Page 1

AN3316

Application note

SPC560B power and mode management

Introduction

This application note is intended for system designers who require a hardware

implementation overview of the low-power modes of the SPC560B product family. It shows

how to use the SPC560B product family in these modes and describes how to take power

consumption measurements. Example firmware is provided with this application note for

implementing and measuring the consumption and wake-up time of the different SPC560B

family’s functioning modes.

November 2010 Doc ID 18232 Rev 1 1/42

www.st.com

Page 2

Contents AN3316

Contents

1 Power consumption factors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2 Dynamic power reduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.3 Static power reduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2 Device modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.1 Modes overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.2 Modes description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.2.1 System modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.2.2 Running modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.2.3 Low Power modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.3 Key advantages of Mode Entry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.3.1 Transition control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.3.2 Modules/peripherals configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.3.3 HW failure and error modes management . . . . . . . . . . . . . . . . . . . . . . . 16

2.4 Application cases . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.4.1 Power-on reset phase (RESET → DRUN) . . . . . . . . . . . . . . . . . . . . . . . 18

2.4.2 Application scenarios . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3 Consumption tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

3.1 Running mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

3.2 Low Power modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

3.2.1 HALT consumption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

3.2.2 STOP consumption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

3.2.3 STANDBY consumption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

3.3 Peripherals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

3.4 Consumption example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

4 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

2/42 Doc ID 18232 Rev 1

Page 3

AN3316 List of tables

List of tables

Table 1. Module configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Table 2. Clock configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Table 3. Loop divide ratio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Table 4. Input divide ratio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Table 5. Output divide ratio. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Table 6. SPC560B54/6x peripheral clock sources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Table 7. Peripherals clock source. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Table 8. RUN0 mode consumption table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Table 9. RUN0 mode consumption example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Table 10. HALT mode consumption table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Table 11. HALT mode consumption example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Table 12. STOP mode consumption table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Table 13. STOP mode consumption example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Table 14. STANDBY mode consumption table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Table 15. Peripherals consumption table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Table 16. Peripherals consumption example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Table 17. Document revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Doc ID 18232 Rev 1 3/42

Page 4

List of figures AN3316

List of figures

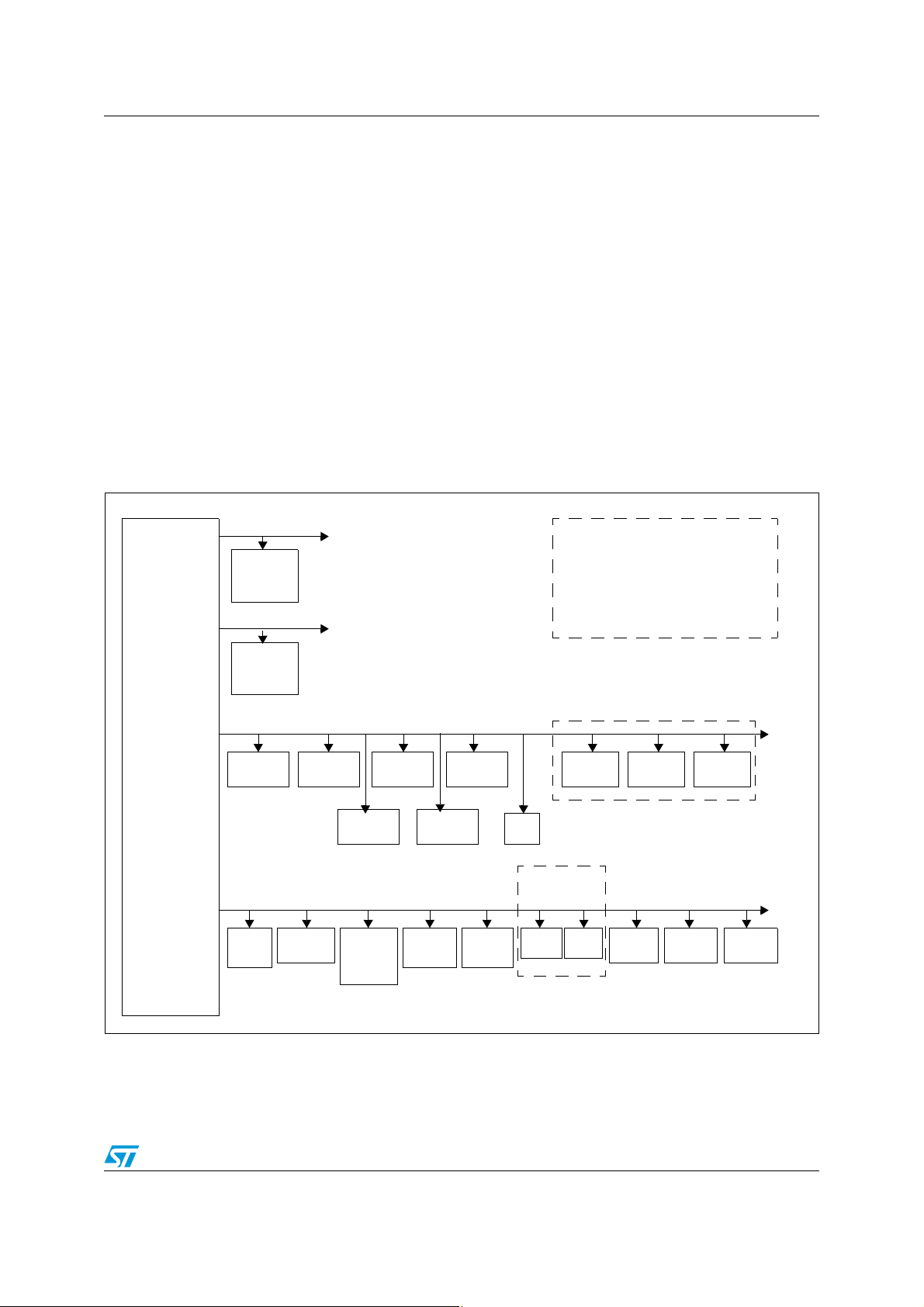

Figure 1. Peripheral clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Figure 2. Global clock tree architecture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Figure 3. SPC560B54/6x power domain structure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

