Page 1

AN2386

Application note

How to achieve the threshold voltage thermal coefficient

of the MOSFET acting on design parameters

Introduction

Today, the MOSFET devices are used mainly as switches in electronic circuits. In such

operational conditions, the MOSFET device works in switch on and switch off modes.

However, in some applications, as in audio amplifiers or air conditioning, the MOSFET

works in a linear zone. The MOSFET works in a linear zone when either it is subject to a

high voltage, or a high current passes through the device. As it is well known in literature,

during the linear zone operation mode the MOSFET could fail if a thermal run-away occurs.

The failure conditions depend on either of the internal structure of MOSFET or of the

package used. The threshold voltage thermal coefficient (TVTC) is one of the big elements

that could bring the MOSFET to fail. TVTC is achieved deriving the MOSFET threshold

voltage against the temperature. TVTC is a negative coefficient because of when the

temperature increases the threshold voltage decreases. When TVTC increases in absolute

value, the MOSFET becomes thermally instable and a failure could occur. Therefore, in

order to understand if a MOSFET device can be used in an application working in linear

zone in safety conditions, a device with a low TVTC value must be considered and, thus, it is

important to achieve a theoretical expression for it.

June 2006 Rev 1 1/30

www.st.com

Page 2

Contents AN2386

Contents

1 MOS structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2 Some considerations on VTH and TVTC equations and real examples .

14

3 Case of DEVICE3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4 Conclusions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

5 References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

6 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

2/30

Page 3

AN2386 List of figures

List of figures

Figure 1. Cross section view of a MOS capacitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Figure 2. Energy band diagram of an ideal MOS capacitor under thermal equilibrium.. . . . . . . . . . . . 5

Figure 3.

Figure 4.

Figure 5.

Figure 6. DEVICE1 V

Figure 7. DEVICE1 TVTC - comparison between simulated and measured data . . . . . . . . . . . . . . . 16

Figure 8. Weight of single term of (Equation 42) on TVTC at different temperatures . . . . . . . . . . . . 17

Figure 9. DEVICE2 V

Figure 10. DEVICE2 TVTC - comparison between simulated and measured data . . . . . . . . . . . . . . . 19

Figure 11. DEVICE1 V

Figure 12. DEVICE1 TVTC simulated data - comparison between different N

Figure 13. DEVICE1 V

Figure 14. DEVICE1 TVTC simulated data - comparison between different N

Figure 15. DEVICE1 V

Figure 16. DEVICE1 TVTC simulated data - comparison between different tox . . . . . . . . . . . . . . . . . 21

Figure 17. DEVICE1 V

Figure 18. DEVICE1 TVTC simulated data - fixing T and acting on N

Figure 19. DEVICE1 V

Figure 20. DEVICE1 TVTC simulated data - fixing T and acting on N

Figure 21. DEVICE1 V

Figure 22. DEVICE1 TVTC simulated data - fixing T and acting on t

Figure 23. V

Figure 24. TVTC simulated data - comparison between DEVICE1 and the new device . . . . . . . . . . . 23

Figure 25. V

Figure 26. TVTC simulated data considering a p-gate doped MOS . . . . . . . . . . . . . . . . . . . . . . . . . . 24

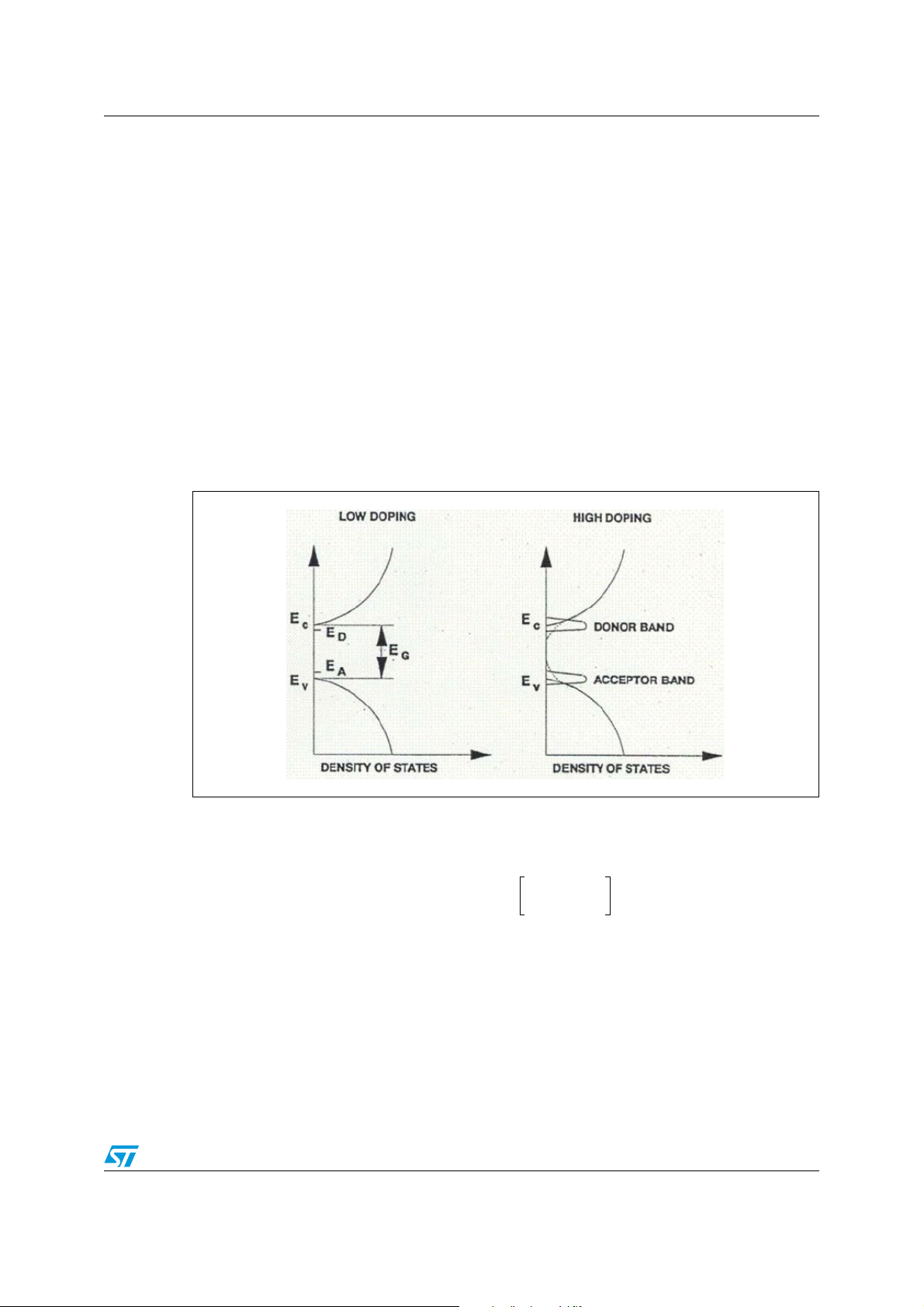

Figure 27. Energy band diagram at low and high doping concentration . . . . . . . . . . . . . . . . . . . . . . . 25

Figure 28. DEVICE3 V

Figure 29. DEVICE3 TVTC - comparison between simulated and measured data . . . . . . . . . . . . . . . 26

Energy band diagram and charge distribution in an ideal MOS capacitor in accumulation condition.. 6

Energy band diagram and charge distribution in an ideal MOS capacitor in accumulation condition. . 6

Energy band diagram and charge distribution in an ideal MOS capacitor in inversion condition . . . . 7

- comparison between simulated and measured data . . . . . . . . . . . . . . . . 16

TH

- comparison between simulated and measured data . . . . . . . . . . . . . . . . 18

TH

simulated data - comparison between different Ng. . . . . . . . . . . . . . . . . . . 19

TH

simulated data - comparison between different Na. . . . . . . . . . . . . . . . . . . 20

TH

simulated data - comparison between different tox. . . . . . . . . . . . . . . . . . . 20

TH

simulated data - fixing T and acting on Ng . . . . . . . . . . . . . . . . . . . . . . . . . 21

TH

simulated data - fixing T and acting on Na . . . . . . . . . . . . . . . . . . . . . . . . . 22

TH

simulated data - fixing T and acting on tox . . . . . . . . . . . . . . . . . . . . . . . . . 22

TH

simulated data - comparison between DEVICE1 and the new device . . . . . . . . . . . . 23

TH

simulated data considering a p-gate doped MOS . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

TH

- comparison between simulated and measured data . . . . . . . . . . . . . . . . 26

TH

. . . . . . . . . . . . . . . . . . . . . . . . 21

g

. . . . . . . . . . . . . . . . . . . . . . . . 22

a

. . . . . . . . . . . . . . . . . . . . . . . . 23

ox

. . . . . . . . . . . . . . . . . 19

g

. . . . . . . . . . . . . . . . . 20

a

3/30

Page 4

List of tables AN2386

List of tables

Table 1. Main electrical parameter simulated by DEVICE1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Table 2. Main electrical parameter simulated by DEVICE2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Table 3. Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4/30

Page 5

AN2386 MOS structure

1 MOS structure

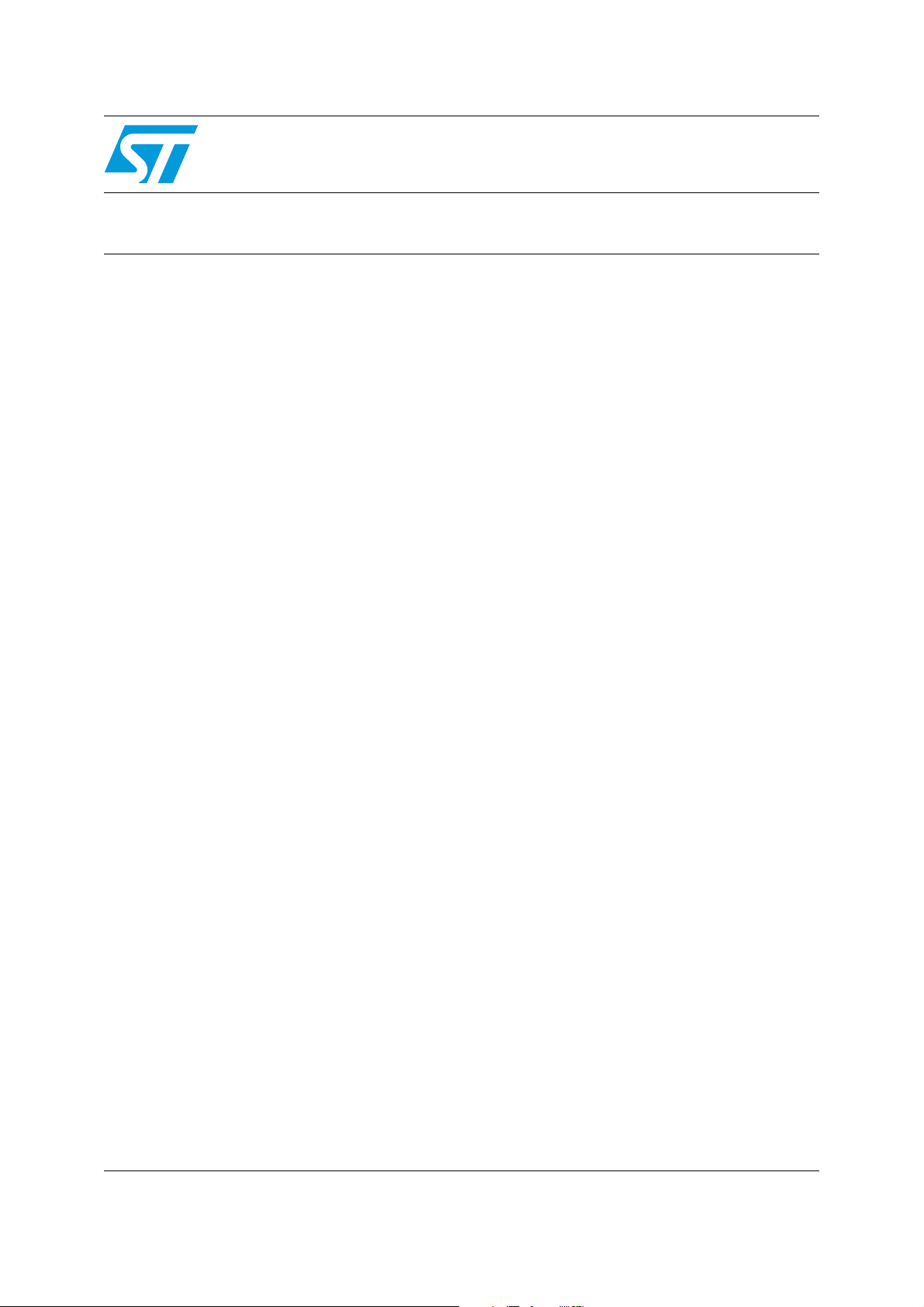

As it is well known, a MOS structure is composed by three layers: the first one is metal or

