AN3424

Application note

STEVAL-ILL042V1: high power factor flyback LED driver

based on the L6562A and TSM101

Introduction

The high-PF flyback configuration, used to drive a new design of the 60 W LED array, is

based on the L6562A and the TSM101 controller (Figure 1).

This configuration uses an isolated feedback with an optocoupler and a secondary side

r e fe r e n c e/ e r ro r a m p l if i e r, t h e T S M 1 0 1, fo r vo l ta g e an d cu r r en t re g u la t i on .

T h e T S M 1 0 1 i n c l u d e s t w o o p a m p s : o n e o p a m p i s u s e d f o r c o n s t a n t v o l t a g e c o n t r o l

and the other for constant current control. A precise internal current generator, available,

can be used to offset the intervention threshold of the constant current regulation.

The L6562A is a PFC controller operating in transition-mode. The highly linear multiplier

includes a special circuit, able to reduce AC input current distortion, that allows wide-rangemains operation with an extremely low THD, even over a large load range.

The TSM101 compares the DC voltage and current level of a switching power supply to an

internal reference. It provides a feedback through an optocoupler to the L6562A controller in

the primary side.

This system, designed by using the L6562A and the TSM101 controller, offers more

advantages in terms of output current and voltage stability.

The input capacitance is so small here that the input voltage is very close to a rectified

sinewave. Besides, the control loop has a narrow bandwidth so as to be little sensitive to the

twice-mains frequency ripple appearing at the output.

Efficiency is high at heavy load, more than 90% is achievable: TM operation ensures slow

turn-on losses in the MOSFET and the high PF reduces dissipation in the bridge rectifier.

The output voltage exhibits a considerable twice-mains frequency ripple, unavoidable if a

high PF is desired. Speeding up the control loop may lead to a compromise between a

reasonably low output ripple and a reasonably high PF. To keep the ripple low, a large output

capacitance (in the thousand F) is anyway required.

Figure 1. Board image

November 2011 Doc ID 018991 Rev 1 1/22

www.st.com

Contents AN3424

Contents

1 Board block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2 Electrical schematic and bill of material . . . . . . . . . . . . . . . . . . . . . . . . . 5

3 Design and calculation parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4 Thermal measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5 EMC tests results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6 Conclusions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

7 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2/22 Doc ID 018991 Rev 1

AN3424 List of figures

List of figures

Figure 1. Board image . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Figure 2. 60 W LED driver block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Figure 3. Electrical schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Figure 4. High-PF flyback characteristic functions: F1(x) diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Figure 5. High-PF flyback characteristic functions: F2(x) diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Figure 6. Flyback characteristic functions: F3(x) diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Figure 7. 60 W high-PF with L6562 and TSM101: electrical schematic. . . . . . . . . . . . . . . . . . . . . . . 13

Figure 8. Pin vs. Vin. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Figure 9. THD vs. Vin. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Figure 10. PF vs. Vin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 11. Efficiency vs. Vin. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 12. Startup @ 230 V L6562A Vcc (red) MOSFET drain voltage (brown) . . . . . . . . . . . . . . . . . 15

Figure 13. Startup 230 V - Iout (green), Vout (blue), L6562A Vcc (red) . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 14. Vin, Iin. PFC @ 185 V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 15. Vin, Iin. PFC @ 230 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 16. Vin, Iin. PFC @ 265 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 17. Peak measure: line wire . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 18. Peak measure: neutral wire . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Doc ID 018991 Rev 1 3/22