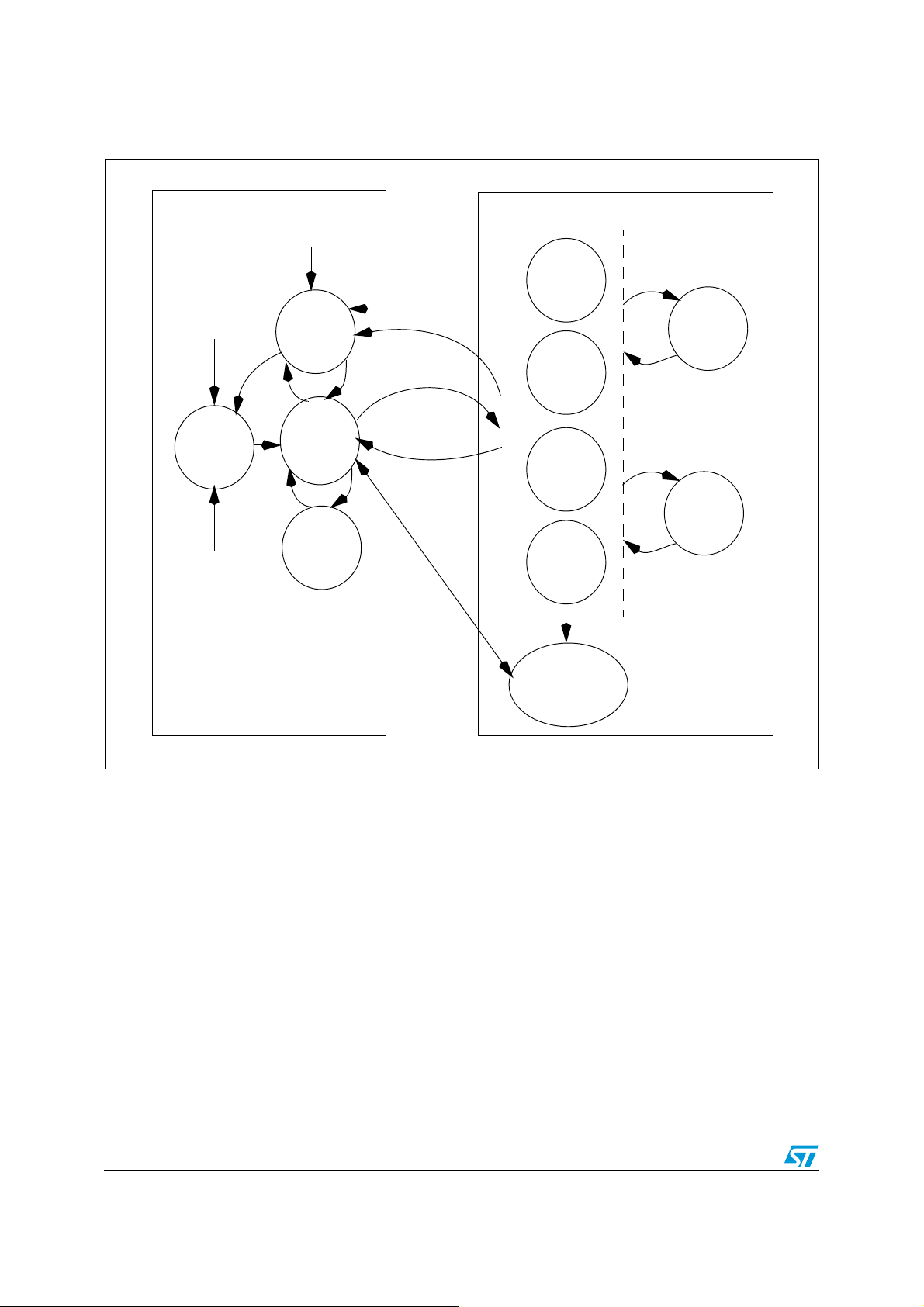

Figure 4. MC_ME mode diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Figure 5. Power Domain 0 architecture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Figure 6. Mode transition example. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Figure 7. Peripheral configuration example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 8. HW failure example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 9. Transition (HW start-up) RESET → DRUN (execution from CFlash) . . . . . . . . . . . . . . . . . 18

Figure 10. Node configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 11. Transition step . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 12. Scenario 2 - finite state machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Figure 13. Scenario 2 - flow chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Figure 14. Scenario 3 - finite state machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Figure 15. Scenario 3 - flow chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Figure 16. Scenario 4 - finite state machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Figure 17. Scenario 4 - flow chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Figure 18. Power domain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Figure 19. STANDBY transition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

4/42 Doc ID 18232 Rev 1

Page 5

AN3316 Power consumption factors

1 Power consumption factors

1.1 Overview

As SPC560B is a CMOS digital logic device, total power consumption is:

P

TOTAL

= P

DYNAM IC

+ P

STATIC

Where:

● P

DYNAMIC

is the dynamic power contribution that depends on the supply voltage and

the clock frequency through following formula:

P

DYNAM IC

= α · CV2f

with:

– C is the CMOS load capacitance

– V is the 5 V supply voltage

– f is the clock frequency

● P

is the static power contribution that depends mainly on the transistor

STATIC

polarization and leakage as in the following formula:

P

STATIC=ISTATIC

V

So to minimize total power consumption, it is needed to minimize each dynamic/static

contribution which strongly depends on clock frequency and the clock structure

implemented.

1.2 Dynamic power reduction

SPC560B adopts a very smart clock tree architecture in which all the clock sources are not

directly routed to peripherals. In fact, a peripheral bus block is located in the middle to divide

or disable all the clocks connected to the peripherals to save power consumption.

Figure 1. Peripheral clock

/

System clk

div 1 to 15

So, looking at the global clock tree architecture:

Doc ID 18232 Rev 1 5/42

Peripheral set x

Page 6

Power consumption factors AN3316

Figure 2. Global clock tree architecture

OSC

&

16MHz

IRC

16MHz

OSC

32KHz

IRC

128KHz

div 1 to 32

div 1 to 32

FMPLL

irc_fast

osca_clk

oscb_clk

irc_slow

div 1 to 32

div 1 to 32

osca_clk_div

irc_fast_div

CMU

osca_clk

osca_fast

fmplla_clk

System

Clock

Selector

(ME)

irc_slow_div

CLKOUT

Selector

RESET

SAFE

INT

system_clk

div 1 to 15

div 1 to 15

div 1 to 15

irc_fast_div

oscb_clk_div

div 1/2/4/8

Core

Platform

Peripheral Set 1

Peripheral Set 2

Peripheral Set 3

API / RTC

SWT

(Watchdog)

CLOCK OUT

It is possible to decrease power consumption through following features:

● Reduced number of directly clocked lines (see red circle on Figure 2)

● Reduced local clock rates through peripheral bus division (see blue circle on Figure 2)

ModeEntry Module is also structured to help reduce dynamic power consumption as:

● Allows to clock-gate each peripheral independently. So, power saving can be achieved

by clock-gating peripherals not used in the application.

● Allows to switch-off the CPU which is the most power-hungry part in the device. For

example, while waiting for an ADC conversion to complete.

6/42 Doc ID 18232 Rev 1

Page 7

AN3316 Power consumption factors

1.3 Static power reduction

The two main system/market constraints that influenced SPC560B definition:

● Request for more performance/integration and cost reductions leading to the usage of

more and more advanced and small technologies

● Carmakers’ constraints to maintain functions even when the car is switched off with a

max consumption of 100µA to 1mA for the overall ECU and depending on its type,

BCM, door module etc.

In order to match these two constraints, ST developed the SPC560B with following features:

● Adopting 90nm technology to meet integration/costs but with using a low leakage

technology (Leakage minimization)

● Subdividing device into following different PD0, PD1, PD2, PD3 power domains to meet

LP function/consumption (Power Segmentation)

These domains are individually disconnected from Power and so eliminates the leakage

from the areas they are turned off.

Figure 3. SPC560B54/6x power domain structure

Vreg

&

power

gating

LV

LV

HV

LV

HV

LV

64K

RAM

24K

RAM

API/

RTC

Wake-up

Logic

PD3

RAM Domain 2

PD2

RAM Domain 1

Platform XOSCZO core

Peripheral

Set One

Reset &

Wake-up

vector

Peripheral

Set Two

128KHz

IRC

JTAG

16 Mhz

IRC

Notes:

LV = Low Voltage(1.2V on SPC560B)

HV = High Voltage(3.3V on SPC560B)

PD = Power Domain

RD = RAM Power Domain

PCU = Power Control Unit

RGM = Reset Generation Module

CGM = Clock Generation Module

CGL = Clock Gating Logic

ME = mode Entry unit

CGM CGL ME

PLL

Part of

Magic Carpet

PCU RGM

8K

RAM

32KHz

XTAL

PD1

Micro

domain

PD0

Always 0

domain

CAN

Sampler

Doc ID 18232 Rev 1 7/42

Page 8

Power consumption factors AN3316

Notice that Power Domains shown on Figure 3 are related to SPC560B54/6x, where:

● Power Domain PD0:

–always on

– wakeup peripheries like the CAN sampler, the RTC, API, etc.

– minimum RAM segment (8 K)

● Power Domain PD1:

– contains all cores and the majority of peripherals

– can be turned off in STOP or STANDBY modes

– must be turned on in RUN modes (although there is a clock gating option for all

peripherals and also a WAIT instruction for the cores to reduce power)

● Power Domain PD2:

– additional RAM segment (24 K)

● Power Domain PD3:

– additional RAM segment (64 K)

– not supplied in standby mode, but implemented to use it in other LP-modes to

reduce leakage

On the other hand, to minimize static power contribution on application side, user should

● Turn-off CPU when possible, using the following autonomous "smart" peripherals:

– API — Autonomous Periodic Interrupt that allows device to recover from very low

power state at selected time intervals

– RTC — Real Time Clock that offers precision time keeping functionality in very low

power state

– ADC — Analog Digital Converter with continuous conversion while running in low

power and triggering wake-up when signal reaches certain level

– DMA — Direct Memory Access that allows data transfer between peripherals

minimising CPU activity

– SCI — Intelligent LIN management that minimizes CPU interrupts and CPU clock

8/42 Doc ID 18232 Rev 1

Page 9

AN3316 Device modes

2 Device modes

Mode Entry Module is a smart module implemented in SPC560B that intends at saving total

device consumption. In fact it allows to manage different level of low-power modes that can

reach, at minimum, few µA.

2.1 Modes overview

Mode Entry (MC_ME) is a SPC560B module that allows the user to centralize the control of

all device modes and related modules/parameters within a unique module. In this way, it

simplifies the implementation of mode management and thus increases its robustness.

The MC_ME is based on several device modes corresponding to different usage models of

the device. Each mode is configurable and can define a policy for energy and processing

power management to fit particular system requirements. An application can easily switch

from one mode to another depending on the current needs of the system.