heavily doped polycrystalline silicon, the second one is an insulator of SiO

one is the semiconductor (see Figure 1.).

Figure 1. Cross section view of a MOS capacitor

and the third

2

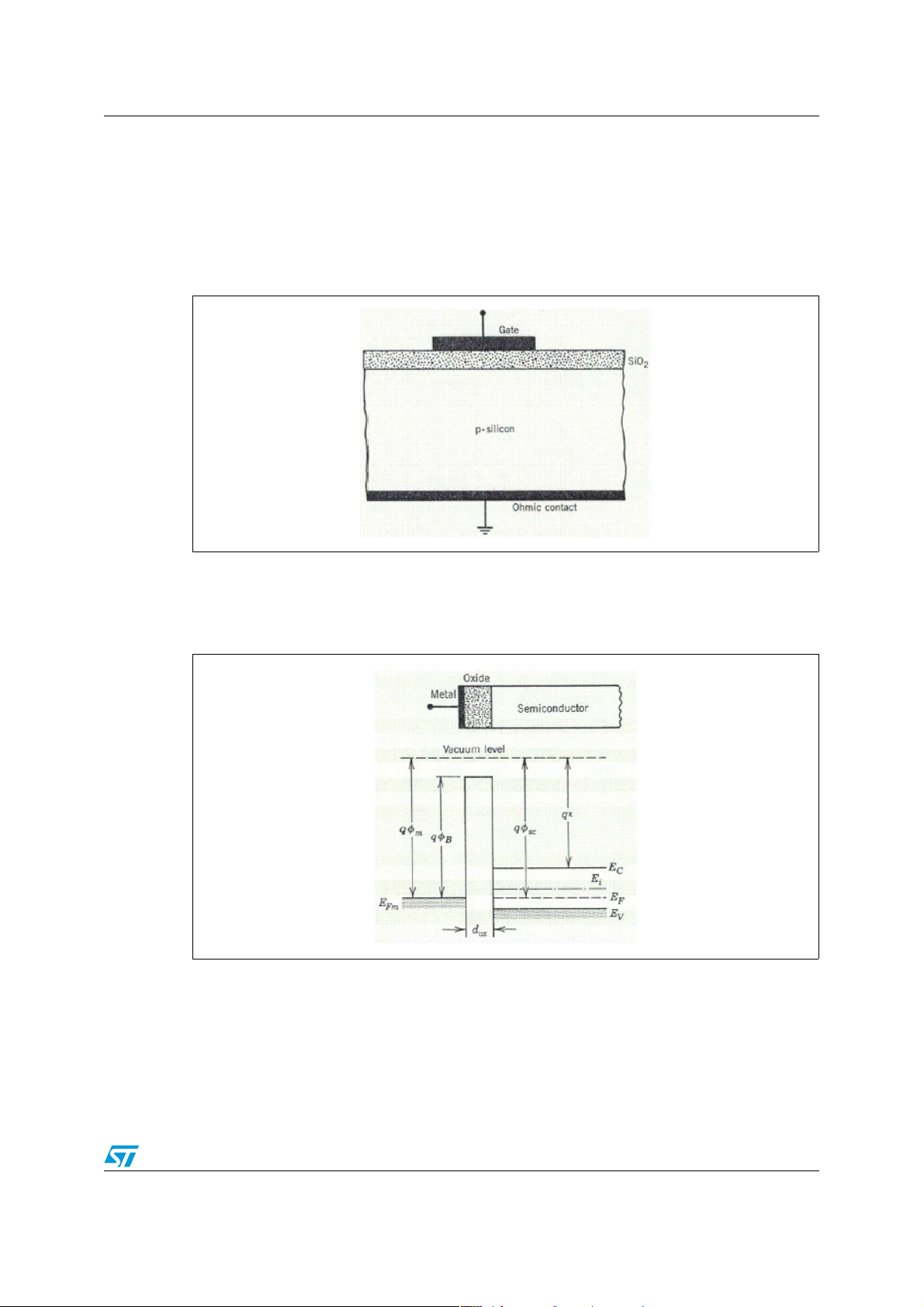

Considering an ideal MOS system with a p-doped semiconductor, the energy band diagram

can be illustrated as in Figure 2.

Figure 2. Energy band diagram of an ideal MOS capacitor under thermal

equilibrium.

q Φ

is the work function (energy that needs to extract an electron from the metal); q ΦB is

m

the energy difference between the oxide conduction band and the metal Fermi energy level

(metal-to-oxide barrier energy); q Φ

is the work function of the semiconductor; q χ is the

sc

energy difference between the vacuum level and the conduction band edge.

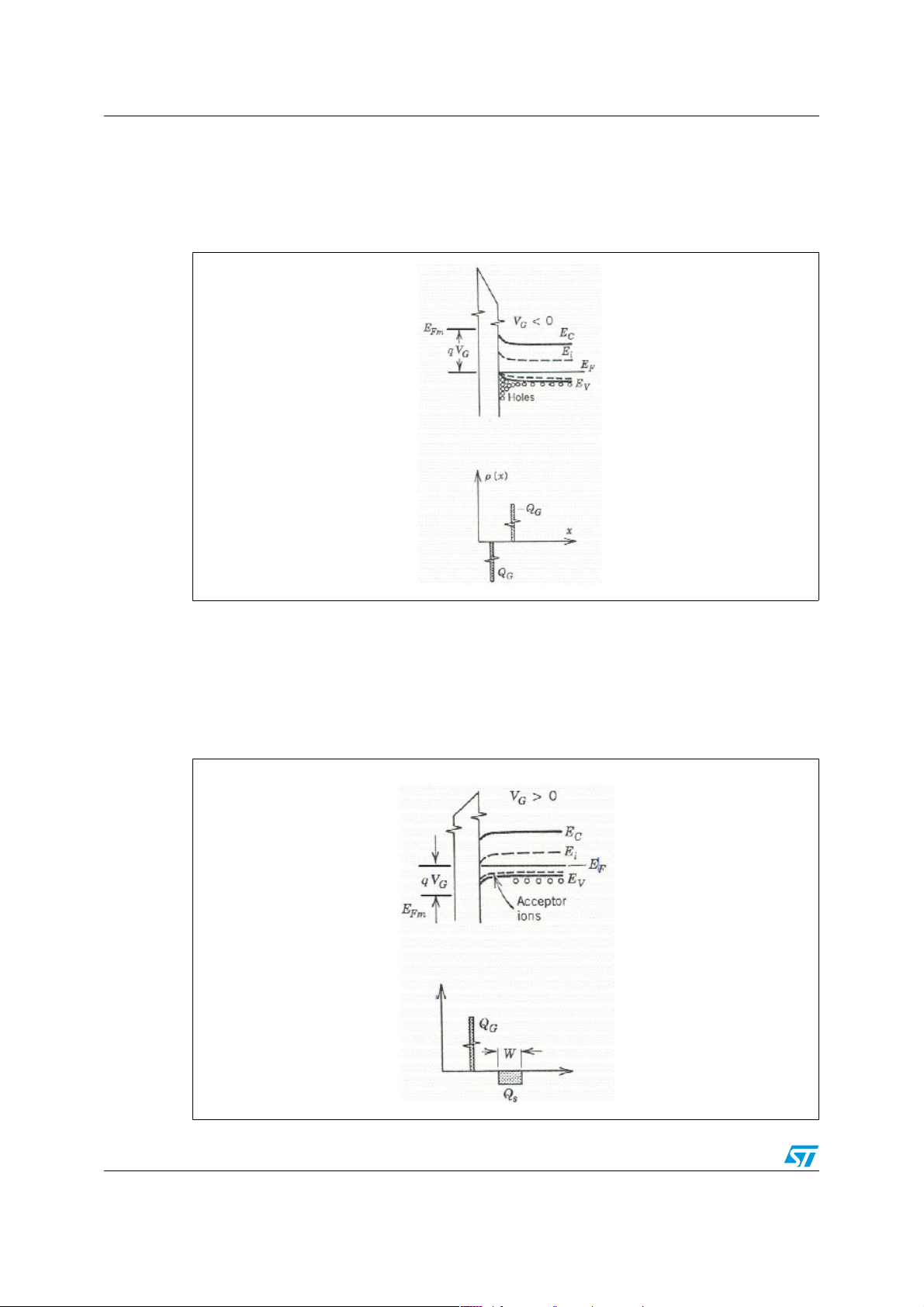

When a negative voltage (V

the Fermi level of the metal raises of qV

) is applied on the gate terminal respect to the semiconductor,

g

compared to the semiconductor side. In moving

g

from the semiconductor to the metal, the vacuum level must bend up gradually to

5/30

Page 6

MOS structure AN2386

accommodate the gate voltage applied. Part of this bending occurs in the semiconductor

and the rest in the oxide. The metal and the semiconductor affinity remain the same (see

Figure 3.).

Figure 3. Energy band diagram and charge distribution in an ideal MOS capacitor

in accumulation condition.

The negative charge on the gate creates an opposite charge on the semiconductor

(enhanced concentration of holes near the oxide interface). When a small positive bias is

applied to the gate, holes are pushed away from the oxide interface and create a depletion

layer in the semiconductor, consisting on the negative charges due to the acceptor ions. The

energy band diagram and the charge distribution are shown in Figure 4.

Figure 4. Energy band diagram and charge distribution in an ideal MOS capacitor

in accumulation condition.

