AN3358

Application note

Turbo2 600 V diodes:

optimized solutions for PFC and other applications

Introduction

In a switched mode power supply, there are a great number of electronic functions where

600 V ultrafast diodes are used. Each diode has a specific function. In one application a

parameter can be critical but secondary in another.

A rectifier manufacturer who wants to propose an optimized solution for each function needs

to develop several families with different trade-offs (mainly between the forward voltage V

and reverse recovery charge Q

STMicroelectronics’ Turbo2 600 V ultrafast diodes offer three different families in order to

offer an optimal solution for each application.

After some general information about this new technology, a discussion of the PFC

application, working in continuous mode, transition mode and fixed-off-time, is presented. In

the case of continuous mode operation, hard switching and soft switching conditions are

considered. Some other conventional functions are also touched upon.

).

rr

F

September 2011 Doc ID 018581 Rev 1 1/18

www.st.com

Contents AN3358

Contents

1 General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.1 Technology information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.2 V

1.3 Platinum doping and low leakage current . . . . . . . . . . . . . . . . . . . . . . . . . 3

, Qrr trade-off for the three families . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

F

2 Main applications of 600 V ultrafast diodes . . . . . . . . . . . . . . . . . . . . . . 5

2.1 Power factor corrector applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.1.1 Boost diode in PFC working in continuous mode . . . . . . . . . . . . . . . . . . 5

2.1.2 Boost diode in PFC working in transition mode . . . . . . . . . . . . . . . . . . . 10

2.1.3 Boost diode working in fixed-off-time (FOT) PFC . . . . . . . . . . . . . . . . . 12

2.2 Other applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3 Conclusion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4 References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2/18 Doc ID 018581 Rev 1

AN3358 General information

1 General information

1.1 Technology information

The Turbo2 families are manufactured using simple rules to insure high quality and

reliability. These diodes are planar structures on epitaxial layers. The wafers are thus

subjected to reduced mechanical stress for planar diodes compared to mesa ones.

The use of epitaxial layers makes the V

trade-off independent of the wafer thickness, the

F/trr

contrary of homogenous diodes. These properties make the manufacturing of large

diameter wafers possible. So the wafers benefit from state-of-the-art technology on recent

equipment.

Epitaxial diodes, which present good drift area thickness, are particularly suitable for diodes

up to 600 V and exhibit a significantly superior V

trade-off. The lifetime control of the

F/trr

carriers for the Turbo2 diodes is obtained through platinum (P

for high junction temperature applications because it results in low reverse current at

elevated temperature and, in this way, presents a low thermal runaway risk.

