Page 1

AN2390

Application note

A flexible universal battery charger

Introduction

In everyday life, more and more portable electronic appliances, such as mobile phones, are

powered by re-chargeable batteries so the demand for battery chargers for charging these

batteries is increasing all the time.

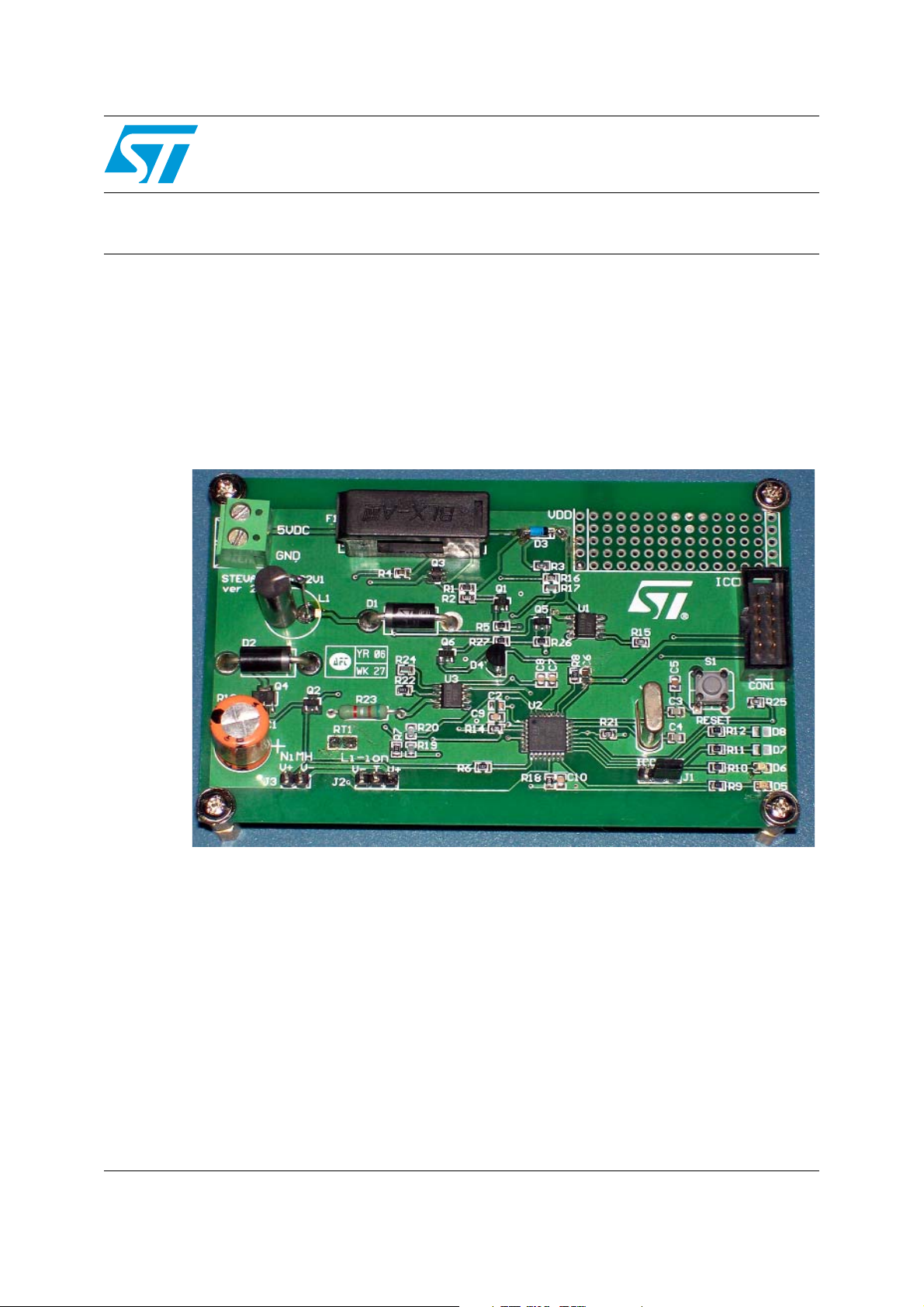

This Application Note describes a cost-effective way to implement an intelligent battery

charger for charging Li-ion and NiMH batteries as shown in Figure 1.

Figure 1. Universal battery charger evaluation board (STEVAL-ISB002V1)

It is based on a evaluation board built around the ST72324L microcontroller with a demo

application code.

While the evaluation board described in this Application note is intended to be used for

single cell Li-ion battery or 2 cell NiMH batteries you can customize this charger for a wide

range of batteries because of the flexibility of the MCU and of the buck boost converter. The

ST72324L MCU was selected for its main features, an embedded 10-bit A/D converter (to

efficiently measure voltage, current and temperature), 16-bit timer (to generate PWM

signals), main clock controller (to generate a time base signal) and 8 Kbytes of program

memory which is more than enough to hold the algorithm for various battery chemistries.

You can choose any other MCU that has similar capability. An LED is also used to indicate

the charge status.

August 2007 Rev 1 1/42

www.st.com

Page 2

AN2390

The evaluation board is powered from a 5 V supply. This supply is purposely chosen to show

the application of the modified buck-boost converter. This is because, while a buck converter

can be used to charge 2 cell NiMH battery from a 5 V supply, it is not generally suitable for

charging a 4.2 V Li-ion battery due to the presence of protection diodes and other

components which induce a voltage drop of around 1 V so you can not use a buck converter

in this case.

The modified non-inverting buck-boost converter circuit used in this application note needs

only one inductor and requires only an extra PWM signal compared to the kind of buck

converter that is normally used. By using the switches in different forms, this converter can

be used either as a buck converter or as a boost converter. Using the flexibility of the MCU,

this converter is capable of charging a wide variety of batteries as can be seen from the

evaluation board, where this converter has been used in buck converter mode to charge

NiMH batteries, while a combination of buck-boost converter and boost converter modes are

used to charge Li-ion batteries. For more details on the buck-boost converter, please refer to

AN2389.

2/42

Page 3

AN2390 Contents

Contents

1 Theory of operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.1 Li-ion battery charging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2 NiMH battery charging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.2.1 Negative delta V method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.2.2 Zero delta voltage method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.2.3 Max temperature detection method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.3 Slot management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.4 Man-machine interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2 Evaluation board implementation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.1 Charging circuitry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.1.1 DC (Buck-Boost) converter component selection . . . . . . . . . . . . . . . . . 10

Inductor selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Capacitor selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

2.1.2 Battery discharge protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.2 Analog measurement circuitry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.2.1 Voltage reference generation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.2.2 Current measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.2.3 Voltage measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.2.4 Temperature sensing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.2.5 Battery recognition mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Li-ion battery recognition scheme. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

NiMH battery recognition scheme . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

2.2.6 Power supply restrictions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.3 MCU software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.3.1 Architecture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.3.2 Use of the ST7 MCU on-chip peripherals . . . . . . . . . . . . . . . . . . . . . . . 19

2.3.3 State diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3 How to use the evaluation board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3.1 Connecting the evaluation board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3.1.1 Jumper Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3.1.2 Powering and running the evaluation board . . . . . . . . . . . . . . . . . . . . . . 28

3.2 Warnings/ Limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

3/42

Page 4

Contents AN2390

3.3 Example test results with evaluation board . . . . . . . . . . . . . . . . . . . . . . . 28

3.3.1 Test environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

3.3.2 Li-ion battery charger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

3.3.3 NiMH battery charger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4 Conclusion: a low-cost flexible solution . . . . . . . . . . . . . . . . . . . . . . . . 35

5 References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Appendix A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

A.1 Source file organization. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