Board block diagram AN3424

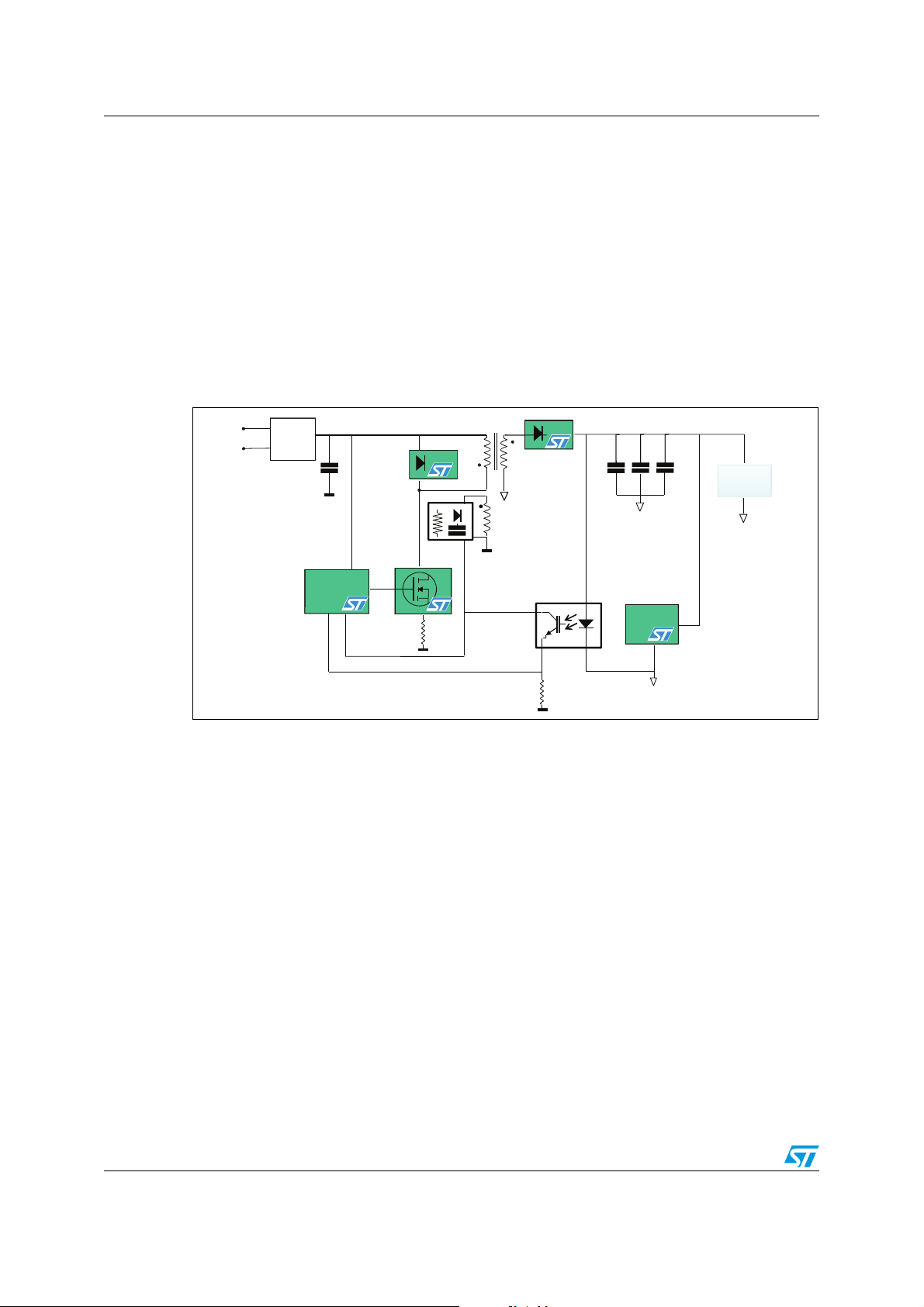

1 Board block diagram

Figure 2 shows a block diagram of the system. The complete circuit is made up of two

stages:

● The flyback converter which regulates the output voltage and performs the power factor

correction.

● The current and voltage controller stage which regulates the current and voltage output

feedback.

This topology, thanks to STMicroelectronics ICs L6265A and TSM101, realizes a high-PF

flyback converter with voltage and current output regulation.