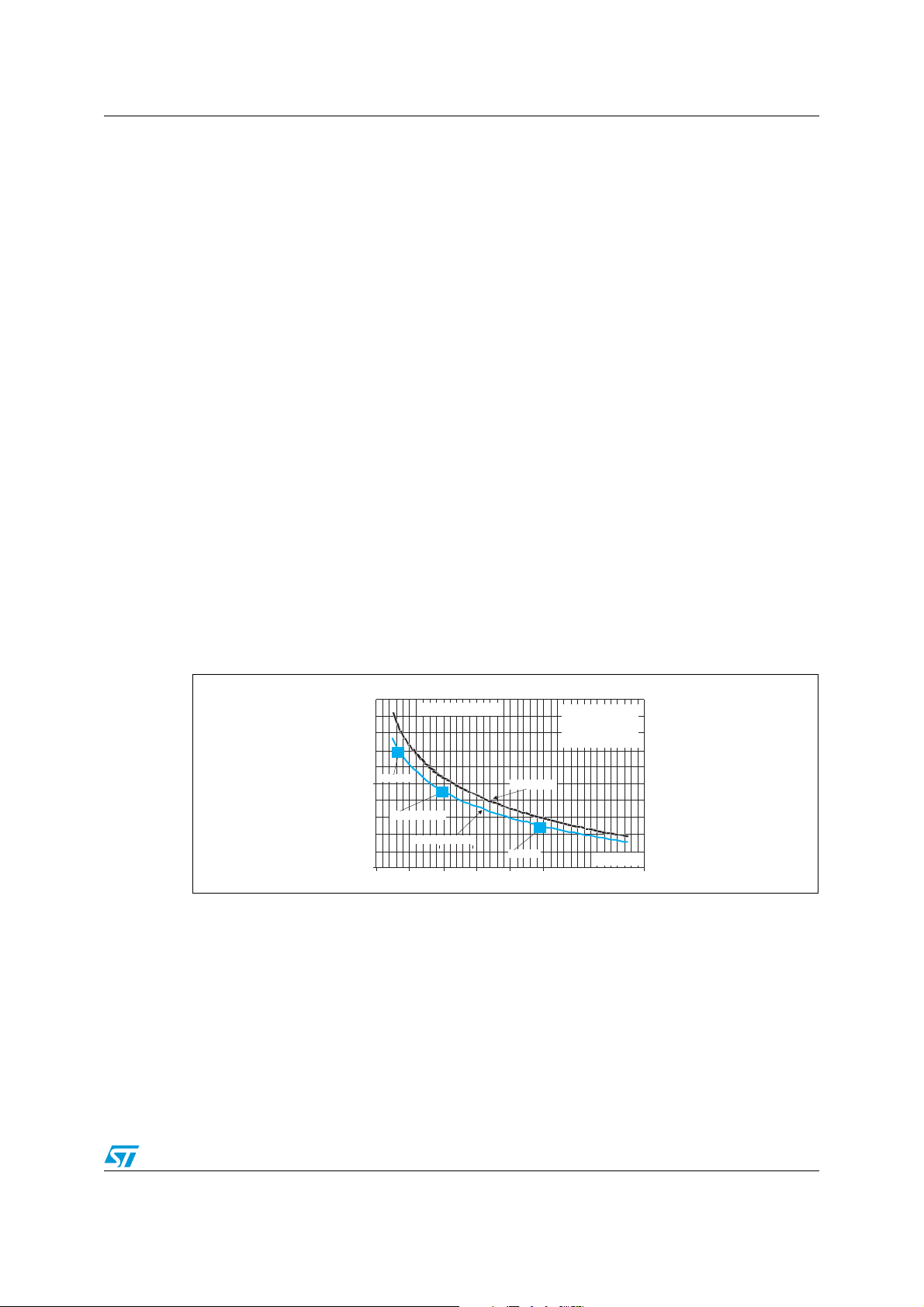

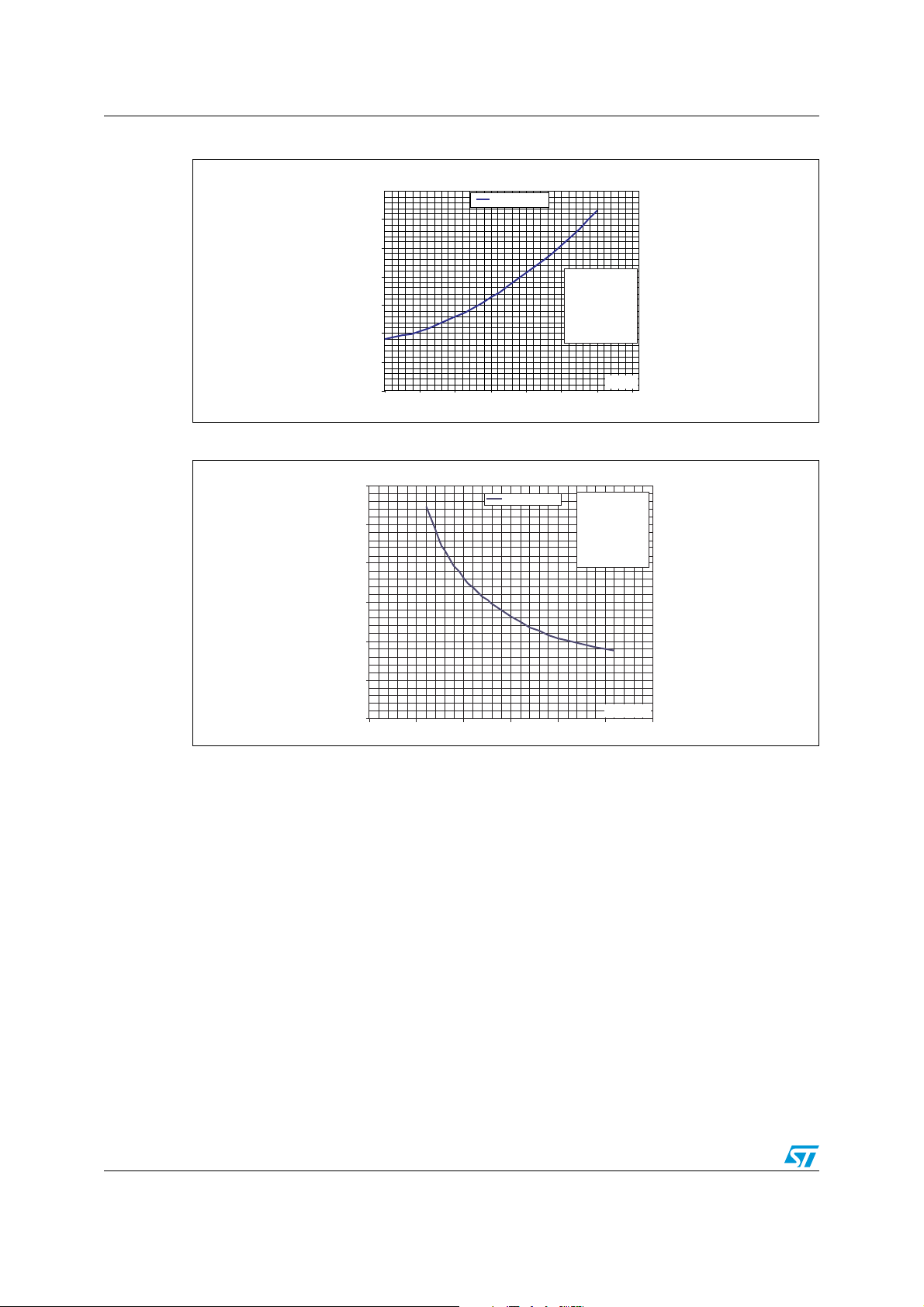

1.2 VF, Qrr trade-off for the three families

The three families are: STTHxxR06 (R stands for rapid with low Qrr), STTHxx06 (medium VF

and Q

Figure 1 shows where a trade-off occurs in three operational areas. A technology using gold

doping is also shown.

Figure 1. V

), and STTHxxL06 (Low forward voltage).

rr

- Qrr trade-off for an 8 A diode

F

V (V)

F

1.7

Typical values

) doping. Pt doping is required

t

IF= 8 A

VR= 400 V

dIF/dt = 200 A/µs

Tj= 125 °C

R Family

1.2

Medium Family

Platinum doping

0.7

0 200 400 600 800 1000 1200 1400 1600

Gold doping

L Family

Qrr(nC)