A.2 Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

A.3 BOM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

4/42

Page 5

AN2390 Theory of operation

1 Theory of operation

1.1 Li-ion battery charging

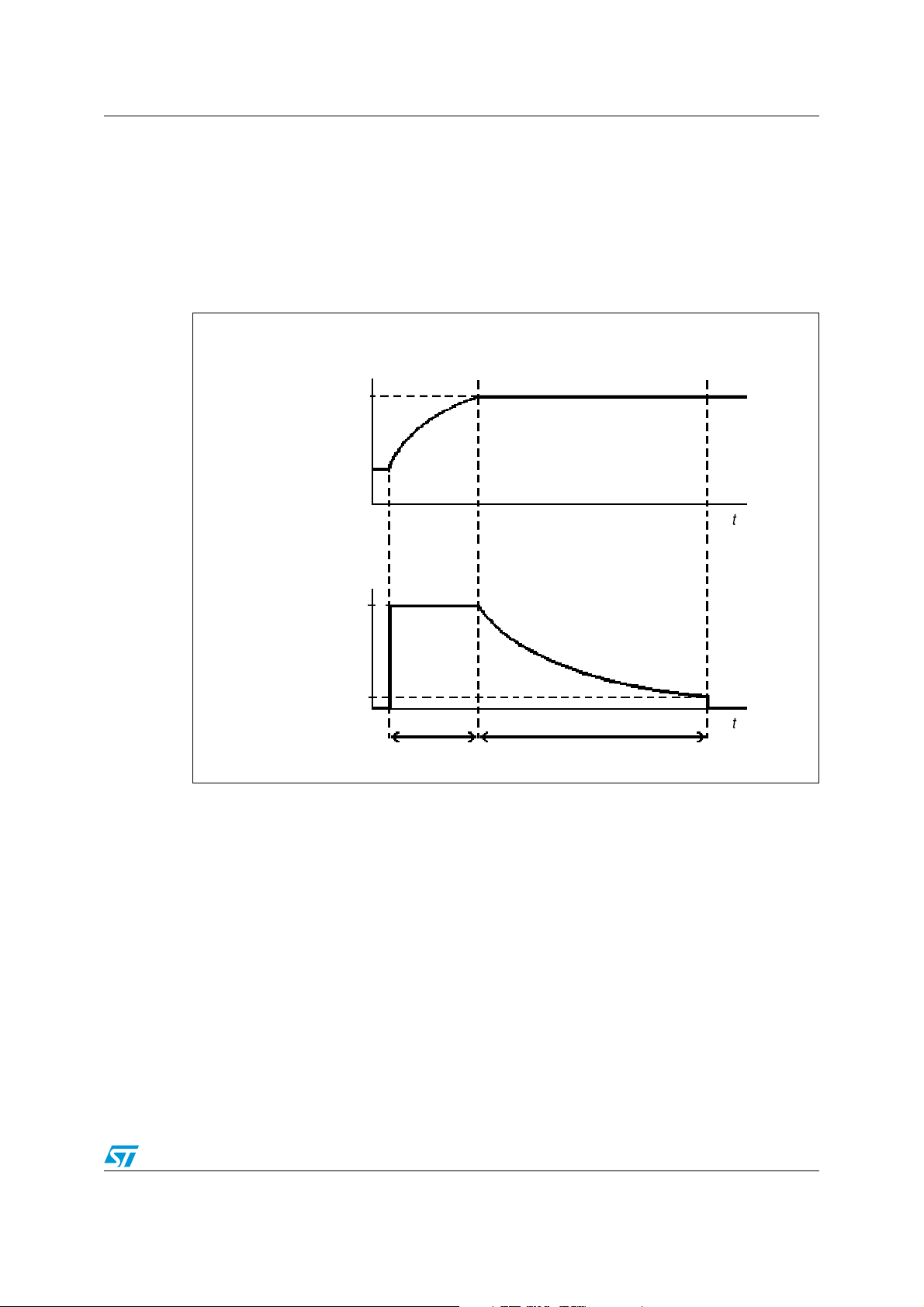

Li-ion batteries have a constant current/constant voltage charging algorithm as shown in

Figure 2.

Figure 2. Li-ion battery charging

Battery

voltage

V

F

Battery

current

I

CONST

I

SAT

Stage 1

Stage 2

During Stage 1 (constant current charge), the charging current is kept at a constant value

(I

) until the battery voltage reaches the final cell voltage (VF). In Stage 2 (constant

const

voltage charge), the voltage is kept constant within this limit by slowly decreasing the

current. Charging is stopped when the current drops below the threshold value fixed by the

manufacturer (I

). This current indicates that the battery is saturated.

SAT

In some cases before stage 1, pre-charging can also be done if the battery is fully

discharged.

A failure condition occurs if even after a certain time (t

voltage remains particularly low (under V

). In this case, charging is stopped and the

SC

) of fast charging, the battery

FAI L

battery is isolated from the charger. The charger also indicates a battery failure without

waiting (protection against short-circuit) if battery current is higher than the threshold I

FAIL

(equals to the maximum supply current).

If the charging time exceeds a certain expiration value (t

battery is not yet saturated. As the t

value is greater than the t

EXP

), charging is stopped even if the

EXP

indicates that the battery is in good condition and fully charged.

5/42

value, the charger

FAI L

Page 6

Theory of operation AN2390

The battery temperature is also monitored. If the battery overheats, charging is suspended

until the battery cools down.

Once the battery is saturated, its voltage is still monitored to prevent the battery from

discharging completely. If the battery voltage drops below V

, charging restarts until VF is

SAT

reached again. Charge time is reset when trickle charging starts.

Table 1. Li-ion charge parameters used in the evaluation board

Symbol Meaning Value Unit

V

V

V

V

I

FAST

I

FAI L

t

FAI L

t

EXP

MAX

V

F

TRI

FAST

SC

SAT

Maximum charging voltage 4.3

Final battery voltage 4.2

Trickle charge voltage 4.12

Fast charge voltage 3.0

Battery failure voltage 1.5

Fast charge current 1000

Battery saturation current 20

mAI

Short circuit current 1200

Battery failure time 30 s

Charge expire time 4 h

V

6/42

Page 7

AN2390 Theory of operation

1.2 NiMH battery charging

The NiMH batteries uses a constant current algorithm as shown in Figure 3.

Figure 3. Variation of NiMH battery voltage

−∆V

(V)

cell

NiMH cell voltage: V

Charging time (t)

-10 mV/cell

The NiMH batteries use constant current charging. The end of charging can be detected by

using the following methods.

1.2.1 Negative delta V method

As shown in Figure 3, the voltage of the NiMH batteries drops a little at the end of charging.

So at the time, when the voltage slope versus time becomes negative, charging is stopped

and trickle charging is started.

1.2.2 Zero delta voltage method

This method is a variant of the Negative delta V method. Actually in case of NiMH, there is a

very slight drop in voltage (5-10 mV/ Cell) at the end of charging which is very difficult to

detect using a 10-bit ADC. Also there is a chance of detecting the wrong end of charging

due to noise. So instead of the negative delta voltage, we use a dV = 0 condition for a

certain time duration. This gives very good approximations for detecting the end of charging.

For this reason, this method is used in the evaluation board example instead of the negative

delta method described in Section 1.2.1.

1.2.3 Max. temperature detection method

In this case if temperature rises above a threshold, charging is stopped and trickle charging

is started.

In this demo the Zero Delta Voltage method is used as the primary technique for terminating

the charging. Time Out, Max Voltage and Max Temperature are used as the secondary or

back up methods for ending the charging.

7/42

Page 8

Theory of operation AN2390

Once the battery is saturated, its voltage is still monitored to prevent the battery from

discharging completely. If the battery voltage drops below V

, charging restarts until VF is

TRI

reached again. Charge time is reset when trickle charging starts.

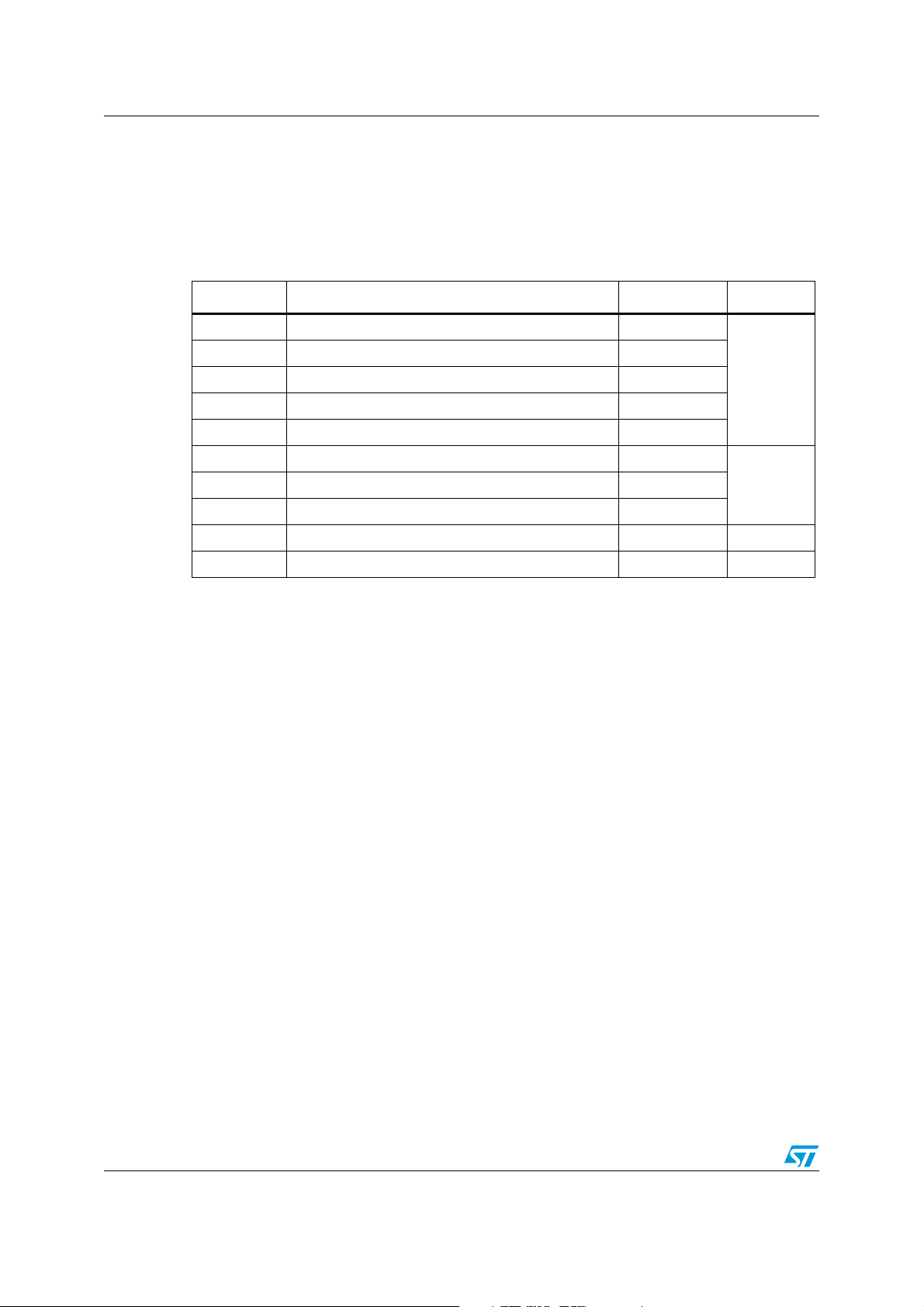

Table 2. NiMH Charge parameters used in the evaluation board

Symbol Meaning Value Unit

V

MAX

TRI

V

FAI L

I

CONST

I

TRICKLE_1

I

SAT

I

FAI L

t

INITIAL

t

FAI L

t

EXP

t

FAST

Max Battery Voltage 1.7/Cell

Trickle Charge Voltage 1.0V/Cell

Battery Failure Voltage 0.9/Cell

Constant Charge Current 1000

Initial Trickle Charging Current 250

Battery Saturation Current 65

Short Circuit Current 1200

Initial Delay 10

Battery Failure Time 30

Charge Expire Time 4

Fast Charging Time 2

1.3 Slot management

In the demo, there are two different kinds of slots for charging Li-ion and NiMH battery

chemistries to show that it can support wide range of batteries. But the positive terminal of

one slot is shorted to the positive slot of another battery and similarly for the negative

terminals. So the system can support charging of only one battery at a time. Hence you

must take care to connect only one battery at a time to the charger. Otherwise the batteries

will be shorted together.

