AN3352

Application note

Dual LNB power supply based on the LNBH24L

supply and control IC with step-up and I²C interface

Introduction

This application note is intended to provide additional information and suggestions for the

correct use of the LNBH24L device. All waveforms shown are based on the demonstration

board order code STEVAL-CBL008V1 described in Section 3.

The LNBH24L is an integrated solution for supplying/interfacing two independent LNB

down-converters in antenna dishes and/or multi-switch box. It gives good performance in a

simple and cheap way, with minimum external components necessary. It includes all

functions needed for LNB supplying and interfacing, in accordance with international

standards. Moreover, it includes an I²C bus interface and, thanks to a fully integrated step-up

DC-DC converter, it functions with a single input voltage supply ranging from 8 V to 15 V.

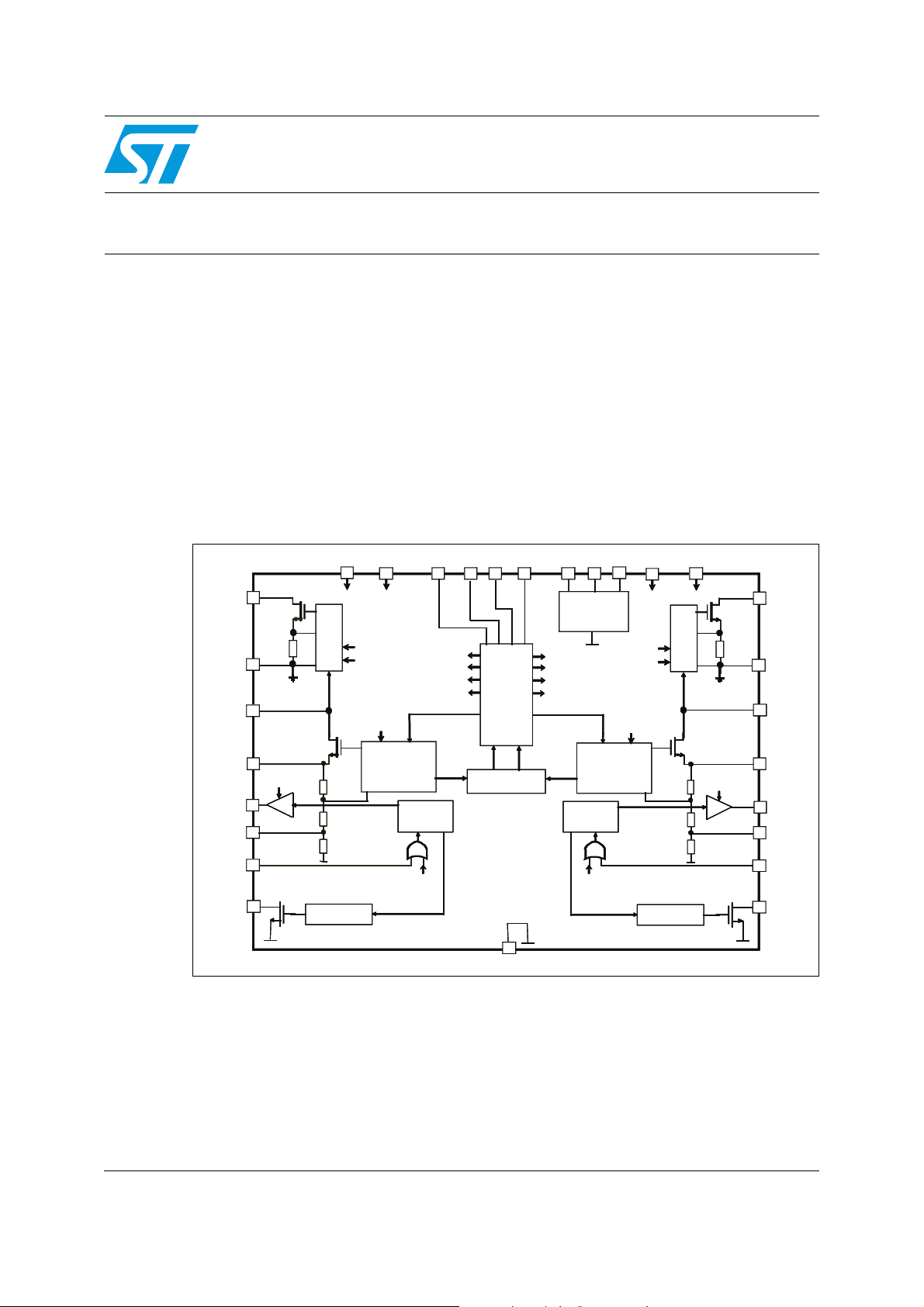

Figure 1. LNBH24L internal block diagram

TTX-

ADDR-

ISEL-

A

A

-

A

SDA SCL

ADDR -

- -- - -

BypVcc

B

Vcc-

L

ISEL-

TTX-

B

B

LX -

-

A

Rsense

P-GND-

- -

A

Vup-

-

A

VoRX-

-

A

A

TTX-

VoTX-

-

A

EXTM-

-

A

DSQIN -

-

A

-

PDC

A

PWM

Controller

Pull Down

Controller

A

EN-

A

VSEL-

A

ISEL-

Linear Post-reg

+Protections

+Diagnostics

FB

FBFBFB

TEN-

EN-

VSEL-

TTX-

VOUT-AControl

-

-

22 kHz

Oscillato r

A

TEN-

A

-

A

-

A

-

A

-

I²C Di agnostics

²

LNBH24L

A-GND

C interface

²

I

I

-

Preregul ator

+U.V.lockout

+P.ON reset

B

B

TEN-

B

EN-

-

B

-

VSEL-

B

TTX-

-

VOUT-BControl

-

Linear Post-reg

+Protections

+Diagnostics

22 kHz

Oscillato r

TEN-

TEN-

PWM

Rsense

B

EN-

B

VSEL-

B

ISEL-

-

FB

FB

B

B

Pull Down

Controller

Rsense

Controller

B

TTX-

AM09362v1

LX -B

-

P-GND-

Vup-

-

B

VoRX-

VoTX-B

EXTM-B

DSQIN -

-

-

PDC

B

-

B

-

-

-

B

B

November 2011 Doc ID 018526 Rev 3 1/26

www.st.com

Contents AN3352

Contents

1 Block diagram and pin function description . . . . . . . . . . . . . . . . . . . . . 5

1.1 Step-up controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2 Pre-regulator block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.3 I²C interface and diagnostic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.4 DiSEqC™ 1.X implementation through EXTM pin . . . . . . . . . . . . . . . . . . . 6

