Page 1

1 Introduction

For designers of STM32 microcontroller applications, it is important to be able to easily

replace one microcontroller type by another one in the same product family. Migrating an

application to a different microcontroller is often needed, when product requirements grow,

putting extra demands on memory size, or increasing the number of I/Os. On the other

hand, cost reduction objectives may force you to switch to smaller components and shrink

the PCB area.

This application note is written to help you and analyze the steps you need to migrate from

an existing STM32F1 devices based design to STM32F2 devices. It groups together all the

most important information and lists the vital aspects that you need to address.

To migrate your application from STM32 F1 series to F2 series, you have to analyze the

hardware migration, the peripheral migration and the firmware migration.

AN3427

Application note

Migrating a microcontroller application

from STM32F1 to STM32F2 series

To benefit fully from the information in this application note, the user should be familiar with

the STM32 microcontroller family. Available from www.st.com.

● The STM32F1 family reference manuals (RM0008 and RM0041), the STM32F1

datasheets, and the STM32F1 Flash programming manuals (PM0075, PM0063 and

PM0068).

● The STM32F2 family reference manual (RM0033), the STM32F2 datasheets, and the

STM32F2 Flash programming manual (PM0059).

For an overview of the whole STM32 series and a comparision of the different features of

each STM32 product series, please refer to AN3364 'Migration and compatibility guidelines

for STM32 microcontroller applications'

July 2011 Doc ID 019001 Rev 1 1/52

www.st.com

Page 2

Contents AN3427

Contents

1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2 Hardware migration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3 Peripheral migration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.1 STM32 product cross-compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.2 System architecture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.2.1 32-bit multi-AHB bus matrix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.2.2 Adaptive real-time memory accelerator (ART Accelerator™) . . . . . . . . 12

3.2.3 Dual SRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.3 Memory mapping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.4 RCC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.5 DMA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.5.1 Interrupts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

3.6 GPIO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

3.6.1 Alternate function mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

3.7 EXTI source selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

3.8 FLASH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

3.9 ADC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

3.10 PWR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

3.11 RTC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

3.12 Miscellaneous . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

3.12.1 Ethernet PHY interface selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

3.12.2 TIM2 internal trigger 1 (ITR1) remapping . . . . . . . . . . . . . . . . . . . . . . . 37

4 Firmware migration using the library . . . . . . . . . . . . . . . . . . . . . . . . . . 38

4.1 Migration steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

4.2 RCC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

4.3 FLASH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

4.4 GPIO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

4.4.1 Output mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

4.4.2 Input mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

4.4.3 Analog mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

2/52 Doc ID 019001 Rev 1

Page 3

AN3427 Contents

4.4.4 Alternate function mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

4.5 EXTI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

4.6 DMA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

4.7 ADC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

4.8 Backup data registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

4.9 Miscellaneous . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

4.9.1 Ethernet PHY interface selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

4.9.2 TIM2 internal trigger 1 (ITR1) remapping . . . . . . . . . . . . . . . . . . . . . . . 50

5 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Doc ID 019001 Rev 1 3/52

Page 4

List of tables AN3427

List of tables

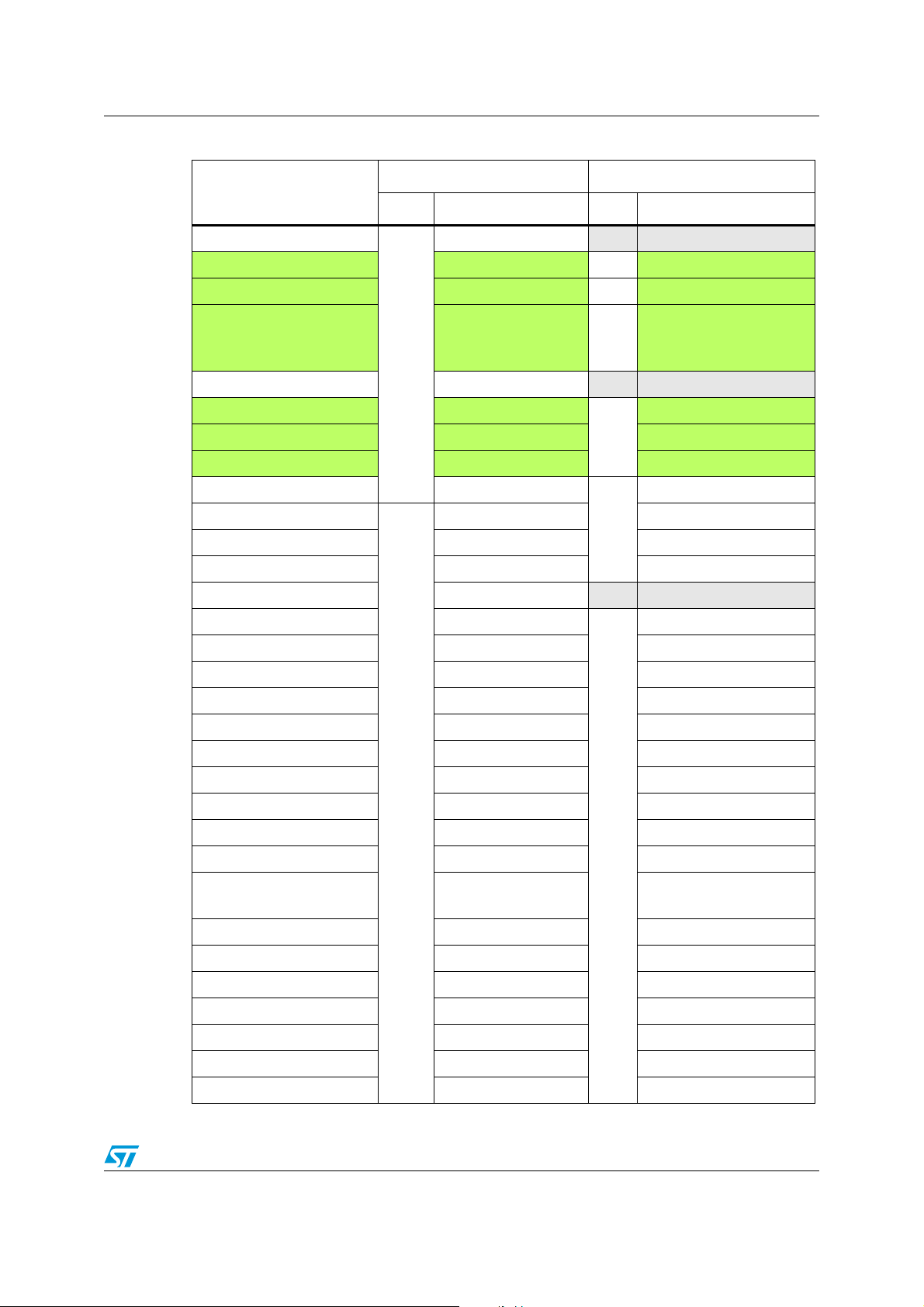

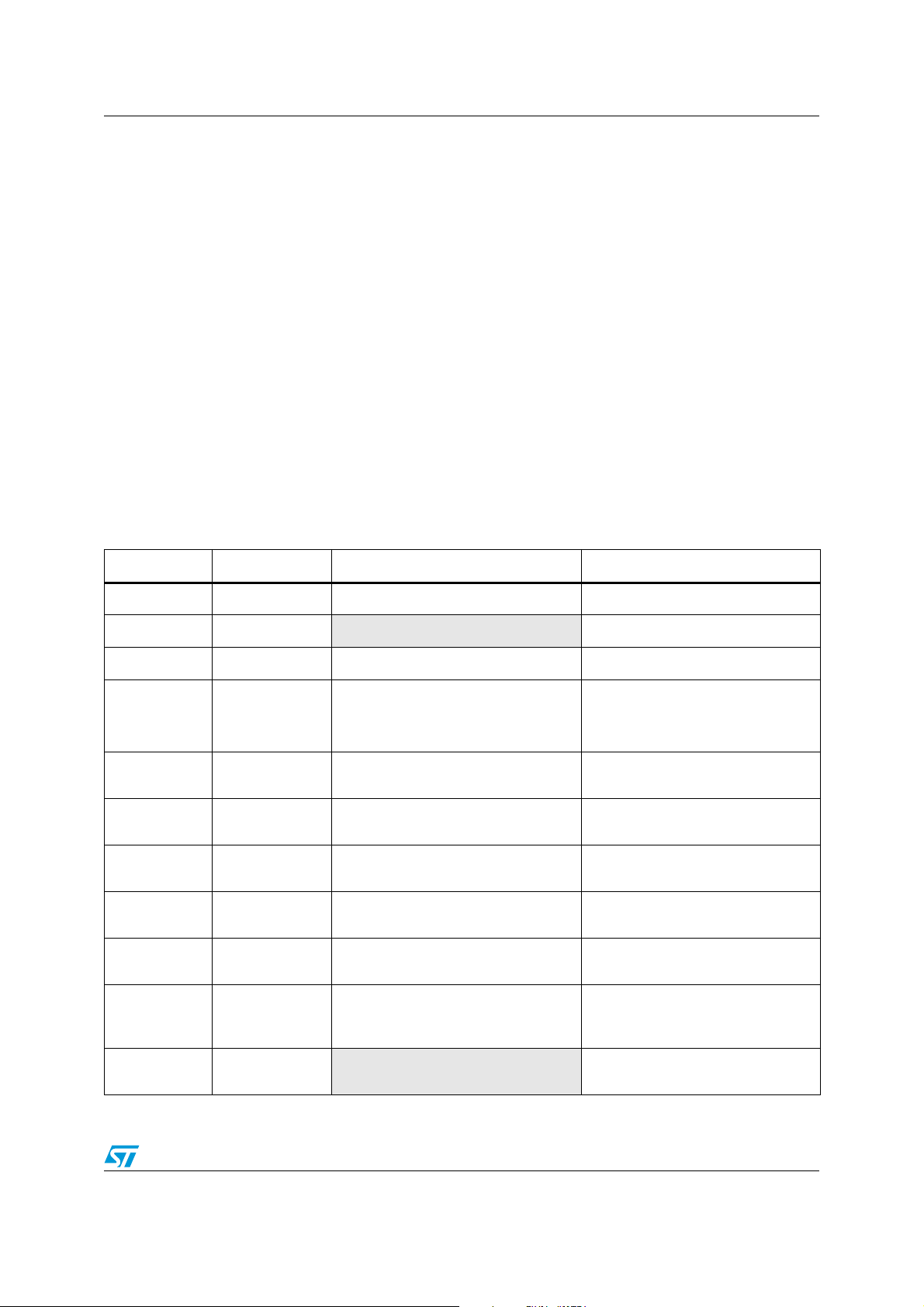

Table 1. STM32 F1 series and STM32 F2 series pinout differences . . . . . . . . . . . . . . . . . . . . . . . . . 6

