Page 1

AN2419

Application note

STR75x hardware development

getting started

Introduction

This application note is intended for system designers who require a hardware

implementation overview of the development board features such as the power supply, the

clock management, the reset control, the boot mode settings and the debug management. It

shows how to use the STR75x product family and describes the minimum hardware

resources required to develop an STR75x application.

Detailed reference design schematics are also contained in this document with descriptions

of the main components, interfaces and modes.

July 2007 Rev 2 1/22

www.st.com

Page 2

Contents AN2419

Contents

1 Power supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.2 Power supply schemes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.2.1 Power scheme 1: single external 3.3V power source . . . . . . . . . . . . . . . 4

1.2.2 Power scheme 2: dual external 3.3V and 1.8V power sources . . . . . . . . 5

1.2.3 Power scheme 3: single external 5V power source . . . . . . . . . . . . . . . . . 6

1.2.4 Power scheme 4: dual external 5.0V and 1.8V power sources . . . . . . . . 7

1.3 Reset and power startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.3.1 Power startup specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.3.2 External reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2 Clocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.1 Clock overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.2 Main 4MHz or 8MHz oscillator (OSC4M) . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.3 Low power 32.768 kHz oscillator (OSC32K) . . . . . . . . . . . . . . . . . . . . . . 11

2.4 USB clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.5 PLL, FREEOSC, and AHB/APB prescalers . . . . . . . . . . . . . . . . . . . . . . . 12

2.6 Clock-out capability: MCO (Main Clock Output) . . . . . . . . . . . . . . . . . . . . 13

2.7 Clock detector (CKD) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3 Boot configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.1 Embedded boot loader mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.2 External memory (SMI) boot mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4 Debug management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.1 ICE debug tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.2 JTAG / ICE connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5 Reference design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.1 Main . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.1.1 Clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.1.2 Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.1.3 Boot mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2/22

Page 3

AN2419 Contents

5.2 JTAG interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6 Schematics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

7 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3/22

Page 4

Power supplies AN2419

1 Power supplies

1.1 Introduction

The device has five power pins:

● V

STANDBY mode.

● V

SRAM and Flash: 1.8V ± 0.15V.

● V

Two embedded regulators are available to supply the internal 1.8V digital power:

V

and V

18

The Main Voltage Regulator (MVREG) supplies V

of 1.8V ± 0.15V.

: power supply for I/Os (3.3V ±0.3V or 5V ±0.5V). Must be kept on, even in

DD_IO

(pins V

18

: Backup Power Supply for STANDBY or STOP Mode

18_BKP

18_BKP

and V18 which are internally shorted): Power Supply for Digital,

18REG

are normally generated internally by these regulators.

18

and V

. It delivers a power supply

18_BKP

The Low Power Voltage Regulator (LPVREG) can supply V

18_BKP

STANDBY mode. It delivers a power supply of around 1.4V.

Two sensitive analog blocks have dedicated power pins:

● V

● V

DDA_PLL

DDA_ADC

: Analog Power supply for PLL (must have the same voltage level as V

: Analog Power supply for ADC (must have the same voltage level as V

1.2 Power supply schemes

The device can be connected in any of the following configurations depending on your

application requirements:

● Power Scheme 1: Single external 3.3V power source

● Power Scheme 2: Dual external 3.3V and 1.8V power sources

● Power Scheme 3: Single external 5.0V power source

● Power Scheme 4: Dual external 5.0V and 1.8V power sources

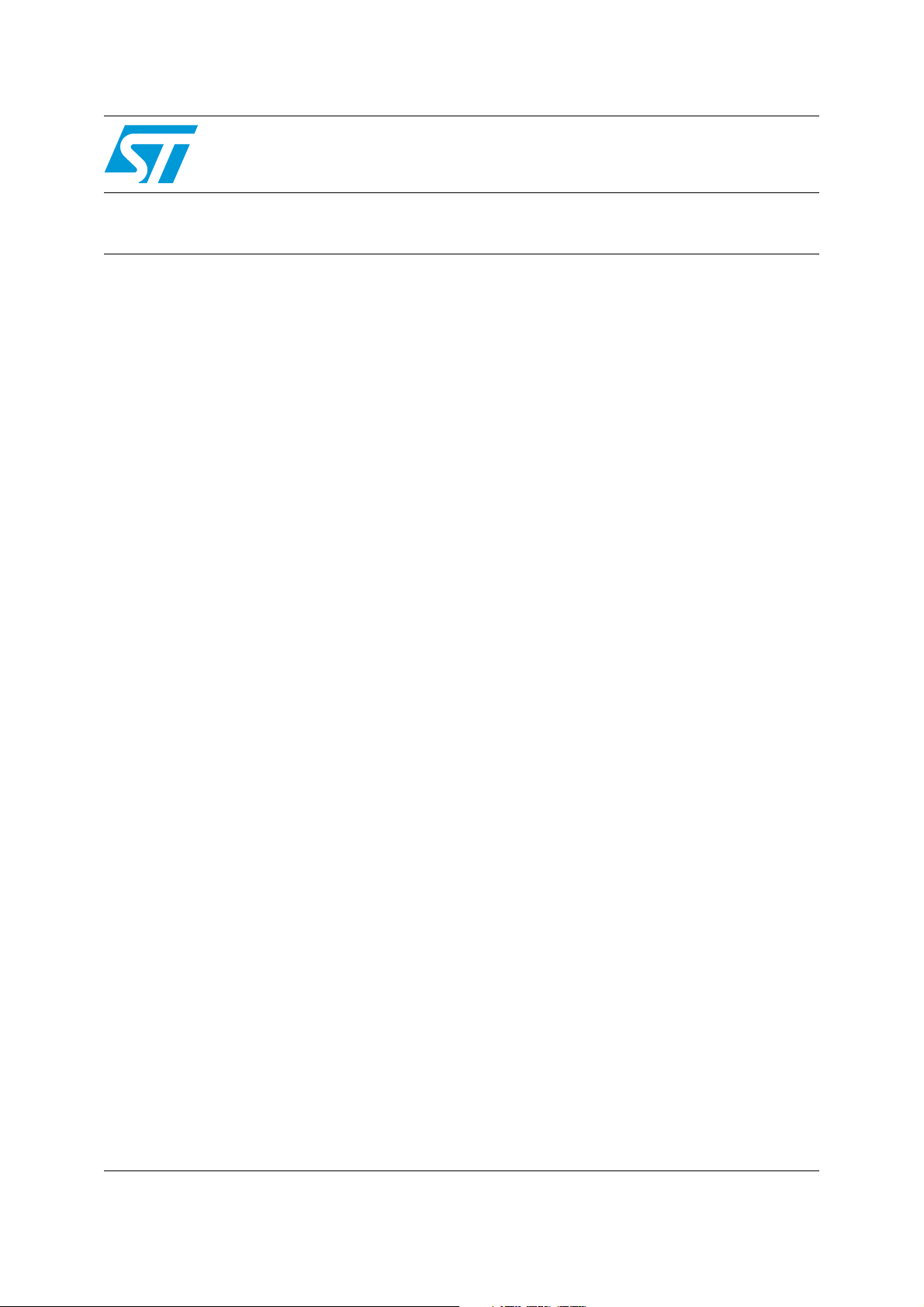

1.2.1 Power scheme 1: single external 3.3V power source

In this configuration, the internal voltage regulators are switched on by forcing the

VREG_DIS pin to low level.

● The V

Tantalum, low series resistance).

● The V

● The V

● A decoupling capacitor of 1µF must be added on the V

V

18REG

pin must be connected to external stabilization capacitors (min. 10 uF

18REG

pin must be connected to external stabilization capacitors (33nF ceramic).

18

pin must be connected to an external stabilization capacitor of 1µF.

18_BKP

DD_IO

pin.

or V18 in STOP or

DD_IO

DD_IO

pin which is closest to the

)

)

4/22

Page 5

AN2419 Power supplies

Figure 1. Power supply scheme 1 (single 3.3V supply, VREGDIS=0) in NORMAL mode

STR750

+3.3V

+3.3V

+3.3V

1µF

1µF

33nF

10µF

V

18_BKP

V

SS_BKP

VREG_DIS

V

18

V

SS18

V

18REG

V

SS18

V

DD_PLL

V

SS_PLL

V

DD_ADC

V

SS_ADC

V

DD_IO

V

SS_IO

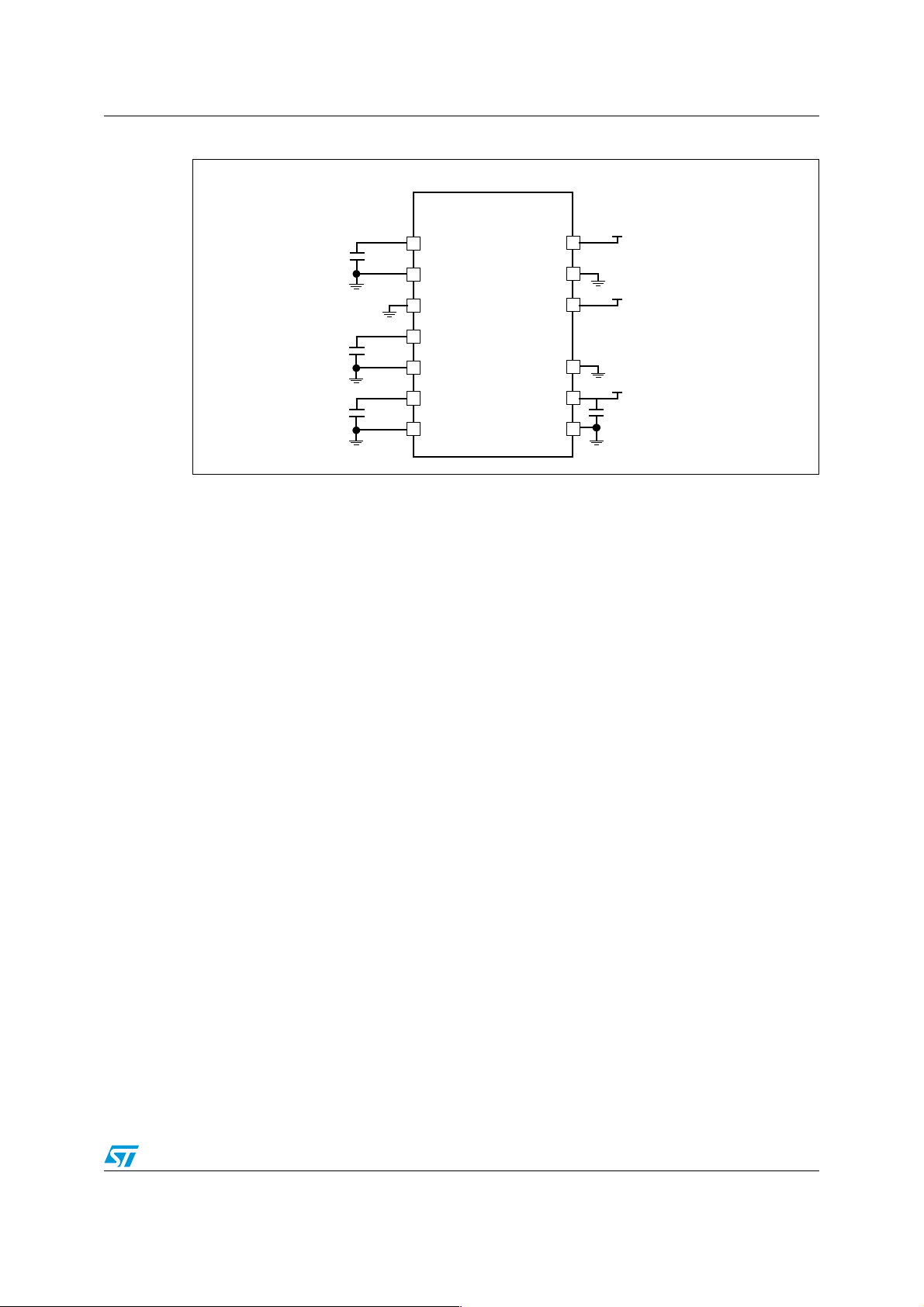

1.2.2 Power scheme 2: dual external 3.3V and 1.8V power sources

In this configuration, the internal voltage regulators are switched off by forcing the

VREG_DIS pin to high level. This scheme has the advantage of saving power consumption

when the 1.8V power supply is already available in the application. V

provided externally through the V

● The external 3.3V power supply must always be kept on.