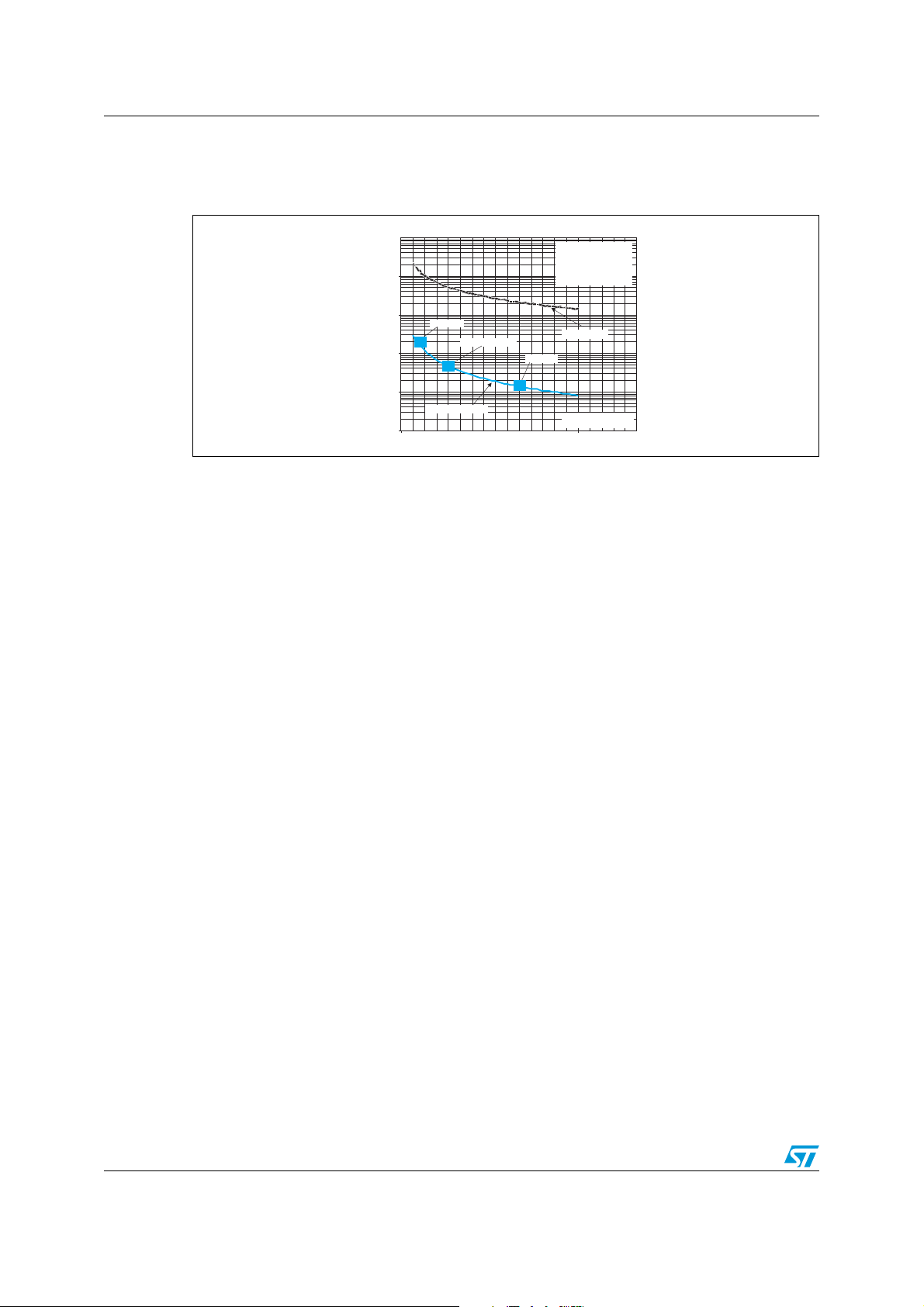

1.3 Platinum doping and low leakage current

Figure 2 shows the trade-off between leakage current IR and Q

areas. The faster the diode, the higher the I

doping. For the same Q

, IR is approximately 100 times lower with platinum doping. The

rr

corresponding “R” family with gold doping would have a high maximum leakage current

(18 mA at 125 °C and 400 V). As shown later in this Application note, with such a leakage

current thermal instability can be reached for operating junction temperatures higher than

125 °C in a conventional application.

Doc ID 018581 Rev 1 3/18

is. This rule is true for both gold and platinum

R

in several operational

rr

General information AN3358

1

10

100

1000

10000

100000

0 500 1000 1500 2000

It will also be shown that IR is also a critical parameter for diodes in axial and SMD

packages.

Figure 2. I

- Qrr trade-off in several operational areas for an 8 A diode

R

I (µA)

Rmax

IF= 8 A

VR= 400 V

dIF/dt = 200 A/µs

Tj= 125 °C

R Family

Medium Family

Platinum doping

L Family

Gold doping

Q

rr typ

(nC)