6/30

Page 7

AN2386 MOS structure

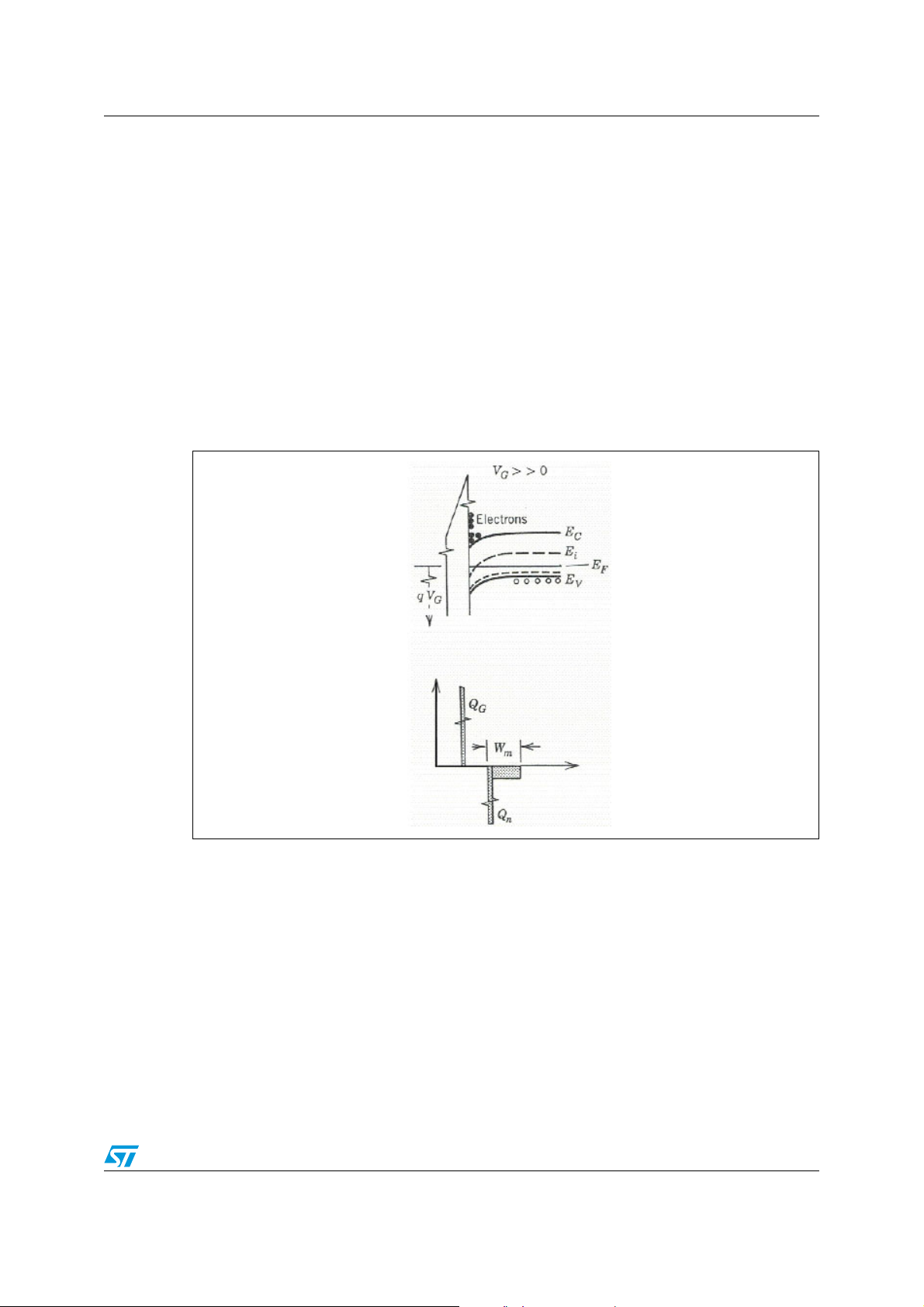

The charge Qs in the semiconductor side near the oxide interface is equal to Qg and it can

be written as:

Equation 1

QsqNaW–=

N

is the acceptor concentration and W is the width of the surface depletion layer. Increasing

a

the gate voltage the bands continue to bend downward until E

energy between the conduction and the valence bands) equals E

(the intermediate level

i

(the Fermi energy level)

F

at the surface. In this condition, at the interface near the oxide, the semiconductor becomes

intrinsic. Increasing the gate voltage again, E

crosses EF and, thus, the minority carriers, in

i

this case the electrons, are attracted to the oxide-semiconductor interface. In this new

condition, the surface layer contains more electrons than holes and it becomes n-type

(inversion layer) (see Figure 5.).

Figure 5. Energy band diagram and charge distribution in an ideal MOS capacitor

in inversion condition

Now, Q

can be written as:

s

Equation 2

Q

is the inversion layer charge.

n

Q

Q–

s

qNaW–=

n

The relationships between the band bending, the electron and hole concentrations in the

interface oxide-semiconductor may be obtained assuming that the semiconductor is non

degenerate and that the doping is uniform. The electron and hole concentrations on the bulk

semiconductor can be written respectively as:

Equation 3

φ

F

------ -

–

•

q

kT

7/30

n

0ni

EFEi–

----------------- -

kT

e

==

nie

Page 8

MOS structure AN2386

Equation 4

EFEi–

----------------- -

p0nie

is the intrinsic electron concentration; Ei is the intrinsic Fermi level; EF is the Fermi level; k

n

i

kT

==

is the Boltzmann constant and it is equal to 1.38x10

Considering that the semiconductor is doped of N

φ

F

------ -

•

q

kT

nie

-23

J/K; ΦF is the Fermi potential.

acceptor, (Equation 4) becomes:

a

Equation 5

•

q

nie

------ -

kT

φ

F

Now, it is possible achieve

Φ

F

as:

N

ani

EFEi–

------------------

–

kT

e

==

Equation 6

N

kT

------ -

Φ

F

q

------ -

ln=

a

n

i

For an intrinsic semiconductor ni can be written in two different ways as:

Equation 7

EcEF–

-------------------

–

n

=

iNc

kT

e

Equation 8

EcEF–

-------------------

–

niNVe

=

kT

Multiplying (Equation 7) and (Equation 8) it is possible obtain:

Equation 9

EcEv–

------------------

2

n

NcNVe

i

N

and NV are the effective density of states at the conduction and valence edges

C

respectively and E

is the energy band-gap. NC and NV can be achieved by the electron and

g

kT

NcNve

==

EgT()

---------------

kT

hole distribution functions and they are equal to:

Equation 10

3

-- -

2

2πm

Nc2

--------------------------- -

=

kT•

e

2

h

Equation 11

3

-- -

2

N

m

* and mh* are the electron and hole density of the states effective masses and h is the

e

v

2πm

--------------------------- -

2

=

kT•

h

2

h

Planck constant. The energy band gap depends on the temperature and it can be written as:

Equation 12

E

gEg0b1

T–=

8/30

Page 9

AN2386 MOS structure

where b1 is equal to 4.76 x 10

E

is equal to 1.21eV and it is the extrapolate value of the band-gap at 0°K while b1 is the

g0

-23

J/K.

rate of energy gap shift with temperature. Now, (Equation 9) can be rewritten as:

Equation 13

Eg0b1T–

-------------------------

2

n

NcNVe

i

kT

NcNve

==

b

1

-----

k

E

g0

---------

kT

e

Considering that for the silicon:

Equation 14

b

1

-----

cNV

k

e

3.88 1016• T

N

3

-- -

2

cm3–[]=

and that:

Equation 15

E

g0

---------

14047 K[]=

k

n

becomes:

i

Equation 16

ni3.88 1016• T

3

-- -

–

2

e

E

g0

----------

2kT

3.88 10

• T

16–

3

–

-- -

2

e

7023

-------------

T

cm3–[]==

In the interface layer oxide-semiconductor, the electron and hole concentrations depend on

the gate voltage and can be written as:

Equation 17

n

sn0

EisEi–

------------------

–

kT

e

==

q

•

n0e

------ -

kT

Φ

s

Equation 18

sn0

e

When

n

Φ

is equal to ΦF the semiconductor surface becomes intrinsic. Instead, increasing Φs

s

again, the layer becomes n-type. When n

EisEi–

------------------

–

kT

==

equals to p0 a "strong inversion" occurs and the

s

q

•

n0e

------ -

kT

Φ

s

minority carriers at the surface become the same of the majority carriers in the bulk. The

potential condition for the strong inversion occurs when:

Equation 19

2Φ

=

Φ

s

F

As explained above, when V

is applied on the MOS structure, VOX (a part of VG) will

G

appear across the oxide and the rest on the silicon surface:

Equation 20

V

GVOXΦs

–=

9/30

Page 10

MOS structure AN2386

If no charges are placed inside the oxide and if the MOS structure can be considered as a

simple parallel plate capacitor, its capacitance can be written as:

Equation 21

Q

ε

is the oxide permittivity (34.5x10

ox

Thus, considering (Equation 21), V

A

C

OXεOX

-12

F/m); tOX is the oxide thickness; A is the plate area.

can be written as:

OX

-------- -

•

t

OX

s

---------- -–==

V

OX

Equation 22

Q

V

OX

s

-----------–=

C

OX

and the gate voltage as:

Equation 23

Q

s

-----------– Φ

V

G

+=

OX

s

C

Considering (Equation 2), neglecting Q

, VG can be rewritten as:

n

Equation 24

qNaW

V

---------------- Φ

G

+=

C

OX

s

By applying the Poisson equation in the semiconductor surface, the following equation can

be obtained:

Equation 25

qN

a

----------

∇2Φ==

ε

s

rotE is the electric field rotor; ∇

silicon permittivity (105.4x10

-12

rotE

2

Φ is the voltage space second order derived; and es is the

F/m). From (Equation 25) the following equation can be

achieved:

Equation 26

2

qNaW

-------------------=

Φ

2

2ε

s

and, thus, the depletion layer width can be achieved as:

Equation 27

2ε

---------------=

qN

sΦs

a

W

will became:

V

G

10/30

Page 11

AN2386 MOS structure

Equation 28

G

2εsqNaΦ

-------------------------- - Φ

V

s

+=

C

OX

s

The gate voltage at the strong inversion condition is the threshold voltage V

of the MOS

TH

and it can be written as:

Equation 29

V

TH

4εsqNaΦ

--------------------------- 2Φ

F

+=

C

OX

F

Up to now, the ideal MOS structure was considered. In the real MOS structure, when no

voltage is applied on the gate, a difference between metal and semiconductor work function

exists, as well as charges in the oxide. In this paper, the charges inside the oxide will be

neglected and also the metal-semiconductor difference work function Φ

will be studied.

ms

The charges inside the oxide are related to the real process flow and they involve a small

threshold voltage shift. In order to consider the effect of Φ

on the threshold voltage, the

ms

following formula must be taken into account:

Equation 30

V

THVFBtOX

V

is the flat-band voltage and it is the gate voltage required to bring the semiconductor

FB

bands flat; Q

are the charges inside the oxide. Such voltage equals to Φms when the

OX

4εsqNaΦ

--------------------------- 2ΦFΦ

F

ε

OX

ms

Q

OX

----------- - t

++ +=++=

C

OX

4εsqNaΦ

-------------------------------

• 2Φ

OX

ε

OX

F

F

charges inside the oxide are neglected.

