Page 1

AN2415

Application note

Using the output detection feature of the high-brightness

LED driver STP08CDC596 evaluation board

Introduction

This document describes how to implement a complete solution for driving a high-brightness

LED array. Based on STP08CDC596 drivers and controlled by an ST7FLITE3x

microcontroller, there are two versions of the evaluation board:

■ STEVAL-ILL002V1 using OSRAM LEDs

■ STEVAL-ILL002V2 using Toshiba LEDs

Note: The STP08CDC596 LED driver is replaced by the new, higher performing STP08DP05 LED

driver. The two available versions of the evaluation board with the STP08DP05 replace the

STEVAL-ILL002V1 and the STEVAL-ILL002V2, and are described in application note

AN2478.

The new boards available are:

■ STEVAL-ILL002V3 using OSRAM LEDs

■ STEVAL-ILL002V4 using VISHAY LEDs

Forty high-brightness LEDs are arranged on the board in a 5x8 matrix. The matrix is driven

by five 8-channel STP08CDC596 drivers.

The main features of the evaluation board are:

■ Brightness and blinking regulation

■ Animated text

■ Error detection on output

■ GUI (graphic user interface)

■ DC-DC converter

The innovative feature of the STP08CDC596 is the full output error detection function which

enables output status checking without invasive testing (via software only).