SPC560B modes can be subdivided in the following groups:

● System modes:

All the modes (RESET, TEST, SAFE, DRUN) in which the device must be initialized and

properly configured

● Running modes:

All the modes (RUN0:3) used to obtain the full device performance

● Low Power modes:

All the modes (HALT, STOP, STANDBY) used to minimize the power consumption

Doc ID 18232 Rev 1 9/42

Page 10

Device modes AN3316

Figure 4. MC_ME mode diagram

SYSTEM MODES

software

request

RESET

non-recoverable

faliure

SAFE

DRUN

TEST

recoverable

hardware

failure

USER MODES

RUN0

HALT0

RUN1

RUN2

STOP0

RUN3

2.2 Modes description

2.2.1 System modes

RESET mode

This is a chip-wide virtual mode during which the application is not active.

The system remains in this mode until all resources are available for the embedded software

to take control of the device. It manages hardware initialization of chip configuration, voltage

regulators, oscillators, PLLs, and Flash modules.

DRUN mode

This is the entry mode for the embedded software.

It provides full accessibility to the system and enables the configuration of the system at

startup. It provides the unique gate to enter USER modes.

STANBY0

10/42 Doc ID 18232 Rev 1

Page 11

AN3316 Device modes

SAFE mode

This is a chip-wide service mode which may be entered on the detection of a recoverable

error. It forces the system into a pre-defined safe configuration from which the system may

try to recover.

TEST mode

This is a chip-wide service mode which is intended to provide a control environment for

device self-test. It may enable the application to run its own self-test like Flash checksum.

2.2.2 Running modes

RUNx (x=0:3) modes

These are software running modes where most processing activity is done. These modes

are intended to be used by software to execute full performance application routines.

The availability of 4 running modes allow to enable different clock and power configurations

of the system with respect to each other.

SPC560B device supports WAIT instruction to stop the core with the capability to restart

with very short latency (< 4 system clocks)

2.2.3 Low Power modes

HALT mode

This mode is intended as a first level low-power mode in which the platform is stopped but

system clock can remain the same as in running mode. This is a reduced-activity low-power

mode during which the clock to the core is disabled. It can be configured to switch off analog

peripherals like PLL, Flash, main regulator etc. for efficient power management at the cost

of higher wakeup latency.

STOP mode

This mode is intended as an advanced low-power mode during which the clock to the

platform is stopped. It may be configured to switch off most of the peripherals including

oscillator for efficient power management at the cost of higher wakeup latency.

STANBY mode

This is a reduced-leakage low-power mode in which only PD0 is connected and power

supply is cut off from most of the device. Wakeup from this mode takes a relatively long time,

and content is lost or must be restored from backup.

Doc ID 18232 Rev 1 11/42

Page 12

Device modes AN3316

Figure 5. Power Domain 0 architecture

LV

HV

API/

RTC

Wake-up

Logic

RESET &

Wake-up

vector

128KHz

IRC

16 MHz

IRC

2.3 Key advantages of Mode Entry

The purpose of the Mode Entry (ME) is to centralize the control of all device modes and

related parameters within a unique module.

Following main advantages:

● Controls the target mode’s parameters and mode transition without CPU intervention

(see Section 2.3.1: Transition control)

● Power modes managment centralaized (see Section 2.3.2: Modules/peripherals

configuration)

● Provides a SAFE mode to manage HW failure (see Section 2.3.3: HW failure and error

modes management)

Part of

Magic carpet

PCU

RGM 8K

RAM

32KHz

XTAL

PD0

(Always On

domain)

CAN

Sampler

2.3.1 Transition control

Mode transition is performed by writing ME_MCTL register twice:

● 1st write: TARGET_MODE + KEY

● 2nd write: TARGET_MODE + INVERTED KEY

Once the double writing is done, the complete transition could be triggered by following bits:

● S_MTRANS bit of Global Status Register (ME_GS)

– S_MTRANS = 0 (Transition not active)

– S_MTRANS = 1 (Transition ongoing)

● I_MTC bit of Interrupt Status Register (ME_IS)

– I_MTC = 0 (No transition complete)

– I_MTC = 1 (Transition complete)

Note: Bit I_MTC is not set in case of transition to low power modes (HALT / STOP)

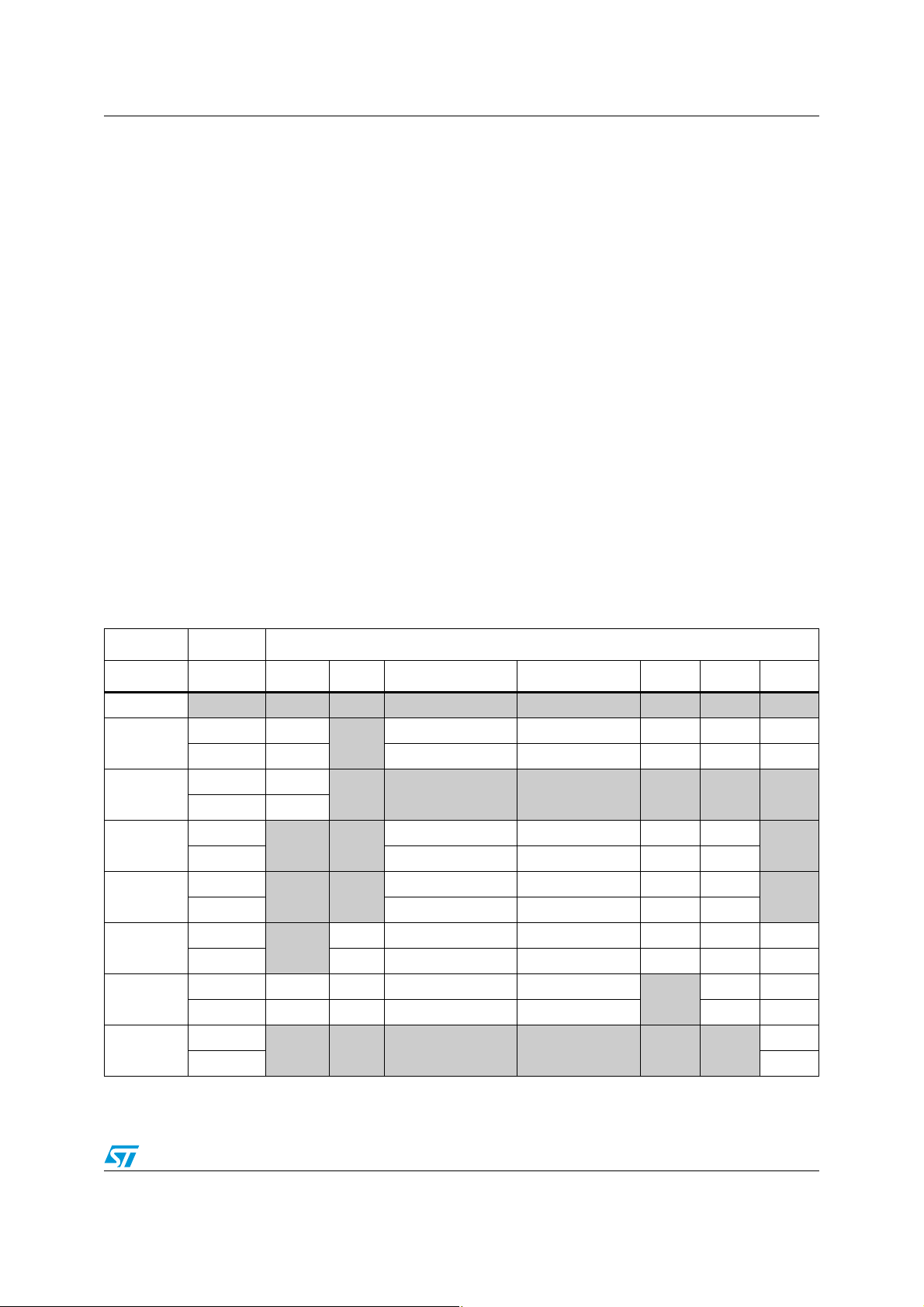

2.3.2 Modules/peripherals configuration

Either modules or peripherals are managed by ME.

