AN3311

Application note

In-home display for ZigBee® smartplug

Introduction

This application note describes the demonstration firmware running on the STM3210CEVAL for the STM32F107VC to manage a smartplug network system.

An embedded graphical user interface (GUI) based on the “multi-input embedded GUI

library 2.0 for STM32F10xxx” described in the AN3128 application note, and working on an

LCD TFT 320 x 240 display and 5-position joystick, allows the user to interact with the

smartplug system made up of one coordinator and two smartplugs connected.

Section 1 describes the document and library rules.

Section 2 highlights the features of the ZigBee smartplug and explains its hardware

interface with a device microcontroller (STM32).

Section 3 describes briefly the “multi-input embedded GUI library”.

Section 4 describes the relevant blocks of the STM3210C-EVAL demonstration board.

Section 5 shows the demonstration firmware/board system setup.

Section 6 describes, in detail, how the “in-home display” firmware is structured, its

architecture and its exported APIs.

Section 7 explains how to get started with the system, how to configure and use the IAR

workspace, and contains an example application source code.

Section 8 illustrates how the “in-home display” GUI application works.

Section 9 illustrates the hardware schematics.

December 2010 Doc ID 18209 Rev 1 1/58

www.st.com

Contents AN3311

Contents

1 Document and library rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.1 Acronyms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2 ZigBee smartplug . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1 Smartplug description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.2 ZigBee module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3 Multi-input embedded GUI library . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4 STM3210C-EVAL demonstration board . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.1 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.2 STM32 peripherals mapping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.3 Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.4 Boot option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.5 Clock source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.6 Reset source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.7 Joystick . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.8 Pushbuttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.9 Storage memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.10 Development and debug support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.11 Display and input devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.12 JTAG debugging connector CN13 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.13 Daughterboard extension connector CN8 and CN9 . . . . . . . . . . . . . . . . . 19

4.14 TFT LCD connector CN14 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.15 Power connector CN18 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5 Demonstration firmware system setup . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.1 Hardware requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.2 STM3210C-EVAL demonstration board setup . . . . . . . . . . . . . . . . . . . . . 24

5.3 STM3210C-EVAL and ZigBee adapter with M24LR62-r memory . . . . . . 24

5.4 How to navigate the demo menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

2/58 Doc ID 18209 Rev 1

AN3311 Contents

6 In-home display firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

6.1 Firmware architecture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

6.2 main.c . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

6.2.1 vSmartPlugSamplingTask . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

6.2.2 vGraphicLibraryTask . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

6.2.3 prvApplicationTask . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

6.2.4 prvSetupHardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

6.2.5 vBoardInit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

7 Getting started with the system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

7.1 Configure IAR tool for building, debugging, and programming the application

31

7.2 Example application - main.c . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

8 In-home display GUI application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

9 Schematics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

9.1 Smartplug board schematics and layout . . . . . . . . . . . . . . . . . . . . . . . . . 45

9.2 ZigBee/RF adapter for smartplug and dual interface memory . . . . . . . . . 46

9.3 STM3210C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

9.4 MCU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

9.5 LCD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

9.6 I/O expander . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

9.7 I/O peripherals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

9.8 Extension connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

9.9 JTAG and trace . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

9.10 Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

9.11 LCD 3.2" module with SPI and 16-bit interface 1 . . . . . . . . . . . . . . . . . . . 55

10 References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

11 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Doc ID 18209 Rev 1 3/58

List of tables AN3311

List of tables

Table 1. List of acronyms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Table 2. Power related jumpers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Table 3. Boot related switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Table 4. Reset related jumper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Table 5. LCD module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Table 6. JTAG debugging connector CN13 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Table 7. Daughterboard extension connector CN8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Table 8. Daughterboard extension connector CN9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Table 9. ZigBee adapter pin description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Table 10. Function description format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Table 11. vSmartPlugSamplingTask task . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Table 12. vGraphicLibraryTask task . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Table 13. prvApplicationTask task . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Table 14. prvSetupHardware function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Table 15. vBoardInit function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Table 16. Document revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

4/58 Doc ID 18209 Rev 1

AN3311 List of figures

List of figures

Figure 1. STM3210C-EVAL block scheme . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Figure 2. Block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Figure 3. I/O expander hardware configuration on the STM3210C-EVAL . . . . . . . . . . . . . . . . . . . . . 10

Figure 4. STM3210C-EVAL demonstration board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Figure 5. Hardware block diagram - STM32 peripherals mapping. . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Figure 6. STM3210C-EVAL demonstration board layout. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Figure 7. JTAG debugging connector CN13 viewed from above the PCB . . . . . . . . . . . . . . . . . . . . 18

Figure 8. Power supply connector CN18 viewed from the front. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Figure 9. In-home display firmware architecture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Figure 10. Application project files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Figure 11. IAR embedded workbench main window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Figure 12. IAR embedded workbench debugger options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Figure 13. ZigBee dongle connection problem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Figure 14. Main menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Figure 15. Searching plugs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Figure 16. No plug detected. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Figure 17. Plugs detected . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Figure 18. Label changing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Figure 19. TRIAC smartplug management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Figure 20. Relay smartplug management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Figure 21. Smartplug statistics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Figure 22. Energy consumption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Figure 23. Global energy consumption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Figure 24. Power consumption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Figure 25. Global power consumption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Figure 26. ZigBee and dual interface EEPROM adapter schematic for STM3210C-EVAL . . . . . . . . . 45

Figure 27. ZigBee and dual interface EEPROM adapter layout for STM3210C-EVAL . . . . . . . . . . . . 46

Figure 28. STM3210C main schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Figure 29. MCU schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Figure 30. LCD schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Figure 31. I/O expander schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Figure 32. I/O peripherals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Figure 33. Extension connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Figure 34. JTAG and trace. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Figure 35. Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Figure 36. LCD 3.2" module with SPI and 16-bit interface 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Doc ID 18209 Rev 1 5/58

Document and library rules AN3311

1 Document and library rules

This document uses the conventions described in the sections below.

1.1 Acronyms

Ta bl e 1 lists the acronyms used in this document.

Table 1. List of acronyms

Acronym Meaning

API Application programming interface

HAL Hardware abstraction layer

MCU Microcontroller unit

I2C Inter-integrated circuit

SPI Serial to parallel interface

OOP Object oriented programming

6/58 Doc ID 18209 Rev 1

AN3311 ZigBee smartplug

2 ZigBee smartplug

2.1 Smartplug description

The smartplug coordinator is connected via an SPI to the STM3210C-EVAL through an “AdHoc” adapter.

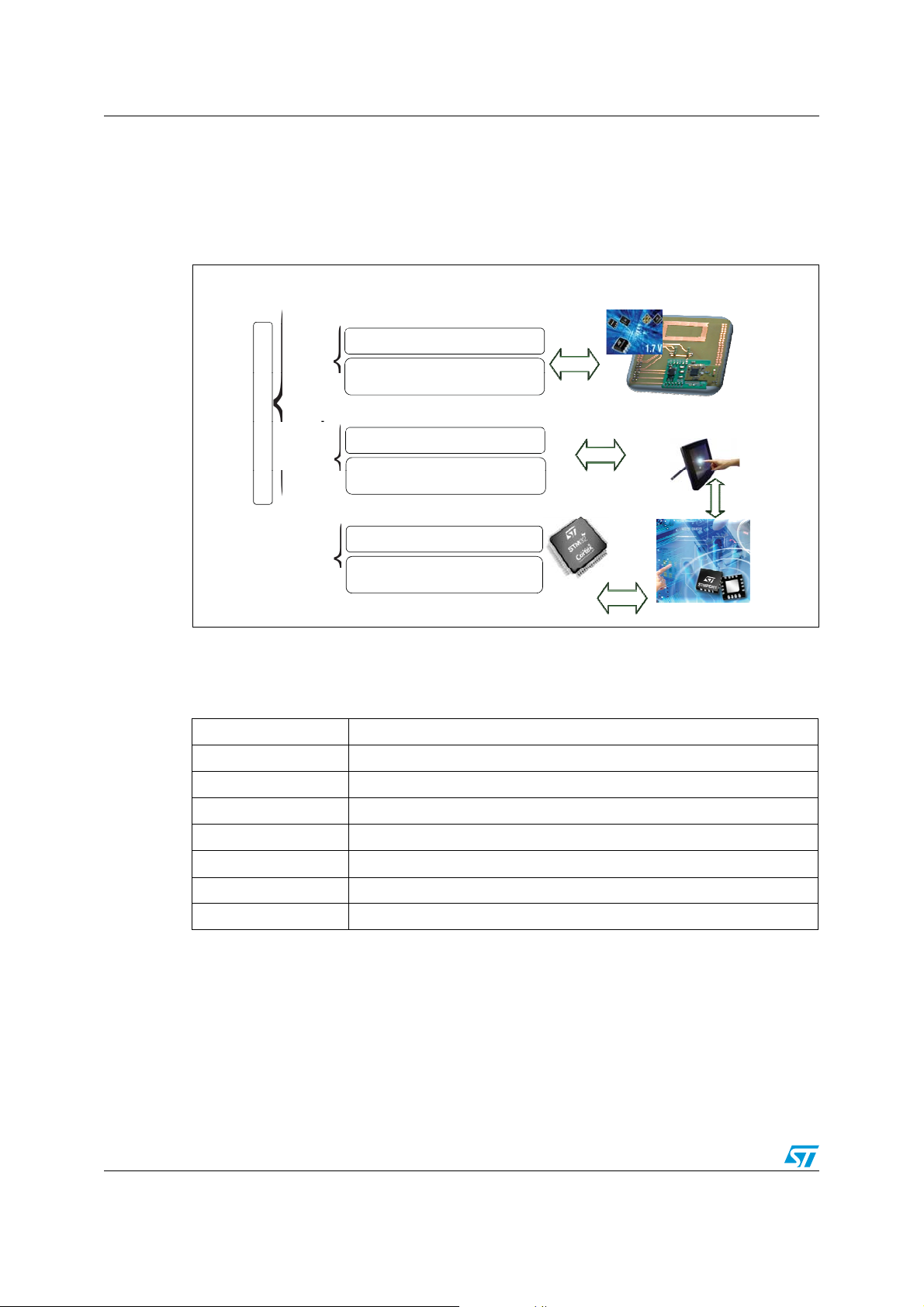

In Figure 1 it is possible to take a quick look at the STM3210C-EVAL board and a smartplug

node block diagram.

Figure 1. STM3210C-EVAL block scheme

An adapter is connected to the extended connectors CN8 and CN9 on the STM3210CEVAL (for more detailed information please refer to the UM0600 user manual), it allows the

connection of a ZigBee smartplug coordinator and the I

2

C/RF dual interface EEPROM

M24LR64-r. The Gerber files of the adapter board are included in the setup package of this

project.

The ZigBee smartplug board can be used as a guide to build a home/building automation

subsystem for energy management. In a typical application, the board is plugged into an

electrical wall socket and supplies an electrical load, monitoring the energy consumption;

using several smartplugs it is possible to monitor and control the home/building energy

consumption socket by socket. The board includes the following functions, shown in the

block diagram of Figure 2:

● Energy measurement

● Load differential current

● Load driving by relay or TRIAC (dimming)

● ZigBee communication capability.

