Page 1

AN2430

Application note

STR75x SystemMemory boot mode

Introduction

This application note describes the features of the SystemMemory boot mode developed for

STR75x Flash microcontrollers providing all the basic functionality to support the

programming of the embedded Flash. As well as the general features, this document also

covers the specific features of the UART boot mode.

Note: The bootloader feature is unavailable on some devices soldered on development tools

(starter kits or evaluation boards). Please refer to Section 4 on page 22 for further

information.

January 2007 Rev 3 1/24

www.st.com

Page 2

Contents AN2430

Contents

1 General description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.1 Entering SystemMemory boot mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.2 Hardware requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.3 Using SystemMemory boot mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.4 Command description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.4.1 Get command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.4.2 Read Memory command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.4.3 Go command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.4.4 Write Memory command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.4.5 Erase command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.4.6 Write Protection command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1.4.7 Write Unprotection command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1.4.8 Readout Permanent Protect command . . . . . . . . . . . . . . . . . . . . . . . . . 14

1.4.9 Readout Temporary Unprotect command . . . . . . . . . . . . . . . . . . . . . . . 15

1.4.10 Readout Permanent Unprotect command . . . . . . . . . . . . . . . . . . . . . . . 16

1.5 Exiting SystemMemory boot mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

1.6 SystemMemory code program flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2 UART SystemMemory boot mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2.1 UART SystemMemory code sequence . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2.2 Choosing the UART baud rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2.2.1 Minimum baud rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2.2.2 The maximum baud rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2.2.3 Higher baud rate deviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3 Conclusion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4 Bootloader availability limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2/24

Page 3

AN2430 General description

1 General description

The STR75x is usually woken up in SystemMemory boot Mode when the Flash is still not

programmed in the manufacturing line environment. In this case the system boot is

performed from SystemMemory sector in the Flash bank0. This mode allows initialization of

the Flash programming via a serial interface and the use of the Internal Free Running

Oscillator.

1.1 Entering SystemMemory boot mode

The STR75x enters the SystemMemory Boot Mode if the BOOT pins are configured as

follows:

● BOOT0 = 1

● BOOT1= 0

The value of the BOOT pin is latched on the 4th rising edge of CK_SYS after Reset.

After Reset, the STR75x CPU begins execution of the SystemMemory code which resides

in the SystemMemory sector.

Table 1. STR75x device configuration in SystemMemory Boot Mode

Feature/Peripheral State Comment

Instruction Set THUMB Save code space with 16-bit instructions

CPU Mode Supervisor Full access with IRQ Enabled and FIQs disabled

Input Clock

UART0_RX Pin Input UART0 Receive

UART0_TX Pin Output UART0 Transmit

UART0 Registers Default Only configured for UART Boot

Internal

FREEOSC

1.2 Hardware requirements

The hardware required to put the STR75x into SystemMemory boot mode consists of any

circuitry, switch, or jumper capable of holding the BOOT0 pin high and the BOOT1 pin low

during Reset.

To connect to the STR75x during SystemMemory boot mode, a RS232 serial interface must

be directly linked to UART0 pins.

For more details, refer to the STR75x hardware development getting started application note

(AN2419).

Allow a Frequency in a range of 2 to 10MHz

3/24

Page 4

General description AN2430

1.3 Using SystemMemory boot mode

The SystemMemory boot mode is executed from RAM and uses the last 4K of 16K RAM,

i.e. from 0x40003000 to 0x40003FFF. So when downloading code to RAM, the user has to

consider only the 12K RAM (from 0x40000000 to 0x40002FFF).

After the serial link initialization sequence (see the following chapters) the SystemMemory

code waits for the user to run some commands.

The supported commands are listed in the table below.

Table 2. Allowed commands

Command

Command

Code

Command Description

Get 0x01

Read Memory 0x11

Go 0x21

Write Memory 0x31

Erase 0x43 Erase from one to all the Flash sectors

Write Protection 0x63

Write Unprotection 0x71 Temporarily disable the write protection for all Flash sectors

Readout Permanent

Protect

Readout Temporary

Unprotect

Readout Permanent

Unprotect

0x82 Permanently enable the the Readout protection

0x91 Temporarily disable the Readout protection

0x92 Permanently disable the Readout protection

Get the SystemMemory version and the number of times

the readout protection is disabled/enabled.