12/42 Doc ID 18232 Rev 1

Page 13

AN3316 Device modes

Modules management

Each mode has a configuration register (ME_XXX_MC) that allows to configure the

following modules:

● Output Configuration

For some modes it is possible to put the IO in power-down status (PDO), forcing

outputs of pads to high impedance state or switching off the pads’ power sequence

driver

● Main Voltage Regulator (MVREG) Configuration

For some modes it is possible to switch-off the MVREG in order to minimize the

consumption

● FLASHs Configuration

For some modes it is possible to configure the code and data Flash in normal, low

power and power down

● Clocks Configuration

ME module is in charge of:

– Main XOSC switching on/off

– IRC fast switching on/off

– FMPLL switching on/off

– System Clock selecting

Not all modules can be configured in each mode. Following a table that describes all the

possible modules configurations for each mode:

Table 1. Module configuration

Mode PDO MVR DATA FLASH CODE FLASH PLL OSC IRC

RESET

TEST

SAFE

DRUN

RUNx

HALT

STOP

STBY

1. √ : module configurable

gray cell: module not configurable

Reset Off On Normal Normal Off Off On

User √

Reset Off Normal Normal Off Off On

User √

Reset On

User

Off On

Reset Normal Normal Off Off

User

Off On

Reset Normal Normal Off Off

User

Off

Reset On Low Power Low Power Off Off On

User √√ √ √

Reset Off On Power Down Power Down Off On

User

Off Off Power Down Power Down Off Off

Reset On

(1)

Module

√√√√√

On

On Normal Normal Off Off On

√√√√

√√√√

√√ √√√√

√√

Off

On

On

√

Doc ID 18232 Rev 1 13/42

Page 14

Device modes AN3316

Moreover, following table describes the possible system clock configurations for each mode:

Table 2. Clock configuration

System

RESET TEST SAFE DRUN HALT STOP STBY

IRC DEFAULT DEFAULT DEFAULT DEFAULT DEFAULT DEFAULT

IRC_DIV √ √√√

XOSC √ √√√

XOSC_DIV √ √√√

PLL √ √√

NO CLK √ √ DEFAULT

1. √ : module configurable

gray cell: module not configurable

(1)

Mode

Following an example that describes how to manage module configuration

● Current mode: Drun with system clock = IRC (default)

● Target mode: RUN0 mode with system clock = XOSC

Steps

● Configuration of RUNO mode

– ME_RUN0_MC.OSCON = 1

– ME_RUN0_MC.SYSCLK = XOSC

● Transition request

– ME_MCTL = DRUN + KEY

– ME_MCTL = DRUN + INVERTED KEY

● Waiting for the transition complete through the ME_IS.I_MTC bit

Figure 6. Mode transition example

DRUN RUN0

sysclk = IRC

sysclk = XOSC

14/42 Doc ID 18232 Rev 1

Page 15

AN3316 Device modes

Peripherals management

Each peripheral clock source can be switched on or off independently when it is not used, to

optimize power consumption. The ME module manages the clock gating of each peripheral,

defining peripherals state (active/frozen) in each mode as following:

● 8 Running registers (ME_RUN_PC[0..7]) to generate 8 different configuration in

running modes

● 8 Low-Power registers (ME_LP_PC[0..7]) to generate 8 different configuration in low

power modes

● One register for each peripheral (ME_PCTL[x]) that address one of the Running

configuration and one of the Low-Power configuration

Following is an example that describes how to clock gate/enable EMIOS peripheral:

Mode Entry - example

EMIOS0 Clock Gating

● Configure EMIOS in the following way

– Active in DRUN, RUN0, STOP mode

– Clock Gated in the others mode

Steps

● Configuration of Running mode

– ME_RUN_PC[1].DRUN = 1

– ME_RUN_PC[1].RUN0 = 1

● Configuration of Low Power mode

– ME_LP_PC[2].STOP = 1

● Configuraion of EMIOS (peripheral number = 72)

– ME_PTCL[72].RUN_CFG = 1

– ME_PTCL[72].LP_CFG = 2

Figure 7. Peripheral configuration example

DRUN

EMIOS active

STOP

Doc ID 18232 Rev 1 15/42

RUN0

Page 16

Device modes AN3316

2.3.3 HW failure and error modes management

ME Provides a SAFE mode to manage either HW failure or errors caused by incorrect mode

transition configurations.

HW failure management

Device can manage some HW failure events to force SAFE mode transition instead of

generating a reset. This is possible through RGM (Reset Generation Module), which, for

examples, allows to configure following less-critical functional events:

● FMPLL failure

● FXOSC failure

● CMU clock frequency higher/lower than reference

● 4.5 V low-voltage detected

● code or data Flash fatal error

So, if one of these happens, the system enters into a pre-defined SAFE configuration from

which it may try to recover. It is also possible that SAFE transition is triggered by an interrupt

through the ME.

Following is an example that describes how crystal failure event can be managed:

Example

● Current mode: DRUN with system clock = IRC (default)

● Target mode: RUN0 mode with system clock = XOSC

● XOSC failure event hapens

Steps

● Configuration of RUN0 mode

– ME_RUN0_MC.OSCON = 1

– ME_RUN0_MC.SYSCLK = XOSC

● Configuration of XOSC failure as SAFE transtition

– ME_RGM_FERD.D_CMU_OLR = 1

– ME_RGM_FEAR.AR_CMU_OLR = 0

● Configuration of SAFE mode interrupt

– ME_IM.M_SAFE = 1

● XOSC failure event hapens

● Software Transition request

– ME_MCTL = RUN0 + KEY

– ME_MCTL = RUN0 + INVERTED KEY

● SAFE mode transition forced and interrupt generated

16/42 Doc ID 18232 Rev 1

Page 17

AN3316 Device modes

Figure 8. HW failure example

SAFE

XOSC failure

svsclk = IRC

DRUN RUN0

svsclk = IRC svsclk = XOSC

Error modes management

Mode Entry Module can generate an interrupt on the following events:

● Invalid mode configuration:

following rules should be respected in order to prevent error configuration event:

– IRC should be ON if: sysclk = rc_clk or sysclk = rc_clk_div

– XOSC should be ON if: sysclk = osc_clk or sysclk = osc_clk_div

– PLL should be ON if: sysclk = pll_clk

– Configuration "00" for the CFLAON and DFLAON bit fields should not be used

– MVR must be ON if any of the following is active: PLL/CFLASH/DFLASH

– System clock configurations marked as ’reserved’ may not be selected

– Configuration "1111" for the SYSCLK bit field is allowed only for STOP0 and TEST

modes

If one of the previous rule is violated, I_ICONF bit in the Interrupt Status register ME_IS is

set

● Invalid mode transition

Following cases should be avoided to complete the transition properly:

– Mode requested when a transition is active (mode transition illegal)

– Target mode not valid with respect to the current (mode request illegal)

– Target mode is disabled in mode enable register (disable mode access)

– Target mode doesn’t exist (non existing mode access)

previous cases are signaled by ME_IMTS register.

2.4 Application cases

This chapter tries to show most significant transition cases managed by mode Entry

Module.

Except for the Power-On Reset phase that is performed through a completely HW transition

(RESET → DRUN), transitions have either HW or SW aspects in the others cases.

Doc ID 18232 Rev 1 17/42

Page 18

Device modes AN3316

2.4.1 Power-on reset phase (RESET → DRUN)

Following, a chart that describes the start-up phase from CFLASH:

Figure 9. Transition (HW start-up) RESET → DRUN (execution from CFlash)

CORE

MODE

IRC 16M

VREG

RESET

(dig.)

STRAT-UP

SEQUENCE

Power-On

Reset

GATED POWERED

RESET

STOP RUNNING

ULTRA LP LOW POWER FULL POWER

ULP-VREGI

SET-UP

10

μ

s

IRC

LVD & MVREG

16M

μ

s

2

33

μ

s

Stabilize Flash

analog supply

20

μ

s

initialization

CFLASH

125

EXECUTE

DRUN

ME

μ

s

5

μ

s

Transition time: ~200

500mA(max)

Transition time: 200

Average conso: ~26mA

CONSUMPTION

PROFILE

25

μ

A

~5mA ~30mA

2.4.2 Application scenarios

The following scenarios shown are the typical ones that well describes the behavior of both

running and low power modes.

18/42 Doc ID 18232 Rev 1

μ

s

μ

s

~20mA

Page 19

AN3316 Device modes

Common HW aspects

As already said, other than sw configuration that should be taken care by the application,

there are some operations that are performed by HW and that are common to the scenarios

after described:

● <target mode> configuration check

While programming the mode configuration registers ME_<target mode>_MC, some rules

must be respected.

For example, if PLL is set to be the system clock in <target mode>, PLL should be turned

on. Otherwise, the write operation is ignored and an invalid mode configuration event may

be generated. Please refer to Error Management Chapter for detailed informations.

● <target mode> transition parameters check

There are some conditions that make the transition request invalid. For example, if the target

mode is not a valid mode with respect to current mode.

In this case, an invalid mode transition event may be generated. Please refer to Error

Management Chapter for detailed informations.

● <target mode> modules/peripherals switching on/off

Once the transition is requested by sw, the HW is in charge of switching on/off all

modules/peripherals. Now, if a module failure happens (i.e: XTAL or PLL lock failures) the

transition stalls in an ongoing status. However, The failures can be managed via software.

Please refer to Error Management Chapter for detailed informations.