Doc ID 18209 Rev 1 7/58

ZigBee smartplug AN3311

Figure 2. Block diagram

The STEVAL-IHP001V3 is a smartplug board based on an STM32F10x microcontroller, a

SPZB260 ZigBee module, and an STPM01 energy metering IC.

It implements a ZigBee metering node which allows the final user to monitor and manage

energy consumption.

The board has been developed as a guide to build a home/building automation subsystem

for energy management. In a typical home system implementation, the board is plugged into

an electrical wall socket and supplies a home appliance or other generic electrical load.

The current, power, energy, and other information, related to the electrical load connected to

the smartplug board, can be displayed locally on an LCD screen, and are sent to a ZigBee

data concentrator through the home/building ZigBee network.

2.2 ZigBee module

ZigBee smartplug communication is based on the SPZB260 module with a DIL adapter. The

module is FCC compliant (FCC ID:S9NZB260A). The module is based on the SN260

ZigBee network processor which integrates a 2.4 GHz, IEEE 802.15.4 compliant

transceiver, as well as IEEE 802.15.4 PHY and MAC. The main features are:

● 0dBm nominal TX output power

● -92dBm RX sensitivity

● +2dBm TX output power in boost mode

● RX filtering for co-existence with IEEE 802.11g and Bluetooth

For further details please refer to the SPZB260 module and the SN260 network processor

datasheet.

Note: For more information, see the UM0608 user manual, STEVAL-IHP001V3 schematics

diagram, and AN2993 application note.

®

devices.

8/58 Doc ID 18209 Rev 1

AN3311 Multi-input embedded GUI library

3 Multi-input embedded GUI library

3.1 Description

This solution enables users, comfortable with the use of standard microcontrollers, to create

higher-end “look and feel” human interfaces by replacing conventional electromechanical

switches with touch-sensing controls.

Users can combine touch-sensing functions using multiple configurations (touchscreen,

joystick, and keys) with traditional MCU features (communication, beeper, LCD control, etc.).

The E-multi-input graphic library is part of the application firmware.

The graphic objects are a set of controls that can be printed on the screen and associated to

an action when pressed.

The library has been developed and tested on an LCD panel of QWGA resolution (320x240)

which is the default, but the library is independent of the LCD resolution, although it has not

been tested with others.

The library supports touchscreen features and includes a low level driver which handles the

analog input (for 12-bit ADC), and a function for the touchscreen calibration based on an

algorithm that uses 5 points.

The multi-input embedded GUI firmware library is fully developed in 'ANSI-C' following an

OOP approach. This means that the final application uses instances of page and graphic

objects according to their public methods and properties. In the end, the PageObj is a

structure containing public properties (data fields) and methods (functions pointers). The

OOP encapsulation feature is assured. The library has been developed and tested on the

“STM3210C” STMicroelectronics demonstration board.

The library can be included in the final application as a library file (multi-input embedded

GUI library.a) and used as a black box through its exported public API, or can be included in

the final application as source files (.c and .h), if the user wants to debug the library itself, or

to change the HAL functions in order to port the library on a different LCD (in model and

resolution) from the one attached to STM3210C-EVAL.

For more information on the graphic library see the AN3128, rev. 2, application note.

The calibration process is part of the post-processing layer. The touchscreen must be

calibrated at first power-on and/or upon user request.

Once the calibration is done, final adjustments on future power-on of the board are not

necessary because the calibration parameters are saved on the Flash memory.

The touchscreen and the joystick are controlled by the STMPE811 devices.

The STMPE811 has a simple 2-wire I

access the data in the touchscreen controller register at any time. It communicates via the

serial interface with a master controller.

Figure 3 shows how the STM32F10xxx microcontroller (master device) must be connected

to the STMPE811 device.

2

C digital serial interface which allows the user to

Refer to the STMPE811 datasheet for more information on the register concerning the data

of the touched points on the touchscreen.

Doc ID 18209 Rev 1 9/58

Multi-input embedded GUI library AN3311

Y-

1

INT

2

A0/Data

Out

3

4

5

VCC

6

Data in

7

IN0

8

IN1

9

GND

10

IN2

11

IN3

12

X+

13

Vio

14

Y+

15

X-

16

U7

STMPE81811

Y-

1

INT

2

A0/Data

Out

3

4

5

VCC

6

Data in

7

IN0

8

IN1

9

GND

10

IN2

11

IN3

12

X+

13

Vio

14

Y+

15

X-

16

U8

STMPE81811

R56

10K

+3V3

I2C

device

address:0x8 2

I2C

device

address:0x88

+3V3

+3V3

R57

100K

R58

100K

TouchScreen_X+

TouchScreen_X-

TouchScreen_Y+

TouchScreen_Y-

EXP_I_IO2

EXP_I_IO3

EXP_I_IO4

EXP_I_IO5

EXP_I_IO6

EXP_I_IO7

EXP_I_IO8

EXP_I_IO9

EXP_I_IO1O10

EXP_I_IO1O11

EXP_I_IO1O12

EXP_I_IO1

R160

10K

R159 0

+3V3

R37

10K

R164

10K

+3V3

C89

100nF

C90

100nF

PB6

PB7

P

B14

SCLK

SDAT

SCLK

SDAT

Figure 3. I/O expander hardware configuration on the STM3210C-EVAL

+3V

C8

100n

IO_Expander_SCK

IO_Expander_SDA

IO_Expander_INT

VC

14

Vio

10

GN

SCLK

B1

R15

+3V

R160

10

+3V

+3V

R3

10

C9

100n

R164

10

+3V

SDAT

Data

A0/Data

Out

ST

devic

address:0x8

VC

14

Vio

10

GN

SCLK

SDAT

Data

A0/Data

Out

R5

ST

10

devic

address:0x8

16

15

13

12

11

16

15

13

12

11

TouchScreen_Y-

TouchScreen_XTouchScreen_Y+

TouchScreen_X+

EXP

EXP

EXP

EXP

R5

100

EXP

EXP

EXP

EXP

EXP

EXP

EXP

EXP

R5

100

AM08449v1

10/58 Doc ID 18209 Rev 1

AN3311 STM3210C-EVAL demonstration board

4 STM3210C-EVAL demonstration board

Figure 4. STM3210C-EVAL demonstration board

Doc ID 18209 Rev 1 11/58

STM3210C-EVAL demonstration board AN3311

4.1 Features

● Three 5 V power supply options: power jack, USB connector, or daughterboard

● Boot from user Flash, system memory or SRAM

● I2S audio DAC, stereo audio jack

● 512 MByte (or bigger) micro-SD cardTM

● Both type A and B smartcard support

2

● I

C compatible serial interface 64-Kbit EEPROM, MEMS and I/O expander

● RS-232 communication

● IrDA transceiver

● USB-OTG full speed, USB mini-AB connector

● IEEE-802.3-2002 compliant Ethernet connector

● Two channels of CAN2.0A/B compliant connection

● Inductor motor control connector

● JTAG and trace debug support

● 3.2" 240x320 TFT color LCD with touchscreen

● Joystick with 4-direction control and selector

● Reset, wake-up, tamper, and user button

● 4 color LEDs

● RTC with backup battery

● MCU consumption measurement circuit

● Extension connector for daughterboard or wrapping board.

4.2 STM32 peripherals mapping

The STM3210C-EVAL demonstration board is designed around the STM32F107VC in a

100-pin TQFP package. The hardware block diagram, Figure 5, illustrates the connection

between the STM32F107VC and peripherals (LCD, EEPROM, MEMS, USART, IrDA, USBOTG, Ethernet, audio, CAN bus, smartcard, micro-SD card, and motor control) and these

features can be located on the actual demonstration board in Figure 6.

12/58 Doc ID 18209 Rev 1

AN3311 STM3210C-EVAL demonstration board

Figure 5. Hardware block diagram - STM32 peripherals mapping

6REGULATOR

-#5

CONSUMPTION

MEASUREMENT

,%$SKEY

%XTENSION

CONNECTORFOR

'0)/S

4&4,#$

-ICRO3$

CARD

-#CONTROL

CONNECTOR

*4!'

4RACE

".#CONNECTOR

0OTENTIOMETER

"ATTERYVOLTAGE

MEASUREMENT

'0)/

30)

-#

$EBUG

!$#

34-&6#4

)3

)#

/4'

-))2-)

#!.

#!.

53!24

53!24

!UDIO$!#

-%-3

%%02/-

)/EXPANDER

53"POWER

SWITCH

0(9

#!.

TRANSCEIVER

#!.

TRANSCEIVER

23

TRANSCEIVER

)R$!

TRANSCEIVER

3MARTCARD

INTERFACE

*OYSTICK

4OUCHSCREEN

53"-INI!"

CONNECTOR

)NTEGRATED2*

CONNECTOR

#!.

$"CONNECTOR

#!.

$"CONNECTOR

53!24

$"CONNECTOR

3MARTCARD

INTERFACE

!-V

For more details of calibration parameters, refer to the STPM01 datasheet on www.st.com.

Doc ID 18209 Rev 1 13/58

STM3210C-EVAL demonstration board AN3311

Figure 6. STM3210C-EVAL demonstration board layout

&1&1%1&

&1

&$1

&1

&$1

&1&1([WHQVLRQKHDGHU

8

)9&7

670

&10RWRUFRQWURO

&1

5-

FRQQHFWRU

&1

56

&1

86%0LFUR$%

FRQQHFWRU

&1

9SRZHU

&1

$XGLR MDFN

&1

0LFUR6'FDUG

&1

6PDUWFDUG

%

5HVHW

4.3 Power supply

The STM3210C-EVAL demonstration board is designed to be powered by a 5 V DC power

supply and protected by PolyZen from a wrong power plug-in event. It is possible to

configure the demonstration board to use any of the following three sources for the power

supply:

● 5 V DC power adapter connected to CN18, the power jack on the board (PSU on silk

screen for power supply unit)

● 5 V DC power with 500 mA limitation from CN2, the USB mini-AB connector (USB on

silkscreen)

● 5 V DC power from both CN8 and CN9, the extension connector for the daughterboard

(DTB for daughterboard on silkscreen).

%:DNHXS

%7DPSHU 8-R\VWLFN

&1

7U D F H

&1

-7$*

&1

&RORU/&'

8

,U'$

59

3RWHQW LR PHWH

%

8VHUNH\

U

!-V

14/58 Doc ID 18209 Rev 1

AN3311 STM3210C-EVAL demonstration board

The power supply is configured by setting the related jumpers JP24 and JP25, as described

in Ta bl e 2 .

Table 2. Power related jumpers

Jumper Description Configuration

JP25

selects one of the three possible power supply resources.

