Page 1

AN2424

Application note

STMPE2401 - Port expander

PWM controller

Introduction

STMPE2401 is the first in the family of ST port-expander logic products. The principle of a

basic expander logic is to provide additional I/Os that can be used by the host processor to

implement additional features such as increasing the number of control signals and mixed

signal lines, or controlling more number of peripherals.

In addition to the above mentioned basic features, STMPE2401 comes with integrated

intelligence to implement advanced features like Keypad scanning, PWM control, and

Rotator dial control. These features enable the processor load to be reduced.

There is also a provision for using a single crystal clock to drive multiple STMPE2401

devices by cascading the devices and using the CLKOUT mode to drive the clock of the

cascaded devices.

STMPE2401 can be widely used in the fields of Mobile Communications, Portable media

players, Game console, Mobile Phones, Smart Phones, Consumer Electronics and

computer peripherals like state-of-the-art printers, Advanced embedded systems etc.

This application note explains the setup and programming of the integrated PWM controller

in STMPE2401 to do LED backlighting, brightness control, and LED blinking patterns.

April 2007 Rev 1 1/22

www.st.com

Page 2

Contents AN2424

Contents

1 Advantages of an integrated PWM controller . . . . . . . . . . . . . . . . . . . . . 4

1.1 STMPE2401 default power-up configuration . . . . . . . . . . . . . . . . . . . . . . . 4

2 PWM controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3 Operation modes and clocking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4 PWM instruction set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4.1 PWM Controller operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

5 Registers in the PWM controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5.1 PWM control and status register (PWMCS) . . . . . . . . . . . . . . . . . . . . . . . 12

5.2 PWM instruction channel_x (PWMICx) . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5.3 Alternate function register (GPAFR_U_msb) . . . . . . . . . . . . . . . . . . . . . . 14

5.4 Interrupt control register (ICR) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5.5 Interrupt enable mask register (IER) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.6 Interrupt status register (ISR) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.7 Programming sequence - example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

6 Conclusion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

7 Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

8 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2/22

Page 3

AN2424 List of tables

List of tables

Table 1. Valid STMPE2401 slave address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Table 2. SYSCON register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Table 3. SYSCON description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Table 4. RAMP instruction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Table 5. RAMP description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Table 6. SMAX instruction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Table 7. SMIN instruction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Table 8. GTS instruction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Table 9. BRANCH instruction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Table 10. BRANCH description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Table 11. END instruction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Table 12. END description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Table 13. TRIG instruction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Table 14. TRIG description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Table 15. PWM controller registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Table 16. PWMCS description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Table 17. PWM instruction description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Table 18. GPAFR description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Table 19. ICR description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Table 20. IER description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Table 21. ISR description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Table 22. Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3/22

Page 4

Advantages of an integrated PWM controller AN2424

1 Advantages of an integrated PWM controller

– Low CPU utilization

– Lower power consumption

– Simpler driver software

– Simpler connection to CPU (only two I

– Advanced programmable ramping/blinking patterns for lighting effects

– Analog/PWM output

– Application: Mobile phone backlighting, LED brightness control

1.1 STMPE2401 default power-up configuration

STMPE2401 operates at a supply voltage of 1.8 V. The clock can be supplied through a 32

KHz crystal connected across XTALIN, XTALOUT pins or through an external oscillator

clock on XTALIN pin. The external oscillator can be low accuracy (16 KHz ~ 32 KHz) and

the clock frequency for normal operation should not exceed 32 KHz. The Reset pin should

be pulled high for the device to come out of reset and operate in the normal operating mode.

The device can be accessed through the I

can be connected to the same I

2

Philip I

C specification Ver 2.1. The slave address is selected by the state of two pins

(GPIO15 and GPIO23). The state of the pins is latched into STMPE2401 at power on and

this address setting is retained until the power is switched off.

2

C bus. STMPE2401 supports 7-bit addressing as per the

2

C lines)

2

C interface and up to four STMPE2401 devices

The address can be changed and latched-in again using the soft_reset bit in the SYSCON

register.

2

The I

C Read/Write is done byte by byte. The R/W bit is added as the LSB to the 7-bit slave

address to make up one byte to be sent through the I

slave address is configured and responding correctly, the internal registers can be accessed

through I

and the I

2

C read and write commands. Ta bl e 1 lists the slave addresses that can be used

2

C Read/Write protocol to access the device registers.

