, enabling bit D7 of register 0x6C

(XCAUTO). By default, this function is disabled (XCAUTO=0)

Doc ID 022081 Rev 3 45/65

Page 46

Software setup to use the STA381BW/STA381BWS devices (ST Map) AN3959

7.3.3 STCompressorTM CRC computation

● Download into RAM the STC band splitter filter coefficients into the RAM (address

0x40-0x53)

● The XOR function calculates bit-to-bit the downloaded coefficients

● Write into RAM the expected value (address 0x72 – CRC expected)

● Enable the NP_CRC_GO bit (bit D0 register 0x5A). The checksum XOR of the band

splitter filter coefficients will be exposed in RAM on the computed CRC (address 0x73)

● It is possible to see the CRC result in register 0x5A bit D2 (NP_CRCRES)

– NP_CRCRES = 0, CRC STCompressor OK

– NP_CRCRES = 1, CRC STCompressor with error

46/65 Doc ID 022081 Rev 3

Page 47

AN3959 Software setup to use the STA381BW/STA381BWS devices (ST Map)

7.4 Startup

ST map selection

● Select register map (ST Map)

– 0x7E (MISC4) bit D7 (SMAP) set to 0 (default is 1)

Clock and SAI configuration

● Set clock selection (register 0x00)

– For each Fs, if BICKI=32*Fs or 64*Fs, MCLK is ignored and the oversampling

clock is BICKI

– If the multiplier is different from 32 or 64, MCLK is mandatory and the

configuration must be written in register 0x00

● Set SAI interface

– Select right digital interface (the default setting is I

0x01

Output configuration

● Select configuration

– 2.0-channel is the default configuration

– 2.1-channel configuration (2 single-ended + 1 BTL)

Register 0x05 (CONFF) bit D1 and D0 (OCFG) must be set to 01

– 2.1-channel configuration with external PWM and controls on auxiliary PWM (2

BTL + external PWM)

Register 0x05 (CONFF) bit D1 and D0 (OCFG) must be set to 10

– 1-channel configuration (for subwoofer application)

Register 0x05 (CONFF) bit D1 and D0 (OCFG) must be set to 11

2

S 24-bit), writing the register

Settings for class-AB

● Select output configuration

– Lineout: default setting (0) bit D7 (HPLN) register 0x55 (HPCFG)

– Headphone: set bit D7 (HPLN) register 0x55 to 1 (HPCFG)

● Enable class-AB

– Set to 0 (default is 1) bit D5 (MUTE) of register 0x55 (HPCFG)

● To verify that the device works properly read register 0x55

– Bit D0 must be 1 (charge pump OK)

– Bit D1 must be 0 (class-AB not in FAULT)

– Bit D2 must be 1 (1.8 V core power supply OK)

Settings for enable F3X

● Set register 0x59 (F3XCFG2) to 0x6D

The default value is 0x6E. This means bit D0 must be set to 1and bit D0 to 0.

– After setting these bits, in F3XL there is analog output of channel 1 and in F3XR

there is analog output of ch 2. The volume control is bypassed.

– To also control the volume it is mandatory to change the LOC1 and LOC0 bits (bit

D6 and D7 reg. 0x06)

Doc ID 022081 Rev 3 47/65

Page 48

Software setup to use the STA381BW/STA381BWS devices (ST Map) AN3959

Figure 52. F3X output

Note: If the digital input is 0 dBFs, the F3X output is 1.8 Vpp (that means 0.64 Vrms).

F3X for HPout

● Write in register 0x58 (F3XCFG1) the value 0x80 (default value 0x00) which enables

the F3XLNK function.

– Setting this bit, the ON/OFF of F3X is due to the power on/off of class-AB

– Setting F3XLNK, bit D1 of register 0x59 (F3X_MUTE) is ignored

● The power on/off is dependent on bit D5 of register 0x55 (MUTE)

● Unset bit D0 of register 0x59 (F3X_ENA)

Figure 53. F3X for HPout

48/65 Doc ID 022081 Rev 3

Page 49

AN3959 Software setup to use the STA381BW/STA381BWS devices (ST Map)

7.5 Short-circuit protection for the STA381BW/STA381BWS

The device is protected to short circuit at power-on:

● Enable the short-circuit check enable bit (SHEN, bit D0 register 0x4C)