Figure 2. 60 W LED driver block diagram

Filter

Mains

+

Bridge

LED

L6562A

TSM101

AM10530v1

4/22 Doc ID 018991 Rev 1

AN3424 Electrical schematic and bill of material

5

D5

1MOhm

5

D5

1MOhm

L6562AT

L6562AT

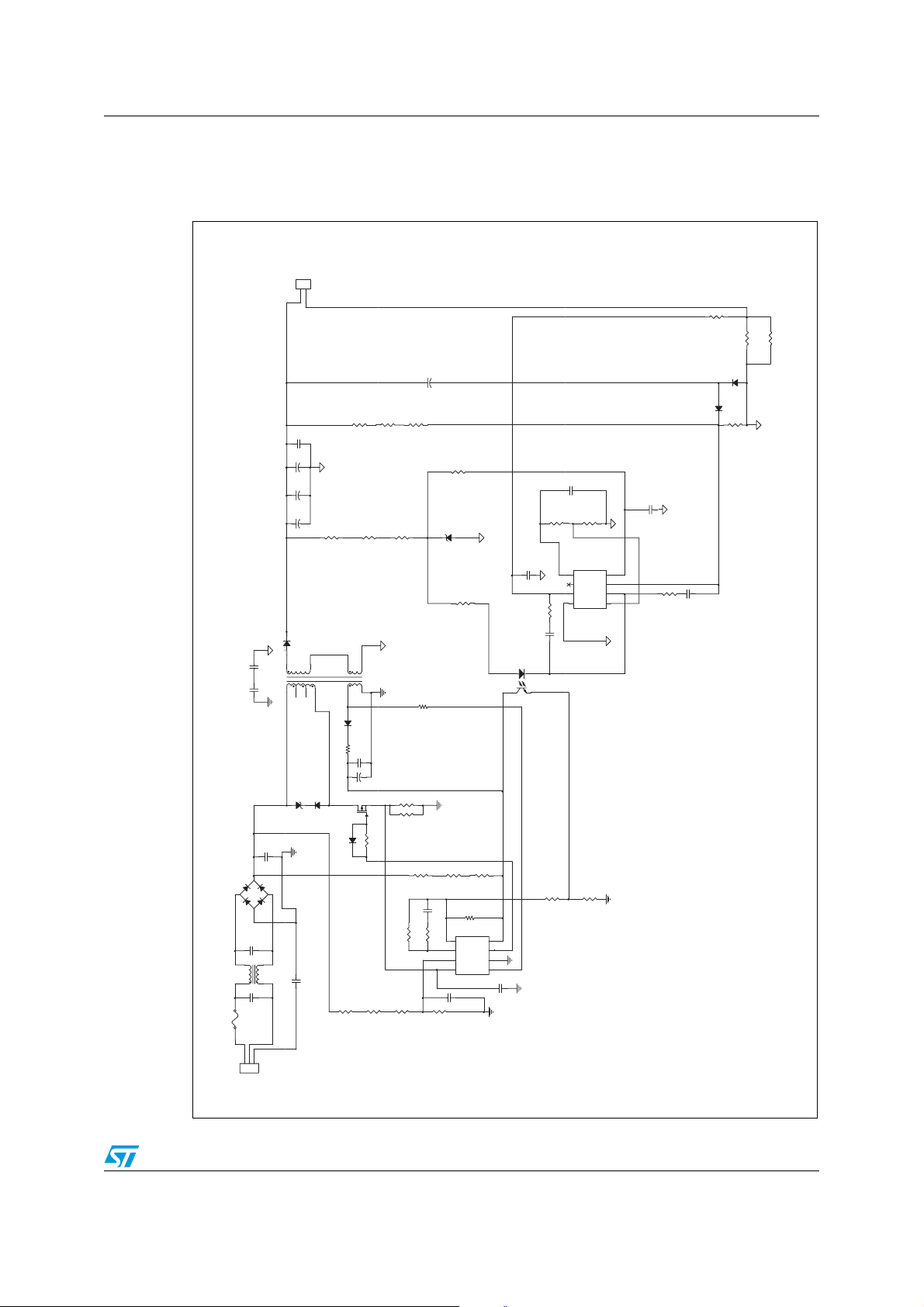

2 Electrical schematic and bill of material

Figure 3. Electrical schematic

J1

CON2

Vout=130 Vac, Iout=0.462A

1

2

R39

18 Ohm

C22

4.7 uF 160V

R37

R19

20 kOhm

68 kOhm

R32

68 kOhm

C13

100 nF

100 Ohm

C24

330uF, 160V

C10

330uF, 160V

R33

12 kOhm

R14

C9

12 kOhm

330uF, 160V

R16

12 kOhm

R15

C25

100 nF 25V

R41

10 kOhm

R42

D9

18V 0.5W

2 kOhm

C27

1uF 50V

D8

D7

TMMBAT46

R17

R43

R40

1.2 Ohm, 1%

1.2 Ohm, 1%

TMMBAT46

1.5 kOhm

C26

C16

2A 1000V

2

L3

2x47mH, 1.5A

F1

3

J3

T1

2.2n-Y1- 250V

2.2n-Y1- 250V

C20

2200nF- 630VDC

1

3

BR1

-+

4

C1B

100nF X2 Cap

43

12

C1A

100nF X2 Cap

FUSE 1A

1

2

CON3

C28

1uF 50V

Vref

VCC

1

8

Csense

Vrin

2

7

Crref

R18

15 kOhm

R38

10KOhm

C19

1uF

