AN3392

Application note

Designing with the SPV1020, an interleaved boost converter with

MPPT algorithm

By Domenico Ragonese, Massimiliano Ragusa

Introduction

The SPV1020 is a monolithic DC-DC boost converter designed to maximize the power

generated by photovoltaic panels independent of temperature and the amount of solar

radiation. The optimization of the power conversion is obtained with embedded logic which

performs the MPPT (maximum power point tracking) algorithm on the PV cells connected to

the converter.

One or more converters can be housed in the junction box of PV panels, replacing the

bypass diodes. Because of the fact that the maximum power point is locally computed, the

efficiency at system level is higher compared to the use of conventional topologies, where

the MPPT is computed in the main centralized inverter.

For a cost effective application and miniaturized solution, the SPV1020 embeds the Power

MOSFETs for active switching and synchronous rectification, minimizing the number of

external devices. Furthermore, the 4-phase interleaved topology of the DC-DC converter

avoids the use of electrolytic capacitors, which can severely limit the system lifetime.

The SPV1020 operates at fixed frequency in PWM mode, where the duty cycle is controlled

by embedded logic running a Perturb&Observe MPPT algorithm. The switching frequency,

internally generated and set by default at 100 kHz, is externally adjustable, while the duty

cycle can range from 5% to 90% in steps of 0.2%.

Safety of the application is guaranteed by stopping the drivers in the case of output

overvoltage or overtemperature.

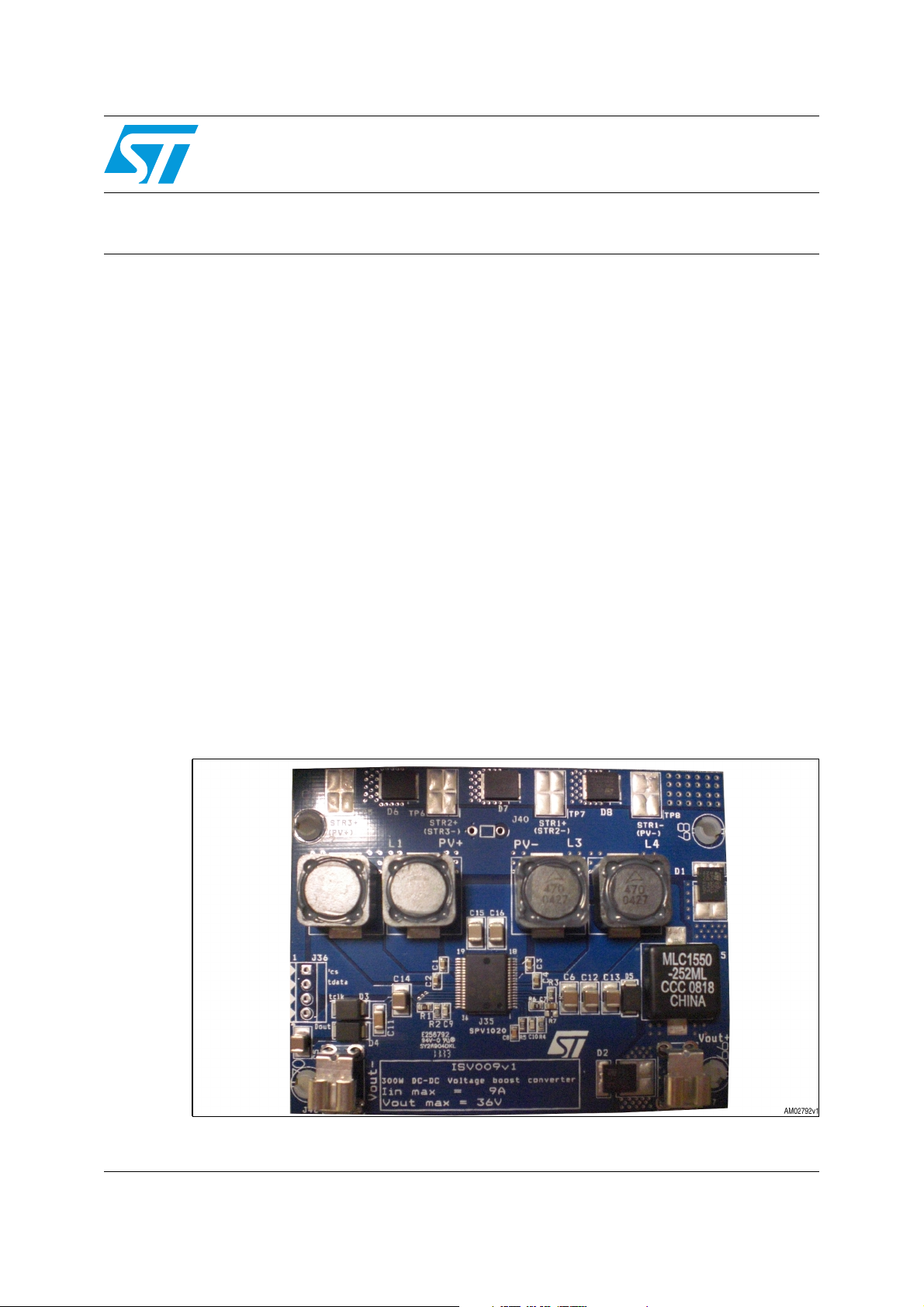

Figure 1. STEVAL-ISV009V1 demonstration board

May 2012 Doc ID 018749 Rev 1 1/57

www.st.com

Contents AN3392

Contents

1 Application overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2 Application information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3 SPV1020 description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4 Output voltage ripple . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5 Application efficiency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

6 SPV1020 functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

6.1 Operating modes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

6.2 OFF-state . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

6.3 Burst mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

6.4 Normal/MPPT mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

7 Voltage regulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

7.1 Overvoltage protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

7.2 Overcurrent protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

7.3 Current balance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

7.4 SPI serial peripheral interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

8 Pin description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

8.1 Pin connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

9 Absolute maximum ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

10 External component selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

10.1 Power and thermal considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

10.2 Inductor selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

10.3 Bootstrap capacitors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

10.4 Internal voltage rail capacitors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

10.5 Input voltage capacitors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

10.6 Input voltage partitioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

2/57 Doc ID 018749 Rev 1

AN3392 Contents

10.7 Input voltage sensing capacitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

10.8 Output voltage capacitors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

10.9 Output voltage partitioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

10.10 Output voltage sensing capacitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

10.11 Internal oscillator frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

10.12 Diode selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

10.13 Protection devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

10.14 Pole-zero compensation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

11 Layout guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

12 Bill of material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Appendix A STEVAL-ISV009V1 application diagram. . . . . . . . . . . . . . . . . . . . . . 40

Appendix B SPV1020 parallel and series connection . . . . . . . . . . . . . . . . . . . . . 41

B.1 SPV1020 parallel connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

B.2 SPV1020 series connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Appendix C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

C.1 Power efficiency, MPPT efficiency and thermal analysis. . . . . . . . . . . . . . 46

13 Package mechanical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

14 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Doc ID 018749 Rev 1 3/57

List of figures AN3392

List of figures

Figure 1. STEVAL-ISV009V1 demonstration board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

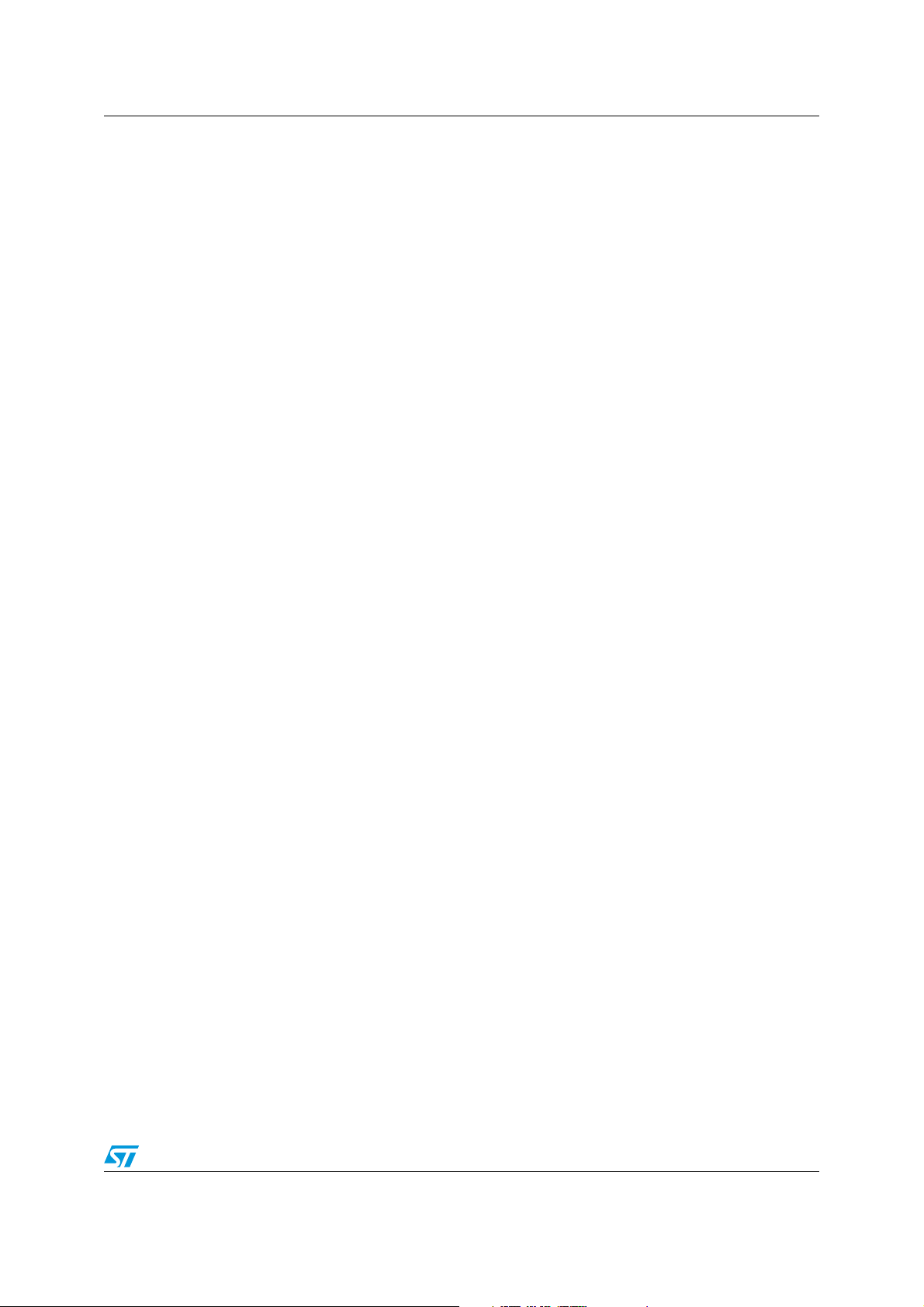

Figure 2. SPV1020 output series connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

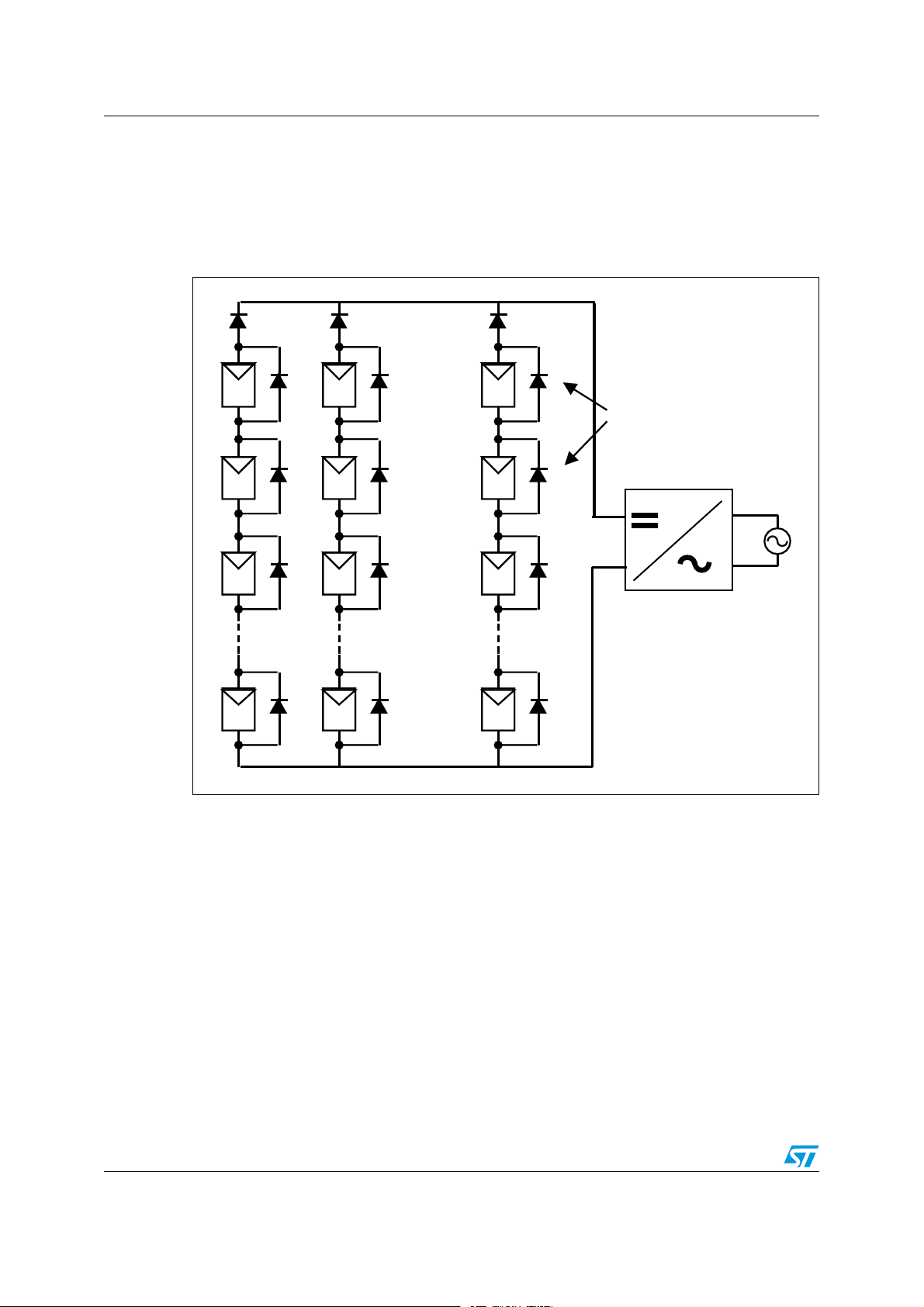

Figure 3. Photovoltaic system with multi-string inverter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