● When the device switches from EAPD = 0 to EAPD = 1 (bit D7 register 0x05), the

protection checks the short-circuit

● It is possible to verify the short, reading register 0x47

– Bit D0 = 0 (OUTSH) means that OUT1B is shorted to OUT2A

– Bit D1 = 0 (VCCSH) means that one output pin is shorted with Vcc

– Bit D2 = 0 (GNDSH) means that one output pin is shorted with GND

● This function is verified ONLY when EAPD toggles from 0 to 1

● The feature is enabled in BTL mode. It is not effective in single-ended mode

7.6 Settings for bridge power-up

● Switch on the bridge

– Register 0x05 bit D7 set to 1 (default is 0)

● Change master volume to desired value (e.g. 0 dB)

– Register 0x07 from 0xFF (mute) to 0x00 (0 dB)

● Change channel volume to desired value (e.g. +3 dB)

– Register 0x08 (Ch1 vol) from 0x60 (0dB) to 0x5A (+3 dB)

– Register 0x09 (Ch2 vol) from 0x60 (0dB) to 0x5A (+3dB)

● By default, the timing between the bridge power-on in seconds and the real bridge on is

1 sec

● To modify this timing it is mandatory to change the value in register 0x2B and 0x2C

– The default value is 0x300C (= 12300)

– The timing is 12300 * 0.083 * 10

● For example, to have 100 msec for power-on, the number that must be witten in register

is 1205 (dec) = 0x04B5

– Write in register 0x2B the value 0x04

– Write in register 0x2C the value 0xB5

-3

= 1.0209 sec

Doc ID 022081 Rev 3 49/65

Page 50

Examples of code (TV SoC) AN3959

8 Examples of code (TV SoC)

8.1 FFX381X_Sample.h

#ifndef FFX_38X_H

#define FFX_38X_H

//#define FFX_I2C_ADDR 0x34

#define FFX_I2C_ADDR 0x38

#define FFX_CONFIGURE_A 0x00

#define FFX_CONFIGURE_B 0x01

#define FFX_CONFIGURE_C 0x02

#define FFX_CONFIGURE_D 0x03

#define FFX_CONFIGURE_E 0x04

#define FFX_CONFIGURE_F 0x05

#define FFX_MUTE 0x06

#define FFX_MAIN_VOLUME 0x07

#define FFX_CHANNEL1_VOL 0x08

#define FFX_CHANNEL2_VOL 0x09

#define FFX_CHANNEL3_VOL 0x0a

#define FFX_AUTO1 0x0b

#define FFX_AUTO2 0x0c

//#define FFX_AUTO3 0x0d

#define FFX_CHANNEL1_CFG 0x0e

#define FFX_CHANNEL2_CFG 0x0f

#define FFX_CHANNEL3_CFG 0x10

#define FFX_TONEBASS 0x11

#define FFX_L1AR_RATE 0x12

#define FFX_L1AR_THRESHOLD 0x13

50/65 Doc ID 022081 Rev 3

Page 51

AN3959 Examples of code (TV SoC)

#define FFX_L2AR_RATE 0x14

#define FFX_L2AR_THRESHOLD 0x15

#define STA381BWX_NEWMAP 0x80

#define STA381BWX_STMAP 0x00

#define STA381BWX_MAPSEL 0x7E

#define STA381BWX_Cross_userdefine 0x00

#define STA381BWX_Cross_80Hz 0x01

#define STA381BWX_Cross_100Hz 0x02

#define STA381BWX_Cross_120Hz 0x03

#define STA381BWX_Cross_140Hz 0x04

#define STA381BWX_Cross_160Hz 0x05

#define STA381BWX_Cross_180Hz 0x06

#define STA381BWX_Cross_200Hz 0x07

#define STA381BWX_Cross_220Hz 0x08

#define STA381BWX_Cross_240Hz 0x09

#define STA381BWX_Cross_260Hz 0x0A

#define STA381BWX_Cross_280Hz 0x0B

#define STA381BWX_Cross_300Hz 0x0C

#define STA381BWX_Cross_320Hz 0x0D

#define STA381BWX_Cross_340Hz 0x0E

#define STA381BWX_Cross_360Hz 0x0F

#define STA381BWX_2_0_HP_Config 0x00

#define STA381BWX_2_1_SE_Config 0x01

#define STA381BWX_0_1_Mono_Config 0x03

void STA381BWX_init(void);

void STA381BWX_OutputConfiguration(unsigned char

FFX_Configuration);

void STA381BWX_SetMasterVolume(unsigned char MasterVolume);

void STA381BWX_SetMasterMute(unsigned char Mute);

void STA381BWX_SetLeftVolume(unsigned char LeftVolume);