2

C interface from the Master. Once the

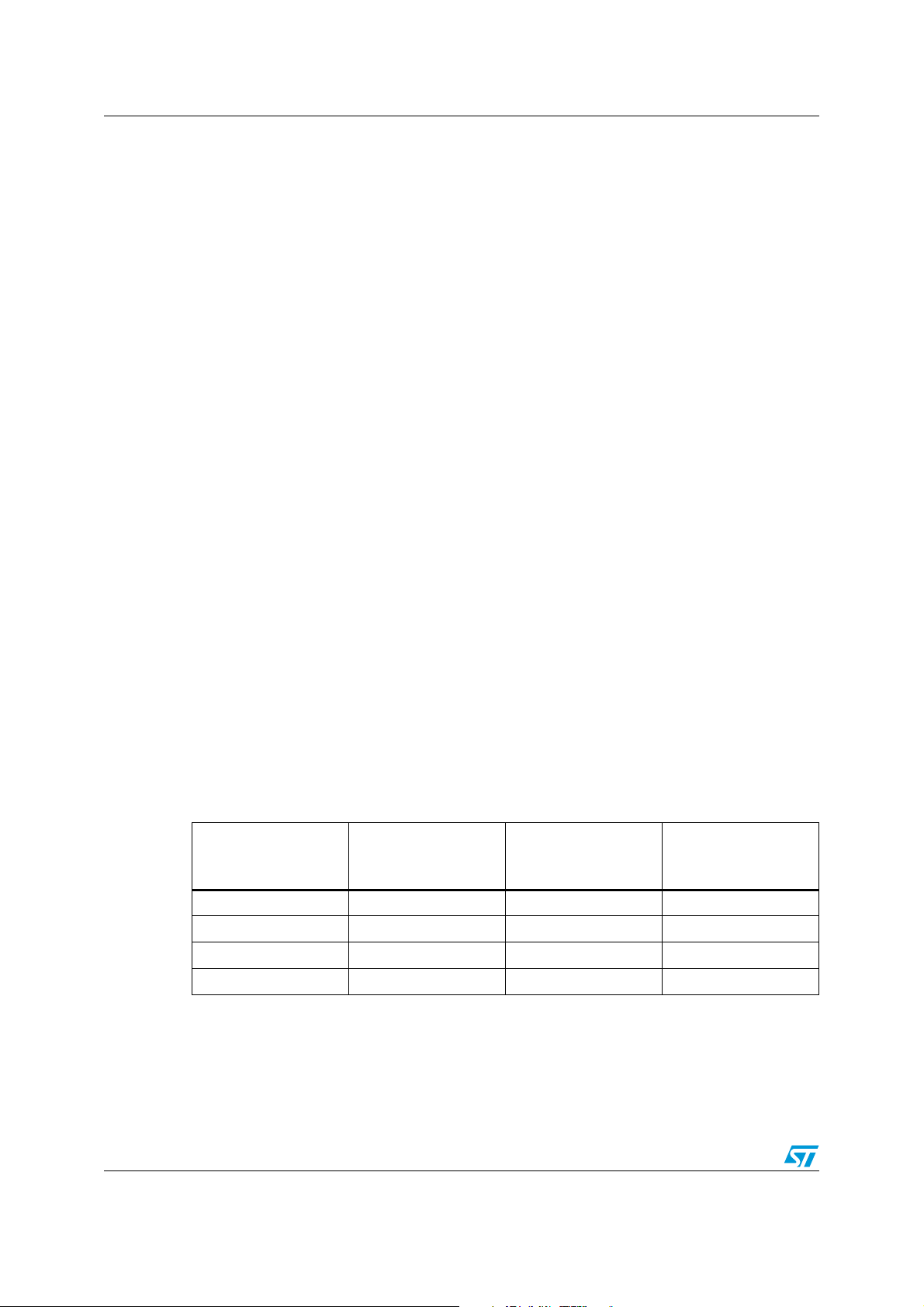

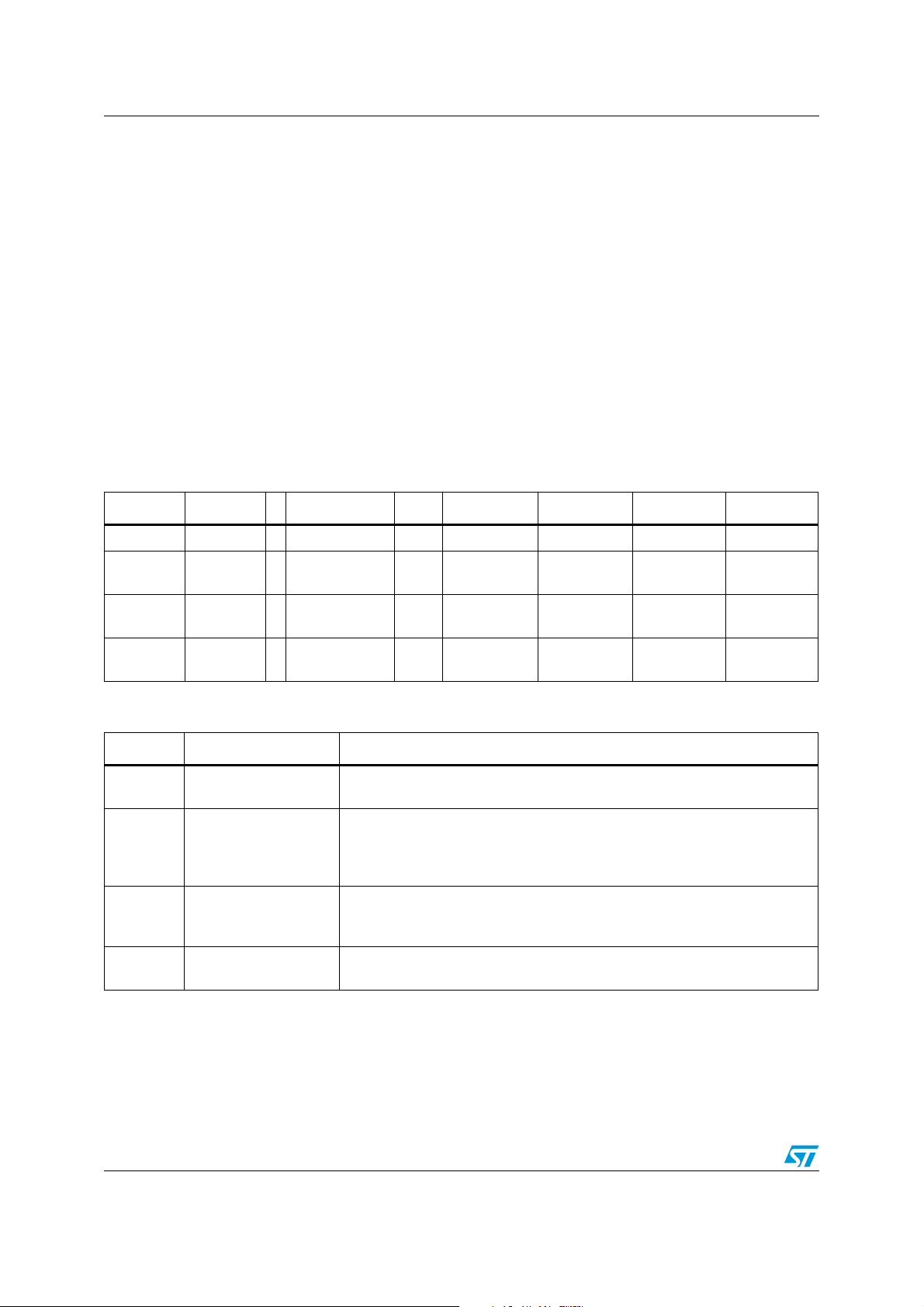

Table 1. Valid STMPE2401 slave address

ADDR1

(GPIO23)

0 0 42h (1000010b) 84h

0 1 43h (1000011b) 86h

1 0 44h (1000100b) 88h

1 1 45h (1000101b) 8Ah

ADDR0

(GPIO15)