STTH2L06

12

10

9

TRAFO

2

4

3

D6

1.5KE350A

D1

C21

1n-Y1- 250V

7

6

D3

TMMBAT46

10 Ohm

R4

C18

100 nF, 50V

C15

STTH1L06

47uF, 35V

Q1

STP7N95K3

R35

D4

TMMBAT46

R29

R30

1 MOhm

R5

68 kOhm

R25

1.1Ohm 0.25W

R44

1.1Ohm 0.25W

R31

100 kOhm

100 kOhm

R34

C14

1nF 25V

R22

82 kOhm

R21

INV

1

0 Ohm

COMP

2

MULT

3

CS

4

C17

2.2nF

8.2 kOhm

R26

R27

1 MOhm

1 2

4 3

ISO1

OPTO ISOLATOR-A

R28

100 kOhm

R36

680k

VCC

8

GD

7

GND

6

ZCD

5

U3

R23

C23

150 pF 25V

Output

3

6

Gnd4Crin

5

U5

TSM101

R24

30 kOhm

2.2kOhm

R20

47kOhm

C29

1uF 50V

Vin=185 to 265 Vac

AM10531v1

Doc ID 018991 Rev 1 5/22

Electrical schematic and bill of material AN3424

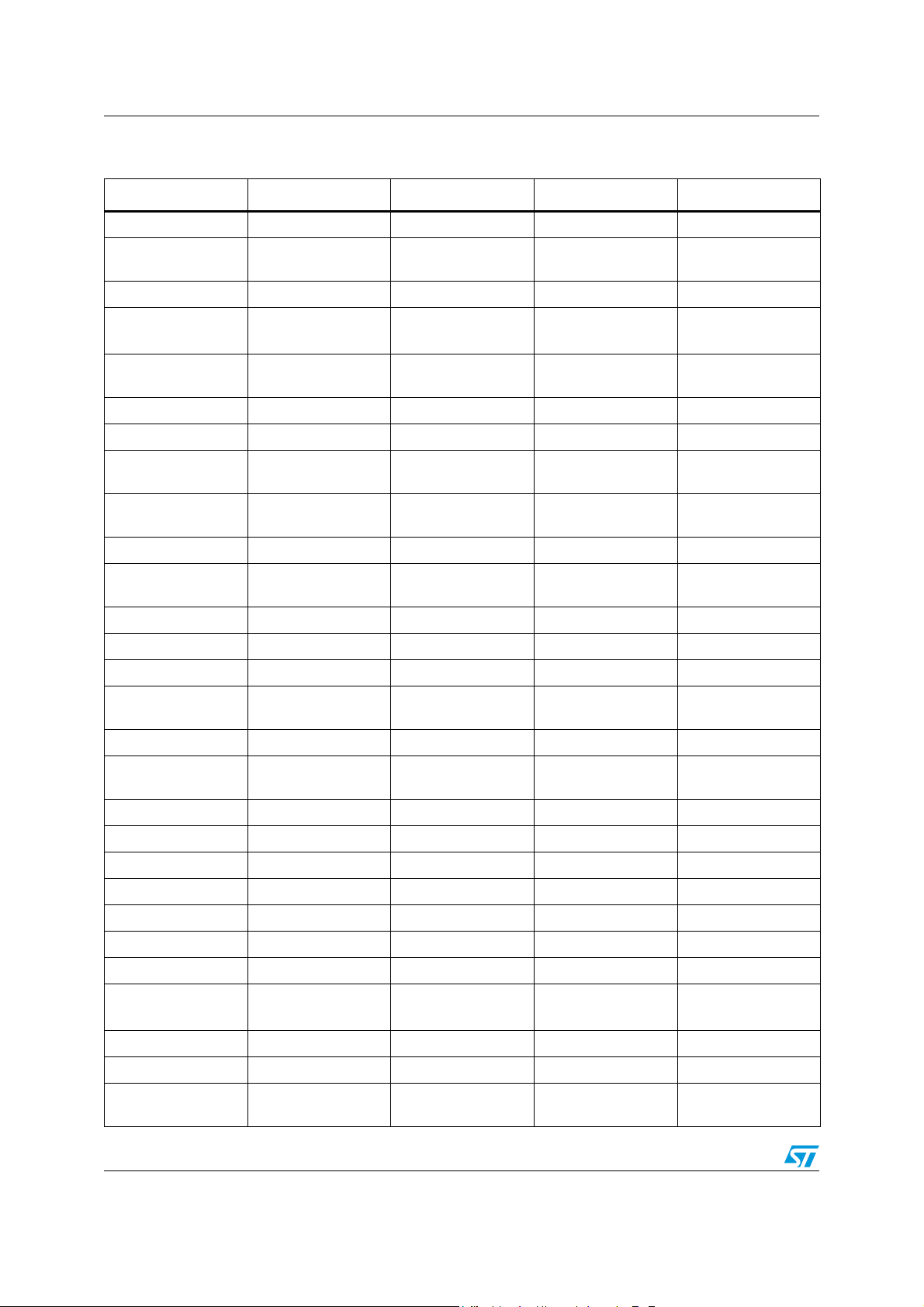

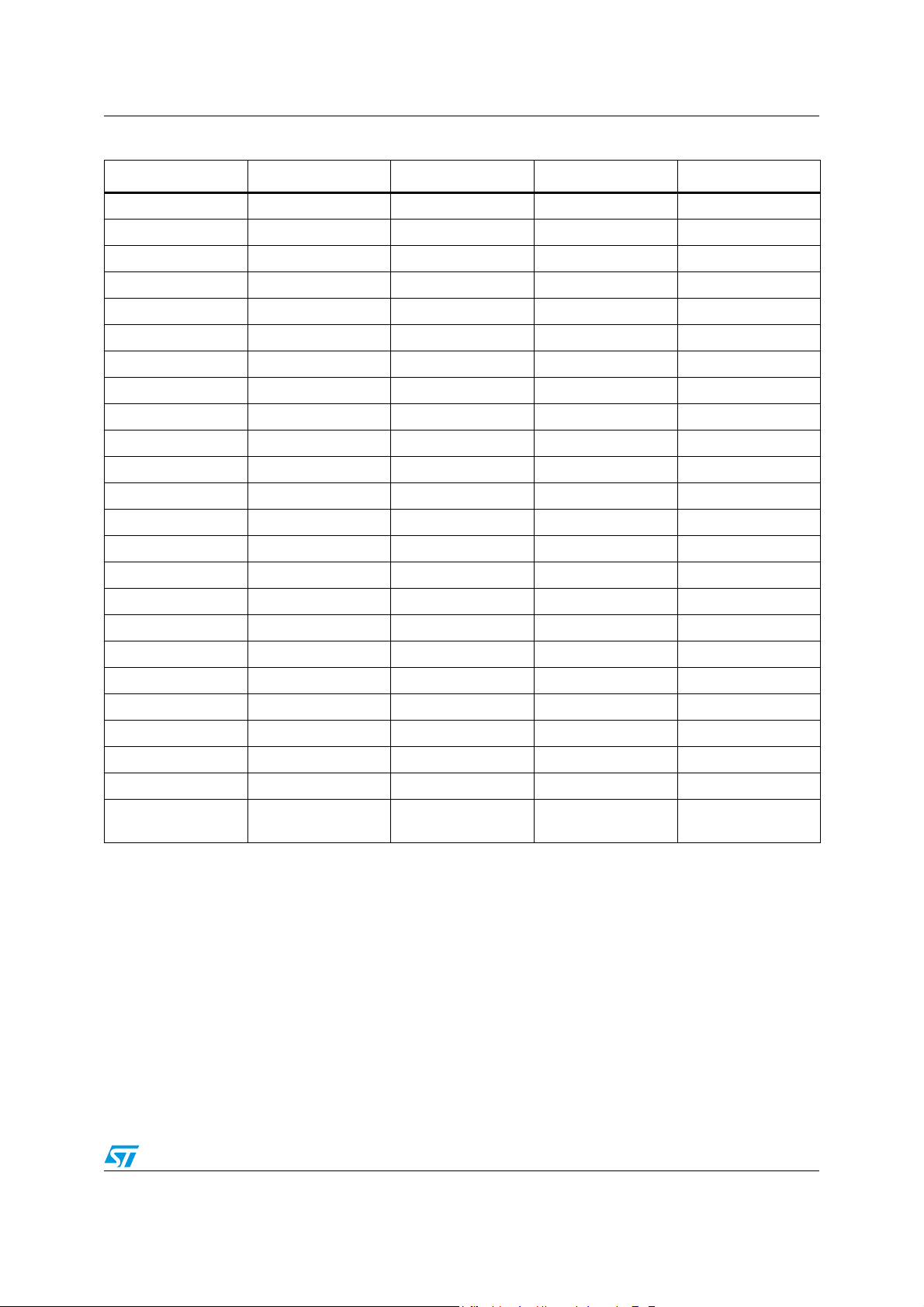

Table 1. Bill of material

Reference Value Rated Type Manufacturer

BR1 2 A/1000 V

C1A, C1B 100 nF 275 Vac

C9, C10, C24 330 µF 160 Vdc Electrolytic capacitor

C13 100 nF 250 Vdc

C14 1 nF 25 Vdc

C15 47 µF 35 Vdc Electrolytic capacitor