1.5 DiSEqC 1.X implementation through VoTX and EXTM . . . . . . . . . . . . . . . 7

1.6 PDC optional circuit for DiSEqC 1.X applications using VoTX signal

on to EXTM pin and 22 kHz tone controlled by DSQIN pin . . . . . . . . . . . . 7

1.7 22 kHz oscillator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.8 DiSEqC communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.9 Linear post-regulator, modulator and protection . . . . . . . . . . . . . . . . . . . . 8

1.10 Pin description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2 Component selection guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.1 DC-DC converter inductor (L1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.2 Output current limit selection (R2-RSEL) . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.3 DC-DC converter Schottky diode (D1) . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.4 TVS diode (D6) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.5 DC-DC output capacitors (C3, C4, C6) and ferrite bead . . . . . . . . . . . . . 16

2.6 Input capacitors (C1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.7 PDC optional external circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.8 EXTM-VOTX resistor (R9) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2.9 Undervoltage protection diode (D2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3 Layout guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.1 PCB layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.2 PCB Thermal managing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4 Startup procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

2/26 Doc ID 018526 Rev 3

AN3352 List of tables

List of tables

Table 1. LNBH24L I²C addresses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Table 2. Output load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Table 3. LNBH24L pin description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Table 4. LNBH24L demo-board BOM list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Table 5. Recommended Inductors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Table 6. Recommended Schottky diode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Table 7. Recommended LNBTVS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Table 8. Document revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Doc ID 018526 Rev 3 3/26

List of figures AN3352

List of figures

Figure 1. LNBH24L internal block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Figure 2. EXTM example of use with 22 kHz IC controller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Figure 3. DiSEqC 1.X tone burst with 22 kHz IC controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Figure 4. DiSEqC timing control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Figure 5. LNBH24L pin configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Figure 6. LNBH24L typical application circuit with internal tone generator . . . . . . . . . . . . . . . . . . . . 11

Figure 7. Typical output current limiting vs. RSEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Figure 8. Example of LNBTVS diode connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 9. DC-DC converter output stage with ferrite bead . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 10. Application circuit with PDC optional solution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Figure 11. PDC optional circuit load calculation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 12. PDC circuit waveform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 13. Tone amplitude vs. R9 value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 14. PBC top layer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 15. PBC bottom layer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Figure 16. PCB components layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Figure 17. PCB connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4/26 Doc ID 018526 Rev 3

AN3352 Block diagram and pin function description

1 Block diagram and pin function description

Here below a description of the LNBH24L internal blocks that includes two completely

independent sections. Except for the V

controlled and contain independent external components. All the specifications below must

be considered equal for both sections (A/B).

1.1 Step-up controller

The LNBH24L features a built-in step-up DC-DC converter that, from a single supply source

ranging from 8 V to 15 V, generates the voltages that allow the linear post-regulator to work

with minimum power dissipation. The external components of the DC-DC converter are

connected to the LX and V

UP

1.2 Pre-regulator block

This block includes a voltage reference connected to the BYP pin, an undervoltage lockout

circuit, intended to disable the whole circuit when the supplied V

threshold (6.7 V typ), and a power-on reset that sets all the I²C registers to zero when the

V

is turned on and rises from zero above the “ON” threshold (7.3 V typ).

CC

pins (see Figure 6). No external power MOSFET is needed.

and I²C inputs, each circuit can be separately

CC

drops below a fixed

CC

1.3 I²C interface and diagnostic

The main functions of the device are controlled via the I²C bus by writing 5 bits on the

system register (SR bits in write mode). In the same register there are 5 bits that can be

read back (SR bits in read mode) and provide 2 diagnostic functions, whereas the other 3

bits are for internal use (TEST1, TEST2, and TEST3).

Two bits report the diagnostic status of the two internal monitoring functions:

– OTF: overtemperature flag. If an overheating occurs (junction temperature exceeds

150 °C), the OTF I²C bit is set to “1”.

– OLF: overload flag. If the output current required exceeds the current limit threshold

or a short-circuit occurs, the OLF I²C bit is set to “1”.

Moreover, three bits report the last output voltage register status (EN, VSEL, LLC) received

by the I²C. The LNBH24L I²C interface address can be selected from two different

addresses for each section A/B by setting the voltage level of the relevant ADDR pin

according to Ta bl e 1 :

Table 1. LNBH24L I²C addresses

Section Pin Set-up Write (HEX) Read (HEX)

A

B

ADDR-A=low or floating 10 11

ADDR-A=high 12 13

ADDR-B=low or floating 14 15

ADDR-B=high 16 16

Doc ID 018526 Rev 3 5/26

Block diagram and pin function description AN3352

1.4 DiSEqC™ 1.X implementation through EXTM pin

The EXTM pin is an analog input to generate the 22 kHz tone superimposed to the V

output voltage. If the EXTM pin is used, the internal 22 kHz generator must be kept OFF

(TTX pin or TTX bit set LOW). A cheaper circuit must be used to couple the modulating

signal source to the EXTM pin (see Figure 2).

The EXTM pin modulates the V

V

(AC) = V

oRX

where:

–V

oRX

and EXTM pin

–G

EXTM

In order to avoid the 22 kHz tone distortion, a dummy output load may be necessary, strictly

dependent on the output bus capacitance.

Table 2. Output load

Output bus capacitance Output load

< 50 nF 10 mA

250 nF (EUTELSAT spec.) 30 mA

750 nF (DIRECT TV spec.) 80 mA

voltage through the series decoupling capacitor, so that:

oRX

(AC) x G

EXTM

(AC) and V

EXTM

(AC) are, respectively, the peak-to-peak voltage on the V

EXTM

is the voltage gain from EXTM to V

oRX

DC

oRX

oRX

.