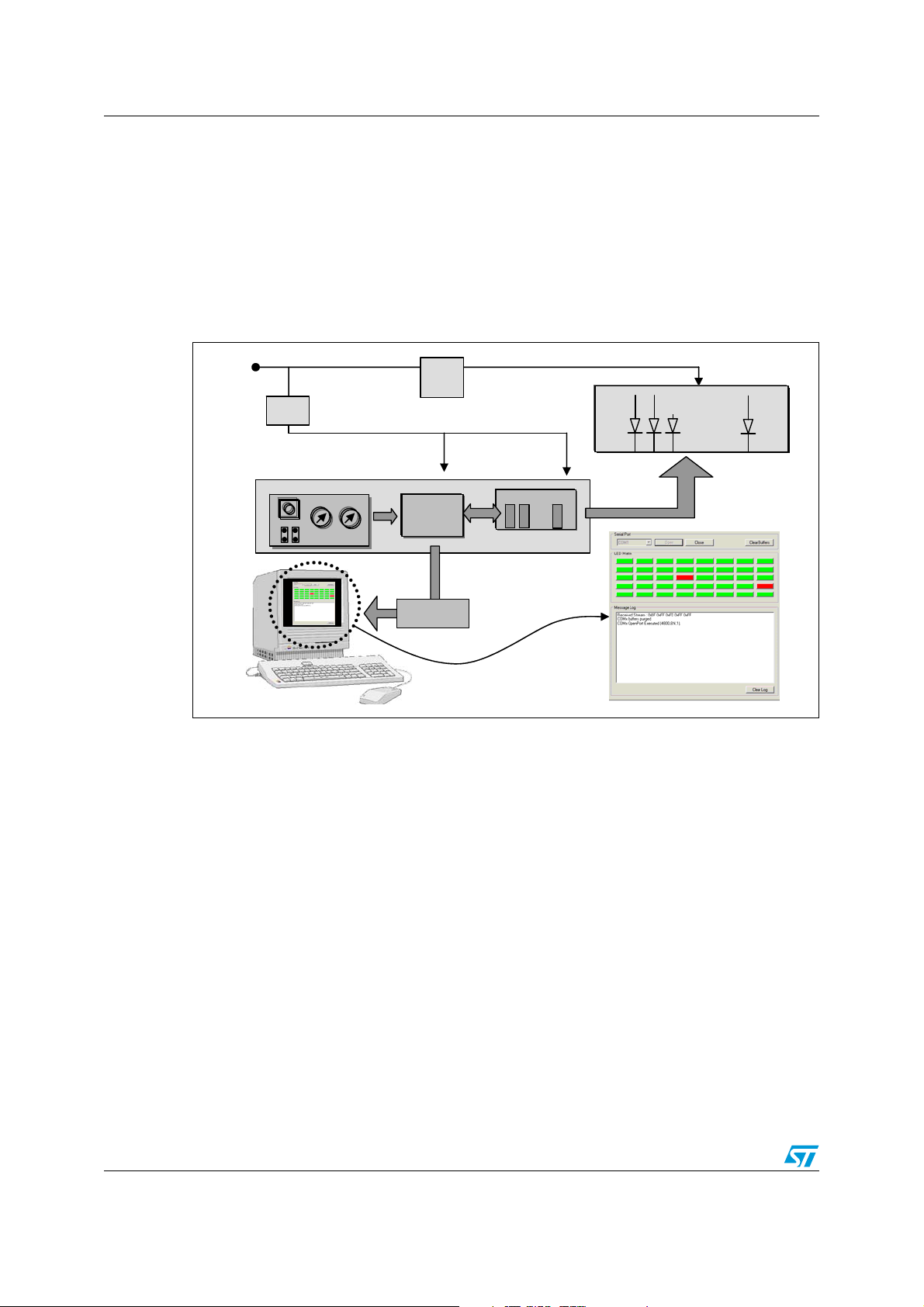

Figure 1. STEVAL-ILL002Vx evaluation board

For more information about other boards based on the STPxxC/L596 driver family, refer to

application note AN2141 which provides details concerning the basic features of the driver

family, the microcontroller interface and chip power dissipation. Refer to user manual

UM0181 for information about how to get started using the evaluation boards.

August 2007 Rev 4 1/11

www.st.com

Page 2

Contents AN2415

Contents

1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2 Operation mode switching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.1 Normal mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.2 Error detection mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3 Firmware implementation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.1 Timing diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.2 Option byte . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.3 GUI features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2/11

Page 3

AN2415 List of figures

List of figures

Figure 1. STEVAL-ILL002Vx evaluation board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Figure 2. STEVAL-ILL002Vx evaluation board block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Figure 3. Error Detection mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Figure 4. Normal mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Figure 5. Timing diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Figure 6. MCU option bytes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Figure 7. LED matrix board application diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3/11

Page 4

Overview AN2415

S

1 Overview

The STEVAL-ILL002Vx evaluation board can be powered with voltages from 7 V up to 32 V.

The SMPS DC-DC converter block is based on the L5970D step-down switching regulator

and the DC-DC block is based on the LE50ABD voltage regulator. The power topology

makes it possible to power the board using a laptop power supply.

Figure 2 shows the block diagram of the evaluation board.

Figure 2. STEVAL-ILL002Vx evaluation board block diagram

SMP

Power Supply

DC/DC

DC/DC

LED M atrix

……

Control Panel

8-bit µC

RS232 Driver

LED Driver

SPI

SPI

…….

The brain of the board is the 8-bit ST7FLITE39 microcontroller. It receives inputs from the

control panel, sends and receives data from the LED drivers through the serial peripheral

interface (SPI) and enables PC communication through the serial communications interface

(SCI). The control panel consists of switches, potentiometers and jumpers. Switches are

used to reset the microcontroller and to enter Detection mode. Potentiometers change the

brightness and text speed. Jumpers are used to simulate errors (open and short circuit) on

the LED matrix.

A LED matrix consists of 40 LEDs arranged in a 5x8 matrix. A dedicated PC GUI displays

the status of the LEDS.

4/11

Page 5

AN2415 Operation mode switching

2 Operation mode switching

To enter Error Detection or Normal mode, the drivers must receive a particular sequence on

the OE and LE pins.

When a one-clock-wide short pulse “101” is sent on the OE pin, the drivers enter the

switching phase. If the LE pin is sampled as high voltage at the 4th rising edge of CLK, the

drivers switch to Error Detection mode (Figure 3). Otherwise, they switch to Normal mode

(Figure 4).