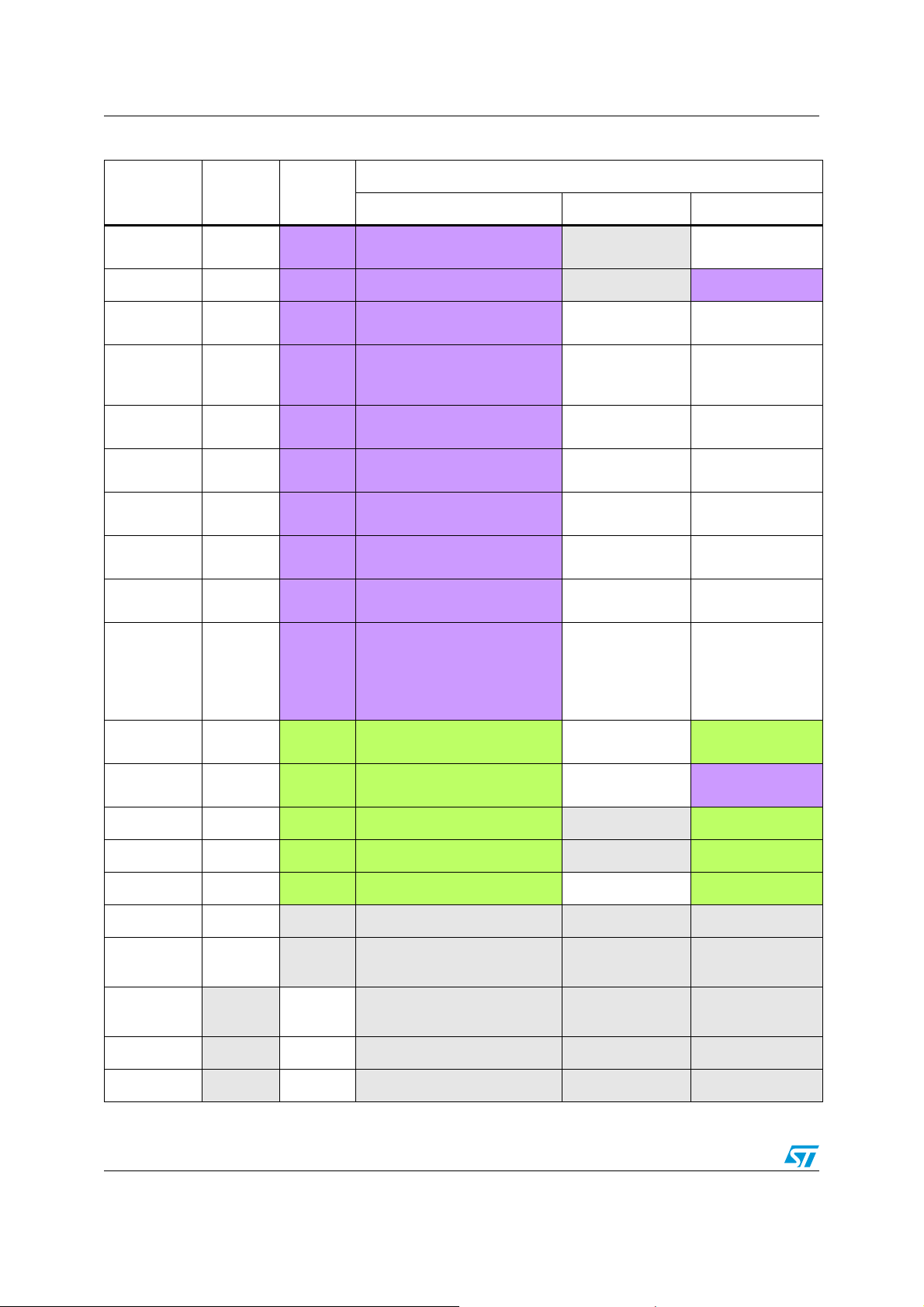

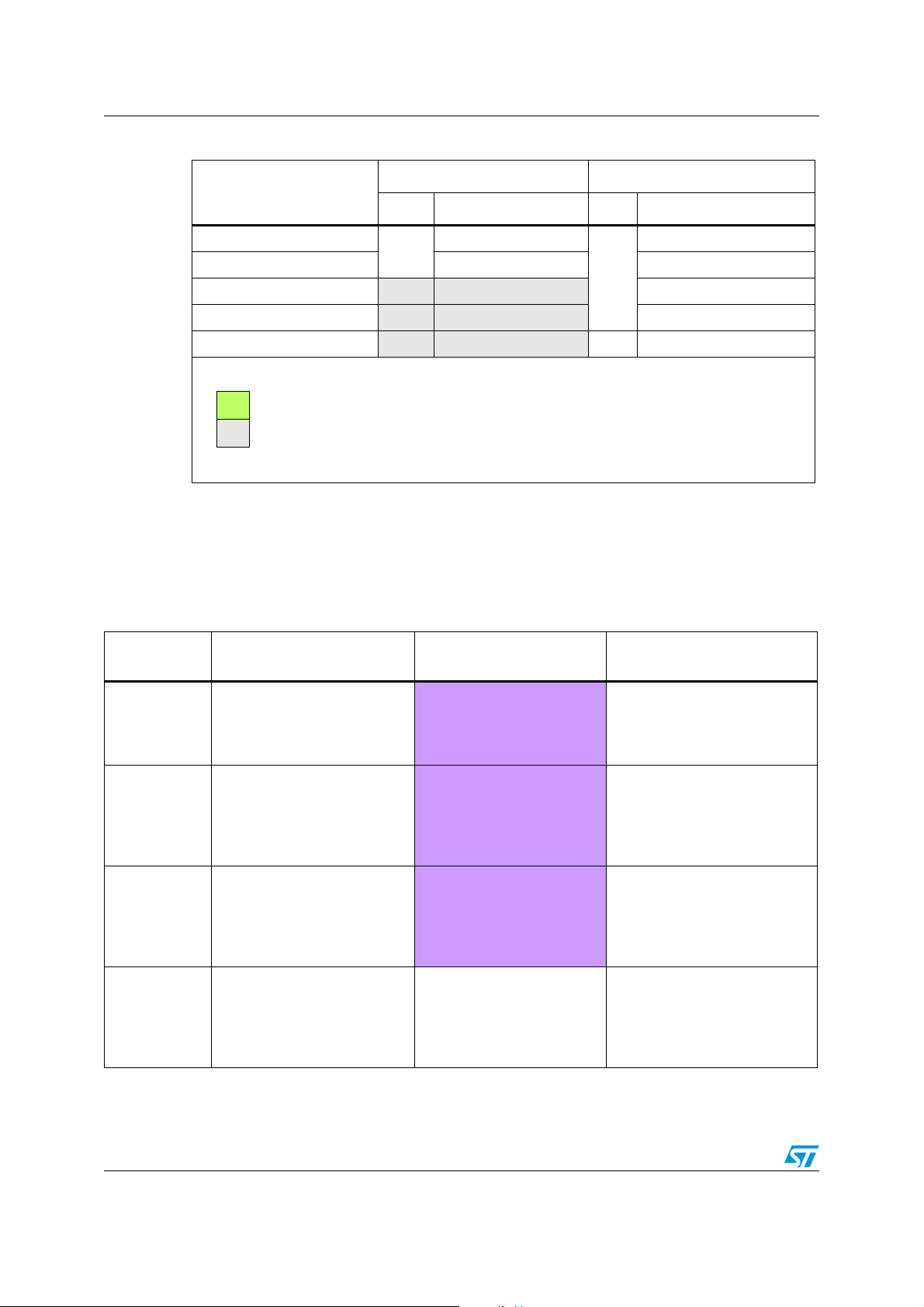

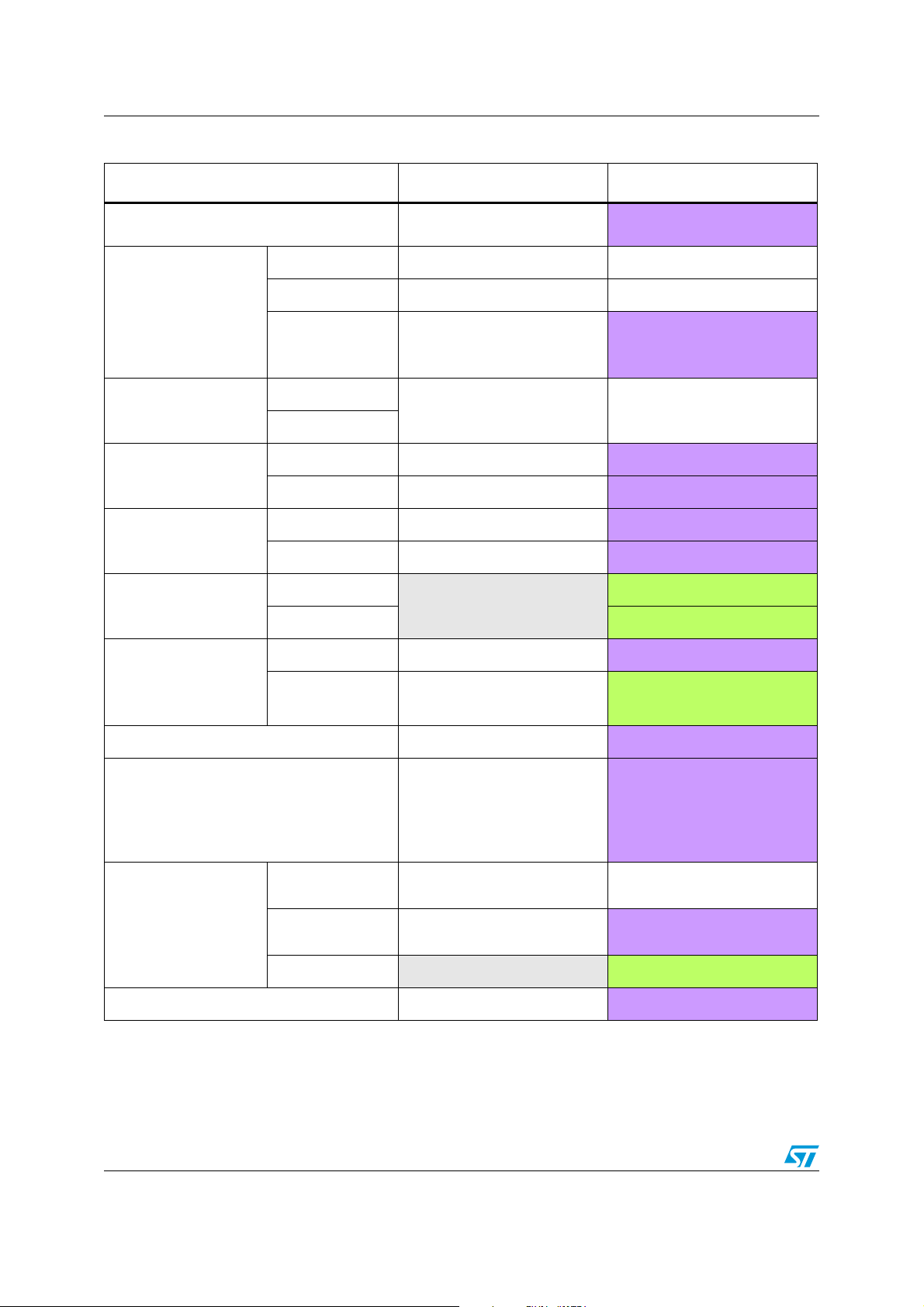

Table 2. STM32 peripheral compatibility analysis F1 versus F2 series . . . . . . . . . . . . . . . . . . . . . . . 9

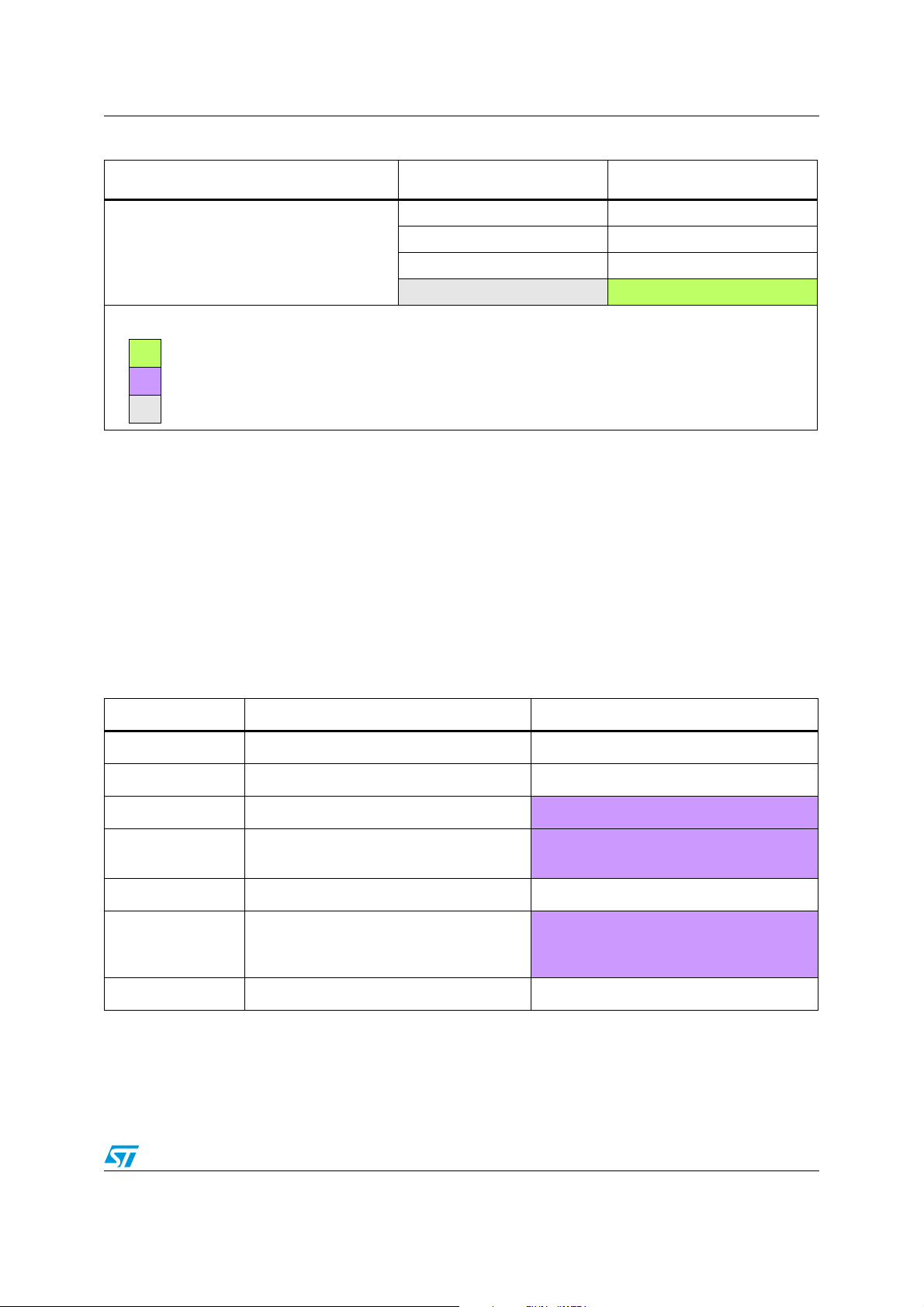

Table 3. IP bus mapping differences between STM32 F1 and STM32 F2 series. . . . . . . . . . . . . . . 13

Table 4. RCC differences between STM32 F1 and STM32 F2 series . . . . . . . . . . . . . . . . . . . . . . . 16

Table 5. Example of migrating system clock configuration code from F1 to F2 series . . . . . . . . . . . 20

Table 6. RCC registers used for peripheral access configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Table 7. DMA request differences between STM32 F1 series and STM32 F2 series . . . . . . . . . . . 23

Table 8. Interrupt vector differences between STM32 F1 series and STM32 F2 series . . . . . . . . . . 27

Table 9. GPIO differences between STM32 F1 series and STM32 F2 series . . . . . . . . . . . . . . . . . 30

Table 10. FLASH differences between STM32 F1 series and STM32 F2 series . . . . . . . . . . . . . . . . 32

Table 11. ADC differences between STM32 F1 series and STM32 F2 series . . . . . . . . . . . . . . . . . . 33

Table 12. PWR differences between STM32 F1 series and STM32 F2 series. . . . . . . . . . . . . . . . . . 35

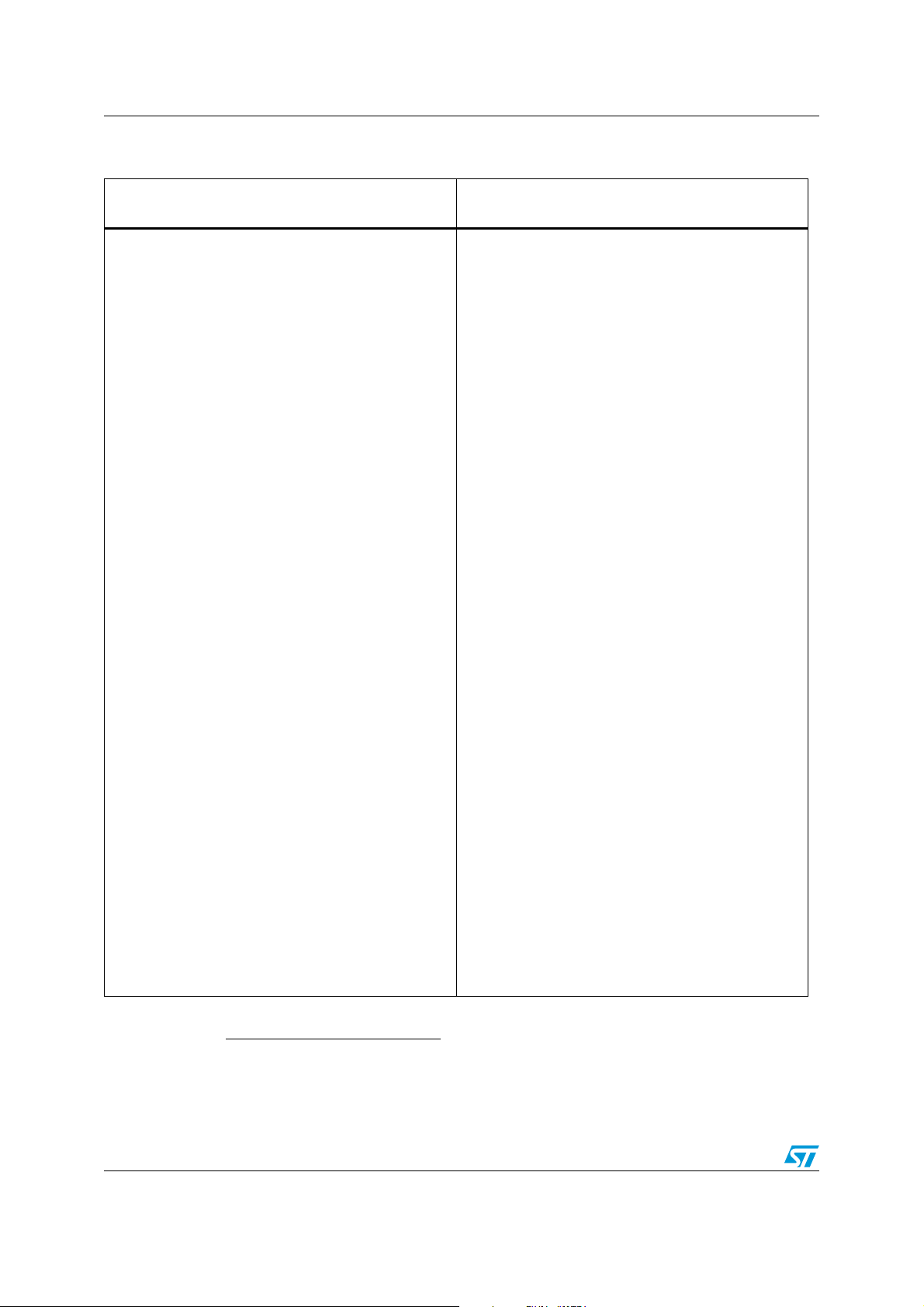

Table 13. STM32F10x and STM32F2xx FLASH driver API correspondence . . . . . . . . . . . . . . . . . . . 41