For the correct DiSEqC implementation, during tone transmission, it is most important that

the DiSEqC_out pin of the 22 kHz IC controller, is set in low impedance and vice versa,

during no-tone transmission, it must be set in high impedance.

Figure 2 shows an example circuit as an appropriate solution with a 22 kHz IC controller to

drive the EXTM pin for the DiSEqC implementation.

Figure 2. EXTM example of use with 22 kHz IC controller

VDD 3V3

22 KHz IC

controller

DISEQC_OUT

PD

R

Vtone signal

R2

R3

15 K

R1

C1

1µF

LNBH24L

EXTM pin

EXTM

Z

VoRX

VoRx OUTPUT

AM09363v1

6/26 Doc ID 018526 Rev 3

AN3352 Block diagram and pin function description

Figure 3. DiSEqC 1.X tone burst with 22 kHz IC controller

High-Z

VoRx OUTPUT

VoRx OUTPUT

Vtone signal

Vtone signal

High-Z

STATE

STATE

Push -pull

Push -pull

Action

Action

High-Z

High-Z

STATE

STATE

Push -pull

Push -pull

1.5 DiSEqC 1.X implementation through V

If an external 22 kHz tone source is not available, it is possible to use the internal 22 kHz

tone generator signal available through the V

V

22 kHz signal is superimposed to the V

oTX

kHz tone (see Figure 6). The internal 22 kHz tone generator, available through the V

must be activated during the 22 kHz transmission by the DSQIN pin or by the TEN bit. The

DSQIN internal circuit activates the 22 kHz tone on the V

delay from the TTL signal present on the DSQIN pin, and it stops with 1 cycle ± 25 µs delay

after the TTL signal has expired. The V

oTX

the TTX function. This can be controlled both through the TTX pin and the I²C bit. As soon

as the tone transmission has expired, the V

The 13/18 V power supply is always provided to the LNB from the V

pin to drive the EXTM pin. In this way the

oTX

DC voltage to generate the LNB output 22

oRX

pin internal circuit must be preventively set ON by

must be disabled by setting the TTX to LOW.

oTX

High-Z

High-Z

STATE

STATE

Action

Action

and EXTM

oTX

output with 0.5 cycles ± 25 µs

oTX

pin.

oRX

oTX

pin,

1.6 PDC optional circuit for DiSEqC 1.X applications using V

signal on to EXTM pin and 22 kHz tone controlled by DSQIN

pin

In some applications, at light output current (< 50 mA), having a heavy LNB output

capacitive load, the 22 kHz tone can be distorted. In this case it is possible to add the

“Optional” external components described on Section 2.7.

1.7 22 kHz oscillator

The internal 22 kHz tone generator is factory-trimmed in accordance with current standards

and can be selected by the I²C interface TTX bit (or TTX pin) and controlled by the DSQIN

pin (TTL compatible), which allows immediate DiSEqC data encoding. If the 22 kHz tone

presence is requested in continuous mode, the internal oscillator can be activated by the I²C

Doc ID 018526 Rev 3 7/26

oTX

Block diagram and pin function description AN3352

interface TEN bit. The rise and fall edges are controlled to be in the 5 µs to 15 µs range, 8 µs

typ for 22 kHz. The duty cycle is 50% typ., it modulates the DC output with a 0.650 V

PP

(typ.)

amplitude as well as the DSQIN pin.

1.8 DiSEqC communication

The following steps must be taken to ensure the correct implementation of the DiSEqC

communication:

Figure 4. DiSEqC timing control

LNBout

LNBout

DSQIN

DSQIN

> 500µs

> 500µs

µ

µ

> 200 µs

> 200 µs

TTX

TTX

2

1

1

T

0

0

T

T

● T0: before starting the DiSEqC transmission. The TTX function must be activated

T

DiSEqC Transmit Mode

DiSEqC Transmit Mode

2

3

3

T

T

T

T

DiSEqC Receive Mode

DiSEqC Receive Mode

(through the TTX pin or TTX I²C bit)

● T1: after 500 µs minimum, the IC is ready to receive the DiSEqC code through the

DSQIN pin (or, alternatively, the TEN I²C bit can be set to HIGH to activate the 22 kHz

burst)

● T2: when the transmission has elapsed, the TTX function is set to LOW (through the

TTX pin or TTX I²C bit) not earlier than 200 µsec after the last falling edge of the

DiSEqC code.

1.9 Linear post-regulator, modulator and protection

The output voltage selection and the current selection commands join this block, which

manages the LNB output function. This block gives feedback to the I²C interface from the

diagnostic block, regarding the status of the thermal protection, overcurrent protection, and

output settings.

1.10 Pin description

The LNBH24L is available in an exposed pad QFN-32 package for surface mount assembly.

Figure 5 shows the device pinout and Tab le 3 briefly summarizes the pin function.

8/26 Doc ID 018526 Rev 3

AN3352 Block diagram and pin function description

Figure 5. LNBH24L pin configuration

Table 3. LNBH24L pin description

QFN 5x5

pin n°

21 V

20 V

5/2

16/25

18/23

17/24

Symbol Name Pin function

CC

CC

LX-A /

LX-B

V

UP

V

UP

V

oRX

V

oRX

V

oTX

V

oTX

-A/

-B

-A/

-B

-A/

-B

Supply input 8 to 15 V IC DC-DC power supply

Supply input 8 to 15 V analog power supply

NMos drain Integrated N-channel power MOSFET drain

Input of the linear post-regulator. The voltage on this pin is monitored

Step-up voltage

by the internal step-up controller to keep a minimum dropout across

the linear pass transistor.

LDO output port Output of the linear post-regulator

Output port during

22 kHz tone TX

TX output to the LNB

6 SDA Serial data Bi-directional data from/to the I²C bus

7 SCL Serial clock Clock from the I²C bus

This pin accepts the DiSEqC code from the main microcontroller. The

LNBH24L uses this code to modulate the internally-generated 22 kHz

carrier. Set this pin to ground if not used.