Read until 256 bytes of memory starting from an address

specified by the user

Jump to an address specified by the user to execute a

loaded code

Write until 256 bytes to the RAM or the Flash starting from

an address specified by the user

Permanently enable the write protection for the needed

sectors

4/24

Page 5

AN2430 General description

1.4 Command description

1.4.1 Get command

Description:

This command allows the user to get the version of the bootloader, the number of times the

Readout protection is both disabled and enabled.

When the bootloader receives the Get command, it transmits four bytes to the user: the first

byte contains the version, the second contains the number of times the Readout protection

is disabled, the third contains the number of times it’s enabled and finally the ACK byte.

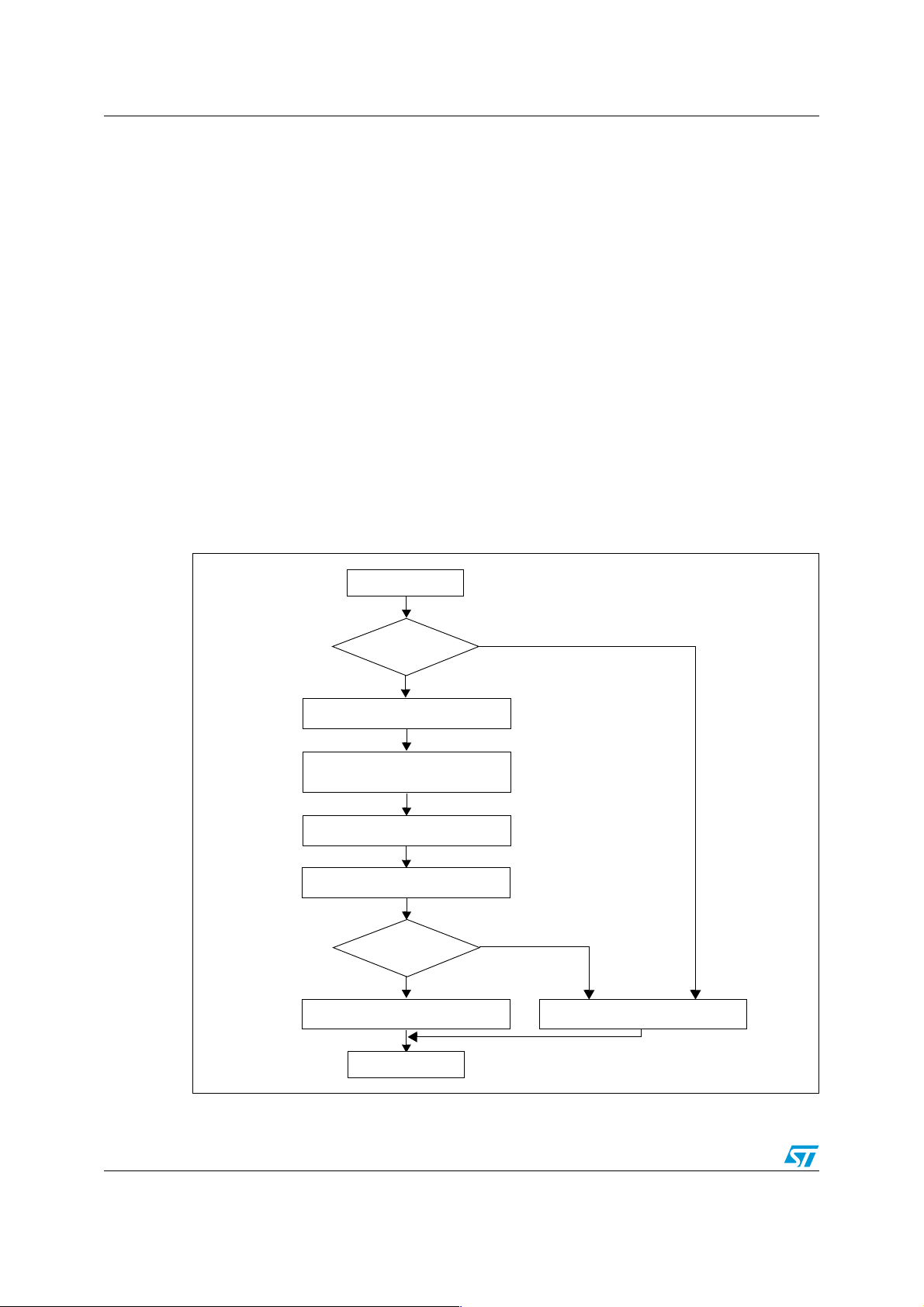

Figure 1. Get command flowchart

Start GC

Received byte

== 0x01?