7-bit slave

addressing

8-bit format to be

used (including R/W

bit in LSB)

4/22

Page 5

AN2424 PWM controller

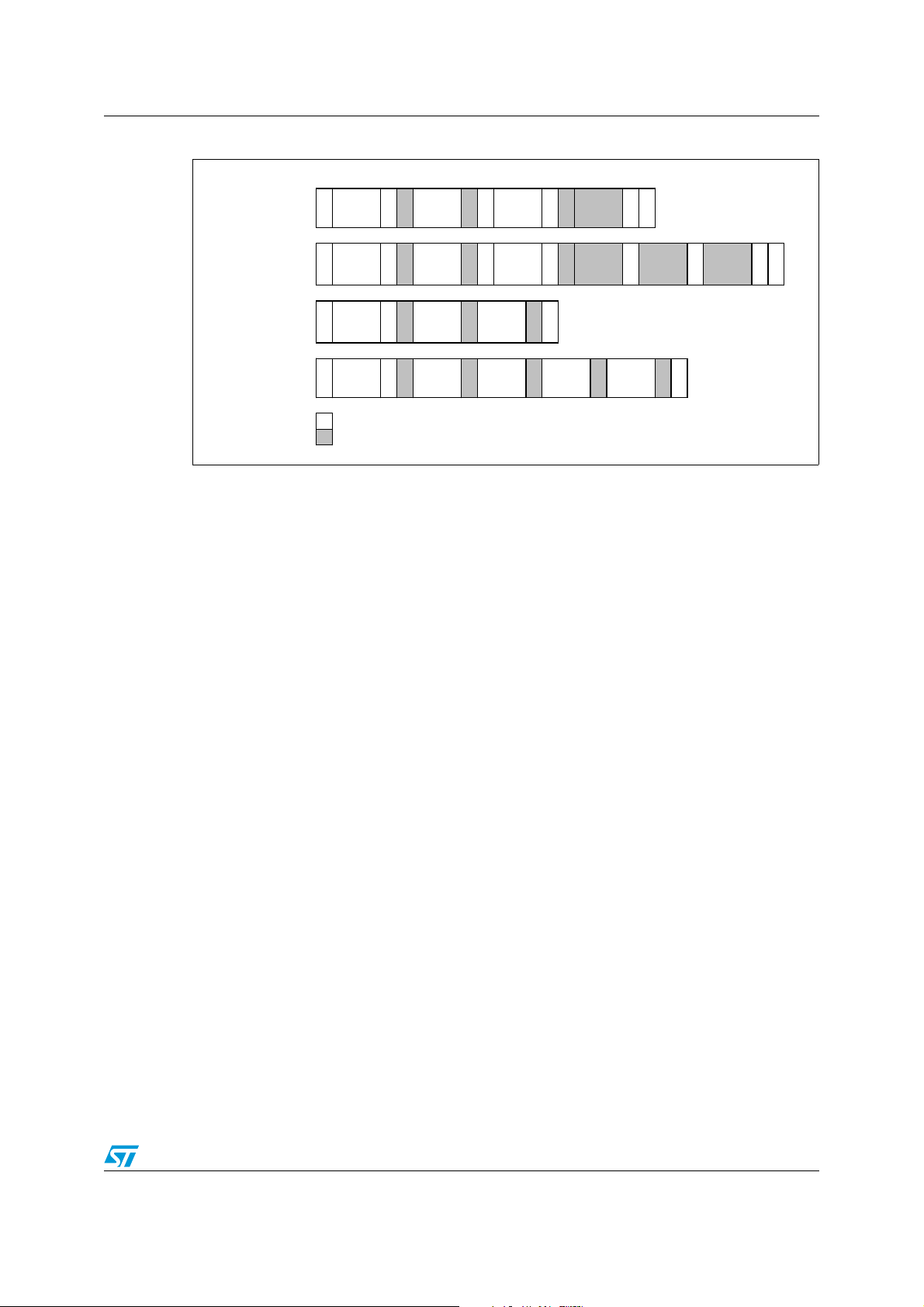

S

S

M

S

Figure 1. I2C Read/Write protocol

One Byt e

Re ad

More than

One Byt e

Re ad

One Byt e

Write

ore than

One Byt e

Write

Dev

Addr

Start

Dev

Addr

Start

Dev

Addr

Start

Dev

Addr

Start

Master

Slave

At power-up all GPIOs function as inputs and by default the interrupt is configured as an

Active Low Level interrupt. The interrupt however remains low irrespective of the settings

until the Global Interrupt bit in the ICR register is enabled (set to '1').

2 PWM controller

Reg

Addr

RnW=0

Ack

Reg

Addr

RnW=0

Ack

Reg

Addr

RnW=0

Ack

Reg

Addr

RnW=0

Ack

Ack

Ack

Ack

Ack

Dev

Addr

reStart

Dev

Addr

reStart

Dat a t o

be

Written

Dat a t o

Write

RnW=1

RnW=1

top

Ack

Data to

Write + 1

Ack

Data

Rea d

Ack

Data

Rea d

Ack

Ack

NoAck

Ack

Data to

Write + 2

top

Dat a

Read + 1

Ack

top

Read + 2

Ack

Data

NoAck

Stop

STMPE2401 comes with an integrated PWM controller that can provide three independent

PWM outputs. These outputs can be used to generate light effects like rapid blinking or

dimming in LEDs. There are three PWM channels and they can be triggered independently.

Each PWM channel can be triggered by the other two channels. The unused PWM output

pins can be used as GPIO.

Each channel comes with a maximum 64 words x 16-bit command memory. The instructions

to be stored in the command memory can be downloaded through the I

2

C connections. Any

attempt to load beyond 64 words causes the internal address pointer to roll-over (0x1f ->

0x00) and the excess instructions overwrite the first address location of the channel and

onwards.

5/22

Page 6

Operation modes and clocking AN2424

3 Operation modes and clocking

The PWM controller can be enabled only in the normal operational mode. In operational

mode, the PWM controller output is generated using the 32 KHz clock. The instruction

fetching and execution is also derived from the 32 KHz clock domain. The internal 5 MHz

clock is used only for the I

PWM is enabled, there is no interruption in the PWM output even though the internal 5 MHz

clock is cut-off in the sleep mode. However, the I

mode and therefore the PWM should be enabled before entering sleep mode.