Table 14. Document revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

4/52 Doc ID 019001 Rev 1

Page 5

AN3427 List of figures

List of figures

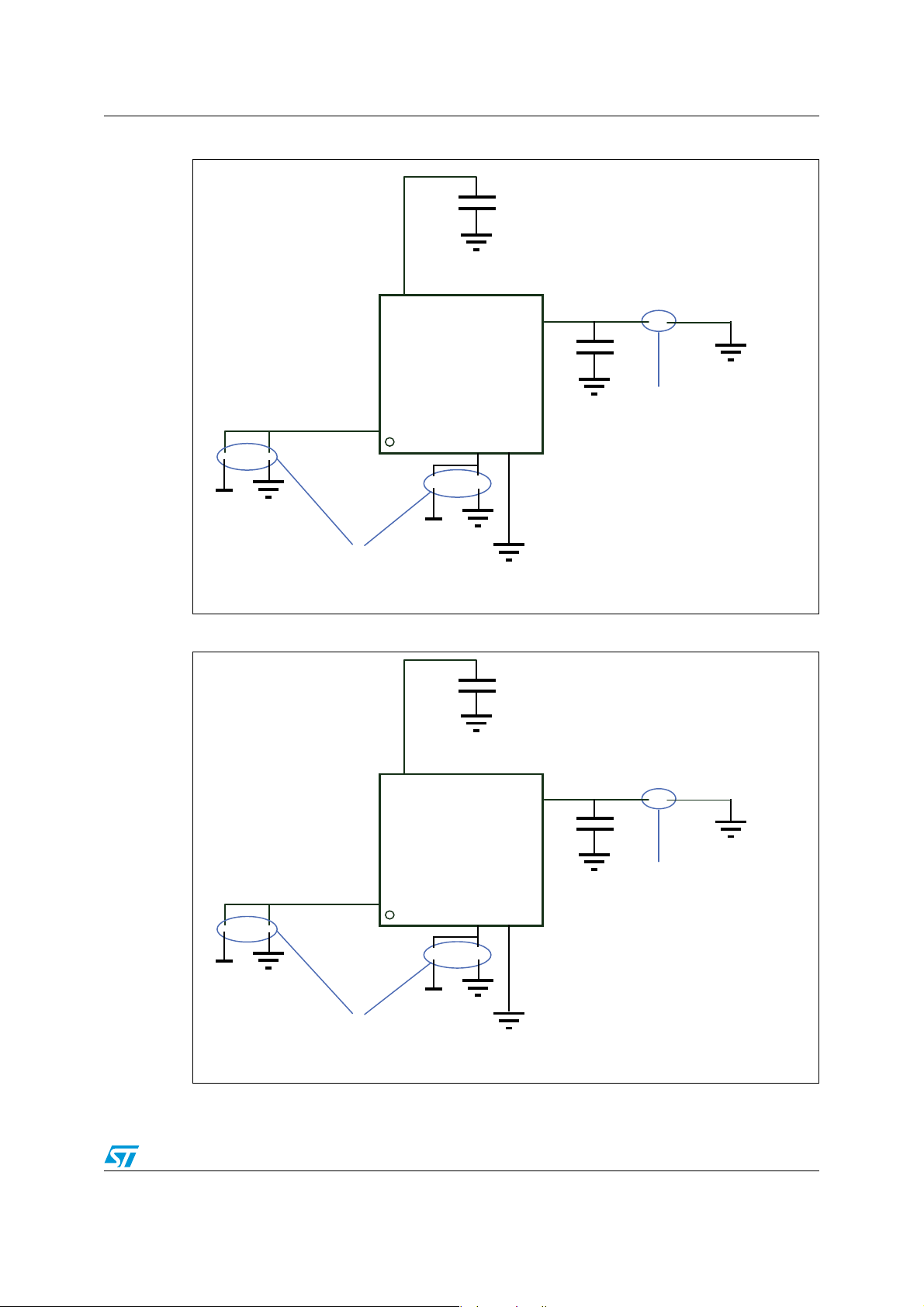

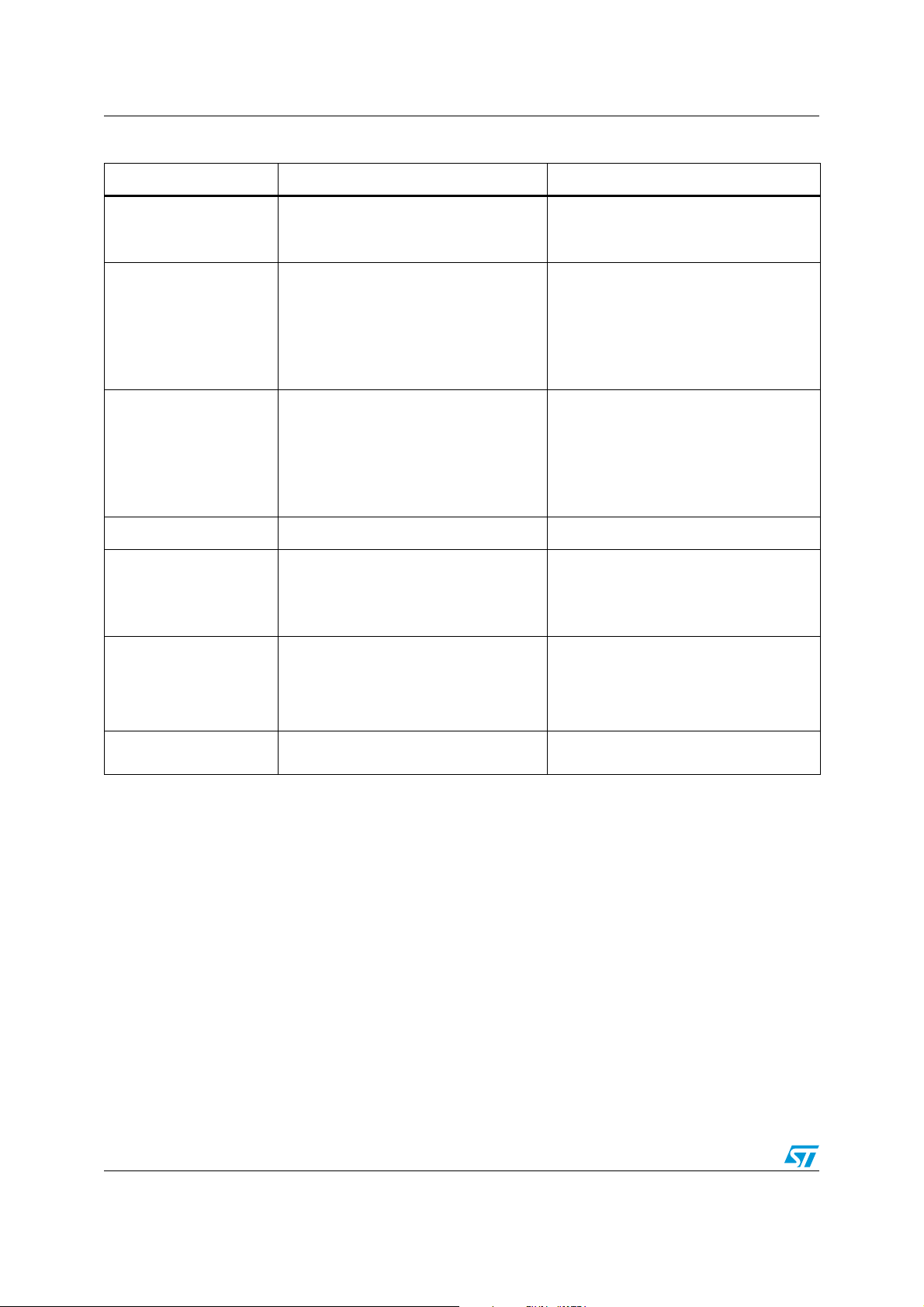

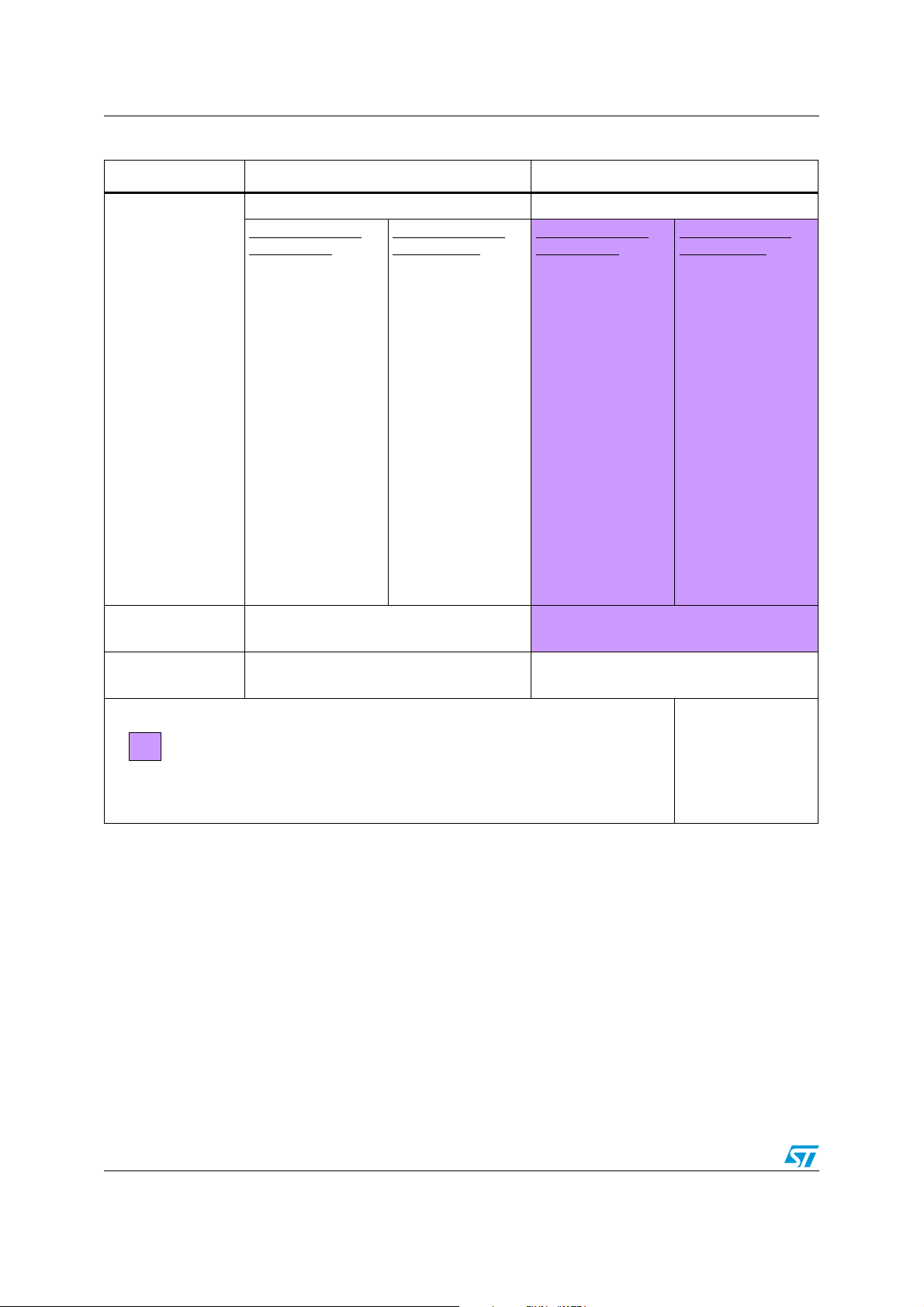

Figure 1. Compatible board design: LQFP144 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Figure 2. Compatible board design: LQFP100 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

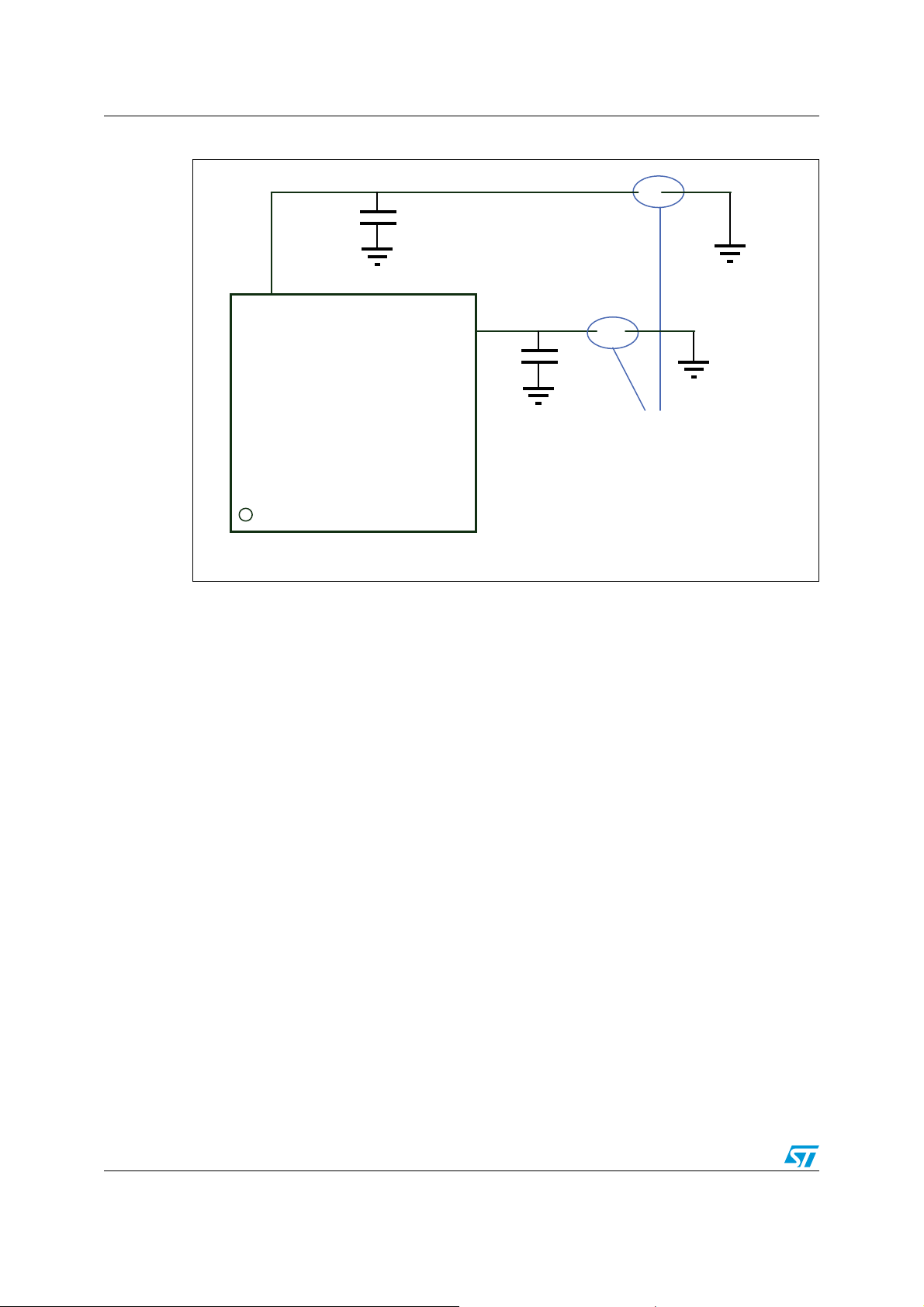

Figure 3. Compatible board design: LQFP64 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Figure 4. STM32 F2 series system architecture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Doc ID 019001 Rev 1 5/52

Page 6

Hardware migration AN3427

2 Hardware migration

All peripherals shares the same pins in the two families, but there are some minor

differences between packages.

In fact, the STM32 F2 series maintains a close compatibility with the whole STM32 F1

series. All functional pins are pin-to-pin compatible. The STM32 F2 series, however, are not

drop-in replacements for the STM32 F1 series: the two families do not have the same power

scheme, and so their power pins are different. Nonetheless, transition from the STM32 F1

series to the STM32 F2 series remains simple as only a few pins are impacted (impacted

pins are in bold in the table below).

Table 1. STM32 F1 series and STM32 F2 series pinout differences

QFP64 QFP100 QFP144 Pinout QFP64 QFP100 QFP144 Pinout

51223PD0 - OSC_IN 5 12 23 PH0 - O SC_ IN

61324PD1 - OSC_OUT 6 13 24 PH1 - O S C _ O U T

12 19 30 VSSA 19 30 VDD

STM32 F1 series STM32 F2 series

20 31 VREF- 12 20 31 VSSA

31 49 71 VSS_1 31 49 71 VCAP1

73 106 NC 47 73 106 VCAP2

47 74 107 VSS_2 74 107 VSS2

63 99 143 VSS_3 63 VSS_3

The figures below show examples of board designs that are compatible with both the F1 and

the F2 series.

6/52 Doc ID 019001 Rev 1

Page 7

AN3427 Hardware migration

AIC

6

$$

6

33

6

33

RESISTORORSOLDERINGBRIDGE

PRESENTFORTHE34-&XXX

CONFIGURATIONNOTPRESENTINTHE

34-&XXXCONFIGURATION

4WO RESISTORSCONNECTEDTO

2&5

6$$633OR.#FORTHE34-&XX

6

$$

FORFUTUREPRODUCTS

PS7

33

Ȱ

Ȱ

6

33

6

33

6

33

6

$$

6

33

633FORTHE34-&X

AIB

6

$$

6

33

6

33

RESISTORORSOLDERINGBRIDGE

PRESENTFORTHE34-&XXX

CONFIGURATIONNOTPRESENTINTHE

34-&XXXCONFIGURATION

4WO RESISTORSCONNECTEDTO

2&5

6$$633OR.#FORTHE34-&XX

6

$$

FORFUTUREPRODUCTS

PS7

33

Ȱ

Ȱ

6

33

6

33

6

33

6

$$

6

33

Figure 1. Compatible board design: LQFP144

Figure 2. Compatible board design: LQFP100

Doc ID 019001 Rev 1 7/52

Page 8

Hardware migration AN3427

½RESISTORORSOLDERINGBRIDGE

AI

6

33

6

33

6

33

6

33

Ȱ

½

PRESENTFORTHE34-&XXX

CONFIGURATIONNOTPRESENTINTHE

34-&XXXCONFIGURATION

Figure 3. Compatible board design: LQFP64

8/52 Doc ID 019001 Rev 1

Page 9

AN3427 Peripheral migration

3 Peripheral migration

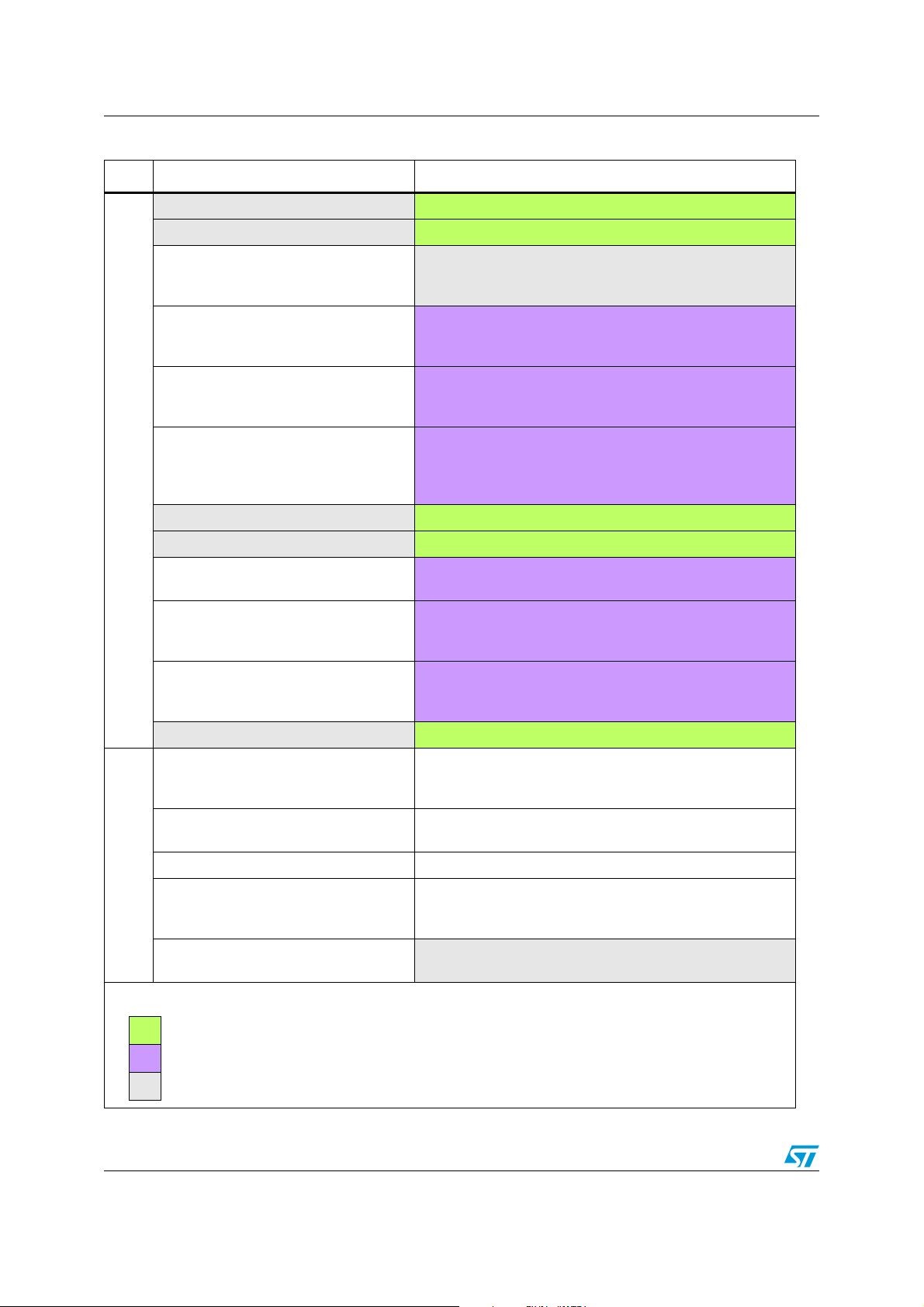

As shown in Table 2 on page 9, there are three categories of peripherals. The common