4/18 Doc ID 018581 Rev 1

AN3358 Main applications of 600 V ultrafast diodes

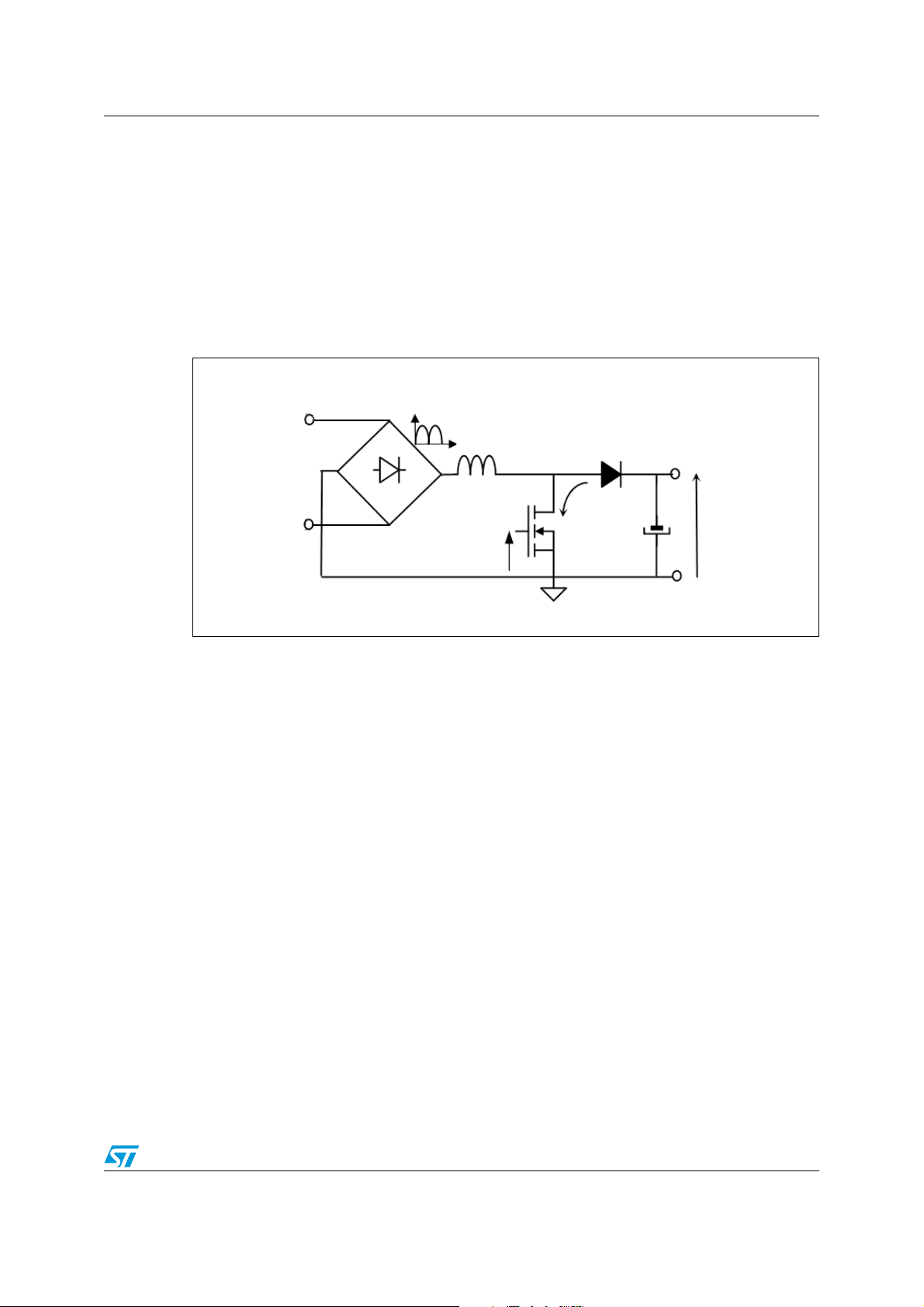

2 Main applications of 600 V ultrafast diodes

This section discusses the trade-offs in a common application. Boost power factor corrector

(PFC) will be widely covered since it is a major application. A typical PFC circuit is shown in

Figure 3.

2.1 Power factor corrector applications

Figure 3. Boost power factor corrector circuit

V

mains

L

V

gate

D

boost

I

RM

2.1.1 Boost diode in PFC working in continuous mode

Hard switching conditions

PFC applications are mainly designed in continuous mode when the power is greater than

200 W.

In such an application, it is well known that the greatest losses due to the diode are the

switching losses in the transistor (P

of the boost diode flows into the MOSFET (Figure 3). Consequently, the best choice in most

cases is the “R” family.

Switching losses due to I

temperature T

and the mains voltage V

j

depend mainly on two parameters: the operating junction

RM

Figure 4 and Figure 5 show that the switching losses for STTH8R06 quickly increase when

T

increases and when V

j

decreases. These curves are drawn with a software tool

mains

realized by these authors.

) when it turns on. The reverse recovery current (IRM)

ontr

.

mains

V

out

If the PFC only works on 240 V mains, with a low operating junction temperature, switching

losses will be less critical and the best trade-off could be the intermediate trade-off:

STTHxx06.

However, most PFCs are designed to work in a wide mains voltage range (85 V-264 V) with

an operating junction temperature (in the worst case) close to 100 °C. The “R” family will be

the family usually recommended.

Doc ID 018581 Rev 1 5/18

Main applications of 600 V ultrafast diodes AN3358

Figure 4. Switching losses versus Tj at turn off of the diode

P diode + P due to the diode (W)

off ontr

14

12

10

STTH8R06D

8

6

4

2

0

0 25 50 75 100 125 150 175

Figure 5. Switching losses versus V

P diode + P due to the diode (W)

off ontr

12

10

8

6

4

2

0

0 50 100 150 200 250 300

V = 90 V

mains

dI/dt = 400 A/µs

L = 0.5 mH

F = 100 kHz

sw

V = 400 V

OUT

P = 400 W

OUT

at turn off of the diode

mains

STTH8R06D

T = 100 °C

dI/dt = 400 A/µs

L = 0.5 mH

F = 100 kHz

sw

V = 400 V

OUT

P = 400 W

OUT

T (°C)

j

j

V (V)

mains

6/18 Doc ID 018581 Rev 1

AN3358 Main applications of 600 V ultrafast diodes

T

before thermal runaway

jmax

The maximum junction temperature T

before thermal runaway can be calculated using

jmax

Equation 1, Equation 2 then Equation 3.

Equation 1

2 V

δ = 1 -

mains peak

π V

OUT

Equation 2

I(V ,T )

R OUT jmax

=

V · c R

1

δ·

OUT th(j-a)

Equation 3

T = 125 +

jmax

1

c

· log

I(V T )

R OUT, jmax

e

(

I (V 125 °C)

Rmax OUT,

(

Where:

● δ is the average duty cycle of the blocking time of the diode given by Equation 3.

● V

● c is a constant with units of °C

is the output voltage.