● VREG_DIS pin is tied to high level which disables the Main Voltage Regulator and

18REG

, V18 and V

18_BKP

power pins.

the Low Power Voltage Regulator.

18

and V

18_BKP

are

Caution: When powered by 5.0V, the USB peripheral cannot operate.

● All digital power pins (V

18REG

, V18 and V

) must be externally shorted to the

18_BKP

same 1.8V power supply source.

● In this scheme, STANDBY Mode is not available.

5/22

Page 6

Power supplies AN2419

Figure 2. Power supply scheme 2 (3.3V and 1.8V supplies, VREGDIS=1)

STR750

V

V

18_BKP

V

+3.3V

+1.8V

+1.8V

NOTE : THE EXTERNAL 3.3V POWER SUPPLY MUST ALWAYS BE KEPT ON

SS_BKP

VREG_DIS

V

18

V

SS18

V

18REG

V

SS18

DD_PLL

V

SS_PLL

V

DD_ADC

V

SS_ADC

V

DD_IO

V

SS_IO

+3.3V+1.8V

+3.3V

+3.3V

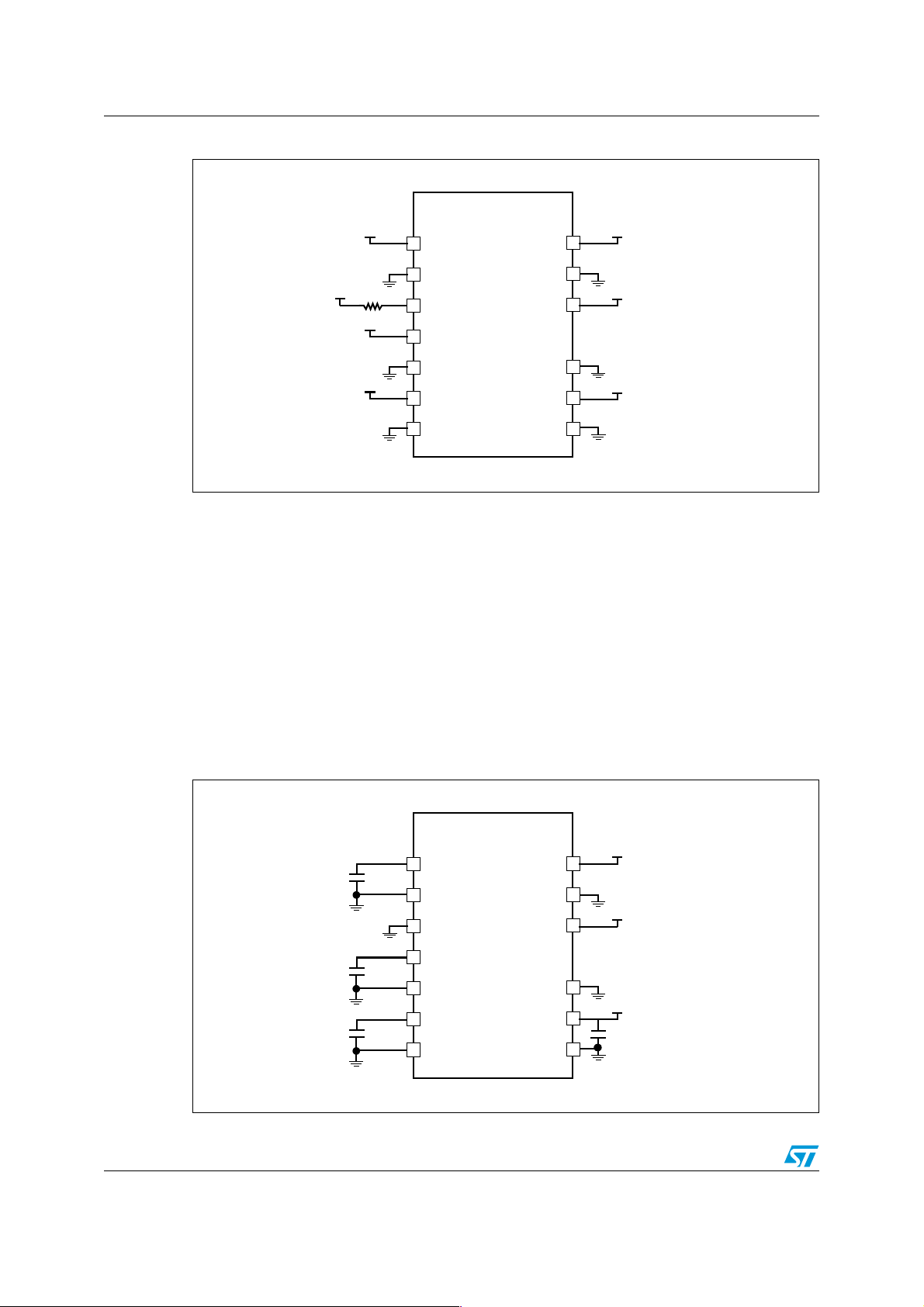

1.2.3 Power scheme 3: single external 5V power source

In this configuration, the internal voltage regulators are switched on by forcing the

VREG_DIS pin to low level.

● The V

pin must be connected to external stabilization capacitors (min. 10 uF

18REG

Tantalum, low series resistance).

● The V

● The V

● A decoupling capacitor of 1µF must be added on the V

V

pin must be connected to external stabilization capacitors (33nF ceramic).

18

pin must be connected to an external stabilization capacitor of 1µF.

18_BKP

DD_IO

pin.

18REG

Caution: When powered by 5.0V, the USB peripheral cannot operate.