For this reason, in order to prevent to stuck the code waiting for transition completion, it

could be better to set a timer, before entering in RUN0 mode, that, if expired, is able to signal

every potential issue.

Timeout calculation should be based on modules/peripherals start-up timing and, so, varies

case by case.

Scenario 1 (DRUN → RUNx)

This scenario is a typical application that starts from a default mode and transits to a full

device performance user mode. Following is the configuration of each mode.

Figure 10. Node configuration

DRUN RUN0

XTAL, PLL = OFF

sysclk = FIRC-16MHz

CFLASH, DFLASH = ON

all periphs = OFF

Following flow diagram describes the transition steps:

XTAL, PLL = OFF

sysclk = PLL-64MHz

CFLASH, DFLASH = ON

SPIO,ADCO = ON

Doc ID 18232 Rev 1 19/42

Page 20

Device modes AN3316

Figure 11. Transition step

DRUN Mode

DRUN Mode

1

XTAL Config

FMPLL config

2

3

mode config

periphs

4

mode config

Timer config

5

Request

6

transition to

RUN0

Application

HW

RUN0 config

check

Transi tion

DRUN → RUN0

7

RUN0 Mode

8

RUN0 Transition parameter

check

RUN0 switching on/off

modules/peripherals

N

Transition done?

Y

N

Time

expired?

Y

Error

management

RUN0 Mode

20/42 Doc ID 18232 Rev 1

Page 21

AN3316 Device modes

For the HW steps, refer to Section : Common HW aspects. Now, see in details the

operations done for each phase:

DRUN mode:

1. XTAL config

– CGM.OSC_CTL.EOCV = xxx (set stabilization counter)

2. FMPLL config:

PLL freq is done by the following formula:

phi

Where:

– clkin = reference clock = XTAL at 8 MHz

– LDF (NDIV) is the Loop Divided Ratio with this configurations:

Table 3. Loop divide ratio

NDIV[6:0] Loop divide ratios

0000000-0011111 NA

0100000 Divide by 32

0100001 Divide by 33

clkin LDF⋅

-----------------------------=

IDF ODF⋅

0100010 Divide by 34

... ...

1011111 Divide by 95

1100000 Divide by 96

1100001-1111111 NA

– IDF is the Input Divided Ratio with following configurations:

Table 4. Input divide ratio

IDF[3:0] Input divide ratios

0000 Divide by 1

0001 Divide by 2

0010 Divide by 3

... ...

1110 Divide by 15

– ODF is the Output Divided Ratio with following configurations:

Doc ID 18232 Rev 1 21/42

Page 22

Device modes AN3316

Table 5. Output divide ratio

ODF[1:0] Output divide ratios

00 Divide by 2

01 Divide by 4

10 Divide by 8

11 Divide by 16

So, to get PLL freq = 64MHz, in case of XTALat8MHz, registers configuration should

be:

CGM.FMPLL[0].CR.B.IDF = 0 (divide by 1)

CGM.FMPLL[0].CR.B.ODF = 2 (divide by 8)

CGM.FMPLL[0].CR.B.NDIV = 64 (multiply for 64)

3. RUN0 mode config:

ME_RUN0_MC.XOSC0ON = 1 (turn-on the XTAL)

ME_RUN0_MC.PLL0ON = 1 (turn-on the PLL)

ME_RUN0_MC.SYSCLK = 4 (set PLL as device system clock)

4. Periphs mode config:

ME_RUN_PC0.RUN0 = 1 (activate running peripheral configuration ’0’ in RUN0)

ME_PCTL[4].RUN_CFG = 0 to select the running peripheral configuration ’0’ for DSPI0

identified by offset = 4 (refer to figure x)

ME_PCTL[32].RUN_CFG = 0 to select the running peripheral configuration ’0’ for ADC

identified by offset = 32 (refer to figure x)

Table 6. SPC560B54/6x peripheral clock sources

Peripheral

RPP_ZOH platform None (managed through ME mode) —

DSPin 4+n 2

FlexCANn 16+n 2

BAM None (31 reserved) —

ADC 32 3

Register gatin address offset

(base = 0xC3FDC0C0)

Peripheral set

5. Timer config:

See Step 7 (DRUN → RUN0 mode)

22/42 Doc ID 18232 Rev 1

Page 23

AN3316 Device modes

6. Request transition to RUN0 mode:

The transition from a mode to another is handled by software by accessing the mode

control ME_MCTL register twice by writing:

– the first time with the value of the key (0x5AF0) into the KEY bit field and the

required target mode into the TARGET_MODE bit field

– the second time with the inverted value of the key (0xA50F) into the KEY bit field

and the required target mode into the TARGET_MODE bit field.

So, in case of DRUN → RUN0 transition, these two register writing should be done:

ME.MCTL.R = 0x40005AF0

ME.MCTL.R = 0x4000A50F

7. DRUN → RUN0 mode:

Once a valid mode transition request is detected, the transition starts. Here, device

switches-on/off modules and peripherals without CPU intervention.

It is possible to check for transition completion through mode Transition Status bit:

While (ME.GS.MTRANS != 0) //transition ongoing

... //transition completed

...

In ordeI to prevent code stucking waiting for transition completion, it could be better to

check transition timing through a timer. Timer timeout calculation should be based on

modules/peripherals start-up timing. In this case this value is close to XTAL start-up

time (at maximum 6 msec).

8. RUN0 mode:

Otherwise, if transition completion is signaled by sw, the RUN0 is properly entered with

the modules configured as expected.

Scenario 2 (RUN0 → HALT → RUN0)

This scenario deals with HALT mode that is the only one allowing to reduce average

consumption while the application is 100% functional. In fact, reducing dynamic

consumption through core switching-off and togheter with maintaining the full functionality is

one of the new challenge in body.

Figure 12. Scenario 2 - finite state machine

Software triggered transition

RUN0 HALT

Hardware triggered transition

XTAL, PLL = ON

sysclk = PLL-64MHz

CFLASH = ON

DFLASH = Low Power

SPI0, ADC0 = ON

XTAL, PLL = ON

sysclk = PLL-64MHz

CFLASH = Low Power

DFLASH = Low Power

SPI0, ADC0 = ON

CAN0 = ON

Doc ID 18232 Rev 1 23/42

Page 24

Device modes AN3316

Figure 13. Scenario 2 - flow chart

Application HW

Application HW

RUN0 Mode

RUN0 Mode

RUN0 Mode

RUN0 Mode

HALT Mode

1 HALT Mode

1

config

periphs config

periphs config

2

2

in HALT Mode

in HALT Mode

3

3

timer config

timer config

Request

4

4

transition to

transition to

HALT Mode

HALT Mode

config

Request

HALT config check

HALT config check

HALT transition parameter

HALT transition parameter

check

check

Transition

Transi tion

RUN0 -> HALT

RUN0 → HALT

5

5

HALT Mode

HALT Mode

6

6

CAN0

CAN0

interrupt event

interrupt event

Transition

Transi tion

HALT -> RUN0

HALT → RUN0

7

7

Transition

Tr an s i ti o n

done?

done?

HALT Mode

HALT Mode

NN

NN

Time

Time

expired?

expired?

YY

YY

Error

Error

management

management

HALT switching

HALT switching

ON/OFF modules/

ON/OFF modules/

peripherals

peripherals

-RUN0 transition

-RUN0 transition

parameter check

parameter check

-RUN0 switching on/off

-RUN0 switching on/off

modules/periphs

modules/periphs

RUN0 Mode

RUN0 Mode

RUN0 Mode

8

8

24/42 Doc ID 18232 Rev 1

RUN0 Mode

Page 25

AN3316 Device modes

For the HW steps, refer to Section : Common HW aspects. Now, see in details the operation

done for each phase:

RUN0 mode:

1. Mode config in HALT:

ME_HALT_MC.CFLAON = 2 (code Flash in Low Power mode)

ME_HALT_MC.DFLAON = 2 (data Flash in Low Power mode)

In this way, at HALT exiting, Flash startup from Low Power to Normal mode is very fast

as it takes less than 1 usec

ME_ HALT_MC.XOSC0ON = 1 (turn-on the XTAL)

ME HALT_MC.PLL0ON = 1 (turn-on the PLL)

ME_ HALT_MC.SYSCLK = 4 (set PLL as device system clock)

2. Periphs mode config HALT mode:

ME_RUN_LP0.HALT = 1 (activate low power peripheral configuration ’0’ in HALT)

ME_PCTL[4].LP_CFG = 0 to select the low power peripheral configuration ’0’ for

DSPI0 identified by offset = 4 (refer to figure x)

ME_PCTL[32].LP_CFG = 0 to select the low power peripheral configuration ’0’ for ADC

identified by offset = 32 (refer to figure x)

ME_PCTL[16].LP_CFG = 0 to select the low power peripheral configuration ’0’ for

FlexCAN0 identified by offset = 16 (refer to figure x)

Table 7. Peripherals clock source

Peripheral

RPP_ZOH Platform

DSPin 4 + n 2

FlexCANn 16 + n 2

BAM None (31 reserved) —

ADC 32 3

Register gatin address offset

(base = 0xC3FDC0C0)

None (managed through ME

mode)

Peripheral set

—

3. Timer config:

See Step 5 (RUN0 → HALT mode)

4. Request transition to RUN0 mode:

So, in case of RUN0 → HALT transition, these two register writing should be done:

ME.MCTL.R = 0x80005AF0

ME.MCTL.R = 0x8000A50F

Doc ID 18232 Rev 1 25/42

Page 26

Device modes AN3316

5. RUN0 → HALT mode:

Once a valid mode transition request is detected, the transition starts. Here, device

switches-on/off modules and peripherals without CPU intervention.