For power supply jack (CN18) to the STM3210C-EVAL only, JP25 is set as shown:

(Default)

For power supply from the daughterboard connectors (CN8 and CN9) to the

STM3210C-EVAL only, JP25 is set as shown:

JP25

For power supply from USB (CN2) to the STM3210C-EVAL only, JP25 is set as shown:

For power supply from power supply jack (CN18) to both the STM3210CEVAL

and daughterboard connected on CN8 and CN9, JP25 is set as

shown to the right (the daughterboard must not have its own power supply

connected):

bat is connected to 3.3 V power when JP24 is set as shown: (Default)

V

JP24

Vbat is connected to battery when JP24 is set as shown:

4.4 Boot option

The STM3210C-EVAL board is able to boot from:

● Embedded user Flash

● System memory with boot loader for ISP

● Embedded SRAM for debugging.

The boot option is configured by setting switches SW1 (BOOT1) and SW2 (BOOT0). The

BOOT0 can be configured also via the RS-232 connector CN6.

Doc ID 18209 Rev 1 15/58

STM3210C-EVAL demonstration board AN3311

Table 3. Boot related switches

Switch Boot from Configuration

STM3210C-EVAL boots from user Flash when SW2 is set as shown on

the right. SW1 setting does not matter in this configuration. (Default)

STM3210C-EVAL boots from system memory when SW1 and SW2 are

SW1 and SW2

set as shown:

STM3210C-EVAL boots from embedded SRAM when SW1 and SW2

are set as shown:

4.5 Clock source

Two clock sources are available on the STM3210C-EVAL demonstration board for

STM32F107VC, and RTC is embedded.

● X2, 32 kHz crystal for embedded RTC

● X3, 25 MHz crystal with socket for an STM32F107VC microcontroller, it can be

removed from the socket when an internal RC clock is used.

4.6 Reset source

The reset signal of the STM3210C-EVAL board is low active and the reset sources include:

● Reset button, B1

● Debugging tools from JTAG connector CN13 and trace connector CN12

● Daughterboard from CN9

● RS-232 connector CN6 for ISP.

Table 4. Reset related jumper

Jumper Description

JP20

Enables reset of the STM32F107VC embedded JTAG TAP controller each

time a system reset occurs. JP20 connects the TRST signal from the JTAG

connection with the system reset signal RESET#.

Default setting: not fitted.

16/58 Doc ID 18209 Rev 1

AN3311 STM3210C-EVAL demonstration board

4.7 Joystick

The joystick is four-directional and includes a selection key.

4.8 Pushbuttons

The following pushbuttons are provided:

● Key: user pushbutton

● Tamper: user pushbutton

● Wake-up: pushbutton used to wake up the processor from low-power mode.

4.9 Storage memory

The ZigBee adapter has a 64-Kbit I2C/RF dual interface memory (M24LR64-r) on board,

and it is connected to the I

2

The I

C address of the memory can be set by using the jumpers JP1 and JP2 on the ZigBee

adapter and must be different from the one already present on the STM3210C-EVAL (with

address 0xA0).

2

C1 peripheral of the MCU.

4.10 Development and debug support

The two debug connectors available on the STM3210C-EVAL demonstration board are:

1. CN13, standard 20-pin JTAG interface connector which is compliant with the debug

tools of ARM7 and ARM9

2. CN12, SAMTEC 20-pin connector FTSH-110-01-L-DV for both SWD and trace which is

compliant with ARM CoreSight

TM

debug tools

4.11 Display and input devices

The 3.2" TFT color LCD connected to SPI3 and 4 general purpose color LED's (LED 1, 2, 3,

4) are available as display devices.

A touchscreen connected to an I/O expander (U7), a 4-direction joystick with selection key, a

general purpose button (B3), a wake-up button (B2), and a tamper detection button (B4) are

available as input devices.

Table 5. LCD module

Pin on CN14 Description Pin connection

1 CS PB2

2RS-

3 WR/SCL PC10

4RD -

3.2" TFT LCD with touchscreen

CN14 (default)

Doc ID 18209 Rev 1 17/58

STM3210C-EVAL demonstration board AN3311

Table 5. LCD module (continued)

3.2" TFT LCD with touchscreen

CN14 (default)

Pin on CN14 Description Pin connection

5 RESET RESET#

22 BL_GND GND

23 BL_Control +5 V

24 VDD 3.3 V

25 VCI 3.3 V

26 GND GND

27 GND GND

28 BL_VDD +5 V

29 SDO PC11

30 SDI PC12

31 XL I/O Expander

32 XR I/O Expander

33 YD I/O Expander

34 YU I/O Expander

4.12 JTAG debugging connector CN13

Figure 7. JTAG debugging connector CN13 viewed from above the PCB

Table 6. JTAG debugging connector CN13

Pin number Description Pin number Description

1 3.3 V power 2 3.3 V power

3 PB4 4 GND

5PA156GND

7PA138GND

9PA1410GND

!-V

18/58 Doc ID 18209 Rev 1

AN3311 STM3210C-EVAL demonstration board

Table 6. JTAG debugging connector CN13 (continued)

Pin number Description Pin number Description

11 RTCK 12 GND

13 PB3 14 GND

15 RESET# 16 GND

17 DBGRQ 18 GND

19 DBGACK 20 GND

4.13 Daughterboard extension connector CN8 and CN9

Two 50-pin male headers, CN8 and CN9, can be used to connect a daughterboard or

standard wrapping board to the STM3210C-EVAL demonstration board. All 80 GPIOs are

available on it. The space between these two connectors and the power position, GND and

RESET pin are defined as a standard, which allows to develop common daughterboards for

several demonstration boards. The standard width between CN8 pin1 and CN9 pin1 is 2700

mills (68.58mm). This standard was implemented on the majority of demonstration boards.

Each pin on CN8 and CN9 can be used by a daughterboard after disconnecting it from the

corresponding function block on the STM3210C-EVAL demonstration board.

Table 7. Daughterboard extension connector CN8

Pin Description Alternate function

1GND -

3PC7 MC

5 PC9 USB power switch On Remove R36

7 PA9 USB VBUS Remove R78

9 PA0 MC/Ethernet/WKUP

11 PC14 via SB1 32 kHz oscillator Remove R161, close SB1

13 PA12 USB_DP Remove R43 or disconnect USB cable

15 PC15 via SB2 32 kHz oscillator Remove R59, close SB2

17 PC10 SPI1_CLK

19 GND -

21 PC12 SPI1_MOSI

23 PD1 CAN1_TX

25 PD3 LD3 Remove R96

How to disconnect with function block on STM3210C-

EVAL board

Disconnect STM3210C-EVAL board from motor power drive

board

Keep JP14 open. Disconnect STM3210C-EVAL board from

motor power drive board.

27 PD5 USART2_TX

29 PD7 LD1 Remove R94

31

Doc ID 18209 Rev 1 19/58

STM3210C-EVAL demonstration board AN3311

Table 7. Daughterboard extension connector CN8 (continued)

Pin Description Alternate function

33 PB3 TDO/SWO

35 PB5 CAN2_RX Remove R45

37 PB7 I2C1_SDA Remove R132

39 GND -

41 PE2 Trace_CK

43 PE4 Trace_D1

45 PB8 MC

47 PE6 Trace_D3

49 D5V

2 PC6 I2S_MCK/MC JP10 open

4PC8 MC

6 PA8 MCO JP4 open

8 PA10 USB_ID Remove R38 or disconnect USB cable

10 GND

12 PA11 USB_DM Remove R42 or disconnect USB cable

How to disconnect with function block on STM3210C-

EVAL board

Disconnect STM3210C-EVAL board from motor power drive

board

Disconnect STM3210C-EVAL board from motor power drive

board

14 PA13 TMS/SWDIO

16 PA14 TCK/SWCLK

18 PC11 SPI1_MISO Remove R135 and LCD

20 PA15 TDI

22 PD0 CAN1_RX Remove R44

24 PD2 MC

26 PD4 LD4 Remove R97

28 PD6 USART2_RX Keep JP16 open

30 GND

32

34 PB4 TRST Keep JP20 open

36 PB6

38 PE0

40 PE1 USB_Overcurrent Remove R35

42 PE3 Trace_D0

44 PE5 Trace_D2

CAN2_TX/

I2C1_SCK

MC/Micro-SD card

detection

Disconnect STM3210C-EVAL board from motor power drive

board.

Keep JP9 open

Remove micro-SD card. Disconnect STM3210C-EVAL board

from motor power drive board.

20/58 Doc ID 18209 Rev 1

AN3311 STM3210C-EVAL demonstration board

Table 7. Daughterboard extension connector CN8 (continued)

Pin Description Alternate function

46 PB9 User button Remove R104

48 3.3 V

50 GND

How to disconnect with function block on STM3210C-

EVAL board

Table 8. Daughterboard extension connector CN9

Pin Description Alternate function

1GND -

3 PD14 MC

5 PD12 Ethernet Remove RS2

7 PD10 Ethernet/smartcard Keep JP11 open

9

11 RESET# -

13 PB15 I2S_DIN

PC13 button

B3

IDD_CNT_EN /

Anti-tamper button

B4

How to disconnect with function block on STM3210C-

EVAL board

Keep JP22 open. Disconnect STM3210C-EVAL board from

motor

power drive board.

Keep JP1 open

15 PB13 I2S_CK/Ethernet Remove RS3

17 PB11 Ethernet Remove RS3

19 D5V -

21 PE14 Smartcard_CMDVCC Remove R166

23

25 PE12 MC

27 PE10 MC

29 PE8 MC

31 PE7 Smartcard_OFF Remove R69

33 PB1 MC Remove R168

35 PC5 VBAT_voltage Remove R154

37 PA7 MC Remove R169

39 GND

41 PA4

43 PA2 Ethernet Remove R162

45 PC3 Ethernet Remove RS1

Micro-SD card/

Audio_DAC

Disconnect STM3210C-EVAL board from motor power drive

board

Keep JP15 open

Doc ID 18209 Rev 1 21/58

STM3210C-EVAL demonstration board AN3311

Table 8. Daughterboard extension connector CN9 (continued)

Pin Description Alternate function

47 PC1 Ethernet

IDD_CNT_EN /

49 PC13

2PD15 MC

4 PD13 LD2 Remove R95

6 PD11 Ethernet Remove RS1

8 PD9 Ethernet/smartcard Keep JP12 open

10 GND

12 PD8 Ethernet/smartcard Keep JP13 open

14 PB14 IO_Expander_INT Remove R159

16 PB12 Ethernet/audio Remove RS3

18 PB10 Ethernet Remove RS2

20 PE15 MC Remove R139

22 PE13 MC

24

26 PE11 MC

28 PE9 MC

30 GND

Anti-tamper button

B4

How to disconnect with function block on STM3210C-

EVAL board

Keep JP1 open

Disconnect STM3210C-EVAL board from motor power drive

board

Disconnect STM3210C-EVAL board from motor power drive

board

Disconnect STM3210C-EVAL board from motor power drive

board

32 PB2 MC Remove R168

34 PB0 MC Remove R167

36 PC4 Potentiometer Remove R103

38 PA6 IDD_Measurement Remove R79

40 PA5 MC Remove R84

42 PA3 MC/Ethernet Keep JP10 open

44 PA1 Ethernet Keep JP3 open

46 PC2 Ethernet Remove RS1

48 PC0 MC/smartcard Remove R165

50 GND

22/58 Doc ID 18209 Rev 1

AN3311 STM3210C-EVAL demonstration board

4.14 TFT LCD connector CN14

One 34-pin male header CN14 is available on the board to connect LCD module board

MB785.