C16, C26 2.2 nF 250 Vac Y1 capacitor

C17 2.2 nF

C18 100 nF 50 Vdc

C19, R38 220 nF, 100 kΩ

C20 220 nF 630 Vdc

C21 1 nF 250 Vac Y1 capacitor

C22 4.7 µF 160 Vdc Electrolytic capacitor

C23 150 pF 25 V Capacitor

C25 100 nF 25 Vdc

C27, C29 1 µF 50 Vdc Ceramic capacitor

Polypropylene film

capacitor X2

Polyester

capacitor

COG ceramic

capacitor

X7R ceramic

capacitor

X7R ceramic

capacitor

Polypropylene film

capacitor

X7R ceramic

capacitor

C28 10 nF 50 Vdc

D1 STTH1R06 1 A/600 V Ultrafast diode STMicroelectronics

D3, D4 TMMBAT 46 100 V STMicroelectronics

D5 STTH2L06 2 A/600 V Ultrafast diode STMicroelectronics

D6 1.5KE350A 350 V/1.5 kW Transil STMicroelectronics

D7, D8 TMMBAT 46 150 mA/100 V STMicroelectronics

D9 18 V/0.5 W Zener diode

F1 1 A/250 V Fuse

ISO1 PC817

J1 CON2

J3 CON3

L3 2 x 47 mH 1.1 A

6/22 Doc ID 018991 Rev 1

X7R ceramic

capacitor

OPTO

ISOLATOR-A

Common mode

choke

AN3424 Electrical schematic and bill of material

Table 1. Bill of material (continued)