2

C interface. Therefore, if the device enters sleep mode while the

2

C interface does not function during sleep

During Hibernate mode, the 32 KHz clock is also shut down and all modules are disabled.

The device resumes normal operation only after an I

2

C wake-up or Reset.

When the PWM function is not in use, power consumption can be reduced by gating off the

clock to the PWM Controller. This can be done by setting the 'Enable_PWM' bit in the

SYSCON register to zero.

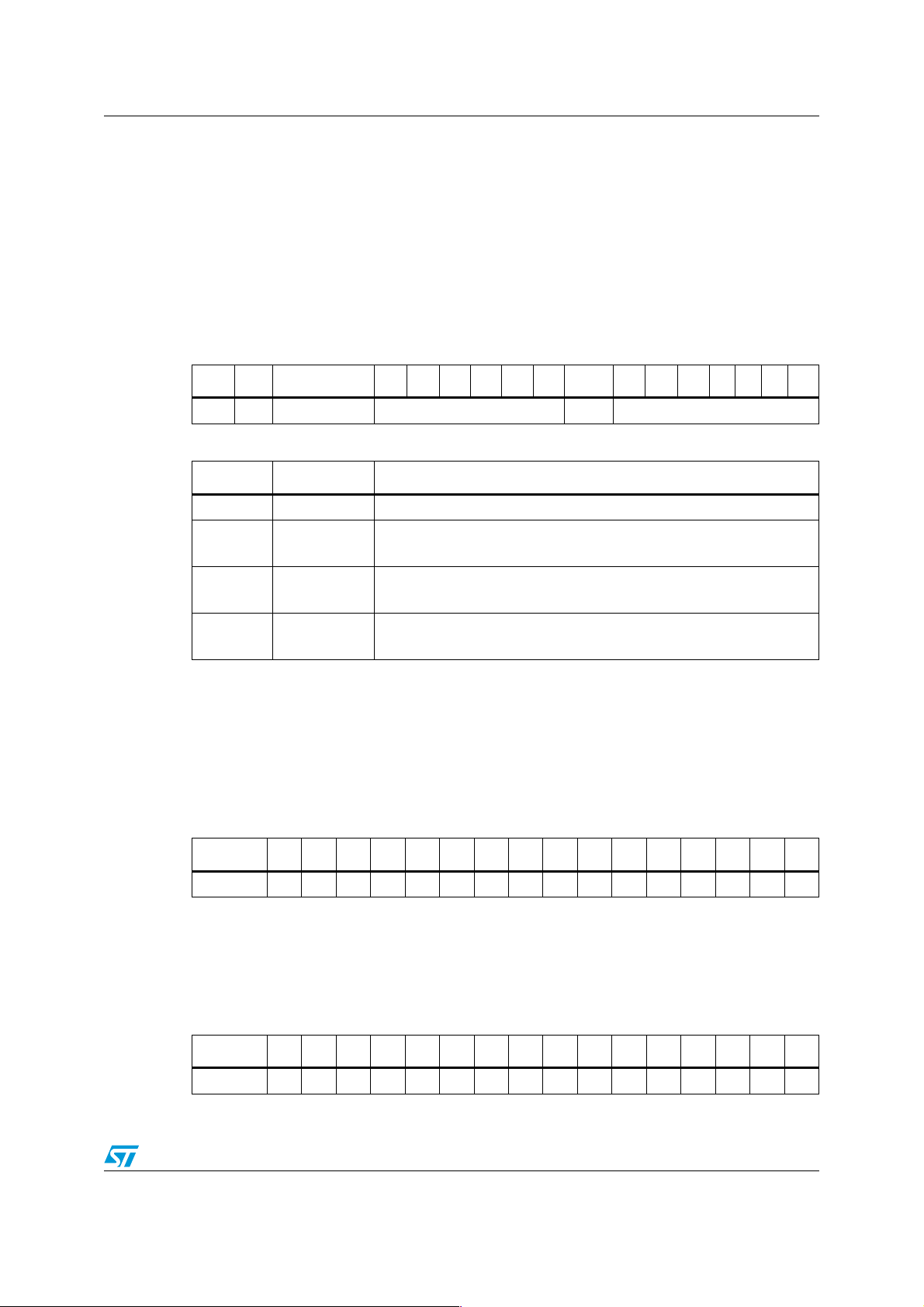

Table 2. SYSCON register

Bit 7 6 5 4 3 2 1 0

Soft_Reset - Disable_32KHz Sleep Enable_GPIO Enable_PWM Enable_KPC Enable_ROT

Read/Write

(IIC)

Read/Write

(HW)

Reset

value

WRWRWRWRWRWRW

RW R RW R R R R

00 01111

Table 3. SYSCON description

Bit Name Description

2 Enable_PWM

4 Sleep

Writing a ‘0’ to this bit gates off the clock to the PWM Controller module, thus

stopping its operation

Writing a ‘1’ to this bit puts the device in sleep mode. When in sleep mode,

all the units which need to work on clocks synchronous to 32 KHz get the

clocks derived from the 32 KHz domain.The internal RC Oscillator shuts

down.

Set this bit to disable the 32 KHz Clk, thus putting the device in hibernate

5 Disable_32 KHz

7 Soft_Reset

6/22

mode. Only a Reset or a wakeup on I2C resumes normal operation of the

device.

Writing a ‘1’ to this bit does a soft reset of the device. Once the reset is done,

this bit is cleared to ‘0’ by the Hardware.

Page 7

AN2424 PWM instruction set

4 PWM instruction set

The STMPE2401 PWM controller works as a simple MCU, with a program space of 64

instructions and a simple instruction set. The instructions are all 16-bits in length. The three

most significant bits are used to identify the command.

● RAMP

This instruction starts the PWM counters and the pwm_output depends on the counter

value.

Table 4. RAMP instruction

Bits 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

0 Prescale Step time Sign Increment

Table 5. RAMP description

Bits Name Description

6:0 Increment Increment size. Takes value between 1-126. ‘0’ setting is not allowed.