Doc ID 022081 Rev 3 51/65

Page 52

Examples of code (TV SoC) AN3959

void STA381BWX_SetRightVolume(unsigned char RightVolume);

void STA381BWX_SetSubWooferVolume(unsigned char SubWooferVolume);

void STA381BWX_CrossOver(unsigned char FFX_CrossOverValue);

void STA381BWX_Poweronoff(unsigned char FFX_Powerflag);

void STA381BWX_Powerdownonoff(unsigned char FFX_Powerflag);

void STA381BWX_DSPBypass(unsigned char DSPBypassFlag);

void STA381BWX_DeEmphasis(unsigned char DeEmphasisFlag);

void STA381BWX_FilterLink(unsigned char FilterlinkFlag);

void STA381BWX_PostscaleLink(unsigned char PostscalelinkFlag);

void STA381BWX_Bass(unsigned char basssetting);

void STA381BWX_Treble(unsigned char treblesetting);

void STA381BWX_CoefficientWrite(unsigned char FilterIndex);

void STA381BWX_CoefficientRead(unsigned char FilterIndex);

#endif

52/65 Doc ID 022081 Rev 3

Page 53

AN3959 Examples of code (TV SoC)

8.2 FFX381X_Sample.C

#include "FFX38X_Sample.h"

/* This is the reference source code of STA381BWX series FFX

amplifier

function reference:

I2Cm_Tx(&valueReg,RegAddress,1,DeviceAddress);//write the data to

I2C register,DeviceAddress=FFX_I2C_ADDR

I2Cm_Rx(&valueReg,RegAddress,1,DeviceAddress);//Read the data

from I2C register,DeviceAddress=FFX_I2C_ADDR

*/

unsigned char oldMasterVolume;

unsigned char oldLeftVolume;

unsigned char oldRightVolume;

unsigned char oldSubWooferVolume;

unsigned char oldMute;

unsigned char MUTEVolSave;

unsigned char I2C_buf1;

/******************************************************************

Global Function Declarations.

*******************************************************************

/

unsigned char

STA381BWX_EQ[]={0x00,0x00,0x00,0x00,0x00,0x00,0x00,0x00,0x00,0x00,0

x00,0x00,0x40,0x00,0x00};

/*

Intial the EQ curve for coefficient data Write

Read Filter data to STA381_EQ[],Filter address FilterIndex=0~4

*/

void STA381BWX_CoefficientRead(unsigned char FilterIndex){

unsigned char STA381BWX_tempj;

//clear 0x17~0x25 IIC register

for(STA381BWX_tempj=0;STA381BWX_tempj<15;STA381BWX_tempj++){

I2C_buf1=0x00;

I2Cm_Tx(&I2C_buf1,(0x17+STA381BWX_tempj),1,FFX_I2C_ADDR);

}

//Set coefficient data address

Doc ID 022081 Rev 3 53/65

Page 54

Examples of code (TV SoC) AN3959

I2C_buf1=FilterIndex*5;

I2Cm_Tx(&I2C_buf1,0x16,1,FFX_I2C_ADDR);

//Write the command to 0x26(3 times)

I2C_buf1=0x08;

I2Cm_Tx(&I2C_buf1,0x26,1,FFX_I2C_ADDR);

I2Cm_Tx(&I2C_buf1,0x26,1,FFX_I2C_ADDR);

I2Cm_Tx(&I2C_buf1,0x26,1,FFX_I2C_ADDR);

Wait(10);//10-20ms delay

//read bank data from 0x17~0x25

for(STA381BWX_tempj=0;STA381BWX_tempj<15;STA381BWX_tempj++){

I2Cm_Rx(&I2C_buf1,(0x17+STA381BWX_tempj),1,FFX_I2C_ADDR);

STA381BWX_EQ[STA381BWX_tempj]=I2C_buf1;

}

}

/*

Intial the EQ curve for coefficient data Write

write Filter data from STA381_EQ[],Filter address FilterIndex=0~4

*/

void STA381BWX_CoefficientWrite(unsigned char FilterIndex)