Figure 3. Power supply scheme 3(single 5V supply, VREGDIS=0) in NORMAL mode

STR750

+5V

+5V

+5V

1µF

1µF

33nF

10µF

V

18_BKP

V

SS_BKP

VREG_DIS

V

18

V

SS18

V

18REG

V

SS18

V

DD_PLL

V

SS_PLL

V

DD_ADC

V

SS_ADC

V

DD_IO

V

SS_IO

pin which is closest to the

6/22

Page 7

AN2419 Power supplies

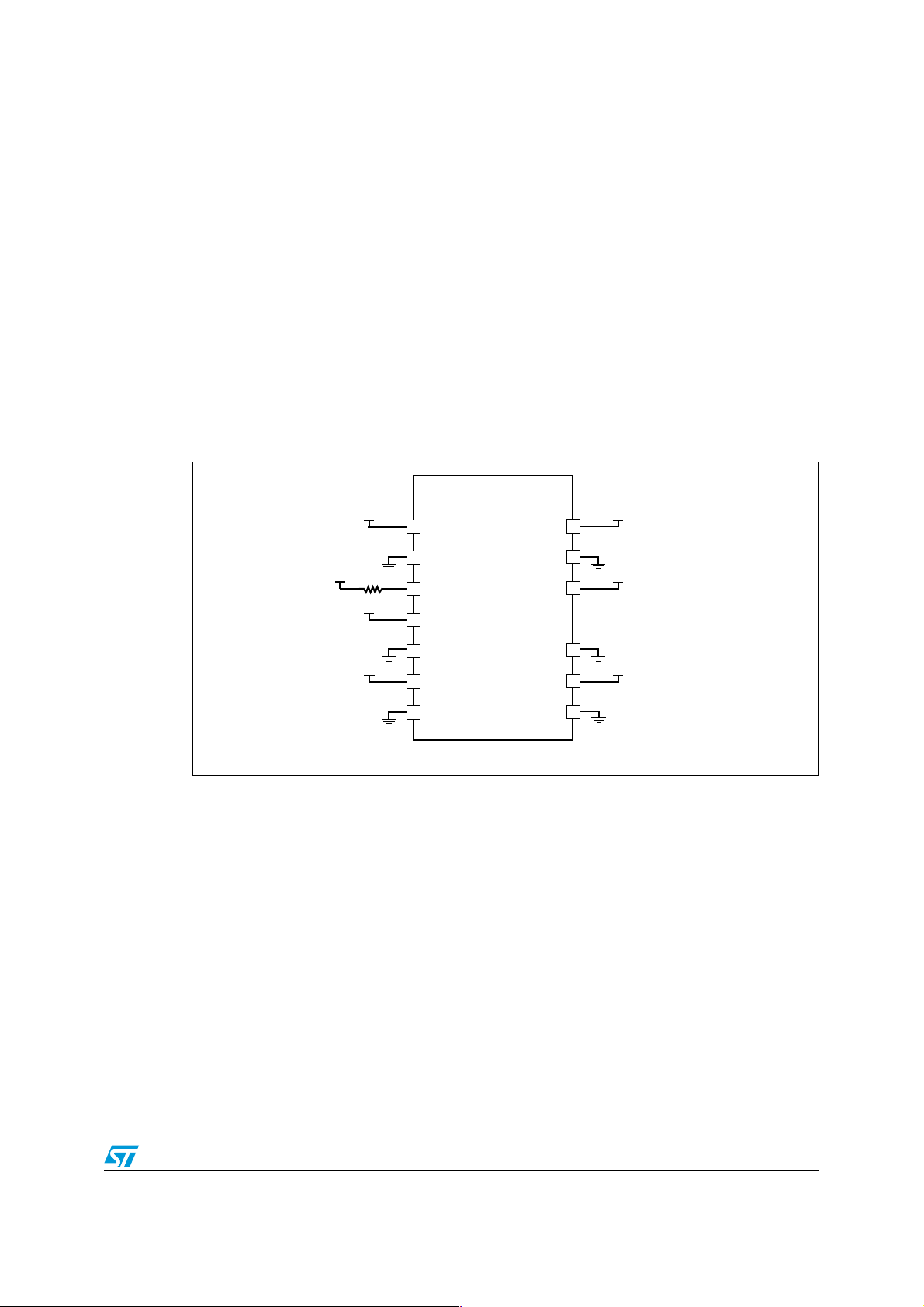

1.2.4 Power scheme 4: dual external 5.0V and 1.8V power sources

In this configuration, the internal voltage regulators are switched off, by forcing the

VREG_DIS pin to high level. This scheme has the advantage of saving power consumption

when the 1.8V power supply is already available in the application and providing 5V I/O

capability. V

power pins.

● VREG_DIS pin is tied to high level which disables the Main Voltage Regulator and the

Low Power Voltage Regulator.

● All digital power pins (V

same 1.8V power supply source.

In this scheme:

● STANDBY Mode is not available

● USB functionality is not available

Figure 4. Power supply scheme 4 (5.0V and 1.8V supplies, VREGDIS=1)

18

and V

18_BKP

+5.0V

are provided externally through the V

18REG

, V18 and V

) must be externally shorted to the

18_BKP

STR750

+1.8V

+1.8V

+1.8V

V

18_BKP

V

SS_BKP

VREG_DIS

V

18

V

SS18

V

18REG

V

SS18

V

DD_PLL

V

SS_PLL

V

DD_ADC

V

SS_ADC

V

DD_IO

V

SS_IO

+5.0V

+5.0V

+5.0V

18REG

, V18 and V

18_BKP

NOTE : THE EXTERNAL 5.0V POWER SUPPLY MUST ALWAYS BE KEPT ON

1.3 Reset and power startup

1.3.1 Power startup specifications

To ensure the MCU starts-up cleanly, the rise time of the V

comprised between 20µs/V and 20ms/V.

In addition, you must provide an external RESET for at least 20µs after the V

supply has reached its minimum working value (3.0V). It is recommended to use an external

Power-On-Reset circuit monitoring V

During V

state, assuming external RESET is asserted.

If you are using an external 1.8V power supply, the rise time of power supply V

comprised between 20µs/V and 20ms/V.

power-up (from 0V to 3.3V or 5.0V), all I/Os are guaranteed to be in HiZ

DD_IO

power supply must be

DD_IO

power

DD_IO

to assert the RESET at power-up .

DD_IO

must be

18

7/22

Page 8

Power supplies AN2419

1.3.2 External reset

The NRSTIN pin acts as an asynchronous RESET active low.

The NRSTIN pad input is a Schmitt Trigger input pin. A filter is added to ignore all incoming

pulses with short duration:

● All negative spikes with a duration less than 150ns are filtered.

● All trains of negative spikes with a ratio of 1/2 are filtered. This means that all spikes

with a maximum duration of 150ns with minimum interval between spikes of 75ns are

filtered.

● An internal pull up is connected on each of the pins NRSTIN and NRSTOUT.

An external reset circuit can be connected (STM1818) to manage the reset signal: both for

power-on reset during startup and management of the reset button (debounce functionality

and pulse duration control).