peripherals are supported with the dedicated firmware library without any modification,

except if the peripheral instance is no longer present, you can change the instance and of

course all the related features (clock configuration, pin configuration, interrupt/DMA

request).

The modified peripherals such as: FLASH, ADC, RCC, DMA, GPIO and RTC are different

from the F1 series ones and should be updated to take advantage of the enhancements and

the new features in F2 series.

All these modified peripherals in the F2 series are enhancements in performance and

features designed to meet new market requirements and to fix some limitations present in

the F1 series.

3.1 STM32 product cross-compatibility

The STM32 series embeds a set of peripherals which can be classed in three categories:

● The first category is for the peripherals which are by definition common to all products.

Those peripherals are identical, so they have the same structure, registers and control

bits. There is no need to perform any firmware change to keep the same functionality at

the application level after migration. All the features and behavior remain the same.

● The second category is for the peripherals which are shared by all products but have

only minor differences (in general to support new features), so migration from one

product to another is very easy and does not need any significant new development

effort.

● The third category is for peripherals which have been considerably changed from one

product to another (new architecture, new features...). For this category of peripherals,

migration will require new development at application level.

Ta bl e 2 below gives a general overview of this classification:

Table 2. STM32 peripheral compatibility analysis F1 versus F2 series

Peripheral F1 series F2 series

FSMC Yes Yes Same features Identical Full compatibility

WWDG

IWDG

DBGMCU

CRC

EXTI

CAN

Compatibility

Comments Pinout SW compatibility

Ye s Yes Same features NA Full compatibility

Ye s Yes Same features NA Full compatibility

Ye s Yes Same features NA Full compatibility

Ye s Yes Same features NA Full compatibility

Ye s Yes Same features Identical Full compatibility

Ye s Yes Same features Identical Full compatibility

Doc ID 019001 Rev 1 9/52

Page 10

Peripheral migration AN3427

Table 2. STM32 peripheral compatibility analysis F1 versus F2 series (continued)

Compatibility

Peripheral F1 series F2 series

Comments Pinout SW compatibility

PWR Ye s Ye s + Enhancement NA

RCC

SPI

USART Ye s Ye s +

I2C

TIM

DAC

Ethernet

SDIO Ye s Ye s + Limitation fix Identical

USB OTG FS Ye s Ye s +

RTC

ADC

Ye s Ye s + Enhancement NA Partial compatibility

Ye s Ye s + TI mode / Max baudrate Identical

Limitation fix / Max baudrate /

One Sample Bit / Oversampling

by 8

Ye s Ye s + Limitation fix Identical

Ye s Ye s +

Ye s Ye s + DMA underrun interrupt Identical

Ye s Ye s +

Ye s Yes++ New peripheral

Ye s Yes++ New peripheral

32-bit Counter in TIM2 and

TIM5

IEEE1588 v2 / Enhanced DMA

descriptor

- Dynamic trimming capability of

SOF framing period in Host

mode

- Embeds a VBUS sensing

control

Identical

Identical

Identical

Identical

Identical for the

same feature

Identical for the

same feature

Full compatibility for

the same feature

Full compatibility for

the same feature

Full compatibility for

the same feature

Full compatibility for

the same feature

Full compatibility for

the same feature

Full compatibility for

the same feature

Full compatibility for

the same feature

Full compatibility for

the same feature

Full compatibility for

the same feature

Not compatible

Partial compatibility

FLASH

DMA

GPIO

CEC

USB FS

Device

Crypto/hash

processor

RNG

DCMI

10/52 Doc ID 019001 Rev 1

Ye s Yes++ New peripheral NA Not compatible

Ye s Yes++ New peripheral NA Not compatible

Ye s Yes++ New peripheral Identical Not compatible

Ye s NA NA NA NA

Ye s NA NA NA NA

NA Ye s NA NA NA

NA Ye s NA NA NA

NA Ye s NA NA NA

Page 11

AN3427 Peripheral migration

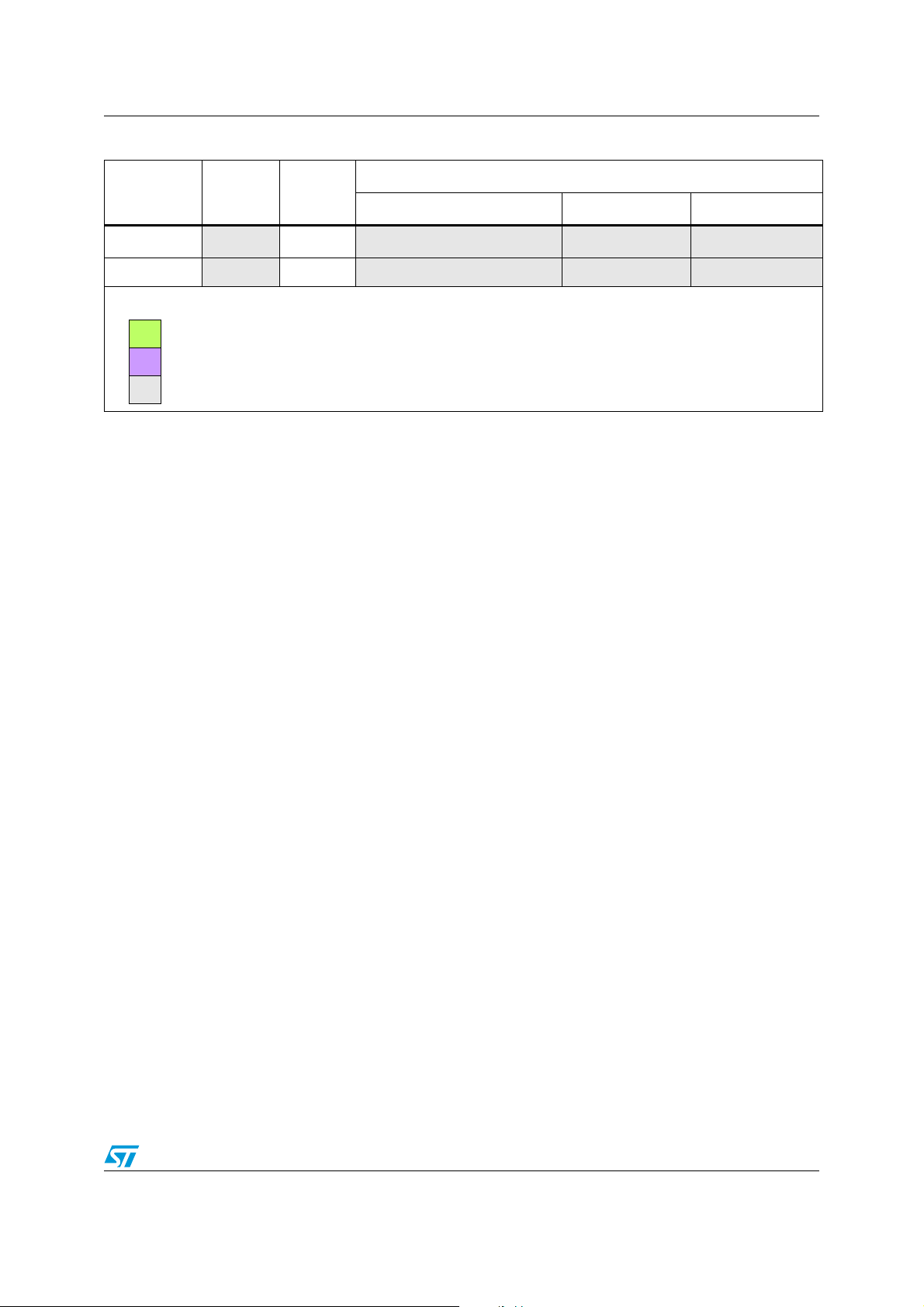

Color key:

= New feature or new architecture (Yes++)

= Same feature, but specification change or enhancement (Yes+)

= Feature not available (NA)

Table 2. STM32 peripheral compatibility analysis F1 versus F2 series (continued)

Compatibility

Peripheral F1 series F2 series

Comments Pinout SW compatibility

USB OTG HS NA Ye s NA NA NA

SYSCFG

NA Ye s NA NA NA

Doc ID 019001 Rev 1 11/52

Page 12

Peripheral migration AN3427

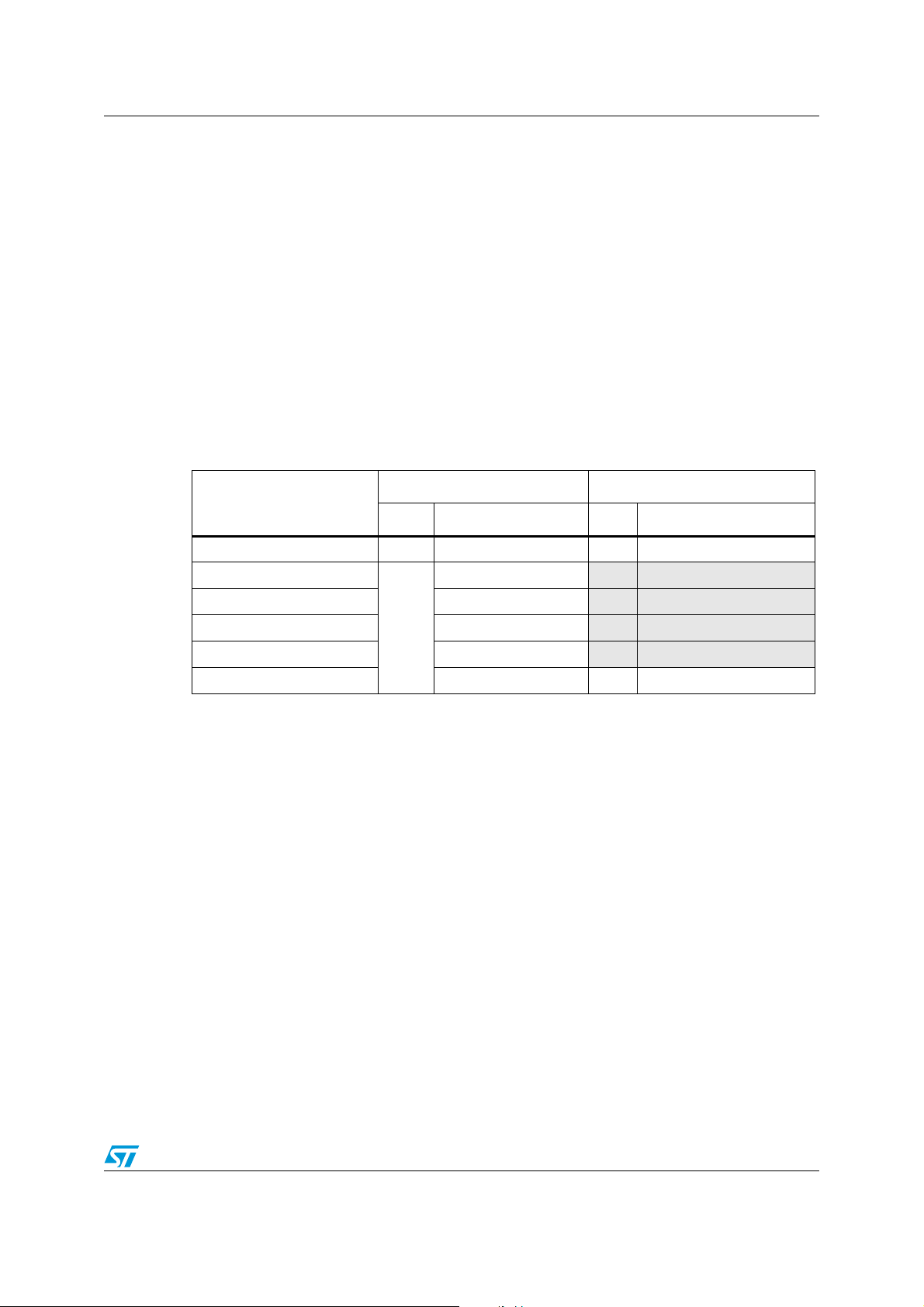

3.2 System architecture

STM32 F2 series are a new generation on STM32 with significant improvement in features

and performance with outstanding results: 150DMIPS at 120MHz and execution from Flash

equivalent to 0-wait state performance.

3.2.1 32-bit multi-AHB bus matrix

The 32-bit multi-AHB bus matrix interconnects all masters (CPU, DMA controllers, Ethernet,

USB HS) and slaves (Flash memory, 2 blocks of RAM, FSMC, AHB and APB peripherals)

and ensures seamless and efficient operation even when several high-speed peripherals

are working simultaneously. For instance, the core can access the Flash through the ART

Accelerator and the 112-Kbyte SRAM, while the DMA2 controller is transferring data from

the camera interface located on the AHB2 peripheral bus to an LCD connected to the

FSMC, and while the USB OTG High Speed interface is storing received data in the 16Kbyte SRAM block.

Figure 4. STM32 F2 series system architecture

3.2.2 Adaptive real-time memory accelerator (ART Accelerator™)

To free the full performance of the Cortex-M3 core, ST has developed a leading-edge 90 nm

process and a unique technology, the adaptive real-time ART Accelerator™. To release the

processor full 150 DMIPS performance at this frequency, the accelerator implements an

instruction prefetch queue and branch cache which increases program execution speed

from the 128-bit Flash memory. Based on the CoreMark benchmark, the performance

achieved thanks to the ART accelerator is equivalent to 0 wait state program execution from

Flash memory at a CPU frequency up to 120 MHz.

By default (after each device reset) the prefetch queue and branch cache are disabled, the

user can enable them using the PRFTEN, ICEN and DCEN bits in the FLASH_ACR register.

12/52 Doc ID 019001 Rev 1

Page 13

AN3427 Peripheral migration

3.2.3 Dual SRAM

The 128KB of SRAM is made of 2 blocks; one 112KB and one 16KB. Both can be accessed

simultaneously by 2 masters in 0 WS (CPU, DMAs, Ethernet, USB HS).

The 16KB SRAM can be used as a buffer for high speed peripherals like USB-HS, Ethernet,

Camera, without impacting the CPU performance.

3.3 Memory mapping

The peripheral address mapping has been changed in the F2 series vs. F1 series, the main

change concerns the GPIOs which have been moved to the AHB bus instead of the APB

bus to allow them to operate at maximum speed.

The tables below provide the peripheral address mapping correspondence between F2 and

F1 series.