Send the version of the bootloader

Send the number of times the Readout

protection is Disabled

Send the number of times the Readout

protection is enabled

Send ACK byte

End of GC

No

Send NACK byte

5/24

Page 6

General description AN2430

1.4.2 Read Memory command

Description:

This command allows the user to read the memory (RAM, Flash and registers).

When the bootloader receives the Read Memory command, it transmits the ACK byte.

After the transmission of the ACK byte, the bootloader waits for an address (4 bytes, byte 1

is the MSB and byte 4 is LSB of the address), checks this address, if the address is valid, it

transmits an ACK byte otherwise it transmits a NACK byte (0x3F) and exits from the

command.

When the address is valid, the bootloader waits for the number of bytes to be transmitted (N

bytes) and then returns to the user the needed data ((N + 1) bytes) starting from the

received address.

Figure 2. Read memory flowchart

Start RM

Received byte

== 0x11?

Send ACK byte

Receive the start address (4 bytes)

Valid Address?

Send ACK byte

Receive the number of bytes to be read

(1 byte)

Send data to the user

End of RM

No

No

Send NACK byte

6/24

Page 7

AN2430 General description

1.4.3 Go command

Description:

This command allows the user to execute the downloaded code or any other code by

making a branch to an address specified by the user.

When the bootloader receives the GO command, it transmits the ACK byte.

After the transmission of the ACK byte, the bootloader waits for an address (4 bytes, byte 1

is the MSB and byte 4 is LSB of the address), checks this address, if the address is valid, it

transmits an ACK byte otherwise it returns a NACK byte (0x3F) and exits from the

command.

When the address is valid, the program counter of the CPU jumps automatically to this

address. Therefore, the SystemMemory boot mode is exited.

Note: During SystemMemory mode, the CPU is in Thumb state.

Figure 3. Go command flowchart

Start GO

Received byte

== 0x21?

Send ACK byte

Receive the start address (4 bytes)

Valid Address?

Send ACK byte

Jump to start address

Exit SystemMemory

boot mode

No

No

Send NACK byte

End of GO

7/24

Page 8

General description AN2430

1.4.4 Write Memory command

Description:

This command allows the user to write data to any address memory (RAM, Flash or

registers).

When the bootloader receives the Write Memory command, it transmits to the user the ACK

byte.

After the transmission of the ACK byte, the bootloader waits for an address (4 bytes, byte 1

is the MSB and byte 4 is LSB of the address), checks this address, if the address is valid, it

transmits an ACK byte otherwise it returns a NACK byte (0x3F) and exits from the

command.

When the address is valid, the bootloader:

● Gets a byte which describes the amount of data to be received (N bytes),

● Receives the user data ((N + 1) bytes),

● Programs the user data to memory starting from the received address,

Finally, at the end of the command, the bootloader transmits the ACK byte if the write

operation is completed successfully otherwise a NACK byte (0x3F) is returned and the

command is exited.

8/24

Page 9

AN2430 General description

Figure 4. Write memory command flowchart

Start WM

Received byte

== 0x31?

Send ACK byte

Receive the start address (4 bytes)

Valid Address?

Send ACK byte

Receive the number of bytes to be written

(1 byte)

RAM Address?

No

No

No

Write the received data to RAM

from the start address

Send ACK byte

End of WM

Write the received data to Flash

from the start address

Write error?

No

Send NACK byte

9/24

Page 10

General description AN2430

1.4.5 Erase command

Description:

This command allows the user to erase from one to all the sectors of the Flash memory.

When the bootloader receives the Sector Erase command, it transmits the ACK byte.

After the transmission of the ACK byte, the bootloader waits for the number of bytes to be

received (number of sectors to be erased) and then receives from the user the Flash sectors

codes.

Finally, at the end of the command, the bootloader transmits the ACK byte if the erase is

completed successfully otherwise a NACK byte (0x3F) is returned and the command is

exited.