{

unsigned char STA381BWX_tempj;

//clear 0x17~0x25 IIC register

for(STA381BWX_tempj=0;STA381BWX_tempj<15;STA381BWX_tempj++){

I2C_buf1=0x00;

I2Cm_Tx(&I2C_buf1,(0x17+STA381BWX_tempj),1,FFX_I2C_ADDR);

}

//Set coefficient data address

I2C_buf1=FilterIndex*5;

I2Cm_Tx(&I2C_buf1,0x16,1,FFX_I2C_ADDR);

//write bank data to 0x17~0x25

for(STA381BWX_tempj=0;STA381BWX_tempj<15;STA381BWX_tempj++){

I2C_buf1=STA381BWX_EQ[STA381BWX_tempj];

I2Cm_Tx(&I2C_buf1,(0x17+STA381BWX_tempj),1,FFX_I2C_ADDR);

}

54/65 Doc ID 022081 Rev 3

Page 55

AN3959 Examples of code (TV SoC)

//Write the command to 0x26(3 times)

I2C_buf1=0x02;

I2Cm_Tx(&I2C_buf1,0x26,1,FFX_I2C_ADDR);

}

/*

initial the system output configuration as below

FFX_Configuration=0; 2.0 2*BTL setting with HP

FFX_Configuration=1; 2.1 2*SE+1*BTL setting

FFX_Configuration=2; 2.1 2*BTL+1*PWMoutput(driver Power stage)

setting

FFX_Configuration=3; .1 mono BTL setting

*/

void STA381BWX_OutputConfiguration(unsigned char

FFX_Configuration){

I2Cm_Rx(&I2C_buf1,FFX_CONFIGURE_F,1,FFX_I2C_ADDR);

I2C_buf1&=0xFC;

I2C_buf1+=FFX_Configuration;

I2Cm_Tx(&I2C_buf1,FFX_CONFIGURE_F,1,FFX_I2C_ADDR);

}

/*

Set the FFX power stage open or close as below

FFX_Powerflag=0;close output power

FFX_Powerflag=1;open output power

*/

void STA381BWX_Poweronoff(unsigned char FFX_Powerflag){

I2Cm_Rx(&I2C_buf1,FFX_CONFIGURE_F,1,FFX_I2C_ADDR);

I2C_buf1&=0x7F;

I2C_buf1+=((FFX_Powerflag)<<7);

I2Cm_Tx(&I2C_buf1,FFX_CONFIGURE_F,1,FFX_I2C_ADDR);

}

/*

Set the FFX power down or not

FFX_Powerflag=0;system standby

FFX_Powerflag=1;system running

Doc ID 022081 Rev 3 55/65

Page 56

Examples of code (TV SoC) AN3959

*/

void STA381BWX_Powerdownonoff(unsigned char FFX_Powerflag){

I2Cm_Rx(&I2C_buf1,FFX_CONFIGURE_F,1,FFX_I2C_ADDR);

I2C_buf1&=0xBF;

I2C_buf1+=((FFX_Powerflag)<<6);

I2Cm_Tx(&I2C_buf1,FFX_CONFIGURE_F,1,FFX_I2C_ADDR);

}

/*

Set Crossover

FFX_CrossOver value have define as constant value

*/

void STA381BWX_CrossOver(unsigned char FFX_CrossOverValue){

I2Cm_Rx(&I2C_buf1,FFX_AUTO2,1,FFX_I2C_ADDR);

I2C_buf1&=0x0F;

I2C_buf1+=(FFX_CrossOverValue<<4);

I2Cm_Tx(&I2C_buf1,FFX_AUTO2,1,FFX_I2C_ADDR);

}

/* the volume system consist of main volume and channel volume, the

main volume is responsible for the overall system control, it's

range from -127.5dB to 0dB, every step as 0.5dB,

Mastervolume=|dbrequest*2|;

0=0dB 0*2

255=-127.5dB 127.5*2

*/

void STA381BWX_SetMasterVolume(unsigned char MasterVolume)

{

I2C_buf1=MasterVolume;

I2Cm_Tx(&I2C_buf1,FFX_MAIN_VOLUME,1,FFX_I2C_ADDR);

return;

}

void STA381BWX_SetMasterMute(unsigned char Mute)