4.15 Power connector CN18

The STM3210C-EVAL demonstration board can be powered from a DC 5 V power supply

via the external power supply jack (CN18) shown in Figure 8. The central pin of CN18 must

be positive.

Figure 8. Power supply connector CN18 viewed from the front

'&9

*1'

For more information on STM3210C-EVAL, please refer to the UM0600 user manual.

!-V

Doc ID 18209 Rev 1 23/58

Demonstration firmware system setup AN3311

5 Demonstration firmware system setup

5.1 Hardware requirements

a) ZigBee adapter board

b) ZigBee module SPZB260-PRO

c) VDC/2A isolated power supply is recommended

d) One JTAG programmer/debugger dongle (J-Link from SEGGER or IAR Systems™

is recommended). It is unnecessary if no modifications to the firmware code have

been performed.

5.2 STM3210C-EVAL demonstration board setup

Set up the STM3210C-EVAL board as follows:

● Close jumper JP19

● Keep JP15 open

● Remove R79, R84, and R169.

5.3 STM3210C-EVAL and ZigBee adapter with M24LR62-r memory

Table 9. ZigBee adapter pin description

STM32 pin no. Pin name

- VDD 3.3 V CN8 - Pin 48 VCC_3V3

- VSS GND CN9 - Pin 50 GND

29 PA4 SPI1_NSS CN9 - Pin 41 ZIG_SS

30 PA5 SPI1_CLK CN9 - Pin 40 ZIG_SCLK

31 PA6 SPI1_MISO CN9 - Pin 38 ZIG_MISO

32 PA7 SPI1_MOSI CN9 - Pin 37 ZIG_MOSI

92 PB6 CAN2_TX/I2C1_SCK CN8 - Pin 36 I2C1_SCK

93 PB7 I2C1_SDA CN8 - Pin 37 I2C1_SDA

2 PE3 Trace_D0 CN8 - Pin 42 ZIG_HOST_INT

3 PE4 Trace_D1 CN8 - Pin 43

4 PE5 Trace_D2 CN8 - Pin 44 ZIG_WAKE

5 PE6 Trace_D3 CN8 - Pin 47 ZIG_RSTB

STM3210C-EVAL I/O

assignment

Extension connector pin

no.

ZigBee adapter I/O

assignment

VCC-GPIO (for M24LR64-

r)

24/58 Doc ID 18209 Rev 1

AN3311 Demonstration firmware system setup

5.4 How to navigate the demo menu

Four basic elements constitute the hardware of the system user interface: a 320 x 240 TFT

LCD display, a resistive touchscreen, a 5-way (left, right, up, down, selection) micro-joystick

and a pushbutton “Key”.

The joystick is primarily used for navigating between the various menu screens, within a

screen and between screen items. In addition, the joystick allows the selection and editing of

item values.

Doc ID 18209 Rev 1 25/58

In-home display firmware AN3311

p

{

ZigB

k

R

u

r

{

t

{

{

t

d

e

{

6 In-home display firmware

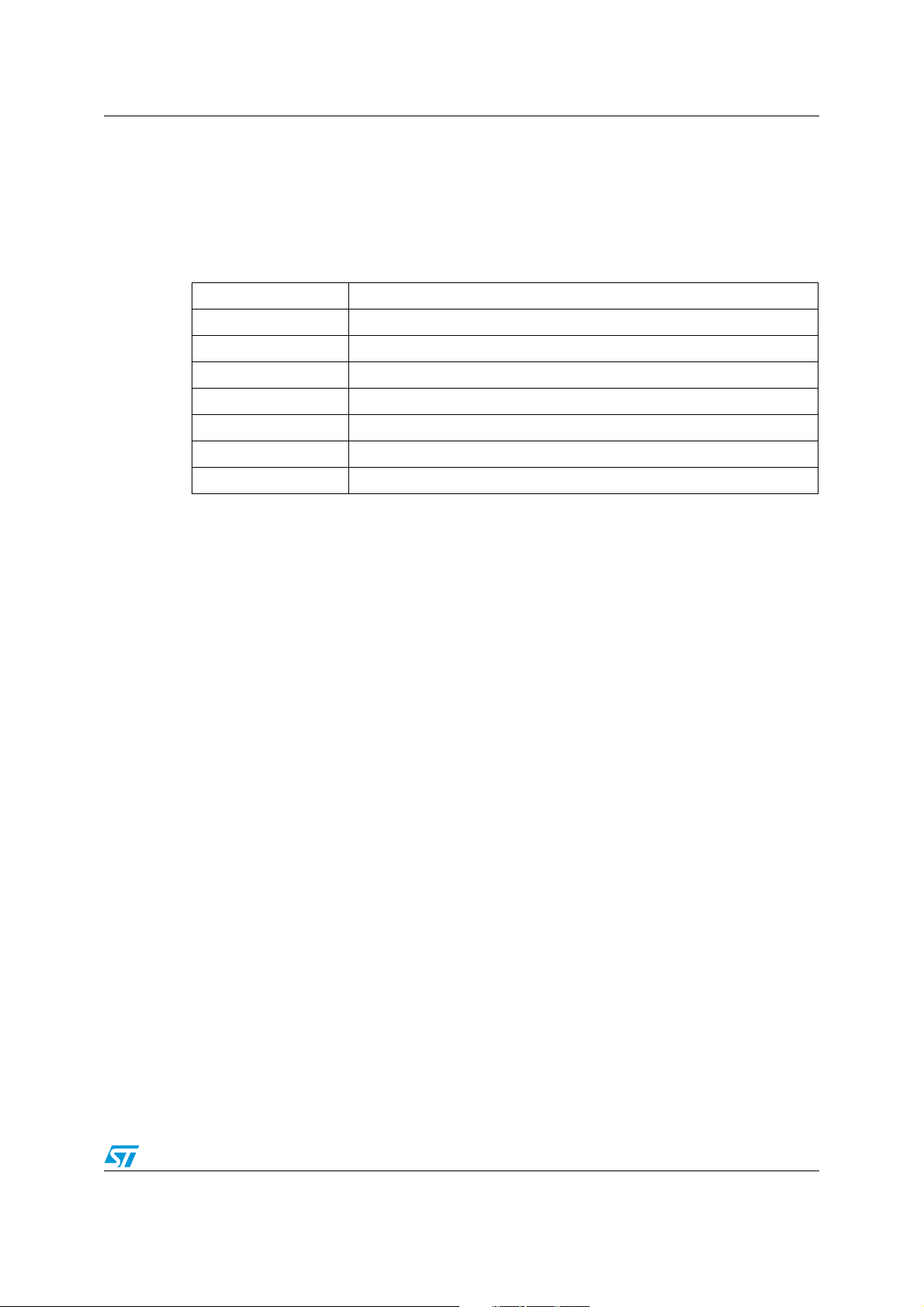

6.1 Firmware architecture

Figure 9. In-home display firmware architecture

InHome Display Firmware Architecture

on

F

r

e

e

T

O

S

licati

Ap

t

i-Inp

Mul

SmartPlug Coordinator

Layer

y

Multi-Input GUI Layer

Libra

GUI

LCD HAL

ee Stac

SPI

ZigBee Adapter and RF

Antenna for I2C Dual

Interface Memory

SPI

ware

nden

Har

Dep

This section describes the firmware implementation. The tasks/functions are described in

the following format:

Table 10. Function description format

Function name The name of the function

Function prototype Prototype declaration of the function

Behavior description Brief explanation of how the function is executed

Input parameter {x} Description of the input parameters

Output parameter {x} Description of the output parameters

Return value Value returned by the function

Required preconditions Requirements before calling the function

Called functions Other library functions called

LCD Libraries

STM32F10xx Libraries

I2C

AM08462v1

26/58 Doc ID 18209 Rev 1

AN3311 In-home display firmware

6.2 main.c

6.2.1 vSmartPlugSamplingTask

Ta bl e 1 1 describes the vSmartPlugSamplingTask task:

Table 11. vSmartPlugSamplingTask task

Function name vSmartPlugSamplingTask

Function prototype void vSmartPlugSamplingTask(void *pvParameters)

Behavior description Read and sample the plug consumption values

Input parameter {x} None

Output parameter {x} None

Return value None

Required preconditions None

Called functions No API/HAL layer functions;

Example:

static void vSmartPlugSamplingTask( void *pvParameters)

{

CoordinatorType* pObjCoordinator = GetCoordinatorObj();

int i=0;

sinkAdvertise();

pObjCoordinator = GetCoordinatorObj();

//Get the Smart-Plug list

ppSmartPlugList = pObjCoordinator->GetSmartPlugList(pObjCoordinator);

while(1)

{

if ( ppSmartPlugList[0] )

{

smart_points1[i%N_SAMPLES] = ppSmartPlugList[0]->Energy;

smart_points1B[i%N_SAMPLES] = ppSmartPlugList[0]->Power;

}

if ( ppSmartPlugList[1] )

{

smart_points2[i%N_SAMPLES] = ppSmartPlugList[1]->Energy;

smart_points2B[i%N_SAMPLES] = ppSmartPlugList[1]->Power;

}

i++;

if(i == N_SAMPLES)

{

i=0;

for(int j=0; j<N_SAMPLES; j++)

{

smart_points1[j] = 0;

smart_points1B[j] = 0;

smart_points2[j] = 0;

smart_points2B[j] = 0;

}

}

if( i%8 == 0 )

Doc ID 18209 Rev 1 27/58

In-home display firmware AN3311

sinkAdvertise();

vTaskDelay(2000); //20 sec

}

}

The application simulates the behavior of the system in a 24 hour period considering an

hour as equal to 20 seconds. After 24 hours (simulated), it resets the array values, so the

GraphCharts and the histograms show a maximum value set to zero.

6.2.2 vGraphicLibraryTask

Ta bl e 1 2 describes the vGraphicLibraryTask task:

Table 12. vGraphicLibraryTask task

Function name vGraphicLibraryTask

Function prototype void vGraphicLibraryTask(void *pvParameters)

Behavior description

Input parameter {x} None

Output parameter {x} None

Check if an input device has been stimulated (touchscreen or

joystick/button)

Return value None

Required preconditions None

Called functions No API/HAL layer functions;

This function checks if an input device has been stimulated (touchscreen or joystick/button)

and calls the graphic library relative function according to the object pressed.