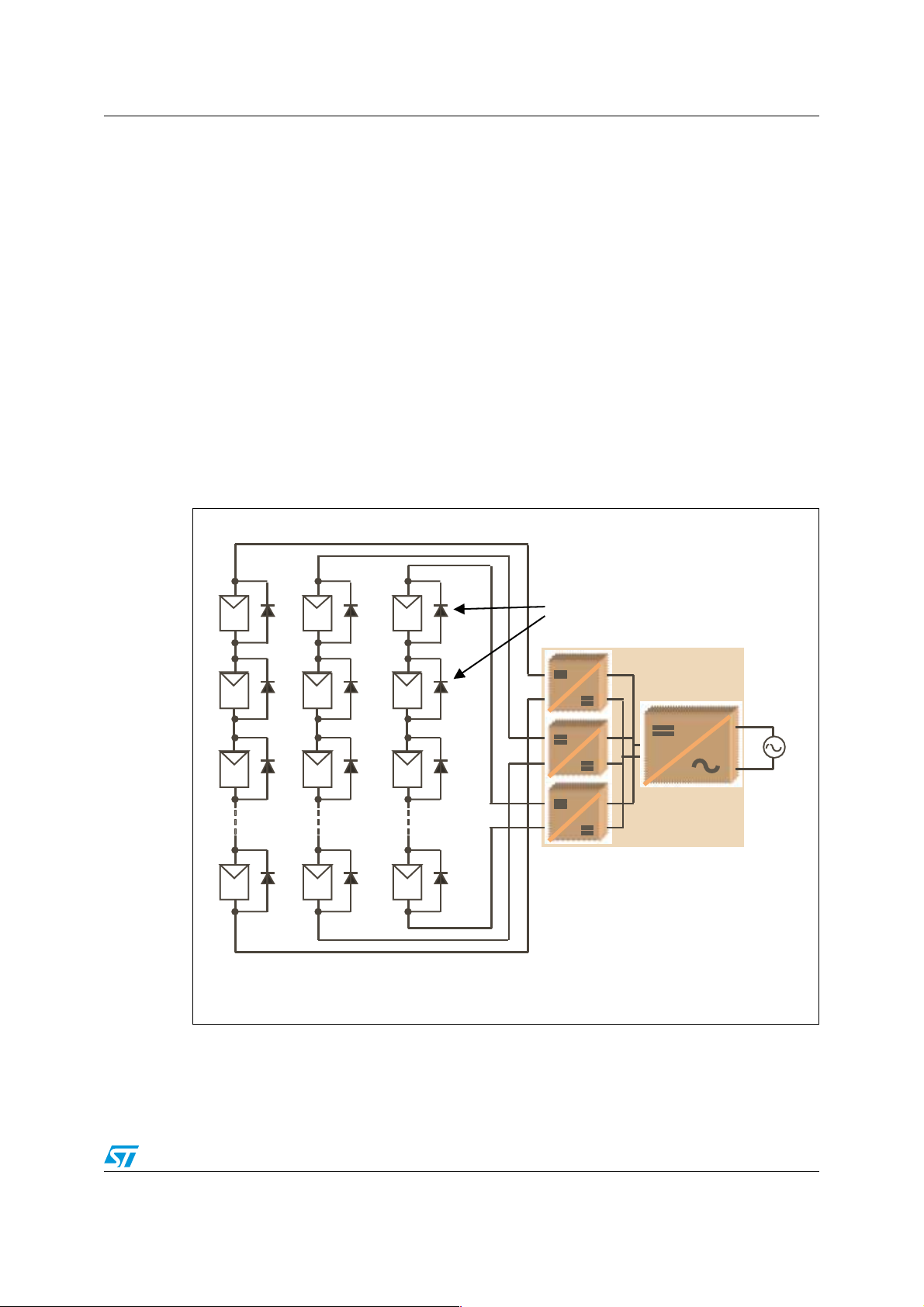

Figure 4. Photovoltaic panel for a distributed architecture. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

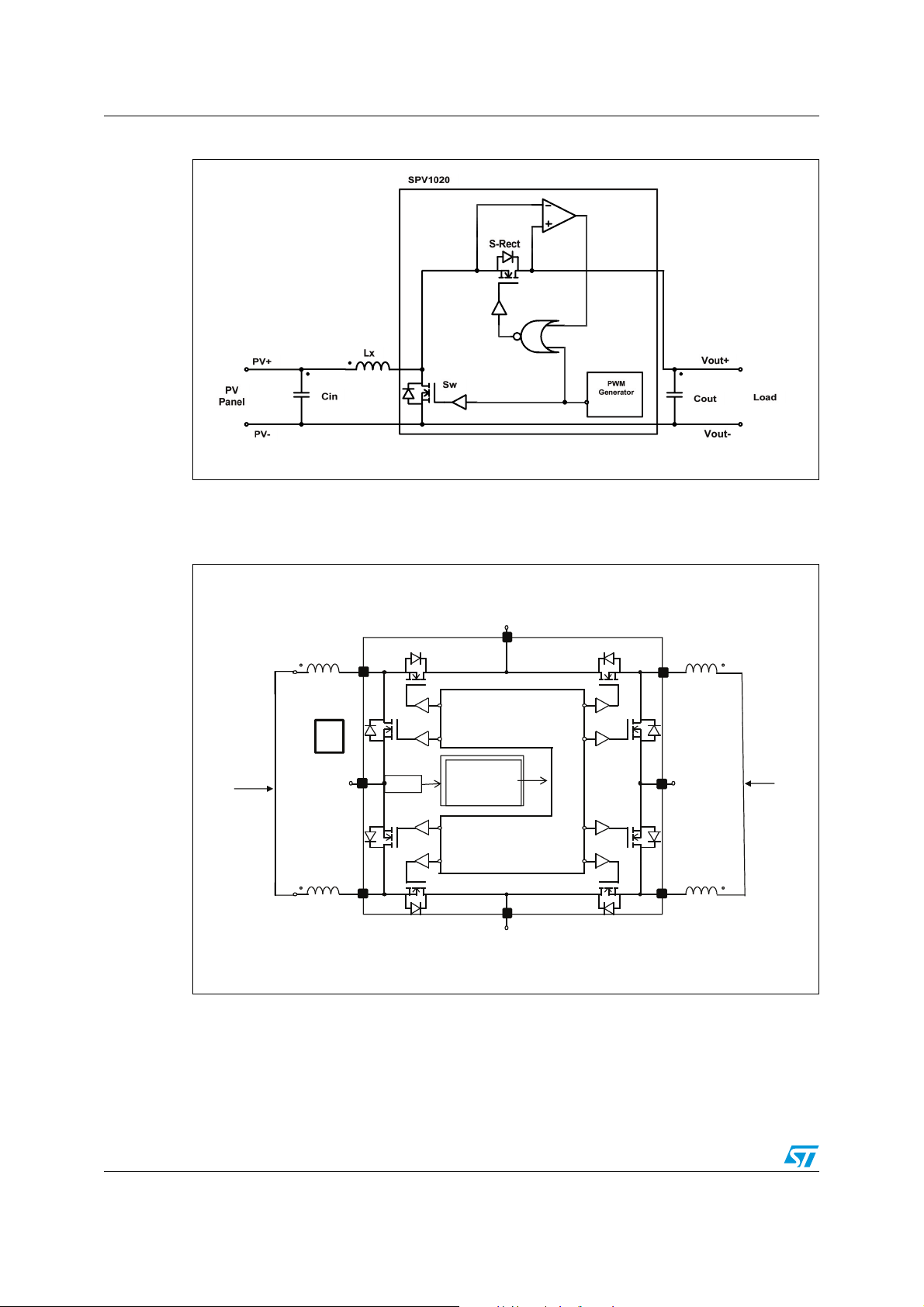

Figure 5. Step-up converter single-ended architecture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Figure 6. Step-up converter in continuous mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Figure 7. Step-up converter in discontinuous mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Figure 8. Boost converter interleaved 4-phase architecture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Figure 9. Synchronous rectification and zero crossing block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Figure 10. Boost IL-4 and SPV1020 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

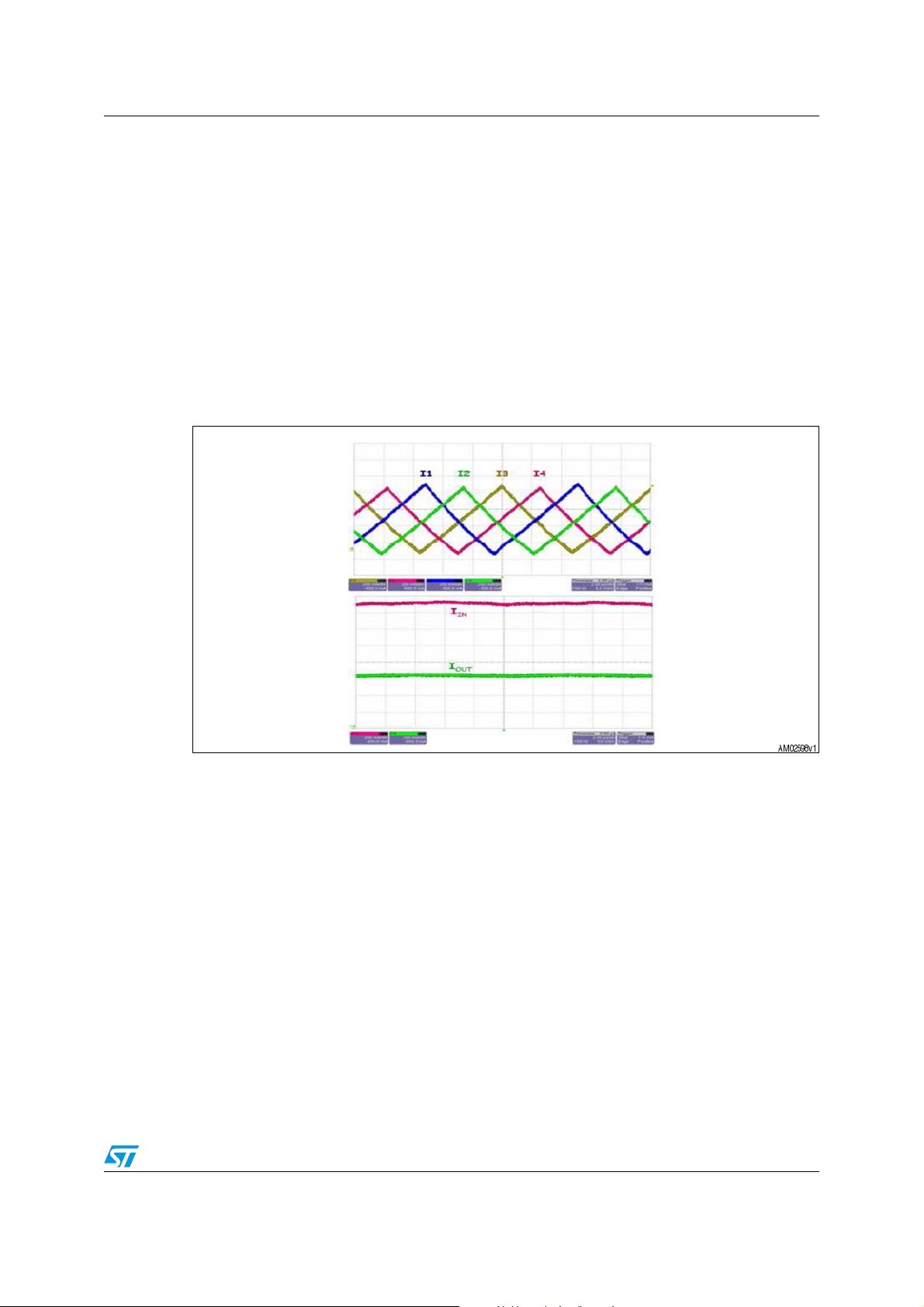

Figure 11. Step-up current waveforms or interleaved 4-phase architecture . . . . . . . . . . . . . . . . . . . . 13

Figure 12. SPV1020 general FSM (finite state machine). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 13. Burst mode FSM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 14. SPV1020 MPPT block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 15. SPV1020 equivalent circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 16. PV panels, power vs. voltage and current vs. voltage curves . . . . . . . . . . . . . . . . . . . . . . 18

Figure 17. MPPT data flow diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Figure 18. MPPT concept flow diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 19. Normal/MPPT mode, DCM vs. CM FSM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 20. Input voltage partitioning, sample circuit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 21. SPI interface: master/slaves connection example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Figure 22. Frame structure: register read operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Figure 23. Pin connection top view PowerSSO-36 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Figure 24. STEVAL-ISV009V1 schematic (PowerSSO-36 package). . . . . . . . . . . . . . . . . . . . . . . . . . 29

Figure 25. PCB layout example (top view). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Figure 26. PCB layout example (bottom view). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Figure 27. STEVAL-ISV009V1 application schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Figure 28. SPV1020, output parallel connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Figure 29. SPV1020, output series connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Figure 30. Measurement environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Figure 31. Power efficiency vs. output voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Figure 32. Power efficiency vs. output voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Figure 33. Power efficiency vs. output voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Figure 34. MPPT accuracy vs. output voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Figure 35. MPPT accuracy vs. output voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Figure 36. MPPT accuracy vs. output voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Figure 37. Vin = 12 V, Iin = 8 A, VOUT = 36 V, Tamb = 25 °C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Figure 38. Vin = 12 V, Iin = 8 A, VOUT = 14 V, Tamb = 25 °C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Figure 39. Vin = 24 V, Iin = 8 A, VOUT = 36 V, Tamb = 25 °C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Figure 40. Vin = 24 V, Iin = 8 A, VOUT = 26 V, Tamb = 25 °C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Figure 41. Vin = 30 V, Iin = 8 A, VOUT = 36 V, Tamb = 25 °C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Figure 42. Vin = 30 V, Iin = 8 A, VOUT = 32 V, Tamb = 25 °C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Figure 43. PowerSSO-36 package dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

4/57 Doc ID 018749 Rev 1

AN3392 List of tables

List of tables

Table 1. Data format for words longer than 8 bits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Table 2. Commands list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Table 3. Pin description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Table 4. Maximum ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Table 5. Bill of material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Table 6. PowerSSO-36 mechanical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Table 7. Document revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Doc ID 018749 Rev 1 5/57

Application overview AN3392

1 Application overview

The following diagram shows the typical architecture of a photovoltaic system for a grid

connected application and consists of a photovoltaic field and an electronic section.