For metal gate, Φ

can be written as:

ms

Equation 31

E

T()

g

--------------- Φ

–=

2q

±+

F

where E

Φ

Φmχ

ms

(T) is the band-gap energy versus the temperature.

g

Instead, for polysilicon gate (the real case usually) of n-type and the semiconductor is of ptype, Φ

can be written as:

ms

Equation 32

N

•

N

is the doping level of the polysilicon.

g

kT

ms

------ -

Φ

gNa

--------------------

ln–=

q

2

ni

TVTC can be, thus, achieved deriving (Equation 30) against the temperature:

Equation 33

∂V

TH

-------------

∂T

∂Φ

ms

------------- t

∂T

OX

4εsqN

------------------------

•

ε

OX

∂Φ

a

------------- -

• 2

∂T

∂Φ

F

F

---------

•++=

∂T

and also:

11/30

Page 12

MOS structure AN2386

Equation 34

∂V

TH

-------------

∂T

∂Φ

ms

------------- t

∂T

OX

εsqN

---------------------

•

εOXΦ

∂Φ

a

---------

• 2

∂T

F

∂Φ

F

F

---------

•++=

∂T

At the beginning, the thermal coefficient of Φ

will be studied.

ms

Deriving (Equation 32), it is possible achieve:

Equation 35

N

•

∂Φ

ms

-------------

∂T

k

gNa

-- -

--------------------

q

2

ni

2kT

----------

qni

∂ni

------- -

•+ln–=

∂T

and, thus:

Equation 36

∂T

ms

Φ

ms

--------- -

T

2kT

----------

qni

∂ni

------- -

•+=

∂T

∂Φ

-------------

Considering (Equation 16) and deriving it versus T is possible obtain:

Equation 37

∂n

-------

∂T

E

g0

1

-----------

-- -

3

i

-- -

3.88 10

2

•• T

2KT

16

2

e

3.88 1016• T

E

3

-----------

-- -

2KT

2

e

g0

•+=

and also:

Equation 38

n

∂n

-------

∂T

i

i

------ -

2T

E

g0

---------+•=

3

KT

E

g0

--------------

2KT

2

Replacing (Equation 38) in (Equation 36) it is possible obtain:

Equation 39

∂Φ

ms

-------------

∂T

Φ

ms

--------- - 3

T

E

K

g0

--- -

---------++=

q

qT

Now, the thermal coefficient of the Fermi voltage is studied. In fact, deriving (Equation 6) it is

possible achieve:

Equation 40

∂Φ

---------

∂T

N

K

--- -

q

a

------ -

n

i

F

KT

------- -

qn

∂n

i

-------

•–ln=

∂T

i

Replacing (Equation 38) in (Equation 40), the following equation can be achieved:

Equation 41

∂Φ

---------

∂T

Φ

------

3

F

-- -

2

T

F

E

K

go

--- -

•–

---------- -–=

q

2qT

Replacing (Equation 41) and (Equation 39) in (Equation 34), TVTC can be rewritten as:

Equation 42

∂V

TH

-------------

∂T

Φ

ms

--------- - 2

T

Φ

F

------

• t

T

OX

εsqN

---------------------

•

εOXΦ

∂Φ

a

F

---------

•++=

∂T

F

12/30

Page 13

AN2386 MOS structure

If the silicon is doped of p-type (n-channel MOSFET) and the polysilicon is also doped of ptype, (Equation 32), Φ

becomes positive and it can be rewritten as:

ms

Equation 43

Φ

and (Equation 39) becomes negative:

Equation 44

∂Φ

-------------

∂T

and, thus, (Equation 42) becames:

Equation 45

∂V

-------------

∂T

TH

Φ

ms

--------- - 2

T

Φ

------

• t

T

ms

F

ms

N

kT

------ -

--------------------

ln=

q

Φ

ms

--------- - 3

T

εsqN

---------------------

•

OX

εOXΦ

•

gNa

2

ni

K

--- -

•–

q

a

F

E

go

---------–=

qT

∂Φ

F

---------

• 6

∂T

K

--- -

•– 2

q

E

go

---------

•–++=

qT

13/30

Page 14

Some considerations on VTH and TVTC equations and real examples AN2386

2 Some considerations on VTH and TVTC equations

and real examples

Looking at (Equation 30) it is possible see that the threshold voltage is the sum of three

components: the metal-oxide work function (it is negative when the polysilicon is of n-type

and the silicon substrate is of p-type, while, it is positive when the polysilicon is of p-type),

two times the Fermi potential (it is positive for p-type silicon substrate) and the voltage drop

on the oxide (it is positive for a p-type silicon substrate). TVTC (see Equation 42) also

depends on three contributes: the metal-oxide work function divided by the temperature (it is

a negative value for n-type gate doped in p-type silicon), two times the Fermi potential

divided by the temperature (for a p-type silicon it is a positive value) and a third contribute

function of the Fermi potential thermal coefficient and other parameters as the oxide

thickness and the body concentration of impurity (it is a negative contribute because of its

negative the Fermi potential thermal coefficient).

Considering low voltage power MOSFETs working in linear zone in applications like air fans,

it is important have devices with standard threshold voltage (around 3V in ambient

temperature) and very low TVTC in absolute value, in order to avoid the thermal instability

behavior that could bring the component to fail.

The modern MOSFETs have TVTC in the negative value range (it becomes more negative

when the temperature increases). Therefore, when the device works in linear zone, a power

pulse is dissipated on the component, the temperature increases, the threshold voltage

decreases and the drain current rises.

To avoid the thermal run-away of the device, it is important to minimize the TVTC in absolute

value. The parameters that make TVTC negative, considering an n-type gate and p-type

silicon, are the metal-oxide work functions divided by the temperature and the term of the

Fermi potential thermal coefficient. Instead, the parameter that makes TVTC positive is the

Fermi potential divided by the temperature (T). As shown in (Equation 32), the metal-oxide

work function divided by T depends on the doping concentration of the gate, silicon and the

intrinsic carrier concentration. This parameter increases in absolute value, increasing the

doping concentration of the gate or substrate, while it decreases in absolute value when the

temperature increases because of the intrinsic carrier concentration increases too. In order

to minimize this parameter, the gate and substrate doping concentration must be lowered.

The Fermi potential divided by T depends on the doping concentration of the substrate and

the intrinsic concentration of the carriers. When the doping concentration of the substrate

increases, the parameter also increases its value. By increasing the temperature, the

parameter decreases because the intrinsic carrier concentration increases. In order to

maximize the parameter, the substrate doping concentration should be increased.

The threshold voltage thermal coefficient (see Equation 41) depends on the Fermi potential

divided by T, minus a constant and minus a term function of the inverse of T. Its value is

negative because the parameter with the minus sign is generally higher than the term, due

to the Fermi potential divided by T. When the temperature increases, the parameter also

increases in absolute value because the Fermi potential decreases too. Thus, in order to

minimize the Fermi potential thermal coefficient, the substrate doping concentration must be

increased. However, the third term of (Equation 42), as previously explained, also depends

on the substrate doping concentration root-square. Therefore, considering the modern

MOSFET technology, this term increases in absolute value when the substrate doping

concentration also increases.

14/30

Page 15

AN2386 Some considerations on VTH and TVTC equations and real examples

In the modern device, it is possible to observe that TVTC (as described in Equation 42)

increases in absolute value when the doping concentration also increases because the first

and third components are higher than the second term.

Another important parameter in order to establish TVTC is the oxide thickness. This

parameter only affects the third term of Equation 42. When the oxide thickness decreases,

the third term in (Equation 42) also decreases and that involves in a TVTC lowering in

absolute value.

A real example of threshold voltage and TVTC compared to the theoretical model

implemented in this paper is shown below. The low voltage power MOSFET takes into

consideration a device of 55V of breakdown voltage and 5mOhm of on resistance

(production line DEVICE1). This device has a gate doping concentration (N

1e+20cm

-3

, a substrate doping concentration peak in the channel (Na) equals to 2e+17cm-

) equals to

g

3, an oxide thickness of 470Å and a channel length of 0.35µm.

The following table summarizes the main simulated electrical parameter function of T (T

range is 250-400K), then some graphs highlight the DEVICE1 measured and simulated

data.