Example:

static void vGraphicLibraryTask( void *pvParameters )

{

/* Menu Initialization*/

MENU_DeInit();

CursorShow(195, 50);

/* Infinite main loop ------------------------------------------------------*/

while (1)

{

ProcessTouchScreenData();

/*Time out calculate for power saving mode*/

TimeOutCalculate();

#ifdef USE_STM3210C_EVAL

if (restart_calibration==1)

{

TS_Calibration();

restart_calibration = 0;

MENU_DeInit();

}

CursorReadJoystick(IOEXP_MODE);

TSC_Read();

#else

28/58 Doc ID 18209 Rev 1

AN3311 In-home display firmware

CursorReadJoystick(POLLING_MODE);

#endif

vTaskDelay(2);

}

}

6.2.3 prvApplicationTask

Ta bl e 1 3 describes the prvApplicationTask task:

Table 13. prvApplicationTask task

Function name prvApplicationTask

Function prototype void prvApplicationTask (void *pvParameters)

Behavior description Start the Smartplug Coordinator Application routine

Input parameter {x} None

Output parameter {x} None

Return value None

Required preconditions None

Called functions No API/HAL layer functions;

This function starts the smartplug coordinator application routine.

Example:

void prvApplicationTask( void * pvParameters )

{

/* The parameters are not used in this task. */

( void ) pvParameters;

for( ;; )

{

applicationTick();

/* Wait until it is time to move onto the next string. */

vTaskDelay(4);

}

}

6.2.4 prvSetupHardware

Ta bl e 1 4 describes the prvSetupHardware function:

Table 14. prvSetupHardware function

Function name prvSetupHardware

Function prototype void prvSetupHardware (void)

Behavior description

Input parameter {x} None

Output parameter {x} None

Initialize the hardware peripheral of the STM32 MCU, and ZigBee

hardware configuration

Return value None

Doc ID 18209 Rev 1 29/58

In-home display firmware AN3311

Table 14. prvSetupHardware function (continued)

Required preconditions None

Called functions No API/HAL layer functions;

This function is intended to initialize the hardware peripherals of the STM32 MCU, and the

ZigBee hardware configuration.

Example:

static void prvSetupHardware( void )

{

SystemInit();

/* Enable GPIOA, GPIOB, GPIOC, GPIOD, GPIOE and AFIO clocks */

RCC_APB2PeriphClockCmd(RCC_APB2Periph_GPIOA | RCC_APB2Periph_GPIOB |

RCC_APB2Periph_GPIOC | RCC_APB2Periph_GPIOD |

RCC_APB2Periph_GPIOE | RCC_APB2Periph_AFIO, ENABLE );

/* Set the Vector Table base address at 0x08000000 */

NVIC_SetVectorTable( NVIC_VectTab_FLASH, 0x0 );

NVIC_PriorityGroupConfig( NVIC_PriorityGroup_4 );

/* Configure HCLK clock as SysTick clock source. */

SysTick_CLKSourceConfig( SysTick_CLKSource_HCLK );

/* Initialize the board */

vBoardInit();

EZSP_Init(); //init OBJ Coordinator

}

6.2.5 vBoardInit

Ta bl e 1 5 describes the vBoardInit function:

Table 15. vBoardInit function

Function name vBoardInit

Function prototype void vBoardInit (void)

Behavior description Initialize the hardware peripheral of the STM3210C-EVAL board

Input parameter {x} None

Output parameter {x} None

Return value None

Required preconditions None

Called functions No API/HAL layer functions;

This function is intended to initialize the hardware peripheral of the STM3210C-EVAL board

and the graphic library hardware parameters.

Regarding the file menu.c, it just uses the API function of the graphic library and some

others of the “ZigBee stack for smartplug”, for more information please refer to the AN3128,

rev. 2, application note.

30/58 Doc ID 18209 Rev 1

AN3311 Getting started with the system

7 Getting started with the system

7.1 Configure IAR tool for building, debugging, and programming the application

Together with the firmware library package, an example application is delivered in order to

provide the final user with a real example of “In-home display” application usage.

The delivered example application has been written and developed using IAR EWARM 5.40

IDE and can be built for both STM32F10xxx medium-density and high-density

microcontroller families.

The workspace is created using the IAR embedded Workbench 5.40 IDE, using the ARM

based 32-bit STM32F10xx firmware library (ver. 3.1.2) CMSIS compliant, and in C

language.

The tree structure of the project is organized separating and grouping the source files with

the header files, both for the project files and the library files, as shown in Figure 10.

Figure 10. Application project files

®

-

In order to load the project, click on File\Open\Workspace and in the window that appears

select, in \project folder\EWARM, the file “Project.eww”.

Doc ID 18209 Rev 1 31/58

Getting started with the system AN3311

Figure 11. IAR embedded workbench main window

On the main node, where the program name located in the files window is shown, right click

the mouse button and select options. In the window which appears, select the debugger

item in the category list box, and select the proper debugging tool in the driver list box, then

press the Ok button. In the proposed example the J-Link dongle is used (Figure 12).

Press the Make icon or click on Project\Rebuild All. No error or warning should appear once

compiling has completed. Connect the J-Link tool to the USB port of the PC, and connect

the flat cable with the programming adapter. Plug the adapter into the dongle connector.

Press the debug icon, CTRL+D or click project\debug. The debugger starts to download the

firmware to the dongle through the J-Link debugger\programmer. Press the Go button, F5 or

click debug\go in order to execute the firmware in debug mode. To run the dongle in

standalone mode, press the stop debugging icon, CTRL+SHIFT+D or click debug\stop

debugging. Then remove the J-link adapter from the dongle and reset the board by

unplugging and plugging the power cable back in.

Figure 12. IAR embedded workbench debugger options

32/58 Doc ID 18209 Rev 1

AN3311 Getting started with the system

In order to use the In-home display application project, it is necessary to:

● Include all the firmware delivered in the In-home display package containing the

FreeRTOS core files. See Figure 10

● Create the desired menu application functions in the file menu.c

● Put inside “picture.c” the HEX dump of the pictures to be used with the application GUI

● Implement a main function as described in the following section.

7.2 Example application - main.c

An example of a main application is given below. The main function contains an example of

the In-home display application initialization/configuration and implements the classic

operations:

/* Standard includes. */

#include <stdio.h>

/* Scheduler includes. */

#include "FreeRTOS.h"

#include "task.h"

#include "queue.h"

#include "semphr.h"

/* Library includes. */

#include "stm32f10x.h"

#include "stm32f10x_it.h"

#include "STM3210c_eval_lcd.h"

#include "LcdHal.h" //SB

/* Demo app includes. */

#include "flash.h"

#include "partest.h"

#include "common.h"

#include "micro_clocks_irqs.h"

#include "micro.h"

#include "menu.h"

#include "graphicObject.h"

#include "cursor.h"

#include "stm32d-eval_io_expander.h"

#include "LcdHal.h"

#include "TscHal.h"

#include "pictures.h"

#include "stm32f10x.h"

#include "stm32f10x_rcc.h"

#include "misc.h"

#include "SmartPlugObj.h"

#include "CoordinatorObj.h"

#include "COORDINATOR_Layer.h"

#include "ZSP_Layer.h"

#ifdef USE_STM3210E_EVAL

#include "stm3210e_eval_lcd.h"

#elif USE_STM3210C_EVAL

#include "stm3210c_eval_lcd.h"

#include "touchscreen.h"

#endif

/* Private define ------------------------------------------------------------*/

Doc ID 18209 Rev 1 33/58

Getting started with the system AN3311

/* Touchscreen Controller and Joystick DEFINES */

#define TSC_GPIO_PORT_SOURCE GPIO_PortSourceGPIOB

#define TSC_GPIO_PIN_SOURCE GPIO_PinSource14

#define JOY_GPIO_PORT_SOURCE GPIO_PortSourceGPIOB

#define JOY_GPIO_PIN_SOURCE GPIO_PinSource14

#define JOY_GPIO_SELECT_PORT GPIOG

#define JOY_GPIO_SELECT_PIN GPIO_Pin_7

#define JOY_GPIO_RIGHT_PORT GPIOG

#define JOY_GPIO_RIGHT_PIN GPIO_Pin_13

#define JOY_GPIO_LEFT_PORT GPIOG

#define JOY_GPIO_LEFT_PIN GPIO_Pin_14

#define JOY_GPIO_UP_PORT GPIOG

#define JOY_GPIO_UP_PIN GPIO_Pin_15

#define JOY_GPIO_DOWN_PORT GPIOD

#define JOY_GPIO_DOWN_PIN GPIO_Pin_3

#define JOY_GPIO_RCC_APB_PERIPH1 RCC_APB2Periph_GPIOG

#define JOY_GPIO_RCC_APB_PERIPH2 RCC_APB2Periph_GPIOG

#define JOY_GPIO_RCC_APB_PERIPH3 RCC_APB2Periph_GPIOG

#define JOY_GPIO_RCC_APB_PERIPH4 RCC_APB2Periph_GPIOG

#define JOY_GPIO_RCC_APB_PERIPH5 RCC_APB2Periph_GPIOD

#define TSC_EXTI_IRQ_CHANNEL EXTI15_10_IRQn

#define JOY_EXTI_IRQ_CHANNEL EXTI15_10_IRQn

#define TSC_EXTI_LINE EXTI_Line14

#define JOY_EXTI_LINE EXTI_Line14

#define TSC_GPIO_PORT GPIOA

#define TSC_GPIO_PIN GPIO_Pin_14

#define TSC_I2C_DEVICE_REGISTER 0x82

#define JOY_I2C_DEVICE_REGISTER 0x88

#define M24LR64_I2C_DEVICE_REGISTER 0x24

#define TSC_I2C_PORT I2C1

/* User Button GPIO Port and Pin*/

#ifdef USE_STM3210C_EVAL

#define USER_BUTTON_PORT GPIOB

#define USER_BUTTON_PIN GPIO_Pin_9

#elif USE_STM3210E_EVAL

#define USER_BUTTON_PORT GPIOG

#define USER_BUTTON_PIN GPIO_Pin_8

#endif

/* LCD Controller DEFINES */

#define LCD_CTRL_PORT_NCS GPIOB

#define LCD_GPIO_DATA_PORT GPIOC

#define LCD_CTRL_PIN_NCS GPIO_Pin_2

#define LCD_CTRL_PIN_NWR GPIO_Pin_15

#define LCD_CTRL_PIN_RS GPIO_Pin_7

#define LCD_GPIO_PIN_SCK GPIO_Pin_10

#define LCD_GPIO_PIN_MISO GPIO_Pin_11

#define LCD_GPIO_PIN_MOSI GPIO_Pin_12

#define LCD_GPIO_RCC_APB_PERIPH RCC_APB2Periph_GPIOC

#define LCD_GPIO_RCC_APB_PERIPH_NCS RCC_APB2Periph_GPIOB

#define LCD_GPIO_REMAP_PORT GPIO_Remap_SPI3

#define LCD_RCC_APB_PERIPH RCC_APB1Periph_SPI3

#define LCD_RCC_AHB_PERIPH RCC_AHBPeriph_FSMC

#define LCD_SPI_PORT SPI3

#ifdef USE_STM3210C_EVAL

#define LCD_CONNECTION_MODE GL_SPI

#elif USE_STM3210E_EVAL

#define LCD_CONNECTION_MODE GL_FSMC

#endif

#define RCC_AHBPeriph_FSMC ((uint32_t)0x00000100)

34/58 Doc ID 18209 Rev 1

AN3311 Getting started with the system

/* Exported variables--------------------------------------------------------*/

LCD_HW_Parameters_TypeDef* pLcdParam;