Figure 2. SPV1020 output series connection

"LOCKING

DIODES

"Y PASS

DI

ODES

'RID

)NVERTER

.

The photovoltaic field is made up of PV panels. Some PV panels are connected in series to

make a PV string. Each string is connected in parallel with the others and then connected to

the electronic section of the system, the “inverter”, which has the role of adapting the

produced power to the characteristics of the public electrical grid.

.

.

!-V

Other electronic components are the bypass diodes and the blocking diodes.

Each bypass diode protects the panel to which it is connected by providing an alternative

path for the current flow generated by other panels. These diodes guarantee both panel

protection and system functionality in case of damaged or shaded panels.

Blocking diodes (or “cut-off” diodes) protect the entire string from current following from

other strings due to a lower voltage of the string, typically caused by shadows on a part of

the string.

6/57 Doc ID 018749 Rev 1

AN3392 Application overview

Inverters are complex systems normally providing three functions (DC-DC conversion, DCAC conversion and Anti-Islanding) managed by a main controller typically implemented by a

microcontroller or DSP and executing the following actions:

● Anti-Island control, a safety control forcing the system to disconnect from the grid when

it is OFF for maintenance.

● Inverter control, for converting the DC power generated by the PV field to AC power

compatible with the power on the public grid (voltage and current amplitude, frequency

and phase).

● The MPPT (maximum power point tracking) control, allowing the extraction of the

maximum amount of power possible from the PV field in order to maximize the power

sourced to the grid.

A limitation of the architecture in Figure 2 is that the MPPT control performs properly only

when the PV field is uniformly irradiated.

A first evolution of the above architecture is shown in Figure 3 (string-distributed), where the

inverter includes more DC-DC converter sub-blocks, each implementing its own MPPT

algorithm.

Figure 3. Photovoltaic system with multi-string inverter

"Y PASS

DI

ODES

'RID

)NVERTER

.

.

Even though this architecture provides for a different shadow on each string, it doesn’t solve

the problem of the partial shading on each panel.

.

!-V

Doc ID 018749 Rev 1 7/57

Application overview AN3392

A better solution for this issue is to place the DC-DC converter and related MPPT algorithm

on each panel. This approach provides for a simpler inverter architecture that doesn’t

require a DC-DC block and related controller.

Furthermore, in order to minimize the impact of partial shading on each panel, it’s possible

to show the concept having a DC-DC converter for each cell of the panel. As a compromise

between cost and performance the following approach splits a panel into 3 different

substrings.

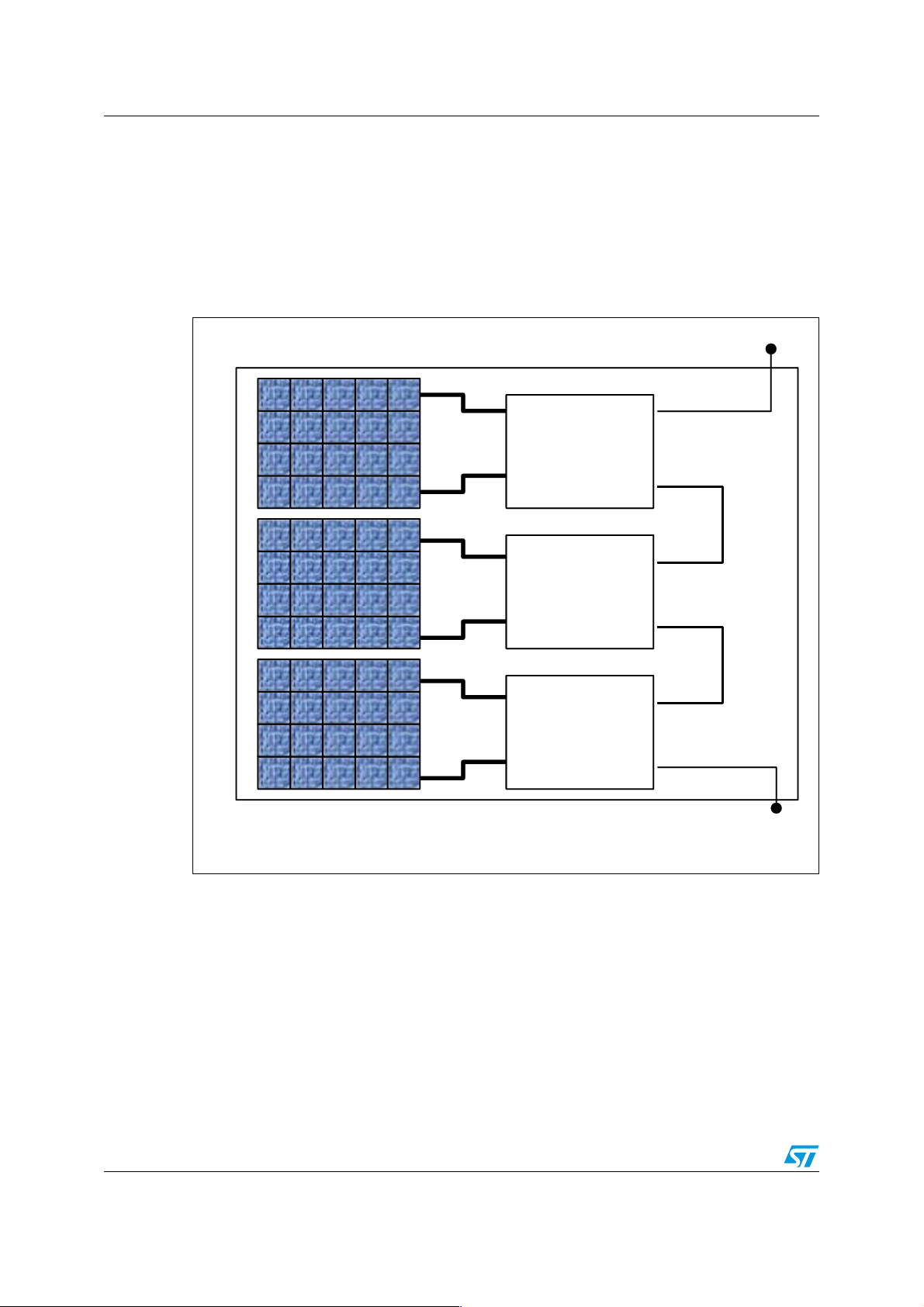

Figure 4. Photovoltaic panel for a distributed architecture

6O

UT

"//34

06

-004

06

06

"//34

-004

"//34

-004

DISTRIBUTED

ARCHITECTURE

6O UT

!-V

8/57 Doc ID 018749 Rev 1

AN3392 Application information

2 Application information

A step-up (or boost) converter is a switching DC-DC converter able to generate an output

voltage higher than the input voltage.

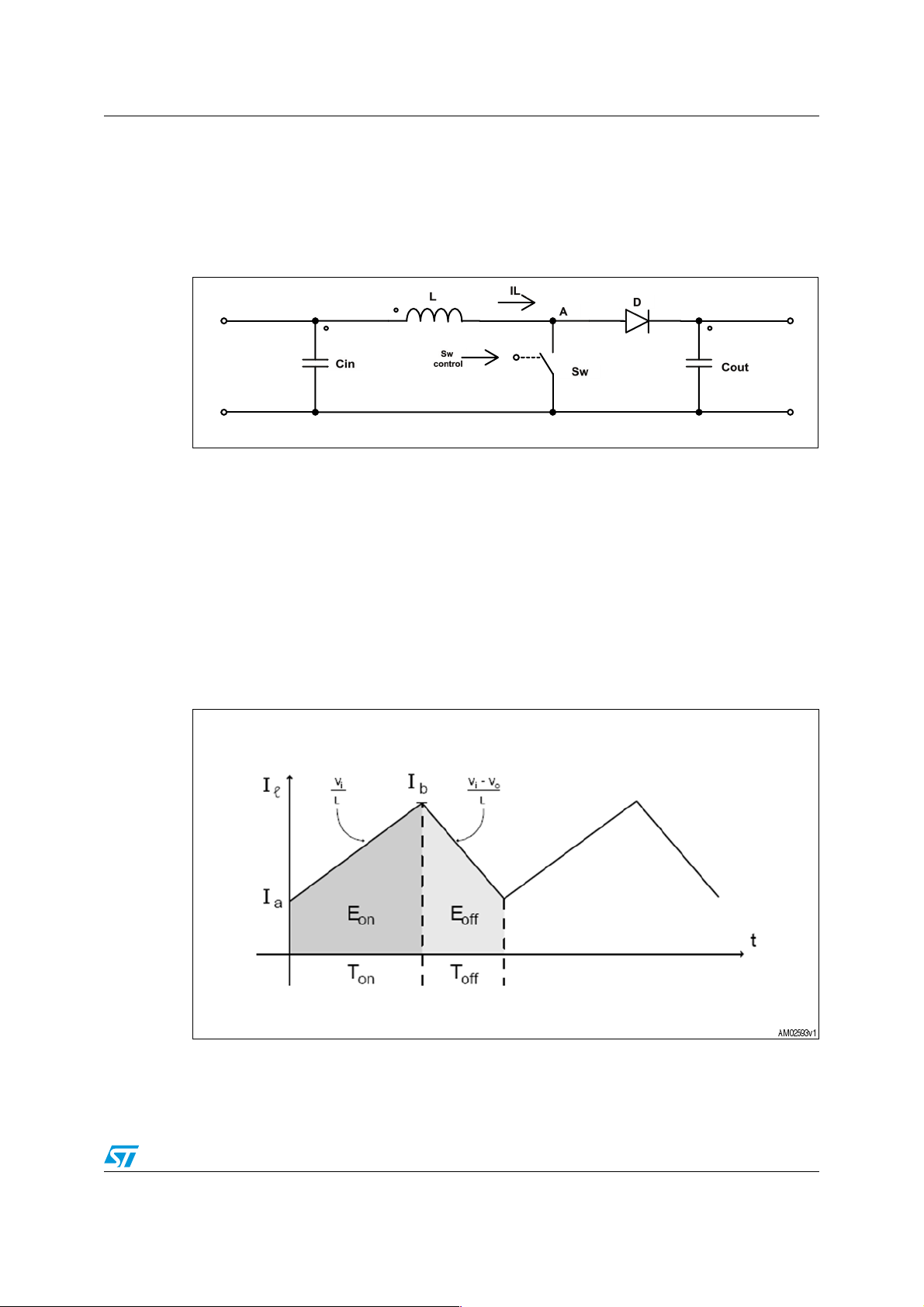

Figure 5. Step-up converter single-ended architecture

!-V

The switching element (Sw) is typically driven by a fixed-frequency rectangular waveform

generated by a PWM controller.

When Sw is closed (T

), the inductor stores energy and its current increases with a slope

on

depending on the voltage across the inductor and its inductance value. During this time the

output voltage is sustained by C

and the diode doesn’t allow any charge transfer from

out

output to input stages.

When Sw is open (T

) the current in the inductor flows toward the output until the voltage

off

on node “A” is higher than the output voltage. During this phase the current in the inductor

decreases while the output voltage increases.

Figure 6 shows the behavior of the current on the inductor.

Figure 6. Step-up converter in continuous mode

Comparing the energy stored in the inductor during T

the relation between V

and Vin is:

OUT

Doc ID 018749 Rev 1 9/57

and the energy released during T

on

off

,

Application information AN3392

Equation 1

V

out

-----------

V

in

-------------=

1D–

1

where “D” is the duty cycle [T

/(Ton+T

on

)] of the rectangular waveform driving the switching

off

element.

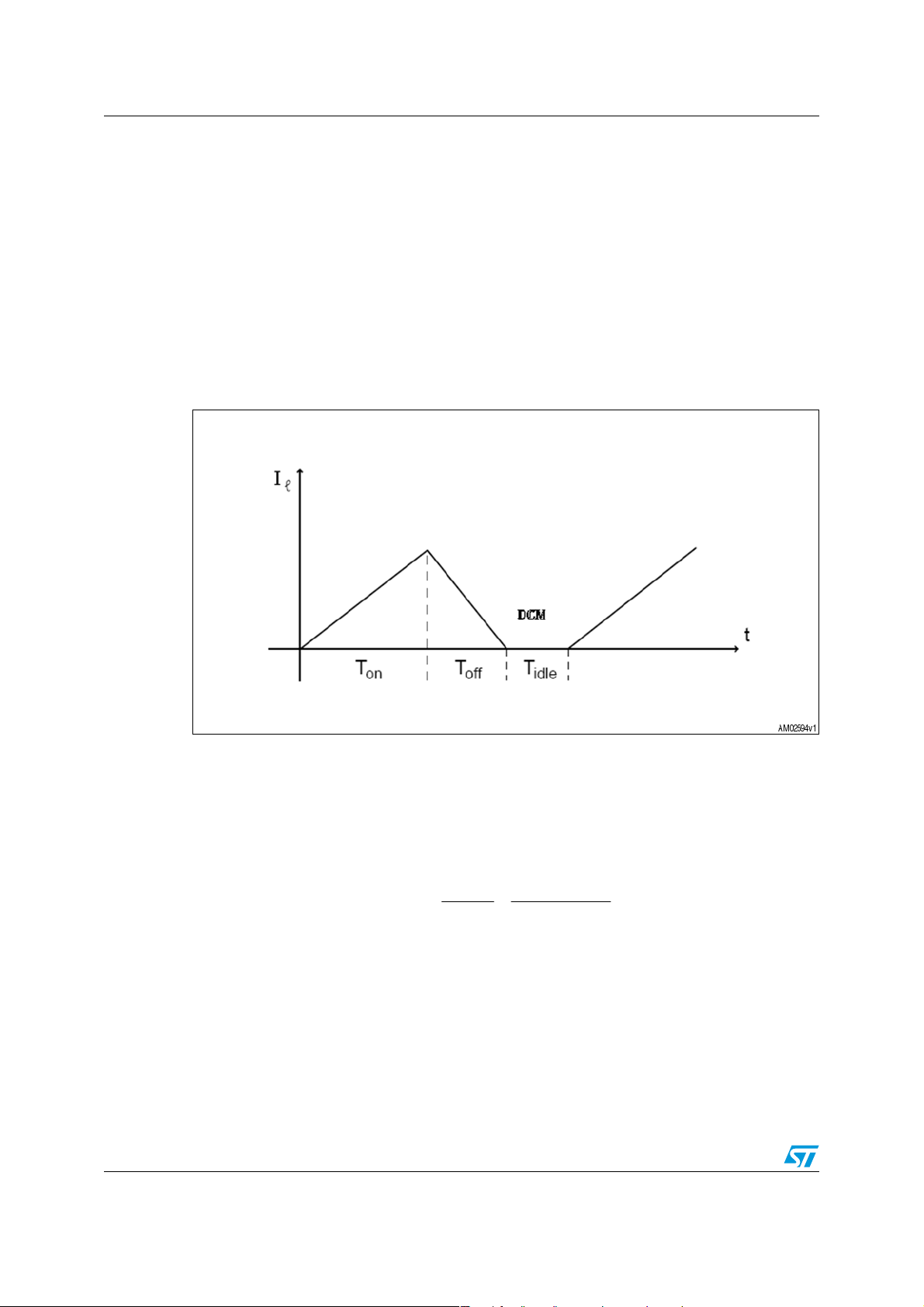

Boost converters can work in two main modes:

● Continuous mode (CM);

● Discontinuous mode (DCM);

depending on whether the current on the inductor becomes zero (DCM), or not (CM), within

the switching period.

