Page 1

AN2439

Application note

27 W Output power ultra wide range input

flyback converter

Introduction

As the telecommunications market grows, the need for suitable PSUs (Power Supply Unit)

for equipment grows as well. For products used in telecommunications, the available

voltage is either the mains voltage (from 88 V

V

). Power supplies that are able to manage input AC voltage in the full range of 88Vrms

DC

to 265Vrms are quite common while ultra wide range (from 36 V

supplies are not as common. The main advantage in using a UWR PSU is the savings in

design and qualification. Instead of designing and qualifying two PSUs, the work is done

once. Cost advantages come from bigger volume production as there is just one product

that meets a larger range of electrical specifications.

Disadvantages are the difficulties in having a high performance system in working

condition. This application note describes a UWR flayback converter that can be used to

supply a DSLM (DSL Multiplexer).

The advantage in using a flyback converter in this application is the moderate variation of

the duty cycle with the input voltage. The main drawback is the high value of the rms current

in the secondary winding, in the output diode and in the output capacitor.

to 265 VAC) or 48 VDC (from 36 VDC to 72

AC

to 264 VAC) power

DC

June 2007 Rev 1 1/20

www.st.com

Page 2

Contents AN2439

Contents

1 Board description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.1 Active start-up with external high voltage current source [2.] . . . . . . . . . . . 4

1.2 Slope compensation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.3 Input section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.4 Buck DC-DC converter post regulator [3.] . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.5 Flyback converter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.6 Transformer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1.7 Board tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1.8 Start-up tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1.9 Dynamic load regulation tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

1.10 Steady state tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

1.11 Static load and line regulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2 Conclusions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3 References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2/20

Page 3

AN2439 Board description

1 Board description

The electrical specifications for this converter are listed in the table below:

Table 1. Electrical specifications

Item Value

Isolated Yes

Input AC and DC voltage

Minimum DC input voltage 36 V

Maximum DC input voltage 72 V

Minimum AC input voltage 88 V

Maximum AC input voltage 265 V

Number of outputs 2

Output voltage 1 5 V

Output voltage 2 3.3 V

Maximum output current 1 2 A

Maximum output current 1 5 A

Maximum precision error on output 1 3%

Maximum precision error on output 2 3%

Total output power 27 W

As already specified, the selected topology is a flyback converter. In continuous mode the

relation between output and input voltage of the converter is:

Equation 1

nV

V

OUT

-------------- n

V

IN

Where n is the turn ratio and V

D

-------------

• D

1D–

the reflected voltage. It is easy to verify that for an input

R

voltage that changes between 36 V and 375 V and 70 V as reflected

•

nV

IN

(

375V 2 265•=

OUT

•+

OUT

--------------------------------------- -

V

V

---------------------- -==⇒=

VINVR+

)V

R

voltage, the duty cycle changes from about 70% (at minimum input voltage) to about 16%.

Buck type topologies are not suitable because the duty cycle varies widely (from 9%- to 90%

for a forward converter in the same condition for example), worsening the efficiency and

making the design very complex.

A second design choice was to use a switching post regulator that has, as input voltage, the

output voltage of the flyback and the output as 3.3 V. The purpose of this is to meet the

requested precision in both outputs and to avoid using another secondary winding where

the root mean square current would be very high. Assuming a 90% of efficiency for this step

down converter, the total current sunk from the output of the flyback is 5.7 A. The buck

converter for the post regulation is described in Section 1.4 on page 7.

In order to limit the high root mean square current at the secondary side, another design

choice was to have a flyback converter that works, most of the time, in continuous

conduction mode. The controller used in this application is the L5991 [1.] which is a current

3/20

Page 4

Board description AN2439

mode controller. In continuous conduction mode for the lower input voltages, the duty cycle

is greater than 50% which requires a slope compensation to ensure stable operation of the

current loop. The slope compensation is implemented through a circuit described in

Section 1.2 on page 5.

The switching frequency was selected to be equal to 70 kHz and the reflected voltage to be

equal to 70 V.

In order to have the same wake-up time for the different input voltages, an active start-up

was implemented instead of the most commonly used passive circuits. The active start-up

circuit is described in Section 1.1.

In order to improve efficiency, the converter has two different inputs, one for the AC voltage

(88 V

ACrms

to 265 V

) and one for the DC voltage (36 VDC to 72 VDC). The input stage

ACrms

of the converter is described in Section 1.3 on page 7.