10/31

DSQIN-A/

DSQIN-B

DiSEqC input

Doc ID 018526 Rev 3 9/26

Block diagram and pin function description AN3352

Table 3. LNBH24L pin description (continued)

12/29

TTX-A/

TTX-B

TTX enable

11/30 Reserved Reserved To be connected to GND

This pin, as well as the TTX I²C bit of the system register, is used to

control the TTX function enable before starting the 22 kHz tone

transmission. Set this pin floating or to GND if not used.

9/32

13/28

PDC-A/

PDC-B

EXTM-A/

EXTM-B

Pull-down control

External modulation

4/3 P-GND Power ground

ePad ePad ePad

To be connected to the external NPN transistor base to reduce the 22

kHz tone distortion in case of heavy capacitive load at light output

current. If not used it can be left floating.

External Modulation Input acts on V

linear regulator output to

ORX

superimpose an external 22 kHz signal. Needs DC decoupling to the

AC source. If not used it can be left floating.

DC-DC converter power ground to be connected directly below the

ePad of the PCB top GND layer

On the bottom side of the QFN-32 package. It must be connected with

power ground and to the ground layer through vias to dissipate heat.

22 A-GND Analog ground Analog circuits ground

Needed for internal pre-regulator filtering. The BYP pin is intended

19 BYP Bypass capacitor

only to connect an external ceramic capacitor. Any connection of this

pin to an external current or voltage sources may cause permanent

damage to the device.

8/1

15/26

ADDR-A/

ADDR-B

ISEL-A/

ISEL-B

Address setting Two I²C bus addresses available by setting the ADDR pin voltage level

connected between I

SEL

SEL

Current selection

The resistor R

linear regulator current limit threshold by the equation: I

10000 / R

SEL

14/27 Reserved Reserved To be left floating. Do not connect to GND.

and GND defines the

(typ.) =

max

10/26 Doc ID 018526 Rev 3

AN3352 Component selection guidelines

V

V

V

V

2 Component selection guidelines

The LNBH24L application schematic in Figure 6 shows the typical configuration for a single

LNB power supply.

Figure 6. LNBH24L typical application circuit with internal tone generator

Vup

Vup

Vup

Vup

C3

C3

C3

C3C3

C3C3

in

in

in

in

12V

12V

12V

12V

C1

C1

C1

C1

C3C3C3C3C3

D1

D1D1

D1

D1D1

L1

L1

L1

L1

Tone Enabl e control

Tone Enabl e control

Tone Enabl e control

TTL

TTL

TTL

C8

C8

C8

C8

C8

C8

220nF

220nF

220nF C8220nF

220nF

220nF

220nF C8220nF

C6

C6

C6

C6

C6

C6

2.2µF

2.2µF

2.2µF

I2C Bus

I2C Bus

I2C Bus

LX

LX

LX

LX

Vcc

Vcc

Vcc

Vcc

Vcc

Vcc

Vcc-L

Vcc-L

Vcc-L

Vcc-L

Vcc-L

Vcc-L

SDA

SDA

SDA

{

{

{

SCL

SCL

SCL

ADDR

ADDR

ADDR

TTX

TTX

TTX

DSQIN

DSQIN

DSQIN

D3

D3D3

D3

D3D3

LNBH24L

LNBH24L

(sections A/B)

(sections A/B)

P-GND A-GND

P-GND A-GNDP-GND A-GND

P-GND A-GND

P-GND A-GNDP-GND A-GND

VoTX

VoTX

EXTM

EXTM

EXTM

EXTM

VoRX

VoRX

VoRX

VoRX

PDC

PDC

PDC

PDC

EXTM

EXTM

ISEL

ISEL

Byp

Byp

R9

R9R9

R9

R9R9

2KOhm

2KOhm

C10

C10

C10

C10

C10

C10

220nF

220nF

220nF

220nF

220nF

220nF

C11

C11

220nF

220nF

C15

C15

C15

C15

47 nF

47 nF

47 nF

47 nF

D4

D4D4

D2D2D2

D2D2D2D2D2D2

R2 (RSEL)

R2 (RSEL)

15kOhm

15kOhm

to LNB

to LNB

to LNB

to LNB

500mA max

500mA max

500mA max

500mA max

Note: TVS D6 diode to be used if surge protection is required (see Section 2.4).

Table 4. LNBH24L demonstration board BOM list

Index Quantity Reference Value / generic part number Package

1 2 RSELA, RSELB 15 kΩ 1/8 W (see Section 2.2) 1206

2 2 R5A, R5B 2.2 kΩ 1/8 W (see Section 2.7) 1206

3 2 R7A, R7B 22 Ω 1/2 W (see Section 2.7) 1206

4 2 R8A, R8B 150 Ω 1/2 W (see Section 2.7) 1206

5 2 R9A, R9B 1.5 kΩ 1/8 W (see Section 2.8) 1206

6 4 C8, C10A, C10B, C11 0.22 µF 1206

7 2 C15A, C15B 47 nF 1206

8 2 C14A, C15B 1 nF 1206

9 2 C4A, C4B, C6A, C6B 0.47 µF (see Section 2.5) 1206

10 1 C1

100 µF > 25 V ESR = 150 mΩ − 350 mΩ higher

value is suitable (see Section 2.6)

El.Al. Radial

Doc ID 018526 Rev 3 11/26

Component selection guidelines AN3352

Table 4. LNBH24L demonstration board BOM list (continued)

Index Quantity Reference Value / generic part number Package

11 2 C3A, C3B

12 2 L1A, L1B 22 µH inductor with I

220 µF > 25 V ESR = 50 mΩ − 350 mΩ (see

Section 2.5)

SAT

> I

(see Section 2.1)Radial

PEAK

El.Al. Radial

13 2 D1A, D2B STPS130A (see Section 2.3)SMB

14 2 D2A, D2B STPS130A (see Section 2.9)SMB

15 2 D3A, D3B S1A or equivalent SMB

16 2 D4A, D4B

BAT54, STPS130A, BAT43, 1N5818, or similar

Schottky diode with V

RRM

> 20 V.