Table 3. IP bus mapping differences between STM32 F1 and STM32 F2 series

STM32 F2 series STM32 F1 series

Peripheral

Bus Base address Bus Base address

FSMC Registers AHB3 0xA0000000 AHB 0xA0000000

RNG

0x50060800

NA NA

HASH 0x50060400

CRYP 0x50060000

DCMI 0x50050000

USB OTG FS 0x50000000 AHB 0x50000000

AHB2

NA NA

NA NA

NA NA

Doc ID 019001 Rev 1 13/52

Page 14

Peripheral migration AN3427

Table 3. IP bus mapping differences between STM32 F1 and STM32 F2 series

STM32 F2 series STM32 F1 series

Peripheral

Bus Base address Bus Base address

USB OTG HS

ETHERNET MAC 0x40028000

DMA2 0x40026400 0x40020400

DMA1 0x40026000 0x40020000

BKPSRAM 0x40024000

Flash interface 0x40023C00

RCC 0x40023800 0x40021000

CRC 0x40023000 0x40023000

GPIO I 0x40022000

GPIO H 0x40021C00

GPIO G 0x40021800

GPIO F 0x40021400 0x40011C00

GPIO E 0x40021000 0x40011800

GPIO D 0x40020C00 0x40011400

GPIO C 0x40020800 0x40011000

GPIO B 0x40020400 0x40010C00

GPIO A 0x40020000 0x40010800

TIM11

TIM10 0x40014400 0x40015000

TIM9 0x40014000 0x40014C00

EXTI 0x40013C00 0x40010400

AHB1

APB2

0x40040000 NA NA

0x40028000

AHB

NA NA

0x40022000

AHB

NA NA

NA NA

0x40012000

APB2

0x40014800 0x40015400

14/52 Doc ID 019001 Rev 1

Page 15

AN3427 Peripheral migration

Table 3. IP bus mapping differences between STM32 F1 and STM32 F2 series

STM32 F2 series STM32 F1 series

Peripheral

Bus Base address Bus Base address

SYSCFG

SPI1 0x40013000 APB2 0x40013000

SDIO 0x40012C00 AHB 0x40018000

ADC1 - ADC2 - ADC3 0x40012000 APB2

APB2

USART6 0x40011400

USART1 0x40011000

TIM8 0x40010400 0x40013400

TIM1 0x40010000 0x40012C00

DAC 0x40007400

PWR

CAN2 0x40006800 0x40006800

CAN1 0x40006400 0x40006400

I2C3 0x40005C00

I2C2 0x40005800

I2C1 0x40005400 0x40005400

UART5 0x40005000 0x40005000

UART4 0x40004C00 0x40004C00

0x40013800

0x40007000 0x40007000

NA NA

NA NA

APB2

APB1

NA NA

ADC3 - 0x40013C00

ADC2 - 0x40012800

ADC1 - 0x40012400

0x40013800

0x40007400

0x40005800

USART3 0x40004800 0x40004800

USART2 0x40004400 0x40004400

SPI3 / I2S3 0x40003C00 0x40003C00

SPI2 / I2S2 0x40003800 0x40003800

IWDG 0x40003000 0x40003000

WWDG 0x40002C00 0x40002C00

RTC

TIM14 0x40002000 0x40002000

TIM13 0x40001C00 0x40001C00

TIM12 0x40001800 0x40001800

TIM7 0x40001400 0x40001400

TIM6 0x40001000 0x40001000

TIM5 0x40000C00 0x40000C00

TIM4 0x40000800 0x40000800

APB1

APB1

0x40002800

(inc. BKP registers)

Doc ID 019001 Rev 1 15/52

0x40002800

Page 16

Peripheral migration AN3427

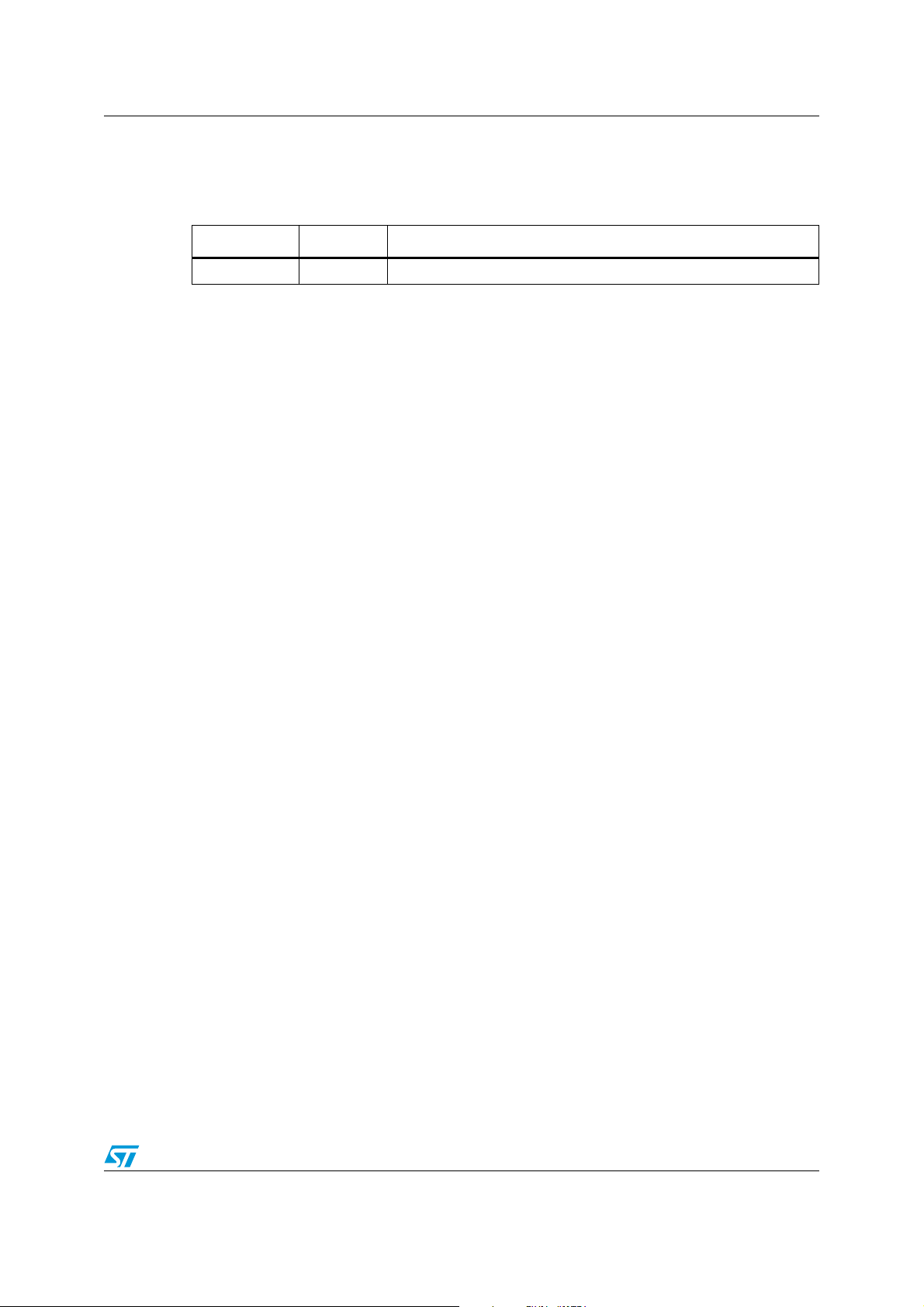

Color key:

= Same feature, but base address change

= Feature not available (NA)

Table 3. IP bus mapping differences between STM32 F1 and STM32 F2 series

STM32 F2 series STM32 F1 series

Peripheral

Bus Base address Bus Base address

TIM3

0x40000400

APB1

TIM2 0x40000000 0x40000000

APB1

BKP registers NA NA 0x40006C00

USB device FS

AFIO

NA NA 0x40005C00

NA NA APB2 0x40001000

3.4 RCC

The main differences related to the RCC (Reset and Clock Controller) in the STM32 F2

series vs. STM32 F1 series are presented in the table below.

Table 4. RCC differences between STM32 F1 and STM32 F2 series

RCC main

features

STM32 F1 series STM32 F2 series Comments

0x40000400

HSI 8 MHz RC factory-trimmed

LSI 40 KHz RC

16 MHz RC factory-trimmed

32 KHz RC

3 - 25 MHz

HSE

Depending on the product line

4 - 26MHz

used

LSE 32.768 KHz 32.768 kHz

No change to SW configuration:

– Enable/disable

RCC_CR[HSION]

– Status flag RCC_CR[HSIRDY]

No change to SW configuration:

– Enable/disable

RCC_CSR[LSION]

– Status flag

RCC_CSR[LSIRDY]

No change to SW configuration:

– Enable/disable

RCC_CR[HSEON]

– Status flag

RCC_CR[HSERDY]

No change to SW configuration:

– Enable/disable

RCC_BDCR[LSEON]

– Status flag

RCC_BDCR[LSERDY]

16/52 Doc ID 019001 Rev 1

Page 17

AN3427 Peripheral migration

Table 4. RCC differences between STM32 F1 and STM32 F2 series

RCC main

features

PLL

System clock

source

System clock

frequency

AHB

frequency

STM32 F1 series STM32 F2 series Comments

There is no change to PLL

enable/disable

RCC_CR[PLLON] and status

– Connectivity line:

+ 2 PLLs for I2S, Ethernet

and OTG FS clock

– Other product lines:

PLL

HSI, HSE or PLL HSI, HSE or PLL

up to 72 MHz depending on the

product line used

8 MHz after reset using HSI

up to 72 MHz

main PLL

main

– Main PLL for system, OTG

FS, SDIO and RNG clock

– Dedicated PLL for I2S

clock

120 MHz

16 MHz after reset using HSI

up to 120 MHz

flag RCC_CR[PLLRDY].

However, PLL configuration

(clock source selection,

multiplication/division factors)

are different. In F2 series a

dedicated register

RCC_PLLCFGR is used to

configure the PLL parameters.

No change to SW configuration:

– Selection bits

RCC_CFGR[SW]

– Status flag RCC_CFGR[SWS]

For STM32 F2, Flash wait states

must be adapted to the system

frequency depending on the

supply voltage range.

No change to SW configuration:

configuration bits

RCC_CFGR[HPRE]

APB1

frequency

APB2

frequency

RTC clock

source

up to 36 MHz

up to 72 MHz

LSI, LSE or HSE/128

up to 30 MHz

up to 60 MHz

LSI, LSE or HSE clock

divided by 2 to 31

No change to SW configuration:

configuration bits

RCC_CFGR[PPRE1].

In F2 series the PPRE1 bits

occupy bits [10:12], instead of

bits [8:10] in F1 series.

No change to SW configuration:

configuration bits

RCC_CFGR[PPRE2].

In F2 series the PPRE2 bits

occupy bits[13:15] of the

register, instead of bits [11:13] in

F1 series.

RTC clock source configuration

is done through the same bits

RCC_BDCR[RTCSEL] and

RCC_BDCR[RTCEN]. However,

in F2 series when HSE is

selected as RTC clock source,

additional bits are used in CFGR

register, RCC_CFGR[RTCPRE],

to select the division factor to be

applied on HSE clock.

Doc ID 019001 Rev 1 17/52

Page 18

Peripheral migration AN3427

Table 4. RCC differences between STM32 F1 and STM32 F2 series

RCC main

features

MCO clock

source

Internal

oscillator

measurement

/ calibration

Interrupt

STM32 F1 series STM32 F2 series Comments

MCO configuration in F2 series

is different from F1:

– For MCO1, the prescaler is

– MCO pin (PA8)

– Connectivity Line: HSI, HSE,

PLL/2, SYSCLK, PLL2, PLL3

or XT1

– Other product lines:

HSE, PLL/2 or SYSCLK

- LSI connected to TIM5 CH4

IC: can measure LSI w/ respect

to HSI/HSE clock

- CSS (linked to NMI IRQ)

- LSIRDY, LSERDY, HSIRDY,

HSERDY, PLLRDY, PLL2RDY

and PLL3RDY (linked to RCC

global IRQ)

HSI,

– MCO1 pin (PA8): HSI,

HSE, LSE or PLL

– MCO2 pin (PC9)

PLL, HSE or SYSCLK

– With configurable

prescaler, from 1 to 5, for

each output.

- LSI connected to TIM5 CH4

IC: can measure LSI w/

respect to HSI/HSE clock

- LSE connected to TIM5

CH4 IC: can measure HSI w/

respect to LSE clock

- HSE connected to TIM11

CH1 IC: can measure HSE

range w/ respect to HSI clock

- CSS (linked to IRQ)

- LSIRDY, L SERDY, H S I RDY,

HSERDY, PLLRDY and

PLLI2SRDY

global IRQ)

: PLLI2S,

(linked to RCC

configured through bits

RCC_CFGR[MCO1PRE] and

the selection of the clock to

output through bits

RCC_CFGR[MCO1]

– For MCO2, the prescaler is

configured through bits

RCC_CFGR[MCO2PRE] and

the selection of the clock to

output through bits

RCC_CFGR[MCO2]

There is no configuration to

perform in RCC registers.

No change on SW configuration:

interrupt enable, disable and

pending bits clear are done in

RCC_CIR register.

In addition to the differences described in the table above, the following additional steps

need to be performed during the migration:

1. System clock configuration

: when moving from F1 series to F2 series only a few

settings need to be updated in the system clock configuration code; mainly the Flash

settings (configure the right wait states for the system frequency, prefetch

enable/disable,...) or/and the PLL parameters configuration:

a) If the HSE or HSI is used directly as system clock source, in this case only the

Flash parameters should be modified.

b) If PLL (clocked by HSE or HSI) is used as system clock source, in this case the

Flash parameters and PLL configuration need to be updated.

18/52 Doc ID 019001 Rev 1

Page 19

AN3427 Peripheral migration

Table 5. below provides an example of porting a system clock configuration from F1 to F2

series:

– STM32F105/7 Connectivity Line running at maximum performance: system clock

at 72 MHz (PLL, clocked by the HSE, used as system clock source), Flash with 2

wait states and Flash prefetch queue enabled.

– F2 series running at maximum performance: system clock at 120 MHz (PLL,

clocked by the HSE, used as system clock source), Flash with 3 wait states, Flash

prefetch queue and branch cache enabled.

As shown in the table below, only the Flash settings and PLL parameters (code in Bold

Italic) need to be rewritten to run on F2 series. However, HSE, AHB prescaler and system

clock source configuration are left unchanged, and the APB’s prescalers are adapted to the

maximum APB frequency in the F2 series.

Note: 1 The source code presented in the table below is intentionally simplified (time-out in wait loop

removed) and is based on the assumption that the RCC and Flash registers are at their

reset values.

2 For STM32F2xx you can use the clock configuration tool,

STM32F2xx_Clock_Configuration.xls, to generate a customized system_stm32f2xx.c file

containing a system clock configuration routine, that you adapt to your application

requirements. For more information, refer to AN3362 “Clock configuration tool for

STM32F2xx microcontrollers”

Doc ID 019001 Rev 1 19/52

Page 20

Peripheral migration AN3427

Table 5. Example of migrating system clock configuration code from F1 to F2 series

STM32F105/7 running at 72 MHz (PLL as clock

source) with 2 wait state

/* Enable HSE ----------------------------*/

RCC->CR |= ((uint32_t)RCC_CR_HSEON);

/* Wait till HSE is ready */

while((RCC->CR & RCC_CR_HSERDY) == 0)

{

}

/* Flash configuration -------------------*/

/* Prefetch ON, Flash 2 wait state */

FLASH->ACR |= FLASH_ACR_PRFTBE |

FLASH_ACR_LATENCY_2;

/* AHB and APBs prescaler configuration --*/

/* HCLK = SYSCLK */

RCC->CFGR |= RCC_CFGR_HPRE_DIV1;

/* PCLK2 = HCLK */

RCC->CFGR |= RCC_CFGR_PPRE2_DIV1;

/* PCLK1 = HCLK */

RCC->CFGR |= RCC_CFGR_PPRE1_DIV2;

/* PLLs configuration -------------------*/

/* PLL2CLK = (HSE / 5) * 8 = 40 MHz

PREDIV1CLK = PLL2 / 5 = 8 MHz */

RCC->CFGR2 |= RCC_CFGR2_PREDIV2_DIV5 |

RCC_CFGR2_PLL2MUL8 |

RCC_CFGR2_PREDIV1SRC_PLL2 |

RCC_CFGR2_PREDIV1_DIV5;

/* Enable PLL2 */

RCC->CR |= RCC_CR_PLL2ON;

/* Wait till PLL2 is ready */

while((RCC->CR & RCC_CR_PLL2RDY) == 0)

{

}

/* PLLCLK = PREDIV1 * 9 = 72 MHz */

RCC->CFGR |= RCC_CFGR_PLLXTPRE_PREDIV1 |

RCC_CFGR_PLLSRC_PREDIV1 |

RCC_CFGR_PLLMULL9;

/* Enable the main PLL */

RCC->CR |= RCC_CR_PLLON;

/* Wait till the main PLL is ready */

while((RCC->CR & RCC_CR_PLLRDY) == 0)

{

}

/* Main PLL used as system clock source --*/

RCC->CFGR |= RCC_CFGR_SW_PLL;

/* Wait till the main PLL is used as system

clock source */

while ((RCC->CFGR & RCC_CFGR_SWS) !=

RCC_CFGR_SWS_PLL)

{

}

STM32F2xx running at 120 MHz (PLL as clock

source) with 3 wait state

/* Enable HSE ----------------------------*/

RCC->CR |= ((uint32_t)RCC_CR_HSEON);

/* Wait till HSE is ready */

while((RCC->CR & RCC_CR_HSERDY) == 0)

{

}

/* Flash configuration -------------------*/

/* Flash prefetch and cache ON, Flash 3 wait

state */

FLASH->ACR = FLASH_ACR_PRFTEN |

FLASH_ACR_ICEN |

FLASH_ACR_DCEN |

FLASH_ACR_LATENCY_3WS;

/* AHB and APBs prescaler configuration --*/

/* HCLK = SYSCLK */

RCC->CFGR |= RCC_CFGR_HPRE_DIV1;

/* PCLK2 = HCLK / 2 */

RCC->CFGR |= RCC_CFGR_PPRE2_DIV2;

/* PCLK1 = HCLK / 4 */

RCC->CFGR |= RCC_CFGR_PPRE1_DIV4;

/* PLL configuration ---------------------*/

/* PLLCLK = ((HSE / PLL_M) * PLL_N) / PLL_P

= ((25 MHz / 25) * 240) / 2

= 120 MHz */

RCC->PLLCFGR = PLL_M | (PLL_N << 6) |

(((PLL_P >> 1) -1) << 16) |

(RCC_PLLCFGR_PLLSRC_HSE) |

(PLL_Q << 24);

/* Enable the main PLL */

RCC->CR |= RCC_CR_PLLON;

/* Wait till the main PLL is ready */

while((RCC->CR & RCC_CR_PLLRDY) == 0)

{

}

/* Main PLL used as system clock source --*/

RCC->CFGR |= RCC_CFGR_SW_PLL;

/* Wait till the main PLL is used as system

clock source */

while ((RCC->CFGR & RCC_CFGR_SWS ) !=

RCC_CFGR_SWS_PLL);

{

}

2. Peripheral access configuration: The address mapping of some peripherals has been

changed in F2 series vs. F1 series, so you need to use different registers to

[enable/disable] or [enter/exit] the peripheral [clock] or [from reset mode].