Note: In the firmware, with SW2 pressure only the drivers enter Error Detection mode, and after an

error detection check, they re-enter Normal mode.

Figure 3. Error Detection mode

Figure 4. Normal mode

2.1 Normal mode

In Normal mode, the serial data is transferred from the microcontroller to the drivers via the

SPI. The serial data from microcontroller is sent to the drivers via the SDI pin, undergoes a

shift in the Shift Register, and exits via the SDO pin. The LE pin can latch the serial data in

the Shift Register to the output latch. The OE pin enables the output driver sink current.

Current is modulated by the potentiometer, which changes the PWM duty cycle on the OE

pin (PWM frequency is set at 244 Hz).

5/11

Page 6

Firmware implementation AN2415

Note: At start-up, the evaluation board works in Normal mode.

2.2 Error detection mode

After entering Error Detection mode as shown in Figure 3, it is recommended to send all

data to the drivers as “1”.

As long as the OE pin is high, the serial data can still be shifted to the Shift Register via the

SDI pin, and out via the SDO pin. The LE pin can also send the data in the Shift Register to

the output latch.

When the state of the OE pin is pulled down to low voltage for at least 2 µs, the drivers

execute the error detection function and load the error status into the Shift Register. The

error status codes saved in the Shift Register can then be shifted out via the SDO pin bit-bybit along with the clock. The SDO pin of the last driver of the chain is connected to the MISO

pin of the microcontroller. Incoming data can be sent to the PC through the SCI and

displayed on the GUI. For more information, refer to the timing diagram shown in Figure 5.

3 Firmware implementation

The purpose of this application note is to explain how to manage the error detection features

of the drivers. Refer to AN2141 for an explanation of the basic driver features.