Figure 5. Reset circuit

EXTERNAL

V

DD

RESET

V

CC

V

SS

STM1818

STM1813*

* use STM1818TWX7F if VDD=3.3V

use STM1813LWX7F if VDD=5.0V

STR750

RST

NRSTIN

NRSTOUT

V

V

DD_IO

R

DD_IO

PU

R

PU

The NRSTOUT pin is an exact image of the system Reset signal (active low) provided to the

device which is used to generate the reset of the AHB System and the reset of each APB

peripherals. Internal circuitry guarantees a minimum reset pulse duration of 20µs.

Some peripheral registers, like the RTC or the BACKUP registers are not reset by a System

Reset but only by an RSM Reset: this means that these registers are only reset at VDD

power up. For more details see the Reference manual UM0191.

8/22

Page 9

AN2419 Clocks

2 Clocks

2.1 Clock overview

Figure 6. Clock overview

XT1

XT2

XRTC1

XRTC2

USB_CK

PLL

FREEOSC

OSC4M

OSC32K

LPOSC

4MHz

CLOCK

DETECTOR

/128

32kHz

300kHz

PLL

1-10 MHz

UP TO 64 MHz

48 MHz

CKD FLAG

CKD FLAG

RTC

HCLK

CK_SYS

ALARM

WAKEUP

For further details see the Reference manual UM0191.

AHB & APB

DIVIDERS

UP TO 64MHz

PCLK

UP TO 32MHz

CK_TIM

UP TO 64MHz

CK_USB

48 MHz

Several on-chip oscillators can feed the MCU system clock (CK_SYS) from which the HCLK

and PCLK derive:

● FREEOSC: Internal Free Running Oscillator providing a clock between 1 and 10MHz,

also used as emergency clock. It consists of the internal VCO of the PLL configured in

free running mode

● OSC4M: 4MHz or 8MHz Main Oscillator (Crystal or Ceramic oscillator or external

clock)

– a 4 MHz Crystal/Ceramic oscillator connected to XT1/XT2

– or an 8 MHz Crystal/Ceramic oscillator to XT1/XT2 followed by a divider by 2

– or external clock connected to XT1

● OSC32K: 32.768kHz Oscillator (Crystal or Ceramic oscillator) which can drive either

the system clock and/or the RTC.

● LPOSC: Internal Low Power RC Oscillator providing a clock around 300kHz which can

drive either the system clock and/or the RTC.

Several configurable dividers provide a high degree of flexibility to the application in the

choice of the APB or AHB frequency, while keeping a fixed frequency value for the USB

clock (48 MHz).

9/22

Page 10

Clocks AN2419

The Clock Detector (CKD) protects the Microcontroller against OSC4M or external clock

failures.

The RTC provides calender, alarm and wake-up functions and can be clocked by any of the

oscillators other than FREEOSC.

Caution: The FREEOSC and PLL are reset during the whole assertion of System RESET. After reset

release, the PLL is disabled and FREEOSC supplies the system clock (1-10 MHz).

2.2 Main 4MHz or 8MHz oscillator (OSC4M)

XT1 and XT2 pins are used to connect the Main Oscillator source, which can be a resonator

(crystal or ceramic) or an external source. Both sources can be used as the input clock to

PLL frequency multiplier (PLL).

Crystal or ceramic resonator

This 4 MHz oscillator (OSC4M) has the advantage of producing a very accurate rate on the

main clock. This oscillator can be directly connected to

● a 4 MHz Oscillator

● or an 8 MHz Oscillator followed by an internal divider by 2.

If an 8 MHz Crystal or Ceramic is connected, You must select the divider by 2

The associated hardware configuration are shown in Figure 7. Refer to the electrical

characteristics section of the datasheet for more details.

Figure 7. Clock sources

Hardware Configuration

STR7

XT1 XT2

(HiZ)

External ClockCrystal/Ceramic Resonators

EXTERNAL

SOURCE

STR7

XT1 XT2

C

L1

LOAD

CAPACITORS

C

L2

The resonator and the load capacitors have to be placed as close as possible to the

oscillator pins in order to minimize output distortion and start-up stabilization time. The

loading capacitance values must be adjusted according to the selected oscillator.

10/22

Page 11

AN2419 Clocks

External Source (Bypass Mode)

In this mode, an external clock source must be provided. The external clock signal (square,

sinus or triangle) with ~50% duty cycle has to drive the XT1 pin while the XT2 pin should be

left hi-Z.

2.3 Low power 32.768 kHz oscillator (OSC32K)

XRTC1 and XRTC2 pins are used to connect the 32k Oscillator source, which can be a

resonator (crystal or ceramic).The OSC32k clock can be used as a low power system clock

Figure 8. Clock sources

Hardware Configuration

STR7

XRTC1 XRTC2

Crystal/Ceramic Resonators

The resonator and the load capacitors have to be placed as close as possible to the

oscillator pins in order to minimize output distortion and start-up stabilization time. The

loading capacitance values must be adjusted according to the selected oscillator.

2.4 USB clock

STR75x series microcontrollers contain a USB 2.0 Full Speed device module interface that

operates at a precise frequency of 48 MHz. This clock is usually generated by the internal

PLL using one single external oscillator for both the system and USB module to save board

space and cost. However, if the chosen system clock is not compatible with the 48 MHz

clock generation (frequency below 48 MHz), the USB clock can also provided by an external

oscillator connected to the USB clock pin USBCLK.

The following diagram shows the basic implementation of the USB external clock.

Figure 9. USB clock oscillator

3V3

OSCILLATOR

48MHz

C

L1

LOAD

CAPACITORS

STR75x

C

L2

OSC_OUT

USB_CK

VSS

11/22

Page 12

Clocks AN2419

2.5 PLL, FREEOSC, and AHB/APB prescalers

Figure 10. PLL, FREEOSC & AHB/APB prescaler scheme

OSC4M

4MHz

CK_OSC4M

FREEOSC

PLL

LOCK

PLLEN

MX[1:0]

RANGE

PLLEN

NCKDF

1-10MHz

UP TO 64MHz

48MHz

CK_RTC

CK_OSC4M

1

0

CKOSCSEL

1

0

CK_PLL1

UP TO 64MHz

CK_PLL2

48MHz

4MHz

CKSEL

1

0

CK_SYS

HPRESC[1:0]

AHB PRESC

/1,2,4 or 8

PPRESC[1:0]

APB PRESC

/1,2,4 or 8

PPRESC[2]

1

/2

0

HCLK

UP TO 64MHz

PCLK

UP TO 32MHz

CK_TIM

UP TO 64MHz

USB_CK

48MHz

The CPU can execute:

● the SRAM up to 64 MHz at zero wait state.