OUT

-1

. Each diode has its own “c” coefficient depending on

the technology of the diode and the reverse voltage V

applied. It can be determined

R

from Equation 3 for two values of leakage curr ent correspond ing to applicatio n reverse

● R

voltage V

th(j-a)

, for example: IR(V

out

,100 °C) and IR(V

out

,125 °C).

out

is the thermal resistance between junction and ambient (heatsink + diode).

With the following conditions:

V

= 400 V, c ≈ 0.055 °C

OUT

V

= 85 V, δ = 0.8, R

mains

Figure 2 gives I

Rmax(400 V, 125 °C)

-1

(for the “R” family)

= 10 °C/W

th(j-a)

= 215 µA for an 8 A “R” family diode and 17 mA for the

equivalent diode in gold doping.

Equation 2 and Equation 3 give T

= 184 °C for Turbo2 and 104 °C for the equivalent

jmax

diode in gold doping.

Soft switching condition

Designers can use a number of techniques to turn on the MOSFET in soft switching

conditions and reduce the switching losses due to I

Figure 6 and Figure 7 show two solutions, widely used with the associated waveforms

during switching time. In the non-dissipative circuit Figure 6, the smaller transistor T2 turns

on before the main one T1. The dl/dt when D

boost

and T1 turns on at zero current. Consequently, the switching-on losses will be close to zero.

With this circuit, the reverse recovery current of the boost diode is less critical. The best

choice, following the application conditions (switching frequency, L

intermediate” or the “L” trade-off.

Doc ID 018581 Rev 1 7/18

.

RM

turns off is controlled by Lr (dl/dt = V

…) will be “the

r

out/Lr

),

Main applications of 600 V ultrafast diodes AN3358

Figure 6. Non-dissipative soft switching solution

V

mains

D

boost

L

r

D

r

T

1on

V

out

T1, T2

L

C

T

1

r

T

2

I

0+IRM

IRM+I

I

DBoost

V

res

T

I

0

I

Lr

2on

V

⎛

⎞

OUT

⎜

⎟

L

⎝

⎠

r

I

RM

I0+IRM+I

I

Dr

Cr

I

T1

t

t

res

t

t

t

t

8/18 Doc ID 018581 Rev 1

AN3358 Main applications of 600 V ultrafast diodes

The topology shown in Figure 7 is more simple but more dissipative than that in Figure 6.

The waveforms in Figure 7 show the MOSFET turning on at zero current, thus reducing the

switching losses. When the diode turns off, the L

inductor is charged with the reverse

r

recovery current of the boost diode. This energy will be dissipated in the resistor.

The higher I

is the higher the losses in the resistor are. In this application IRM is more

RM

critical than in the previous one. The best choice for the boost diode trade-off will be “R” or

medium family depending on the application conditions.

Figure 7. Dissipative soft switching solution

D

V

mains

L

DBoost

V

DS

r

L

r

V

RC

V

OUT

T

450 V

250 V

I

T

V

DS

20 A

10 A

180.8

180.8

0A

-10 A

20 A

10 A

0A

-8 A

0V

-250 V

60 V

40 V

20 V

0V

180.0

180.0

I

DBoost

180.4

180.4

180.5

180.5

180.6

180.6

t (µs)

180.7

t (µs)

180.7

V

180.1

RC

180.1

I

RM

180.2

I

Dr

180.2

180.3

I

DBoost

I

Lr

180.3

Q

rr

Another very interesting alternative soft switching solution is described in the application

note AN3276, “ST solution for efficiency improvement in PFC applications, back current

circuit (BC2)”. AN3276 presents a patented soft switching circuit from STMicroelectronics

offering performance similar to that of SiC Schottky diodes.

Doc ID 018581 Rev 1 9/18

Main applications of 600 V ultrafast diodes AN3358

2.1.2 Boost diode in PFC working in transition mode

The transition mode (TM) is widely used for low power PFC (<200 W). The particularity of

this control mode working between continuous and transition mode is a simple control and a

few external components. This control mode results in variable frequency operation and a

constant on time of the MOSFET.

Consequently, the current flowing through the Boost inductor is triangular (Figure 8). It

increases through the MOSFET following the slope defined by V

through the diode following a low dl/dt given in Equation 4.

Equation 4

mains

V

-

OUT

L

dI

V

=

dt

In this case dI/dt may have a value up to 0, the necessary condition for the next cycle.

Figure 8. Inductor current waveform and MOSFET timing

P

I

P

K

=2 2x

OUT

V

mains

Average

input current

/L, and decreases

mains

Inductor

current

V

mains

L

V-V

mains out

L

T =

2 · F

1

mains

N

=

F

SW

On

MOSFET

Off

t fixed

on

T variable

SW

The ZCD circuit (zero current detection) turns on the MOSFET at zero current, avoiding high

switching losses in the MOSFET due to the recovery charge of the diode.