Figure 7. Step-up converter in discontinuous mode

Even though a boost converter may work both in CM and DCM modes, efficiency is normally

higher when it works in CM, if the switching frequency is constant.

Inductance and switching frequency (F

) determine the working mode. In order to have the

sw

system working in CM, the following rule should be used:

Equation 2

Vout

L

Pin

∗>

Worst case for L in the above formula is D = 50%.

10/57 Doc ID 018749 Rev 1

22

−

))D1(*D(

Fsw*2

AN3392 SPV1020 description

3 SPV1020 description

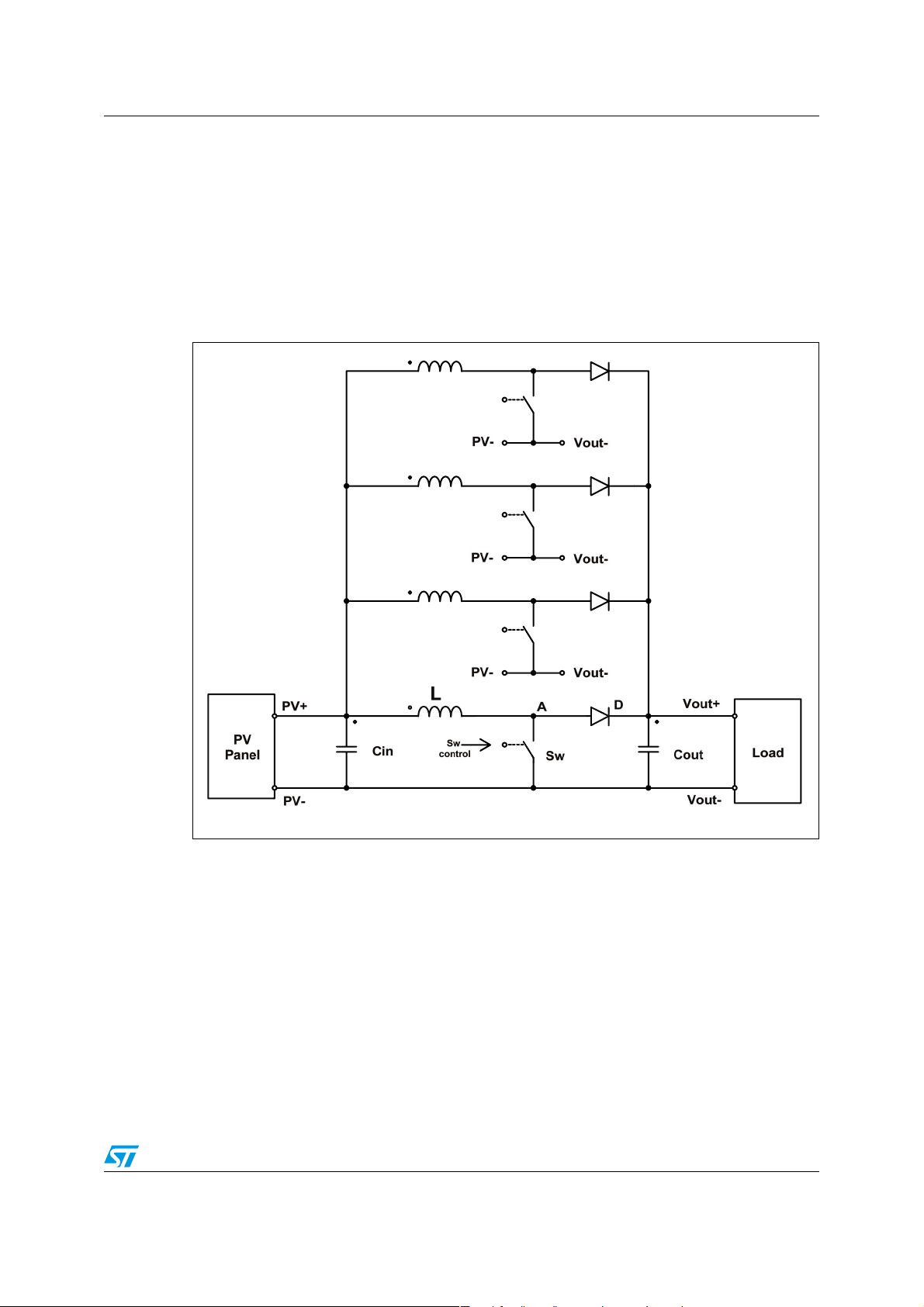

The SPV1020 is an IC designed to provide a boost with a 4-phase interleaved topology

when supplied by photovoltaic panels.

In a 4-phase topology, the inductor-switch-diode branch is cloned 3 times and the resulting

four branches are connected in parallel. The resulting architecture is shown in Figure 8

below:

Figure 8. Boost converter interleaved 4-phase architecture

!-V

The SPV1020 drives the four switching elements with the same waveform but shifted by

T

/4.

SW

In order to increase application efficiency each diode can be replaced by a switching

element driven complimentary with respect to the corresponding switch. Furthermore, these

four switching elements (synchronous rectifiers) must be driven in order to prevent current

flow from the output to the input.

The SPV1020 integrates four zero crossing blocks (ZCB), one for each branch. Their role is

to turn off the related synchronous rectifier to prevent reverse current flow from output to

input.

Doc ID 018749 Rev 1 11/57

SPV1020 description AN3392

Figure 9. Synchronous rectification and zero crossing block

".W

Finally, in order to minimize the entire bill of material, the SPV1020 integrates the eight

switching elements.

Figure 10. Boost IL-4 and SPV1020

VREF

PV+

PV-

MPPT

VOUT

PWM

GEN

VOUT

DC

PV-

PV+

SHIFTING

AM02597v1

Even though the interleaved topology increases the bill of material and the wiring of the final

PCB, it is preferable to the single-ended approach especially in high-power applications.

In fact, output voltage ripple and efficiency are critical parameters for boost applications.

The following is a brief description of a boost interleaved 4 (IL-4) architecture.

12/57 Doc ID 018749 Rev 1

AN3392 Output voltage ripple

4 Output voltage ripple

Assuming a resistive load, the output voltage ripple is directly related to the output current

ripple.

In a single-ended architecture, the output current is the current flowing on the inductor when

it recirculates through the rectifiers. Referring to Figure 6, the larger the inductance, the

smaller the current ripple (I

In IL-4 architecture, output current is the sum of the four currents flowing in each inductor.

Even if the current on each branch is the same as in the single-ended architecture, the

T

/4 shift between the driving signals implies that output current has a small amount of

SW

ripple. Figure 11 shows both the current in each branch and the final I

Figure 11. Step-up current waveforms or interleaved 4-phase architecture

b-Ia

).

.

OUT

With respect to single-ended architecture, input and output current ripple are significantly

reduced due to both the split of the incoming current in the four branches and the related

phase shift.

Doc ID 018749 Rev 1 13/57

Application efficiency AN3392

5 Application efficiency

In designing a boost application, a typical constraint is the maximum output current ripple.

Once frequency, input, and output voltage are defined, this ripple is directly related to the

inductance value in the application:

Equation 3

V

D

in

--------

I

rippleILmaxILmin

The inductance value can be designed for a single-ended architecture and then divided by 4

in the case of IL-4 architecture.

---------

⋅=–=

L

F

sw

Each inductor, due to its internal resistance (R

), can affect system efficiency. For high

L

current applications, an inductor with a compact geometry may compromise the efficiency

requirements.

Using the same ferromagnetic material, higher inductance can be achieved by increasing

the inductor geometry, or by increasing the number of turns but using a thinner wire.

In order to save space and cost, the latter solution is preferred but this increases the internal

resistance and the saturation current of the inductor.

14/57 Doc ID 018749 Rev 1

AN3392 SPV1020 functions

6 SPV1020 functions

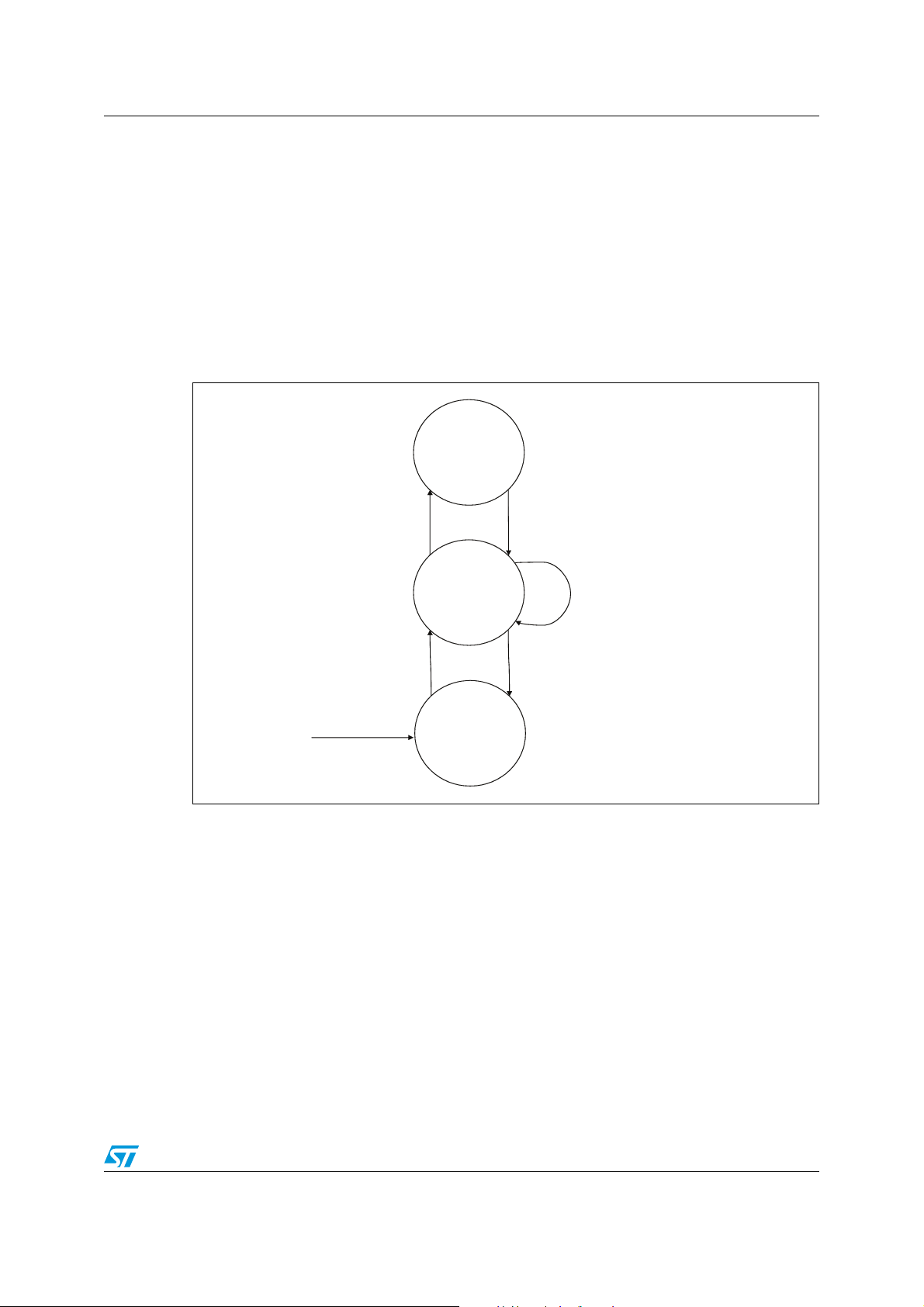

6.1 Operating modes.

The SPV1020 works between three operating modes or states, depending on the voltage

provided by the supply source and by the previous mode or state:

● OFF-state

● Burst mode

● Normal (or MPPT) mode.

Figure 12. SPV1020 general FSM (finite state machine)

Normal/MPPT

Mode

6.2 OFF-state

The SPV1020 has a UVLO (undervoltage lockout) with hysteresis of 500 mV. The two

thresholds are 6.5 V (UVLO_H) for turn-on and 6.0 V for turn-off (UVLO_L).

At power-up, while the supply source provides a voltage lower than UVLO_H, the SPV1020

stays in the OFF-state. In this state, no switching is applied to the switching elements and all

the current provided by the PV panel (supply source) is directly transferred to the output

node through the intrinsic diode of the synchronous rectifiers.

All 4 Phases ON

[VCC > UVLO_H]

POWER UP

Burst

Mode

OFF State

[VCC < UVLO_L]

Not all phases ON

&

Default < N < Max

[VCC < UVLO_L]

&

N = default

AM02599v1

When the applied voltage reaches UVLO_H, the SPV1020 goes into burst mode. Burst

mode guarantees a soft startup and shutdown. When in burst mode, the SPV1020 updates

an internal counter according to the comparison between the sampled supply voltage and

UVLO thresholds. The SPV1020 goes back into the OFF-state when the internal counter

returns to its default value.

Doc ID 018749 Rev 1 15/57

SPV1020 functions AN3392

6.3 Burst mode

This mode guarantees a correct startup for the SPV1020, avoiding voltage oscillations. After

the input voltage is applied, the converter begins operation when the input voltage exceeds

6.5 V (ULVO_H).

Burst mode contains four internal states, which guarantee to gradually activate phase “1”

and sequentially the four phases. Figure 13 shows the FSM of burst mode (the grey circles

are the burst mode states).

Each phase is driven with a set of 10 “pulses”. Each pulse can be “ON”, driving the phase

with a signal at a minimum PWM duty cycle of 5%, or “OFF”, with the driving signal

completely low.