It is possible to check for transition completion through mode Transition Status bit:

while (ME.GS.MTRANS != 0) //transition ongoing

... //transition completed

in order to prevent code stucking waiting for transition completion, it could be better to

check transition timing through a timer. Timer timeout calculation should be based on

modules/peripherals start-up timing. As, in this case, as there aren’t any slow-start-up

peripherals to switch-on, timeout could be considered equal to few clock cycles.

6. HALT mode:

At the end of the transition, device enters in HALT mode with core switched-off,

FlexCAN0 switched-on and CFLASH in Low Power mode. All others peripherals are

maintained in the same status of the RUN0 mode.

As already said, the advantage of this configuration is that core switching-off allows to

reduce average consumption while the application is still 100% functional.

At this point, if a FlexCAN0 interrupt event is generated, the device, automatically,

starts the transition to go back to the previous RUN0

7. Transition HALT → RUN0 mode:

During the HALT → RUN0 transition, the device automatically restores the

peripherals/modules as they were configured before entering in HALT. So, core is

already on and CFLASH comes back to Normal mode

8. RUN0 mode:

At the end of the transition, device enters in RUN0 mode with initial configuration

Scenario 3 (RUN0 → STOP → RUN0)

This scenario is a typical transition from the application when going from

Running → Standby when the car is switched off. However, the application does not go

directly to the lowest consumption STANDBY mode but rather in 2 or even 3 steps. And here

STOP could be the last step before STANDBY where the application still monitor for a

certain time the activity in the vehicle.

Figure 14. Scenario 3 - finite state machine

Software triggered transition

RUN0 STOP

Hardware triggered transition

XTAL, PLL = ON

sysclk = PLL-64MHz

CFLASH = ON

DFLASH = Low Power

CAN0 = ON

XTAL, PLL = ON

PLL = OFF

sysclk = FIRc-16MHz

CFLASH = Power Down

DFLASH = Low Power

CAN0 = ON

26/42 Doc ID 18232 Rev 1

Page 27

AN3316 Device modes

Figure 15. Scenario 3 - flow chart

Application HW

Application HW

RUN0 Mode

RUN0 Mode

RUN0 Mode

RUN0 Mode

STOP Mode

1

1 HALT Mode

config

config

STOP config check

HALT config check

periphs config

periphs config

2

2

in STOPMode

in HALT Mode

3

3

timer config

timer config

Request

Request

4

4

transition to

transition to

STOP Mode

HALT Mode

STOP transition parameter

HALT transition parameter

check

check

Transi tion

Transition

RUN0 → STOP

RUN0 -> HALT

5

5

STOP Mode

HALT Mode

6

6

CAN0

CAN0

interrupt event

interrupt event

Transition

Transi tion

HALT -> RUN0

STOP → RUN0

7

7

Tr an s i ti o n

Transition

done?

done?

STOP Mode

HALT Mode

NN

NN

Time

Time

expired?

expired?

YY

YY

Error

Error

management

management

STOP switching

HALT switching

ON/OFF modules/

ON/OFF modules/

peripherals

peripherals

-RUN0 transition

-RUN0 transition

parameter check

parameter check

-RUN0 switching on/off

-RUN0 switching on/off

modules/periphs

modules/periphs

RUN0 Mode

RUN0 Mode

8

8

RUN0 Mode

RUN0 Mode

Doc ID 18232 Rev 1 27/42

Page 28

Device modes AN3316

For the HW steps, refer to Chapter : Common HW aspects. Now, see in details operation

done for each phase:

RUN0 mode:

1. Mode config in STOP:

ME_STOP_MC.CFLAON = 1 (code Flash in Power-Down)

ME_STOP_MC.DFLAON = 2 (data Flash in Low Power mode)

In this way, at STOP exiting, Flash startup from Power-Down to Normal mode takes few

usecs

ME_ STOP_MC.XOSC0ON = 1 (turn-on the XTAL)

The XTAL is maintained on in STOP in order to clock CAN protocol handler: in this way

PLL jitter issues are avoided

ME_ STOP_MC.SYSCLK = 0 (set FIRC as device system clock)

2. Periphs mode config STOP mode:

ME_RUN_LP0.STOP = 1 (activate low power peripheral configuration ’0’ in STOP)

ME_PCTL[16].LP_CFG = 0 to select the low power peripheral configuration ’0’ for

FlexCAN0 identified by offset = 16 (refer to figure x)

3. Timer config:

See Step 5 (RUN0 → HALT mode)

4. Request transition to RUN0 mode:

in case of RUN0 → STOP transition, these two register writing should be done:

ME.MCTL.R = 0xA0005AF0

ME.MCTL.R = 0xA000A50F

5. RUN0 → STOP mode:

Once a valid mode transition request is detected, the transition starts. Here, device

switches-on/off modules and peripherals without CPU intervention.

It is possible to check for transition completion through mode Transition Status bit:

while (ME.GS.MTRANS != 0) //transition ongoing

... //transition completed

...

in order to prevent code stucking waiting for transition completion, it could be better to

check transition timing through a timer. As, in this case, as there aren’t any slow-startup peripherals to switch-on, timeout could be considered equal to few clock cycles.

6. STOP mode:

At the end of the transition, device enters in STOP mode with core switched-off,

FlexCAN0 switched-on and CFLASH in Power Down. All others peripherals are

maintained in the same status of the RUN0 mode.

At this point, if a FlexCAN0 interrupt event is generated, the device, automatically,

starts the transition to go back to the previous RUN0

7. transition STOP → RUN0 mode:

During the STOP → RUN0 transition, the device automatically restores the

peripherals/modules as they were configured before entering in STOP. So, core is

already on and CFLASH comes back to Normal mode

28/42 Doc ID 18232 Rev 1

Page 29

AN3316 Device modes

8. RUN0 mode:

At the end of the transition, device enters in RUN0 mode with initial configuration

Scenario 4 (RUNx → STANDBY → RUNx)

This scenario is a typical application that remains in STANDBY for most of time minimizing

at maximum the power consumption and wakeup periodically to execute some operations

(for example ADC acquisition).

Figure 16. Scenario 4 - finite state machine

Software triggered transition

RUN0

Hardware triggered transition

XTAL, PLL = ON

sysclk = PLL-64MHz

CFLASH = ON

DFLASH = Low Power

STANBY

FIRC, sysclk = ON

SIRC = ON

RAM size = 8 KB

CFLASH = Power Down

periodic wakeup with API

booting from RAM

Doc ID 18232 Rev 1 29/42

Page 30

Device modes AN3316

Figure 17. Scenario 4 - flow chart

HWApplication

RUN0 Mode

Transition

RUN0 → STBY

5

RUN0 Mode

STBy Mode

1

config

booting

config in

2

STBY Mode

3

API config

Request

transition to

4

STBY Mode

STBY config check

STBY config parameter

check

STBY switching on/off

modules/peripherals

STBY Mode

6

STBY Mode

Transition

STBY → RESET → DRUN

7

DRUN Mode

8

DRUM Mode

(in RAM)

period

NAPI

expired?