7Sign

13:8 Step Time

14 Prescale

‘0’ – Step up counter

‘1’ – Step Down counter

‘0’ – Immediate action

1-63 – Step time per increment

‘0’ – Divide clock by 16

‘1’ – Divide clock by 512 clock

Each increment is broken down into the number of steps specified by the 'Step time'

parameter and the time taken for each step is based on the prescale clock. (refer : Example

2: in section 4.1)

● SMAX (Set Maximum)

This instruction loads the PWM counter with the maximum value of 0xff and the resulting

pwm_output is logic level low.

Table 6. SMAX instruction

Bits 1514131211109876543210

Note: 1 “x“ don‘t care

● SMIN (Set Minimum)

This instruction loads the PWM counter with the minimum value of 0x0 and the resulting

pwm_output is logic level high.

Table 7. SMIN instruction

Bits 1514131211109876543210

Note: 1 “x“ don‘t care

0x

1

0x

1

00000001111111

00000011111111

7/22

Page 8

PWM instruction set AN2424

● GTS (Go To Start)

This instruction branches to internal address 0x0 and executes from 0x0.

Table 8. GTS instruction

Bits 1514131211109876543210

Note: 1 “x“ don‘t care

● BRANCH

This instruction branches to an absolute or relative location and executes with looping

capability. There are 4 loop counters available and these allow 4 nested loops.

– Absolute Branching: The Absolute branch option jumps to the absolute address

(relative to internal address 0x0) specified by the value of the step size. This is in

the nature of a JUMP instruction for forward jump and if it is backward jump, it

results in a "forever loop" execution.

– Relative Branching: Relative Branch jumps in a backward manner relative to the

current address location, that is, a step size of 1 means jump to the previous

instruction location and step size 0 means NOP. When looping, once the loop

count is reached, the loop counter resets.

Table 9. BRANCH instruction

Bits151413121110987 6 543210

101

Table 10. BRANCH description

Bits Name Description

0x

1

00000000000000

Loop

counter

Loop count

Absolute/

Relative Step

size

Step size

12:11 Loop counter

10:7 Loop count

6

5:0 Step size

Absolute/Relative

Step size

0-3.

Four loop counters that can be used as nested loops also.

0-15

‘0’ Forever loop.

‘0’ – Absolute branch

‘1’ – Relative branch

0-63

Absolute address (relative to 0x0) for absolute branch.

Relative address (relative to the current location) for relative branch.

Note: Each jump step size points to an internal address location of width 16-bits.

● END

This instruction resets the instruction counter to the starting internal address if Bit 11 is set

and generates an interrupt to the host (if Bit 12 is set).

Note: This instruction does not stop the execution of the PWM channel. The PWM operation can

be disabled only through the PWMCS register.

8/22

Page 9

AN2424 PWM instruction set

Table 11. END instruction

Bits151413 12 11 10987 6 543210

110

Interrupt

host

Reset

counter

Reserved bits

Table 12. END description

Bits Name Description

12 Interrupt Host If this bit is ‘1’ an interrupt is generated to the host.

11 Reset Counter

● TRIG (Trigger)

If this bit is set to ‘1’, the instruction counter is reset and the output of

the pwm is set to level 0.

This command enables a PWM channel to send a trigger to the other two channels and/or

wait for a trigger from other channels to start/resume execution.

This instruction is useful when LEDs have to be triggered in sequence for running displays,

for example.

Table 13. TRIG instruction

Bits 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Wait

Wait

111000

CH2

CH1

Wait

CH0

000

Send

CH2

Send

CH1

Send

CH0

X

Table 14. TRIG description

Bits Name Description

Makes the PWM channel-x wait for a trigger from Channel-2 before

9 Wait CH2

8 Wait CH1

7 Wait CH0

3 Send CH2

2 Send CH1

1 Send CH0

0 X Don’t care

starting execution. Continues execution if all selected triggers are

present.

Makes the PWM channel-x wait for a trigger from Channel-1before

starting execution. Continues execution if all selected triggers are

present.

Makes the PWM channel-x wait for a trigger from Channel-0 before

starting execution. Continues execution if all selected triggers are

present.

Sends a trigger to CH2. Continues if there is no “Wait for Trigger” in this

instruction.

Sends a trigger to CH1. Continues if there is no “Wait for Trigger” in this

instruction.

Sends a trigger to CH0. Continues if there is no “Wait for Trigger” in this

instruction.

9/22

Page 10

PWM instruction set AN2424

Figure 2. PWM controller operation

Divide by “Step Time”

Up/Down by “Step

Sign”

64Hz-2KHz

Prescaler

(Divide by 16 or 512)

32KHz

Primary Clock

PWM Ref

Counts from 0-255

repeatedly

1Hz-2KHz

Increment

Counter

Instruction Word

Instruction Word

Instruction

Instruction Word

Processor

Instruction Word

A B

Comparator

PWM Counter

Count from 0-255

based on

instructions

PWM Output

Trigger Bus

INT

4.1 PWM Controller operation

Figure 2. depicts the operation of the STMPE2401 PWM Controller and Figure 3. shows the

PWM-output for a given RAMP instruction set in the command memory. There is a

Reference PWM counter that continuously counts from 0-255 independently (Point A

output). The instructions written into the command memory determine the slope of the

Ramp at point B. A comparator is used to get the PWM_output based on the A and B point

signals as shown in Figure 3.

Figure 3. PWM output waveform

10/22

Page 11

AN2424 PWM instruction set

● PWM_out = HIGH if A > B

● PWM_out = LOW if A < B

For instance, the instruction SMAX will load the counter at B to 255 giving a low at the PWM

output. And similarly for SMIN instruction the counter will be set to 0, giving a HIGH at the

PWM_output. A suitable filter at the PWM output can be used to get a signal of a specified

frequency by varying the increment size in the RAMP instruction.

If there is no succeeding instruction after the RAMP instruction, the PWM counter continues

to run until the average PWM output becomes 0V or 1.8 V.

Example 1:

Prescale = '0' (Divide by 16 => 32 KHz/16 = 2 KHz)

Increment cycles = 126.