When activated, a phase is driven with 1 pulse “ON” and 9 pulses “OFF”. The number of

“ON” pulses can be increased up to 10 (in this case, another phase is activated), or

decreased down to 0 (the phase is always OFF).

An increase or decrease of “ON” pulses depends on the status of the ULVO signal that

checks if the input voltage is greater than the minimum threshold or not.

Figure 13. Burst mode FSM

[UVLO is ON ]

[UVLO is ON ]

Normal

Mode

[UVLO is OF F]

[UVLO is ON ]

Phases 1 & 3 active

@DC=5%

[UVLO is OF F]

[Check UVLO]

When all four phases are active, the system enters normal (or MPPT) mode.

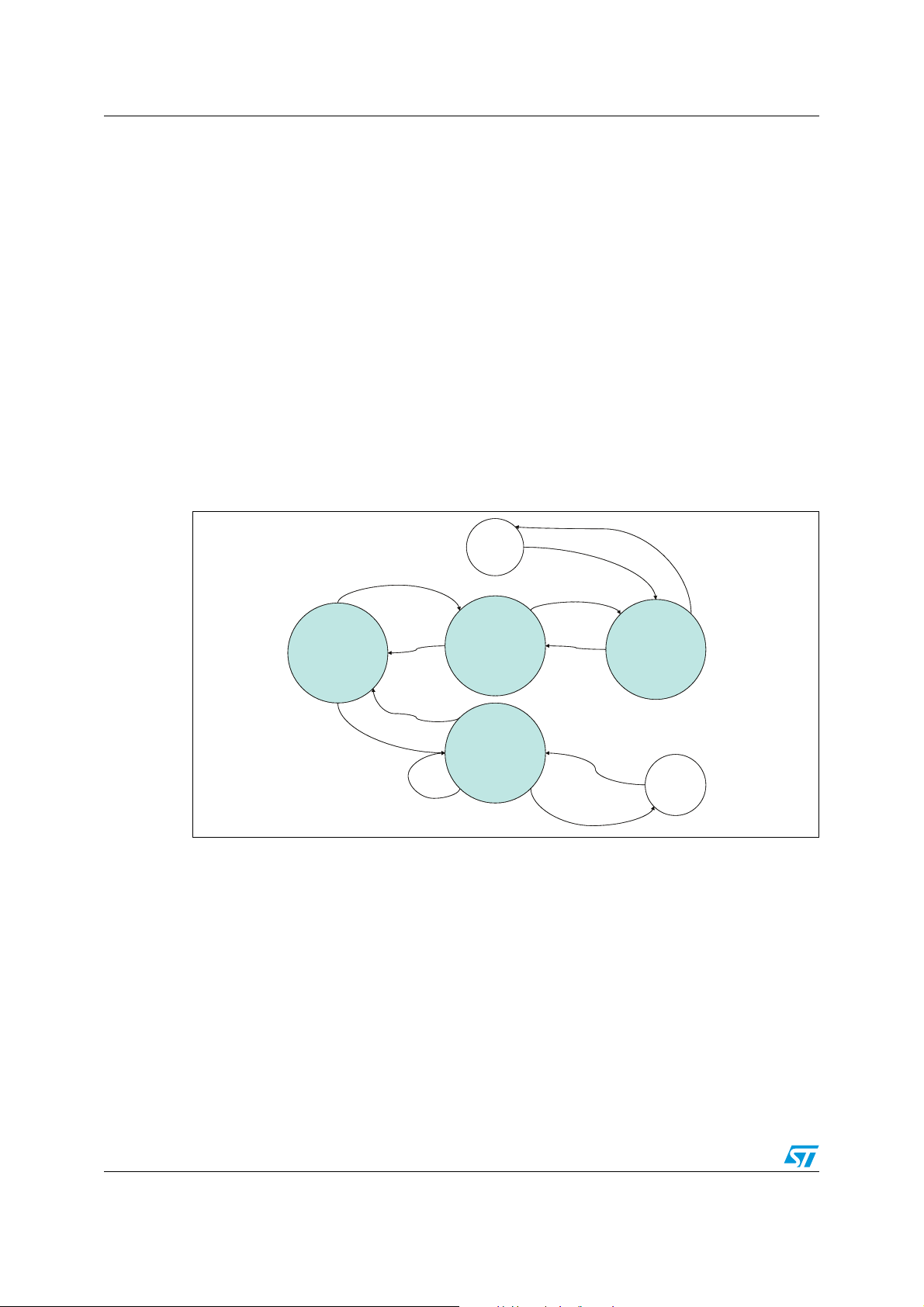

6.4 Normal/MPPT mode

This mode guarantees the maximum power extraction from a photovoltaic input supply by

executing an MPPT algorithm.

The MPPT algorithm generates a voltage reference (Vref) for a PWM generator. The

resulting waveform, with a duty cycle (DC) proportional to Vref, drives the eight internal

switching elements.

[UVLO is OF F]

[UVLO is ON ]

& [n is 10]

Phases 1, 3 & 2 active

@DC=5%

Only Ph ase “1” is active

•n pulses @DC=5%

• (10-n) pulses @DC=0%

If UVL O is ON [n = n+1]

else [n = n -1]

[UVLO is OF F]

[UVLO is OF F]

&

[n is 1]

Phases 1, 3, 2 & 4 active

[UVLO is ON ]

@DC=5%

OFF State

[n = 1]

AM02600v1

16/57 Doc ID 018749 Rev 1

AN3392 SPV1020 functions

Figure 14. SPV1020 MPPT block

VOUT

PV+

PV-

MPPT

VREF

PWM

GEN

VOUT

DC

PV-

PV+

SHIFTING

AM02601v1

This application is equivalent to matching the impedance of the output load to the

impedance of the input source (PV panel). The value of the impedance (Z) that matches the

impedance of the input source depends on the duty cycle (DC) set by the SPV1020.

Figure 15. SPV1020 equivalent circuit

SPV1020

in

I

in

C

in

V

gm Vin

C

out

I

out

R

out

V

out

PV

DC

Panel

Z

AM02602v1

Each Z affects the power transfer between the input source and output load, and for each Z

an input voltage (V

algorithm is to regulate the proper DC in order to guarantee Z = Z

impedance of the source and Z is the impedance assuming Z

which the power extracted from the supply source (P

) and current (Iin) can be measured. The purpose of the MPPT

in

= Vin * Iin) is maximum

in

, where ZM is the

M

as the impedance value for

M

(MPP = VMP * IMP).

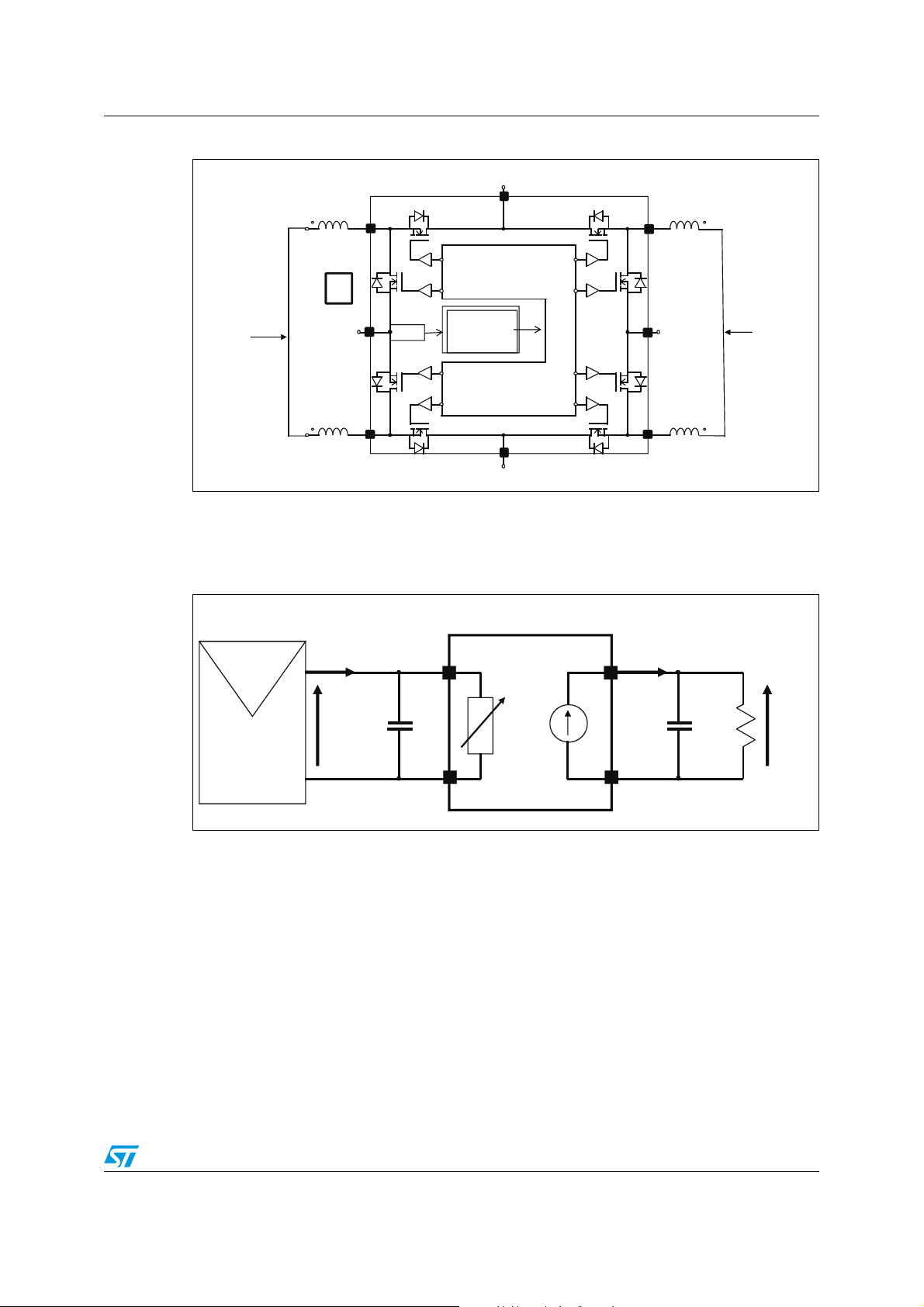

Figure 16 shows both the typical curves, power vs. voltage and current vs. voltage of a

photovoltaic panel.

Doc ID 018749 Rev 1 17/57

SPV1020 functions AN3392

Figure 16. PV panels, power vs. voltage and current vs. voltage curves

The voltage-current curve shows all the available working points of the PV panel at a given

solar irradiation. The power-voltage curve is derived by the voltage-current curve, plotting

the product V*I for each voltage applied.

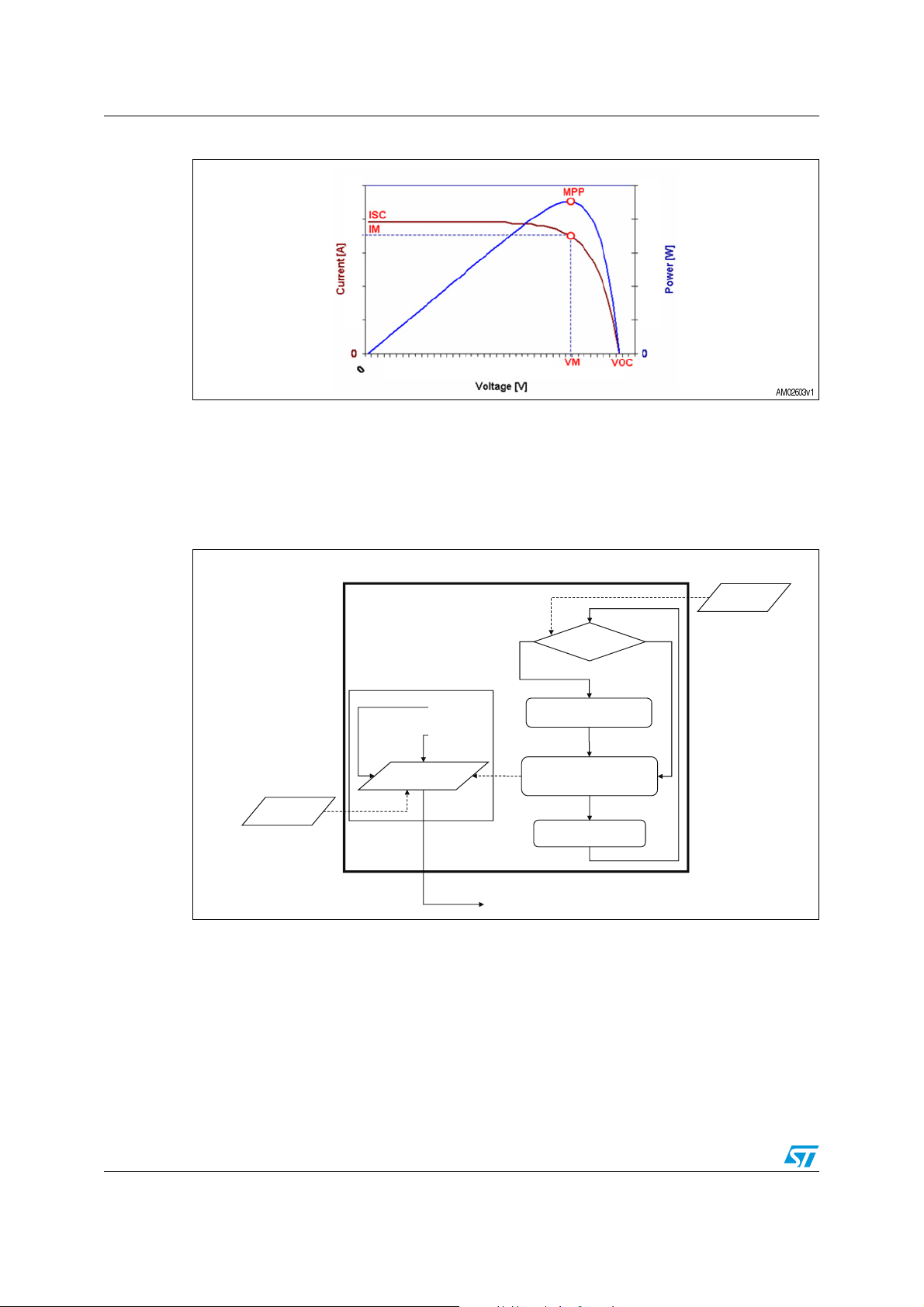

Figure 17 shows the dataflow diagram of the MPPT algorithm implemented by the

SPV1020:

Figure 17. MPPT data flow diagram

MPPT algorithm

P(tn)

FV

P(tn) > P(t

)

n-1

Output voltage monitoring

V

o-max

V

o-th

V

ref

Sign = Inv(Sign)

V

=

ref

V

+ Sign * Step

ref

Vo (tn)

Update P(t

to DAC

The voltage reference generated by the MPPT algorithm is always limited by the overvoltage

(V

This algorithm is defined as Perturb&Observe because the system is excited (perturbed)

with a certain duty cycle (DC), the power is then monitored (observed), and then perturbed

with a new DC depending on the monitoring result.