VV

mA

minutes

h

1.4 Man-machine interface

The charger periodically checks for battery presence so no button is needed to start or stop

charging. An LED is used to indicate the charge status as listed in Table 3..

Table 3. LED slot status color code

LED output Charging status

OFF No battery in the slot

Flashing @ 1 Hz Charging ongoing

Flashing @ 2 Hz Problem in charging

ON Battery Present/ Charging Complete

A reset button is also included on the evaluation board to manually reset the application.

8/42

Page 9

AN2390 Evaluation board implementation

2 Evaluation board implementation

2.1 Charging circuitry

The evaluation board implements a solution with an external low-voltage DC supply.

To obtain a constant voltage or constant current during various stages, the ST7

microcontroller measures the battery voltage (V

feedback, it provides the regulated output power to the battery under charge using a noninverting buck-boost converter circuit.

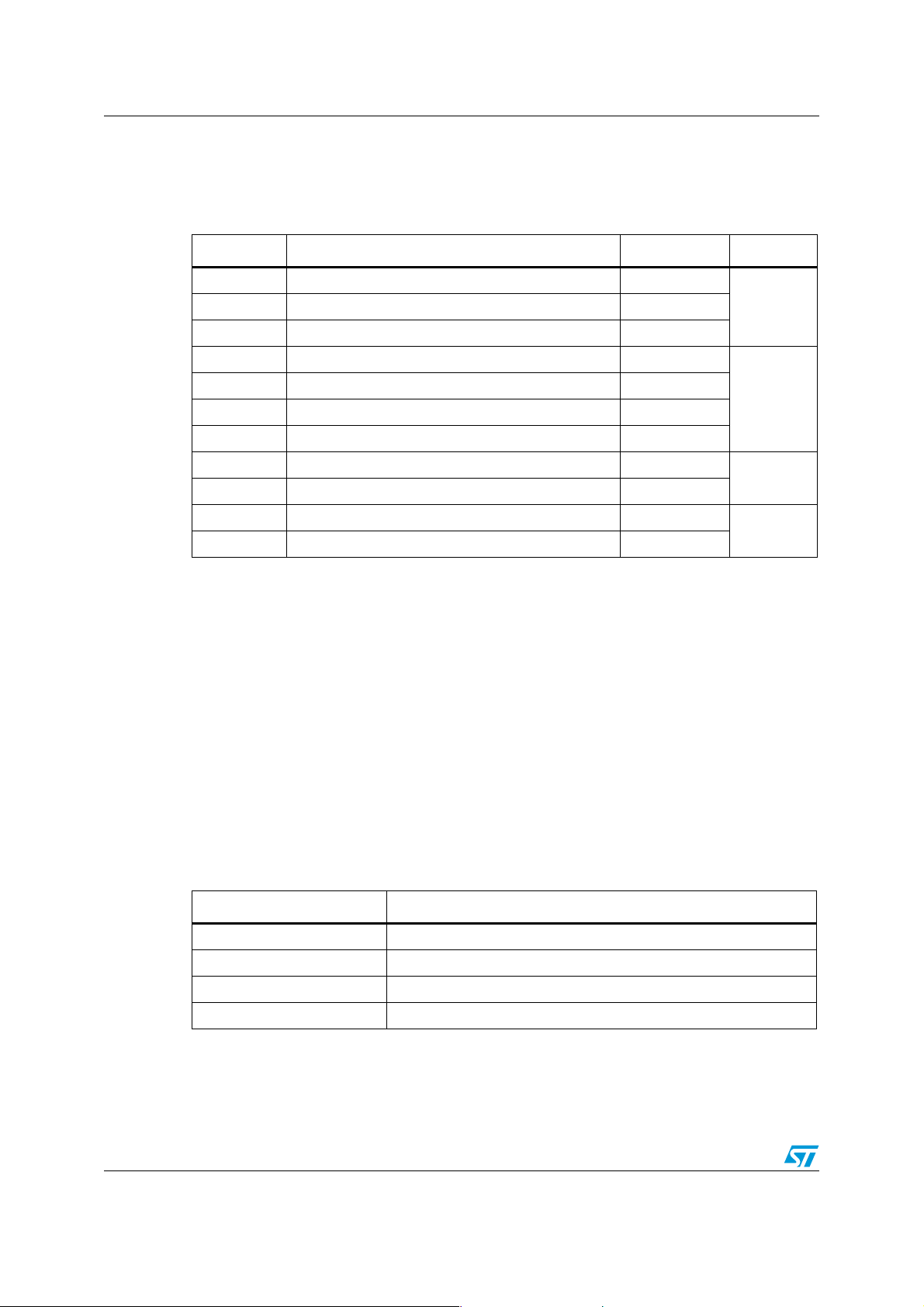

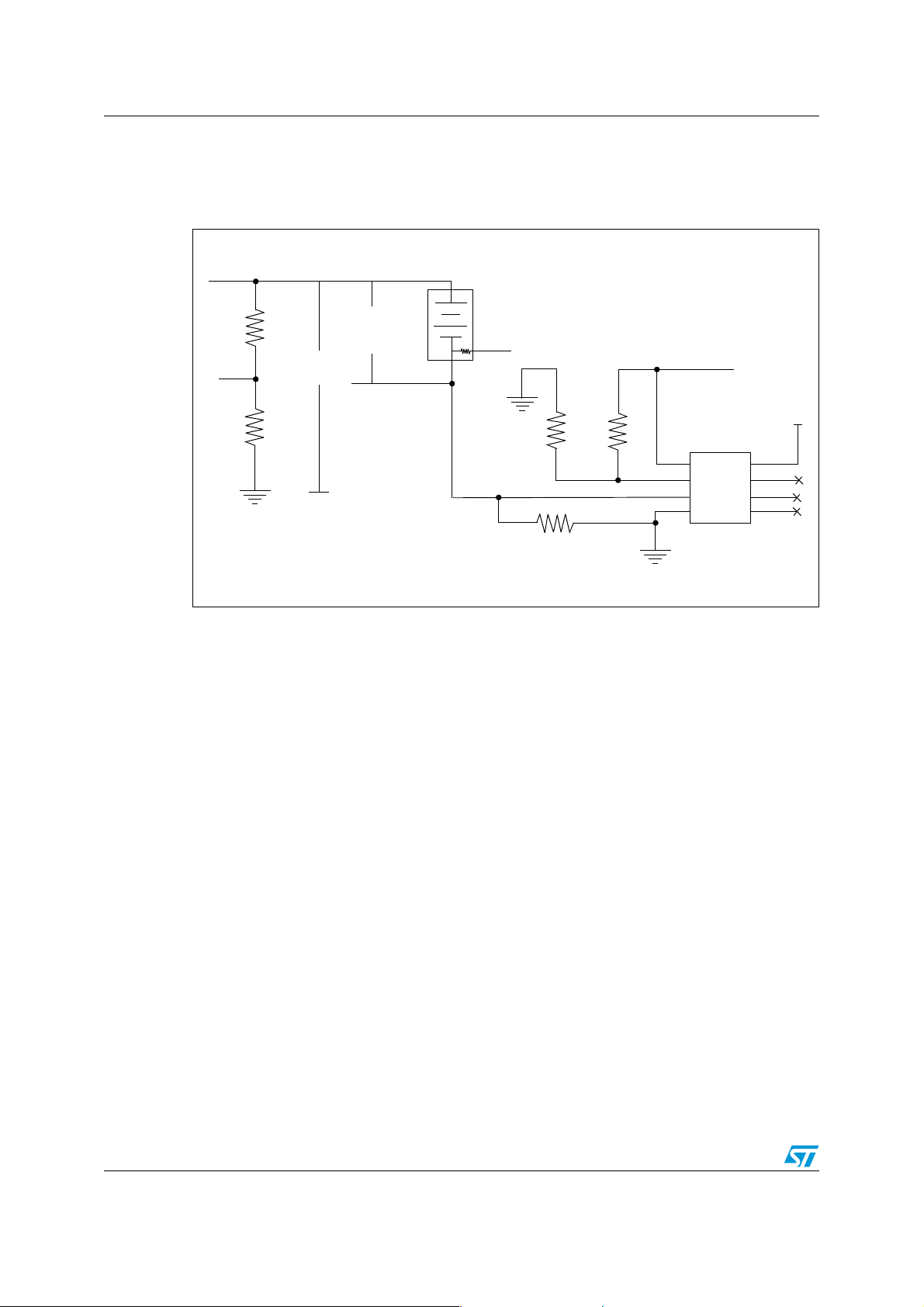

The buck boost converter is controlled by 2 PWM signals coming from the microcontroller as

shown in basic circuit diagram (Figure 4). For more details on the buck/boost converter,

please refer to AN2389.

Figure 4. Basic circuit diagram of MCU-based non-inverting buck-boost converter

) and current (I

BAT

). Along with this

BAT

P+

P-

d1

PWM1

L

PWM2

d2

C

V

OUT

9/42

Page 10

Evaluation board implementation AN2390

2.1.1 DC (Buck-Boost) converter component selection

The value of inductor L and capacitor C are selected by the following section. For more

detail please refer to AN2389.

Inductor selection

The minimum value of the inductor can be selected by choosing the maximum of the values

given by the following two formulae:

Lmin =

T * [ ( Vin - Vsat1) * D1 - Vsat2 * D2 - Vout * (D1 - D2))]

2 * Iout

T * [ Vd1 + Vout] * ( 1 - D1)

Lmin =

2 * Iout

Here Vsat1 and Vsat2 are the saturation voltages of the two switches Sw1 and Sw2.

Iout and Vout are the maximum output current and voltage respectively.

Vd1 and Vd2 is the voltage drop across diodes d1 and d2.

The duty cycle of the PWM signals driving switch Sw1 (PWM1) and Sw2 (PWM2) are D1

and D2 respectively.

Capacitor selection

The minimum capacitor value can be selected using the following formula to keep the

variation in Vout with in 1%:

Cmin =

In practice we take inductor and capacitor values that are 25% more than the values

calculated using the above formulae.