20/52 Doc ID 019001 Rev 1

Page 21

AN3427 Peripheral migration

Table 6. RCC registers used for peripheral access configuration

Bus Register Comments

RCC_AHB1RSTR Used to [enter/exit] the AHB1peripheral from reset

AHB1

AHB2

RCC_AHB1ENR Used to [enable/disable] the AHB1 peripheral clock

RCC_AHB1LPENR

RCC_AHB2RSTR Used to [enter/exit] the AHB2 peripheral from reset

RCC_AHB2ENR Used to [enable/disable] the AHB2 peripheral clock

RCC_AHB2LPENR

RCC_AHB3RSTR Used to [enter/exit] the AHB3 peripheral from reset

Used to [enable/disable] the AHB1 peripheral clock in low

power Sleep mode

Used to [enable/disable] the AHB2 peripheral clock in low

power Sleep mode

AHB3

APB1

APB2

RCC_AHB3ENR Used to [enable/disable] the AHB3 peripheral clock

RCC_AHB3LPENR

RCC_APB1RSTR Used to [enter/exit] the APB1 peripheral from reset

RCC_APB1ENR Used to [enable/disable] the APB1 peripheral clock

RCC_APB1LPENR

RCC_APB2RSTR Used to [enter/exit] the APB2 peripheral from reset

RCC_APB2ENR Used to [enable/disable] the APB2 peripheral clock

RCC_APB2LPENR

Used to [enable/disable] the AHB3 peripheral clock in low

power Sleep mode

Used to [enable/disable] the APB1 peripheral clock in low

power Sleep mode

Used to [enable/disable] the APB2 peripheral clock in low

power Sleep mode

To configure the access to a given peripheral you have first to know to which bus this

peripheral is connected, refer to Table 3 on page 13, then depending on the action needed

you have to program the right register as described in Table 6. above. For example, USART1

is connected to APB2 bus, to enable the USART1 clock you have to configure the

APB2ENR register as follows:

RCC->APB2ENR |= RCC_APB2ENR_USART1EN;

to disable USART1 clock during Sleep mode (to reduce power consumption) you have to

configure APB2LPENR register as follows:

RCC->APB2LPENR |= RCC_APB2LPENR_USART1LPEN;

3. Peripheral clock configuration:

some peripherals have a dedicated clock source

independent from the system clock, and used to generate the clock required for their

operation::

a) I2S: in the F2 series the I2S clock can be derived either from a specific PLL

(PLLI2S) or from an external clock mapped on the I2S_CKIN pin:

To use PLLI2S as I2S clock source: set RCC_CFGR[I2SSRC] bit to 1, configure

the PLLI2S parameters (using RCC_PLLI2SCFGR[PLLI2SR] and

RCC_PLLI2SCFGR[PLLI2SN] bits) then enable it (set RCC_CR[PLLI2SON] bit to

Doc ID 019001 Rev 1 21/52

Page 22

Peripheral migration AN3427

1), finally enable the I2S clock (using RCC_APB1ENR[SPI2EN] or/and

RCC_APB1ENR[SPI3EN] bits)

To use external clock as I2S clock source: set RCC_CFGR[I2SSRC] bit to 0,

then enable the I2S clock (using RCC_APB1ENR[SPI2EN] or/and

RCC_APB1ENR[SPI3EN] bits)

b) USB OTG FS and SDIO: in the F2 series the USB OTG FS requires a frequency

of 48 MHz to work correctly, while the SDIO requires a frequency less than or

equal to 48 MHz to work correctly. This clock is derived from the PLL through the

Q divider.

c) ADC: in the F2 series the ADC features two clock schemes:

Clock for the analog circuitry: ADCCLK, common to all ADCs. This clock is

generated from the APB2 clock divided by a programmable prescaler that allows

the ADC to work at f

/2, /4, /6 or /8. The maximum value of ADCCLK is 30

PCLK2

MHz when the APB2 clock is at 60 MHz. This configuration is done using

ADC_CCR[ADCPRE] bits.

Clock for the digital interface (used for register read/write access): This clock

is equal to the APB2 clock. The digital interface clock can be enabled/disabled

individually for each ADC through the RCC_APB2ENR register (ADC1EN,

ADC2EN and ADC3EN bits). However, there is only a single bit

(RCC_APB2RSTR[ADCRST]) to reset the three ADCs at the same time.

22/52 Doc ID 019001 Rev 1

Page 23

AN3427 Peripheral migration

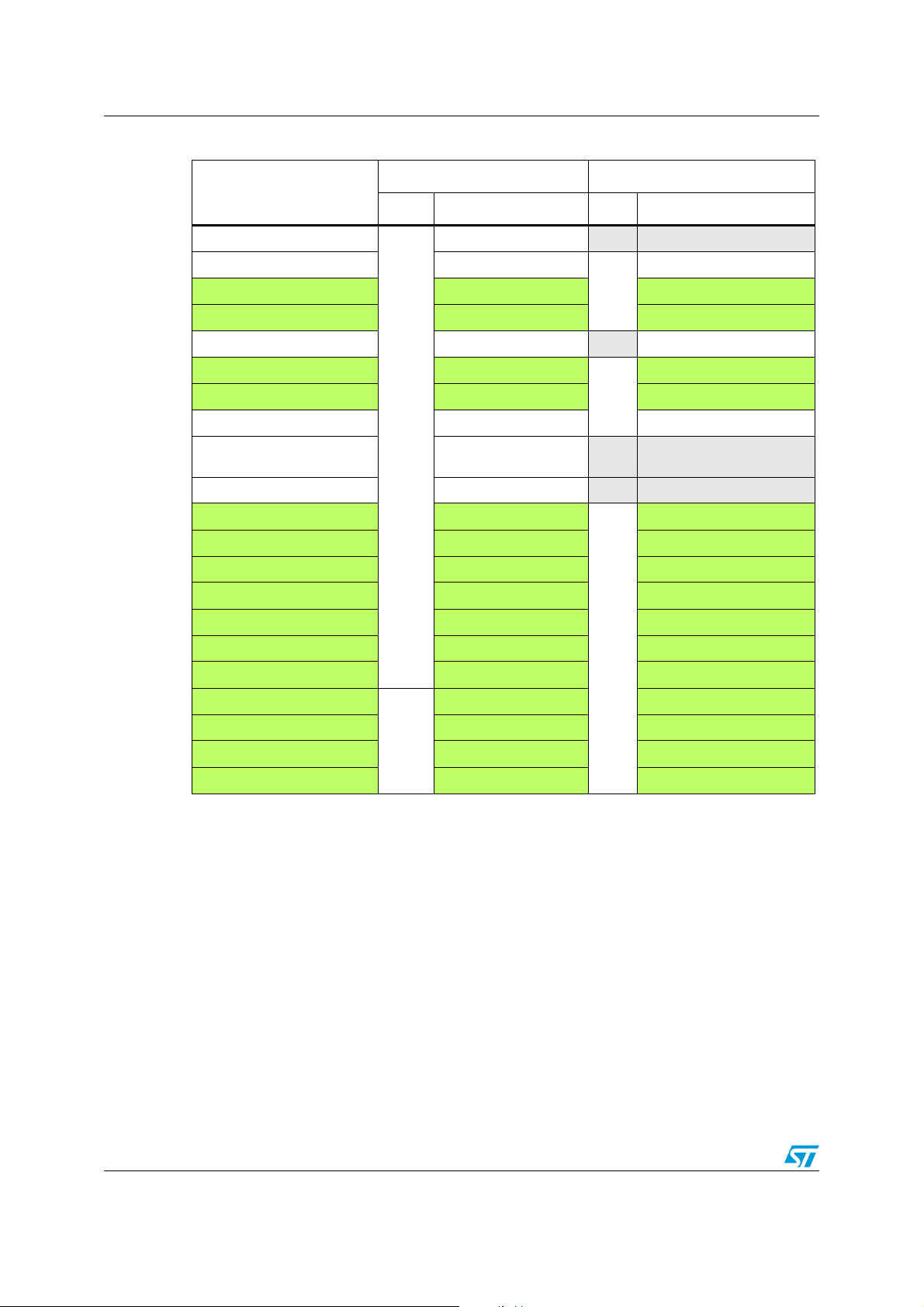

3.5 DMA

STM32 F2 series features a new DMA controller specially designed to get optimum system

bandwidth, based on a complex bus matrix architecture. Thus the architecture, features and

registers of this controller are different from the DMA embedded in the F1 series, i.e. any

code on F1series using the DMA needs to be rewritten to run on F2 series.

STM32 F1 series embeds two DMA controllers, each controller has up to 7 channels. Each

channel is dedicated to managing memory access requests from one or more peripherals. It

has an arbiter for handling the priority between DMA requests.

STM32 F2 series embeds two DMA controllers, each controller has 8 streams, each stream

is dedicated to managing memory access requests from one or more peripherals. Each

stream can have up to 8 channels (requests) in total. Each has an arbiter for handling the

priority between DMA requests.

The table below presents the correspondence between peripheral’s DMA requests in

STM32 F1 series and STM32 F2 series.

For more information about STM32 F2’s DMA configuration and usage, please refer to

section "Stream configuration procedure" in DMA chapter of STM32F2xx Reference Manual

(RM0033).

Table 7. DMA request differences between STM32 F1 series and STM32 F2 series

Peripheral DMA request STM32 F1series STM32 F2 series

ADC1 ADC1 DMA1_Channel1 DMA2_Channel0: stream0 / stream4

ADC2 ADC2

ADC3 ADC3 DMA2_Channel5 DMA2_Channel2: stream0 / stream1

DAC

SPI1

SPI2

SPI3

USART1

USART2

USART3

DAC_Channel1

DAC_Channel2

SPI1_Rx

SPI1_Tx

SPI2_Rx

SPI2_Tx

SPI3_Rx

SPI3_Tx

USART1_Rx

USART1_Tx

USART2_Rx

USART2_Tx

USART3_Rx

USART3_Tx

NA DMA2_Channel1: stream2 / stream3

DMA2_Channel3 / DMA1_Channel3

DMA2_Channel4 / DMA1_Channel4

DMA1_Channel2

DMA1_Channel3

DMA1_Channel4

DMA1_Channel5

DMA2_Channel1

DMA2_Channel2

DMA1_Channel5

DMA1_Channel4

DMA1_Channe6

DMA1_Channel7

DMA1_Channe3

DMA1_Channel2

(1)

DMA1_Channel7: stream5

(1)

DMA1_Channel7: stream6

DMA2_Channel3: stream0 / stream2

DMA2_Channel3: stream3 / stream5

DMA1_Channel0: stream3

DMA1_Channel0: stream4

DMA1_Channel0: stream0 / stream2

DMA1_Channel0: stream5 / stream7

DMA2_Channel4: stream2 / stream5

DMA2_Channel4: stream7

DMA1_Channel4: stream5

DMA1_Channel4: stream6

DMA1_Channel4: stream1

DMA1_Channel4: stream3 /

DMA1_Channel7: stream4

USART6

USART6_Rx

USART6_Tx

NA

DMA2_Channel5: stream1 / stream2

DMA2_Channel5: stream6 / stream7

Doc ID 019001 Rev 1 23/52

Page 24

Peripheral migration AN3427

Table 7. DMA request differences between STM32 F1 series and STM32 F2 series (continued)

Peripheral DMA request STM32 F1series STM32 F2 series

UART4

UART5

I2C1

I2C2

I2C3

SDIO SDIO DMA2_Channel4 DMA2_Channel4: stream3 / stream6

TIM1

TIM8

TIM2

UART4_Rx

UART4_Tx

UART5_Rx

UART5_Tx

I2C1_Rx

I2C1_Tx

I2C2_Rx

I2C2_Tx

I2C3_Rx

I2C3_Tx

TIM1_UP

TIM1_CH1

TIM1_CH2

TIM1_CH3

TIM1_CH4

TIM1_TRIG

TIM1_COM

TIM8_UP

TIM8_CH1

TIM8_CH2

TIM8_CH3

TIM8_CH4

TIM8_TRIG

TIM8_COM

TIM2_UP

TIM2_CH1

TIM2_CH2

TIM2_CH3

TIM2_CH4

DMA2_Channel3

DMA2_Channel5

DMA2_Channe4

DMA2_Channel1

DMA1_Channe7

DMA1_Channel6

DMA1_Channel5

DMA1_Channel4

NA

DMA1_Channel5

DMA1_Channel2

DMA1_Channel3

DMA1_Channel6

DMA1_Channel4

DMA1_Channel4

DMA1_Channel4

DMA2_Channel1

DMA2_Channel3

DMA2_Channel5

DMA2_Channel1

DMA2_Channel2

DMA2_Channel2

DMA2_Channel2

DMA1_Channel2

DMA1_Channel5

DMA1_Channel7

DMA1_Channel1

DMA1_Channel7

DMA1_Channel4: stream2

DMA1_Channel4: stream4

DMA1_Channel4: stream0

DMA1_Channel4: stream7

DMA1_Channel1: stream0 / stream5

DMA1_Channel1: stream6 / stream7

DMA1_Channel7: stream2 / stream3

DMA1_Channel7: stream7

DMA1_Channel3: stream2

DMA1_Channel3: stream4

DMA2_Channel6: stream5

DMA2_Channel0: stream6 /

DMA2_Channel6: stream1 / stream3

DMA2_Channel0: stream6 /

DMA2_Channel6: stream2

DMA2_Channel0: stream6 /

DMA2_Channel6: stream6

DMA2_Channel6: stream4

DMA2_Channel6: stream 0 / stream4

DMA2_Channel6: stream4

DMA2_Channel7: stream1

DMA2_Channel0: stream2 /

DMA2_Channel7: stream2

DMA2_Channel0: stream2 /

DMA2_Channel7: stream3

DMA2_Channel0: stream2 /

DMA2_Channel7: stream4

DMA2_Channel7: stream7

DMA2_Channel7: stream7

DMA2_Channel7: stream7

DMA1_Channel3: stream1 / stream7

DMA1_Channel3: stream5

DMA1_Channel3: stream6

DMA1_Channel3: stream1

DMA1_Channel3: stream6 / stream7

TIM3_UP

TIM3_CH1

TIM3

24/52 Doc ID 019001 Rev 1

TIM3_TRIG

TIM3_CH3

TIM3_CH4

TIM3_CH2

DMA1_Channel3

DMA1_Channel6

DMA1_Channel6

DMA1_Channel2

DMA1_Channel3

NA DMA1_Channel5: stream5

DMA1_Channel5: stream2

DMA1_Channel5: stream4

DMA1_Channel5: stream4

DMA1_Channel5: stream7

DMA1_Channel5: stream2

Page 25

AN3427 Peripheral migration

Table 7. DMA request differences between STM32 F1 series and STM32 F2 series (continued)

Peripheral DMA request STM32 F1series STM32 F2 series

TIM4

TIM5

TIM4_UP

TIM4_CH1

TIM4_CH2

TIM4_CH3

TIM5_UP

TIM5_CH1

TIM5_CH2

TIM5_CH3

TIM5_CH4

TIM5_TRIG

DMA1_Channel7

DMA1_Channel1

DMA1_Channel4

DMA1_Channel5

DMA2_Channel2

DMA2_Channel5

DMA2_Channel4

DMA2_Channel2

DMA2_Channel1

DMA2_Channel1

TIM6 TIM6_UP DMA2_Channel3 / DMA1_Channel3

TIM7 TIM7_UP DMA2_Channe4 / DMA1_Channel4

TIM15

TIM16

TIM17

TIM15_UP

TIM15_CH1

TIM15_TRIG

TIM15_COM

TIM16_UP

TIM16_CH1

TIM17_UP

TIM17_CH1

DMA1_Channel5

DMA1_Channel5

DMA1_Channel5

DMA1_Channel5

DMA1_Channel6

DMA1_Channel6

DMA1_Channel7

DMA1_Channel7

DMA1_Channel2: stream6

DMA1_Channel2: stream0

DMA1_Channel2: stream3

DMA1_Channel2: stream7

DMA1_Channel6: stream0 / stream6

DMA1_Channel6: stream2

DMA1_Channel6: stream4

DMA1_Channel6: stream0

DMA1_Channel6: stream1 / stream3

DMA1_Channel6: stream1 / stream3

(1)

DMA1_Channel7: stream1

(1)

DMA1_Channel1: stream2 / stream4

NA

NA

NA

DCMI DCMI

CRYP_OUT

CRYP

CRYP_IN

HASH_IN

1. For High-density value line devices, the DAC DMA requests are mapped respectively on DMA1 Channel 3 and DMA1

Channel 4

NA DMA2_Channel1: stream1 / stream7

DMA2_Channel2: stream5

NA

DMA2_Channel2: stream6

DMA2_Channel2: stream7

Doc ID 019001 Rev 1 25/52

Page 26

Peripheral migration AN3427

3.5.1 Interrupts

The table below presents the interrupt vectors in STM32 F2 series vs. F1 series

The changes in F2 interrupt vectors impact only a few peripherals:

1. ADC: in F1 series there are two interrupt vectors for the ADCs; ADC1_2 and ADC3.

However in F2 series there is a single interrupt vector for all ADCs; ADC_IRQ. As

consequence, when moving to F2 series you have to add some code in the ADC IRQ

handler to know which ADC has generated the Interrupt.