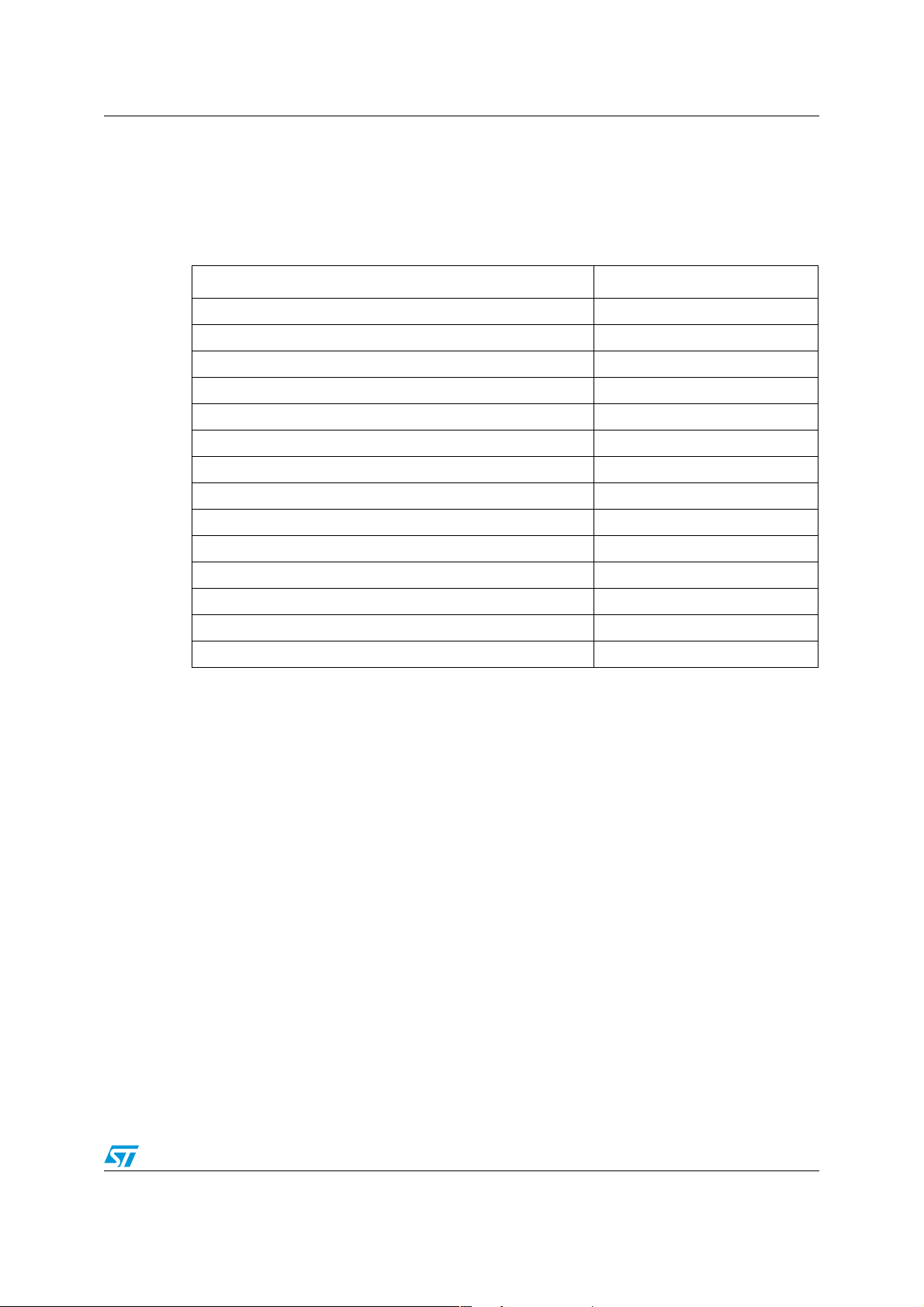

1.1 Active start-up with external high voltage current source [2.]

The circuit of the active start-up is shown in Figure 1. Through R1 and R2 the 600 V

MOSFET M

diode and D

the resistor R

current provided to the capacitor connected to V

constant current generator and its current can be calculated according to the following

equation:

(STQ1NK60ZR) is switched on. The back-to-back diodes (D1 is a 15 V zener

1

is a standard diode 1N4148) are used to set the voltage between the gate and

2

pin not connected with the source of M1. The resistor R3 is used to limit the

3

of the L5991. The circuit behaves as a

CC

Equation 2

V

– VTH–

ZVd

I

------------------------------------=

R

3

Where V

biased and V

is the D1 zener break-down voltage, Vd the diode D2 voltage drop when forward

Z

is the gate to source on threshold voltage of the MOSFET M1.

TH

Figure 1. Active start up circuit

To Bulk Capacitor +

R

1

R

2

M

1

D

To V

REF

Pin of the L5991

T1

1

R

D

2

3

To V

Pin of the

CC

L5991

I

When we connect the converter to the mains, the controller (L5991) is initially off, and the

small signal bipolar transistor T

R

and R2 and the current generator starts to work charging the VCC capacitor. As the VCC

1

voltage exceeds its On Threshold, the L5991 starts to operate and sets the V

to 5 V. This voltage turns on the small bipolar transistor T

is also off. The gate of the MOSFET M1 is biased through

1

pin (pin 4)

that pulls down the gate of M1

1

REF

4/20

Page 5

AN2439 Board description

⎝⎠

switching it off. As a result, as the controller is on, the current generator stops working, and

the controller is supplied by the auxiliary winding of the flyback converter.