100 * Iout * (1 - D1) * T

Vout

2.1.2 Battery discharge protection

If the charger is not powered on or if the battery is already fully charged, the PNP transistor

is kept permanently off which isolates the battery from the charger. Because of series diode

available in the buck-boost circuitry there is no reverse current flowing into the charger.

Therefore, the battery discharges into the output capacitor and resistive bridge. This allows

battery voltage measurement while consuming very little current. Also some leakage current

flows through the output capacitor.

10/42

Page 11

AN2390 Evaluation board implementation

2.2 Analog measurement circuitry

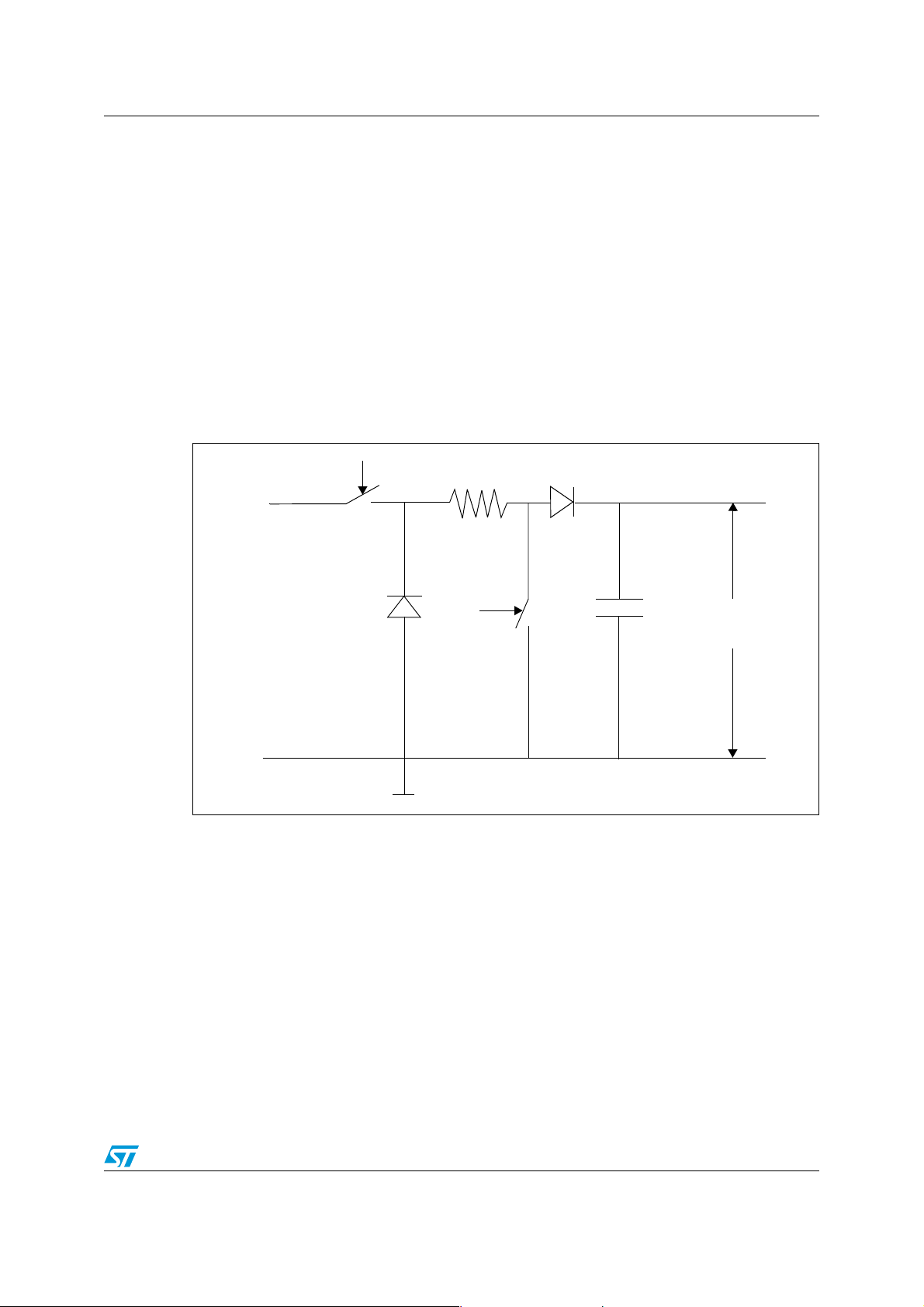

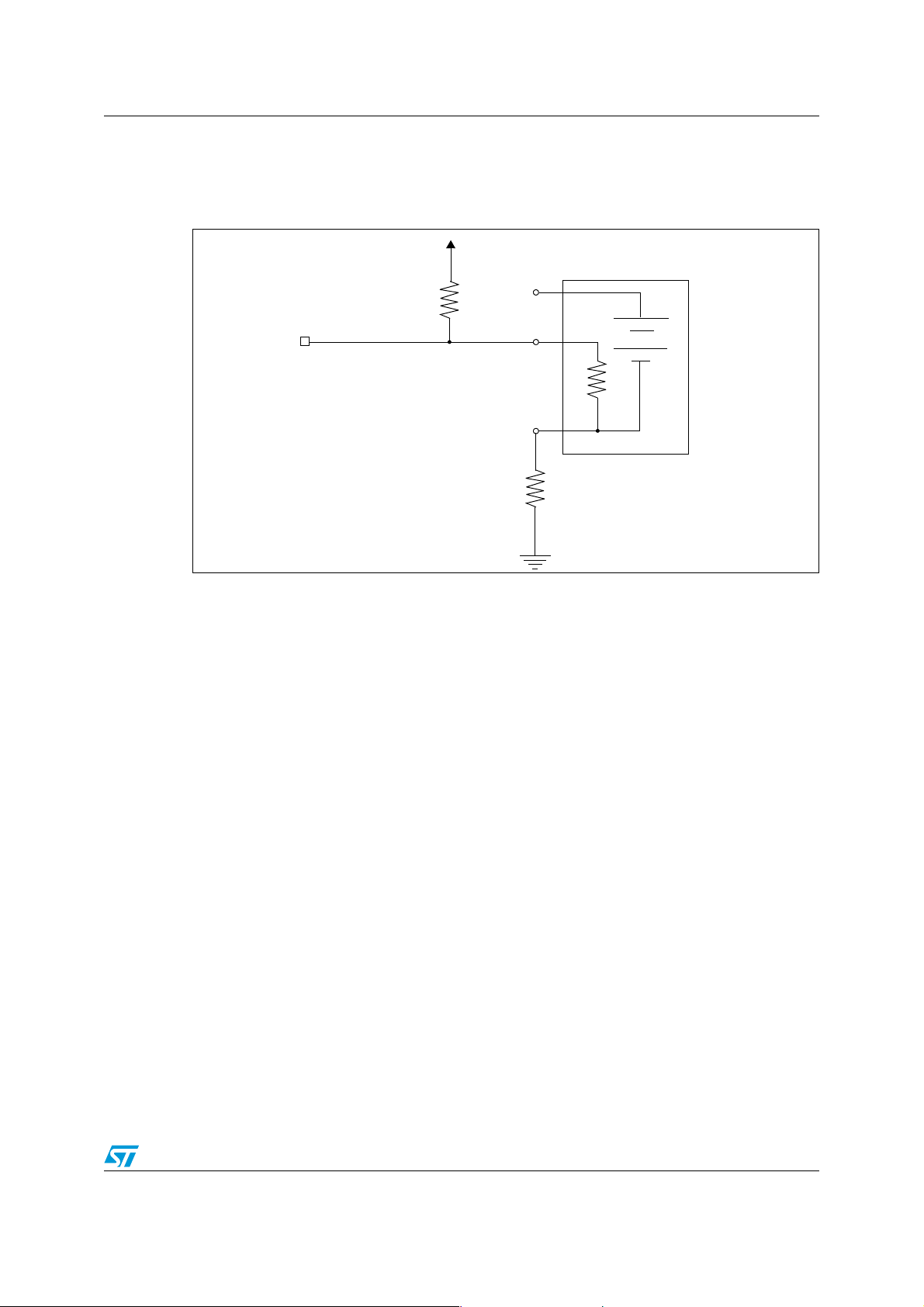

2.2.1 Voltage reference generation

In the evaluation board, TL1431 is used to provide the reference voltage for the ADC

measurement as shown in Figure 5.

Figure 5. Voltage reference generation circuit

V

IN

R3

100 (1%)

R16

4.7k (0.1%)

R17

15k (0.1%)

1

TL1431AIZ

2

VAREF

D4

This device provides a reference voltage to the ADC and provides a reference of precision

better than the 0.5% needed for the battery charger application.

By choosing the appropriate value of R16 and R17 with the proper accuracy, we can provide

the required reference voltage to the VAREF pin of the ST7 MCU using the following

formula:

VAREF_VALUE = 2.5 V * (1 + R16 / R17)

11/42

Page 12

Evaluation board implementation AN2390

2.2.2 Current measurement

The current measurement circuit is given in Figure 6.

Figure 6. Voltage and current measurement circuit

V+

BTI

LI-ION BATTERY

AIN0

R19

5k (0.5%)

V

V

BAT

B

th

AIN8

V-

AIN1

R20

5k (0.5%)

As shown in the above diagram, a shunt (R

to measure the charging current. The drop across this sense resistor is further amplified by

using the OP-AMP (Operational Amplifier) LM258A for better resolution and this amplified

voltage is measured by the ST7 microcontroller using ADC channel AIN1. The amplification

factor is chosen such that the OP-AMP output has a voltage range between ground and

V

.

DD

2.2.3 Voltage measurement

The voltage measurement circuit is also given in Figure 6 above, where the ST7 ADC

channel, AIN0 is used for voltage measurement. In the evaluation board, while the input

supply voltage V

not possible to read the battery voltage directly, but this voltage is attenuated by using a

resistor bridge (R

whole ADC input range (0 to V

Note: The ST7 MCU does not measure V

I

). Some calculation must be performed on the conversion results to get the actual

BAT

battery voltage.