Step time = '0' (immediate action)

Two RAMP_UP instructions

Two RAMP_DN instructions

Frequency at the end of these set of instructions can be calculated as:

– Period to complete the instructions = (1/Prescale freq) x Increment cycles per

RAMP instruction x step time x No.of. RAMP_UP instructions x No.of RAMP_DN

instructions

– Period = (1/2000) x 126 x 1x 2 x 2 = 0.252 secs.

The frequency of the signal after the filter would be 1/0.252 = 3.97 Hz.

Example 2:

For the PWM output to RAMP for 1 second:

Prescale = '0' (Divide by 16 => 32 KHz/16 = 2 KHz)

Increment cycles = 126

Step time = 16

RAMP instruction time can be calculated as:

Period = (1/prescale freq) x increment cycles x step time per increment

Period = (1/2000) x 126 x 16 = 1 sec.

Therefore, to get a PWM output ramp of 1 sec, we would need 1 RAMP instruction of period

1 secs.

11/22

Page 12

Registers in the PWM controller AN2424

5 Registers in the PWM controller

The main system registers to configure the PWM are as given in Ta bl e 1 5 .

Table 15. PWM controller registers

Auto-Increment

Address Register name Description

0x30 PWMCS PWM Control and Status register Yes

(during

Read/Write)

0x38 PWMIC0

0x39 PWMIC1

0x3A PWMIC2

PWM instructions for channel-0 are initialized

through this data port.

PWM instructions for channel-1 are initialized

through this data port.

PWM instructions for channel-2 are initialized

through this data port.

5.1 PWM control and status register (PWMCS)

PWMCS register is used to control the three PWM channels and also display the status of

an illegal instruction if any are given during the PWM execution. The instructions can be

written into the command memory only when the respective PWM channel is in reset state.

Figure 4. PWMCS register

Table 16. PWMCS description

No

No

No

Bits Name Description

PWM Channel 0 Enable bit.

0EN0

1EN1

2EN2

12/22

'1' - Enable the PWM Channel 0

'0' - Reset the PWM Channel 0.

PWM Channel 1 Enable bit.

'1' - Enable the PWM Channel 1

'0' - Reset the PWM Channel 1.

PWM Channel 2 Enable bit.

'1' - Enable the PWM Channel 2

'0' - Reset the PWM Channel 2.

Page 13

AN2424 Registers in the PWM controller

Table 16. PWMCS description (continued)

Bits Name Description

PWM Invalid Instruction Status bit for PWM Channel 0

'0' - No invalid command encountered during the instruction

3 II0

4 II1

5 II2

execution.

'1' - Invalid command encountered and this puts the PWM

Channel 0 into reset state.

PWM Invalid Instruction Status bit for PWM Channel 1

'0' - No invalid command encountered during the instruction

execution.

'1' - Invalid command encountered and this puts the PWM

Channel 1 into reset state.

PWM Invalid Instruction Status bit for PWM Channel 2

'0' - No invalid command encountered during the instruction

execution.

'1' - Invalid command encountered and this puts the PWM

Channel 2 into reset state.

5.2 PWM instruction channel_x (PWMICx)

This PWMICx is the dataport that allows the instructions to be loaded into the PWM

channel. The three PWM channels have unique dataport addresses and each have their

own 64 x 16 command memory.

The 'x' refers to the particular PWM Instruction channel and takes value 0,1 or 2

corresponding to the PWM channel to be used.

Figure 5. PWM instruction

Table 17. PWM instruction description

Bits Name Description

As an instruction is 16-bits wide, writing the instruction into this 8-bit

7:0 IB[x]

Using I

The I

2

C to load the Command memory:

2

C interface is used to load the instructions into the PWM command memory. This is

done by writing continuously to the respective PWM dataport. As this dataport address falls

in the non-auto increment region, continuous write operation on I

PWMICx dataport requires two 8-bit data write. The most significant byte of

the 16-bit instruction is to be written first, followed by the least significant

byte of the instruction. The same order applies to the read operation.

2

C writes into the same

dataport address.

13/22

Page 14

Registers in the PWM controller AN2424

To access these dataports, the corresponding ENx in the PWMCS register must be set to 0

first to put the PWM channel in reset state.

Only when the PWM channel is in reset state, can the stream of commands be written into

its dataport.

5.3 Alternate function register (GPAFR_U_msb)

The three PWM channels are the Alternate Functions of GPIO23-21. So to enable the

particular PWM channel, the corresponding GPAFR_U_msb bits should be set to '01'.

Figure 6. GPAFR register [Address: 0x9B]

Table 18. GPAFR description

Bits Name Description

GPIO Pin 'x' Alternate Function Select (where x = 23 to 20).

'00' - The corresponding GPIO pin (GPIO[x]) is configured to Primary

Function.

'01' - The corresponding GPIO pin (GPIO[x]) is configured to Alternate

23:16 AF[x]

Function 1.

'10' - The corresponding GPIO pin (GPIO[x]) is configured to Alternate

Function 2.

'11' - The corresponding GPIO pin (GPIO[x]) is configured to Alternate

Function 3.

5.4 Interrupt control register (ICR)

ICR register is used to configure the Interrupt Controller. It has a global enable interrupt

mask bit (IC0) that controls the interruption to the host. This bit should be set to '1' to enable

interrupts to the host. The type of interrupt and polarity can be set with the IC1 and IC2 bits.

Figure 7. ICR Register [ICR_lsb Address: 0x11]

14/22

Page 15

AN2424 Registers in the PWM controller

Table 19. ICR description

Bits Name Description

Global Interrupt Mask bit

0IC[0]

1IC[1]

2IC[2]

When this bit is set to '1', it will allow interruption to the host. If it is set to

'0', it disables all interruption to the host. Writing to this bit does not affect

the IER value.

Output Interrupt Type

'0' = Level interrupt

'1' = Edge interrupt

Output Interrupt Polarity

'0' = Active Low / Falling Edge

'1' = Active High / Rising Edge

5.5 Interrupt enable mask register (IER)

IER register should be used to enable the interruption from a particular interrupt source to

the host. In this case the PWM controller interrupt mask (IE5, IE6 and IE7) should be set to

'1' to detect the END interrupt for each PWM channel separately.