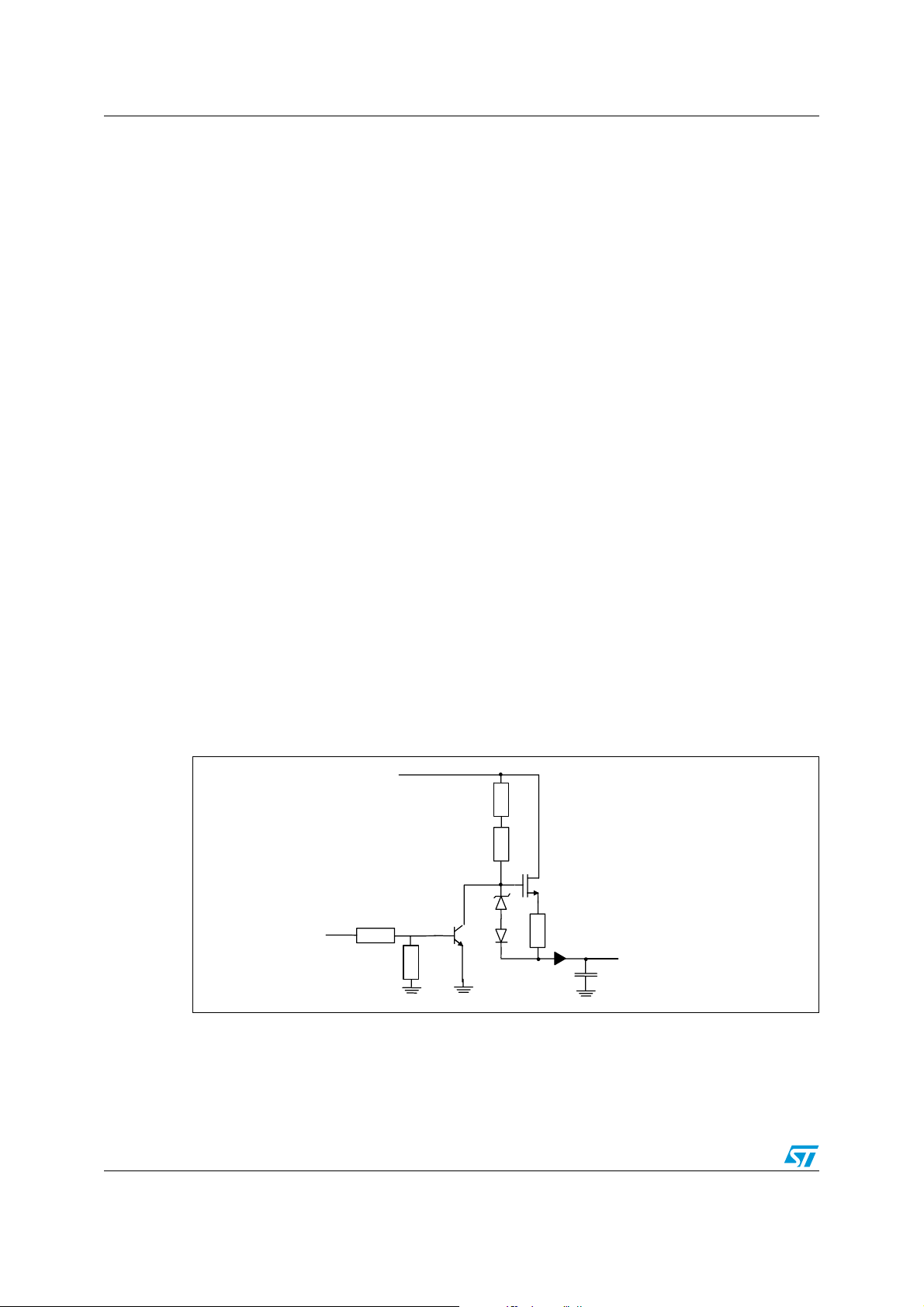

1.2 Slope compensation

The circuit for slope compensation is shown in Figure 2. When the main MOSFET

(STP10NK70Z) is switched on, the GD pin (Gate Driver) of the L5991 goes high up to a

voltage of about 14 V. Capacitor C

large enough, compared to the switching period, we can assume that the voltage across

capacitor C

the partition divider R

the MOSFET M

diode D

is a linear ramp. This voltage is added to the CS pin (Current Sense) through

2

. Capacitor C2 is then fast discharged and ready for the next cycle.

1

1

, R1+R

3

is switched off, the gate driver pin of the L5991 pulls down the anode of

Figure 2. Slope compensation circuit

is charged through resistor R2. If the time constant RC is

2

and provides the needed slope compensation. When

SENSE

STP10NK70

M1

RSENSE

. In this

2

CS Pin of L5991

R2 22k

C2

1.8 nF

R3

15k

Bat49

RGATEGD Pin of L5991

D1

R1 1.5k

C1

100 pF

Equation 3 gives the waveform expression of the voltage across the capacitor C

formula V

is the forward voltage drop on diode D1 and VGD is the voltage on gate driver pin

D

of the L5991 (Pin 10), when it is high. As a rule of thumb, in order to have approximately a

linear ramp across C

, the time constant C2RT is selected in the range of ten times the

2

switching period.

Equation 3

Neglecting R

VCt() V

SENSE

GD

it can be simplified as:

R1R3R

++

------------------------------------------------------------- -

R

+++

1R2R3RSENSE

SENSE

t–

--------------------

⎛⎞

C

•

2RT

1e

–

⎜⎟

+•• e

V

D

•=

t–

--------------------

C

•

2RT

Equation 4

R1R3+

t() V

V

C

R

is the equivalent resistance across capacitor C2:

T

--------------------------------- -

GD

R

++

1R2R3

Equation 5

R2R1R3– R

----------------------------------------------------------------- -

R

τ

R

+++

1R2R3RSENSE

–()•

⎛⎞

⎜⎟

⎝⎠

SENSE

C

1e

–

•

2RT

≅=

VD+•• e

R

2R1R3

--------------------------------------

R

++

1R2R3

–()•

t–

--------------------

•≅

t–

--------------------

•

C

2RT

5/20

Page 6

Board description AN2439

The slope compensation voltage added on CS Pin of the L5991 is:

Equation 6

Vst()

R

1RSENSE

------------------------------------------------

R

++

2R3RSENSE

VCt()•

R

1

--------------------

R2R3+

VCt()•≅=

–

We know that if we add a ramp whose slope is one half of the primary side equivalent

demagnetizing current slope (m

), the current loop is stable for any duty cycle lower than

a

one. As consequence the requested amount of slope compensation needed to guarantee

stable operation is:

Equation 7

V

1

R

-------

-- -

•=

S

• R

L

2

SENSE

m

m

In the last equation V

primary side. The value of R

compensation we add and of course the maximum peak current at the primary side (I

is the reflected voltage and Lm the magnetizing inductance at

R

has to be calculated taking into account the slope

SENSE

PKP

Equation 8

R

SENSE

--------------------------------------------------------- -=

I

PKP

1V

V

-------

L

D

R

MAX

-------------- -

••+

f

m

sw

1

-- -

2

The maximum value of the voltage we add at the current sense pin is:

Equation 9

V

SMAX

D

MAX

-------------- -

m

•

s

f

sw

R

1

--------------------

R2R3+

D

⎛⎞

-------------- -

V

•==

C

⎝⎠

MAX

f

sw

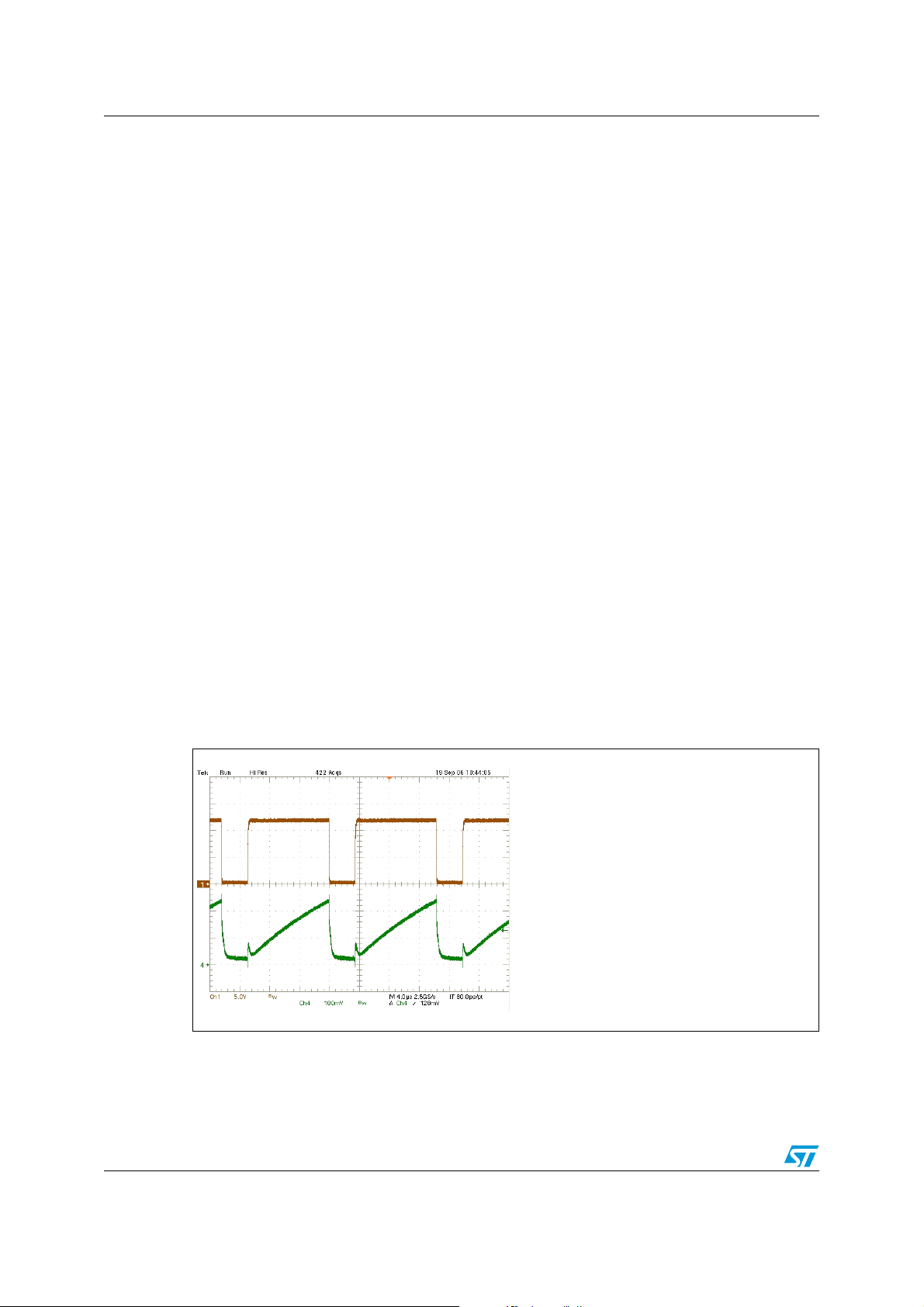

Figure 3 shows the gate driver signal and the slope compensation signal measured at the

CS pin.

Figure 3. Slope compensation signal

).