Table 1. Main electrical parameter simulated by DEVICE1

TNi Φ

250 9.67E+13 -1.058 0.000868 -0.00423 0.462 -0.00070 0.0018 3.40 -0.0026 3.27 -0.0031

255 1.73E+14 -1.053 0.000873 -0.00413 0.458 -0.00070 0.0018 3.39 -0.0026 3.25 -0.0031

260 3.02E+14 -1.049 0.000878 -0.00403 0.455 -0.00071 0.0017 3.38 -0.0026 3.24 -0.0032

265 5.18E+14 -1.045 0.000883 -0.00394 0.451 -0.00071 0.0017 3.36 -0.0026 3.22 -0.0032

270 8.70E+14 -1.040 0.000888 -0.00385 0.448 -0.00071 0.0017 3.35 -0.0027 3.21 -0.0032

275 1.43E+15 -1.036 0.000892 -0.00377 0.444 -0.00071 0.0016 3.34 -0.0027 3.19 -0.0032

280 2.33E+15 -1.031 0.000897 -0.00368 0.441 -0.00072 0.0016 3.32 -0.0027 3.17 -0.0032

285 3.71E+15 -1.027 0.000901 -0.00360 0.437 -0.00072 0.0015 3.31 -0.0027 3.16 -0.0033

290 5.82E+15 -1.022 0.000906 -0.00352 0.433 -0.00072 0.0015 3.30 -0.0027 3.14 -0.0033

295 9.00E+15 -1.018 0.000910 -0.00345 0.430 -0.00072 0.0015 3.28 -0.0028 3.12 -0.0033

300 1.37E+16 -1.013 0.000915 -0.00338 0.426 -0.00073 0.0014 3.27 -0.0028 3.11 -0.0033

305 2.07E+16 -1.009 0.000919 -0.00331 0.423 -0.00073 0.0014 3.25 -0.0028 3.09 -0.0033

310 3.07E+16 -1.004 0.000923 -0.00324 0.419 -0.00073 0.0014 3.24 -0.0028 3.07 -0.0034

315 4.50E+16 -0.999 0.000927 -0.00317 0.415 -0.00073 0.0013 3.23 -0.0028 3.06 -0.0034

320 6.53E+16 -0.995 0.000931 -0.00311 0.412 -0.00073 0.0013 3.21 -0.0029 3.04 -0.0034

325 9.37E+16 -0.990 0.000935 -0.00305 0.408 -0.00074 0.0013 3.20 -0.0029 3.02 -0.0034

330 1.33E+17 -0.985 0.000939 -0.00299 0.404 -0.00074 0.0012 3.18 -0.0029 3.01 -0.0034

335 1.87E+17 -0.981 0.000943 -0.00293 0.401 -0.00074 0.0012 3.17 -0.0029 2.99 -0.0035

∂Fms/∂T Φms/T Φ

ms

∂ΦF/∂T ΦF/T V

F

∂VOX/∂TVth∂Vth/∂T

OX

340 2.60E+17 -0.976 0.000947 -0.00287 0.397 -0.00074 0.0012 3.15 -0.0029 2.97 -0.0035

345 3.59E+17 -0.971 0.000951 -0.00281 0.393 -0.00074 0.0011 3.14 -0.0030 2.95 -0.0035

350 4.90E+17 -0.966 0.000955 -0.00276 0.389 -0.00074 0.0011 3.12 -0.0030 2.94 -0.0035

15/30

Page 16

Some considerations on VTH and TVTC equations and real examples AN2386

Table 1. Main electrical parameter simulated by DEVICE1

TNi Φ

355 6.64E+17 -0.962 0.000958 -0.00271 0.386 -0.00075 0.0011 3.11 -0.0030 2.92 -0.0035

360 8.93E+17 -0.957 0.000962 -0.00266 0.382 -0.00075 0.0011 3.09 -0.0030 2.90 -0.0036

365 1.19E+18 -0.952 0.000965 -0.00261 0.378 -0.00075 0.0010 3.08 -0.0031 2.88 -0.0036

370 1.58E+18 -0.947 0.000969 -0.00256 0.375 -0.00075 0.0010 3.06 -0.0031 2.87 -0.0036

375 2.07E+18 -0.942 0.000972 -0.00251 0.371 -0.00075 0.0010 3.05 -0.0031 2.85 -0.0036

380 2.70E+18 -0.937 0.000976 -0.00247 0.367 -0.00076 0.0010 3.03 -0.0031 2.83 -0.0037

385 3.51E+18 -0.933 0.000979 -0.00242 0.363 -0.00076 0.0009 3.02 -0.0031 2.81 -0.0037

390 4.52E+18 -0.928 0.000982 -0.00238 0.359 -0.00076 0.0009 3.00 -0.0032 2.79 -0.0037

395 5.78E+18 -0.923 0.000986 -0.00234 0.356 -0.00076 0.0009 2.99 -0.0032 2.77 -0.0037

400 7.36E+18 -0.918 0.000989 -0.00229 0.352 -0.00076 0.0009 2.97 -0.0032 2.76 -0.0038

∂Fms/∂T Φms/T Φ

ms

∂ΦF/∂T ΦF/T V

F

∂VOX/∂TVth∂Vth/∂T

OX

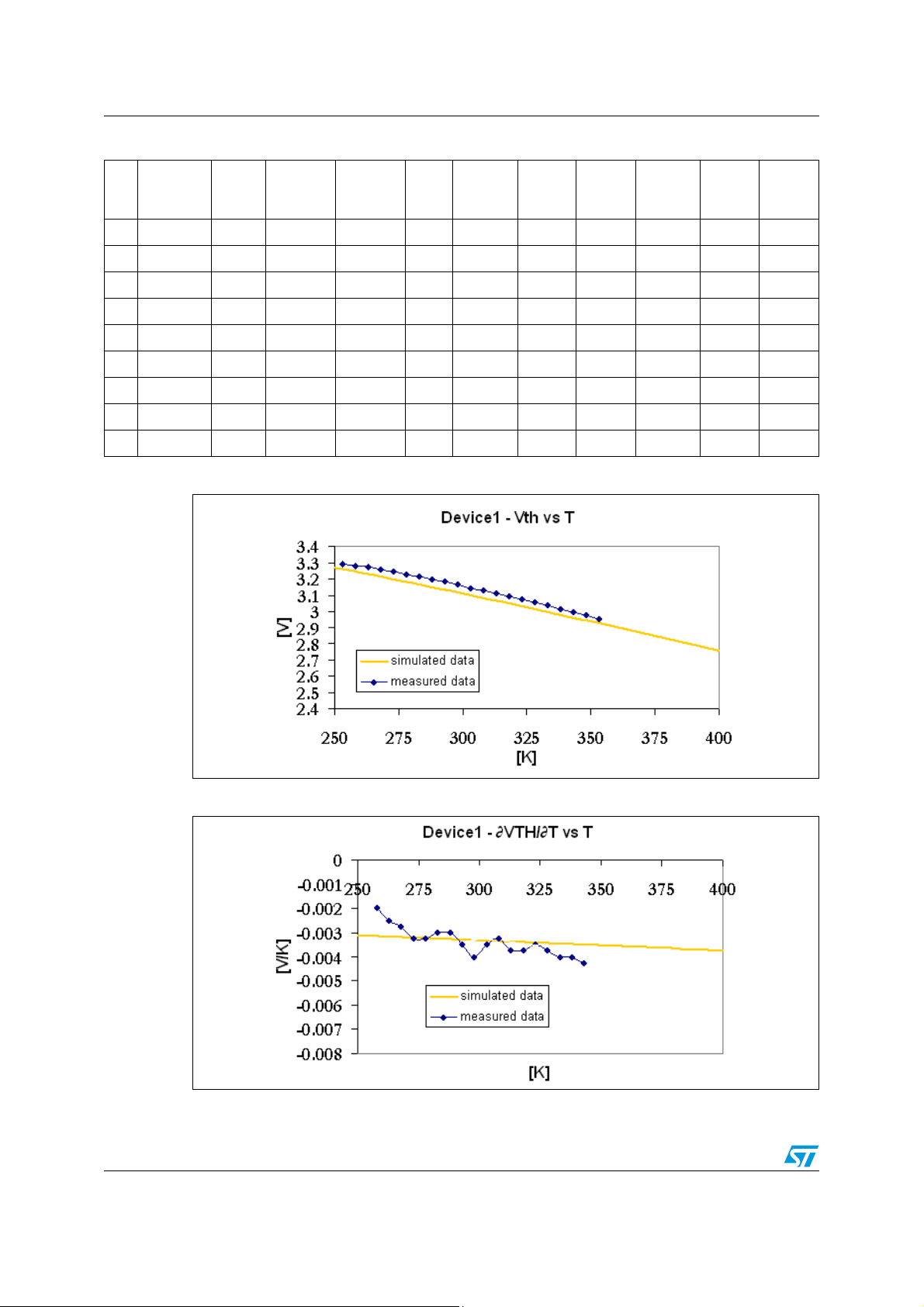

Figure 6. DEVICE1 VTH - comparison between simulated and measured data

Figure 7. DEVICE1 TVTC - comparison between simulated and measured data

16/30

Page 17

AN2386 Some considerations on VTH and TVTC equations and real examples

As shown in Figure 6. and Figure 7., the data simulated and measured are quite close to

each other. In this case, for DEVICE1, the threshold voltage is around 3.2V (standard V

TH

)

and TVTC is around 3mV/K at ambient temperature. In the next Figure 8. the contribution of

each component of (Equation 42) is highlighted.

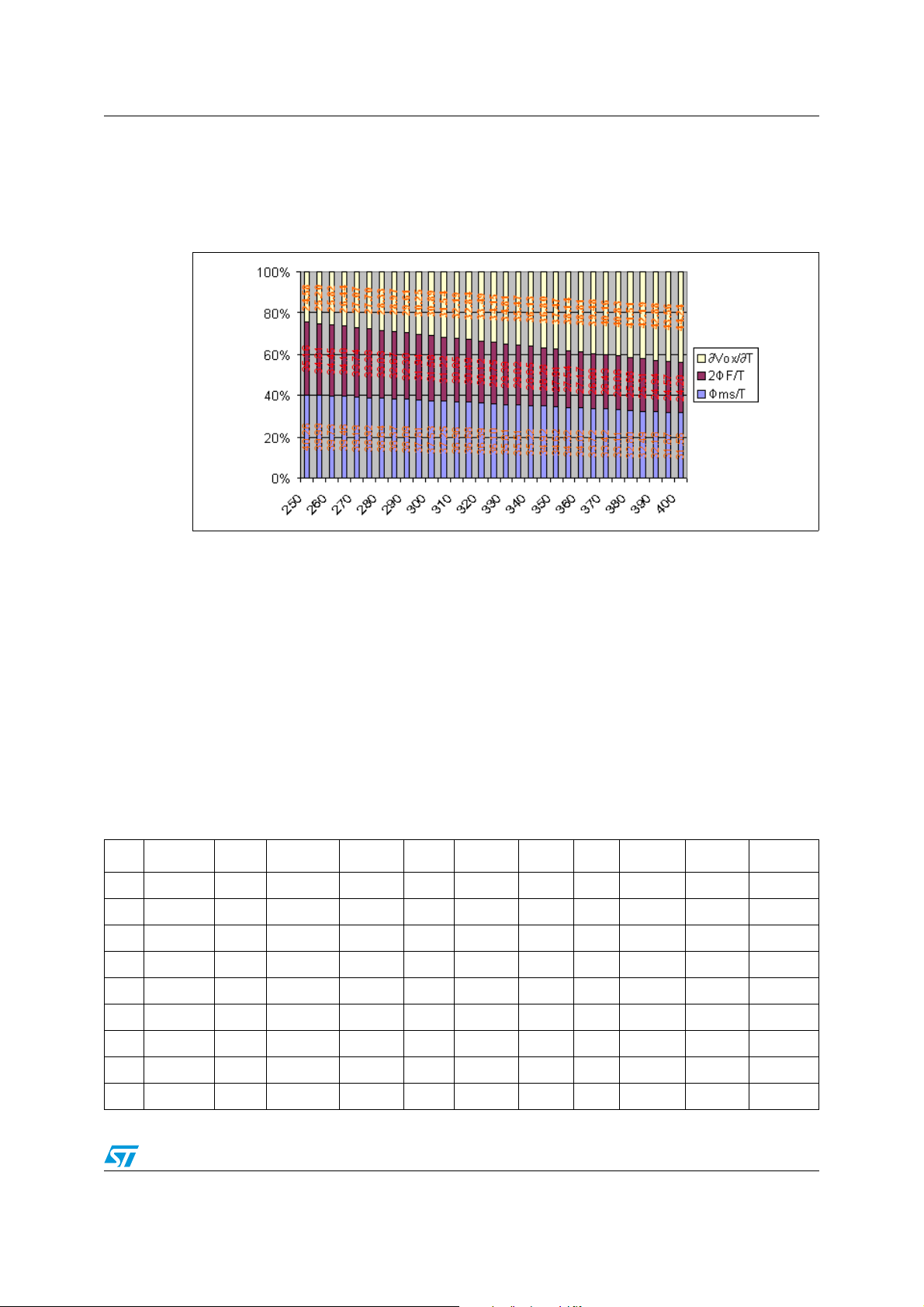

Figure 8. Weight of single term of (Equation 42) on TVTC at different temperatures

In the graph above it is possible see that at a low temperature, the higher weight in the

TVTC formula is established by the parameters Φ

/T and 2ΦF/T. The first term is negative

ms

and makes TVTC negative, while the second term in positive and makes TVTC positive.

When the temperature increases, TVTC increases in absolute value because even if Φ

decreases, 2Φ

/T also decreases and in particular, the weight of ∂Vox/ ∂T increases too.

F

ms

/T

Another real example of threshold voltage and TVTC compared to the theoretical model

implemented is shown below. The low voltage power MOSFET takes into consideration a

device of 55V of breakdown voltage and 6.5mOhm of on resistance (production line

DEVICE1). This device has a gate doping concentration (N

substrate doping concentration peak in the channel (N

) equal to 1e+20cm-3, a

g

) equal to 1e+17cm-3, an oxide

a

thickness of 350Å and a channel length of 0.35µm. The following tab summarizes the main

simulated electrical parameter function of T (T range is 250-400K) and then a graphs

highlights the DEVICE2 measured and simulated data.