Figure 8. IER register [IER_lsb Address: 0x13]

Table 20. IER description

Bits Name Description

Interrupt Enable Mask (where x = 8 to 0)

IE0 = Wake-up Interrupt Mask

IE1 = Keypad Controller Interrupt Mask

IE2 = Keypad Controller FIFO Overflow Interrupt Mask

IE3 = Rotator Controller Interrupt Mask

8:0 IE[x]

IE4 = Rotator Controller Buffer Overflow Interrupt Mask

IE5 = PWM Channel 0 Interrupt Mask

IE6 = PWM Channel 1 Interrupt Mask

IE7 = PWM Channel 2 Interrupt Mask

IE8 = GPIO Controller Interrupt Mask

Writing a '1' to the IE[x] bit enables the interruption to the host.

5.6 Interrupt status register (ISR)

ISR register monitors the status of the interruption from a particular interrupt source to the

host. Regardless of whether the IER bits are enabled, the corresponding ISR bits are

updated. Writing a '1' clears the corresponding interrupt.

15/22

Page 16

Registers in the PWM controller AN2424

Figure 9. ISR register [ISR_lsb Address: 0x15]

Table 21. ISR description

Bits Name Description

Interrupt Status (where x = 8 to 0)

Read: IS0 = Wake-up Interrupt Status

IS1 = Keypad Controller Interrupt Status

IS2 = Keypad Controller FIFO Overflow Interrupt Status

IS3 = Rotator Controller Interrupt Status

IS4 = Rotator Controller Buffer Overflow Interrupt Status

8:0 IS[x]

IS5 = PWM Channel 0 Interrupt Status

IS6 = PWM Channel 1 Interrupt Status

IS7= PWM Channel 2 Interrupt Status

IS8 = GPIO Controller Interrupt Status

Write:

A write to a IS[x] bit with a value of '1' clears the interrupt and a write

with a value of '0' has no effect on the IS[x] bit.

5.7 Programming sequence - example

Before enabling the PWM controller operation, proper setup should be done by configuring

the clock, input and output ports involved. This is achieved by programming the following

registers.

● The Enable_PWM bit in the SYSCON register should be set to '1' to provide the

required clock signals.

● The GPIO alternate function register (GPAFR_U_msb) bits for the respective PWM

channel should be set to alternate function '01'. The unused PWM outputs can be used

as GPIO and in this case, the alternate function should be set to '00'.

● Load the instructions into the PWM channel x by writing into the corresponding

PWMICx. The ENx of the PWMCS register should be kept '0' while loading. By default,

it has a value of '0'.

● The PWM channel x has a 64-word depth (16-bit width). Any instructions of size less

than or equal to 64 words can be loaded into the channel. Any attempt to load beyond

16/22

Page 17

AN2424 Registers in the PWM controller

64 words results in internal address pointer roll-over (0x1f → 0x00) and the excess

instructions over-write the first address location of the channel and onwards.

● After loading the command memory, the instruction pointer should be reset to the

starting location (0x0) by performing a read on some other register (eg. CHIP_ID

register).

● Enable the corresponding interrupt mask bit to allow interruption to the host in IER_lsb

register.

● After the instructions are loaded in, the PWM channel x can be enabled by writing a '1'

to the ENx bit in the PWMCS register.

The pseudo-code for configuring the PWM channels is given below.

The code below triggers each PWM channel successively and the LEDs connected to each

PWM channel blinks successively one after another to create a rolling effect and this cycle is

repeated indefinitely.

/* Function prototypes */

write_data(reg_addr, number_words, data_source)

read_reg(reg_addr);

/* Address initialization */

PWM0_Addr = 0x38;

PWM1_Addr = 0x39;

PWM2_Addr = 0x3A;

/* Instructions to be downloaded into command memory in 8-bit

words*/

inst_pwm0[128];

inst_pwm1[128];

inst_pwm3[128];

/* PWM-Ch0 instructions: SMAX RAMP(DN) RAMP(UP) BRANCH SMIN TRIGCH1 WAIT-CH2 GTS */