TSC_HW_Parameters_TypeDef* pTscParam;

JOY_HW_Parameters_TypeDef* pJoyParam;

BTN_HW_Parameters_TypeDef* pBtnParam;

extern volatile GL_u8 touch_done;

GL_s16 smart_points1[N_SAMPLES];

GL_s16 smart_points1B[N_SAMPLES];

GL_s16 smart_points2[N_SAMPLES];

GL_s16 smart_points2B[N_SAMPLES];

SmartPlugType** ppSmartPlugList;

SmartPlugType* pCurrentSmartPlug;

extern GL_Page_TypeDef pageS2B;

extern GL_Page_TypeDef pageS2C;

/* Private macro -------------------------------------------------------------*/

/* Private variables ---------------------------------------------------------*/

static volatile ErrorStatus HSEStartUpStatus /*= SUCCESS*/;

volatile GL_u8 restart_calibration = 0;

GPIO_InitTypeDef GPIO_InitStructure;

static u32 TimingDelay;

static xTaskHandle xEmberTaskHandle, xApplTaskHandle, xSmartSamplingTaskHandle,

xGraphLibTaskHandle;

/* The time between cycles of the 'check' functionality (defined within the tick

hook. */

#define mainCHECK_DELAY ( ( portTickType ) 5000 / portTICK_RATE_MS )

/* Task priorities. */

#define EMBER_Task ( tskIDLE_PRIORITY + 3 )

#define APPLICATION_Tick_Task ( tskIDLE_PRIORITY + 2 )

#define mainINIT_TASK_PRIORITY ( tskIDLE_PRIORITY + 1 )

/* The period of the system clock in nano seconds. This is used to calculate the

jitter time in nano seconds. */

#define mainNS_PER_CLOCK ((unsigned portLONG)((1.0 /

(double)configCPU_CLOCK_HZ)*1000000000.0))

/*-----------------------------------------------------------*/

/* Configure the hardware for the demo. */

static void prvSetupHardware( void );

static void vEmberTickTask( void *pvParameters );

extern void EZSPInit(void);

static void prvApplicationTask( void * pvParameters );

void vApplication_EXIT2_ISRFunc( void );

void vApplication_USART0_ISRFunc( void );

/* Configure the hardware for the demo. */

static void prvSetupHardware( void );

/* Configure the board, LCD, Joystick, Button, GPIO and other peripherals as required

by the demo. */

static void vBoardInit( void );

/* Check Touchscreen, Joystick, Button in polling mode as required by the demo. */

static void vGraphicLibraryTask(void *pvParameters);

/* Check the SmartPlug Energy data as required by the demo. */

static void vSmartPlugSamplingTask( void *pvParameters);

Doc ID 18209 Rev 1 35/58

Getting started with the system AN3311

/*

* Configures the high frequency timers - those used to measure the timing

* jitter while the real time kernel is executing.

*/

extern void vSetupHighFrequencyTimer( void );

u16 ticksSinceLastHeard[APPLICATION_ADDRESS_TABLE_SIZE];

EmberNetworkStatus networkState = EMBER_NO_NETWORK;

/* insert Start */

xSemaphoreHandle xSemaphore_Ember = NULL;

xSemaphoreHandle xSemaphore_Serial = NULL;

extern void EZSP_Init(void);

extern void emberTick(void);

extern void processSerialInput(void);

extern void applicationTick(void);

/* insert End */

/*-------------------------*/

int main( void )

{

#ifdef DEBUG

debug();

#endif

pLcdParam = NewLcdHwParamObj ();

pTscParam = NewTscHwParamObj ();

pJoyParam = NewJoyHwParamObj ();

pBtnParam = NewBtnHwParamObj ();

prvSetupHardware();

/* Start the tasks. FreeRTOS API. */

xTaskCreate( vEmberTickTask, "EMBER", configMINIMAL_STACK_SIZE, NULL, EMBER_Task,

xEmberTaskHandle );

xTaskCreate( vSmartPlugSamplingTask, ( signed portCHAR * ) "SmartPlugSampling",

configMINIMAL_STACK_SIZE, NULL, tskIDLE_PRIORITY,

xSmartSamplingTaskHandle );

xTaskCreate( vGraphicLibraryTask, ( signed portCHAR * ) "GraphicLibrary",

configMINIMAL_STACK_SIZE*2, NULL, tskIDLE_PRIORITY+1,

xGraphLibTaskHandle );

/* Start the scheduler. */

vTaskStartScheduler();

// emberLeaveNetwork();

/* Will only get here if there was insufficient memory to create the idle task. The

idle task is created within vTaskStartScheduler(). */

for( ;; );

}

The initialization process is charged with preparing the basic mechanism of the system:

● Hardware peripheral configuration and initialization

● ZigBee stack initialization

● FreeRTOS task creation

● Starting system.

36/58 Doc ID 18209 Rev 1

AN3311 Getting started with the system

The clock distribution and the interrupt settings are two components that are strongly

dependent on the target project. An example of clock rate may be 72 MHz as the maximum

speed of the current STM32 microcontroller. It can be decreased to reduce the power

consumption. The clock rate assumptions are:

● System HCLK - 72 MHz

● Low speed peripheral PCLK1 - 72 MHz

● High speed peripheral PCLK2 - 36 MHz

● Analog to digital converter ADCCLK - 36 MHz

The interrupt setting situation is very similar to clock distribution. The library functions

involved with interrupt managing do not take the priorities into account; they only perform

very necessary and absolutely common settings to make them serviceable.

Doc ID 18209 Rev 1 37/58

In-home display GUI application AN3311

8 In-home display GUI application

If the ZigBee dongle is not connected or the resistors R79, R84, and R169 have not been

removed from the STM3210C-EVAL, the following screen is shown:

Figure 13. ZigBee dongle connection problem

After a board reset, if the firmware is correctly loaded into the Flash memory and the board

power is correctly supplied, the main screen is displayed as shown in Figure 14.

Figure 14. Main menu

38/58 Doc ID 18209 Rev 1

AN3311 In-home display GUI application

If Search Plugs is selected, the coordinator scans for smartplug devices for a certain length

of time and the display shows the following screens in loop:

Figure 15. Searching plugs

After that, if some plugs are connected, it adds them to the smartplug list and then shows

the home screen.

Doc ID 18209 Rev 1 39/58

In-home display GUI application AN3311

If you click on Management two situations are possible:

● If no plug is connected to the smartplug coordinator, the following screen is shown:

Figure 16. No plug detected

● Once more plugs are detected, the following screen is shown:

Figure 17. Plugs detected

There are three main buttons: identify, modify, and control. They allow to manage the

smartplug device.

The Identify button is useful to activate the LED flashing on the relative plug, so this way the

user can easily identify which plug they are going to manage through the GUI.

If Modify is clicked, the user can change the label of the selected plug, through the screen

shown in Figure 18, choosing the new label from a list contained in a combobox.

40/58 Doc ID 18209 Rev 1

AN3311 In-home display GUI application

Figure 18. Label changing

The user should scroll the list of the labels and click on the Apply button in order to save the

information and set the label also in the plug device via ZigBee protocol.

When Control is clicked, it is possible to switch ON/OFF the smartplug, in case of relay type,

or regulate the output power, in case of TRIAC type. The following screens show both

possibilities:

Figure 19. TRIAC smartplug management

Doc ID 18209 Rev 1 41/58

In-home display GUI application AN3311

Figure 20. Relay smartplug management

In the home screen, by clicking on Statistics, it is possible to see the electrical consumption

of the single smartplug device or the total consumption related to all plugs connected to the

smartplug coordinator. The following screen is shown:

Figure 21. Smartplug statistics

42/58 Doc ID 18209 Rev 1

AN3311 In-home display GUI application

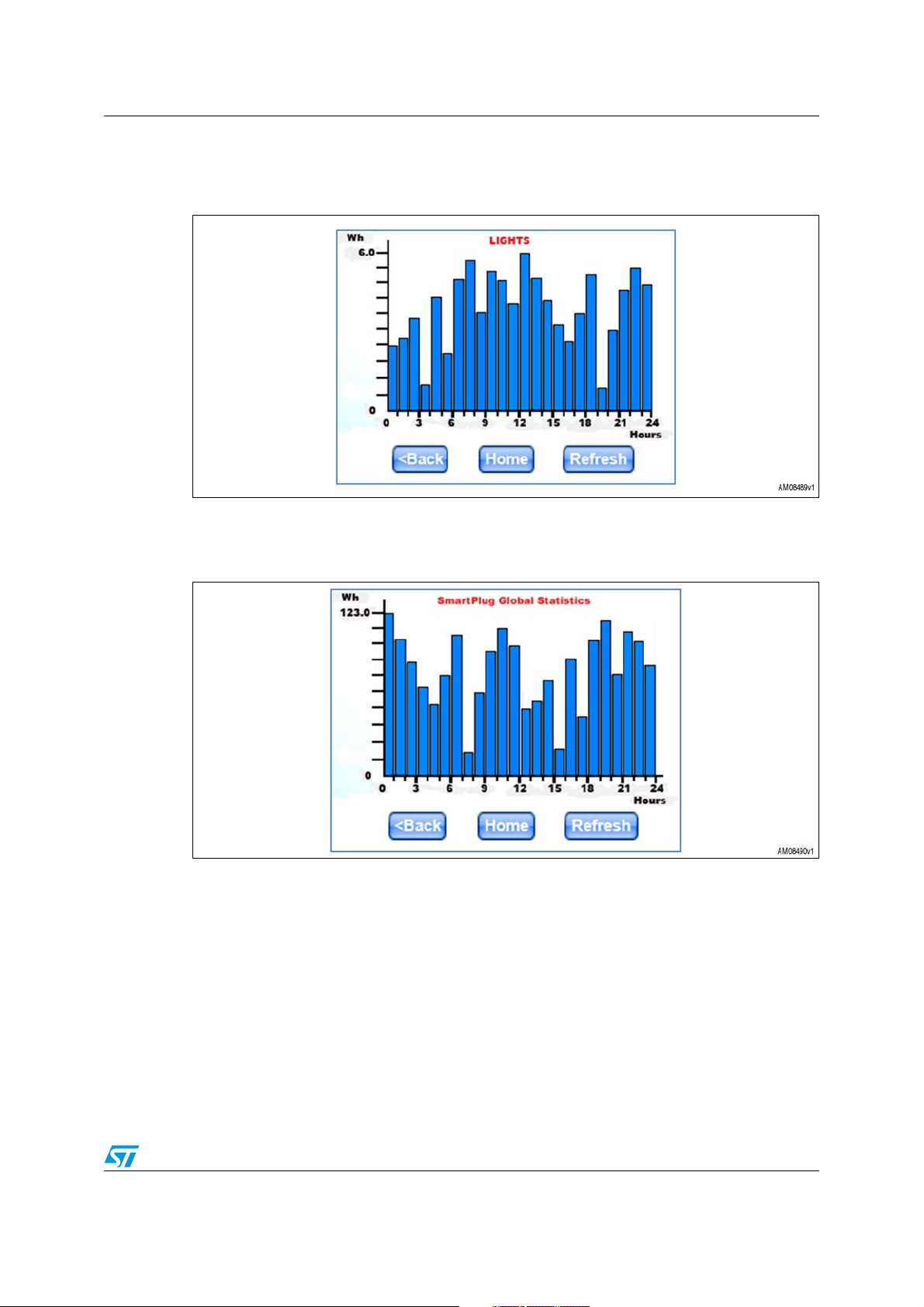

When Energy is clicked, the following screen, representing the energy consumption of the

selected smartplug device, is shown:

Figure 22. Energy consumption

When Global Energy is clicked, the following screen, representing the energy consumption

of the whole smartplug network, is shown:

Figure 23. Global energy consumption

Doc ID 18209 Rev 1 43/58

In-home display GUI application AN3311

When Power is clicked, the following screen, representing the power consumption of the

selected smartplug device, is shown:

Figure 24. Power consumption

When Global Power is clicked, the following screen, representing the power consumption of

the whole smartplug network, is shown:

Figure 25. Global power consumption

When the Refresh button is clicked, it is possible to make a refresh of the graph chart in

relation to the sampled points of the power consumption.