● the Flash up to 60 MHz speed in burst mode (zero wait state for consecutive accesses,

1 wait state for any non-consecutive access)

● the Flash up to 32 MHz at zero wait state

The PLL provides a Frequency Multiplier starting from a single input clock (OSC4M source)

and providing the 2 following independent output clocks:

● CK_PLL1 output with 4 programmable multiplication factors (up to 64 MHz) used for

generating CK_SYS

● CK_PLL2 output with fixed 48 MHz frequency when input clock is 4 MHz used for

generating CK_USB

FREEOSC provides a Free Running Oscillator for the system clock: this clock is selected

when:

● The PLL is disabled: FREEOSC acts as an oscillator source

● The clock failure flag is active: FREEOSC acts as an emergency clock source.

For security, hardware prevents the software from making certain unrecoverable errors:

● Software cannot switch CK_SYS to CK_PLL1 (multiplied clock output) until the PLL is

locked.

● CK_USB is gated until the software enables the PLL2EN bit in the MRCC_CLKCTL

register.

12/22

Page 13

AN2419 Clocks

The AHB and APB prescalers allow you to choose the AHB and APB frequencies from a

wide range of possibilities:

● HCLK (AHB Clock) can be generated from CK_SYS divided by 1, 2, 4 or 8

● PCLK (APB Clock) can be generated from HCLK divided by 1, 2, 4, 8 or 16

The clock provided to the Timers (CK_TIM) can have twice or the same frequency as PCLK.

This allows the timers to count at high frequency (up to 64MHz)

Ta bl e 1 gives some typical clock configurations:

Table 1. Typical prescaler uses

f

OSC4M

(MHz)

PLL

Factor

f

CK_SYS

(MHz)

HPRESC

[1:0]

f

HCLK

(MHz)

PPRESC

[1:0]

f

CK_TIM

(MHz)

PPRESC2

f

PCLK

(MHz)

f

CK_USB

(MHz)

x16 64 00 64

00 64

01 32 16

x15 60 00 60 00 60 30

4

x14 56 00 56 00 56 28

x12 48 00 48 00 48 24

x16 64 01 32 00 32 16

The software must respect the configuration constraints of the PLL.

2.6 Clock-out capability: MCO (Main Clock Output)

The Main Clock Output (MCO) capability allows you to output a clock on the external MCO

pin. The configuration registers of corresponding GPIO port must programmed in alternate

function mode. You can select one of 4 clock signals as MCO clock.

● CK_PLL2

● HCLK

● PCLK

● CK_OSC4M

The selection is controlled by the MCOS[1:0] bits of CLKCTL register. A dedicated prescaler

(divide by 1 or 2, selected by MCOP bit) can be applied to this clock before outputting it to

the MCO pin. Care must be taken when switching MCO clock selection, the alternate

function should be disabled to avoid any glitches on the MCO pin.

32

1

48

2.7 Clock detector (CKD)

A CKD (Clock Detector) is implemented to:

● detect if no clock is present on OSC4M (broken or disconnected resonator) and prevent

the software from selecting it.

● automatically feeds the MCU with the FREEOSC used as emergency clock if no clock

is detected.

● generate an interrupt if enabled, allowing the MCU to perform some rescue operations

For more detail see the Reference Manual (UM0191).

13/22

Page 14

Boot configuration AN2419

3 Boot configuration

In the STR750, 4 different boot modes can be selected by means of the BOOT[1:0] pins as

shown in Ta bl e 2 .

Table 2. Boot modes

BOOT Mode

Selection Pins

BOOT1 BOOT0

Boot Mode Aliasing Note

0 0 Embedded Flash

1 0 Embedded SRAM

0 1 SystemMemory

11

External SMI Serial Flash

memory

Embedded FLASH sector

B0F0 mapped at 0h

Embedded SRAM mapped

at 0h

SystemMemory mapped

at 0h

SMI Bank 0 mapped at 0h -

All FLASH sectors

accessible except

SystemMemory

sector

-

Figure 11. Boot mode selection implementation example

STR75x

3V3

* these values are given only as typical example

10K*

3V3

10K*

BOOT0

BOOT1

TEST

GND

This aliases the physical memory associated with each boot mode to Block 000 (boot

memory).The value of the BOOT pin is latched on the 4th rising edge of CK_SYS after

Reset.

It is up to the user to manage the BOOT1 and BOOT0 pins at reset release to select the

required boot mode. Note that the user should also manage these pins when exiting

Standby mode as the BOOT pins are resampled.

Even when aliased in the boot memory space, the related memory (FLASH, SRAM or SMI)

is still accessible at its original memory space.

After this start-up delay has elapsed, the ARM CPU will start code execution from the boot

memory space, located at the bottom of the memory space starting from 0x0000_0000h.

The application can read the status of the boot pins that was latched at start-up and change

the memory aliasing on-the-fly by modifying the SW_BOOT bits in the CFG_GLCONF

register.

Caution: The TEST pin of the STR75x must always be forced to ground (ST reserved test pin)

14/22

Page 15

AN2419 Boot configuration

3.1 Embedded boot loader mode

Embedded Boot Loader Mode is used to re-program the FLASH using one of the serial

interfaces (typically a UART). This program, called, ICP boot loader, is located in the

SystemMemory and is programmed by ST during production.

Refer to the STR7 Family Flash Programming Reference Manual for details.

3.2 External memory (SMI) boot mode

When SMI boot mode is selected the Serial Memory Interface is automatically configured as

follows:

● Chip Select Polarity = low

● SMI bank 0 is selected and the associated I/O alternate functions are enabled.

● Boot Space (0000_0000h to 00FF_FFFFh -16MB) is aliased to SMI bank 0.

● The SMI is configured as NORMAL READ MODE (reset value)

● The SMI_PRESCALER is set to “2” (reset value)

Programming considerations when booting from SMI

After RESET, the PLL is disabled and both CK_SYS and HCLK are clocked by the internal

FREEOSC oscillator (1-10MHz). Consequently, the SMI clock output is also between 0.5

and 5MHz (SMI_PRESCALER reset state is 2). To use a higher frequency, software has to

configure the clock and PLLs.