The Erase command procedure is as follows:

1. Receive one byte which contains the number (N) of sectors to be erased.Here, N can

be a value from 0 to 9,

2. Receive (N + 1) bytes, each byte contains a sector code. Below all the STR75x sector

codes.

Table 3. Sector codes

Flash Sector Sector Code

Bank 0 Sector 0 0x00

Bank 0 Sector 1 0x01

Bank 0 Sector 2 0x02

Bank 0 Sector 3 0x03

Bank 0 Sector 4 0x04

Bank 0 Sector 5 0x05

Bank 0 Sector 6 0x06

Bank 0 Sector 7 0x07

Bank 1 Sector 0 0x10

Bank 1 Sector 1 0x11

10/24

Page 11

AN2430 General description

Figure 5. Erase command flowchart

Start ER

Received byte

== 0x43?

Send ACK byte

Receive the number of sectors

to be erased (1 byte)

Receive the sector codes

Erase the correspondent sectors

Erase error?

Send ACK byte

End of ER

No

Ye s

Send NACK byte

11/24

Page 12

General description AN2430

1.4.6 Write Protection command

Description:

This command allows the user to permanently enable the write protection for one, many or

all Flash sectors.

When the bootloader receives the write protection command, it transmits the ACK byte to

the user.

After the transmission of the ACK byte, the bootloader waits for the number of bytes to be

received (sectors to be protected) and then receives from the user the Flash sectors codes.

Finally, at the end of the command, the bootloader transmits the ACK byte if the write

protection is enabled successfully otherwise a NACK byte (0x3F) is returned and the

command is exited.

The write protection command procedure is as follows:

1. Receive one byte which contains the number (N) of sectors to be write protected. Here,

N can be a value from 0 to 9,

2. Receive (N + 1) bytes, each byte contains a sector code. Refer to Table 3 on page 10

for the STR75x sector codes.

Figure 6. Write protection command flowchart

Start PR

Received byte

== 0x63?

Send ACK byte

Receive the number of sectors

to be write protected (1 byte)

Receive the sectors codes

Protect the correspondent sectors

Protection error?

Send ACK byte

No

Ye s

Send NACK byte

End of PR

12/24

Page 13

AN2430 General description

1.4.7 Write Unprotection command

Description:

This command allows the user to temporarily disable the write protection for all the Flash

sectors.

When the bootloader receives the write unprotection command, it transmits to the user the

ACK byte.

After the transmission of the ACK byte, the bootloader disables the write protection for all

the Flash sectors.

Finally, at the end of the command, the bootloader transmits the ACK byte if the

unprotection is completed successfully otherwise a NACK byte (0x3F) is returned to the

user and the command is exited.

Figure 7. Write unprotection command flowchart

Start UN

Received byte

== 0x71?

Send ACK byte

Disable the write protection for all

the Flash sectors

Unprotection error?

Send ACK byte

End of UN

No

Ye s

Send NACK byte

13/24

Page 14

General description AN2430

1.4.8 Readout Permanent Protect command

Description:

This command allows the user to permanently enable the readout protection for the entire

Flash.

When the bootloader receives the Readout Permanent Protect command, it transmits to the

user the ACK byte.

After the transmission of the ACK byte, the bootloader permanently enables the readout

protection for the entire Flash.

Finally, at the end of the command, the bootloader transmits the ACK byte if the readout

protection is completed successfully otherwise a NACK byte (0x3F) is returned to the user

and the command is exited.

Note: When the readout protection is enabled only the following commands are available:

– The Get Command,

– The Readout Temporary Unprotect command,

– The Readout Permanent Unprotect command.

When the readout protection is enabled, in order to boot from the SystemMemory it is

mandatory to reset to ground the pin NJRST.

Figure 8. Readout permanent protect command flowchart

Start ROP_PRM

Received byte

== 0x82?

Send ACK byte

Permanently Enable the Readout

protection for the entire Flash

Protection error?

Send ACK byte

End of ROP_PRM

No

Ye s

Send NACK byte

14/24

Page 15

AN2430 General description

1.4.9 Readout Temporary Unprotect command

Description:

This command allows the user to temporarily disable the readout protection for the entire

Flash.

When the bootloader receives the Readout Temporary Unprotect command, it transmits the

ACK byte.