{

unsigned char Tempdata1,Tempdata2,Tempdata3,Tempdata;

if(Mute==0)

{

56/65 Doc ID 022081 Rev 3

Page 57

AN3959 Examples of code (TV SoC)

I2Cm_Rx(&I2C_buf1,FFX_MAIN_VOLUME,1,FFX_I2C_ADDR);

MUTEVolSave = I2C_buf1; // Save the current Gain

I2C_buf1=0xFE;

I2Cm_Tx(&I2C_buf1,FFX_MAIN_VOLUME,1,FFX_I2C_ADDR);

Wait(10);//10-20ms delay

}

else

{

I2Cm_Tx(&MUTEVolSave,FFX_MAIN_VOLUME,1,FFX_I2C_ADDR);

Wait(10);//10-20ms delay

}

return;

}

/*the channel volume is responsible for the each channel volume

control, it's range from -79.5dB to 48dB, every step as 0.5dB,

channelvolume=255-((dbrequest+79.5)*2);

0=48dB (255-(48+79.5)*2)

255=-79.5dB (255-(-79.5+79.5)*2)

0x60=0dB (255-(0+79.5)*2)

*/

void STA381BWX_SetLeftVolume(unsigned char LeftVolume)

{

I2C_buf1 =LeftVolume;

I2Cm_Tx(&I2C_buf1,FFX_CHANNEL1_VOL,1,FFX_I2C_ADDR);

return;

}

void STA381BWX_SetRightVolume(unsigned char RightVolume)

{

I2C_buf1 =RightVolume;

I2Cm_Tx(&I2C_buf1,FFX_CHANNEL2_VOL,1,FFX_I2C_ADDR);

return;

}

void STA381BWX_SetSubWooferVolume(unsigned char SubWooferVolume)

{

I2C_buf1 =SubWooferVolume;

I2Cm_Tx(&I2C_buf1,FFX_CHANNEL3_VOL,1,FFX_I2C_ADDR);

Doc ID 022081 Rev 3 57/65

Page 58

Examples of code (TV SoC) AN3959

return;

}

/*

Set the FFX DSP bypass or not

DSPBypassFlag=0;DSP not bypass

DSPBypassFlag=1;DSP bypass

*/

void STA381BWX_DSPBypass(unsigned char DSPBypassFlag)

{

I2Cm_Rx(&I2C_buf1,FFX_CONFIGURE_D,1,FFX_I2C_ADDR);

I2C_buf1&=0xFB;

I2C_buf1+=(DSPBypassFlag<<2);

I2Cm_Tx(&I2C_buf1,FFX_CONFIGURE_D,1,FFX_I2C_ADDR);

}

/*

Set the FFX DeEmphasis or not

DeEmphasisFlag=0; DeEmphasis disable

DeEmphasisFlag=1; DeEmphasis enable

*/

void STA381BWX_DeEmphasis(unsigned char DeEmphasisFlag)

{

I2Cm_Rx(&I2C_buf1,FFX_CONFIGURE_D,1,FFX_I2C_ADDR);

I2C_buf1&=0xFD;

I2C_buf1+=(DeEmphasisFlag<<1);

I2Cm_Tx(&I2C_buf1,FFX_CONFIGURE_D,1,FFX_I2C_ADDR);

}

/*

Set the FFX Filter Linker or not

FilterlinkFlag=0;each channel use the own filter

FilterlinkFlag=1;each channel's filter setting same as channel1's

*/

void STA381BWX_FilterLink(unsigned char FilterlinkFlag)

{

I2Cm_Rx(&I2C_buf1,FFX_CONFIGURE_D,1,FFX_I2C_ADDR);

I2C_buf1&=0xEF;

58/65 Doc ID 022081 Rev 3

Page 59

AN3959 Examples of code (TV SoC)

I2C_buf1+=(FilterlinkFlag<<4);

I2Cm_Tx(&I2C_buf1,FFX_CONFIGURE_D,1,FFX_I2C_ADDR);

}

/*

Set the FFX PostScale Link or not

PostscalelinkFlag=0;each channel use the own filter

PostscalelinkFlag=1;each channel's filter setting same as

channel1's

*/

void STA381BWX_PostscaleLink(unsigned char PostscalelinkFlag)

{

I2Cm_Rx(&I2C_buf1,FFX_CONFIGURE_D,1,FFX_I2C_ADDR);