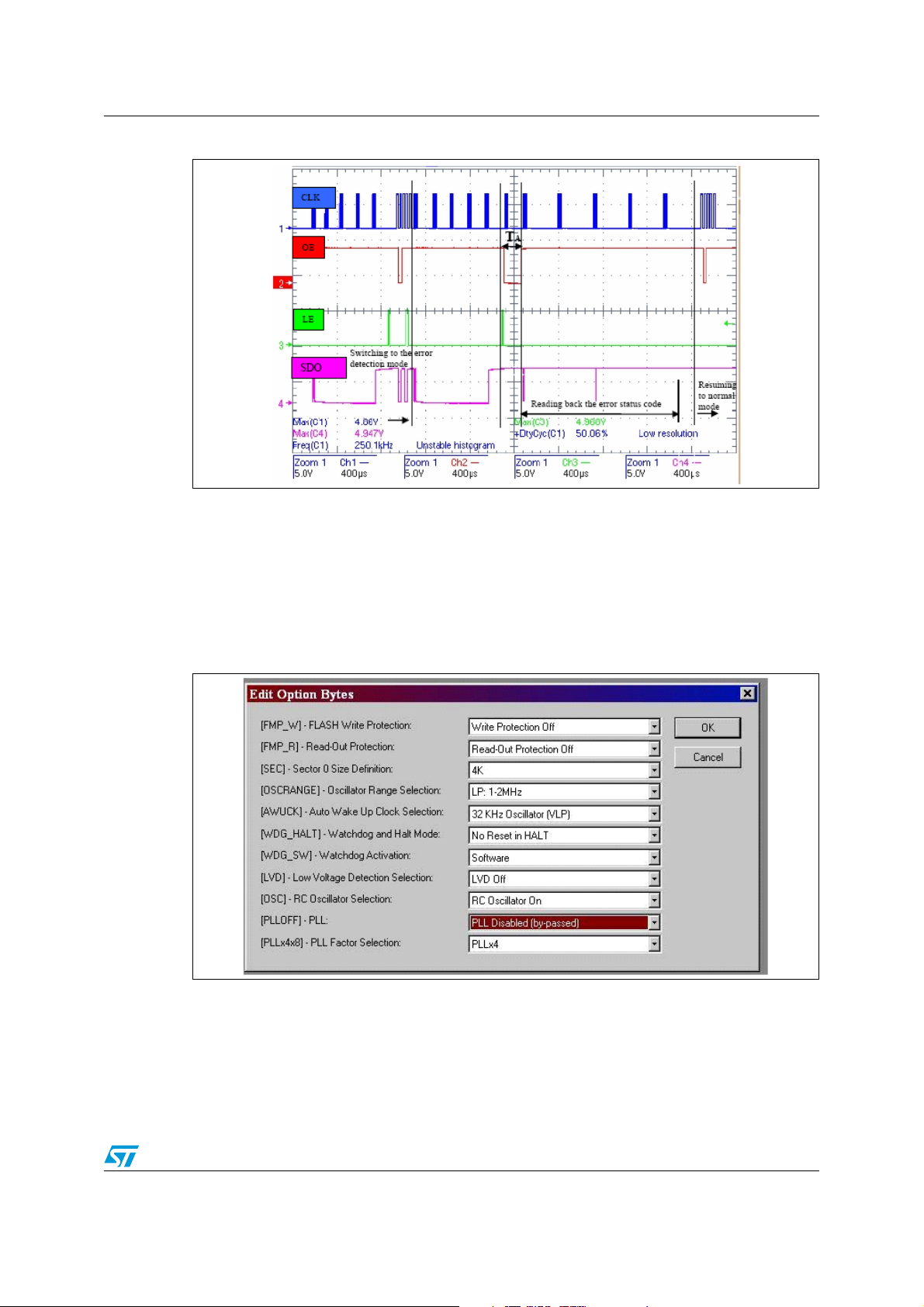

3.1 Timing diagram

At power-up, the microcontroller sends data to the drivers’ Shift Register via the SPI

configured at 250 kHz. The maximum communication frequency for this driver is 25 MHz to

satisfy high volume data transmissions. (Please refer to the device datasheet for more

details). The two potentiometers are connected to ADC inputs. The analog voltage inputs

are converted to a digital value. According to this digital value, it will change the PWM

duty-cycle signal for brightness and data time delay for text speed. By default, the

microcontroller works in Normal mode and only enters Error Detection mode when an

external interrupt pin connected to SW2 is triggered. The related ISR disables the SPI I/O

function and sends a specific sequence to the driver via the CLK, OE, and LE pins as shown

in Figure 5.

After the driver has received the specific sequence, the microcontroller enables the SPI and

sends 0xFF data for each driver. The drivers have already entered Error Detection mode

and the microcontroller maintains pin OE low for detecting the error status. Drivers send

back the LED status to the microcontroller via the MISO pin (connected to the SDO pin).

Then, the microcontroller resumes Normal mode operation, sending the specific sequence

to the drivers. Figure 5 shows each phase, switching from Error Detection to Normal modes.

6/11

Page 7

AN2415 Firmware implementation

Figure 5. Timing diagram

Note: T

Note: The SDO of the E driver is connected to the MISO pin of the MCU.

must be at least 2 µs to detect the error status.

A

3.2 Option byte

Figure 6 shows the option byte settings.

Figure 6. MCU option bytes

3.3 GUI features

A dedicated graphical user interface (GUI) displays the LEDs, status on the PC. The serial

parameters are: 4800, 8, N, 1 (baud rate, 8 bit, parity none, 1 bit stop). The microcontroller,

7/11

Page 8

Application diagram AN2415

after resuming Normal mode, manages the SCI peripheral and sends data to the PC using

the ST232ABN driver interface.