After the transmission of the ACK byte, the bootloader erases all the Flash sectors then

temporarily disables the readout protection for the entire Flash.

If an error occurs during the erase operation the command is exited and the readout

protection remains enabled.

Finally, at the end of the command, the bootloader transmits the ACK byte if the readout

unprotection is completed successfully otherwise a NACK byte (0x3F) is returned to the

user and the command is exited.

Figure 9. Readout temporary unprotect command flowchart

Start ROU_TMP

Received byte

== 0x91?

Send ACK byte

Erase all the Flash sectors

Erase error?

Temporarily Disable the Readout

protection for the entire Flash

Protection error?

Send ACK byte

No

Ye s

Ye s

Send NACK byte

End of ROU_TMP

15/24

Page 16

General description AN2430

1.4.10 Readout Permanent Unprotect command

Description:

This command allows the user to permanently disable the readout protection for the entire

Flash.

When the bootloader receives the Readout Permanent Unprotect command, it transmits the

ACK byte to the user.

After the transmission of the ACK byte, the bootloader erases all Flash sectors then

permanently disables the readout protection for the entire Flash.

If an error occurs during the erase operation the command is exited and the readout

protection remains enabled.

Finally, at the end of the command, the bootloader transmits the ACK byte if the readout

unprotection is completed successfully otherwise a NACK byte (0x3F) is returned to the

user and the command is exited.

Figure 10. Readout permanent unprotect command flowchart

Start ROU_PRM

Received byte

== 0x92?

Send ACK byte

Erase all the Flash sectors

Erase error?

Permanently disable the Readout

protectionfor the entire Flash

Protection error?

Send ACK byte

No

Ye s

Ye s

Send NACK byte

End of ROU_PRM

16/24

Page 17

AN2430 General description

1.5 Exiting SystemMemory boot mode

SystemMemory boot mode must be exited in order to execute a program in a normal User

mode. The STR75x may exit this mode by applying a hardware Reset. At the time of Reset,

the BOOT pins (BOOT0 and BOOT1) must be set at the proper levels to enter the desired

user mode. Following the Reset, the STR75x CPU begins executing code from location

0x00000000.