inst_pwm0[0]=0x0; //SMAX - MSB

inst_pwm0[1]=0x7F; //SMAX - LSB

inst_pwm0[2]=0x0; //RAMP (DN) - MSB

inst_pwm0[3]=0xBF; //RAMP (DN) - LSB

inst_pwm0[4]=0x0; //RAMP (DN) - MSB

inst_pwm0[5]=0xBF; //RAMP (DN) - LSB

inst_pwm0[6]=0x0; //RAMP (DN) - MSB

17/22

Page 18

Registers in the PWM controller AN2424

inst_pwm0[7]=0xBF; //RAMP (DN) - LSB

inst_pwm0[8]=0x0; //RAMP (DN) - MSB

inst_pwm0[9]=0xBF; //RAMP (DN) - LSB

inst_pwm0[10]=0x0; //RAMP (UP) - MSB

inst_pwm0[11]=0x3F; //RAMP (UP) - LSB

inst_pwm0[12]=0x0; //RAMP (UP) - MSB

inst_pwm0[13]=0x3F; //RAMP (UP) - LSB

inst_pwm0[14]=0x00; //RAMP(UP) - MSB

inst_pwm0[15]=0x3F; //RAMP(UP) - LSB

inst_pwm0[16]=0x00; //RAMP(UP) - MSB

inst_pwm0[17]=0x3F; //RAMP(UP) - LSB

inst_pwm0[18]=0xA7; //Loop 16 times with relative address 0x8 - MSB

inst_pwm0[19]=0xC8; //Loop 16 times with relative address 0x8 - LSB

inst_pwm0[20]=0x0; //SMIN - MSB

inst_pwm0[21]=0xFF; //SMIN - LSB

inst_pwm0[22]=0xE0; //Send CH1 Trigger - MSB

inst_pwm0[23]=0x04; //Send CH1 Trigger - LSB

inst_pwm0[24]=0xE2; //Wait CH2 Trigger - MSB

inst_pwm0[25]=0x00; //Wait CH2 Trigger - LSB

inst_pwm0[26]=0x00; //GTS - MSB

inst_pwm0[27]=0x00; //GTS - LSB

/* PWM-Ch1 instructions: WAIT-CH0 SMAX RAMP(DN) RAMP(UP) BRANCH SMIN

TRIG-CH2 GTS */

inst_pwm1[0]=0xE0; //Wait for CH0 Trigger - MSB

inst_pwm1[1]=0x80; //Wait for CH0 Trigger - LSB

inst_pwm1[2]=0x0; //SMAX - MSB

inst_pwm1[3]=0x7F; //SMAX - LSB

inst_pwm1[4]=0x0; //RAMP (DN) - MSB

inst_pwm1[5]=0xBF; //RAMP (DN) - LSB

inst_pwm1[6]=0x0; //RAMP (DN) - MSB

inst_pwm1[7]=0xBF; //RAMP (DN) - LSB

inst_pwm1[8]=0x0; //RAMP (DN) - MSB

inst_pwm1[9]=0xBF; //RAMP (DN) - LSB

inst_pwm1[10]=0x0; //RAMP (DN) - MSB

18/22

Page 19

AN2424 Registers in the PWM controller

inst_pwm1[11]=0xBF; //RAMP (DN) - LSB

inst_pwm1[12]=0x0; //RAMP (UP) - MSB

inst_pwm1[13]=0x3F; //RAMP (UP) - LSB

inst_pwm1[14]=0x0; //RAMP (UP) - MSB

inst_pwm1[15]=0x3F; //RAMP (UP) - LSB

inst_pwm1[16]=0x0; //RAMP (UP) - MSB

inst_pwm1[17]=0x3F; //RAMP (UP) - LSB

inst_pwm1[18]=0x00; //RAMP(UP) - MSB

inst_pwm1[19]=0x3F; //RAMP(UP) - LSB

inst_pwm1[20]=0xAF; //Loop 16 times starting from address 0x2 - MSB

inst_pwm1[21]=0xC8; //Loop 16 times starting from address 0x2 - LSB

inst_pwm1[22]=0x0; //SMIN - MSB

inst_pwm1[23]=0xFF; //SMIN - LSB

inst_pwm1[24]=0xE0; //Send CH2 Trigger - MSB

inst_pwm1[25]=0x08; //Send CH2 Trigger - LSB

inst_pwm1[26]=0x0; //GTS - MSB

inst_pwm1[27]=0x0; //GTS - LSB

/* PWM-Ch2 instructions: WAIT-CH1 SMAX RAMP(DN) RAMP(UP) BRANCH SMIN

TRIG-CH0 GTS */

inst_pwm2[0]=0xE1; //Wait for CH1 Trigger - MSB

inst_pwm2[1]=0x00; //Wait for CH1 Trigger - LSB

inst_pwm2[2]=0x0; //SMAX - MSB

inst_pwm2[3]=0x7F; //SMAX - LSB

inst_pwm2[4]=0x0; //RAMP (DN) - MSB

inst_pwm2[5]=0xBF; //RAMP (DN) - LSB

inst_pwm2[6]=0x0; //RAMP (DN) - MSB

inst_pwm2[7]=0xBF; //RAMP (DN) - LSB

inst_pwm2[8]=0x0; //RAMP (DN) - MSB

inst_pwm2[9]=0xBF; //RAMP (DN) - LSB

inst_pwm2[10]=0x0; //RAMP (DN) - MSB

inst_pwm2[11]=0xBF; //RAMP (DN) - LSB

inst_pwm2[12]=0x0; //RAMP (UP) - MSB

inst_pwm2[13]=0x3F; //RAMP (UP) - LSB

19/22

Page 20

Registers in the PWM controller AN2424

inst_pwm2[14]=0x0; //RAMP (UP) - MSB

inst_pwm2[15]=0x3F; //RAMP (UP) - LSB

inst_pwm2[16]=0x00; //RAMP(UP) - MSB

inst_pwm2[17]=0x3F; //RAMP(UP) - LSB

inst_pwm2[18]=0x00; //RAMP(UP) - MSB

inst_pwm2[19]=0x3F; //RAMP(UP) - LSB

inst_pwm2[20]=0xB7; //Loop 16 times starting from address 0x2 - MSB

inst_pwm2[21]=0xC8; //Loop 16 times starting from address 0x2 - LSB

inst_pwm2[22]=0x0; //SMIN - MSB

inst_pwm2[23]=0xFF; //SMIN - LSB

inst_pwm2[24]=0xE0; //Send CH0 Trigger - MSB

inst_pwm2[25]=0x02; //Send CH0 Trigger - LSB

inst_pwm2[26]=0x0; //GTS - MSB

inst_pwm2[27]=0x0; //GTS - LSB

/* Load instructions into the PWMIC_x */

write_data(PWM0_Addr, 28, inst_pwm0); //Write into PWM-0 memory

read_reg(CHIP_ID_ADDR); //To reset the internal

pointer to 0x0

write_data(PWM1_Addr, 28, inst_pwm1); //Write into PWM-1 register

rad_reg(CHIP_ID_ADDR); //To reset the internal pointer to 0x0

write_data(PWM2_Addr, 28, inst_pwm2); //Write into PWM-3 register

read_reg(CHIP_ID_ADDR); //To reset the internal pointer to 0x0

/* Configure Alternate Function to PWM mode for all 3 PWM channels

*/

write_reg(0x9B,0x54);

/* Enable all three PWM Channels */

write_reg(0x30,0x7);

/* Disable PWM Channels and change Alternate functions back to GPIO

*/

20/22

Page 21

AN2424 Conclusion

write_reg(0x30,0x0);

write_reg(0x9B,0x0);

To further reduce power consumption, the clock signals to PWM module can be cut off by

setting the Enable_PWM bit in the SYSCON register to '0'.

6 Conclusion

The PWM controller integrated into the STMPE2401 packs a powerful instruction set which

can be used to control LED brightness, Blinking/display patterns and save CPU resources

by controlling the display panel independently of the CPU with pre-loaded instructions. The

interface to the CPU is also simple through just 2 wires of the I

STMPE2401 serves as a powerful device to save power and CPU resources in digital

engines.

2

C interface. This way

7 Reference

● AN2422: STMPE2401 GPIO port expander Hardware Interface guide.

8 Revision history

Table 22. Revision history

Date Revision Changes

04-Apr-2007 1 Initial release.

21/22

Page 22

AN2424

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZED ST REPRESENTATIVE, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2007 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

22/22

Loading...

Loading...