Unlike the continuous mode, the Q

of the diode it is not the key parameter any more. In the

rr

transition mode, the main losses of the diode are due to the forward voltage. It is then

possible to optimize the V

parameter to the detriment of Qrr, due to the low dl/dt

F

of the

off

diode (<1 A/µs) fixed by the inductor.

10/18 Doc ID 018581 Rev 1

AN3358 Main applications of 600 V ultrafast diodes

Nevertheless, an accurate study at switch-off of the diode shows that the Qrr parameter

cannot be indefinitely relaxed. Figure 9 highlights this phase when the current of the diode

reaches 0, and shows that this time is composed of 3 phases:

● Phase 1 [t0,t1]: The diode is open. There is a resonant circuit between the equivalent

capacitance (C

condition the I

● Phase 2 [t1,t2]: V

conduction and the current linearly increases through the V

● Phase 3 at t2: The ZCD circuit turns the MOSFET on and the current continues to

linearly rise through the R

MOS + Cj diode) and the boost inductance, which has as its initial

ds

of the diode.

RM

reaches 0 and the body diode of the MOSFET enters in

DS

DS(on)

.

of the body diode.

F

Figure 9. Switch-off comparison between STTH1L06 and a slower diode

t

t

t

2

1

0

I

RM

I

Diode

VdsV

ds

Slower diode

V

grille

I

Mos

STTH1L06

It can be observed that the dead time (t0,t2) increases with the I

of the diode. This time a

RM

negative current flows through the power MOSFET and is the source of additional losses.

This duration depends on the slope (versus V

, L) and also on the IRM of the diode (the

mains

initial condition of phase 1). During this time there is no power transferred to the load. In this

way, with a very slow diode, the sum of the losses due to high I

compared to these of the conduction losses. Therefore, there is a limit for Q

cannot be negligible

RM

. This limit

rr

appears for the full range PFC at 110 V. In this condition the current in the power MOSFET

takes more time to reach 0 (maximum dead time).

The maximum Q

of the “L” family has been optimized taking these considerations into

rr

account.

According to the application conditions (P

out

, V

mains

, dI/dt

, Fsw, Tj), the medium trade-off

max

could be also considered. The optimum choice between low forward voltage trade-off

(STTHxxL06) and the medium trade-off (STTHxx06) could be determined by efficiency

measurement.

In transition mode a diode with a small current rating is used. It is generally a small package

(axial or SMD packages) with high thermal resistances. Consequently, the junction

Doc ID 018581 Rev 1 11/18

Main applications of 600 V ultrafast diodes AN3358

temperature of the diode, which is mainly fixed by the conduction losses, can be high.

Equation 2 in Section 2.1 shows that the thermal resistance is a critical parameter for the

thermal runaway limit. Tabl e 1 compares the thermal runaway limit between Turbo2 and a

gold-doped diode working in a transition mode PFC in the following conditions:

R

= 75 °C/W, c ≈ 0.072 °C

th(j-a)

Table 1. T

125 °C, 400 V 15 µA 1.5 mA

I

Rmax

T

before thermal runaway

jmax

comparison between Turbo2 and gold doping diode

jmax

limit is reached.

-1

, V

= 400 V, V

OUT

= 85 V, δ = 0.808

mains

STTH3L06 Gold Doping

176 °C 112 °C

This comparison shows that gold-doped diodes are limited in high temperature. There is no

thermal runaway risk when Turbo2 uses platinum doping. For all these reasons, in most

cases, the “L” family is recommended for the PFC application working in transition mode.

2.1.3 Boost diode working in fixed-off-time (FOT) PFC

In this third PFC operating mode, instead of maintaining the on-time fixed, such as TM PFC,

the T

drained from the source according to the load.

is kept constant and the Ton is free to be changed in order to modulate the power

off

This modulation method, is described in the Application note AN1792, “Design of fixed-offtime controller PFC pre-regulators with L6562”.

As shown in Figure 10 in FOT mode, the PFC works in DCM and CCM modes along the line

semi period.

Figure 10. Inductor, switch and diode currents in a CCM FOT-controlled PFC stage

DCM

Switch current

Switch

CCM

ILpk

θt

OFF OFF

Inductor current

peak envelope

DCM

Low frequency

inductor current

Diode current

ON

OFF

π−θt

12/18 Doc ID 018581 Rev 1

AN3358 Main applications of 600 V ultrafast diodes

In this operating mode, according to the application conditions the optimal diode will be the

medium trade-off (V

) or the rapid trade-off (“R” family). The designer should make

F/QRR

some measurements of efficiency to confirm the good trade-off diode in its application.