When the Home button is clicked, it returns to the home screen.

44/58 Doc ID 18209 Rev 1

AN3311 Schematics

9 Schematics

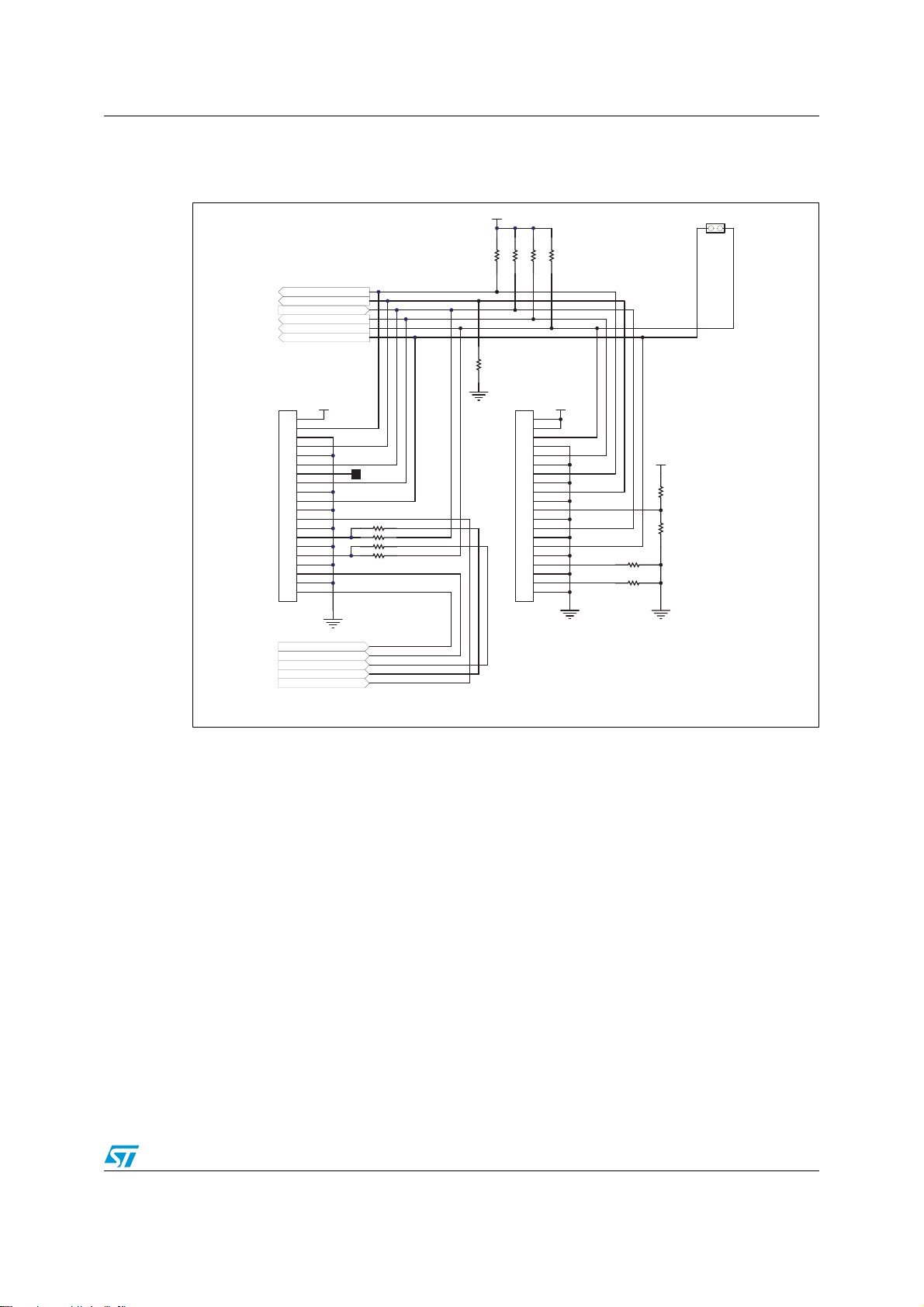

9.1 Smartplug board schematics and layout

Figure 26. ZigBee and dual interface EEPROM adapter schematic for STM3210C-EVAL

48R ev

o

meR -

)

KL

C_

1IPS(

5AP

PA6 (SPI1_MISO) - Remove R79

GND

ZIG_MISO

ZIG_SCLK

CN9

CN9

181920

10

8

14

5 6

1 2

3 4

9

7

111213

17

15 16

21 22

36

33 34

35

37 38

ZIG_MOSI

3940414243 44

9

6

SS_

1R

e

G

IZSS_GIZ

vo

meR - )IS

46

49 50

45

47 48

Header 25x2 (Female-Bottom)

Header 25x2 (Female-Bottom)

26

23 24

27 28

29 30

31 32

25

VCC_3V3

VCC_3V3

R3

4k7R34k7

2

Jumper

Jumper

1

R2

U1

3

GND

4k7R24k7

1

Jumper

Jumper

E1

VCC-GPIO

8

VCC

E01AC0

E0

JP2

JP2

3

JP1

JP1

2

I2C1_SDA

I2C1_SCK

5

7

6

E1

SCL

SDA

M24LR64U1M24LR64

VSS

AC1

3

2

4

GND

L1

4.7uHL14.7uH

SMD 7.8mm diameter, 5.3mm height

101112

CN8

CN8

1 2

3 4

5 6

7 8

9

13 14

O

M_1I

P

S( 7AP

PA4 (SPI1_NSS) - Keep JP15 open

ZIG_SCLK

ZIG_MOSI

ZIG_MISO

VCC_3V3

VCC_3V3

VCC_3V3

15 16

17 18

19 20

21 22

232425262728293031 32

MOSI

VBRDVBRD

1

23456

J2

J2

1

J4

J4

2

HOST_INT

ZIG_HOST_INT

R1

I2C1_SCK

36

33 34

35

MISO

SCLK

nSSEL

345

WAKE

RSTB

GND

ZIG_WAKE

ZIG_RSTB

4k7R14k7

PE3

42

39 40

37 38

41

I2C1_SDA

GND

6

GNDVCC-GPIO

VCC_3V3

3V3

PE5

444546

43

47 48

PE4

PE6

ZigBee - CONN1

ZigBee - CONN1

ZigBee - CONN2

ZigBee - CONN2

49 50

ZIGBEE/SPZB260-PRO

Header 25x2 (Female-Bottom)

Header 25x2 (Female-Bottom)