Care is needed if the program performing the PLL and clock configuration is executed

directly from serial memory. The software must ensure that a proper clock frequency is

provided to the serial memory when changing the SMI_PRESCALER and switching the

system clock. That is why the SMI_PRESCALER must be changed first before switching the

system clock to the PLL output clock.

For example, to use the SMI in NORMAL READ MODE with a 60 MHz HCLK frequency, set

the SMI_PRESCALER to 4 before switching HCLK to 60 MHz. The SMI clock frequency is

then 60 MHz / 4 = 15 MHz.

It is possible to obtain the highest SMI frequency using the FAST READ MODE, if the serial

memory supports this mode. For instance, f

can be set to 48 MHz and the

HCLK

SMI_PRESCALER can be be loaded to "1" to address a high speed Serial Memory at 48

MHz (for read only).

Note: Make sure that the SMI clock frequency (resulting from of your AHB clock and

SMI_PRESCALER settings) does not exceed the maximum allowed value. The maximum

frequency of the SMI is limited by the I/O speed.

Take care to load the SMI_PRESCALER and the FAST_READ mode with the same write

transaction. This can be done by a program which is executed from the serial Flash. In this

case, the SMI will change the clock and the READ MODE only at the end of this access. For

more details refer to the Reference Manual.

15/22

Page 16

Debug management AN2419

4 Debug management

The Host/Target interface is the hardware equipment that connects the Host to the

application board. This interface is made of three components: a hardware debug tool, such

as Micro-ICE from ARM, a JTAG connector and a cable connecting the host to the debug

tool.

Figure 12 shows the connection of the host to the STR75x board.

Figure 12. Host to board connection

ICE Debug tool

ICE connector

HOST PC

4.1 ICE debug tool

ICE Debug tool is a host interface that connects a PC to an STR75x development board

featuring a debug interface as shown in Figure 12. The Embedded ICE is an intelligent host

interface that provides fast access to host services, access to on-chip emulation and debug

facilities. When the STR75x board is configured as a stand-alone system, the ICE Debug

tool can be used to download programs.

The STR75x development kit supports the ARM RealView ICE Micro Edition. The Micro-ICE

is plugged in to the host via a USB cable.

4.2 JTAG / ICE connector

The ICE connector enables JTAG hardware debugging equipment, such as RealView-ICE,

to be connected to the STR75x board. It is possible to both drive and sense the systemreset line, and to then send a JTAG reset to the core through the ICE connector. Figure 13

shows the ARM ICE connector pin-out.

The STR75x has a user debug interface. This interface contains a five-pin serial interface

conforming to JTAG, IEEE standard 1149.1-1993, “Standard Test Access Port-Scan

Boundary Architecture”. JTAG allows the ICE device to be plugged to the board and used to

debug the software running on the STR75x.

STR75x EVAL

Power

Supply

JTAG emulation allows the core to be started and stopped under the control of the

connected debugger software. The user can then display and modify registers and memory

contents, and set break and watch points.

16/22

Page 17

AN2419 Debug management

Figure 13. Ice connector implementation

3V3

3V3

STR75x

3V3

10K*10K*

nJTRST

JTDI

JTMS

JTCK

RTCK

JTDO

NRSTIN

10K*

* these values are given only as typical examples

J4

See

Note 1

3V3

Note: 1 The JTAG reset pin (nJTRST) is a dedicated pin:

When JTAG communication is used on the application board, nJTRST must be connected to

a pull-up. However, it is mandatory to apply one negative pulse on nJTRST pin after powerup otherwise the MCU may enter unexpected test modes. For instance, nJTSRT can be

connected to the system reset which is pulled-up.

When JTAG communication is not used on the application board, nJTRST can be connected

to the system reset or it can be also indefinitely grounded.

10K*

10K*

10K*

3V3

10K*

10K*

3V3

JTAG Connector CN9

CONN_2*10

(1)

VTref

(3) nTRST

(5) TDI

(7) TMS

(9) TCK

(11) RTCK

(13) TDO

(15) nSRST

(17) DBGRQ

(19) DBGACK

10K*

3V3

(2)

(4)

(6)

(8)

(10)

(12)

(14)

(16)

(18)

(20)

GND

Caution: When the internal Flash is readout protected, the Flash will not execute if nJRST is not

continuously reset because it is considered as an intrusion. Consequently, in this case, it is

mandatory that the nJRST pin sees a continuous low level after reset when the user

application is running.

17/22

Page 18

Debug management AN2419

Table 3. JTAG connector pins

Std

Name

STR75x Description Function

nTRST JTRST

TDI JTDI

TMS JTMS

TCK JTCK

RTCK RTCK

TDO JTDO

nSRST NRSTIN

Test Reset

(from JTAG

equipment)

Test data in

(from JTAG

equipment)

Test mode

select (from

JTAG

equipment)

Test clock (from

JTAG

equipment)

Return TCK (to

JTAG

equipment)

Test data out

(to JTAG

equipment)

System reset

(bidirectional)

This active LOW open-collector is used to reset the JTAG

port and the associated debug circuitry. It is asserted at

power-up by each module, and can be driven by the JTAG

equipment.

TDI goes down the stack of modules to the motherboard

and then back up the stack, labelled TDO, connecting to

each component in the scan chain.

TMS controls transitions in the tap controller state machine.

TMS connects to all JTAG components in the scan chain as

the signal flows down the module stack.

TCK synchronizes all JTAG transactions. TCK connects to

all JTAG components in the scan chain. Series termination

resistors are used to reduce reflections and maintain good

signal integrity. TCK flows down the stack of modules and

connects to each JTAG component. However, if there is a

device in the scan chain that synchronizes TCK to some

other clock, then all down-stream devices are connected to

the RTCK signal on that component.

Using a mechanism called adaptive clocking, the RTCK

signal is returned by the core to the JTAG equipment, and

the clock is not advanced until the core had captured the

data. In adaptive clocking mode, the debugging equipment

waits for an edge on RTCK before changing TCK.

TDO is the return path of the data input signal TDI.

nSRST is an active LOW open-collector signal that can be

driven by the JTAG equipment to reset the target board.

Some JTAG equipment senses this line to determine when

a board has been reset by the user.

When the signal is driven LOW by the reset controller on the

core module, the motherboard resets the whole system by

driving nSYSRST low.