6/20

Ch1 (yellow): gate driver signal

Ch4 (green): slope compensation ramp on

current sense pin

Page 7

AN2439 Board description

V

V

1.3 Input section

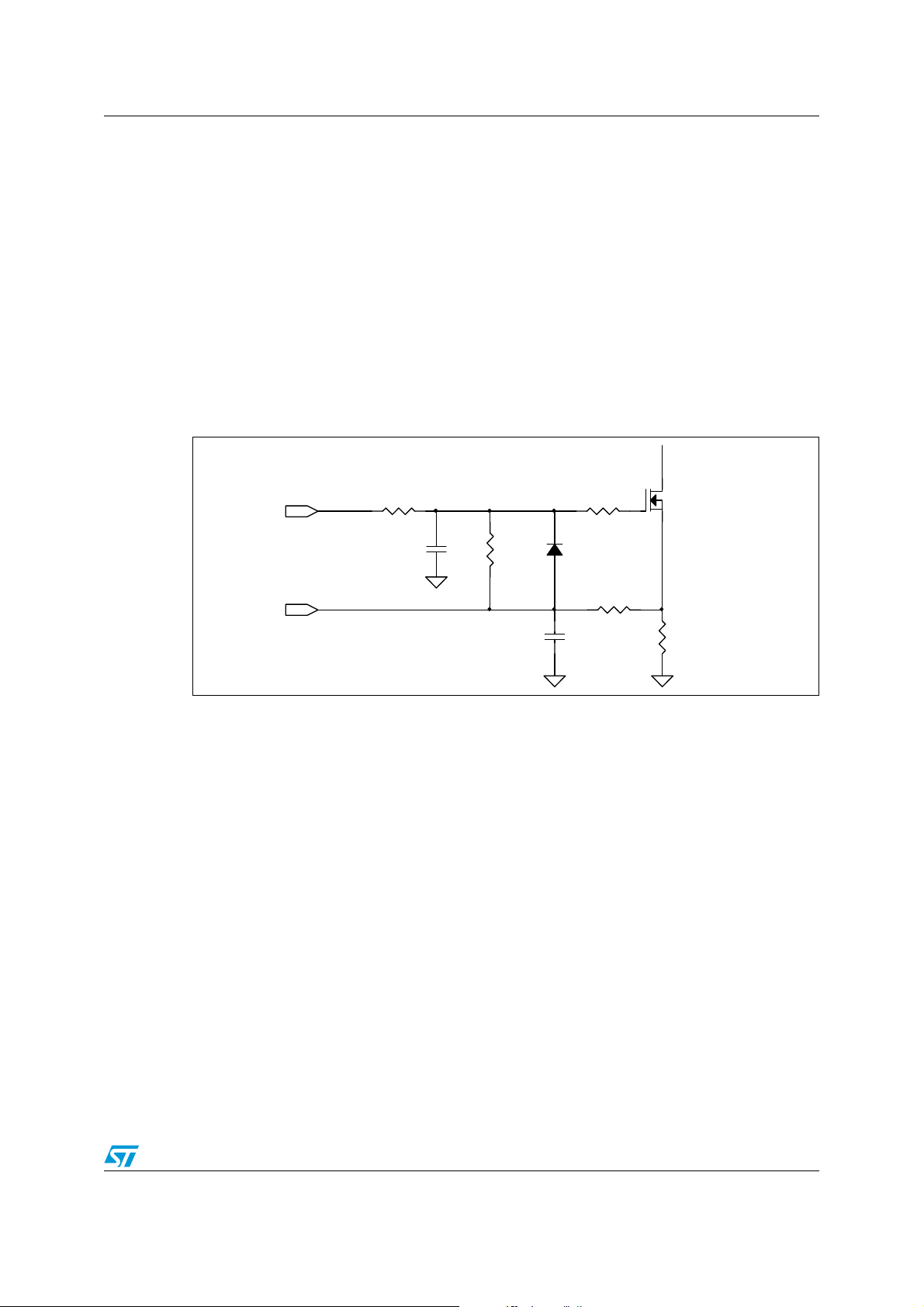

The schematic of the input section is given in Figure 4. We used two separated connectors

for the AC input voltage (88 V

The system works correctly if we feed the converter with the Dc voltage in the AC input

voltage connector. We used a separated connector in order to gain efficiency.

Using the additional connector for the Dc input voltage we use two different NTCs to limit the

inrush current in the two cases. NTC1 has to limit the inrush current, considering as worst

case the maximum AC Peak input voltage. NTC2 has to limit the inrush current, considering

as worst case the maximum DC voltage (72 V) which means that NTC2 can be lower than

NTC1 and dissipates less energy.

The DC voltage is connected to the bulk capacitors through one diode (used for protection in

case we connect the Dc input with the wrong polarity) so we cut one half of power

dissipation compared to the power we would dissipate in the bridge.

Figure 4. Input section

t

1 2

NTC18. 2 2A

Ac Input

oltage

J1

2

1

CON2

1 2

+

Dc Input

oltage

J2

CON2

-

2

1

to 265 VAC) and for the DC input voltage (36 VDC to 72VDC).

AC

Start up C ir c uit

C1

1nF Y1

C2

100nF

C3

1nF Y1

2

-+

BR1

BRIDGE

3

1

4

F1 2A

C5

33 uF

4

3

FILTER1

Lin Filt er

1

2

t

NTC2.82 2A

D8 600V 3A diode

C222

100nF

Primary +

C4

33uF

1.4 Buck DC-DC converter post regulator [3.]

The second output of 3.3 V, able to provide up to 5 A to its load, is obtained using a

switching post regulation. The post regulator is a synchronous buck converter based on the

L6725 controller and the schematic is given in Figure 5.