SOD123

17 1 IC1 To be placed as close as possible to EXTM pin QFN32

18 2 TR1A, TR1B BC817 SOT23-3L

19 2 D8A, D8B LL4148 MINIMELF

20 3 CN3, CN6, CN7 Strip 4p M HDR1X4

CN1, CN4, CN5,

21 9

JP1-A, JP1-B, JP2-A,

JP2-B, LNBOUT-A,

Strip 2p M HDR1X2

LNBOUT-B

2.1 DC-DC converter inductor (L1)

The LNBH24L operates with a standard 22 µH inductor for the entire range of supply

voltages and load current. The inductor saturation current rating (where inductance is

approximately 70% of zero current inductance) must be greater than the switch peak current

(I

> I

SAT

– maximum load (I

– minimum input voltage (V

– maximum DC-DC output voltage (V

In this condition the switch peak current is calculated using the formula in Equation 1:

) calculated at:

PEAK

OUTmax

)

INmin

)

UPmax

= V

OUTmax

+ 0.75 V typ.)

Equation 1

maxmax*

Ipeak

IO UTVUP

min*

VINEff

where:

– Eff is the efficiency of the DC-DC converter (93% typ. at highest load)

– L is the inductance (22 µH typ.)

– F is the PWM frequency (220 kHz typ.)

Example:

Application conditions:

V

OUTmax

V

INmin

12/26 Doc ID 018526 Rev 3

= 19.2 V (supposing EN=VSEL=1, LLC=0)

= 11 V

VIN

min

⎛

−+=

1

⎜

2

LF

⎝

VIN

VUP

min

max

⎞

⎟

⎠

AN3352 Component selection guidelines

V

I

UPmax

OUTmax

= V

OUTmax

= 500 mA

+ V

DROP

Eff = 90% (worst-case in these conditions)

Based on Equation 1 and the preceding application conditions, I

Equation 2

Ipeak

=

Then, in this example, an inductor with saturation current > 1.52 A should be recommended.

Several inductors suitable for the LNBH24L are listed in Ta bl e 5 , although there are many

other manufacturers and devices that can be used. Consult each manufacturer for more

detailed information and for their entire selection of related parts, as many different shapes

and sizes are available. Ferrite core inductors should be used to obtain the best efficiency.

Choose an inductor that can handle at least the I

that the inductor has a low DCR (copper wire resistance) to minimize power losses and,

consequently, to maximize the total efficiency.

Table 5. Recommended Inductors

= 19.2 V + 0.75 V = 19.95 V

−

11

current without saturating, and ensure

PEAK

5.095.19

∗

119.0

∗

is:

PEAK

11

⎛

1

−+

⎜

36

10*220*10*22*2

⎝

⎞

⎟

95.19

⎠

A52.1

=

Vendor Part number I

Sumida

To ko

Panasonic

Coilcraft

CD104-220MC

RHC110-220M

822LY-220K

824LY-220K

A671HN-220L

A814LY-220M

ELC08D220E

ELC10D220E

DC1012-223

PVC-0-223-03

DO3316P-223

(A) DRC (m?) Mounting type

SAT

1.6

2.4

1.3

1.72

2.44

2.0

1.8

3.2

2.5

3

2.6

67

88

70

76

21

75

51

40

46

35

85

2.2 Output current limit selection (R2-RSEL)

The linear regulator current limit threshold can be set through an external resistor connected

to the I

equation:

Equation 3

pin. The resistor value defines the typical output current threshold limit by the

SEL

10000

Aax

)(Im =

Rsel

SMD

Through-hole

Through-hole

Through-hole

Through-hole

SMD

Through-hole

Through-hole

Through-hole

Through-hole

SMD

Doc ID 018526 Rev 3 13/26

Component selection guidelines AN3352

=+=

=−=

=+=

where R

limit threshold is 0.650 A typ. with R

is the resistor connected between I

SEL

SEL

= 15 kΩ.

and GND. The highest selectable current

SEL

To set the current limitation, ±15% tolerance, referred to the typical I

be considered. At this tolerance, the tolerance of the R

resistor must be added.

SEL

For example:

resistor = 15 kΩ ± 1%

R

SEL

10000

To calculate the I

max(min.)

and I

max(max.)

)typ(axIm ==

15000

values:

mA666

%16%1%15ceTotToleran

where:

– 15% is the LNBH24L tolerance

– 1% is the R

tolerance

SEL

and then:

mA559%16mA666(min)axIm

current value, must

max

Figure 7. Typical output current limiting vs. R

1.4

1.4

1.2

1.2

0.8

0.8

[mA]

[mA]

0.6

0.6

MAX

MAX

I

I

0.4

0.4

0.2

0.2

VCC=12V

VCC=12V

1

1

0

0

10 12 14 16 18 20 22 24 26 28 30 32

10 12 14 16 18 20 22 24 26 28 30 32

The formula below allows correct dimensioning of the R

R

R

SEL

SEL

SEL

[K ]

[K ]

mA772%16mA666(min)axIm

total power dissipation:

SEL

14/26 Doc ID 018526 Rev 3

AN3352 Component selection guidelines

)I(RselΩ=

V1

)(Rsel

supposing:

R

resistor = 15 kΩ

SEL

V1

Ω

)(15000

W

RSEL

= R

SEL(I)

2

x R

)I(Rsel μ=

=

= (66 µA) 2 x 15000 = 65 µW

SEL

2.3 DC-DC converter Schottky diode (D1)

In typical application conditions it is beneficial to use a 1 A Schottky diode which is suitable

for the LNBH24L DC-DC converter. Taking into account that the DC-DC converter Schottky

diode must be selected depending on the application conditions (V

Schottky diode such as the STPS130A is suitable.

The average current flowing through the Schottky diode is lower than I

calculated by

output current, a Schottky diode capable of supporting the I

can be calculated using

Equation 4. In worst-case conditions, such as low input voltage and higher

Equation 1.

A66

> 25 V), in general a

RRM

PEAK

should be selected. I

PEAK

and can be

PEAK

Equation 4

Table 6. Recommended Schottky diode

STMicroelectronics

Vendor Part number IF (av) VF (max.)