) and voltage regulation (V

o-max

) control of the output.

o-th

)

n-1

AM02604v1

The SPV1020 executes the MPPT algorithm with a period equal to 256 times the switching

period. The switching period is 10 µs, therefore the MPPT algorithm period is 2.56 ms. This

time is required for the application to reach the new steady-state (voltage and current) after

18/57 Doc ID 018749 Rev 1

AN3392 SPV1020 functions

the perturbation of the DC. The resolution of the duty cycle perturbation is 0.2 % over most

of its range.

An increase or decrease of the DC depends on the update done in the previous step and by

the direction of the input power.

The MPPT algorithm compares the current input power (P

in the previous step (P

). If the power is increasing then the update is in the same

tn-1

) with the input power computed

tn

direction as in the previous step. Otherwise the update is swapped (from increasing to

decreasing or vice-versa).

When the system is at the MPP, the user can see the duty cycle oscillating between three

values within a time window of 256*3 = 768 times the switching period (7.68 ms).

Figure 18 shows the sampling/working points (red circles) set by the SPV1020 and how they

change (red arrows) during normal operating mode.

Figure 18. MPPT concept flow diagram

The input for the MPPT algorithm is the incoming power but its computation depends on the

working mode of the application, either DCM or CM.

The SPV1020 discriminates between DCM and CM by the zero crossing blocks (ZCB), refer

to Section 3 (Figure 9) for details.

The SPV1020 moves between DCM and CM states implementing a sort of hysteresis,

depending on how many of the four ZCBs (Figure 9) have their own outputs activated.

Figure 19 shows the related finite state machine (FSM) implementation within the

normal/MPPT mode:

Doc ID 018749 Rev 1 19/57

SPV1020 functions AN3392

Figure 19. Normal/MPPT mode, DCM vs. CM FSM

OR:#"ACTIVE

OR:#"ACTIVE

#-

$#-

OR:#"ACTIVE

OR:#"ACTIVE

!-V

In the case of DCM, input current can be negligible and its sampled value may be strongly

affected by the noise caused by the switching elements. Input power is computed as follows,

avoiding the use of the input current:

Equation 4

P

tn()

V2T

on

TonT

+()⋅⋅=

off

In the case of CM, input power is computed by multiplying the sampled voltage and the

sampled current:

Equation 5

tn()

VI⋅=

P

Input voltage is sampled by an external resistive divider, while the input current is sampled

internally to reduce the number of external components in the application. Figure 20 shows

a simple schematic of the input voltage sensing circuitry (see Section 10 for values of the

components shown).

20/57 Doc ID 018749 Rev 1

AN3392 SPV1020 functions

Figure 20. Input voltage partitioning, sample circuit

PV+

PV

Panel

PV -

To LX

D4

C5

To SPV1020 supply (Vin)

R1

C9

To SPV1020 voltage sense (Vin_sns)

To SPV1020 voltage sense ref (Vin_sns_m)

AM02607v1

Doc ID 018749 Rev 1 21/57

Voltage regulation AN3392

7 Voltage regulation

In order to protect both the device itself and the load, the SPV1020 implements a dual

control of the output voltage (V

Control of V

is done through the V

OUT

(see Section 10 for resistance values). The control consists of comparing V

two internal thresholds:

1. 1.00 V, for voltage regulation

2. 1.04 V, for overvoltage protection.

OUT

).

OUT_SNS

pin, connected to V

by a resistive divider

OUT

OUT_SNS

with

When V

OUT_SNS

increases up to 1 V, the output feedback loop enters regulation, limiting the

output voltage. Regulation is achieved by creating an upper limit for the DC generated by the

MPPT algorithm.

The stability of the loop must be externally compensated by connecting a resistor and a

capacitor (pole-zero combination) between the PZ_OUT pin and SGND pin (see Section 10

for values).

7.1 Overvoltage protection

If the V

OUT_SNS

controller which stops the drivers and produces a fault, setting the bit OVV in the status

register. This information is accessible through the SPI interface by the Read Status

command (op code 0x07). When V

converter is switched ON again and the converter restarts the MPP search from the

minimum duty cycle (5 %).

exceeds 1.04 V, a fault signal is generated and transmitted to the fault

OUT_SNS

7.2 Overcurrent protection

To guarantee the safety of the entire application, the SPV1020 implements an overcurrent

protection on the low-side power switches. In fact, when Lx is accidentally shorted to V

V

, or when the current flowing through the inductor exceeds the peak current limit

OUT

(4.5 A), the related low-side power switch is immediately turned OFF and the linked

synchronous rectifier is enabled to turn on. The low-side power switch is turned on again at

the next PWM cycle.

drops back down to 1.04 V the DC-DC

in

or

In the case of overcurrent on branch x [x = 1..4], the related OVC bit of the status register is

set. This information is accessible through the SPI interface by the Read Status command

(op code 0x07).

7.3 Current balance

Different parasitic resistances between the four branches of the IL-4 architecture can be the

root cause of unbalanced current flow between the four branches. This should be avoided

as it may result in lower efficiency or damage to external components (inductors) and/or the

SPV1020.

It is recommended that the four branches in the PCB layout have symmetrical paths and the

inductors be matching or from the same production lot.

22/57 Doc ID 018749 Rev 1

AN3392 Voltage regulation

The SPV1020 implements an internal control guaranteeing the current balance between the

four branches, monitoring the current flowing on each branch with a maximum variation of

350 mA.

7.4 SPI serial peripheral interface

The SPV1020 implements a 4-pin compatible SPI interface. The SPI allows full duplex,

synchronous, serial communication between a host controller (the master) and the

SPV1020 peripheral device (the slave). The SPV1020 provides the following 4 pins:

● XCS (or SS)

● SPI_CLOCK (or SCLK)

● SPI_DATA_IN (or MOSI)

● SPI_DATA_OUT (or MISO).

Figure 21. SPI interface: master/slaves connection example

The SPI master selects one of the slaves, provides the synchronizing clock and starts the

communication. The idle state of the serial clock for the SPV1020 is high, while data pins

are driven on the falling edges of the serial clock and are sampled on its rising edges (SPI

control bits CPOL = 1, and CPHA = 1). The bit order of each byte is MSB first.

When the master initiates a transmission, a data byte is shifted out through the MOSI pin to

the slave, while another data byte is shifted out through the MISO pin to the master; the

master controls the serial clock on the SCLK pin. The SS (active low) pin must be driven low

by the master during each transmission.

Doc ID 018749 Rev 1 23/57

Voltage regulation AN3392

Figure 22. Frame structure: register read operation

The SPV1020 register file is accessible by the host through the SPI bus. Therefore, the host

can read some registers of the SPV1020 control parameters. Each data frame includes at

least one command byte followed by some data bytes whose direction depends on the type

of command. If the command byte requires some data to be read from the register file, those

data are transmitted from the slave to the master through the MISO pin; therefore the master

appends a number of NOPs (0x00) to the command, so that the entire data can be

transmitted, see Figure 22. In other words, the master must transmit a byte to receive a byte.

If the SS wire goes high before the completion of a command byte in the data frame, the

SPV1020 rejects that byte and the frame is closed; then the next data frame is considered

as a new one, starting with a command byte.

Some data words can be longer than 8 bits, such as ADC results (10 bits); in such cases,

data is first extended to the nearest multiple of one byte (it is right justified), then it is split

into bytes, e.g. the ADC result R is formatted as follows:

Table 1. Data format for words longer than 8 bits

Bit 7

MSB

Byte 1000000

Byte 2R7R6R5R4R3R2R1

Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1

R9

MSB

Bit 0

LSB

R8

R0

LSB

24/57 Doc ID 018749 Rev 1

AN3392 Voltage regulation

Ta bl e 2 shows a list of commands. Each command addresses a memory location of a

certain width and sets the direction of the related data.

Table 2. Commands list

Code (Hex) Name R/W Comment

00 Reserved Reserved

01 NOP No operation

02 SHUT Shuts down SPV1020

03 Turn-on Required only after SHUT command

04 Read current Read Read 10 bits in 2 bytes (MSB is first received bit)

05 Read vin Read Read 10 bits in 2 bytes (MSB is first received bit)

06 Read pwm Read Read 9 bits in 2 bytes (MSB is first received bit)

07 Read status Read

Read 7 bits:

OVC (4bits), OVV (1bit), OVT (1bit), CR (1bit)

For further information on the SPI interface, such as timing diagrams, please refer to the

SPV1020 datasheet.

Doc ID 018749 Rev 1 25/57

Pin description AN3392

8 Pin description

Table 3. Pin description

Pin

(PSSO-36)

34 V

Name Type Description

in

Supply DC input power

Boost output voltage, pins 7 and 8 are internally shorted and connected

7,8,17,18,19,

20,29,31

V

OUT

Supply

to pins 29 and 30.

Pins 17 and 18 are internally shorted and connected to pins 19 and 20.

All of the V

pins must be connected to the V

OUT

rail of the PCB.

OUT

12,13,24,25 PGND Ground Power ground to be connected to the ground plane of the PCB.

1 SGND Ground Signal ground to be connected to the ground plane of the PCB.

10,11,14,15,

22,23,26,27

9,16,21,28 CB1…4 I/O

LX1…4 I Boost inductor connection.

External bootstrap capacitors to be connected between these pins and

LXi.

Chip select for SPI interface:XCS = HIGH => SPI device is not active

31 XCS I

XCS = LOW => SPI device is active

If this pin is left floating an internal resistor pulls the XCS pin up,

switching the SPI off.

32 SPI_DATA_IN I

33 SPI_CLK I

Input pin for SPI data flow. If not used, this pin should be connected to

ground.

Input pin for SPI clock signal. If not used, this pin should be connected to

ground.

35 VIN_SNS I

Sense pin of input voltage. To be biased with a resistor divider between

VIN and SGND.

36 VIN_SNS_M I Dedicated reference pin for voltage sensing.

2PZ_OUTI/O

3V

OUT_SNS

This pin is used to compensate the feedback loop of the output voltage.

A series of resistors and capacitors must be connected to SGND.

Sense pin of output voltage. To be biased with a resistor divider between

I

V

OUT

and SGND.

Pin for adjusting the switching frequency. To set the default value (100

4OSC_INI

kHz) this pin must be tied to VREG, otherwise for adjustment it must be

biased through a resistor to SGND.

5VREGI/O

Power supply for internal low-voltage circuitry; an external capacitor

must be connected from this pin to the ground plane of the PCB.

6 SPI_DATA_OUT O Output pin for SPI data flow. If not used, this pin should be left floating.

26/57 Doc ID 018749 Rev 1

AN3392 Pin description

28

CB2

CB4

9

8.1 Pin connection

Figure 23. Pin connection top view PowerSSO-36

19

20

21

22

23

24

25

26

27

29

30

31

32

33

34

35

36

VOUT

VOUT

CB1

LX1

LX1

PGND

PGND

LX2

LX2

VOUT

VOUT

XCS

SPI_DATA_OUT

SPI_DATA_IN

SPI_CLK

VIN

VIN_SNS

VIN_SNS_M

VOUT

VOUT

CB3

LX3

LX3

PGND

PGND

LX4

LX4

VOUT

VOUT

VREG

OSC _IN

VOUT_SNS

PZ-OUT

SGND

18

17

16

15

14

13

12

11

10

8

7

6

5

4

3

2

1

Doc ID 018749 Rev 1 27/57

Absolute maximum ratings AN3392

9 Absolute maximum ratings

Table 4. Maximum ratings

Symbol Parameter

V

V

in

OUT

Power supply [-0.3, 40] V

Power supply [-0.3, 40] V

Range

[min., max.]

Unit

PGND Power ground 0 V

SGND Signal ground [-0.3, 0.3] V

V

OUT_SNS

LX1….4 Analog input [-0.3, V

Analog input [-0.3, V

+ 0.3] V

out

+ 0.3] V

out

CB1…4 Analog input/output [Lxi – 0.3, Lxi + 5] V

VREG Analog input/output [-0.3, 6] V

VIN_SNS Analog input [-0.3, 3.3 + 0.3] V

XCS Digital input [-0.3, 3.3 + 0.3] V

OSC_IN Analog input [-0.3, 3.3 + 0.3] V

PZ_OUT Analog input/output [-0.3, VIN + 0.3] V

SPI_DATA_OUT Analog output [-0.3, 3.3 + 0.3] V

SPI_CLK Digital input [-0.3, 3.3 + 0.3] V

SPI_DATA_IN Digital input [-0.3, 3.3 + 0.3] V

VIN_SNS_M Dedicated ground [-0.3, + 0.3] V

28/57 Doc ID 018749 Rev 1

AN3392 External component selection

10 External component selection

The SPV1020 requires a set of external components and their proper selection guarantees

both the best chip functionality and system efficiency.