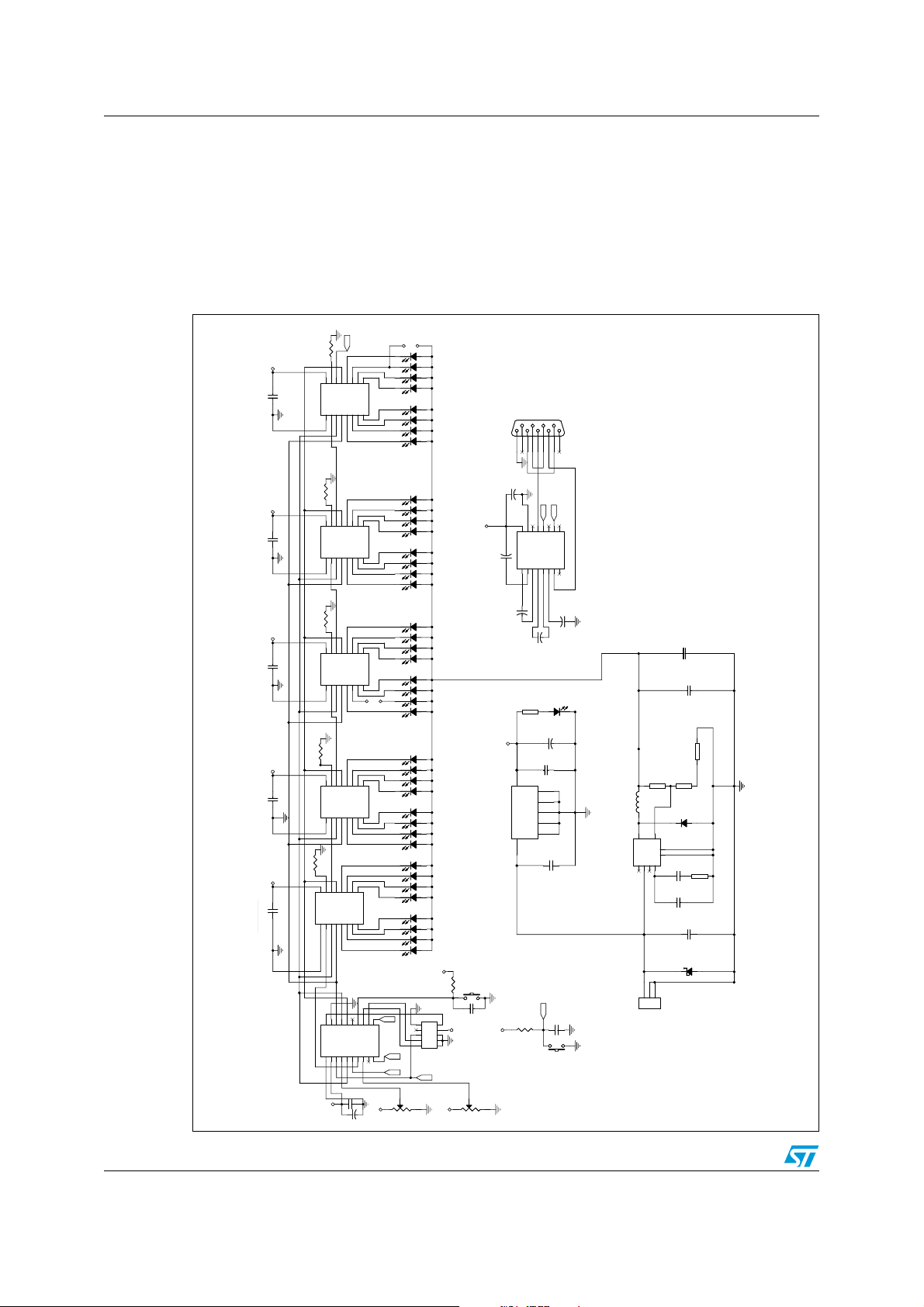

Appendix A Application diagram

Figure 7. LED matrix board application diagram

JP1

JP1

SD0

R7 1k3R7 1k3

13

16

10

14

9

15

9

1212111110

/OE

Vdd

C7

100nFC7100nF

C6

100nFC6100nF

R-EXT

GND1SDI2CLK3/LE45566778

U5

R6

1k3R61k3

16

15

Vdd

R-EXT

GND1SDI2CLK3/LE45566778

U4

SDO

STP08CDC596/EU5STP08CDC596/E

8

13

10

14

9

9

1212111110

/OE

SDO

STP08CDC596/DU4STP08CDC596/D

8

1 2

JUMPER

JUMPER

P1

VCC

C12

C12

470nF

470nF

C11

C11

594837261

2.2uF

2.2uF

16

RDI

TxD

15

13

12

14

Vdd

T1IN11T2IN

GND

R1IN

T1OUT

R1OUT

C1+1V+2C1-3C2+4C2-5V-6T2OUT7R2IN

CONNECTOR DB9P1CONNECTOR DB9

STEVAL-ILL002V1 (OSRAM LEDs)

STEVAL-ILL002V2 (TOSHIBA LEDs)

RxD

TDO

10

9

R2OUT

U6 ST232ABNU6 ST232ABN

8

<Doc> <RevCode>

DiagnosticLED Driver

<Doc> <RevCode>