7/20

Page 8

Board description AN2439

+

Figure 5. Synchronous buck converter post regulator

C31

100nF

R24 0.1

C21

1uF Ceramic Cap

R25 6.8k

C28 220nF

C22 3.9nF R27 6.8k

C25 330pF R29

1

COMP

2

SS/INH

3

EAREF

4

OCL

5

OCH

6

PHASE

7

HGATE

8 9

BOOT PGND

U4 L6725

FB

SGND

N.C.2

N.C.1

VCC

VCCDR

LGATE

D11 STPS1L30M

16

15

14

13

12

11

10

1.5k

RG1 3.3

RG2 3.3

C23 10nFR28 330

U6

1

S1

2

S2

3

S3

4

Gate

STS9NF3LL

U5

1

8

S1

D4

2

7

S2

D3

3

6

S3

D2

4

5

Gate

D1

STS9NF3LL

8

D4

7

6

5

D12

STPS1L30M

D3

D2

D1

R26

C24

1.2k

1nF

R30

2.4k

L4 3.9uF

C26

NM

R31

NM

In+

Out-In-

Out

C27

220uF 6.3V

C30

220uF 6.3V

The two MOSFET STS12NF3LL (U5 and U6 in the schematic) are driven with 180 degrees

of phase shift. The gate driver signal value is 5 V when high, as the L6725 is supplied with

the 5 V that is, the output of the flyback main converter.

This situation is not optimum for the two MOSFETs, as their R

is higher when the gate

DSON

signal is 5 V compared to when the gate signal is 10 V [4.]. It could seem that the two

MOSFETs are oversized, but taking into account the low driving signal, they are not.

1.5 Flyback converter

The primary side of the flyback converter schematic is given in Figure 6 and the secondary

side is given in Figure 7.

The bill of material of the entire circuit is given in Ta ble 2, 3, 4, and 5.

8/20

Page 9

AN2439 Board description

A

3

A

Figure 6. Flyback converter primary side schematic

R8

22k

Primary +

Primary -

R12

15k

D5

BAT49

R11 1.5k

C8

100pF

C10

1.8nF

RCLAMPB1

18k 2W

R7 10

RSB1

0.66 1/2W

CCLAMP1

1.2nF 400V

D2

STTH1L06

STP10NK70

1

RSB2

0.66 1/2W

23

M1

23

uxiliary +

R1 1 Meg

STQ1NK60ZR

Q1

1

R5

4.7k

1 2

10uF 35V

D3

1N4148

D4

12V

D12B1STTH102

C12

R2

1 Meg

Q2

BC337

R14 10k

Start up C i rc uit

Q3 STX715

1 2

R10 100kR9 100k

D6

15Vz

R3 6. 8k 1%

5.6k 1%

CVCC1

47uF 25V

HeatSink 15 C / W

1

1

Mosfet M1 Heat Sink

R4 N.M.

RA 1

4.3k 1%

R6

C7

100nF

4.7nF

Opto Colle c t or

CSS1

C9

47nF

C11

2.2nF

1

SYNC

2

RCT

3

DC-C

4

Vref

5

VFB

6

Comp

7

SS

8

Vcc

R13 8.2

L5991

ST-BY

DC lim

SGND

PGND

16

15

14

DIS

13

CS

12

11

10

GD

9

Vc

Figure 7. Flyback converter secondary side schematic

D10

12

OPTO1

PC817

3

2 1

C13

1800uF 16V MCZ

R21

1k N. M.

R22 22k

C15

1800uF 16V MCZ

R18 470

R23

82k 1%

C17

1800uF 16V MCZ

R20

82k 1%

C191uF

Primary +

Primary -

uxiliary +

HS1

Diode D7 Heat Si nk

1

P

HeatSink 10 C/W

C212 CY1

1

3

6

7

Transf ormer

T1

14

13

9

8

Opto Collector

TEST POINT

TP2

D7 DIODE

4

3

TL1431

1

L3 8.2uH 2.5A

C14

+

1800uF 16V MCZ

Dc-Dc Coverter

In+

In-

Out+

Out-

33uF

C16

J3

1

2

3

CON

9/20

Page 10

Board description AN2439

Table 2. Input section (schematic Figure 4)

Quantity Part reference Part name Description

1 BR1 Bridge 600 V 3 A Bridge diodes

2 C3,C1 1 nF Y1

1 C2, C222 100 nF

1NTC2.82 2ª

1 D8 600 V 3 A 600 V 3 A diode

1F12 A

2 C4, C5 33 µF 400 V Electrolytic capacitor

1 Filter1 4.7 mH 3A Line filter

1 NTC1 8.2 2ª

Table 3. Primary side flyback converter (schematic Figure 6)

Quantity Part reference Part name Description

2R2,R11 Meg

1 R5 4.7 k

2 R10,R9 100 k

1 R3 6.8 k 1%

1 R6 5.6 k 1%

1 R14 10 k

1 RA1 4.3 k 1%

1R4N.M.

1 R13 8.2

1 R12 15 k

1 R8 22 k

1R710

1 R11 1.5 k

2 RSB2,RSB1 0.66 1/2 W

1 RCLAMPB1 18 k 2 W

1 U2 L5991

1D2STTH1L06

STMicroelectronics primary controller

with standby

STMicroelectronics turbo 2 ultra fast high

voltage rectifier

1 D3 1N4148

1 D4 12Vz 12 V Break down Zener diodeo

1D5BAT42

10/20

STMicroelectronics small signal Schottky

diode

Page 11

AN2439 Board description

Table 3. Primary side flyback converter (schematic Figure 6) (continued)