Reference Value Rated Type Manufacturer

Q1 STP7N95K3 950 V/1.1 Ω SuperMESH™III STMicroelectronics

R4, R35 10 Ω 0.25 W

R5, R19, R32 68 kΩ 0.25 W, 1%

R14, R16, R33 12 kΩ 0.25 W

R15 100 Ω 0.25 W

R17 1.5 kΩ 0.25 W

R18 15 kΩ 0.25 W

R20 47 kΩ 0.25 W

R22 82 kΩ

R23 30 kΩ

R24 2.2 kΩ 1%

R25, R44 1.1 Ω 0.25 W, 1% Metal film resistor

R26, R29, R30 1 MΩ 0.25 W, 1%

R27 8.2 kΩ 0.25 W, 1%

R28, R31, R34 100 kΩ 0.25 W

R36 680 kΩ 0.25 W, 1%

R37 20 kΩ 0.25 W

R39 18 Ω 0.25 W

R40, R43 1.2 Ω 0.25 W, 1% Metal film resistor

R41 10 kΩ 1%

R42 2 kΩ 1%

T1 TRAFO 0.9 mH

U3 L6562A TM, PFC controller STMicroelectronics

U5 TSM101

Voltage and current

controller

STMicroelectronics

Doc ID 018991 Rev 1 7/22

Design and calculation parameters AN3424

3 Design and calculation parameters

Figure 4. High-PF flyback characteristic functions: F1(x) diagram

Figure 5. High-PF flyback characteristic functions: F2(x) diagram

The following is a step-by-step design of the L6562A-based high-PF flyback converter:

1. Design specifications:

– Mains voltage range: V

– Minimum mains frequency: f

– DC output voltage: V

out

= 185 Vac, V

ACmin

= 47 Hz

L

= 130 V

– Maximum output current: Iout = 0.462 A

– Maximum 2fL output ripple: ΔV

% = 1.0%

O

2. Pre-design choices:

– Minimum switching frequency: f

– Reflected voltage: V

= 195 V

R

SWmin

= 57 Kz

– Leakage inductance spike: Vspike; 100 V

– Expected efficiency: 92%

3. Preliminary calculations:

– Minimum input peak voltage: (4 V

total drop on R

8/22 Doc ID 018991 Rev 1

DS(ON, RS, …)

V

PKminVACmin

ACmax

= 265 Vac

2 185 2 4V–⋅=⋅ 257V==

AN3424 Design and calculation parameters

– Maximum input peak voltage:

– Maximum output power:

– Maximum input power:

– Peak-to-reflected voltage ratio:

P

V

PKmin

P

OUTVoutIout

P

out

= 10 0

in

η

K

100

V

60

92

V

V

V

ACmax

2 265 2 4V–⋅=⋅ 371V==

130 0.462⋅=⋅ 60W==

65.2W

=⋅=⋅

257

minPK

R

=1.32

==

195

– Characteristic functions value: F1(1.32) = 0.35, F2(1.32) = 0.24, F3(1.32) = 0.20

4. Operating conditions:

– Peak primary current: I

– RMS primary current: I

– Peak secondary current: I

– RMS secondary current: I

PKp

RMSp

PKs

RMSs

=

=

⋅

P2

in

⋅

I

PKp

=

⋅

⋅

=

)K(2FV

Vmi nPK

)K(2F

V

3

I2

out

=

)K(2FK

VV

KI

VPKs

⋅

2.652

=

11.2

⋅

462.02

⋅

)K(3F

V

3

=

24.06,257

24.0

3

=

2.11A

0.595A

=⋅=⋅

2.916A

32.1916.2

3

⋅

24.032.1

Figure 6. Flyback characteristic functions: F3(x) diagram

2.0

0.865A

=⋅⋅=⋅⋅

5. Primary inductance: Lp=

– Primary-to-secondary turns ratio:

– Minimum area product calculation:

Pmin

⎡

=

⎢

⎢

⎣

⋅

P460

in

⋅+⋅

Doc ID 018991 Rev 1 9/22

A

V

mi nPK

316.1

⎤

⎥

⎥

)K(2F)K1(f

VVminSW

⎦

=

⋅⋅+

If)K1(

PKpminSWV

V

n

R

=

⎡

=

⎢

⎢

⎣

=

+

)VV(

fout

3

6.257

3

195

+

⋅

2.65460

⋅+⋅⋅

=

11.21057)32.11(

⋅⋅⋅+

1.49

=

)6.0130(

316.1

⎤

⎥

24.0)32.11(1057

⎥

⎦

mH922.0

=0.363cm

4

Design and calculation parameters AN3424

This calculation highlights that the minimum AP required is about 0.36 cm4. An ETD34 core

(AP = 1.1175 cm

simultaneously L

4

) is used. This value of APmin reduces the number of turns N and

is reduced (leakage inductance) as reported in the following formulas:

lk

Equation 1

Ll

AAAAAP

=⋅=⋅=

weNminmin

⋅

e

N

⋅μ⋅μ

oe

so, with primary and secondary inductance in the transformer fixed, the AP

L

=

22

Nk

⋅

is inversely

min

proportional to the square of the turns N.