I2C_buf1&=0xF7;

I2C_buf1+=(PostscalelinkFlag<<3);

I2Cm_Tx(&I2C_buf1,FFX_CONFIGURE_D,1,FFX_I2C_ADDR);

}

void STA381BWX_Bass(unsigned char basssetting)

{

basssetting=basssetting+1;

I2Cm_Rx(&I2C_buf1,FFX_TONEBASS,1,FFX_I2C_ADDR);

I2C_buf1&=0xF0;

I2C_buf1+=basssetting;

I2Cm_Tx(&I2C_buf1,FFX_TONEBASS,1,FFX_I2C_ADDR);

}

/*

Set the FFX Treble value, 2dB every step

treblesetting=0=-12dV

treblesetting=12=+12dB

*/

void STA381BWX_Treble(unsigned char treblesetting)

{

treblesetting=treblesetting+1;

I2Cm_Rx(&I2C_buf1,FFX_TONEBASS,1,FFX_I2C_ADDR);

I2C_buf1&=0x0F;

Doc ID 022081 Rev 3 59/65

Page 60

Examples of code (TV SoC) AN3959

I2C_buf1+=(treblesetting<<4);

I2Cm_Tx(&I2C_buf1,FFX_TONEBASS,1,FFX_I2C_ADDR);

}

/* Write coefficient into the FFX controller using the IIC driver */

void STA381BWX_init(void)

{

unsigned char I2C_buf1;

I2C_buf1=STA381BWX_STMAP;

I2Cm_Tx(&I2C_buf1,STA381BWX_MAPSEL,1,FFX_I2C_ADDR);

/* the master clock select, 256fs, fault detect enable */

I2C_buf1=0x63;

I2Cm_Tx(&I2C_buf1,FFX_CONFIGURE_A,1,FFX_I2C_ADDR);

/* the serial input format select, I2s format, MSB first*/

I2C_buf1=0x80;

I2Cm_Tx(&I2C_buf1,FFX_CONFIGURE_B,1,FFX_I2C_ADDR);

/* Use default output mode*/

I2C_buf1=0x9F;//=0x97; When STA381BWS application

I2Cm_Tx(&I2C_buf1,FFX_CONFIGURE_C,1,FFX_I2C_ADDR);

/* High pass enbale, No De-emphasis, No DSP by pass, Anti-Clipping

Mode,coefficient Link,PostScale link*/

// STA381BWX_DSPBypass(0);

// STA381BWX_DeEmphasis(0);

// STA381BWX_FilterLink(1);

// STA381BWX_PostscaleLink(1);

/* Use standard MPC, AM mode disable, normal output speed*/

// I2C_buf1=0xc2;

// I2Cm_Tx(&I2C_buf1,FFX_CONFIGURE_E,1,FFX_I2C_ADDR);

60/65 Doc ID 022081 Rev 3

Page 61

AN3959 Examples of code (TV SoC)

/* Switching frequency determined by AMAM setting and set the

crossover as 260Hz*/

// STA381BWX_CrossOver(STA381BWX_Cross_260Hz);

/* flat mode EQ*/

// I2C_buf1=0x00;

// I2C_sendbuf(1,&I2C_buf1,FFX_I2C_WRITE_ADD,FFX_AUTO3);

/* channel1 no limit, tone and treble control enable*/

// I2C_buf1=0x00;

// I2Cm_Tx(&I2C_buf1,FFX_CHANNEL1_CFG,1,FFX_I2C_ADDR);

/* channel2 no limit, tone and treble control enable*/

// I2C_buf1=0x40;

// I2Cm_Tx(&I2C_buf1,FFX_CHANNEL2_CFG,1,FFX_I2C_ADDR);

/* channel3 no limit, tone and treble control enable*/

// I2C_buf1=0x80;

// I2Cm_Tx(&I2C_buf1,FFX_CHANNEL3_CFG,1,FFX_I2C_ADDR);

/* tone and treble are 0 dB*/

// STA381BWX_Treble(6);

// STA381BWX_Bass(6);

/* Limiter1 attack and rease rate*/

// I2C_buf1=0x6a;

// I2Cm_Tx(&I2C_buf1,FFX_L1AR_RATE,1,FFX_I2C_ADDR);

/* Limiter1 attack=+3dB and rease threshold=-3dB*/

// I2C_buf1=0x8c;