Quantity Part reference Part name Description

1D615Vz

1 Q1 STQ1NK60ZR

1Q2BC337

1 Q3 STX715 STMicroelectronics NPN transistor

1 U1 HeatSink 15 C/W

1M1STP10NK70Z

1 D12B1 STTH102

1 C12 10 µF 35 V

1 CVCC1 47 µF 25 V

1 CCLAMP1 1.2 nF 400 V

1 CSS1 47 nF

1 C8 100 pF

1 C9 4.7 nF

1 C10 1.8 nF

1 C11 2.2 nF

4 C2 100 nF

STMicroelectronics N-CHANNEL 600 V

SuperMESH™ MOSFET

STMicroelectronics N-Channel 700 V

Zener-protected SuperMESH™

MOSFET

STMicroelectronics high efficiency ultra

fast diode

Table 4. Secondary side flyback (schematic Figure 7)

Quantity Part reference

1C212CY1

1 C16 33 µF

4

1C191µF

1 D7 STPS16H100

1 T1 Transformer

1 D10 TL1431

1C241nF

1R18470

2 R20,R23 82 k 1%

C13, C14, C15,

C17

Part name or

value

1800 µF 16 V

MCZ

Rubycon high current low ESR

electrolytic capacitor

STMicroelectronics high voltage power

Schottky rectifier

STMicroelectronics programmable

voltage reference

Description

11/20

Page 12

Board description AN2439

Table 4. Secondary side flyback (schematic Figure 7) (continued)

Quantity Part reference

1R211k N.M.

1 L3 8.2uH 2.5°

2 R22,R8 22k

1 OPTO1 PC817 Optocoupler

Part name or

value

Table 5. DC-DC converter (schematic Figure 4)

Quantity Part reference

1 C25 330 pF

1 R24 0.1 Ω

2 R25,R27 6.8 kΩ

1 R26 1.2 kΩ

1 R28 330 Ω

1 R29 1.5 kΩ

1 R30 2.4 kΩ

1R31N.M.

2 RG2,RG1 3.3 Ω

1 C21 1 µF Ceramic capacitor

Part name or

value

Description

Description

1 C22 3.9 nF

1 C23 10 nF

1 C24 1 nF

1 C25 330 pF

1 C26 N.M. Not mounted

1 C27, C30 220 µF 6.3 V ZA Rubycon ZA electrolytic capacitor

1 C28 220 nF

4 C31 100 nF

2 D12,D11 STPS1L30M

1 L4 3.9 µF 6A Rated current inductor

1 U4 L6725

2 U5,U6 STS12NF3LL

STMicroelectronics low drop power

Schottky rectifier

STMicroelectronics low cost adjustable

step-down controller

STMicroelectronics N-Channel 30 V low

gate charge STripFET™ II Power

MOSFET

12/20

Page 13

AN2439 Board description

1.6 Transformer

The details of the transformer used are listed below.

● Electrical characteristics

– Primary inductance value: 450

– Primary leakage inductance: 12

● Magnetic core

– Material: N67

–Type: ETD29

– Air gap: ≈ 0.2 mm

Table 6. Winding size

Winding Number of turns Wire size

Primary winding 46 AWG26

Secondary winding 4 AWG26X4

Auxiliary winding 10 AWG40

Figure 8 describes the used and suggested placing of the windings.

µH

µH

Figure 8. Transformer winding placing

Insulation

Auxiliary Winding

Secondary Winding

1.7 Board tests

The tests performed aim to evaluate the converter behavior in terms of efficiency, safe

operating area of the devices, and line and load regulation.

1.8 Start-up tests

½ Primary Winding

½ Primary Winding

In a flyback converter the most critical conditions for the mains switch (when no abnormal

event occurs), in terms of maximum drain current and of maximum drain voltage, are during

the start-up phase. The max values for drain voltage and current were measured in both full

13/20

Page 14

Board description AN2439

load and no load condition that are the two extreme points in terms of load and for minimum,

maximum, and nominal input voltages. The results are shown in Tabl e 7 .

Table 7. Start-up measures

V

in

V

drainMax

(V) I

No load Full load No load Full load

36 V

48 V

72 V

88 V

115 V

230 V

265 V

DC

DC

DC

AC-rms

AC-r ms

AC-r ms

AC-r ms

235 288 2.03 2.55

256 313 2.09 2.66

277 320 2.07 2.50

320 318 2.06 2.26

362 391 2.18 2.45

526 543 2.37 2.54

562 581 2.13 2.5

The drain voltage is well below the break down voltage of the MOSFET. In the worst case

there is at least 100 V of safety margin. The maximum peak value of the drain current,

during the start-up phase, is higher then the steady state value (around 2 A). The difference

is not too high, thanks also to the soft start, and it means that there is no risk for the

transformer to saturate during start-up.

1.9 Dynamic load regulation tests

The behavior of the system was verified also in dynamic load condition. Both loads are

square wave shaped. Both have step change between 10% and 90% of their respective

maximum nominal load and vice versa. The results are shown in Figure 9.

drainMax

(A)

14/20

Page 15

AN2439 Board description

Figure 9. Dynamic load waveforms

a

b

Ch1 (yellow): 5 V output voltage

Ch4 (green): 3.3 V output voltage

Ch2 (blue): load current of the 5 V

output

Ch2 (purple): load current of the 3.3 V

output

c

15/20

Page 16

Board description AN2439

1.10 Steady state tests

The aim of these tests is to evaluate the performance of the converter in steady state

condition, measuring the converter efficiency for minimum, maximum and nominal input

voltages.