The following sections refer to the connections and component labels shown in Figure 24

below:

Figure 24. STEVAL-ISV009V1 schematic (PowerSSO-36 package)

J47

J47

FASTON

L52u5H L52u5H

D2

C15 4.7uFC15 4.7uF

C6 4.7uFC6 4.7uF

100nFC4100nF

C8 22nFC8 22nF

C4

C7 470nFC7 470nF

0

FASTON

J48

J48

FASTON

FASTON

L347uH L347uH

OSC_IN

L447uH L447uH

4

123

123

4

VIN3L3L

R7 dnmR7 dnm

Vout+

Vout-

VOUT_SNSVOUT_SNS

VIN4L4L

C10

C10

220pF

220pF

V_OUT

R3

3.9MR33.9M

1 2

R4

110kR4110k

1 2

0

0

D1 SPV1001N40D1 SPV1001N40

V_OUT

C134.7uF C134.7uF

C124.7uF C124.7uF

D5

TP5

TP5

1

PV+_1

PV+_1

D6

SPV1001-N30D6SPV1001-N30

TP6

TP6

1

PV-_1

PV-_1

D7

SPV1001-N30D7SPV1001-N30

TP7

TP7

1

PV+_1

PV+_1

D8

SPV1001-N30D8SPV1001-N30

TP8

TP8

1

PV-_1

PV-_1

VIN

J40

J40

CONN FLEX 2

CONN FLEX 2

D3STPS160UD3STPS160U

VCC

C11

C11

1uF

1uF

VIN

PV+

D4

1

SMB36CAD4SMB36CA

2

PV-

R1

3.3MR13.3M

1 2

C5

VIN_SNSVIN_SNS

4u7FC54u7F

0

R2

110kR2110k

1 2

VIN_SNS_M

0

J36

J36

C9

220pFC9220pF

4 HEADER

4 HEADER

VIN L2

C1 100nFC1 100nF

L1 47uHL1 47uH

V_OUTV_OUT

C16 4.7uFC16 4.7uF

C2

100nFC2100nF

V_OUT

L1

L2

SHUT/SPI_XCS

TEST_DATA/SPI_DATA_IN

TEST_CLK/SPI_CLK

VIN_SNS_M

0 0

C14 4.7uFC14 4.7uF

1

2

3

4

DIAG/SPI_DATA_OUT

L2 47uHL2 47uH

CB1CB1CB1CB1CB1

L1VIN

20

21

CB1

22

23

24

25

26

27

28

CB2

29

30

31

32

33

34

VCC

35

VIN_SNS

36

SPV1020 (PSSO36 package)

SPV1020 (PSSO36 package)

CB2CB2CB2CB2CB2

SMB36CAD5SMB36CA

J35

J35

00

1819

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

CB3CB3CB3CB3CB3

V_OUT

CB3

PGNDPGND

CB4

Vreg

OSC_IN

VOUT_SNSVOUT_SNSVOUT_SNSVOUT_SNS

PZ_OUT

AGND

CB4CB4CB4CB4CB4

SPV1001N40D2SPV1001N40

L3

L4

V_OUT

DIAG/SPI_DATA_OUT

R6 0R6 0

R5 1kR5 1k

C3 100nFC3 100nF

High Current Path Legend

Iin path

Iout path

Ground path

ST SOLAR KEY PRODUCT Legend

SPV1001-N30 SPV1001-N40 SPV1020

Please note the connections to OSC_IN are alternative connections. For the default

switching frequency of 100 kHz, connect OSC_IN to VREG. For frequencies other than 100

kHz, connect a resistor between OSC_IN and SGND (see Section 10.11).

Doc ID 018749 Rev 1 29/57

External component selection AN3392

10.1 Power and thermal considerations

The SPV1020 performance is strongly impacted by the power capability of the PowerSSO36 package, as well as the application board. According to the technical note TN0054,

R

“2s2p” multi-layer board with thermal vias and a metal plate for an external heatsink.

of the PowerSSO-36 can be decreased to 10 °C/W if the package is soldered onto a

TH(j-a)

Starting from this value, it is possible to calculate the P

Equation 6

TJT

AMBRTH j a–()PD

Equation 7

1 η–()P

⋅=

MAX

The SPV1020 efficiency (

η ) is ≥ 98%; the thermal shutdown threshold is 140 °C;

typical ambient temperature (T

P

D

) for a photovoltaic application is 85 °C.

AMB

Calculating maximum power dissipation Pd:

Equation 8

TJT

–

AMB

------------ ------------

P

D

R

TH j a–()

5.5W==

Equation 9

P

D

P

MAX

--------------- -

1 η–()

275W==

MAX

⋅+=

.

If the package is soldered onto a “2s2p” multi-layer board with thermal vias, the R

20 °C/W and then P

is 138 W. (PCB with 4 layers: 2 soldered layers, top and bottom,

MAX

and 2 power layers (inner layers for power dissipation).

10.2 Inductor selection

Inductor selection is a critical element for this application.

Inductor selection must take into account the following application conditions:

● Maximum input current (i.e. Imp and Isc of the PV panel)

● Maximum input voltage (i.e. Vmp and Voc of the panel)

● Overcurrent threshold of the SPV1020

● Maximum duty cycle, according to maximum output voltage

Input current from the PV panel is split between the 4 inductors of each branch, so:

Equation 10

I

mp

rms()

I

Lx

30/57 Doc ID 018749 Rev 1

------- -

is

TH(j-a)

I

sc

------

<≅

4

4

AN3392 External component selection

According to Figure 6, during the charge phase (switch ON), peak current on each inductor

depends on the applied voltage (V

), on the inductance (Lx) and on the time (TON).

in

Equation 11

1

Vmp

-------------

ILxpk()ILxrms()

-- -

⋅⋅+≅

2

T

L

ON

x

Taking into account the overcurrent threshold (4.5 A):

Equation 12

A5.4)pk(I

<

Lx

Finally, inductance should be chosen according to the following formula:

Equation 13

×

V

1

mpTON

----------- ------------- ----------- --

---

L

x

4.5 I

2

Lx

rms()–

1

-- -

2

V

mpTON

------------ ------------ -----

×=⋅>

4.5

⋅

I

mp

--------–

4

Considering the possible unbalance of the currents and the inductance drop due to self

heating effect, a more conservative choice would be to replace 4.5 A with 3.15 A (70%).

Triggering the overcurrent threshold will cause limitation of the duty cycle and consequently

limitation of the input and output powers.

Usually, inductances ranging between 22 µH to 100 µH satisfy most application

requirements.

Critical parameters for the inductor choice are inductance (analyzed above), Irms current,

saturation current, and size.

The current flowing through an inductor causes its internal temperature increase (selfheating effect). Irms typically indicates the current value causing a temeprature increase of

20, 30, or 40 °C. The higher the temeprature, the higher the inductance drop with respect to

its nominal value.

For the same physical size, smaller inductance values provide for faster response to load

transients and higher efficiency. Inductor size also affects the maximum current deliverable

to the load. The saturation current of the inductor should be higher than the peak current

limit of the input source. The suggested saturation current should be > 4.5 A.

Inductors with low series resistance are suggested to guarantee high efficiency.

10.3 Bootstrap capacitors

C1, C2, C3, and C4 are four capacitors used to guarantee internal functionality of the

SPV1020. Their role is to maintain the required voltage level on pins CB1, CB2, CB3, and

CB4 even during the charging phase of the inductors.

Capacitance value is the same for all four capacitors and is not application dependant. The

suggested value is in the range of 22 nF to 100 nF. Each capacitor switches synchronously

with the related inductor (at 100 kHz). The maximum voltage is fixed by the internal voltage

regulator (~5 V).

Doc ID 018749 Rev 1 31/57

External component selection AN3392

Low ESR capacitors are a good choice to increase the entire system efficiency.

10.4 Internal voltage rail capacitors

C7 is a tank capacitor used to guarantee the voltage level (5 V) of the internal SPV1020

voltage regulator.

The suggested value is 470 nF and is not application dependent.

The voltage range is the same as for the boost capacitors. Maximum voltage must be higher

than 5 V.

Low ESR capacitors are recommended in order to increase the entire system efficiency.

10.5 Input voltage capacitors

C5 is the input capacitance added at the input to reduce the voltage ripple.

The maximum voltage of this capacitor is dependent upon the input source (typically

between 25 V and 50 V).

Low-ESR capacitors are recommended in order to increase the whole system efficiency.

Suggested minimum input capacitance is 2 µF.

In order to reduce the ESR effect, it is suggested to split the input capacitance into 2

capacitors connected in parallel.

Another capacitor (C11) is connected to the supply input pin of the SPV1020 (V

to stabilize the voltage as much as possible on this pin which may be affected by the ripple

of the PV panel voltage.

Considering the maximum current (Isc) provided by the PV panel connected at the input, the

following formula can be used to select the proper capacitance value (Cin) for a specified

maximum input voltage ripple (V

in_rp_max

Equation 14

Cin

10.6 Input voltage partitioning

The input voltage must be scaled to the reference voltage (1.25 V) of the ADC integrated in

the SPV1020.

R1 and R2 are the 2 resistors used for partitioning the input voltage.

When the the open circuit voltage (Voc) of the PV panel is known, the said R1 and R2 must

be selected according to the following rule:

):

I

sc

------------ ------------- ----------- -------

≥

V

in_rp_maxFsw

⋅

). Its role is

in

Equation 15

V

R1

------- -

R2

32/57 Doc ID 018749 Rev 1

oc

----------- 1–=

1.25

AN3392 External component selection

In order to optimize the efficiency of the entire system, the selection of R1 and R2, should

take their power dissipation into account.

Assuming negligible the current flowing through pin VIN_SNS, maximum power dissipation

of the series R1+R2 is:

Equation 16

P

vin_sns

=

------------ ----------

R1 R2+

Voc()

2

Empirically, R1 and R2 should be selected according to:

Equation 17

P

vin_sns

1% V

in_maxIin_max

⋅()«

Note: In order to guarantee the proper functionality of pin VIN_SNS, current flowing in the series

R1+R2 should be in the range between 20 µA and 200 µA.

10.7 Input voltage sensing capacitor

C9 is placed in parallel with R2 and as close as possible to pin VIN_SNS.

Its role is to stabilize as much as possible the voltage sensed by pin VIN_SNS.

Critical parameters for the capacitor are: capacitance, maximum voltage, and ESR.

Maximum voltage: if R1 and R2 have been properly chosen, to partition V

the maximum voltage of this capacitor can be in the range from 3.3 V or higher.

The capacitance value depends on the time constant (τ

C6*R1//R2) and by the system switching frequency (F

) composed with R1+R2 (τin=

in

= 4*FSW).

SSW

Assuming R1 >> R2 (so, R1//R2 ~= R2):

Equation 18

1

----------- -

10

τ

⋅≅

in

F

ssw

to 1.25 V, then

in

so,

Equation 19

C9 10

Note: Even if the SPV1020 controls each phase at F

frequency (F

) is four times the single-phase switching frequency (by default 400 kHz).

SSW

10.8 Output voltage capacitors

A minimum output capacitance must be added at the output, in order to reduce the voltage

ripple.

Doc ID 018749 Rev 1 33/57

1

⋅⋅≅

------------

F

SW

1

------- -

R2

ssw

(by default 100 kHz), the system switching

External component selection AN3392

Critical parameters for capacitors are: capacitance, maximum voltage and ESR.

Maximum voltage of this capacitor is strictly dependent upon the output voltage range. The

SPV1020 can support up to 40 V. The minimum suggested voltage for these capacitors is

50 V.

Low ESR capacitors are a good choice in order to increase the entire system efficiency.

The suggested minimum output capacitance is 28 µF. In the case of series connection (see

Appendix B: SPV1020 parallel and series connection), it is suggested to increase the output

capacitance up to 100 µF.

In order to reduce the ESR effect it is suggested to split the output capacitance into three

capacitors connected in parallel.

In accordance with the maximum current (Isc) provided by the PV panel connected at the

input, the following formula can be used in order to select the proper capacitance value

(Cout) for a specified maximum output voltage ripple (V

out_rp_max

):

Equation 20

I

------------- ------------- ---------- ----------

C

≥

out

V

sc

out_rp-maxFSW

⋅

It is suggested to split the capacitance into four capacitors, each to be connected to each of

the four V

pins of the SPV1020. This helps to balance the impedance of the four tracks.

OUT

10.9 Output voltage partitioning

R3 and R4 are the two resistors used for partitioning the output voltage.

If V

OUT_MAX

according to the following rule:

Equation 21

Also, in order to optimize the efficiency of the entire system, when selecting R3 and R4, their

power dissipation must be taken into account.

Assuming negligible current flowing through pin V

the series connection of R3 and R4 is:

Equation 22

Empirically, R3 and R4 should be selected according to:

Equation 23

is the maximum output voltage at the load, then R3 and R4 must be selected

R3

------- -

R4

P

vout_sns

P

vo u t _sns

V

out_max

------------- --------- 1–=

1.00

V

()

out_max

------------- ------------- - -

=

R3 R4+

1% V

out_maxIou t_max

OUT_SNS

2

⋅()«

, maximum power dissipation in

34/57 Doc ID 018749 Rev 1

AN3392 External component selection

Note: In order to guarantee the proper functionality of V

connection of R3 and R4 should be between 20 µA and 200 µA.

10.10 Output voltage sensing capacitor

C10 is placed in parallel with R4 and is as close as possible to V

Its role is to maximize the stability of the voltage sensed by the V

If R3 and R4 are chosen properly and partition V

capacitor can be 3.3 V or higher.

The capacitance value depends on the time constant (τ

C8*R3//R4) and by the system switching frequency (F

Assuming R4<<R3 (so, R3//R4

Equation 24

so,

Equation 25

≅ R4):

T

C10 10

OUT

10

⋅⋅≈

------------- - -

F

SSW

OUT_SNS

OUT

----------- -

⋅≈

F

1

current flowing in the series,

OUT_SNS

OUT_SNS

.

pin.

to 1.25 V, the voltage rating of this

) composed with R4 (τ

out

1

ssw

SSW

1

------- -

R4

= 4*F

SW)

.

out

=

Note: Even if the SPV1020 controls each phase at F

switching frequency (System-Fswitch) is four times the single-phase switching frequency (by

default 400 kHz).

10.11 Internal oscillator frequency

The SPV1020 controls the boost application by a PWM signal operating at the default

switching frequency of 100 kHz.

Default switching frequency is guaranteed by connecting the OSC_IN pin to 5 V (VREG).

The user can change the default value by placing a proper resistor (R6), as shown in

Figure 24, to ground.

The internal oscillator works with an integrated resistor of 120 kΩ. Frequency is proportional

to the current provided to the oscillator block.

To change F

following formula:

Equation 26

to the desired switching frequency, R7 must be selected according to the

switch

R7 kΩ[]

(by default 100 kHz), the entire system

SW

100()120()⋅

------------ ------------ ----------- - -=

F

switch

kHz[]

Doc ID 018749 Rev 1 35/57

External component selection AN3392

10.12 Diode selection

The SPV1020 requires 3 Schottky diodes: D1, D2 and D3, as shown in Figure 24.

D3 (with C11) protects the SPV1020 supply by filtering system switching noise.

D3 should be chosen for low forward drop so that it doesn’t impact system efficiency.

Maximum forward current is according to the maximum current required by the SPV1020. A

safe choice is around 20 mA. Maximum voltage applied to D3 depends on the PV panel, and

does not exceed 45 V due to the maximum allowable SPV1020 input voltage.

D1 is the alternative path for current flow when the SPV1020 is down and V

V

.

OUT

D2 is a bypass diode. It turns on in the case of shaded cells and provides an alternative path

for the current flowing from other panels.

D1 and D2 are power Schottky diodes that must support both:

● Forward current comparable with the maximum current provided by the PV cells.