2. DMA: in F2 series you have to check first to which DMA stream the peripheral DMA

request is connected, then in the associated DMA stream IRQ add the code needed to

manage the DMA interrupt request (in F2 series there are five interrupt request

sources, while there are only three in F1 series).

– Let’s consider the following example; an application uses the DMA to transfer data

from memory to the I2S2 data out register and at each end of DMA transfer, an

interrupt is generated to reconfigure the I2S/DMA parameters. In F1 series the

I2S2 DMA request is configured to be served by DMA1_Channel4, so the code

used to manage DMA end of transfer is put in the DMA1_Channel4 IRQ handler.

In F2 series the I2S2 DMA request is configured to be served by

DMA1_Stream3_Channel0, so the code used to manage DMA end of transfer is

put in the in DMA1_Stream3 IRQ handler.

3. TIM6: in F2 series the TIM6 interrupt vector is shared with the DAC interrupt, so when

TIM6 and DAC interrupts are used in the same application you have to add some code

to check which peripheral has generated the interrupt.

26/52 Doc ID 019001 Rev 1

Page 27

AN3427 Peripheral migration

Table 8. Interrupt vector differences between STM32 F1 series and STM32 F2 series

Position STM32 F1 series STM32 F2 series

0 WWDG WWDG

1 PVD PVD

2 TAMPER TAMP_ STAMP

3RTC RTC_WKUP

4 FLASH FLASH

5RCC RCC

6 EXTI0 EXTI0

7 EXTI1 EXTI1

8 EXTI2 EXTI2

9 EXTI3 EXTI3

10 EXTI4 EXTI4

11 DMA1_Channel1

12 DMA1_Channel2

13 DMA1_Channel3

14 DMA1_Channel4

15 DMA1_Channel5

16 DMA1_Channel6

DMA1_Stream0

DMA1_Stream1

DMA1_Stream2

DMA1_Stream3

DMA1_Stream4

DMA1_Stream5

17 DMA1_Channel7

18 ADC1_2

19

20

CAN1_TX / USB_HP_CAN_TX

CAN1_RX0 / USB_LP_CAN_RX0

(1)

(1)

DMA1_Stream6

ADC

CAN1_TX

CAN1_RX0

21 CAN1_RX1 CAN1_RX1

22 CAN1_SCE CAN1_SCE

23 EXTI9_5 EXTI9_5

24 TIM1_BRK / TIM1_BRK _TIM9

25 TIM1_UP / TIM1_UP_TIM10

26

TIM1_TRG_COM /

TIM1_TRG_COM_TIM11

(1)

(1)

(1)

TIM1_BRK _TIM9

TIM1_UP_TIM10

TIM1_TRG_COM_TIM11

27 TIM1_CC TIM1_CC

28 TIM2 TIM2

29 TIM3 TIM3

30 TIM4 TIM4

31 I2C1_EV I2C1_EV

32 I2C1_ER I2C1_ER

33 I2C2_EV I2C2_EV

Doc ID 019001 Rev 1 27/52

Page 28

Peripheral migration AN3427

Table 8. Interrupt vector differences between STM32 F1 series and STM32 F2 series

Position STM32 F1 series STM32 F2 series

34 I2C2_ER I2C2_ER

35 SPI1 SPI1

36 SPI2 SPI2

37 USART1 USART1

38 USART2 USART2

39 USART3 USART3

40 EXTI15_10 EXTI15_10

41 RTC_Alarm RTC_Alarm

42 OTG_FS_WKUP / USBWakeUp

43

44

45

TIM8_BRK / TIM8_BRK_TIM12

TIM8_UP / TIM8_UP_TIM13

TIM8_TRG_COM /

TIM8_TRG_COM_TIM14

(1)

(1)

(1)

46 TIM8_CC TIM8_CC

47 ADC3

OTG_FS_WKUP

TIM8_BRK_TIM12

TIM8_UP_TIM13

TIM8_TRG_COM_TIM14

DMA1_Stream7

48 FSMC

49 SDIO

FSMC

SDIO

50 TIM5 TIM5

51 SPI3 SPI3

52 UART4 UART4

53 UART5 UART5

54 TIM6 / TIM6_DAC

(1)

TIM6_DAC

55 TIM7 TIM7

(1)

DMA2_Stream0

DMA2_Stream1

DMA2_Stream2

DMA2_Stream3

56 DMA2_Channel1

57 DMA2_Channel2

58 DMA2_Channel3

59

60

61

62

63

64

65

DMA2_Channel4 / DMA2_Channel4_5

DMA2_Channel5 DMA2_Stream4

ETH ETH

ETH_WKUP ETH_WKUP

CAN2_TX CAN2_TX

CAN2_RX0 CAN2_RX0

CAN2_RX1 CAN2_RX1

66

67

CAN2_SCE CAN2_SCE

OTG_FS OTG_FS

28/52 Doc ID 019001 Rev 1

Page 29

AN3427 Peripheral migration

Color key:

= Different Interrupt vector

= Interrupt Vector name changed but F1 peripheral still mapped on the same Interrupt Vector

position in F2 series

= Feature not available (NA)

Table 8. Interrupt vector differences between STM32 F1 series and STM32 F2 series

Position STM32 F1 series STM32 F2 series

68 NA DMA2_Stream5

69

70

71

72

73

74

75

76

77

78

79

80

NA DMA2_Stream6

NA DMA2_Stream7

NA USART6

NA I2C3_EV

NA I2C3_ER

NA OTG_HS_EP1_OUT

NA OTG_HS_EP1_IN

NA OTG_HS_WKUP

NA OTG_HS

NA DCMI

NA CRYP

NA HASH_RNG

1. Depending on the product line used

3.6 GPIO

The STM32 F2 GPIO peripheral embeds new features compared to F1 series, the main

ones are listed below:

● GPIO mapped on AHB bus for better performance

● I/O pin multiplexer and mapping: pins are connected to on-board peripherals/modules

through a multiplexer that allows only one peripheral alternate function (AF) to be

connected to an I/O pin at a time. In this way, there can be no conflict between

peripherals sharing the same I/O pin.

● More possibilities and features for I/O configuration

The F2 GPIO peripheral is a new design and thus the architecture, features and registers

are different from the GPIO peripheral in the F1 series, i.e. any code on F1series using the

GPIO needs to be rewritten to run on F2 series.

For more information about STM32 F2’s GPIO programming and usage, please refer to

section "I/O pin multiplexer and mapping" in the GPIO chapter of STM32F2xx Reference

Manual (RM0033).

The table below presents the differences between GPIOs in the STM32 F1 series and

STM32 F2 series.

Doc ID 019001 Rev 1 29/52

Page 30

Peripheral migration AN3427

Table 9. GPIO differences between STM32 F1 series and STM32 F2 series

Input mode

General purpose

output

Alternate Function

output

Input / Output Analog Analog

Output speed

Alternate function

selection

GPIO STM32 F1 series STM32 F2 series

Floating

PU

PD

PP

OD

PP

OD

2 MHz

10 MHz

50 MHz

To optimize the number of peripheral I/O

functions for different device packages, it

is possible to remap some alternate

functions to some other pins (software

remap).

Floating

PU

PD

PP

PP + PU

PP + PD

OD

OD + PU

OD + PD

PP

PP + PU

PP + PD

OD

OD + PU

OD + PD

2 MHz

25 MHz

50 MHz

100 MHz

Highly flexible pin multiplexing allows no

conflict between peripherals sharing the

same I/O pin.

Max IO toggle frequency 16 MHz 60 MHz

3.6.1 Alternate function mode

In STM32 F1 series

1. The configuration to use an I/O as alternate function depends on the peripheral mode

used. For example, the USART Tx pin should be configured as alternate function pushpull while USART Rx pin should be configured as input floating or input pull-up.

2. To optimize the number of peripheral I/O functions for different device packages

(especially with those with low pin count), it is possible by software to remap some

alternate functions to other pins. For example, the USART2_RX pin can be mapped on

PA3 (default remap) or PD6 (done through software remap) pin.

In STM32 F2 series

1. Whatever the peripheral mode used, the I/O must be configured as alternate function,

then the system can use the I/O in the proper way (input or output).

2. The I/O pins are connected to onboard peripherals/modules through a multiplexer that

allows only one peripheral’s alternate function to be connected to an I/O pin at a time.

30/52 Doc ID 019001 Rev 1

Page 31

AN3427 Peripheral migration

In this way, there can be no conflict between peripherals sharing the same I/O pin.

Each I/O pin has a multiplexer with sixteen alternate function inputs (AF0 to AF15) that

can be configured through the GPIOx_AFRL and GPIOx_AFRH registers:

– After reset all I/Os are connected to the system’s alternate function 0 (AF0)

– The peripherals’ alternate functions are mapped from AF1 to AF13

– Cortex-M3 EVENTOUT is mapped on AF15

3. In addition to this flexible I/O multiplexing architecture, each peripheral has alternate

functions mapped onto different I/O pins to optimize the number of peripheral I/O

functions for different device packages. For example, the USART2_RX pin can be

mapped on PA3 or PD6 pin

Note: Please refer to the “Alternate function mapping” table in the STM32F20x and STM32F21x

datasheets for the detailed mapping of the system and peripherals’ alternate function I/O

pins.

4. Configuration procedure

– Configure the desired I/O as an alternate function in the GPIOx_MODER register

– Select the type, pull-up/pull-down and output speed via the GPIOx_OTYPER,

GPIOx_PUPDR and GPIOx_OSPEEDER registers, respectively

– Connect the I/O to the desired AFx in the GPIOx_AFRL or GPIOx_AFRH register

3.7 EXTI source selection

In STM32 F1 the selection of the EXTI line source is performed through the EXTIx bits in the

AFIO_EXTICRx registers, while in F2 series this selection is done through the EXTIx bits in

the SYSCFG_EXTICRx registers.

Only the mapping of the EXTICRx registers has been changed, without any changes to the

meaning of the EXTIx bits. However, the range of EXTIx bits values has been extended to

0b1000 to support the two ports added in F2, port H and I (in F1 series the maximum value

is 0b0110).

3.8 FLASH

The table below presents the difference between the FLASH interface in the STM32 F1 and

STM32 F2 series, these differences are the following:

● New interface, new technology

● New architecture, sectors instead of pages

● New read protection mechanism, 3 read protection levels with JTAG fuse

As consequence the F2 Flash programming procedures and registers are different from the

the F1 series, i.e. any code on F1 series using the Flash needs to be rewritten to run on F2

series.

For more information on programming, erasing and protection of the F2 Flash memory,

please refer to the STM32F2xx Flash programming manual (PM0059).

Doc ID 019001 Rev 1 31/52

Page 32

Peripheral migration AN3427

Table 10. FLASH differences between STM32 F1 series and STM32 F2 series

Flash STM32 F1 series STM32 F2 series

Wait States up to 2

up to 7 (depending on the

supply voltage)

Start Address 0x0800 0000 0x0800 0000

Main/Program

memory

EEPROM memory

End Address up to 0x080F FFFF up to 0x080F FFFF

4 sectors of 16 Kbytes

1 sector of 64 Kbytes

7 sectors of 128 Kbytes

(1)

Available by SW emulation

Granularity

Start Address

Page of 2 Kbytes size

except for Low and Medium

density Page of 1 Kbytes

Available by SW emulation

End Address

Start Address 0x1FFF F000

0x1FFF 0000

System memory

End Address 0x1FFF F7FF

Start Address 0x1FFF F800

0x1FFF 77FF

0x1FFF C000

Option Bytes

OTP

End Address 0x1FFF F80F

Start Address

NA

End Address

0x1FFF C007

0x1FFF 7800

0x1FFF 79FF

(2)

Start address 0x4002 2000

Flash interface

Programming

procedure

Same for all product lines

Erase granularity Page (1 or 2 Kbytes)

0x4002 3C00

Different from F1 series

Sector

Byte

Half word

Program mode Half word

word

Double word (with external VPP

supply)

Read Protection

Unprotection

Protection

JTAG fuse

Read protection disable

RDP = 0xA55A

Read protection enable

RDP != 0xA55A

NA Level 2 RDP = 0xCC

Level 0 no protection

RDP = 0xAA

Level 1 memory protection

RDP != (Level 2 & Level 0)

Write protection Protection by 4Kbytes Protection by sector

(3)

32/52 Doc ID 019001 Rev 1

Page 33

AN3427 Peripheral migration

Color key:

= New feature or new architecture

= Same feature, but specification change or enhancement

= Feature not available (NA)

Table 10. FLASH differences between STM32 F1 series and STM32 F2 series

Flash STM32 F1 series STM32 F2 series

STOP STOP

User Option bytes

1. For more details refer to Application note AN2594 EEPROM emulation in STM32F10x microcontrollers

2. For more details refer to Application note AN3390 EEPROM emulation in STM32F2xx microcontrollers

3. Memory read protection Level 2 is an irreversible operation. When Level 2 is activated, the level of protection cannot be

decreased to Level 0 or Level 1.

STANDBY STANDBY

WDG WDG

NA BOR level

3.9 ADC

The table below presents the differences between the ADC interface of STM32 F1 series

and STM32 F2 series, these differences are the following:

● New digital interface

● New architecture and new features

Table 11. ADC differences between STM32 F1 series and STM32 F2 series

ADC Type SAR structure SAR structure

Instances ADC1 / ADC2 / ADC3 ADC1 / ADC2 / ADC3

Max Sampling freq 1 MSPS

Number of

channels

Resolution 12-bit 12-bit,10-bit, 8-bit, 6-bit

Conversion Modes

DMA Ye s Ye s

ADC STM32 F1 series STM32 F2 series

2 MSPS

up to 21 channels

Single / continuous / Scan / Discontinuous /

Dual Mode

up to 24 Channels

Single / continuous /

Scan / Discontinuous

Dual Mode / Triple Mode

Doc ID 019001 Rev 1 33/52

Page 34

Peripheral migration AN3427

Color key:

= Same feature, but specification change or enhancement

Table 11. ADC differences between STM32 F1 series and STM32 F2 series (continued)

ADC STM32 F1 series STM32 F2 series

Ye s Ye s

External trigger

External event for

regular group

For ADC1 and ADC2:

TIM1 CC1

TIM1 CC2

TIM1 CC3

TIM2 CC2

TIM3 TRGO

TIM4 CC4

EXTI line 11 /

TIM8_TRGO

For ADC3:

TIM3 CC1

TIM2 CC3

TIM1 CC3

TIM8 CC1

TIM8 TRGO

TIM5 CC1

TIM5 CC3

External event for

injected group

For ADC1 and ADC2:

TIM1 TRGO

TIM1 CC4

TIM2 TRGO

TIM2 CC1

TIM3 CC4

TIM4 TRGO

EXTI line15 /

TIM8_CC4

For ADC3:

TIM1 TRGO

TIM1 CC4

TIM4 CC3

TIM8 CC2

TIM8 CC4

TIM5 TRGO

TIM5 CC4

Supply requirement 2.4 V to 3.6 V

Input range V

<= VIN <= V

REF-

REF+

External event for

regular group

TIM1 CC1

TIM1 CC2

TIM1 CC3

TIM2 CC2

TIM2 CC3

TIM2 CC4

TIM2 TRGO

TIM3 CC1

TIM3 TRGO

TIM4 CC4

TIM5 CC1

TIM5 CC2

TIM5 CC3

TIM8 CC1

TIM8 TRGO

EXTI line11

External event for

injected group

TIM1 CC4

TIM1 TRGO

TIM2 CC1

TIM2 TRGO

TIM3 CC2

TIM3 CC4

TIM4 CC1

TIM4 CC2

TIM4 CC3

TIM4 TRGO

TIM5 CC4

TIM5 TRGO

TIM8 CC2

TIM8 CC3

TIM8 CC4

EXTI line15

2.4 V to 3.6 V for full speed

1.8 V to 3.6 V for reduced speed

V

<= VIN <= V

REF-

REF+

34/52 Doc ID 019001 Rev 1

Page 35

AN3427 Peripheral migration

3.10 PWR

In STM32 F2 series the PWR controller presents some differences vs. F1 series, these

differences are summarized in the table below. However, the programming interface is

unchanged.