Table 4. Mode Pin vs. memory mapping

BOOT1 BOOT0 Boot Mode Aliasing Note

0 0 Embedded Flash

1 0 Embedded SRAM

0 1 SystemMemory

Embedded Flash sector

B0F0 mapped at 0h

Embedded SRAM mapped

at 0h

SystemMemory mapped at

0h

1 1 External SMI SMI bank 0 mapped at 0h -

1.6 SystemMemory code program flow

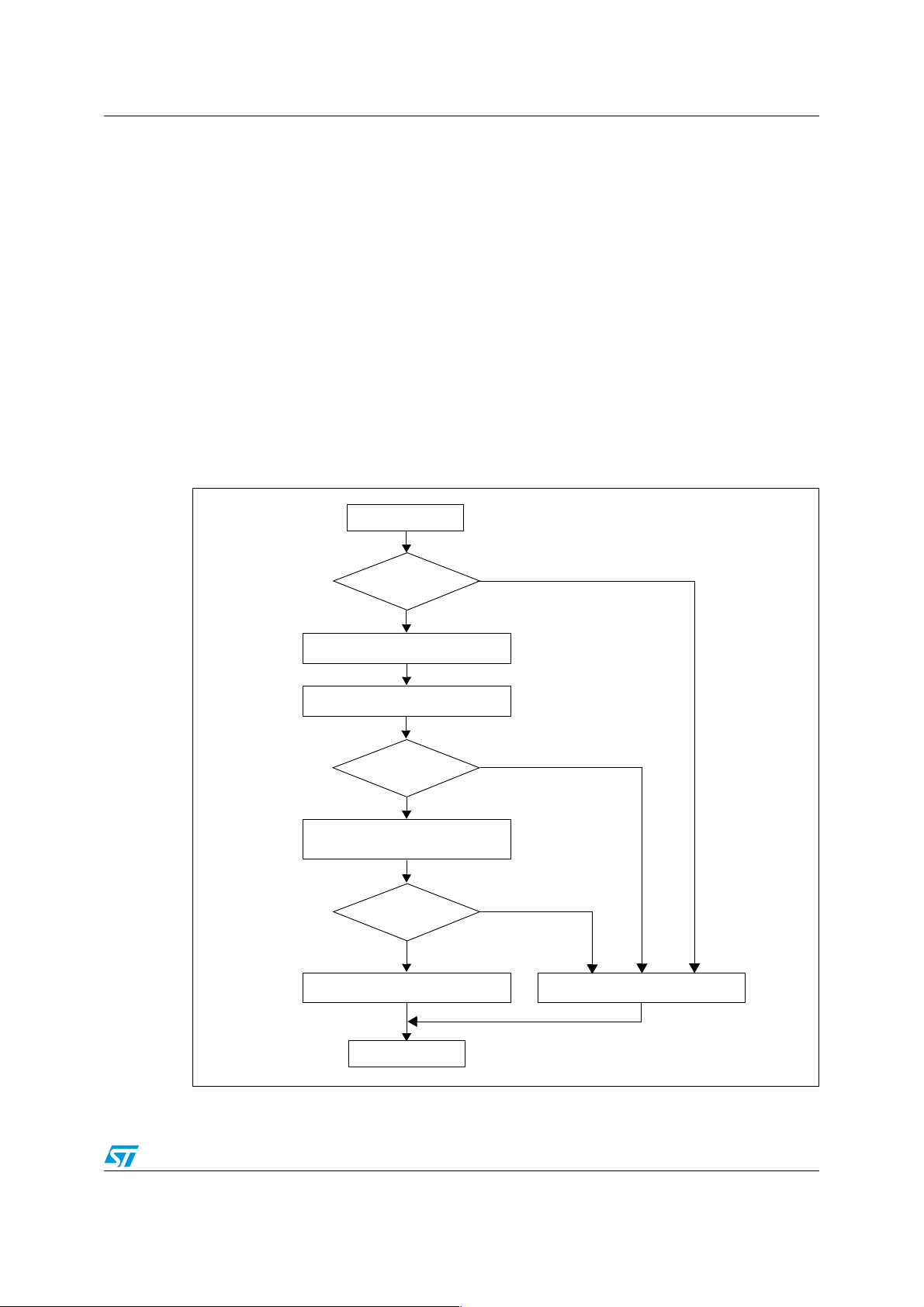

Figure 11. SystemMemory code program flow

Start

Falling Edge on

UART0 Rx ?

Start Timer Base

No

All FLASH sectors

accessible except

SystemMemory sector

-

-

No

Falling Edge on

UART0 Rx ?

Stop Timer Base

Initialize UART0

Send Acknowledge

Clear the bit 22 of

the Flash Control

Register (Remap)

Done

Wait for a command

17/24

Page 18

General description AN2430

Figure 11 shows the program flow of the SystemMemory code. A few points worth noting

are:

● Not all the commands are available when readout protection is active, for more details

about the allowed commands please refer the section Readout Permanent Protect

command.

● The UART interface is only initialized if UART boot mode is detected.

Note: The STR75x Timer Base (TB) is used to automatically detect the serial baud rate. Once

initialized the UART configuration is 8-bits, No Parity, and 1 Stop bit.

18/24

Page 19

AN2430 UART SystemMemory boot mode

2 UART SystemMemory boot mode

2.1 UART SystemMemory code sequence

After SystemMemory mode is entered and the STR75x is configured as described above,

the SystemMemory code begins to scan the RxD0 line, waiting to receive a 0x7F data. (One

start bit, 0x7F data bits, and one stop bit).

The duration of this data byte is measured using the Timer Base. The count value of the

timer is then used to calculate the corresponding baud rate factor with respect to the current

system clock.

Next, the code initializes the serial interface accordingly, and sets up pin TxD0 to an

alternate function, push-pull output. Using this calculated baud rate, an acknowledge byte is

returned to the host which signals that the STR75x is ready to receive user commands.

Note: The acknowledge byte is 0x75 for the STR75x devices.

2.2 Choosing the UART baud rate

The calculation of the serial baudrate for UART0, from the length of the first byte that is

received, allows the operation of the STR75x SystemMemory bootloader within a wide

range of baud rates. However, the upper and lower limits have to be kept, in order to ensure

proper data transfer.

Baud Rate Divider = F

The STR75x uses the Timer Base to measure the length of the initial byte. The quantization

uncertainty of this measurement implies the first deviation from the theoretical baud rate.