= 5 V, the microcontroller is supplied with VDD = 3.3 V. Therefore, it is

supply

, R20). However, this attenuation must still allow us to make full use of the

19

DD

R22

3.3k (0.5%)

0.5,1W (0.5%)

) is connected in series to the battery in order

23

R24

13.32k (0.5%)

R23

).

, it measures VB, which is proportional to (V

BAT

U3

1

O1

2

1-

3

1+

4

GND

LM258AD

VCC

O2

22+

8

7

6

5

BAT

V

IN

+ RS*

12/42

Page 13

AN2390 Evaluation board implementation

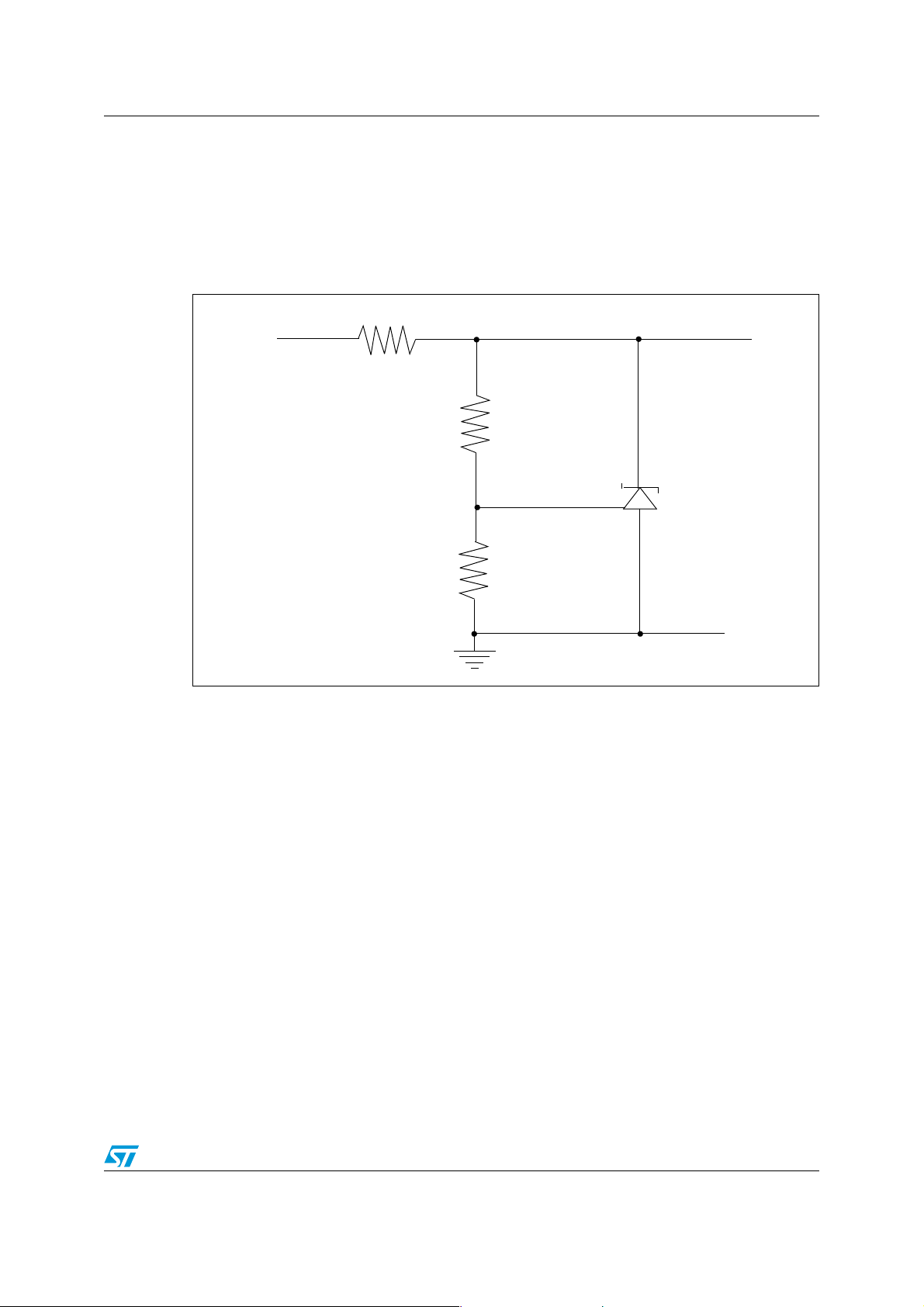

2.2.4 Temperature sensing

The circuit for the temperature measurement is given in Figure 7.

Figure 7. Temperature measurement circuit

V

ST7 analog input

(AIN8 or AIN14)

DD

R

S

Battery

For Li-ion, there is an inbuilt NTC so there is no need for an external thermistor but for NiMH,

an external NTC is connected to the negative terminal of the battery.

The same measurement technique is used for both cases. Here the ST7 ADC channel AIN8

is used for the Li-ion temperature measurement and ST7 ADC channel AIN14 is used for

NiMH.

For this demo application, we do not need to monitor the temperature very extensively. We

only need to detect extreme hot or cold conditions. For this reason, rather than using a lookup table to calculate the temperature, certain predefined parameters are used and these

parameters are compared with the temperature reading in terms of NTC resistance which

simplifies the calculation.

13/42

Page 14

Evaluation board implementation AN2390

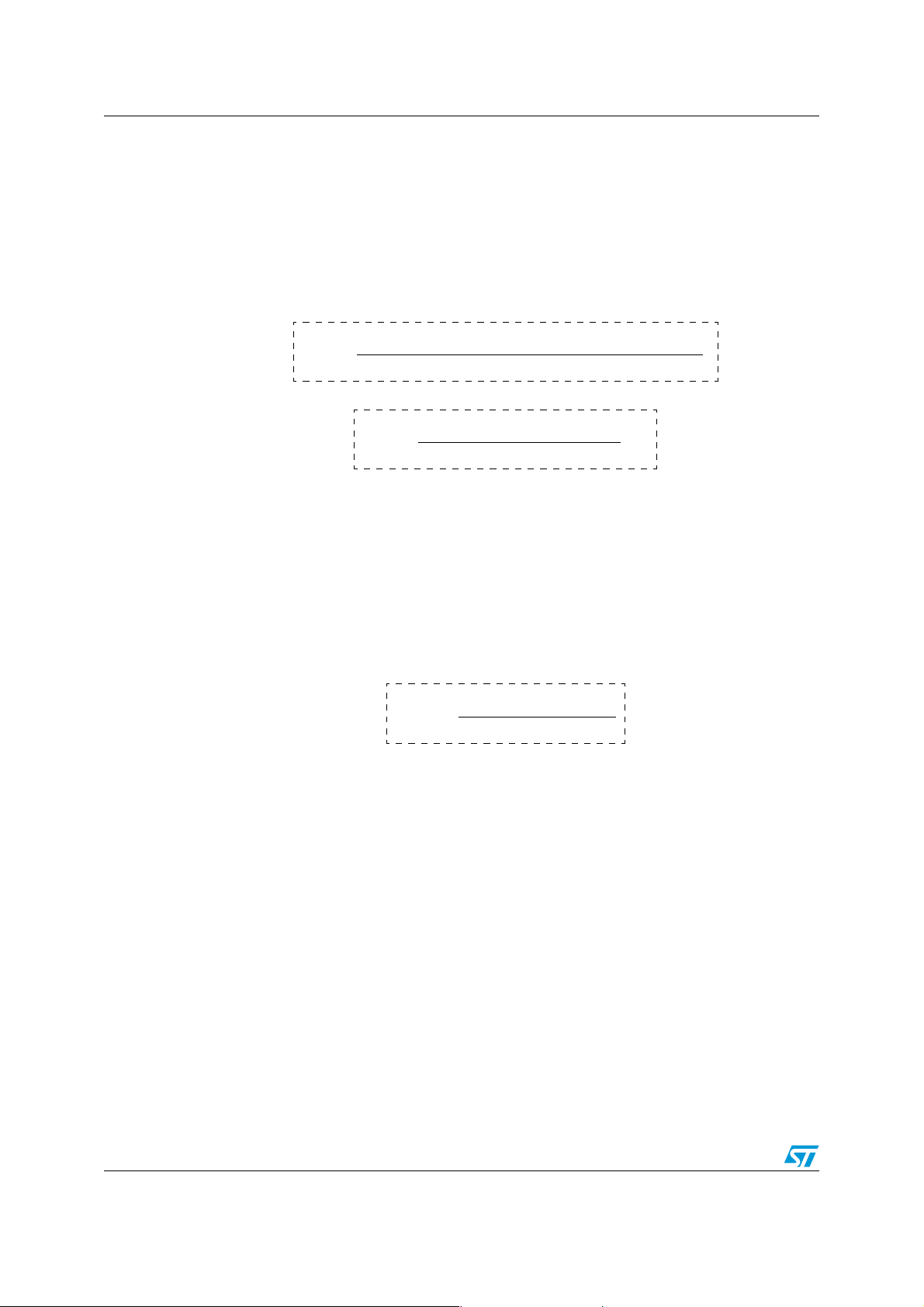

Figure 8. NTC resistance value indication for Li-ion

No battery present

R

det

Cold condition

R

cold

Battery under normal temperature conditions

R

heat

Heat condition

Note: 1 Here R

corresponds to 45°C as the temperature limit for Heat Condition and R

heat

corresponds to 0°C as the temperature limit for Cold condition for safe charging for both Liion and NiMH batteries.

2R

is a dummy condition to detect when no battery is in the slot. This threshold is used to

DET

detect the battery presence for Li-ion battery only. For NiMH we use a different battery

recognition scheme as explained in the following section.

2.2.5 Battery recognition mechanism

In this demo, different techniques are used for Li-ion and NiMH batteries to recognize

whether a battery is present in the evaluation board or not.