Table 2. Main electrical parameter simulated by DEVICE2

TniΦ

250 9.67E+13 -1.043 0.000927 -0.00417 0.447 -0.00076 0.0018 1.76 -0.0015 1.61 -0.0021

255 1.73E+14 -1.038 0.000932 -0.00407 0.443 -0.00076 0.0017 1.75 -0.0015 1.60 -0.0021

260 3.02E+14 -1.033 0.000937 -0.00397 0.439 -0.00077 0.0017 1.74 -0.0015 1.59 -0.0021

265 5.18E+14 -1.029 0.000942 -0.00388 0.436 -0.00077 0.0016 1.74 -0.0015 1.58 -0.0021

270 8.70E+14 -1.024 0.000947 -0.00379 0.432 -0.00077 0.0016 1.73 -0.0015 1.57 -0.0021

275 1.43E+15 -1.019 0.000952 -0.00371 0.428 -0.00077 0.0016 1.72 -0.0016 1.56 -0.0022

280 2.33E+15 -1.015 0.000957 -0.00362 0.424 -0.00078 0.0015 1.71 -0.0016 1.55 -0.0022

285 3.71E+15 -1.010 0.000961 -0.00354 0.420 -0.00078 0.0015 1.71 -0.0016 1.54 -0.0022

290 5.82E+15 -1.005 0.000966 -0.00347 0.416 -0.00078 0.0014 1.70 -0.0016 1.53 -0.0022

∂ms/∂T Φms/T Φ

ms

∂ΦF/∂T ΦF/T V

F

∂VOX/∂TVth∂Vth/∂T

OX

17/30

Page 18

Some considerations on VTH and TVTC equations and real examples AN2386

Table 2. Main electrical parameter simulated by DEVICE2

TniΦ

∂ms/∂T Φms/T Φ

ms

∂ΦF/∂T ΦF/T V

F

∂VOX/∂TVth∂Vth/∂T

OX

295 9.00E+15 -1.000 0.000970 -0.00339 0.412 -0.00078 0.0014 1.69 -0.0016 1.51 -0.0022

300 1.37E+16 -0.995 0.000974 -0.00332 0.408 -0.00078 0.0014 1.68 -0.0016 1.50 -0.0022

305 2.07E+16 -0.990 0.000979 -0.00325 0.404 -0.00079 0.0013 1.67 -0.0016 1.49 -0.0022

310 3.07E+16 -0.985 0.000983 -0.00318 0.400 -0.00079 0.0013 1.67 -0.0016 1.48 -0.0022

315 4.50E+16 -0.980 0.000987 -0.00311 0.397 -0.00079 0.0013 1.66 -0.0017 1.47 -0.0022

320 6.53E+16 -0.976 0.000991 -0.00305 0.393 -0.00079 0.0012 1.65 -0.0017 1.46 -0.0023

325 9.37E+16 -0.971 0.000995 -0.00299 0.389 -0.00080 0.0012 1.64 -0.0017 1.45 -0.0023

330 1.33E+17 -0.966 0.000999 -0.00293 0.385 -0.00080 0.0012 1.63 -0.0017 1.44 -0.0023

335 1.87E+17 -0.961 0.001003 -0.00287 0.381 -0.00080 0.0011 1.62 -0.0017 1.42 -0.0023

340 2.60E+17 -0.956 0.001007 -0.00281 0.377 -0.00080 0.0011 1.61 -0.0017 1.41 -0.0023

345 3.59E+17 -0.951 0.001011 -0.00276 0.373 -0.00080 0.0011 1.61 -0.0017 1.40 -0.0023

350 4.90E+17 -0.945 0.001014 -0.00270 0.369 -0.00080 0.0011 1.60 -0.0017 1.39 -0.0023

355 6.64E+17 -0.940 0.001018 -0.00265 0.365 -0.00081 0.0010 1.59 -0.0018 1.38 -0.0024

360 8.93E+17 -0.935 0.001022 -0.00260 0.361 -0.00081 0.0010 1.58 -0.0018 1.37 -0.0024

365 1.19E+18 -0.930 0.001025 -0.00255 0.356 -0.00081 0.0010 1.57 -0.0018 1.35 -0.0024

370 1.58E+18 -0.925 0.001029 -0.00250 0.352 -0.00081 0.0010 1.56 -0.0018 1.34 -0.0024

375 2.07E+18 -0.920 0.001032 -0.00245 0.348 -0.00081 0.0009 1.55 -0.0018 1.33 -0.0024

380 2.70E+18 -0.915 0.001035 -0.00241 0.344 -0.00082 0.0009 1.54 -0.0018 1.32 -0.0024

385 3.51E+18 -0.910 0.001039 -0.00236 0.340 -0.00082 0.0009 1.53 -0.0018 1.31 -0.0024

390 4.52E+18 -0.904 0.001042 -0.00232 0.336 -0.00082 0.0009 1.53 -0.0019 1.29 -0.0025

395 5.78E+18 -0.899 0.001045 -0.00228 0.332 -0.00082 0.0008 1.52 -0.0019 1.28 -0.0025

400 7.36E+18 -0.894 0.001049 -0.00223 0.328 -0.00082 0.0008 1.51 -0.0019 1.27 -0.0025

Figure 9. DEVICE2 VTH - comparison between simulated and measured data

18/30

Page 19

AN2386 Some considerations on VTH and TVTC equations and real examples

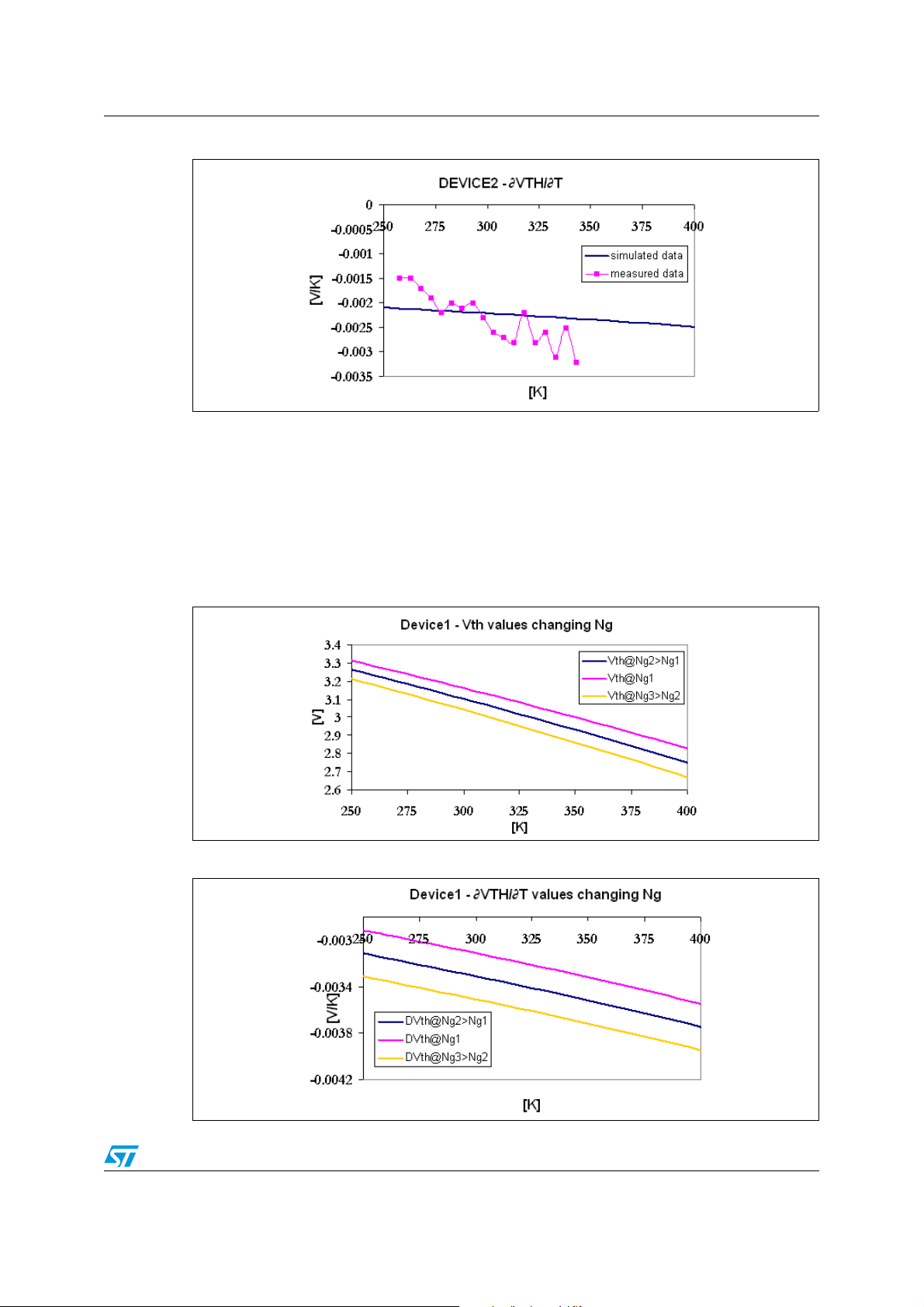

Figure 10. DEVICE2 TVTC - comparison between simulated and measured data

Also in this new case, the data simulated and measured are quite close to each other. In this

case, for DEVICE2, the threshold voltage is around 1.5V and TVTC is around 2mV/K at

ambient temperature.

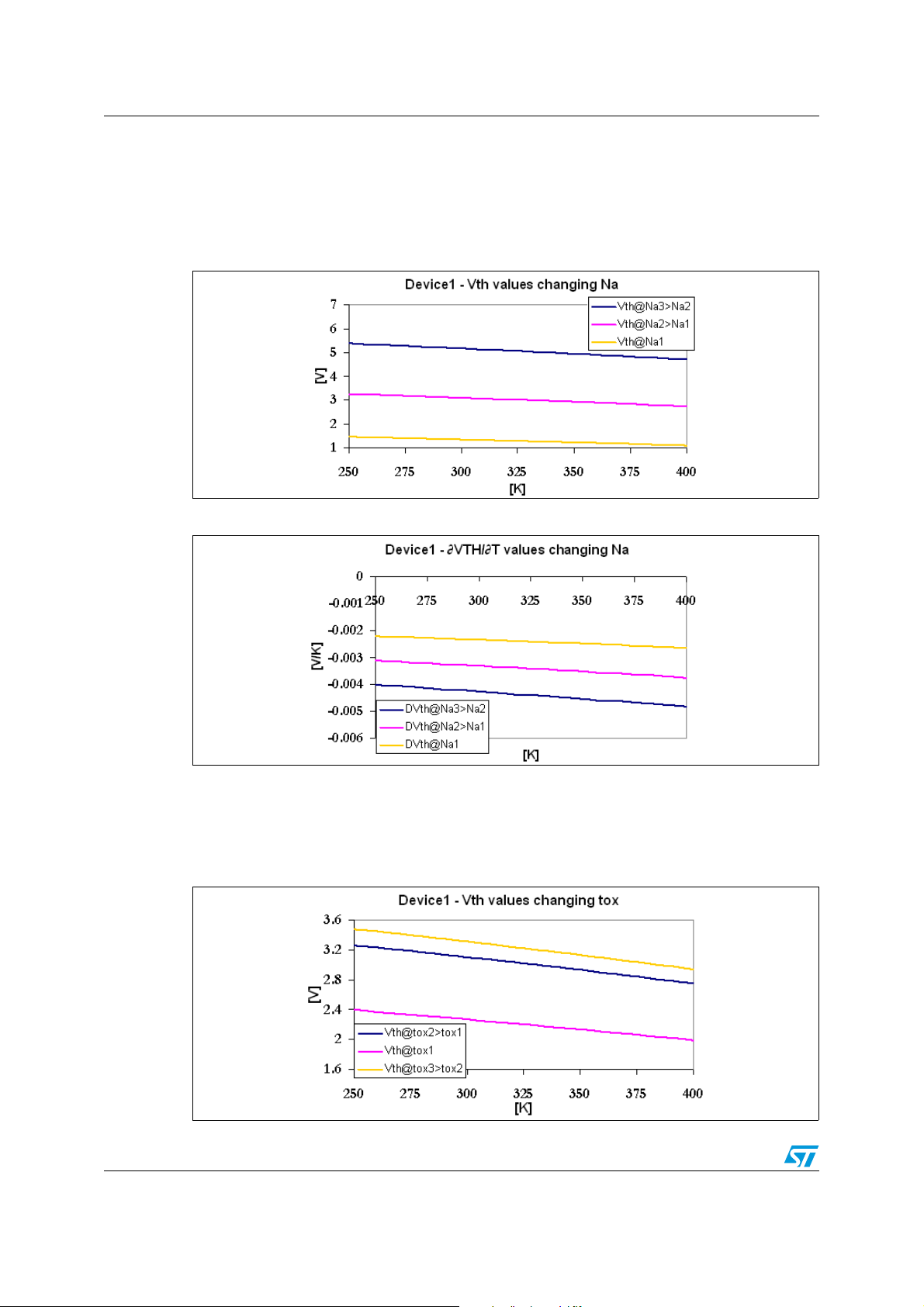

Now it is possible to consider the DEVICE1 device and simulate the V

behavior changing N

, Na and tox respectively.