1N5818 1 A 0.50 V

1N5819 1 A 0.55 V

STPS130A 1 A 0.46 V

STPS1L30A 1 A 0.30 V

STPS2L30A 2 A 0.45 V

1N5822 3 A 0.52 V

STPS340 3 A 0.63 V

STPS3L40A 3 A 0.5 V

2.4 TVS diode (D6)

The LNBH24L device is directly connected to the antenna cable in a set-top box.

Atmospheric phenomenon can cause high voltage discharges on the antenna cable causing

Vout

IoutId ×=

Vin

Doc ID 018526 Rev 3 15/26

Component selection guidelines AN3352

damage to the attached devices. In applications where it is required to protect against

lightning surges, transient voltage suppressor (TVS) devices like the LNBTVSx-22xx can be

used to protect the LNBH24L and the other devices electrically connected to the antenna

cable.The LNBTVSx-22xx diodes, developed by STMicroelectronics, are dedicated to

lightning and electrical overstress surge protection for LNBHxx voltage regulators. These

protection diodes were designed to comply with the stringent IEC61000-4-5 standard with

surges up to 500 A in a whole range of products.

Note: TVS diodes have intrinsic capacitance that attenuates the RF signal. For this reason, the

LNBTVSx-22xx cannot be directly connected to the I

(RX/TX) cable connector that carries

F

the RF signals coming from the LNB. To suppress effects of the intrinsic capacitance, an

inductance must be placed in series with the TVS diode (see Figure 6 example). The goal of

the L series inductance added to the CLNBTVS is to be transparent at 22 kHz and to reject

frequencies higher than 900 MHz.The value of the series inductance is usually >13 nH, with

a current capability higher than the I

Figure 8. Example of LNBTVS diode connection

D3

1N4007

(peak pulse current) expected during the surge.

PP

LNBH24L

The selection of the TVS diode must be based on the maximum peak power dissipation that

the diode is capable of supporting.

Table 7. Recommended LNBTVS

Vendor Part number VBR

STMicroelectronics

VoTX

EXTM

VoRX

C10

C10

R9

R9

C15

D2

D2

IF Connector

Lseries >13nH

D6

LNBTVSx -22xx

(V) Ipp (A) 8/20 µs

TYP

LNBTVS4-220S 23.1 334

LNBTVS4-221S 23.1 334

LNBTVS4-222S 23.1 334

LNBTVS6-221S 23.1 500

Select the TVS diode which is capable of supporting the required Ipp (A) value indicated in

Ta bl e 7 .

16/26 Doc ID 018526 Rev 3

AN3352 Component selection guidelines

2.5 DC-DC output capacitors (C3, C4, C6) and ferrite bead

An electrolytic low cost capacitor is needed on the DC-DC converter output stage (C3 in

Figure 6). Moreover, two ceramic capacitors are recommended to reduce the high

frequency switching noise. The switching noise is due to the voltage spikes of the fast

switching action of the output switch, and to the parasitic inductance of the output

capacitors. To minimize these voltage spikes, special low-inductance ceramic capacitors

can be used, and their lead lengths must be kept short and as close as possible to the IC

pins (C4 and C6 in

the C6 capacitor up to 4.7 µF, 2.2 µF is a good compromise to reduce the switching noise.

Figure 9. DC-DC converter output stage with ferrite bead

Figure 9). In the case of high switching noise, it is possible to increase

The most important parameter for the DC-DC output electrolytic capacitors is the effective

series resistance (ESR). The DC-DC converter control loop circuit has been designed to

work properly with low-cost electrolytic capacitors which have ESR in the range of 200 mΩ.

A 220 µF with ESR between 100 mΩ and 350 mΩ is a good choice in most application

conditions. If it is requested to further reduce the switching noise, a ferrite bead with a

current rating of at least 2 A and impedance higher than 60 Ω at 100 MHz may be used.

In this case, it is recommended to use two electrolytic capacitors of 100 µF (see C3 and C3A

in

Figure 9) with ESR between 150 mΩ and 350 mΩ adding the ferrite bead in accordance

Figure 9.

to

The DC-DC capacitor's voltage rating must be at least 25 V, but higher voltage capacitors

are recommended.

2.6 Input capacitors (C1)

An electrolytic bypass capacitor (C1 in Figure 6) between 100 µF and 470 µF, located close

to the LNBH24L, is needed for stable operation. In any case, a ceramic capacitor (C2 in

Figure 6) between 100 nF and 470 nF is recommended to reduce the switching noise at the

input voltage V

CC

pins.

Doc ID 018526 Rev 3 17/26

Component selection guidelines AN3352

V

V

V

V

2.7 PDC optional external circuit

This optional circuit, internally controlled by the PDC output pin, acts as an active pull-down

discharging the output capacitance only when the internal 22 kHz tone is activated

(TEN=TTX=1 or DSQIN=1).

This optional circuit is not needed in standard applications having I

capacitive load up to 250 nF where the PDC pin can be left floating.

Figure 10. Application circuit with PDC optional solution

D3

D3D3

D3

D3D3

Vup

Vup

Vup

Vup

C3

C3

C3

C3C3

C3C3

in

in

in

in

12V

12V

12V

12V

C1

C1

C1

C1

C3C3C3C3C3

D1

D1D1

D1

D1D1

L1

L1

L1

L1

Tone Enable control

Tone Enable control

Tone Enable control

TTL

TTL

TTL

C8

C8

C8

C8

C8

C8

220nF

220nF

220nF C8220nF

220nF

220nF

220nF C8220nF

C6

C6

C6

C6

C6

C6

2.2µF

2.2µF

2.2µF

I2C Bus

I2C Bus

I2C Bus

EXTM

EXTM

EXTM

LNBH24L

LNBH24L

(sections A/B)

(sections A/B)