Y

-Request sequence

-DRUN Mode entering

30/42 Doc ID 18232 Rev 1

Page 31

AN3316 Device modes

For the HW steps, refer to Section : Common HW aspects. Now see in details the operation

done for each phase:

RUN0 mode:

1. Mode config in STDBY:

STANDBY mode, by default has already following configuration:

– CFLASH/DFLASH in Power Down

–XTAL OFF

– Sysclk OFF

So, the only sw configurations to perform are:

ME_ STANDBY_MC.FIRCON = 0 (turn-off the FIRC)

CGM_ LPRC.LPRCON_STDBY = 1 (turn-on the LPRC in STANDBY)

Moreover, it needs that all peripherals are clock-gated, otherwise, STANDBY mode is

not entered properly, so:

ME_ RUN_LPx.STANDBY = 0 (all low power peripheral configuration registers used

should have STANDBY disabled)

2. STDBY Boot config:

RGM_STDBY.BOOT_FROM_BKP_RAM = 1 (boot from SRAM on STANDBY exit)

ME_DRUN_MC.CFLAON = 1 (code Flash in Power-Down)

PCU_PCONF2.STDBY0 = 0 (SRAM 24K powered-off)

with these settings, after exiting from STANDBY, device enters in DRUN booting from

SRAM (8K backup) with CFLASH in Power-Down, minimizing consumption

3. API config:

This step should configure the API to generate a periodic wakeup to exit device from

STANDBY

4. Request transition to RUN0 mode:

in case of RUN0 → STANDBY transition, these two register writing should be done:

ME.MCTL.R = 0xD0005AF0

ME.MCTL.R = 0xD000A50F

5. RUN0 → STANDBY mode:

Once a valid mode transition request is detected, the transition starts. Here, device

switchs-off core and all the modules/peripherals that belong to Power-Domain #1. Only

Power-Domain #2 is maintained on.

Doc ID 18232 Rev 1 31/42

Page 32

Device modes AN3316

Figure 18. Power domain

PCON

F1[new mode]

new mode

wakeup

PCON

F2[new mode]

new mode

wakeup

Determine new

power state

Determine new

power state

power down

power up

power down

power up

PCU

SRAM (8K), Power Control Unit(PCU), RESET

Generation Module(RGM), Voltage regulator.

Wakeup Unit, API, CAN sampler, 16MHz & 128

KHz RC oscillator, RC digital interface & voltage

FSN

FSN

Power domain #1

Core Flash

#1

#2

Supply

Peripheral

set #1

PLL0

Power Domain #2

SRAM(24KB)

VREG

2

ME

JTAG

...

Power Domain #0

Note:

represents a power switching device. For the sake of simplicity this has been drawn as a mechanical switch.

Ground

It is possible to check for transition completion through mode Transition Status bit:

while (ME.GS.MTRANS != 0) //transition ongoing

... //transition completed

...

No timer is used here to check for the transition completion as timers are switched-off

during RUN0 → STANDBY transition

6. STANDBY mode:

At the end of the transition, device enters in STANDBY and stay there until the API not

generates a wakeup event. At this time the STANDBY exiting starts

7. Transition STANDBY → RESET → DRUN mode:

Once the wakeup event is generated, the device re-executes the Power-On Reset

phase staying in RESET mode. At the end, device enters in DRUN mode, where the

DRUN configuration register resets except for the DRUN.CFLAON/DFLAON that

maintains the values configured before STANDBY entering. This allows to put

CFLASH/DFLASH in Power Down once in DRUN.

32/42 Doc ID 18232 Rev 1

Page 33

AN3316 Device modes

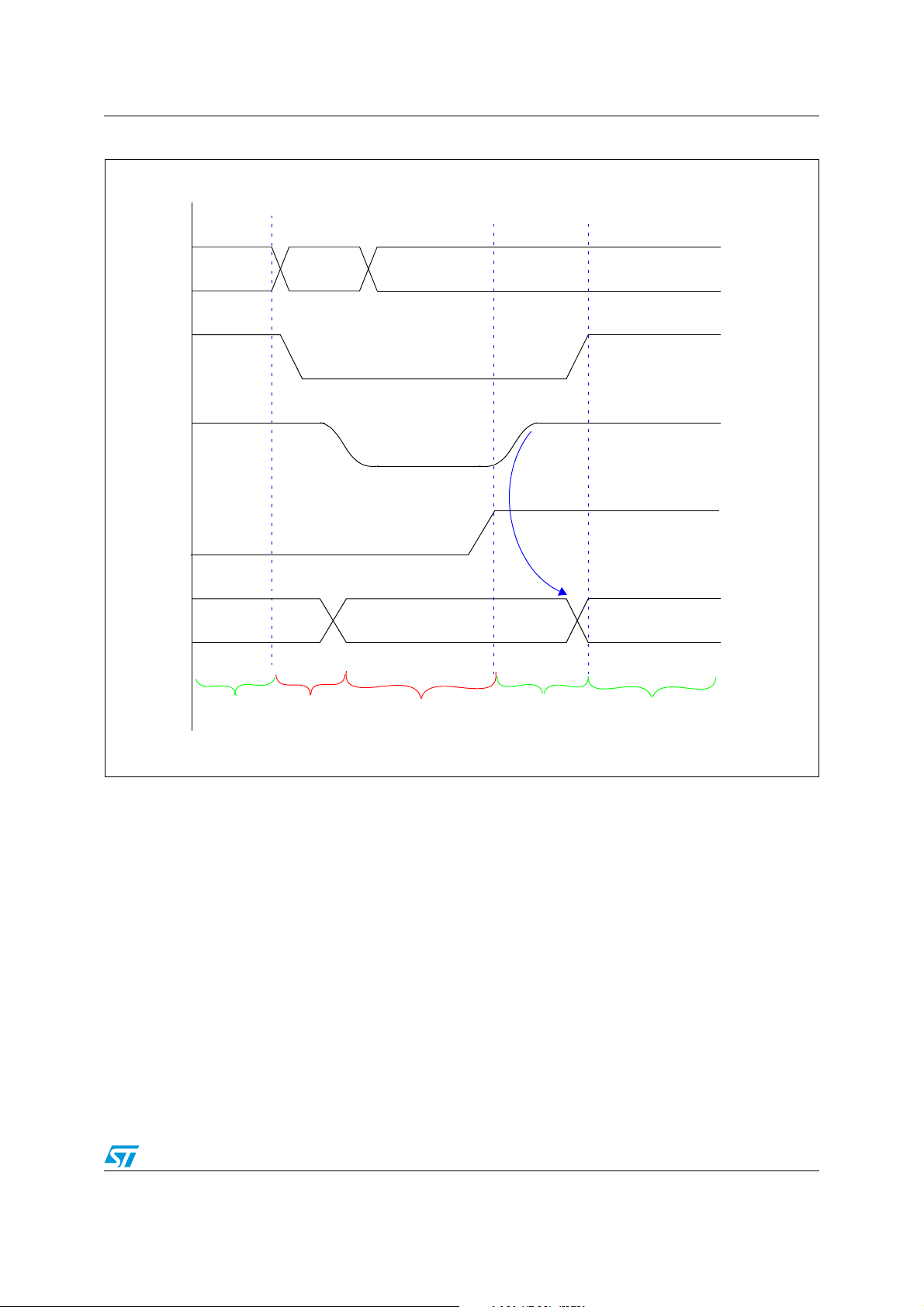

Figure 19. STANDBY transition

new mode

requested

by ME

PSTAT.PDI

voltage in

power

domain #1

RUNo STANBY0 mode set due to reset being asserted to power domain

#1

wakeup

request

current

mode

RUN0 STANBY0 DRUN

power-up

state

● 8 - DRUN mode:

powerdown

phase

power-down state power-up

phase

power-up state

At the end of the transition, device enters in DRUN mode fetching the code from the first

SRAM location (0x40000000).

Doc ID 18232 Rev 1 33/42

Page 34

Consumption tables AN3316

3 Consumption tables

The target is to show the consumption of Running and Low Power modes for different

configurations. These values should be based on Bol1.5M cut2.0 measurements.

3.1 Running mode

This table shows modules consumption contributions in running mode with following

features:

● Code: continuous data transfer from Flash to RAM

● fsys = system clock (MHz)

● code executing from Flash

● all peripherals gated

Table 8. RUN0 mode consumption table

IP Conso (mA)

FIRC-16MHz 0.6

FOSC-8MHz 1.78

PLL 0.0303 * fsys

Low Power Normal

0.89 7.22

Low Power Normal

0.6 4.29

RUN0

mode

CFLASH

DFLASH

MVREG 1.06

Platform + PD0 0.4434 * fsys + 0.7765

Where PDO = Power Domain 0

In this way, it is possible to calculate the total consumption related to a specific configuration

easily.