Li-ion battery recognition scheme

As explained in the previous section, for Li-Ion batteries, the in-built NTC thermistor is used

to detect battery presence as shown in Figure 8

NiMH battery recognition scheme

In this case, there is no inbuilt NTC in the NiMH as there is in a Li-ion battery. Hence we can

not use the same technique for recognizing a NiMH battery. The NiMH battery recognition

circuit is shown in Figure 9.

cold

14/42

Page 15

AN2390 Evaluation board implementation

Figure 9. NiMH battery recognition circuit

Q5

31

V

IN

V+

R7

1k

To charger

2STR1215

R26

470

2

BT2

Ni-MH BATTERY

R27

470

3

V-

Q6

2

E_FRONT

2STR1215

1

Here the combination of two transistors works as a switch which is controlled by the E_Front

signal coming from the ST7 MCU. The algorithm for NiMH battery recognition is as follows.

15/42

Page 16

Evaluation board implementation AN2390

Figure 10. NiMH battery recognition algorithm

NiMH BATT

Recog Algo

IF (I

BAT

> I

OPEN

NO

)

Exit

YES

ENABLE THE SWITCH AND

MEASURE THE BATTERY

VOLTAGE

NO

IF (V

BAT

> V

OPEN

)

BATTERY PRESENT

YES

BATTERY NOT PRESENT

END

Here if the battery current is less than a predefined threshold, switch (Q5) as shown in

Figure 9, is enabled and the battery voltage is measured if the battery voltage is lower than

the certain threshold the battery is considered connected otherwise it is considered not to

be connected to the evaluation board.

2.2.6 Power supply restrictions

The battery characteristics have a direct influence on the choice of the DC power supply.

The supply must be able to drive enough current to charge the battery, even in fast charge

mode.

● V

SUPPLY

Also the MCU, Buck-Boost DC-DC converter, LED and OpAmp consumption must be taken

into account as well. R

In this demo, a DC supply providing 5 V and 2 A is chosen which is sufficient to satisfy the

above condition.

16/42

must be larger than (VCE|

is the sense resistor, indicated as R23 in Figure 6.

S

SAT

+ V

diode

+ V

BAT_MAX

+ RS* I

CONST

).

Page 17

AN2390 Evaluation board implementation

2.3 MCU software

2.3.1 Architecture

The software provided in this demo has state machine architecture. To explain more, various

charging states can be defined for each slot. Each slot is driven by its state machine, with

some interactions to implement front slot priority.

In order to measure the charge time, a timekeeper is implemented and counters are

incremented periodically. Most of the time, slot states are unchanged. This implies that the

PWM duty cycle, charge enable signals and LED on/off states are constant. Periodically, the

ST7 microcontroller measures the battery current, battery voltage and thermistor voltage of

both slots. Using the measurements and the timekeeper values, it updates slot states and

the output configuration. If necessary, it resets the timekeeper.

17/42

Page 18

Evaluation board implementation AN2390

Figure 11. Main software flowchart

RESET

Initialize I/O ports and peripherals

Initialize slot states

Launch timekeeper

Wait for

state update request

from main time base

Perform the measurements

Correct battery voltage measurements

with battery current measurements

Poll Li-ion

battery

Ye s

No

Poll NiMH

battery

Ye s

No

Front Rear

Voltage mean of 16 mean of 16

Current mean of 16 mean of 16

Thermistor mean of 16 mean of 16

Li-ion slot monitor

Updates front slot state depending on:

Previous

slot states

Update output configuration

NiMH slot monitor

Updates front slot state depending on:

Previous

slot states

Measurements

Timekeeper

Measurements

Timekeeper

18/42

Update output configuration

?

Reset timekeeper

Page 19

AN2390 Evaluation board implementation

2.3.2 Use of the ST7 MCU on-chip peripherals

The time base is generated using the Main Clock Controller and the PWM is generated by

the 16-bit timer. In order to minimize supply current, the ST7 core puts itself into WAIT

mode between two state updates which is updated @50 ms for Li-ion and @5 s for NiMH

but the PWM duty cycle for both is updated @50 ms. The reason for keeping the state

update high for NiMH is to detect the end of charging conditions properly which requires

monitoring the voltage difference (Zero Delta Voltage Condition) for a long period of time,

keeping a low value might result in wrong detection. The selection of state update request

for NiMH depends on the user application.

In this demo, the same interrupt condition (Timer reaching zero) also increments the

timekeeper counters. This means the timekeeper is synchronized with the state updates.

The timekeeper divides the standard timer frequency. To do this, it has three counters: tick,

timeKeeper_Low and timeKeeper_Hi.

Table 4. Charge timekeeper counters

tick timeKeeper_Low timeKeeper_hi

Increment Condition Timer Zero IT tick = 0 timeKeeper_Low = 0

Period

General T

Evaluation

board

TMZ

2 ms 250 ms 1 min

125 * T

TMZ

60,000 * T

TMZ

The analog to digital converter (ADC) is used intensively before each slot state update. In

most cases, the PWM output cannot be disabled, so due to switching noise, the ADC

accuracy is not optimal. To reduce errors, the ADC measures battery voltage, battery

current and battery temperature 16 times in a row and takes the average as the final value.

The software is able to remove any spurious errors due to noise to avoid any wrong

interpretations. The slot state monitoring software works with the mean values.

As explained earlier, battery voltage measurements must be corrected with battery current

measurements. These corrections require some computing, performed on the 16-bit words.

19/42

Page 20

Evaluation board implementation AN2390

2.3.3 State diagrams

A slot can be in one of the nine states as described in following table. These states are

updated periodically as described earlier in Section 2.3.1

Table 5. Slot state definitions

Output configuration

Name Meaning

Slot outputs PWM duty cycle

IDLE Slot empty

TRI_1 1st Trickle charge state

CI Constant current charge

CV

Constant voltage charge,

duty cycle down

TRI_2 2nd Trickle charge state

SAT Battery saturated

EXP Charge time expired

FAIL Battery failure

Charge disabled,

LEDs off

Charge enabled,

LED blinking @ 1Hz

Charge disabled,

LED ON

Unchanged

Updated periodically to

bat

= I

tri_1

have I

Updated periodically to

have I

bat

= I

const

Updated periodically to

bat

= V

F

have V

Updated periodically to

bat

= I

tri_2

have I

Unchanged

Charge disabled,

HEAT

Charge suspended

by overheat

LED blinking @ 2Hz

It is important to understand that this choice of states is only one solution and that there are

many possible ways to manage the behavior of the charger.

The state transition diagram is too complex to be shown in a single figure, it has been

divided into six parts shown in Figure 12 through Figure 17. In the diagrams, 't' stands for

the timekeeper value. The rectangles represent actions performed once during a state

transition.

20/42

Page 21

AN2390 Evaluation board implementation

Figure 12. General charging flow – Li-ion charging state diagram (1/3)

Li-ion charging

algorithm

EXP

If V

BAT

< V

TRI_2

SAT

IDLE

If V

> V

If (I

TRI_1

BAT

> I

If V

) OR if (V

FAIL

BAT

FAIL

> V

BAT

FAST

CC mode

< V

AND t > t

SC

FAI L

SAT

)

CV mode

If I

BAT

BAT

> I

F

SAT

Trickle charging

to maintain

current = 0.2C

CI_D

CI_U

Heat

If V

> V

BAT

F

Suspend PWM until

it gets to normal

condition

CV_D

CV_U

21/42

Page 22

Evaluation board implementation AN2390

Figure 13. Time expiry condition – Li-ion charging state diagram (2/3)

Li-ion charging

algorithm

IDLE

EXP

TRI_2

TRI_1

FAIL

CC mode

CI_D

CI_U

If t >= t

Heat

SAT

EXP

CV mode

CV_D

CV_U

22/42

Page 23

AN2390 Evaluation board implementation

Figure 14. Battery Idle condition – Li-ion charging state diagram (3/3)

IDLE

TRI_1

Heat (Suspend

PWM)

No battery present

CC mode

CI_D

CI_U

EXP or SAT

FAIL

CV mode

CV_D

CV_U

23/42

Page 24

Evaluation board implementation AN2390

Figure 15. General charging flow – NiMH charging state diagram (1/3)

NiMH charging

algorithm

EXP

TRI_1

Trickle charging

to maintain

current = 0.2C,

no -dV checking

FAIL

If (I

I

f

V

B

A

T

>

V

T

R

I

IDLE

> I

BAT

FAIL

CC mode

CI_D

) OR if (V

BAT

< V

If (dV/dt for timeCheck)

Or, if V

Or, if (t > t

BAT

> V

FAS T

AND t > 30 min)

FAIL

MAX

SAT

)

CI_U

Trickle charging

to keep current

= 0.033C to 0.05C

Heat

24/42

Suspend PWM

Page 25

AN2390 Evaluation board implementation

Figure 16. Time expiry condition - NiMH Charging State Diagram (2/3)

NiMH charging

algorithm

EXP

FAIL

TRI_1

IDLE

CC mode

CI_D

CI_U

Heat

If t >= t

SAT

EXP

25/42

Page 26

Evaluation board implementation AN2390

Figure 17. Battery Idle Condition – NiMH Charging State Diagram (3/3)

NiMH charging

algorithm

EXP IDLE

No battery present

FAIL

SAT

TRI_1

CC mode

CI_D

CI_U

Heat

26/42

Page 27

AN2390 How to use the evaluation board

3 How to use the evaluation board

3.1 Connecting the evaluation board

3.1.1 Jumper Connections

The following jumpers must be correctly configured for proper operation of the evaluation

board.

J1: This is a 3-pin connector for selecting between ICC clock and resonator clock.

Figure 18. ICC connector

EXT

123

OSC1 ICC_OSC

J1

ICC clock is used only when we need to re-program the ST7 microcontroller. For normal

operation please short pin 1 and pin 2.

J2, J3: These jumpers are used to connect charger slots for different batteries as shown in

Figure 19.

Figure 19. J2 and J3 connections

UNIVERSAL BATTERY

RT1: NTC

CONNECTOR

CHARGER

J2 CONNECTOR FOR NiMH

V+

V-

J3 CONNECTOR FOR Li-ION

V+

TV-

Put NTC

close to slot

2-CELL NiMH

BATTERY CHARGER SLOT

27/42

1-CELL Li-ION

BATTERY CHARGER SLOT

Page 28

How to use the evaluation board AN2390

The role of each jumper is as follows:

J2: Used to connect NiMH Battery Charger Slot

J3: Used to connect NiMH Battery Charger Slot

RT1: RT1 is used to connect external NTC. This NTC is put close to the NiMH charger slot

to correctly monitor the NiMH battery temperature.