LX

LX

LX

LX

Vcc

Vcc

Vcc

Vcc

Vcc

Vcc

Vcc-L

Vcc-L

Vcc-L

Vcc-L

Vcc-L

Vcc-L

SDA

SDA

SDA

{

{

{

SCL

SCL

SCL

ADDR

ADDR

ADDR

TTX

TTX

TTX

DSQIN

DSQIN

DSQIN

P-GND A-GND

P-GND A-GNDP-GND A-GND

P-GND A-GND

P-GND A-GNDP-GND A-GND

EXTM

VoRX

VoRX

VoRX

VoRX

VoTX

VoTX

VoTX

VoTX

PDC

PDC

PDC

PDC

ISEL

ISEL

ISEL

ISEL

ISEL

ISEL

Byp

Byp

Byp

Byp

Byp

Byp

Byp

Byp

R9

R9R9

R9

R9R9

2KOhm

2KOhm

C15

C15

C15

C15

47 nF

47 nF

47 nF

47 nF

D4

D4D4

C10

C10

C10

C10

C10

C10

220nF

220nF

220nF

220nF

220nF

220nF

*R5

*R5

*R5

*R5

2.2K Ohm

2.2K Ohm

2.2K Ohm

2.2K Ohm

C11

C11

C11

C11

C11

C11

C11

C11

C11

C11

220nF

220nF

220nF

220nF

220nF

220nF

220nF

220nF

220nF

220nF

3.3V

3.3V

3.3V

3.3V

> 50 mA and

OUT

D2

D2D2

D2

D2D2

D8

D8

1N4148

1N4148

*C14

*C14

*C14

*C14

1nF

1nF

1nF

1nF

R2 (RSEL)

R2 (RSEL)

R2 (RSEL)

R2 (RSEL)

R2 (RSEL)

R2 (RSEL)

R2 (RSEL)

R2 (RSEL)

15kOhm

15kOhm

15kOhm

15kOhm

15kOhm

15kOhm

15kOhm

15kOhm

to LNB

to LNB

to LNB

to LNB

500mA max

500mA max

500mA max

500mA max

*R8

*R8

*R8

*R8

150 Ohm

150 Ohm

150 Ohm

150 Ohm

*TR1

*TR1

*TR1

*TR1

*R7

*R7

*R7

*R7

22 Ohm

22 Ohm

22 Ohm

22 Ohm

(*)OPTIONAL components.

(*)OPTIONAL components.

(*)OPTIONAL components.

(*)OPTIONAL components.

(*)OPTIONAL components.

(*)OPTIONAL components.

To be used only in case

To be used only in case

To be used only in case

To be used only in case

To be used only in case

To be used only in case

of heavy capacitive load

of heavy capacitive load

of heavy capacitive load

of heavy capacitive load

of heavy capacitive load

of heavy capacitive load

The formula to calculate the transistor IC current with PDC circuit is:

Equation 5

--

--

V

BYP

BYP

R

R

+

+

7

7

V

V

V

D

D

R

R

5

5

TR1hfe

TR1hfe

BE

BE

V

V

=

=

I

I

C

C

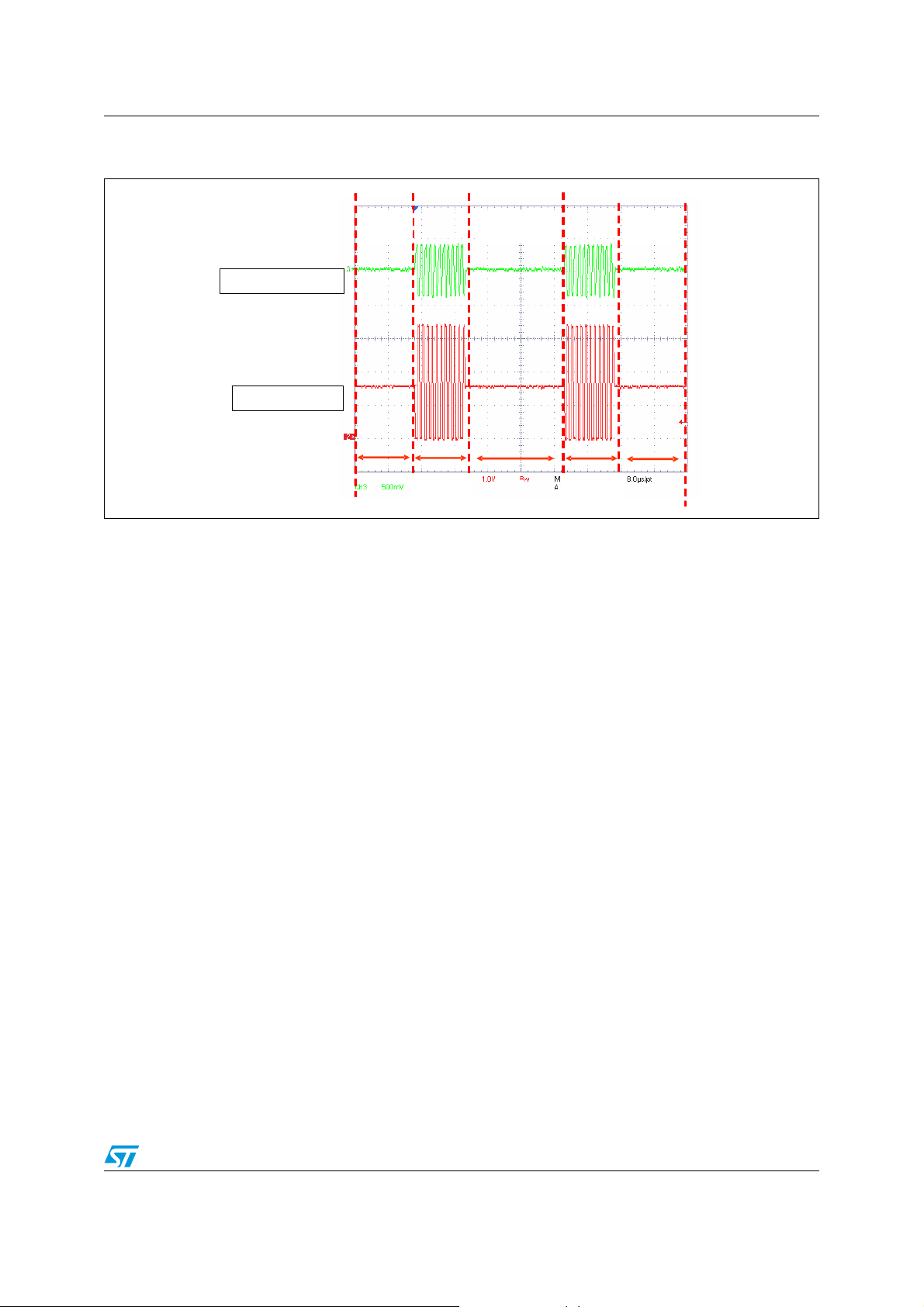

The current flows through R8, TR1, and R7 during fall time of 22 kHz tone and the power

dissipated by these passive components is 1/3 because the D.C. is 30% (see

18/26 Doc ID 018526 Rev 3

Figure 11).