The next deviation is implied by the computation of the Baud Rate Divider reload value from

the timer contents. The formula below shows the association:

TB_CNT / 8 = 1 Bit Time in F

Baud Rate Divider = TB_CNT / 8 / 16 = TB_CNT / 128

/ (16 * STR75x Baud Rate)

cpu

(8 Bit Times the first byte)

cpu

For a correct data transfer from the host to the STR75x, the maximum deviation between the

internal initialized baud rate for UART0 and the real baud rate of the host should be below

2.5%. The deviation (f

B

be calculated via the formula below:

f

= abs( (STR75x Baud Rate - Host Baud Rate) / STR75x Baud Rate) * 100%

B

f

<= 2.5%

B

Note: Function (f

) does not consider the tolerances of oscillators and other devices supporting

B

the serial communication.

This baud rate deviation is a non linear function depending on the CPU clock and the baud

rate of the host. The maximum of the function (f

due to the smaller baud rate pre-scale factors, and the implied higher quantization error.

2.2.1 Minimum baud rate

B

is the minimum baud rate determined by the maximum count capacity of Timer Base

Low

when measuring the first byte. This will be directly related to system clock frequency. Using

the maximum TB_CNT value of 65535 in the equations above we end up with a minimum

, in percent) between the host baud rate and STR75x baud rate can

) increases with the host baud rate. This is

B

19/24

Page 20

UART SystemMemory boot mode AN2430

Baud Rate of 1220 at F

2400. Baud rates below B

= 10MHz. The lowest standard Baud Rate for this case would be

cpu

would cause TB to overflow. If this occurs, it would not be

Low

possible to properly initialize the UART0.

2.2.2 The maximum baud rate

B

is the highest baud rate in which the deviation still does not exceed the limit. All baud

High

rates between B

Low

and B

are below the deviation limit.

High

Using the minimum TB_CNT value of 1in the equations above we end up with a maximum

Baud Rate of 125000 at F

= 2MHz. The highest standard Baud Rate for this case would

cpu

be 115000.

2.2.3 Higher baud rate deviations

A baud rate may be used as long as the actual deviation does not exceed the limit. Certain

lower baud rates may violate the deviation limit, while an even higher baud rates stays very

well below it. This relationship depends on the host interface.

20/24

Page 21

AN2430 Conclusion

3 Conclusion

The STR75x SystemMemory loader provides a convenient method for downloading user

code into on chip memories for a variety of applications. The UART interface provides an

easy and inexpensive, readily available serial link for desktop users.

21/24

Page 22

Bootloader availability limitations AN2430

4 Bootloader availability limitations

The bootloader feature is unavailable on some devices soldered on development tools

(starter kits or evaluation boards). Please check the date code written on the device. This

date code consists of 3 digits and is located as shown in Figure 12 below. If the device

soldered on the board displays a date code below 636, the bootloader feature is not

activated.

Note: If available, the bootloader version number (currently at V1.1) can be obtained through the

use of the Get command. Refer to Section 1.4.1 on page 5 for further details.

ST wants to highlight that this issue ONLY impacts devices soldered on a development tool

with the affected date codes. Any sample ordered separately from ST (or its distributors) has

the bootloader feature enabled (even if date code is below 636).

To those affected by this issue, ST offers the following recommendations:

● Use STR750 samples ordered separately (for example for building application

prototypes) to test the bootloader functionality.

● Use the free sample service from www.st.com . From the home page, type the correct

order code in the "Search Part #" field. From the results page, click the green

"Samples" button and follow the procedure. If the "Samples" button is not available, the

stock is in the process of being renewed and can be checked again at a later date.

● For further options or information, please contact your local distributor or ST sales

office.

Figure 12. Datecode marking on device

A

B

CD

F

a

E

G

J

HI

L

Areas H and I on the device marking

represent the date code in the following

manner:

● H: Year (Y)

● I: Week (WW)

22/24

Page 23

AN2430 Revision history

5 Revision history

Date Revision Changes

27-Sep-2006 1 Initial release

1-Dec-2006 2 Section 4: Bootloader availability limitations on page 22 added

08-Jan-2007 3

All references to GPIO0.4 pin removed

Section 1.7 removed

23/24

Page 24

AN2430

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZED ST REPRESENTATIVE, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2007 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

24/24

Loading...

Loading...