g

and TVTC thermal

TH

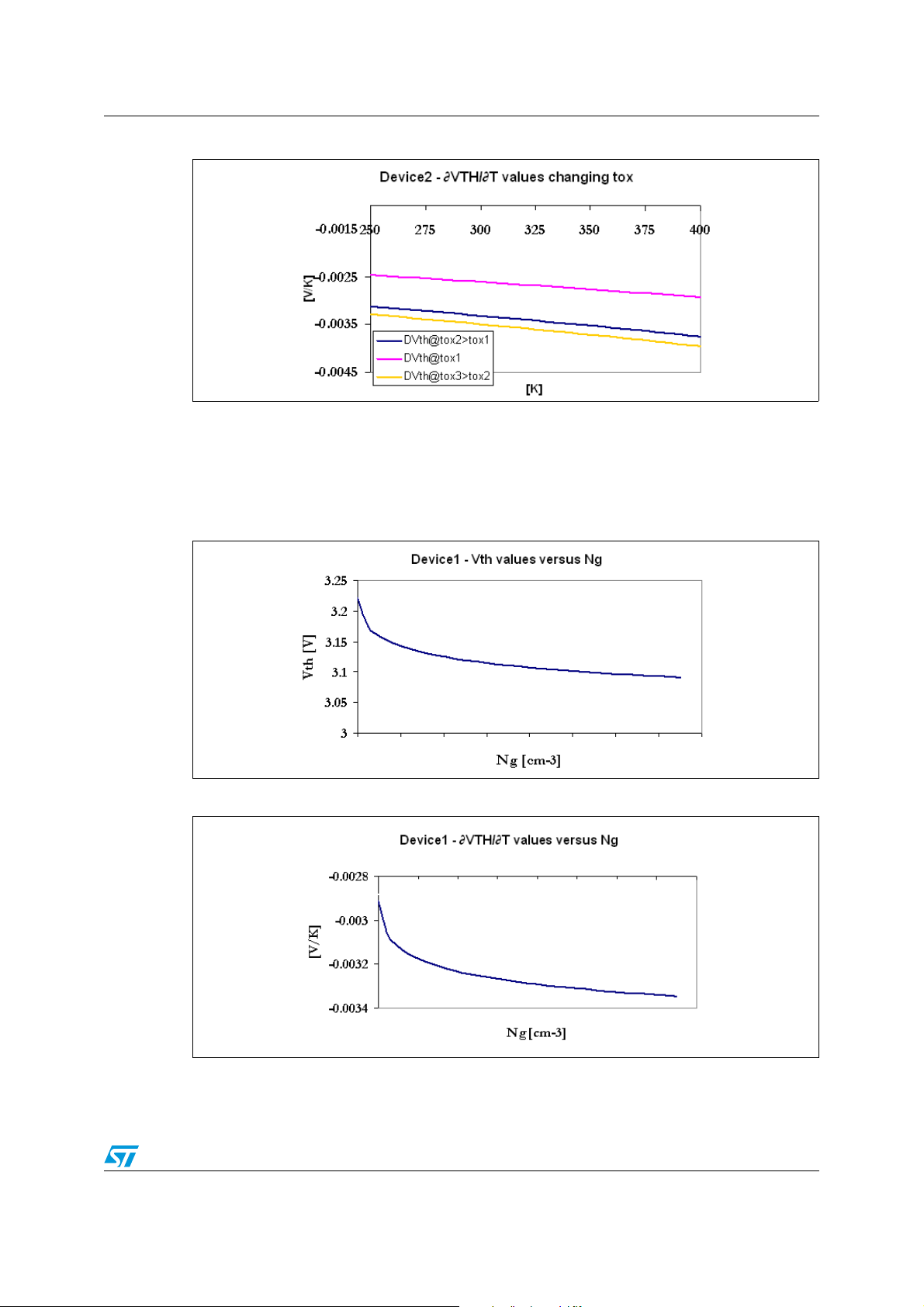

At the beginning, the thermal behavior increasing and decreasing the gate doping

concentration is simulated (see Figure 11. and Figure 12.).

Figure 11. DEVICE1 V

simulated data - comparison between different N

TH

g

Figure 12. DEVICE1 TVTC simulated data - comparison between different N

g

19/30

Page 20

Some considerations on VTH and TVTC equations and real examples AN2386

When the gate concentration doping increases from 1e+20cm-3 to 1e+21cm-3 the threshold

voltage decreases its value, while, TVTC increases in absolute value and vice versa,

decreasing the gate concentration doping from 1e+20cm

-3

to 1e+19cm-3. Now, the thermal

behavior increasing and decreasing the substrate doping concentration is simulated (see

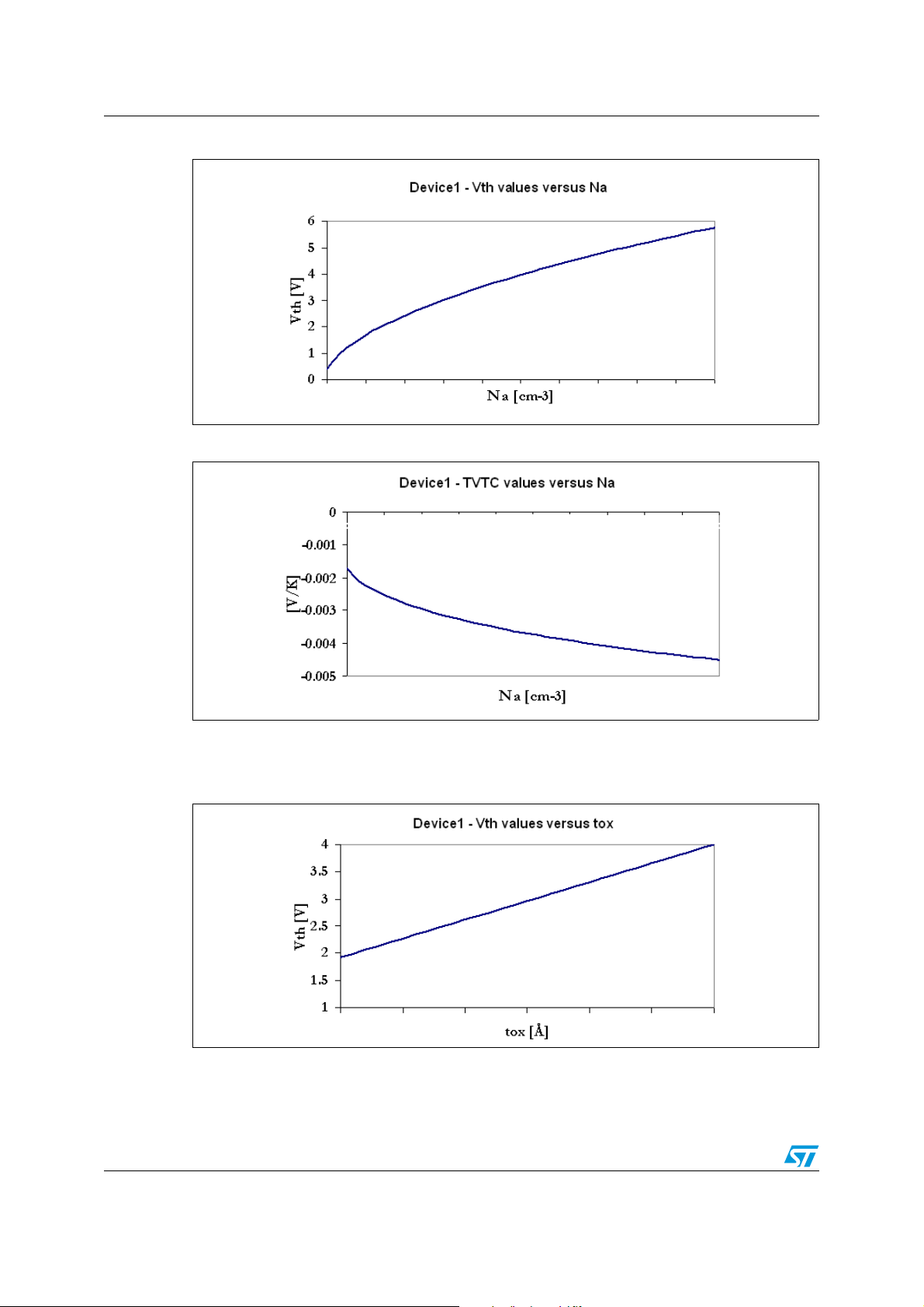

Figure 13. and Figure 14.).

Figure 13. DEVICE1 V

simulated data - comparison between different N

TH

a

Figure 14. DEVICE1 TVTC simulated data - comparison between different N

a

When the substrate concentration doping increases from 2e+17cm-3 to 5e+17cm-3 the

threshold voltage increases its value and also TVTC increases in absolute value and vice

versa, decreasing the substrate concentration doping from 2e+17cm

the case of different thickness oxide will be studied (see Figure 15. and Figure 16.).