DiagnosticLED Driver

<Doc> <RevCode>

DiagnosticLED Driver

B

B

B

Title

Size DocumentNumber Rev

Title

Size DocumentNumber Rev

Title

Size DocumentNumber Rev

470nF

470nF

C10

1k3R51k3

100nFC5100nF

100nFC4100nF

100nFC3100nF

R5

16

15

Vdd

R-EXT

U3

GND1SDI2CLK3/LE45566778

R4

1K3R41K3

15

16

Vdd

R-EXT

GND1SDI2CLK3/LE45566778

U2

R3

1k3R31k3

16

14

15

Vdd

SDO

R-EXT

GND1SDI2CLK3/LE45566778

U1

201918171615141312

U8

123456789

VCC

13

14

10

9

9

1212111110

/OE

SDO

STP08CDC596/CU3STP08CDC596/C

8

D18D18

1 2

JP2

JP2

JUMPER

JUMPER

10

13

9

14

9

1212111110

/OE

SDO

STP08CDC596/BU2STP08CDC596/B

8

13

10

9

9

1212111110

/OE

STP08CDC596/AU1STP08CDC596/A

8

D1 D20 D28D25D8 D12 D40D4 D9 D30D27D24D5 D7 D26 D29D6 D33D10 D34D2 D21 D37D16 D36D3 D39D17 D35D15 D32D23 D38D13D11 D14 D22D19 D31