As an example, consider following configuration at fsys = 16 MHz:

34/42 Doc ID 18232 Rev 1

Page 35

AN3316 Consumption tables

Table 9. RUN0 mode consumption example

IP Status Formula (mA) Conso (mA)

FIRC-16MHz On 0.6 0.6

FOSC-8Mhz On 1.78 1.78

PLL On 0.0303 * fsys 0.4848

CFLASH Normal

RUN0 mode

DFLASH

MVREG

Platform + PD0 0.4434 * fsys + 0.7765 7.8709

Total conso evaluated 23.3057

Total conso measured 23.51

3.2 Low Power modes

Following tables show how to calculate low power modes (HALT/STOP/STANDBY)

consumption respectively, summing the contributions of each module

3.2.1 HALT consumption

This table shows modules consumption contributions in HALT mode:

Table 10. HALT mode consumption table

IP conso(mA)

Power

Down

Always On

Low Power Normal

7.22

0.89 7.22

Low Power Normal

4.29

0.6 4.29

1.06 1.06

FIRC-16MHz 0.6

FOSC-6MHz 1.78

PLL mA = 0.0303 * MHz

Low Power Normal

CFLASH

0.89 7.22

Low Power Normal

HALT mode

DFLASH

0.6 4.29

MVREG 1.06

(1)

PD0

(always on)

(2)

PDI

1. Core/Platform + Power Domain 0 (always On) consumption

2. Consumption of Power Domain 1 that depends on the system clock (divided or not) provided to the

pheripherals

mA = 0.0668 * MHz + 0.5791

mA = 0.2092 * MHz + 0.077

Doc ID 18232 Rev 1 35/42

Page 36

Consumption tables AN3316

So, the HALT lowest consumption is 1.21 mA obtained with following configuration:

– FIRC on → 0.6 mA

– sysclk = FIRC/32 → PD0 conso = 0.0668 * 0.5 + 0.5791

– all others modules/peripherals off

As an example, consider following HALT mode configuration with fsys = 64 MHz and all

peripherals clocked at 32 MHz

Table 11. HALT mode consumption example

IP Status Formula(mA) Conso(mA)

FIRC-16MHz On 0.6 0.6

FOSC-6MHz On 1.78 1.78

PLL On 0.0303 * fsys 1.9392

Low Power Normal

7.22

0.89 7.22

Low Power Normal

0

0.6 4.29

HALT mode

CFLASH Normal

DFLASH Power Down

MVREG On 1.06 1.06

(1)

PD0

(always on)

(2)

PDI

On mA = 0.0668*64 + 0.5791 4.8543

On mA = 0.2092*32 + 0.077 6.7714

Total conso evaluated 25.2249

Total conso measured 25.41

1. Core/Platform + Power Domain 0 (always On) consumption

2. Consumption of Power Domain 1 that depends on the system clock (divided or not) provided to the

pheripherals

3.2.2 STOP consumption

This table shows modules consumption contributions in STOP mode:

36/42 Doc ID 18232 Rev 1

Page 37

AN3316 Consumption tables

Table 12. STOP mode consumption table

IP Conso (mA)

FIRC-16MHz 0.6

FOSC-8MHz 1.78

PLL Non onfigurable

CFLASH

Low Power Normal

0.89 7.22

Low Power Normal

DFLASH

STOP mode

0.6 4.29

MVREG 1.06

Power-Down output 0.44

(1)

PD0

(2)

PD1

1. Core/Platform + Power Domain 0 (always on consumption

2. Consumption of Power Domain 1 that depends on the system clock (divided or not) provided to the

peripherals

0.0585*fsys + 0.2

0.194*fsys + 0.1978

So, the STOP lowest consumption is 0.2 mA obtained with following configuration:

– Sysclk off → PD0 conso = 0.2 mA

– all others modules/peripherals off

As an example, consider following STOP mode configuration with fsys = 8 MHz and all

peripherals clocked at 2 MHz:

Table 13. STOP mode consumption example

IP Status Formula(mA) Conso(mA)

FIRC-16MHz On 0.6 0.6

FOSC-8MHz Off 1.78 0

PLL Off Non Configurable 0

Low Power Normal

CFLASH Normal

0.89 7.22

Low Power Normal

DFLASH Power down

STOP mode

0.6 4.29

MVREG On 1.06 1.06

Power-Down Output On 0.44 0

(1)

PD0

PD1

(2)

0.194*2 + 0.1978 0.5858

Total conso evaluated 10.1338

Total conso measured 10.41

1. Core/Platform + Power Domain 0 (always on consumption

Doc ID 18232 Rev 1 37/42

7.22

0

0.0585*8 + 0.2 0.668

Page 38

Consumption tables AN3316

2. Consumption of Power Domain 1 that depends on the system clock (divided or not) provided to the

peripherals

3.2.3 STANDBY consumption

This table shows modules consumption contributions in STANDBY mode:

Table 14. STANDBY mode consumption table

IP conso (μA)

FIRC-16MHz 290

FOSC-8MHz OFF (not config)

PLL OFF (not config)

CFLASH Power Down (not config)

DFLASH Power Down (not config)

MVREG OFF (not config)

Power-Down output

STANBY mode

SIRC-128KHz 3

SRAM-24KB 0.8

PD0

PD1

(1)

(2)

ON (not config)

21 (not config)

OFF (not config)

1. Core/Platform + Power Domain 0 (always on consumption

2. Consumption of Power Domain 1 that depends on the system clock (divided or not) provided to the

peripherals

So, the STANDBY lowest consumption is 21 µA obtained with following configuration:

– PD0 conso = 0.2 mA

– FIRC,SIRC,SRAM-24K off

On the other hand, maximum consumption (FIRC,SIRC,SRAM-24K on) is 314.8 µA.

3.3 Peripherals

In order to evaluate peripheral consumption contributions measured on ballast voltage

(IDD_BV), following table can be used that provides for all the main device peripherals,

either dynamic or static consumption.

38/42 Doc ID 18232 Rev 1

Page 39

AN3316 Consumption tables

Table 15. Peripherals consumption table

Symbol C Parameter Conditions

500 Kbps Total (static + dynamic)

CAN

I

DD_BV(CAN)

CC T

(FlexCAN)

supply current

on V

DD_BV

125Kbps 8 * f

Static consumption:

– eMIOS channel OFF

IDD_BV(eMIOS) CC T

eMIOS supply

current on

V

DD_BV

– Global prescaler enabled

Dynamic consumption:

– It does not change by varying the frequency

(0.003 mA)

Total (static + dynamic) consumption:

– LIN mode

– Baudrate: 20 Kbps

I

DD_BV(SCI)

CC T

SCI(LINFlex)

supply current

on V

DD_BV

Ballast static condition (only clocked) 1

Ballast dynamic condition (continuous

communication):

– Baudrate: 2 Mbit

– Transimmisio every 8 s

I

DD_BV(SPI)

CC T

SPI(DSPI)

supply current

on V

DD_BV

– Frame: 16 bits

consumption:

– FlexCAN in loop-back mode

– XTAL at 8 MHz used as CAN

engine clocksource

– Message sending period is 580s

8 * f

29 * f

5 * f

16 * f

Value

Type

periph

periph

periph

3

periph

periph

Unit

+ 85

+ 27

μA

+ 31

V

DD = 5.5V

V

DD = 5.5V

V

DD = 5.5V

V

DD = 5.5V

I

DD_BV(ADC)

I

DD_HV_ADC(ADC)

CC T

CC T

ADC supply

current on

V

DD_BV

ADC supply

current on

V

DD_HV_ADC

3.4 Consumption example

So, to calculate the peripheral consumption refer to the following scenario:

● Fperiph = PLL at 32 MHz

● Fcan = XTAL at 8 MHz (to avoid PLL glitches)

Each peripheral is showed in the following table:

Ballast static consumption (no

conservation)

Ballast dynamic consumption

(continuous conservation)

Analog static consumption (no

conservation)

Analog dynamic consumption

(continuous conservation)

41 * f

5 * f

2 * f

75 * f

periph

periph

µA

periph

periph + 32

Doc ID 18232 Rev 1 39/42

Page 40

Consumption tables AN3316

Table 16. Peripherals consumption example

IP Formula (µA) Conso (mA)

2 x CAN at 500 Kbps 2 x (8 * Fcan + 85) 0.234

4 x eMIOS PWM at 200 Hz 29 * Fperiph + 3 0.931

4 x LIN at 20 Kbps 4 x (5 * Fperiph + 31) 0.764

3 x SPI at 2 Mbps 3 x (16 * Fperiph) 1.536

24 x ADC (continous conv.)

Total peripherals conso 4.937

46 * Fperiph 1.472

40/42 Doc ID 18232 Rev 1

Page 41

AN3316 Revision history

4 Revision history

Table 17. Document revision history

Date Revision Changes

17-Nov-2010 1 Initial release.

Doc ID 18232 Rev 1 41/42

Page 42

AN3316

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZED ST REPRESENTATIVE, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE

SUSTAINING APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN

PERSONAL INJURY, DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT

SPECIFIED AS "AUTOMOTIVE GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2010 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Philippines - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

42/42 Doc ID 18232 Rev 1

Loading...

Loading...