Table 8. Steady state full load and half load condition efficiency measures

Vin (V) Full load Half load

P

36 V

48V

72V

88V

115 V

230V

265V

DC

DC

DC

AC

AC

AC

AC

(W) P

IN

43.5 27 62 19.4 13.5 70

39.8 27 68 18.7 13.5 72

37.6 27 72 18.3 13.5 74

38.6 27 70 19.2 13.5 70

37.8 27 71 18.9 13.5 71

37.4 27 72 19.1 13.5 71

37.5 27 72 19.2 13.5 70

(W) η (%) PIN (W) P

OUT

(W) η (%)

OUT

The efficiency as it is possible to see from Ta b l e 8 is not high, ranging between 64% and

72% in full load condition and between 70% and 74% in half load condition. The main

reason of this poor efficiency is the high power dissipation on the output diode of the flyback

(more than 5 W at low input voltage) that returns to the rest of the flyback converter. The

transformer has to deliver more power than necessary, increasing the losses on the

transformer itself. Because of this, the power MOSFET has to conduct more current than

necessary. The Input section is also affected because the diode or the bridge diodes and the

NTC have to conduct higher current.

Figure 10. Efficiency chart

Efficie ncy

75

70

65

60

30 80 130 180 230 280

Full Load

Half Load

1.11 Static load and line regulation

These tests aim to evaluate the precision of the output voltage and how it is affected by line

voltage and load in steady state condition. Tabl e 9 and Tab l e 1 0 show the output voltages in

different load conditions for different input voltages. For the 5 V output the minimum and

maximum values are 5.099 V and 5.145 V inside the tolerance specified in Ta bl e 1 . The

16/20

Page 17

AN2439 Board description

minimum and maximum values for the 3.3 V output are 3.348 and 3.357 which are both

inside the tolerance.

Table 9. Static line and load regulation

Vin (V) Both output in full load Both output in no load

V

36 V

48 V

72 V

88 V

115 V

230 V

265 V

DC

DC

DC

AC

AC

AC

AC

(V) V

OUT1

5.099 3.357 5.145 3.351

5.099 3.355 5.145 3.351

5.100 3.354 5.144 3.351

5.100 3.355 5.145 3.350

5.100 3.355 5.145 3.350

5.100 3.352 5.145 3.350

5.100 3.352 5.145 3.351

(V) V

OUT2

(V) V

OUT1

OUT2

(V)

Table 10. Static line regulation and crossed load regulation

Vin (V) V

36 V

DC

48 V

DC

72 V

DC

88 V

AC

115 V

AC

230 V

AC

265 V

AC

Full load V

OUT1

V

(V) V

OUT1

no load Vout1 No load Vout2 full load

OUT2

(V) V

OUT2

(V) V

OUT1

5.116 3.348 5.129 3.357

5.116 3.348 5.129 3.357

5.116 3.348 5.129 3.357

5.117 3.349 5.129 3.356

5.117 3.349 5.129 3.356

5.117 3.349 5.129 3.356

5.117 3.349 5.129 3.356

Figure 11 and Figure 12 show the drain voltage (Ch3, purple waveform) and current (Ch2

blue waveform) of the flyback MOSFET. Figure 11 shows the waveforms when the circuit is

fed with the input voltage of 36 V

shows when the input is 265 V

, which is the minimum input voltage, and Figure 12

DC

which is the maximum input voltage.

AC

The load is the maximum for both the output. Figure 11 and Figure 12 allow comparing the

difference between the two extreme points of the input voltage range. When the input is at

its minimum, the flyback is working in continuous mode with a peak current close to 2 A and

a maximum duty cycle near to 75%. When the input voltage is at its maximum, the system

works in discontinuous mode with a duty cycle close to 15% and a peak current of about 1.8

A. Figure 13 shows the same waveforms when circuit is fed with the nominal values of the

input voltage (48 V

, 115 VAC and 230 VAC) and in full load condition.

DC

OUT2

(V)

17/20

Page 18

Board description AN2439

Figure 11. Steady state waveforms with

minimum and maximum input

voltage - full load at 36 V

DC

Figure 13. Steady state waveforms with nominal input voltage

Figure 12. Steady state waveforms with

minimum and maximum input

voltage - full load at 264 V

AC

a

c

18/20

b

Ch2 (blue): drain current

Ch3 (purple): drain voltage

(a) Full load waveforms at 48 V

(b) Full load waveforms at 115 V

(c) Full load waveforms at 230 V

DC

AC

AC

Page 19

AN2439 Conclusions

2 Conclusions

In this application note an ultra-wide range input voltage converter was presented. The

topology used for the main converter is the well known flyback topology. The additional

circuits used as active start-up circuit and slope compensation were described in detail. The

tests results of the board were also presented. The most obvious result is the moderate

efficiency of the converter. This result is only slightly related to the ultra wide range input. It

is mainly due to the low output voltage and high current load of the flyback converter. In the

secondary side flyback diode, the power dissipation is close to 5 W. This high power

dissipation in the secondary side affects the performances, in terms of power dissipation, of

the transformer, the primary side part of the flyback and of the input section.

In order to increase efficiency we can use a flyback with higher output voltage, 12 V for

example, for the same power rate and obtain the output voltages requested in the electrical

specifications with two switching post regulators. In this case, of course, the cost increases.

3 References

1. L5991 datasheet

2. AN1729 "L6565 - Based low cost SMPS for TV with Less then 1 W stand by

consumption"

3. L6725 datasheet

4. STS12NF3LL datasheets

4 Revision history

Table 11. Revision history

Date Revision Changes

25-Jun-2006 1 First issue

19/20

Page 20

AN2439

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZED ST REPRESENTATIVE, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2007 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

20/20

Loading...

Loading...