For more details on the JTAG port refer to the IEEE standard 1149.1-1993, “Standard Test

Access Port-Scan Boundary Architecture” specification.

18/22

Page 19

AN2419 Reference design

5 Reference design

5.1 Main

This reference design is based on the STR750, a highly integrated microcontroller, running

at 64MHz that combines the popular ARM7TDMI-S

embedded Flash, 16Kbytes of high speed SRAM

5.1.1 Clock

Two clock sources are used for the microcontroller.

● X1-32 kHz crystal for embedded RTC

● X2-4 MHz crystal for STR750Fx microcontroller

5.1.2 Reset

The reset signal on this STR750-REF schematic is active low.

The reset sources include:

● Power On Reset from STM1818 (U2)

● Reset button (PB1)

● Debugging tools via the connector CN1

5.1.3 Boot mode

The STR750 is able to boot from:

● Embedded User Flash

● Embedded SRAM for debugging

● System memory with boot loader for ISP

● External SPI Interface Flash

TM

32-bit RISC CPU with 256 Kbytes of

.

The boot option is configured by setting switches SW1 (Boot 0) and SW2 (Boot 1).

5.2 JTAG interface

Refer to the section Section 4: Debug management on page 16.

19/22

Page 20

Schematics AN2419

6 Schematics

Figure 14. STR750F microcontroller connections

4

+3V3

3

1

SW1

2

R1

10K

P002

P001P101

P003

P004

P000

79

4

3

2

100

3

TIM2_TI1/P0.03

TIM2_OC1/P0.02

MCO/TIM0_TI1/P0.01

BOOT0/TIM0_OC1/P0.00

TIM2_TI2/P1.03

TIM2_OC2/P1.0268PWM_EMERG/P1.10

TIM0_TI2/P1.01

TIM0_OC2/P1.00

U1

67

91

94

95

2

P102

P103

P104

P100

+3V3+3V3

10KR310KR410KR510KR610KR810K

TRST

R2

TDI

1

3

SW2

2

R7

P010

P011

P005

P006

P007

P009

77

28

27

76

78

30

29

I2C_SCL/P0.08

I2C_SDA/P0.09

SSP0_SCLK/P0.05

SMI_CS0/SSP0_NSS/P0.04

SMI_CS3/UART0_RX/P0.10

SMI_DIN/SSP0_MISO/P0.06

SMI_DOUT/SSP0_MOSI/P0.07

PWM1/P1.09

PWM1N/P1.08

PWM2/P1.07

PWM2N/P1.06

PWM3/P1.05

PWM3N/P1.04

80

81

87

88

89

90

P111

P107

P105

P109

P108

P106

P110

TCK

TMS

RTCK

+3V3

1

10K

P012

26

SMI_CS1/UART0_CTS/P0.12

BOOT1/SMI_CS2/UART0_TX/P0.11

P1.12

UART0_RTS/P1.1134WAKUP/P1.15

1

P112

TDO

P019

P014

P015

P020

P016

P017

P018

RTCK

25

64

17

63

39

40

41

42

CAN_TX/P0.15

CAN_RX/P0.14

UART1_RX/P0.20

SSP1_MOSI/P0.18

SSP1_MISO/P0.17

SSP1_SCLK/P0.16

RTCK/UART0_RTS/P0.13

SSP1_NSS/USB_CLK/P0.19

JTMS/P1.19

JTCK/P1.18

JTDO/P1.17

JTDI/P1.16

P1.1492P1.13

18

19

20

21

60

93

P113

P115

TDI

TDO

TCK

TMS

P114

+3V3

10K

10K

R9

R10

RESET

DBGRQ

DBGACK

P021

P023

P022

16

11

15

UART1_TX/P0.21

UART1_CTS/P0.22

24

P200

P201

P202

R11

10K

P029

P024

P025

P027

P026

P028

37

8

7

38

35

36

TIM1_OC1/P0.28

UART2_TX/P0.25

UART2_RX/P0.24

UART1_RTS/P0.23

UART2_RTS/P0.27

UART2_CTS/P0.26

TIM2_OC1/P2.04

UART1_RTS/P2.03

P2.0214P2.0123P2.00

PWM2N/P2.07

PWM3/P2.06

PWM3N/P2.05

12

13

83

84

85

86

P203

P204

P207

P208

P205

P206

JP2

JP1

TRST RESET

3V3

P030

P031

6

5

TIM1_TI2/P0.31

TIM1_TI1/P0.29

TIM1_OC2/P0.30

PWM2/P2.08

82

P210

P211

P209

JP3

4

C1

1uF

C3

33nF

C2

10uF

C4

1uF

GND

3V3

3V3

VREG_DIS

49

74

Vss33

XRTC256XRTC1

48

98

Vss33

Vss33

USB_DP

65

66

USB_D+

USB_D-

X1

10

Vss33

XT246XT1

53

47

41

97

Vss18

22

TRST

R13

73

Vss18

Vssa_ADC

1M

C6

32

C5

54

VssBKP

Vssa_PLL

TEST9NJTSRST

X2

22pF

MC306_32KHz

22pF

STR750

4MHz

C8

22pF

C7

22pF

99

V33

V33

V33

P212

P213

P214

P215

R12

10K

P216

V18

P2.1643P2.1550P2.1451P2.1361P2.1262P2.1171P2.1072PWM1N/P2.09

33

P217

V18REG

P218

P219

45

V18BKP

Vdda_PLL

P2.1931P2.1832UART2_RTS/P2.17

2

PB1

1

RST

VSS

U2

Vdda_ADC

VREG_DIS

NRSTOUT

NRSTIN59USB_DN

57

58

RESET

RSTOUT

RESET

4 3

GND

+3V3

VCC

STM1818TWX7F

75

70

55

52

44

69

96

23/08/06

Date:

B.1(PCB.SCH)

STR750-REF

001 11

STMicroelectronics

Title:

Number: Rev: Sheet of

3

2

1

12345678910111213141516171819

CN1

A A

20

JTAG connector

B B

20/22

C C

D D

Page 21

AN2419 Revision history

7 Revision history

Table 4. Document revision history

Date Revision Changes

20-Nov-2006 1 Initial release.

09-Jul-2007 2

References to VREF_ADC pin removed from document

Table 1: Typical prescaler uses on page 13 enhanced

21/22

Page 22

AN2419

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZED ST REPRESENTATIVE, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2007 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

22/22

Loading...

Loading...