This reduces strongly the power dissipation in the clamp network by increasing the system

efficiency.

The ferrite used is N87, which guarantees low losses and high saturation.

Table 2. Gapped

Material g (mm) AL value approx. nH µ

0.20 ± 0.02

N87

0.50 ± 0.05

1.00 ± 0.05

In this specific design g =

≈1 mm, A

482

251

153

is the inductance referred to number of turns = 1:

L

310

161

98

e

Equation 2

where:

● µ

● A

, µ0 are respectively effective permeability and magnetic field constant

e

is effective magnetic cross section

e

Table 3. Calculation factors

Relationship between air

Material

N87 153 -0.713 240 -0.796 222 -0.873

gap - A

K1 (25 °C) K2 (25 °C) K3 (25 °C) K4 (25 °C) K3 (25 °C) K4 (25 °C)

value

L

Note: K1, K2:0.10 mm<s<2.50 mm.

K3, K4: 80 nH<A

<780 nH.

L

L

A

L

2

N

μ⋅μ

==

oe

l

e

A

e

Calculation of saturation current

10/22 Doc ID 018991 Rev 1

AN3424 Design and calculation parameters

6. MOSFET selection:

Maximum drain voltage: V

DSmax

= V

PKmax+VR

+ΔV = 372 + 195 + 100 = 667 V

There is some margin to select a 950 V device. This minimizes gate drive and

capacitive losses. Assuming that the MOSFET dissipates 5% of the input power, that

losses are due to conduction only, and that R

R

at 25 °C should be about 2 Ω. An STP7N95K3 (R

DS(on)

doubles at working temperature, the

DS(on)

1.35 Ω max.) in TO-220

DS(on)

Zener-protected SuperMESH3 is selected.

7. Catch diode selection:

V

Maximum drain voltage: .

V

maxREV

maxPK

V

n

out

371

493.1

378V

=+=+= 130

A suitable device is an STTH3L06, a TURBO 2 ultrafast high voltage rectifier with

I

= 3 A (minimum current rating is 1.166 A), V

F

= 600 V (V

RRM

RRM>VREVmax

).

From the relevant datasheet the power dissipation is estimated as:

Equation 3

2

IRIVP

RMSsthou tfout

=⋅+⋅=

0.89 0.462 0.055 0.8620.45W=⋅+⋅

This means , acceptable value.

T

jTambRthPout

75 75 0.45⋅+=⋅+ 108.75°C==

8. Output capacitor selection:

The minimum capacitance value that meets the specification on the 100/120 Hz ripple

is:

Equation 4

I

C

mi nout

1

=

f

⋅π

L

)K(2H

out

V

)K(2F

V

=

⋅⋅

V

Δ

o

462.0*

124.04714.3

⋅⋅⋅

F1025

μ=

Three 330 µF electrolytic capacitors have an ESR low enough (max. 446 mΩ) to consider

the high frequency ripple negligible as well as sufficient AC capability.

9. Clamp network:

With a proper construction technique, the leakage inductance can be reduced less than

1% of the primary inductance, which it is in the present case. A Transil clamp is

selected.

The clamp voltage is V

= VR+ΔV = 195 + 100 = 295 V. The steady-state power

CL

dissipation is estimated to be about 1 W. A 1.5KE350A Transil is selected. The blocking

diode is an STTH1L06.

10. Multiplier bias and sense resistor selection:

Assuming a peak value of 2.6 (@ V

peak value at minimum line voltage is V

= 265 V) on the multiplier input (MULT, 3) the

AC

185

--------- -

MULTpkmin

2.6

= which,

265

1.81V=⋅

multiplied by the maximum slope of the multiplier, 1, gives 1.81 V peak voltage on

current sense (CS, pin 4).

Since the linearity limit (3 V) is not exceeded, this is acceptable. The driver ratio is

then . Considering 260 µA for the divider, the lower resistor

2.6

-------------------------- 6.93 10

2265⋅()

3–

⋅=

Doc ID 018991 Rev 1 11/22

Design and calculation parameters AN3424

is 10 kΩ, and the upper one 1 MΩ. Choose the sense resistor 0.5 Ω, while its

power rating is .

PS0.5 I

2

RMSp

0.5 0.5952177m W=⋅=⋅=

11. Feedback and control loop:

The selected optocoupler is an ISO1-CNY-17.

The TSM101 is a voltage and current controller that regulates the output and current

voltage provided to the LED.

By considering V

V band-gap voltage reference, the V

= 130 V and that the value at pin 7 is compared to the internal 1.24

out

pin7

is:

Equation 5

VV

R

6

130

⋅=

out7pin

RR

+

76

⋅=

k5.1

k156k5.1

+

V24.1

=

with R6 = 1.5 kΩ, R7 = 156 kΩ.

= 0.6 Ω is the sense resistor used for current measurement. The current regulation

R

5

is effective when the voltage drop across it is equal to the voltage on pin 5 of TSM101.