3.1.2 Powering and running the evaluation board

After all the jumpers are connected as described in Section 3.1.1, you can connect the

power supply. To connect the power supply there is a power jack X1 (5V, Gnd) available on

the evaluation board. You need to connect a DC power supply of (5V, 2A) to this connector.

After connecting the power supply, you need to press the Reset button on the evaluation

board for correct operation.

Now the evaluation board is in running mode and you can monitor the charging status

through LED D5 status as mentioned in Tab le 3 .

Note: It is necessary to press the Reset button once after connecting the power supply as the LVD

feature is not used in this evaluation board. However the LVD can be implemented in a real

application

3.2 Warnings/ Limitations

The user should be aware of the following warnings/limitations when using this evaluation

board.

1. Only one type of battery can be charged at a time and there is no protection to prevent

shorting the batteries if they are connected simultaneously in both slots. So the user

has to make sure to connect only one battery at a time.

2. There is no protection for reverse battery polarity connection but it can be provided on

customer request.

3. To minimize noise spikes at the input power supply, please connect a capacitor of 100 220 uF between the input power supply and Gnd.

3.3 Example test results with evaluation board

3.3.1 Test environment

In this implementation of the buck-boost converter, the following values are taken into

account.

Transistor drop |V

V

= 0.5V, F

sense

timer is updated at 500 Hz.

| (SAT) = 0.2V, Diode drop |Vd| = 0.55 V, L = 75 mH, C = 470 uF, Max

CE

= 8 MHz, F

cpu

= 16 kHz and Ambient Temperature = 24 deg C. Also the

pwm

28/42

Page 29

AN2390 How to use the evaluation board

3.3.2 Li-ion battery charger

The following parameter values are used in the Li-ion charger:

Table 6. Li-ion battery charger parameters

SL No Parameter name Value

Input Parameter

1 Input Supply Voltage 5 V

2 Max Input Supply Current 2A

Output Parameter

3 Max Battery Output Voltage 4.2V

4 Max Output Current 1000 mA

The following values are programmed for the different phases:

1) Precharge Phase:

Here Vbat <= 3.0 V and charging current: 200 mA

2) Constant Current Phase:

Here 3.0 < Vbat < 4.2 V and charging current: 500 mA

3) Constant Voltage Phase:

Here 4.15< Vbat < 4.2 V

Ta bl e 9 shows the results of an experiment with the evaluation board charging a single Li-ion

battery.

29/42

Page 30

How to use the evaluation board AN2390

Table 7. Li-ion test results

SL No Time (minutes)

Input voltage

(V)

Input current

(mA)

Output voltage

(V)

Output current

1 0 5 1230 3.9 1050

2 3 5 1230 4 1050

3 8 5 1280 4.05 1050

4 13 5 1350 4.1 1050

5 18 5 1360 4.14 1050

6 23 5 1380 4.18 1050

7 28 5 1390 4.2 1050

8 30 5 1470 4.2 1080

9 31 5 1300 4.2 1045

10 32 5 1270 4.2 975

11 34 5 1260 4.2 968

12 36 5 1150 4.2 906

13 38 5 1070 4.2 867

14 40 5 970 4.2 799

15 42 5 850 4.2 712

16 44 5 720 4.2 616

(mA)

17 46 5 650 4.2 555

18 58 5 330 4.2 280

19 60 5 310 4.2 260

20 62 5 270 4.2 224

21 65 5 240 4.2 205

22 68 5 200 4.2 160

23 70 5 200 4.2 160

24 73 5 163 4.2 129

25 75 5 150 4.2 123

26 78 5 124 4.2 94

27 80 5 120 4.2 90

28 83 5 110 4.2 81

29 85 5 92 4.2 64

30 88 5 90 4.2 61

31 93 5 74 4.2 45

32 99 5 54 4.2 27

30/42

Page 31

AN2390 How to use the evaluation board

The total time was around 99 minutes in which the constant current phase remained for

around 30 minutes. Figure 20 shows the graph of the output current versus time.

Figure 20. Output Current vs. Time

Output Current (mA) Vs Ti m e (Minutes)

1200

1000

800

600

400

Current (mA)

200

0

0

13

28

32

38

44

60

68

75

83

93

Time (Minutes)

The variation in the output current was around +/- 10mA and the variation in output voltage

was +/- 20 mV.

3.3.3 NiMH battery charger

The following parameter values are used for the NiMH charger.

Table 8. Table 8: NiMH battery charger parameters

SL No Parameter name Value

1 Input Supply Voltage 5 V

2 Max Input Supply Current 2 A

3 Max Battery Output Voltage 1.7 V / cell

4 Output Current 1000 mA

The following values are programmed for the different phases:

1) Pre-charging Phase:

Here Vbat <= 1.0 V and charging current: 0.1 C = 200 mA

Charging time taken by the battery: 10 minutes (approximately)

Input Parameter

Output Parameter

2) Constant Current Phase:

Charging Current = 1 A and Programmed charging time = 2 Hr

31/42

Page 32

How to use the evaluation board AN2390

3) Saturation Phase:

Charging Current = 0.03 C = 60 mA, and Expiry Time = 4 Hr.

In this case the C rate is 1000 mA. After the expiry time is over, charging is stopped till a new

battery is inserted.

Ta bl e 9 shows the results of an experiment for constant current charging phase for a 2 Cell

NiMH battery charger.

32/42

Page 33

AN2390 How to use the evaluation board

Table 9. NiMH test results

SL No Time (minutes)

Input voltage

(V)

Input current

(A)

Output voltage

(V)

Output current

1 0 5 1.01 3.16 1015

2 5 5 1.01 3.165 1015

3 10 5 1.01 3.168 1015

4 15 5 1.01 3.172 1015

5 20 5 1.01 3.168 1015

6 25 5 1.01 3.16 1015

7 30 5 1.01 3.168 1015

8 35 5 1.03 3.172 1015

9 40 5 1.03 3.175 1015

10 45 5 1.03 3.186 1015

11 50 5 1.03 3.2 1015

12 55 5 1.03 3.206 1015

13 60 5 1.03 3.214 1015

14 65 5 1.03 3.223 1015

15 70 5 1.03 3.231 1015

16 75 5 1.03 3.245 1015

(mA)

17 80 5 1.05 3.252 1015

18 85 5 1.05 3.264 1015

19 90 5 1.05 3.282 1015

20 95 5 1.05 3.3 1015

21 100 5 1.08 3.35 1020

22 105 5 1.08 3.4 1020

23 110 5 1.08 3.38 1020

24 115 5 1.08 3.37 1020

25 120 5 1.08 3.37 1020

26 125 5 1.08 3.37 1020

27 130 5 1.08 3.36 1020

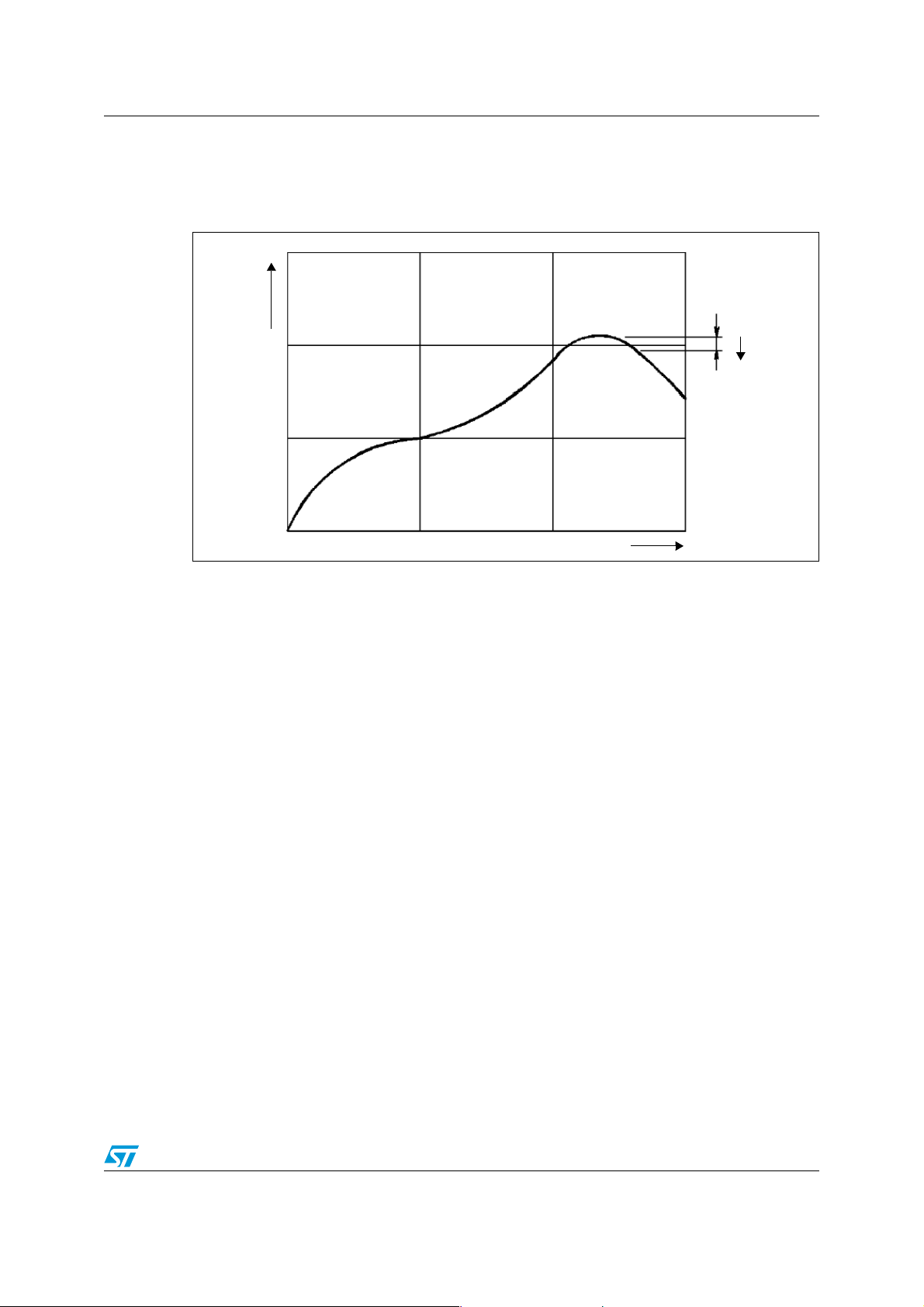

The variation in the output current was around +/- 10 mA and the variation in output voltage

was +/- 20 mV. Figure 21 shows the graph of the output current versus time.