Prior to using this adapter, remove the required

resistance from the STM3210C-Eval Board

AM08515v1

Doc ID 18209 Rev 1 45/58

Schematics AN3311

9.2 ZigBee/RF adapter for smartplug and dual interface memory

Figure 27. ZigBee and dual interface EEPROM adapter layout for STM3210C-EVAL

46/58 Doc ID 18209 Rev 1

AN3311 Schematics

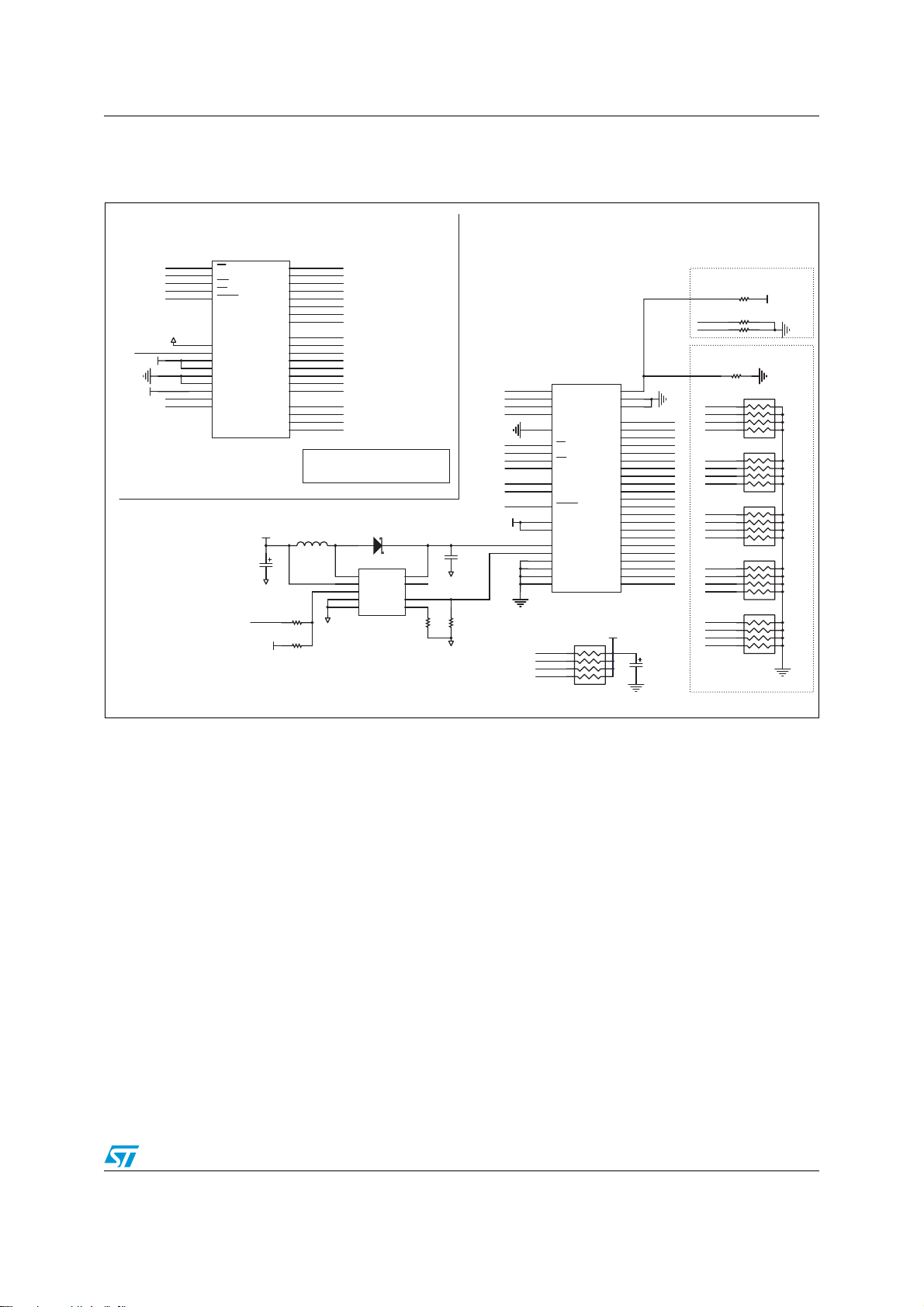

9.3 STM3210C

Figure 28. STM3210C main schematic

BNC1

MC_EmergencySTOP

MC_CurrentA

U_IO Peripherals

BNC2

JOY_SEL

LED4

LED3

LED1

LED2

IO Peripherals.SchDoc

JOY_LEFT

JOY_RIGHT

JOY_DOWN

EEPROM_SCK

EEPROM_SDA

MEMS_SCK

JOY_UP

MEMS_INT1

MEMS_INT2

Potentiometer

Anti_Tamper

MEMS_SDA

WAKEUP

User_Button

EXP_IO10

EXP_IO11

EXP_IO12

IO_Expander_SCK

IO_Expander_SDA

IO_Expander_INT

U_IO_Expander

IO_Expandor.SchDoc

R132 0

R131 0

EXP_IO9

R134

R133

EXP_IO1

TouchScreen_X-

TouchScreen_Y-

TouchScreen_X-

TouchScreen_Y-

TouchScreen_X+

TouchScreen_Y+

4K7

4K7

+3V3

U_LCD

LCD_CS

LCD.SchDoc

TouchScreen_X+

TouchScreen_Y+

LCD_CLK

LCD_DO

LCD_DI

RESET#

PA[0..15]

PB[0..15]

PC[0..15]

PD[0..15]

PE[0..15]

U_ExtensionConnector

RESET#

ExtensionConnector.SchDoc

USB_P owerSwitchOn

USB_DM

USB_DP

U_USB_OTG_FS

USB_OTG_FS.SchDoc

USB_OverCurrent

USB_VBUS

USB_ID

EXP_IO2

EXP_IO3

EXP_IO4

EXP_IO5

EXP_IO6

EXP_IO7

EXP_IO8

BNC1

BNC2

MC_PFCsync1

MC_PFCsync2

MC_WL

U_MotorControl

MotorControl.SchDoc

MC_VH

MC_VL

MC_UH

MC_UL

MC_WH

MC_NTC

MC_DissipativeBrake

MC_PFCpwm

MC_CurrentC

MC_EnA

MC_EnB

MC_HeatsinkTemperature

MC_BusVoltage

MC_EnIndex

MC_CurrentB

U_MCU

MCU.SchDoc

U_Audio

Audio.SchDoc

MC_VH

MC_WL

MC_PFCsync1

MC_PFCsync2

Audio_DAC_OUT

Audio_RST

Audio_SCK

Audio_SDA

Audio_DAC_OUT

MC_VL

I2S_CK

I2S_CK

MC_UH

I2S_DIN

I2S_DIN

MC_UL

MC_WH

I2S_CMD

I2S_MCK

I2S_MCK

I2S_CMD

MC_NTC

U_CAN

MC_EnB

MC_EnIndex

MC_PFCpwm

MC_BusVoltage

MC_DissipativeBrake

MC_HeatsinkTemperature

CAN1_TX

CAN1_RX

CAN2_TX

CAN2_RX

CAN1_TX

CAN2_TX

CAN1_RX

CAN2_RX

CAN.SchDoc

MC_EnA

MC_CurrentB

MC_CurrentC

MC_CurrentA

MC_EmergencySTOP

MicroSDCard_Detection

MicroSDCard_MISO

MicroSDCard_Detection

U_MicroSDCard

MicroSDCard.SchDoc

LED4

LED3

MicroSDCard_CS

MicroSDCard_CS

MicroSDCard_SCK

MicroSDCard_MOSI

U_JTAG&Trace

LED1

LED2

RESET#

TDI

TRST

TMS/SWDIO

TCK/SWCLK

TDI

TRST

RESET#

TMS/SWDIO

TCK/SWCLK

JTAG&Trace.SchDoc

WAKEUP

Anti_Tamper

Potentiometer

TRACE_D0

TRACE_CK

TDO/SWO

TDO/SWO

TRACE_D0

TRACE_CK

User_Button

TRACE_D3

TRACE_D2

TRACE_D1

TRACE_D3

TRACE_D2

TRACE_D1

I2C1_SCK

I2C1_SDA

IO_Expander_INT

MII_TX_CLK

MII_TX_CLK

U_Ethernet

Ethernet.SchDoc

IDD_Measurement

VBAT_Voltage_OUT

VBAT_Voltage

IDD_Measurement

Power.SchDoc

USB_ID

USB_DP

USB_DM

USB_P owerSwitchOn

IDD_CNT_EN

VBAT_DIV

LP_WAKEUP

IDD_CNT_EN

USB_VBUS

USB_VBUS

USB_OverCurrent

USART2_TX

USART2_RX

Bootloader_RESET

RS232/IrDA_TX

RS232/IrDA_RX

Bootloader_RESET

U_USART&IrDA

USART&IrDA.SchDoc

Bootloader_BOOT0

Bootloader_BOOT0

LCD_CS

SPI3_SCK

SPI3_MISO

SPI3_MOSI

MII_TX_EN

MII_RX_ER

MII_RX_DV/RMII_CRSDV

MII_COL

MII_CRS

MII_MDC

MII_TXD0

MII_TXD1

MII_TXD2

MII_TXD3

MII_RX_CLK/RMII_REF_CLK

MII_INT

MII_TXD0

MII_TXD1

MII_TXD2

MII_TXD3

MII_TX_EN

MII_RX_ER

MII_RX_DV/RMII_CRSDV

MII_RX_CLK/RMII_REF_CLK

MII_RXD0

MII_RXD0

MII_RXD1

MII_RXD1

MII_RXD2

MII_RXD2

MII_RXD3

MII_RXD3

MII_MDIO

MCO

MCO

MII_CRS

MII_COL

MII_MDC

MII_MDIO

PHY_RESET#

U_SmartCard

SmartCard.SchDoc

PB[0..15]

PC[0..15]

PA[0..15]

SmartCard_3/5V

SmartCard_IO

SmartCard_RST

SmartCard_CLK

SmartCard_CMDVCC

SmartCard_IO

SmartCard_RST

SmartCard_CLK

SmartCard_3/5V

SmartCard_CMDVCC

PE[0..15]

PD[0..15]

SmartCard_OFF

SmartCard_OFF

U_Power

AM08494v1

Doc ID 18209 Rev 1 47/58

Schematics AN3311

9.4 MCU

Figure 29. MCU schematic

PA[0..15]

PB[0..15]

PC[0..15]

PD[0..15]

PE[0..15]

PA[0..15]

PB[0..15]

PC[0..15]

PD[0..15]

PE[0..15]

MII_RX_DV/RMII_CRSDV

SmartCard_IO

SmartCard_RST

SmartCard_CLK

JP1

USB_P owerSwitchOn

SPI3_SCK

PC8

PC9

PC10

66

PC1078PC1179PC12

MC_EnA

I2S_MCK

321

MC_EnB

MC_EnIndex

VBAT_Voltage_OUT

PC5

PC6

PC7

34

PC663PC764PC865PC9

JP10

MII_TX_CLK

Potentiometer

PC2

PC3

PC4

18

PC433PC5

SmartCard_3/5V

MII_MDC

MII_TXD2

PC1

MC_HeatsinkTemperature

R165

0

MC_PFCpwm

LED2

MII_RXD2

MII_RXD3

PD11

PD12

PD13

PD14

PD15

PC0

62

PC015PC116PC217PC3

Anti_Tamper

IDD_CNT_EN

MC306-G-06Q-32.768 (manufacturer JFVNY)

R161

0

R59

0

321

SPI3_MISO

SPI3_MOSI

PC11

PC12

PC13

PC14

PC15

8

7

9

80

X2

C16

10pF

4 1

3 2

C17

10pF

MII_RXD0

MII_RXD1

321

321

JP12

USART2_TX

USART2_RX

LED4

PD3

PD4

PD5

LED3

PD2

321

MC_NTC

0DP51BP

PD1

JP13

CAN1_RX

MC_EmergencySTOP

PE15

46

PD081PD182PD283PD384PD485PD586PD687PD7

I2C device open / CAN2

==================================================

JP1: 2<->3 / Anti_Temper 1<->2 / MCU current measurement

JP9: close /

MC_WL

MC_WH

PE12

default set/ feature enabled another set/ feature enabled

MC_VH

MC_VL

PE10

PE11

PE1041PE1142PE1243PE1344PE1445PE15

PE9

40

MC_UH

MC_UL

PE8

JP10: 1<->2 / I2S Audio 2<->3 / MC

PE7

Jumper conguration:

SmartCard_CMDVCC

PE13

PE14

JP11

LED1

PD6

PD7

PD8

PD9

PD10

56

88

PD855PD9

PD1057PD1158PD1259PD1360PD1461PD15

1<->2 / Smartcard

/ Ethernet 2<->3 / WKUP & MC

JP11: 2<->3 / Ethernet

JP12: 2<->3 / Ethernet 1<->2 / Smartcard

JP13: 2<->3 / Ethernet 1<->2 / Smartcard

JP14: 1<->2

SmartCard_OFF

TRACE_D3

TRACE_D2

TRACE_D1

TRACE_D0

PE3

PE4

PE5

PE6

5

PE738PE839PE9

close / BL_Boot0

JP18: open/ BL_Boot0 disabled

JP19: open/ BL_Reset disabled close / BL_Reset

JP15: close / SDcard CS open / output for audio DAC

MC_PF Csync2

TRACE_CK

USB_OverCurrent

PE0

PE1

PE2

98

PE21PE32PE43PE54PE6

PE097PE1

JP26

U9A

TP6

MCO

321

WAKEUP

MII_CRS

MC_DissipativeBrake

PC14-OSC32_IN

PC15-OSC32_OUT

PC13-ANTI_TAMP

PA0-WKUP23PA124PA225PA326PA429PA530PA631PA7

PA0

PA1

PA2

PA3

PA4

PA5

MII_MDIO

MII_RX_CLK/RMII_REF_CLK

JP14

MII_COL

PA867PA968PA1069PA1170PA1271PA13

32

PA6

PA7

PA8

PA9

MCO

MC_CurrentA

MC_BusVoltage

IDD_Measurement

R78

USB_VBUS

JP15

MicroSDCard_CS

Audio_DAC_OUT

PA10

USB_ID

0

PA11

PA12

USB_DM

+3V3

72

PA13

PA14

USB_DP

TMS/SWDIO

2

SW1

1

PA1476PA15

77

PA15

PB0

TDI

TCK/SWCLK

R60 10K

09.03290.01

3

PB035PB136PB2

PB389PB490PB591PB692PB7

37

PB1

PB2

PB3