For medium currents (<1 A), a voltage drop across R

R

can be realized with standard low cost 0.4 W resistors in parallel.

5

of 200 mV = VR5 is a good value,

5

Equation 6

V

R

5R

5

Ich

(two 1.2 Ω resistors in parallel)

Ω== 57.0

R2 and R3 can be chosen using the following formula:

Equation 7

⎛

⎜

RR

⋅=

32

⎜

⎝

Fixed R3 = 2 kΩ, we can have R2 = 10 kΩ.

⎞

VV

−

5Rref

⎟

V

⎟

5R

⎠

12/22 Doc ID 018991 Rev 1

AN3424 Design and calculation parameters

The complete electrical schematic of this application is illustrated in Figure 7.

Figure 7. 60 W high-PF with L6562 and TSM101: electrical schematic

Vout

2.2uF

18O

3x330uF

36kO

1.5KE350A

STTH1L06

10O

18kO

10O

100nF

47uF

18V

R7=156kO

0.5W

R5

2x1.2O

LL4148

LL4148

R6=1.5kO

5

3

8

TSM101

6

4

R2=10kO R3=2kO

1

7

47kO

68kO

100nF

1uF

0.5O

STP7N95K3

1N4148

1MO

2.2nF

100nF

+

Filter

Bridge

Mains

10O

10kO

3

7

4

150pF

L6562

8

2

300kO

1nF

750kO

65

1

0O

30kO

2.2kO

AM10535v1

Doc ID 018991 Rev 1 13/22

Design and calculation parameters AN3424

12. Experimental results:

These results have been obtained at input voltage between 185 and 265 V.

Ambient temperature: 23 °C

–V

–I

–P

= 118.7 V

OUT

= 358 mA

OUT

= 42.5 W

OUT

Figure 8. Pin vs. Vin

Figure 9. THD vs. Vin

14/22 Doc ID 018991 Rev 1

AN3424 Design and calculation parameters

Figure 10. PF vs. Vin

Figure 11. Efficiency vs. Vin

Figure 12. Startup @ 230 V L6562A Vcc (red) MOSFET drain voltage (brown)

Doc ID 018991 Rev 1 15/22

Design and calculation parameters AN3424

Figure 13. Startup 230 V - Iout (green), Vout (blue), L6562A Vcc (red)

Figure 14. Vin, Iin. PFC @ 185 V

Figure 15. Vin, Iin. PFC @ 230

16/22 Doc ID 018991 Rev 1

AN3424 Design and calculation parameters

Figure 16. Vin, Iin. PFC @ 265 V

Doc ID 018991 Rev 1 17/22

Thermal measurements AN3424

4 Thermal measurements

These measurements were performed at ambient temperature of 25 °C and at minimum

input voltage (185 V, worst case for PFC section).

Thermal measurement on the power device was performed on the board using infrared

thermocamera FLUKE.

For the PFC section, the temperature was measured on the power MOSFET and on the

diode.

On the power MOSFET with a mounted heatsink, having thermal resistance R

°C/W, the temperature on the top of the package was 40 °C. On the top of the Transil diode

the temperature was 35 °C, for the clamp diode 35 °C, for the IC driver 47 °C, and for the

output diode 55 °C.

= 11.40

th

18/22 Doc ID 018991 Rev 1

AN3424 EMC tests results

5 EMC tests results

EMC test was conducted according to the EN55015A standard.

The test was performed using the following apparatus:

● EMC ANALYZER Agilent E7401A

● LISN EMCO model 3825/2, 50 Ω, 10 kHz - 100 MHz.

The test was performed using peak detector and the limits of average and quasi peak of EN

55015A standard in the range 150 kHz - 30 MHz at 230 V 50 Hz input voltage.

Figure 17. Peak measure: line wire

In Figure 17 it is possible to observe that the conduced emissions are out of the limits in the

range 5 - 6 MHz.

Figure 18. Peak measure: neutral wire

Doc ID 018991 Rev 1 19/22

Conclusions AN3424

6 Conclusions

The high-PF flyback configuration used to drive a new design of the 60 W LED array and

based on the PFC L6562A and on the voltage and current TSM101 controller works

correctly in a single range [185 - 265] V. In the same range the efficiency is very high, more

than 92% (

Thermal measurements show that the power MOSFET reaches T = 40 °C.

Thanks to the TSM101, the system offers an excellent LED current regulation in terms of

current precision and works properly in all input conditions and output load, by offering high

performance with a simple and reliable design.

Figure 11).

20/22 Doc ID 018991 Rev 1

AN3424 Revision history

7 Revision history

Table 4. Document revision history

Date Revision Changes

08-Nov-2011 1 Initial release.

Doc ID 018991 Rev 1 21/22

AN3424

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY TWO AUTHORIZED ST REPRESENTATIVES, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2011 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Philippines - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

22/22 Doc ID 018991 Rev 1

Loading...

Loading...