Assuming a PV panel with 6” poly crystalline silicon solar cells, then the maximum

current is 9 A.

● Maximum reverse voltage according to the output voltage partitioning. This should be

at least 45 V due to the voltage rating of the SPV1020.

Furthermore, the forward voltage and reverse current of D1 and D2 should be as low as

possible in order to minimize the impact on system efficiency.

10.13 Protection devices

The SPV1020 demo board uses a protection Transil™ D4 to trigger voltage spikes higher

than 45 V (AMR of the SPV102) on the V

This component must be chosen according to the following rules:

VBR > V

and

OUT

_max;

OUT

pins.

is higher than

in

VCL

≤ 45 V.

The STEVAL-ISV009V1 uses D4 which has VBR = 37 V and VCL = 40 V.

10.14 Pole-zero compensation

The SPV1020 controls the whole system stability by an internal loop on V

The transfer function of the loop depends on both the output capacitor and load.

Even though the stability can be fine tuned by trimming R5 and C8 on pin PZ_OUT, as

shown in Figure 24, their suggested values (R5 = 1 kΩ and C8 = 22 nF) guarantee stability

in most applications.

In order to increase system response to output voltage changes without causing overvoltage

threshold triggering, C8 can be decreased down to 2.2 nF.

36/57 Doc ID 018749 Rev 1

OUT_SNS

.

AN3392 Layout guidelines

11 Layout guidelines

The PCB layout is very important in order to minimize noise, high frequency resonance

problems and electromagnetic interference.

Paths between each inductor and its relative pin must be designed with the same

resistance. Different resistances between the four branches can be the root cause of an

unbalanced current flow among the four branches. Unbalanced currents can cause damage

and a poor tracking of the MPPT.

The same approach must be followed for the four V

It is essential to keep the paths where the high switching current circulates as small as

possible. This reduces radiation and electromagnetic resonance problems.

Large traces for high current paths and an extended ground plane under the metal slug of

the package help reduce noise and heat dissipation (which is strongly impacted by the

thermal vias as well), and also increase efficiency.

Boost capacitors must be connected as close as possible to the Lx and CBx pins.

It is also suggested to connect the bootstrap capacitor directly to the Lx track making sure

there is no voltage drop between the Lx pin and bootstrap capacitor connection due to

current flowing through Lx.

The output and input capacitors should be very close to the device.

The external resistor dividers, if used, should be as close as possible to the VIN_SNS and

V

OUT_SNS

noise pickup.

As an example of a recommended layout, see the demonstration board in Figure 25 and 26:

Figure 25. PCB layout example (top view)

of the device, and as far as possible from high current circulating paths, to avoid

OUT

tracks.

Doc ID 018749 Rev 1 37/57

Layout guidelines AN3392

Figure 26. PCB layout example (bottom view)

38/57 Doc ID 018749 Rev 1

AN3392 Bill of material

12 Bill of material

Ta bl e 5 shows a list of suggested external components to configure the SPV1020 in an

application with V

= 30 V, Imp = 9 A, V

OC

out_max

Table 5. Bill of material

Component Name Value Supplier Serial number

= 36 V and FSW = 100 kHz.

C1, C2, C3,

C4

C11 Die supply capacitor 1 µF Murata EPCOS

C5 PV input capacitor 4.7 µF Murata EPCOS

C9, C10 Voltage sensing capacitors 220 pF Murata EPCOS

C8 Compensation capacitor 22 nF Murata EPCOS

C7 Internal reference voltage capacitor 470 nF Murata EPCOS

C6, C12,

C13, C14,

C15, C16

D3 Decoupling of supply pin STPS160U ST STPS160U

R1 Input voltage partitioning resistor 3.3 MΩ VISHAY D11/CRCW0603 3.3M

R2 Input voltage partitioning resistor 110 kΩ Cyntec RR0816R-114-DN-11

R3 Output voltage partitioning resistor 3.9 MΩ VISHAY D11/CRCW0603 3.9M 1%

R4 Output voltage partitioning resistor 110 kΩ Cyntec RR0816R-114-DN-11

Bootstrap capacitors 100 nF Murata EPCOS

Output capacitors 4.7 µF Murata EPCOS

GRM188R71C104KA01

C1608X7R1H104K

GRM31MR71H105KA88

C3216X7R1H105K

GRM31MR71H475KA88

C3216X7R1H475K

GRM188R71E221KA01

C1608C0G1H221J

GRM188R71C223KA01

C1608X7R1H223K

GRM188R71A474KA61

C1608X7R1C474K

GRM32ER71H475KA88K

C3225X7R1H475K

R5 Compensation resistor 1 kΩ Cyntec RR0816R-102-DN-11

Pull-up resistor

R6

R7

(optional)

L1, L2, L3,

L4

D6, D7, D8 PV panel bypass diodes SPV1001N30 ST SV1001-N30

(Note: R6 must be removed if R7 is

soldered)

Oscillator resistor

(Note: R6 must be removed if R7 is

soldered)

Phase x (x=1..4) inductors 47 µH

Doc ID 018749 Rev 1 39/57

0 Ω

Depending

on desired

F

sw

Cyntec PIMB136T-470MS-11

Coilcraft MSS1278T-473ML

EPCOS

Murata 49470SC

B82477G4473M003

B82477G4473M

Bill of material AN3392

Table 5. Bill of material (continued)

Component Name Value Supplier Serial number

D1, D2 Controller bypass diodes SPV1001N40 ST SPV1001N40

J35 Voltage boost controller SPV1020 ST SPV1020

J36 SPI I/F connector

4-pin

connector

PHOENIX

CONTACT

1723672

D4

J47, J48 Output connector

J40 Alternative input connector

L5 Output current ripple filter 2.5 µH Coilraft MLC1550-252ML

600 W, 40 V bi-directional

protection Transil

SMBJ36CA ST SMBJ36A-TR

FASTON

connector

2-pin

connector

PHOENIX

CONTACT

40/57 Doc ID 018749 Rev 1

AN3392 STEVAL-ISV009V1 application diagram

Appendix A STEVAL-ISV009V1 application diagram

The following figure shows how to connect the STEVAL-ISV009V1 to a photovoltaic panel.

Figure 27. STEVAL-ISV009V1 application schematic

67(9$/,699

3

9

39SDQHO

9RXW

9RXW

3

9

6391

639

6391

It is possible to utilize a PV string by connecting the output stages of the SPV1020 in series

to guarantee the voltage level required by the specific application.

Maximum voltage for the STEVAL-ISV009v1 is 36 V, according to R3/R4 partitioning.

For example, if the application requires 400 V (V

STEVAL-ISV009V1 to be connected in series (Ns_min) is:

Equation 27

V

Ns

_min

out_tot

------------ -----------

V

out_max

In order to guarantee the performance of the whole PV string (e.g. in the case of shaded

panels), a minimum redundancy (10%) on Ns_min is suggested.

Furthermore, considering that the SPV1020 is a voltage boost converter, it is required that

the maximum input voltage (Vo of each PV panel) must be lower than its output voltage. So

the maximum number of devices in series is also limited by the following rule:

) then the minimum number of

out_tot

400

--------- - 12==≥

36

Equation 28

V

out_tot

Ns_max

Doc ID 018749 Rev 1 41/57

------------------ -

≤

V

oc

SPV1020 parallel and series connection AN3392

Appendix B SPV1020 parallel and series connection

The output pins of the SPV1020s can be connected both in parallel and in series. In both

cases the output power (Pout) depends on light irradiation of each panel (Pin), application

efficiency, and on the specific constraint of the selected topology.

The objective of this section is to explain how output power is impacted by the selected

topology.

Examples with three PV panels are presented, but the result can be extended to a larger

number of PV panels.

In the case of the SPV1020 being ON (I.e. there is enough light irradiation so that V

=

in

6.5 V):

Equation 29

Poutx η= Pinx x 1..3=[]

In the case of the SPV1020 being OFF, the system efficiency depends on the drop of the

bypass diode D1 (according to the schematic in Figure 24):

Equation 30

Poutx η

P= inx x 1..3=[]

bp

Finally, in the case of the panel being completely shaded:

Equation 31

Poutx 0=

42/57 Doc ID 018749 Rev 1

AN3392 SPV1020 parallel and series connection

B.1 SPV1020 parallel connection

This topology guarantees the desired output voltage even if only one of the panels is

irradiated. Of course, the constraint of this topology is that V

voltage ratings.

The following figure shows a detail of the parallel connection topology:

Figure 28. SPV1020, output parallel connection

is limited to the SPV1020

OUT

9R

XW

9R

9R

9R

9R

9R

9R

9RXW

".W

39

39

39

39

,69Y

39

39

,69Y

39

39

,69Y

39

The output partitioning (R3/R4) of the three SPV1020s must be in accordance with the

desired V

OUT

.

According to the topology:

Equation 32

Vout Vout1 Vout2 Vout3===

Equation 33

Iout Iout1 Iout2 Iout3++=

According to the light irradiation on each panel (Pin) and to the system efficiency (

power is:

Equation 34

Pout Pout1 Pout2 Pout3===

Equation 35

Poutx Voutx Ioutx x 1..3=[]⋅=

Doc ID 018749 Rev 1 43/57

η), output

SPV1020 parallel and series connection AN3392

Equation 36

Pinx Vinx Iinx X 1..3=[]⋅=

so,

Equation 37

Pout Vout Iout1 Iout2 Iout3++()η Pin1 η Pin2 η Pin3++==

Each SPV1020 contributes to the output power providing Ioutx according to the irradiation of

its panel.

Furthermore, the desired V

is guaranteed if at least one of the 3 PV panels provides

OUT

enough power to turn on the related SPV1020.

B.2 SPV1020 series connection

This topology provides an output voltage that is the sum of the output voltages of each

SPV1020 connected in series. The following shows how the output power is impacted by the

topology.

Figure 29 shows a detail of the series connection topology:

Figure 29. SPV1020, output series connection

06

06

"//34

-004

"//34

-004

6O

UT

06

DISTRIBUTED

ARCHITECTURE

In this case, the topology implies:

Equation 38

Iout Iout1 Iout2 Iout3===

Equation 39

Vout Vout1 Vout2 Vout3++=

44/57 Doc ID 018749 Rev 1

"//34

-004

6O U T

!-V

AN3392 SPV1020 parallel and series connection

In the case where the irradiation is the same for each panel:

Equation 40

Pin1 Pin2 Pin3==

Equation 41

Pout 3 Poutx x 1..3=[]⋅=

Equation 42

1

Poutx

-- -

Pout=

3

Equation 43

Poutx Voutx Ioutx Voutx Iout⋅=⋅=

so,

Equation 44

1

Voutx

For example, assuming Pout = 90 W and, if desired V

-- -

Vout=

3

= 90 V, then Voutx = 30 V.

OUT

Lower irradiation for one panel, for example on panel 2, causes lower output power, so lower

Vout2 due to the Iout constraint:

Equation 45

Poutx

------------ ----=

Iout

The output voltage (V

Voutx

) required by the load can be supplied by the 1st and 3rd SPV1020

OUT

but only up to the limit imposed by their R3/R4 partitioning.

Some examples can help to understand the various scenarios assuming the following

conditions: R3/R4 limiting Voutx = 40 V and desired V

OUT

= 90 V.

Example 1:

Panel 2 has 75% of the irradiation that panels 1 and 3 have:

3

Vout2

-- -

Vout1

4

Pout1 Pout2 Pout3==

3

Pout2

-- -

Pin1 22.5W==

4

3

-- -

Vout3⋅=⋅=

4

Pout Pout1 Pout2 Pout3 82.5W=++=

Doc ID 018749 Rev 1 45/57

SPV1020 parallel and series connection AN3392

Iout

Pout

-------------

Vout

Vout1 Vout3

Vout2

82.5

----------- 0.92A===

90

30

---------- - 32.6V===

0.92

22.5

----------- 24.45V==

0.92

Two of the SPV1020s (1st and 3rd) supply most of the voltage drop due to the lower

irradiation on panel 2.

Note: The SPV1020 is a boost controller, so Voutx must be higher than Vinx, otherwise the

SPV1020 turns off and the input power is transferred to the output stage through the bypass

diode D1 (refer to the schematic in Figure 24).

Example 2:

Panel 2 has 25% more irradiation than panels 1 and 3:

Vout2

1

---

4

Vout1

1

---

Vout3⋅=⋅=

4

Pout1 Pout2 30==

Pout2

1

-- -

Pin1 7.5W==

4

Pout Pout1 Pout2 Pout3 67.5W=++=

Iout

Pout

-------------

Vout

Vout1 Vout3

Vout2

67.5

---------- - 0.75A===

90

30

----------- 40V===

0.75

7.5

----------- 10V==

0.75

In this case the system is at its limit. A lower irradiation on panel 2 impacts Vout1 and/or

Vout3 which are already delivering as much voltage as possible (40 V), imposed by R3/R4

partitioning.

Example 3:

Panel 2 completely shaded.

In this case the maximum V

Diode D2 (refer to schematic in Figure 24) across the 2

can be 80 V (Vout1+Vout3).

OUT

nd

SPV1020 allows Iout to flow.

46/57 Doc ID 018749 Rev 1

AN3392

Appendix C

C.1 Power efficiency, MPPT efficiency and thermal analysis

The aim of this appendix is to show the efficiency and MPPT accuracy of the STEVALISV009V1.

The following equipment has been used:

1. Agilent Technologies E4360A Modular SAS Mainframe with module E4361A

2. Chroma 6314A DC ELECTRONIC LOAD Mainframe

3. LeCroy WaveRunner 6100 A.

4. Agilent 34401A digit Multimeter (as voltmeter)

5. Agilent U1242 digital Multimeter (as ammeter)

6. STEVAL-ISV009V1 (SPV1020 application board)

The following image shows the setup of the above environment.

Figure 30. Measurement environment

The following figure (Figure 31) shows the power conversion when @V

ranges from 1 A to 8 A (step 1 A), and P ranges between 12 W and 96 W. The minimum

efficiency at P=96 W is 97 %.

Doc ID 018749 Rev 1 47/57

MPP

=12 V, I

MPP

Figure 31. Power efficiency vs. output voltage

0OWER EFFICIENCY 6

AN3392

ϭϬϬϬϬй

ϵϬϬϬй

ϴϬϬϬ

ϳϬϬϬй

ϲϬϬϬй

й

Wсϵϲt

Wсϴϰt

WсϳϮt

WсϲϬt

ϱϬϬϬй

Wсϰϴt

Wсϯϲt

WсϮϰt

WŽƵƚWŝŶй

ϰϬϬϬй