// I2Cm_Tx(&I2C_buf1,FFX_L1AR_THRESHOLD,1,FFX_I2C_ADDR);

/* Limiter2 attack and rease rate*/

// I2C_buf1=0x6a;

// I2Cm_Tx(&I2C_buf1,FFX_L2AR_RATE,1,FFX_I2C_ADDR);

Doc ID 022081 Rev 3 61/65

Page 62

Examples of code (TV SoC) AN3959

/* Limiter2 attack=+4dB and rease threshold=-2dB*/

// I2C_buf1=0x9d;

// I2Cm_Tx(&I2C_buf1,FFX_L2AR_THRESHOLD,1,FFX_I2C_ADDR);

STA381BWX_OutputConfiguration(STA381BWX_2_0_HP_Config);

STA381BWX_Poweronoff(1);

STA381BWX_SetMasterVolume(0);

STA381BWX_SetLeftVolume(0x60);

STA381BWX_SetRightVolume(0x60);

// STA381BWX_SetSubWooferVolume(0x60);

return;

}

62/65 Doc ID 022081 Rev 3

Page 63

Appendix A Mono BTL schematic

Figure 54. Mono BTL schematic

+3V3

R3

0 ohm

R1

0 ohm

C11

100nF

626364

RESET

NS

NS

100nF

R4

R2

C2

SCL

5758596061

AN3959 Mono BTL schematic

+3V3

R5

10K

C4

1nF

SDI1

SDA

INT_LINE

PWRDN

495051

5253545556

OUT+

OUT-

SWPA6045S220MT

20(S)

330P(S)

SWPA6045S220MT

L3

C32

C37

100nF

100nF

R42

C44

L1

R10

6R2

6R2

R11

100nF

100nF

C36

C38

C47

1N(S)

C46

470nF

C50

1N(S)

1

2

J9

Doc ID 022081 Rev 3 63/65

41

46

43

44

45

47

2

47R

2

47R

1

2

3

4

5

6

7

8

9

10

11

12

C1

100nF

*

10uF/10V

C51

10uF/10V

C52

48

VDDDIG2

VCC_REG

VSS_REG

OUT2B

GND2

VCC2

OUT2A

OUT1B

VCC1

GND1

OUT1A

VDD_REG

GND_REG

HALFVDD

13

14

1718192021

C56

100nF

1

3

1

3

GNDDIG2

F3XL15F3XR16HPIN_L

1uF/10V

TESTMODE

SA

SCL

SDA

IC1

STA381BWS

IC3

STA381BWS_NEW

HPIN_R18LINEHPOUT_L

17

2223242526

C53

R8

27K

2

SW2

2

SW3

OUT-

+VS

NS

NS

NS

C428

470U/35V

+

C34

C33NSC14

C35

J19

HPJCKX3.5-06

Line in

1

2

3

J2

HPJCKX3.5-06

1

2

3

J7

HEADER2X2

2

1

34

Line out

100nF

1uF/50V

C429

C426A

NOTE:

C56

100nF

C6

NS

100nF

C427A

C30

1uF/10V

C31

1uF/10V

C7

3.3nF/10V

100nF

1uF/50V

C427B

C426B

OUT+

CONFIGURATION

2.0CH & 2.1CH

MONO BT L

J15

1

2

J16

R6

11K

R7

11K

47K

47K

3.3nF/10V

R39

R40

F3XR

F3XL

1

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

2

1

J14

R35

1K

C54

100nF

R46

470R

R37

1

J18

R44

1K

C55

100nF

R45

470R

R38

42

INTLINE

LINEHPOUT_R20GNDA21SOFTMUTE

19

R9

27K

40

SDI

PWDN

RESET

VDD3V323CPVSS

22

2728293031

37

38

39

BICKI

LRCKI

36

MCLK

35

AGNDPLL

34

VREGFILT

33

FFX4B

32

FFX4A

31

FFX3B

30

FFX3A

29

GNDDIG1

28

VDDDIG1

27

VDD3V3CHP

26

CPP

25

GNDPSUB

CPM

24

32

SOFTMUTE

C9

1uF/10V

R36

0ohm

C29

100nF

C10

1uF/10V

STA381BWS

48

47

46

45

C3

2u2/10V

44

43

42

41

40

39

38

37

36

35

34

33

LRCKI