33/42

Page 34

How to use the evaluation board AN2390

Figure 21. Output voltage vs. time (in minutes)

Output Volta ge Vs Time

3.45

3.4

3.35

3.3

3.25

3.2

3.15

3.1

Output Voltage (in V)

3.05

3

0

10

20

30

0

40

60

5

Time (In Minutes)

70

80

90

100

110

120

13

0

Figure 21 shows the variation in output voltage versus time for the constant current charging

phase. Here the programmed time for constant current is increased by 10 minutes just to

show the behavior of the charger.

34/42

Page 35

AN2390 Conclusion: a low-cost flexible solution

4 Conclusion: a low-cost flexible solution

Everything on the evaluation board has been designed to make it easy to adapt in any way

(to other types of battery, new behavior specifications, additional design constraints, etc.).

● The demo is developed with an ST72324L microcontroller device but you can choose

another MCU device if you so desire.

● Because of the flexibility of the MCU, you can modify the firmware for wide variety of

applications and this is well supported by the flexible non inverting buck boost converter

which can adapt to different supply voltages. For example, you could easily make a

USB charger to charge a 4.2 V Li-ion battery.

● The firmware is developed in ‘C’ language. So it is easily upgradeable.

● The number of components needed for each slot (charging and feedback) is minimal,

so replacing them is inexpensive.

● The code size is approximately 3 Kbytes. The current firmware supports Li-ion and

NiMh battery chemistry but it can be easily converted to charge other battery

chemistries, for example to charge SLA batteries.

● ST’s low cost PNP and NPN transistors and diodes are used to implement this

converter which makes it even more cost-effective.

35/42

Page 36

References AN2390

5 References

[1] AN2389: “An MCU-based low cost non-inverting buck-boost converter for battery

chargers”, STMicroelectronics

36/42

Page 37

AN2390

Appendix A

A.1 Source file organization

The code is written in ‘C’ language. The Code Size is approximately 3 Kbytes. The source

code consists of 3 source files and 3 header files as listed below:

● main.c: it consists of the main subroutine.

● BC_func.c: These files contain the definitions of all the functions used in the main

subroutine.

● Interrupt_vector.c: it consists of the interrupt vector mapping files.

● BC_func.h: it consists of the declarations of all the global variables and the functions

used in the main.

● ST7lib_config.h: It is the configuration file and also consists of the #define statements

for assembly language instructions like ‘NOP’ etc.

● st7lites2_5_reg.h: It contains the declarations of the hardware registers.

This modular organization makes it easier to perform minor modifications to the software.

Table 10. Examples of minor software modifications

If you want to change… …only modify…

Voltage thresholds

PWM frequency

State update frequency

Timing thresholds

I/O Configuration BC_InititalizePeripheral() in BC_Func.c

State diagram

State definitions

BC_SlotMonitor() function in BC_Func.c

Transition conditions

Transition priority

BC_Func.h

37/42

Page 38

A.2 Schematic

D

8

Li-ION BATTERY

123

J2

V+

AIN8

100 (1%)

D3

Vsupply

F1

12

TL1431AIZ

R16

4.7k (0.1%)

IN4148

FUSE2

U1

V-

D4

8

Vin

Vout1GND2GND3NC

VDD

7654321

VAREF

R3

Vin

Universal Battery Charger

Ni-MH BATTERY

1

2

J3

V+

V-

Vin

7

8

O2

VCC

O111-21+3GND

U3

AIN1

R24

13.32k (0.5%)

R22

3.3k (0.5%)

AIN8

BT1

Li-ION BATTERY

th

C2

100nF(Not To Be Mounted)

3

R17

7

5

GND6GND

INHIBIT

4

Q3

R1

330

V+

R19

15k (0.1%)

R15

10k

KF33BDTR

6

4

E

C5C

C1C2B

3

5k (0.5%)

C1

470uF/16V

D2

1N5821

R4

L1

STT818B

100

75uH/1000mA

Vsupply

D1

1N5821

R2

100

31

6

5

2-

2+

LM258AD

4

R23

0.5,1W(0.5%)

Vin

13

Q5

V-

R7

R20

5k (0.5%)

AIN0

Q4

23

31

2

Q1

AN2390

C

LEDD6LEDD7LEDD8LED

D5

470

470

470

R9

R10

R11

R12

LED1

LED2

LED3

LED4

E_FRONT

2

2STR1215

Q6

31

R26

470

R27

470

2

2STR2215

1k

BT2

Ni-MH BATTER Y

2STF1360

1

Q2

R5

2STR1215

R13

68

2STR1215

R6

1k

2

PWM-1

470

AIN14

t

RT1

4.7k/NTC

V-

PWM-2

B

R25

10k

ICCSEL

ICCDATA

ICCCLK

RESET

470

33pFC433pF

Y1

C3

OSC_EXT

R8

1k

E_FRONT

1 2

3 4

5 6

7 8

9 10

CON1

U2

J1

PE0

PE1

GND

VDD

3

2

1

OSC_EXT

VDD

R21

4.7k

GND

OSC1

OSC2

22

23

VDD

OSC124OSC2

PB0

PB3

(HS)/PB4

PDO

PD1

VAREF1VSS2AIN8/PF03PF14AIN10/PF45PF6

AIN8

GND

VAREF

10k (1%)

R14

VDD

VSS

C5

RESET

21

HEADER 5X2

10nF

ICCSEL

20

RESET

S1

LED4

ICCSEL

6

PWM-1

OSC1

PA719PA618PA4

LED3

ST72F324LK2T6

7

C6

LED2

17

PA3

PC7

PC6

PC5

PC4

PC3

PC2

PC1

PF7

PC0

8

ICC

16MHz

OSC2

25

VDD

26

27

28

29

30

31

AIN0

32

AIN1

A

1of1

STMicroelectronicsPvt Ltd

Plot no. 1 , Knowledge P ark III,

Greater Noida -201308, UP

INDIA

UNIVERSAL_ BATT_CHARGER

2.2 uF/16V

100nF

100nF

C7

C8

C9

VDD

AIN0

AIN1

16

LED1

15

14

ICCCLK

13

AIN14

12

ICCDATA

11

10

9

PWM-2

Scale Sheet

Size FCSMNo. DWG No. Rev

A3 1

100nF

100nF

C10

AIN8

AIN14

R18

4.7k (1%)

VDD

1

2

X1

D

C

38/42

1 2 3 4 5 6 78

B

A

Page 39

AN2390

A.3 BOM

Table 11. Bill of material

Index Qty Reference

1 1 C1 470uF/16V RB-.2/.4 Any

26

3 1 C6 2.2 uF/ 16V 805 Any

4 1 C5 10nF 805 Any

5 1 CON1 HEADER 5X2 IDC-10B Any

6 2 D1, D2 1N5821

C3, C4, C7,

C8, C9, C10

Value / Generic

Part Number

Package

100nF 805 Any

DO-

201AD

Manufacturer’s

Manufact

urer

ordering code /

Recordable Part

ST 1N5821

Number

7 1 D3 IN4148

DO-35-

TH

Any

8 2 D4 TL1431 TO-92 ST TL1431AIZ

94

D5, D6, D7,

D8

LED LED Any

10 1 F1 FUSE2 FUSE Any

11 1 J1 CON3 SIP-3 Any

12 1 J2 CON3 SIP-3 Any

13 1 J3 CON2 SIP-2 Any

14 1 L1 75uH/1000mA IND Any

15 3 Q1, Q2, Q6 2STR1215 SOT-23 ST 2STR1215

16 1 Q3 STT818B

SOT23-

6L

ST STT818B

17 1 Q4 2STF1360 SOT-89 ST 2STF1360

18 1 Q5 2STR2215 SOT-23 ST 2STR2215

19 1 R1 330 805 Any

R5, R9, R10,

20 7

R11, R12,

470 805 Any

R26, R27

21 1 R13 68 805 Any

22 2 R14, R15 10k (1%) 805 Any

23 1 R16 4.7k (0.1%) 805 Any

24 1 R17 15k (0.1%) 805 Any

25 1 R18 4.7k (1%) 805 ST

26 2 R19, R20 5k (0.5%) 805 Any

27 1 R2, R7 100 805 Any

39/42

Page 40

Table 11. Bill of material

Manufacturer’s

Index Qty Reference

28 1 R21 4.7k 805 Any

29 1 R22 3.3k (0.5%) 805 Any

30 1 R23 0.5, 1W (0.5%) RES Axail Any

31 1 R24 13.32k (0.5%) 805 Any

32 1 R25 10k 805 Any

33 1 R3 100 (1%) 805 Any

34 1 R4 100 805 Any

35 3 R6, R8 1k 805 Any

36 1 RT1 4.7k/NTC RAD-0.1 Any

37 1 S1 SW-PB PUSH Any

38 1 U1 KF33 SO-8 ST KF33BDTR

39 1 U2 ST72F324L TQFP-32 ST ST72F324LK2T6

Value / Generic

Part Number

Package

Manufact

urer

ordering code /

Recordable Part

Number

AN2390

40 1 U3 LM258AD SO-8 ST LM258AD

41 1 X1

42 1 Y1 16MHz XTAL-1 Any

Power

Connector

Euro 2 pin Any

40/42

Page 41

AN2390 Revision history

Revision history

Table 12. Document revision history

Date Revision Changes

21-Aug-2007 1 Initial release.

41/42

Page 42

AN2390

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZED ST REPRESENTATIVE, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2007 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

42/42

Loading...

Loading...