Table 12. PWR differences between STM32 F1 series and STM32 F2 series

PWR STM32 F1 series STM32 F2 series

Power supplies

Battery backup

domain

Power supply

supervisor

1. VDD = 2.0 to 3.6 V: external power

supply for I/Os and the internal

regulator. Provided externally through

VDD pins.

2. VSSA, VDDA = 2.0 to 3.6 V: external

analog power supplies for ADC, DAC,

Reset blocks, RCs and PLL (minimum

voltage to be applied to VDDA is 2.4 V

when the ADC or DAC is used). VDDA

and VSSA must be connected to VDD

and VSS, respectively.

3. VBAT = 1.8 to 3.6 V: power supply for

RTC, external clock 32 kHz oscillator

and backup registers (through power

switch) when VDD is not present.

NA

– Backup registers

–RTC

–LSE

– PC13 to PC15 I/Os

Note: in F1 series the Backup registers

are integrated in the BKP peripheral.

NA

Integrated POR / PDR circuitry

Programmable Voltage Detector (PVD)

NA Brownout reset (BOR)

1. VDD = 1.8 to 3.6 V: external power supply for I/Os

and the internal regulator (when enabled), provided

externally through VDD pins. On WLCSP package, VDD

ranges from 1.65 to 3.6 V.

VDD/VDDA minimum value of 1.65 V is obtained when

the device operates in a reduced temperature range.

2. VSSA, VDDA = 1.8 to 3.6 V: external analog power

supplies for ADC, DAC, Reset blocks, RCs and PLL.

VDDA and VSSA must be connected to VDD and VSS,

respectively.

3. VBAT = 1.65 to 3.6 V: power supply for RTC, external

clock 32 kHz oscillator and backup registers (through

power switch) when VDD is not present.

Note: in UFBGA and WLCSP packages, the internal

regulator can be switched off

– RTC with backup registers

–LSE

– PC13 to PC15 I/Os, plus PI8 I/O (when available)

Note: in F2 series the backup registers are integrated in

the RTC peripheral

4 Kbytes backup SRAM when the low power backup

regulator is enabled (this SRAM can be used as

EEPROM as long as the VBAT supply is present)

Integrated POR / PDR circuitry

Programmable voltage detector (PVD)

Low-power

modes

Sleep mode

Stop mode

Standby mode (1.8V domain powered-

off)

Doc ID 019001 Rev 1 35/52

Sleep mode + peripherals automatic clock gating(*)

Stop mode

Standby mode (1.2 V domain powered off)

(*)To further reduce power consumption in Sleep mode

the peripheral clocks can be disabled prior to executing

the WFI or WFE instructions.

Page 36

Peripheral migration AN3427

Color key:

= New feature or new architecture

= Same feature, but specification change or enhancement

Table 12. PWR differences between STM32 F1 series and STM32 F2 series

PWR STM32 F1 series STM32 F2 series

Wake-up

sources

Configuration

Sleep mode:

– Any peripheral interrupt/wakeup event

Stop mode:

– Any EXTI line event/interrupt

Standby mode:

– WKUP pin rising edge

–RTC alarm

– External reset in NRST pin

– IWDG reset

NA

Sleep mode:

– Any peripheral interrupt/wakeup event

Stop mode:

– Any EXTI line event/interrupt

Standby mode:

– WKUP pin rising edge

– RTC alarm A, RTC alarm B, RTC Wakeup, Tamper

event, TimeStamp event

– External reset in NRST pin

– IWDG reset

In F2 two additional bits have been added:

– PWR_CR[FPDS] used to power down the Flash in

Stop mode

– PWR_CSR[BRE] used to enable/disable the Backup

regulator

3.11 RTC

The STM32 F2 series embeds a new RTC peripheral vs. F1 series; the architecture,

features and programming interface are different.

As a consequence the F2 RTC programming procedures and registers are different from the

the F1 series, i.e. any code on F1series using the RTC needs to be rewritten to run on F2

series.

This new RTC provides best-in-class features:

● BCD timer/counter

● Time-of-day clock/calendar with programmable daylight saving compensation

● Two programmable alarm interrupts

● Digital calibration circuit

● Time-stamp function for event saving

● Periodic programmable wakeup flag with interrupt capability

● Automatic wakeup unit to manage low power modes

● 20 backup registers (80 bytes) which are reset when a tamper detection event occurs.

For more information about STM32 F2’s RTC features, please refer to RTC chapter of

STM32F2xx Reference Manual (RM0033).

For advanced information about the RTC programming, please refer to the Application Note

AN3371 Using the STM32 HW real-time clock (RTC).

36/52 Doc ID 019001 Rev 1

Page 37

AN3427 Peripheral migration

3.12 Miscellaneous

3.12.1 Ethernet PHY interface selection

In STM32 F1 series the Ethernet PHY interface selection is done in the AFIO peripheral

(MII_RMII_SEL bit in AFIO_MAPR register), while in F2 series this configuration is done in

the SYSCFG peripheral (MII_RMII_SEL bit in SYSCFG_PMC register).

3.12.2 TIM2 internal trigger 1 (ITR1) remapping

The example below shows how to select USB OTG FS SOF output or ETH PTP trigger

output as input for TIM2 ITR1 in STM32 F1 series:

1. In F1 series to select USB OTG FS SOF output as input for TIM2 ITR1, set to 1 the bit

TIM2ITR1_IREMAP in AFIO_MAPR register. Reset this bit to 0 to connect the Ethernet

PTP trigger output to TIM2 ITR1 input.

2. In F2 series to select USB OTG FS SOF output as input for TIM2 ITR1, set to [10] the

bits ITR1_RMP[1:0] in TIM2_OR register. Set these bits to [01] connect the Ethernet

PTP trigger output to TIM2 ITR1 input.

Doc ID 019001 Rev 1 37/52

Page 38

Firmware migration using the library AN3427

4 Firmware migration using the library

This section describes how to migrate an application based on STM32F1xx Standard

Peripherals Library in order to use the STM32F2xx Standard Peripherals Library.

The STM32F1xx and STM32F2xx libraries have the same architecture and are CMSIS

compliant, they use the same driver naming and the same APIs for all compatible

peripheral.

Only a few peripheral drivers need to be updated to migrate the application from an F1

series product to an F2 series product.

Note: In the rest of this chapter (unless otherwise specified), the term “STM32F2xx Library” is

used to refer to the STM32F2xx Standard Peripherals Library and the term “STM32F10x

Library” is used to refer to the STM32F10x Standard Peripherals Library.

4.1 Migration steps

To update your application code to run on STM32F2xx Library, you have to follow the steps

listed below:

1. Update the toolchain startup files

a) Project files: device connections and Flash memory loader. These files are

provided with the latest version of your toolchain that supports STM32F2xxx

devices. For more information please refer to your toolchain documentation.

b) Linker configuration and vector table location files: these files are developed

following the CMSIS standard and are included in the STM32F2xx Library install

package under the following directory:

Libraries\CMSIS\CM3\DeviceSupport\ST\STM32F2xx\

2. Add STM32F2xxx Library source files to the application sources

a) Replace the stm32f10x_conf.h file of your application with stm32f2xx_conf.h

provided in STM32F2xx Library.

b) Replace the existing stm32f10x_it.c/stm32f10x_it.h files in your application with

stm32f2xx_it.c/stm32f2xx_it.h provided in STM32F2xx Library.

3. Update the part of your application code that uses the RCC, DMA, GPIO, FLASH, ADC

and RTC drivers. Further details are provided in the next section.

Note: The STM32F2xx Library comes with a rich set of examples (84 in total) demonstrating how

to use the different peripherals (under Project\STM32F2xx_StdPeriph_Examples\).

4.2 RCC

1. System clock configuration: as presented in Section 3.4: RCC the STM32 F2 and F1

series have the same clock sources and configuration procedures. However, there are

some differences related to the PLL configuration, maximum frequency and Flash wait

state configuration. Thanks to the CMSIS layer, these differences are hidden from the

application code; you only have to replace the system_stm32f10x.c file by

system_stm32f2xx.c file. This file provides an implementation of SystemInit() function

38/52 Doc ID 019001 Rev 1

Page 39

AN3427 Firmware migration using the library

used to configure the microcontroller system at start-up and before branching to the

main() program.

Note: For STM32F2xx you can use the clock configuration tool,

STM32F2xx_Clock_Configuration.xls, to generate a customized SystemInit() function

depending on your application requirements. For more information, refer to the application

note AN3362 “Clock configuration tool for STM32F2xx microcontrollers”

2. Peripheral access configuration

: as presented in Section 3.4: RCC you need to call

different functions to [enable/disable] or [enter/exit] the peripheral [clock] or [from reset

mode]. For example, GPIOA is mapped on AHB1 bus on F2 series (APB2 bus on F1

series), to enable its clock you have to use the

RCC_AHB1PeriphClockCmd(RCC_AHB1Periph_GPIOA, ENABLE);

function instead of:

RCC_APB2PeriphClockCmd(RCC_APB2Periph_GPIOA, ENABLE);

in the F1 series. Refer to Table3 on page13 for the peripheral bus mapping changes

between F2 and F1 series.

3.

Peripheral clock configuration

a) I2S: in STM32 F2 series the I2S clock can be derived either from a specific PLL

(PLLI2S) or from an external clock mapped on the I2S_CKIN pin. Refer to the

code given below, that should be used in both cases:

/******************************************************************************/

/* PLLI2S used as I2S clock source */

/******************************************************************************/

/* Select PLLI2S as I2S clock source */

RCC_I2SCLKConfig(RCC_I2S2CLKSource_PLLI2S);

/* Configure the PLLI2S clock multiplication and division factors

Note: PLLI2S clock source is common with the main PLL (configured in

RCC_PLLConfig function )

*/

RCC_PLLI2SConfig(PLLI2SN, PLLI2SR);

/* Enable PLLI2S */

RCC_PLLI2SCmd(ENABLE);

/* Wait till PLLI2S is ready */

while(RCC_GetFlagStatus(RCC_FLAG_PLLI2SRDY) == 0)

{

}

/* Enable I2Sx’s APB interface clock (I2S2/3 are subset of SPI2/3 peripherals) */

RCC_APB1PeriphClockCmd(RCC_APB1Periph_SPIx, ENABLE);

/******************************************************************************/

/* External clock used as I2S clock source */

/******************************************************************************/

/* Select External clock mapped on the I2S_CKIN pin as I2S clock source */

RCC_I2SCLKConfig(RCC_I2S2CLKSource_Ext);

/* Enable I2Sx’s APB interface clock (I2S2/3 are subset of SPI2/3 peripherals) */

RCC_APB1PeriphClockCmd(RCC_APB1Periph_SPIx, ENABLE);

b) USB OTG FS and SDIO: in STM32 F2 series the USB OTG FS requires a

frequency of 48 MHz to work correctly, while the SDIO requires a frequency of less

Doc ID 019001 Rev 1 39/52

Page 40

Firmware migration using the library AN3427

than or equal to 48 MHz to work correctly. The following is an example of the main

PLL configuration to obtain 120 MHz as system clock frequency and 48 MHz for

the OTG FS and SDIO.

/* PLL_VCO = (HSE_VALUE / PLL_M) * PLL_N = 240 MHz */

#define PLL_M 25

#define PLL_N 240

/* SYSCLK = PLL_VCO / PLL_P = 120 MHz */

#define PLL_P 2

/* USB OTG FS, SDIO and RNG Clock = PLL_VCO / PLLQ = 48 MHz */

#define PLL_Q 5

...

/* Configure the main PLL */

RCC_PLLConfig(RCC_PLLSource_HSE, PLL_M, PLL_N, PLL_P, PLL_Q, 0);

/* Wait till PLL is ready */

while(RCC_GetFlagStatus(RCC_FLAG_PLLRDY) == 0)

{

}

...

/* Enable USB OTG FS's AHB interface clock */

RCC_AHB2PeriphClockCmd(RCC_AHB2Periph_OTG_FS, ENABLE);

/* Enable SDIO's APB interface clock */

RCC_APB2PeriphClockCmd(RCC_APB2Periph_SDIO, ENABLE);

c) ADC: in STM32 F2 series the ADC features two clock schemes:

– Clock for the analog circuitry: ADCCLK, common to all ADCs. This clock is

generated from the APB2 clock divided by a programmable prescaler that allows

the ADC to work at f

/2, /4, /6 or /8. The maximum value of ADCCLK is 30

PCLK2

MHz when the APB2 clock is at 60 MHz. This configuration is done using the ADC

registers.

– Clock for the digital interface (used for register read/write access). This clock is

equal to the APB2 clock. The digital interface clock can be enabled/disabled

individually for each ADC through the RCC APB2 peripheral clock enable register

(RCC_APB2ENR). However, there is only a single bit to reset the three ADCs at

the same time.

/* Enable APB interface clock for ADC1, ADC2 and ADC3 */

RCC_APB2PeriphClockCmd(RCC_APB2Periph_ADC1 | RCC_APB2Periph_ADC2 |

RCC_APB2Periph_ADC3, ENABLE);

/* Reset ADC1, ADC2 and ADC3 */

RCC_APB2PeriphResetCmd(RCC_APB2Periph_ADC, ENABLE);

RCC_APB2PeriphResetCmd(RCC_APB2Periph_ADC, DISABLE);

4.3 FLASH

The table below presents the correspondence between the FLASH driver APIs in the

STM32F10x and STM32F2xx Libraries. You can easily update your application code by

replacing STM32F10x functions by the corresponding function in STM32F2xx Library.

40/52 Doc ID 019001 Rev 1

Page 41

AN3427 Firmware migration using the library

Table 13. STM32F10x and STM32F2xx FLASH driver API correspondence

STM32F10x Flash driver API STM32F2xx Flash driver API

void FLASH_SetLatency(uint32_t

FLASH_Latency);

void

FLASH_PrefetchBufferCmd(uint32_t

FLASH_PrefetchBuffer);

void FLASH_SetLatency(uint32_t FLASH_Latency);

void FLASH_PrefetchBufferCmd(FunctionalState

NewState);

void

FLASH_HalfCycleAccessCmd(uint32_t

NA

FLASH_HalfCycleAccess);

NA

void FLASH_InstructionCacheCmd(FunctionalState

NewState);

NA void FLASH_DataCacheCmd(FunctionalState NewState);

Interface configuration

NA void FLASH_InstructionCacheReset(void);

NA void FLASH_DataCacheReset(void);

void FLASH_ITConfig(uint32_t

FLASH_IT, FunctionalState NewState);

void FLASH_ITConfig(uint32_t FLASH_IT, FunctionalState

NewState);

void FLASH_Unlock(void); void FLASH_Unlock(void);

void FLASH_Lock(void); void FLASH_Lock(void);

FLASH_Status

FLASH_ErasePage(uint32_t

Page_Address);

FLASH_Status

FLASH_EraseAllPages(void);

FLASH_Status

FLASH_EraseOptionBytes(void);

NA

FLASH_Status

FLASH_ProgramWord(uint32_t Address,

Memory Programming

uint32_t Data);

FLASH_Status

FLASH_ProgramHalfWord(uint32_t

Address, uint16_t Data);

NA

FLASH_Status FLASH_EraseSector(uint32_t

FLASH_Sector);

FLASH_Status FLASH_EraseAllSectors(void);

NA

FLASH_Status FLASH_ProgramDoubleWord(uint32_t

Address, uint64_t Data);

FLASH_Status FLASH_ProgramWord(uint32_t Address,