2.2 Other applications

There are numerous other electronic functions, where 600 V ultrafast diodes are used. For

example, rectification, demagnetization, snubber, bootstrapping, clamping, or East-West

correction in a horizontal deflection circuit for TV or monitor (Figure 11).

Figure 11. Traditional applications of 600 V ultrafast diodes

Clamping diode

Snubber diode

Demagnetization diode

Bootstrap diode

Modulator diode in horizontal deflection circuit

Doc ID 018581 Rev 1 13/18

Main applications of 600 V ultrafast diodes AN3358

It is not possible in this document to analyze each function in detail. We will focus on the

clamping function used in flyback converters. The function of the clamping circuit is to

protect the MOSFET against the overvoltage due to the energy in the leakage inductance of

the transformer. The associated waveforms are represented in Figure 12.

Figure 12. 600 V ultrafast diode waveforms in clamping function

V

mains

V

Lf

or

V

V

IN

C

V

DCL

m

D

CL

V

D

R

V

OUT

DS

V

DS

I

CL

D

I

CL

I

DR

V

DCL

D

Qrr

Breakdown voltage of the MOS transistor

VDS=VIN+VC+V

V

Lf

I

DR

VIN+(V

V

FP

/m)

OUT

IN

V

CEsat

V

FP

V

Rmax=VIN+VC

+S

pike

14/18 Doc ID 018581 Rev 1

AN3358 Main applications of 600 V ultrafast diodes

When the MOSFET turns off, the inductive circuit opens and an overvoltage VLf appears in

addition to the voltage across the primary inductor V

turns on the clamping diode. Thus, the drain voltage is equal to V

V

is the peak forward voltage across the 600 V diode. VC is a DC voltage realized either

FP

/m. The effect of this overvoltage

OUT

= VIN + VC +VFP.

DS

by an RC circuit in parallel or by a clamping diode such as a Transil™.

The first key parameter of the diode is V

of the MOSFET. If V

is too high the designer may be obliged to choose a higher voltage

FP

FP. VDS

has to be lower than the breakdown voltage

MOSFET (for example 800 V instead of 600 V).

To avoid thermal runaway problems a low value of leakage current is necessary as the diode

is normally a 1 A device in an SMD or axial package. A low I

will also contribute to the

R

reduction of consumption in stand-by mode. The forward voltage is not a critical parameter

because the diode conducts about ten nanoseconds every switching period.

When the clamping voltage is made with a Transil, it is generally better to use an ultrafast

type diode. When an RC solution is used, the capacitance is discharged through the reverse

recovery current of the diode, thus reducing the losses in the resistor.

The Turbo2 technology, which allows low leakage current and low peak forward voltage, is

well suited for this application. The best trade-off with a Transil, will be the “R” or the medium

family. With an RC solution the choice will generally be between the “L” and the “medium”

families.

TM: Transil is a trademark of STMicroelectronics

Doc ID 018581 Rev 1 15/18

Conclusion AN3358

3 Conclusion

This Application note presents the main applications of the 600 V ultrafast diodes. These

applications are numerous, each requiring a slightly different trade-off among the diode

parameters. In order to propose an optimized solution for each one, three trade-offs are

proposed by STMicroelectronics. There are some general rules to define the right trade-off.

For example, the “R” family for PFC working in continuous mode and hard switching

condition and the “L” family for PFC working in transition mode. However, there are also

applications for which a deeper study will be necessary.

An important benefit of the platinum doping implemented in the Turbo2 technology resides

in the use of the diodes at high junction temperature without thermal runaway risk in normal

prescribed condition of use (<175 °C).

16/18 Doc ID 018581 Rev 1

AN3358 References

4 References

[1] ST Application note AN628, “Designing a high power factor switching preregulator with

the l4981 continuous mode”

[2] PCIM, Nuremburg, 2000 “New solution to optimize diode recovery in PFC boost

converter”, B. Rivet.

[3] ST Application note AN667, “Designing a high power factor switching preregulator with

the l6560 transition mode”

[4] ST Application note AN966, “Enhanced transition mode power factor corrector”

[5] ST Application note AN1792, “Design of fixed-off-time controller PFC preregulator with

the L6562”

[6] ST Application note AN3276, “ST solution for efficiency improvement in PFC

applications, back current circuit (BC

5 Revision history

Table 2. Document revision history

Date Revision Changes

14- Sep-2011 1 First issue

2

)”

Doc ID 018581 Rev 1 17/18

AN3358

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY TWO AUTHORIZED ST REPRESENTATIVES, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2011 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Philippines - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

18/18 Doc ID 018581 Rev 1

Loading...

Loading...