VCC

R8

10kR810k

J1ICP J1ICP

9

10

7

8

TDO

11

ST7lite3U8ST7lite3

10

C13

10nF

C13

10nF

13

+

+

VCC

C2

C2

0uF

0uF

5

6

VCC

3

4

1

2

SD0 RDI

RES

2

R2

10kR210k

R1

13

VCC

VCC VCCVCC VCCVCC

C5

C4

C3

C10

VCC

1

VOUT

VIN

U7 LE50/SOU7 LE50/SO

8

SW2SW2

C14

C14

2

R9

10nF

10nF

VCC

10kR110k

R14

R14

10kR910k

INHIB

GND

GND

GND

GND

470nFC8470nF

C8

220uF/25V

220uF/25V

C21

C21

+

21

L1 33uHL1 33uH

1

682

123

J5 CON3J5 CON3

INPUT VOLTAGE

R11

R11

5

7

3

4

FROM 7V UP TO 32V

+

C22

C22

100uF/16V

100uF/16V

R13

360

R13

360

6k8

6k8

R12

2K2

R12

2K2

D41

D41

STPS340U

STPS340U

C18

22nF

C18

22nF

R10

4k7

R10

4k7

C20

C20

220pF

220pF

C19

C19

10uF/35V

10uF/35V

D44

SMAJ33A-TR

D44

SMAJ33A-TR

C9

470nFC9470nF

D42

D42

560

560

GREEN L ED

GREEN L ED

C1

2.2uFC12.2uF

C15

C15

100nF

100nF

5

7

6

3

2

C17

100nF

C17

100nF

IO5 L5970DIO5 L5970D

RES

C16

10nF

C16

10nF

SW1SW1

8/11

Page 9

AN2415 Bill of materials

Appendix B Bill of materials

Table 1. Bill of materials

Item Qty Reference Part Description Order code Supplier

1 2 C1 and C12 2.2 µF/50 V Electrolytic capacitor

2 1 C2 10 µF/35 V Electrolytic capacitor

37

44

5a 2 C14 and C16 10 nF/50 V

5b 1 C13 10 nF/50 V

6 1 C18 22 nF/50 V

7 1 C19 10 µF/35 V Tantal capacitor

8 1 C20 220 pF/50 V

9 1 C21 220 µF/25 V Electrolytic capacitor

10 1 C22 100 µF/16 V Tantal capacitor

11 40

C3, C4, C5, C6,

C7, C15 and

C17

C8, C9, C10

and C11

D1, D2, D3, D4,

D5, D6, D7, D8,

D9, D10, D11,

D12, D13, D14,

D15, D16, D17,

D18, D19, D20,

D21, D22, D23,

D24, D25, D26,

D27, D28, D29,

D30, D31, D32,

D33, D34, D35,

D36, D37, D38,

D39 and D40

100 nF/50 V

470 nF/16 V

LED

Ceramic capacitor

SMD 0805

Ceramic capacitor

SMD 0805

Ceramic capacitor

SMD 0805

Ceramic capacitor

SMD 1206

Ceramic capacitor

SMD 0805

Ceramic capacitor

SMD 0805

OSRAM SMD BLUE

LED LB T68C-P2S1-35

or TOSHIBA

LED - TLGE1100

OSRAM or

TOSHIBA

12 1 D41 STPS340U Diode STPS340U STMicroelectronics

13 1 D42 GREEN LED SMD LED 1206

14 1 D44 SMAJ33A-TR Transil SMAJ33A-TR STMicroelectronics

15 1 IO5 L5970D DC-DC converter L5970D STMicroelectronics

16 2 JP1 and JP2 JUMPER Jumpers + switches

17 1 J1 ICP Programming connector

18 1 J5 CON3 Input connector

9/11

Page 10

Revision history AN2415

Table 1. Bill of materials (continued)

Item Qty Reference Part Description Order code Supplier

19 1 L1 33 µH Inductor DO3316P-333ML Coilcraft

20 1 P1

21a 2 R1 and R2 10 k

21b 2 R8 and R9 10 k SMD resistors 0805

22 5

23 1 R10 4k7 SMD resistors 0805

24 1 R11 6k8 SMD resistors 1206

25 1 R12 2K2 SMD resistors 1206

26 1 R13 360 SMD resistors 1206

27 1 R14 560 SMD resistors 1206

28 2 SW1 and SW2

29 5

30 1 U6 ST232ABD RS232 driver ST232ABD STMicroelectronics

31 1 U7 LE50/SO Linear voltage regulator LE50ABD STMicroelectronics

32 1 U8 ST7lite3 Microcontroller ST7FLITE39F2M6 STMicroelectronics

R3, R4, R5, R6

and R7

U1, U2, U3, U4

and U5

CONNECTOR

DB9

1k3 SMD resistors 1206

Push-button

switch

STP08CDC596 LED drivers STP08CDC596TTR STMicroelectronics

CAN connector - 9 pin

Potentiometers with

axis

Switch

4 Revision history

Table 2. Revision history

Date Revision Changes

7-Sept-2006 1 Initial release.

31-Jan-2007 2

08-Feb-2007 3 Bill of materials table modified.

30-Aug-2007 4 Minor text changes

10/11

Bill of materials table and LED matrix board application diagram

modified.

Page 11

AN2415

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZED ST REPRESENTATIVE, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2007 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

11/11

Loading...

Loading...