AN3352 Component selection guidelines

Figure 11. PDC optional circuit load calculation

Figure 12. PDC circuit waveform

2.8 EXTM-V

resistor (R9)

OTX

The LNBH24L device offers the possibility to customize the output tone amplitude through

the R9 resistor variation. According to the graph in

modified to change the output tone amplitude when the internal 22 kHz tone generator is

used. Values between 1 kΩ and 2.7 kΩ are recommended.

Figure 13, the R9 resistor can be slightly

Doc ID 018526 Rev 3 19/26

Component selection guidelines AN3352

Figure 13. Tone amplitude vs. R9 value

0.9

0.85

0.8

0.75

0.7

0.65

0.6

0.55

0.5

0.45

0.4

Tone Amplitude (Vpp)

0.35

0.3

0.511.522.533.544.5

R9 value (kohm)

2.9 Undervoltage protection diode (D2)

During a short-circuit event on the LNB output, negative voltage spikes may occur on the

pin. To prevent reliability problems, a low-cost Schottky diode with low VF clamping

V

oRX

voltage is used between this pin and GND (see D2 in

the protection diode cathode as close as possible to the V

Figure 6). It is recommended to place

pin.

oRX

20/26 Doc ID 018526 Rev 3

AN3352 Layout guidelines

3 Layout guidelines

Due to high current levels and fast switching waveforms, which radiate noise, a proper

printed circuit board (PCB) layout is essential. Sensitive analog grounds can be protected by

using a star ground configuration. Also, lead lengths should be minimized to reduce stray

capacitance, trace resistance, and radiated noise. Ground noise can be minimized by

connecting GND, the input bypass capacitor ground lead, and the output filter capacitor

ground lead to a single point (star ground configuration). Place input bypass capacitors (C1,

C2, and C8) as close as possible to V

and C6) as close as possible to V

undervoltage protection circuitry, resetting the I²C internal registers. If this occurs, the

registers are set to zero and the LNBH24L is put into shutdown mode.

An LNB power supply demonstration board is available.

3.1 PCB layout

Any switch-mode power supply requires a good PCB layout in order to achieve maximum

performance. Component placement and GND trace routing and width, are the major

issues. Basic rules commonly used for DC-DC converters for good PCB layout should be

followed. All traces carrying current should be drawn on the PCB as short and as thick as

possible. This should be done to minimize resistive and inductive parasitic effects, and

increase system efficiency. White arrows indicate the suggested PCB (ring) ground plane to

avoid spikes on the output voltage (this is related to the switching side of the LNBH24L).

Good soldering of the ePad helps on this issue.

UP

and GND, and the DC-DC output capacitors (C3

CC

. Excessive noise at the VCC input may falsely trigger the

Figure 14. PBC top layer

Doc ID 018526 Rev 3 21/26

Layout guidelines AN3352

Figure 15. PBC bottom layer

Figure 16. PCB component layout

22/26 Doc ID 018526 Rev 3

AN3352 Layout guidelines

3.2 PCB thermal management

The LNBH24L power dissipation inside the IC is mainly due to the DC-DC integrated

MOSFET power loss plus the linear regulator power dissipation. The total power dissipation

calculated, considering both the DC-DC and linear regulator power loss at the maximum

output current (500 mA for each output) with 18 V for LNB output and V

W. The heat generated due to this power dissipation level requires a suitable heatsink to

keep the junction temperature below the overtemperature protection threshold at the rated

ambient temperature inside the set-top box.

The best thermal and electrical performance can be achieved when an array of copper vias

barrel plating is incorporated in the land pattern at 1.2 mm grid. It is also recommended that

the via diameter should be 0.30 mm to 0.33 mm with 1 oz copper via barrel plating.

If the copper plating does not plug the vias, a solder mask material must be used to cap the

vias with a dimension equal to the via diameter + 0.1 mm minimum. This prevents the solder

from not being well spread through the thermal via and potentially creating a solder void

between the package bottom and the ground plane of the PCB.

Taking into account that the solder mask diameter should be at least 0.1 mm larger than the

via diameter.

However, different layouts are also possible. Basic principles suggest keeping the IC and its

ground exposed pad approximately in the middle of the dissipating area; to provide as many

vias as possible; to design a dissipating area having a shape as square as possible and not

interrupted by other copper traces.

= 11 V, is around 2

IN

Doc ID 018526 Rev 3 23/26

Startup procedure AN3352

4 Startup procedure

Testing the demonstration board requires a PC with a parallel port (ECP printer port), an I²C

bus interface, software (LNBxx control suite), a dual-output power supply (3 A clamp current

or higher), and an electronic load.

– Step 1: Install the LNBxx control suite software (Software installation)

– Step 2: Plug the I²C connector on CN3

– Step 3: Supply the demo-board through CN2

– Step 4: Manage the demo-board through LNBxx control suite software

Figure 17. PCB connector

24/26 Doc ID 018526 Rev 3

AN3352 Revision history

5 Revision history

Table 8. Document revision history

Date Revision Changes

29-Apr-2011 1 Initial release

16-Sep-2011 2

– Removed watermark from document pages

– Minor text changes

25-Nov-2011 3

Updated Table 1 on page 5, removed paragraph 1.3.1

Doc ID 018526 Rev 3 25/26

AN3352

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY TWO AUTHORIZED ST REPRESENTATIVES, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2011 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Philippines - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

26/26 Doc ID 018526 Rev 3

Loading...

Loading...