Figure 15. DEVICE1 V

20/30

simulated data - comparison between different t

TH

-3

to 5e+16cm-3. Now,

ox

Page 21

AN2386 Some considerations on VTH and TVTC equations and real examples

Figure 16. DEVICE1 TVTC simulated data - comparison between different t

ox

When the oxide thickness increases from 470Å to 500Å, the threshold voltage increases its

value and also TVTC increases in absolute value and vice versa, decreases the thickness

oxide from 470Å to 350Å. Now, it is possible simulate V

temperature is fixed to 300K and the gate doping concentration changes in the range of

1e+18-1.5e+20cm

Figure 17. DEVICE1 V

-3

(see Figure 17. and Figure 18.).

simulated data - fixing T and acting on N

TH

and TVTC supposing that the

TH

g

Figure 18. DEVICE1 TVTC simulated data - fixing T and acting on N

g

The graph in Figure 19. and Figure 20. show VTH and TVTC trend fixing the temperature to

300K and changing N

in the range of 1e+16-6.1e+17cm-3.

a

21/30

Page 22

Some considerations on VTH and TVTC equations and real examples AN2386

Figure 19. DEVICE1 VTH simulated data - fixing T and acting on N

a

Figure 20. DEVICE1 TVTC simulated data - fixing T and acting on N

a

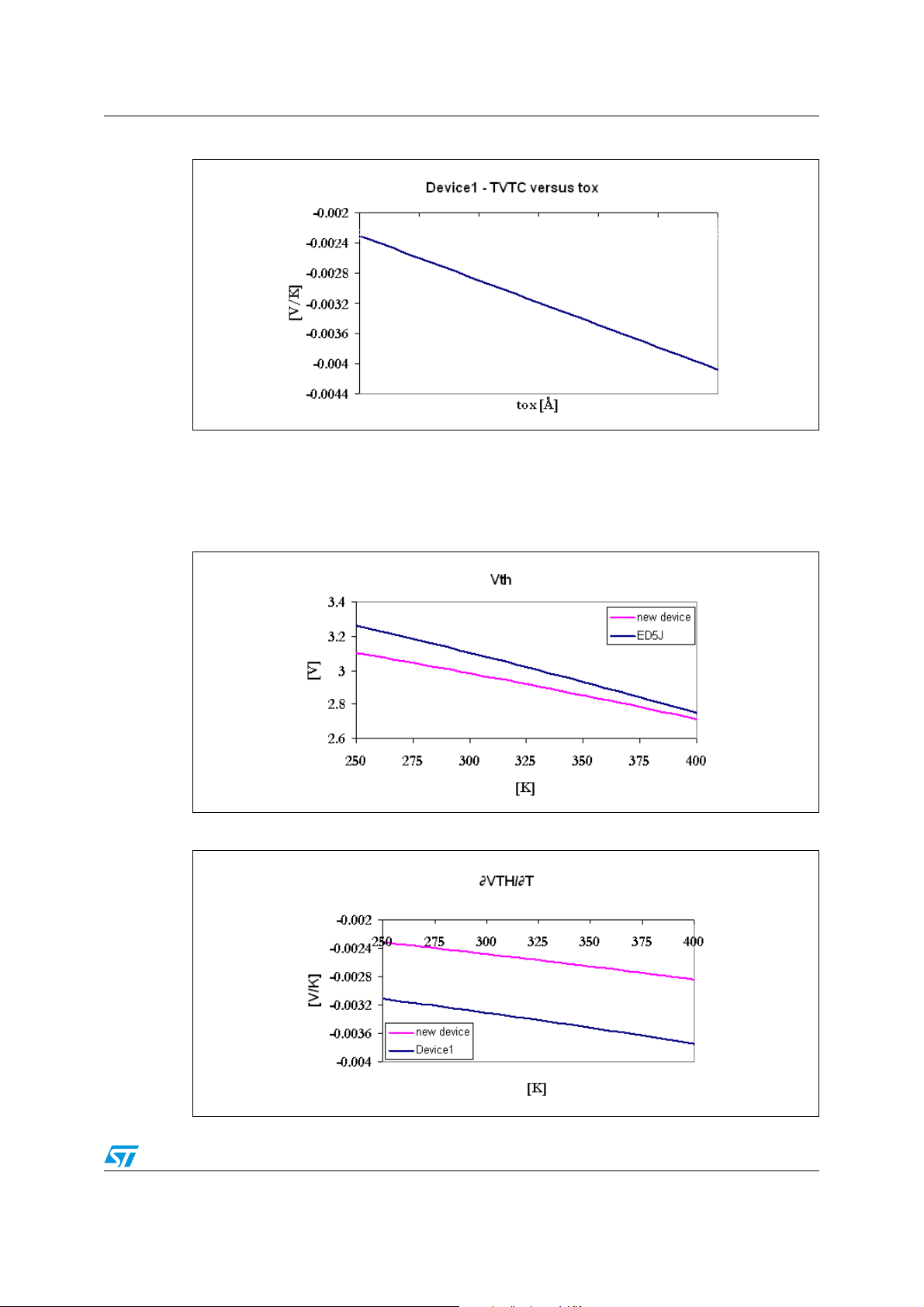

The graph inFigure 21. and Figure 22. shows VTH and TVTC trend fixing the temperature to

300K and changing t

Figure 21. DEVICE1 V

22/30

in the range of 300-600Å.

ox

simulated data - fixing T and acting on t

TH

ox

Page 23

AN2386 Some considerations on VTH and TVTC equations and real examples

Figure 22. DEVICE1 TVTC simulated data - fixing T and acting on t

ox

The next graphs show the simulated data of VTH and TVTC considering DEVICE1 and a

hypothetical new device with standard threshold voltage and minimized TVTC. This device

is obtained changing on N

equal to 1e+18cm

Figure 23. V

-3

, Na is equal to 3e+17cm-3 and tox is equal to 350Å.

simulated data - comparison between DEVICE1 and the new device

TH

, Ng and tox together. For example, this new device has Ng is

a

Figure 24. TVTC simulated data - comparison between DEVICE1 and the new device

23/30

Page 24

Some considerations on VTH and TVTC equations and real examples AN2386

It is possible see that by rearranging Ng, Na and tox the threshold voltage remains fixed and

TVTC decreases in absolute value.

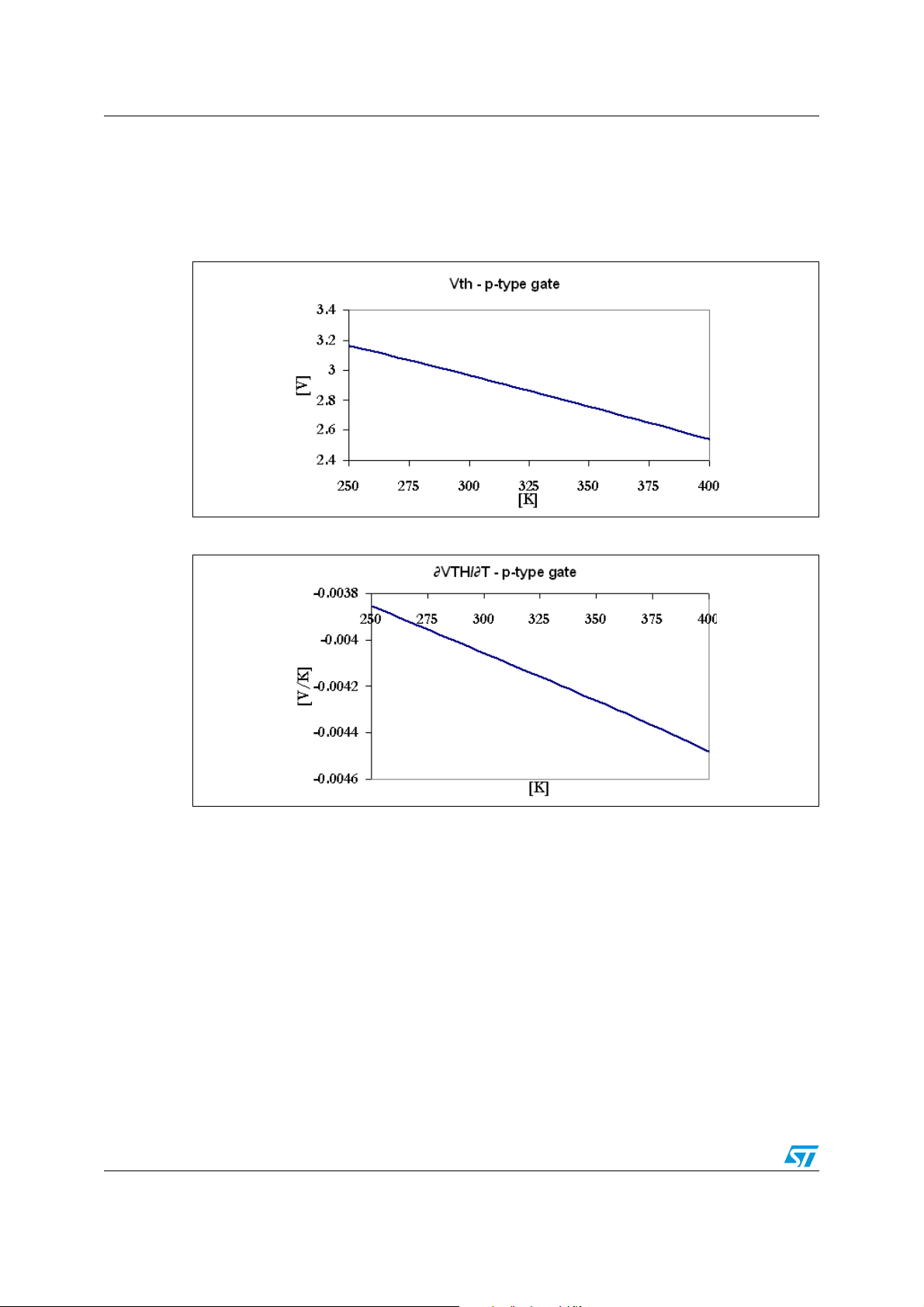

Finally, the following graphs highlight the V

doped MOS with N

Figure 25. V

equal to 1e+21cm-3, Na is equal to 3e+16cm-3 and tox is equal to 470Å.

g

simulated data considering a p-gate doped MOS

TH

and TVTC trend simulates a p-type gate

TH

Figure 26. TVTC simulated data considering a p-gate doped MOS

The only difference with the n-type doped gate is that increasing the gate doping

concentration, TVTC decreases in absolute value instead of increasing.

24/30

Page 25

AN2386 Case of DEVICE3

3 Case of DEVICE3

The device DEVICE3 has similar characteristics of DEVICE1 in terms of tox (470Å), gate

doping (1e+20cm

-3

), silicon doping (2.4e+17cm-3) and breakdown voltage 55V. The main

difference between the two devices consists in the channel length (0.8µm) and the source

doping thermal process activation; DEVICE3 perform a form while DEVICE1 an RTA

thermal process.

The only difference on the length channels between the two devices should not have an

effect on the threshold voltage and TVTC. Instead, the different source thermal process

doping activation could bring a variation on the TVTC because the net charge peak

concentration in the channel near the source well is higher in the silicon processed in the

form compared to the RTA one. In fact, when the net charge concentration in the silicon

overcomes typically 1e+17[cm

-3

], a band-gap narrowing effect occurs (see Figure 27.)

because new impurity band states are created inside the forbidden silicon band near the

conduction and valence edges.

Figure 27. Energy band diagram at low and high doping concentration

In order to consider this effect the Slotboom-De Graaf model is used.

Equation 46

1

-- -

2

0.5+

Eg∆ b1T

=

∆Eg is the band-gap narrowing value; N

N

T

----------- -

+ln

17

10

(expressed in cm-3) is the net charge

T

2

-----

ln

concentration (the sum of acceptor and donor doping elements concentration).

The net charge concentration is not easy to establish so, in order to fit the real data, a net

charge concentration of 3.5e+17cm

-3

was considered for DEVICE3.

The real data on DEVICE3 using RTA process are shown in the following figures where are

compared to the simulated and the data of the device using the form process.

25/30

Page 26

Case of DEVICE3 AN2386

Figure 28. DEVICE3 VTH - comparison between simulated and measured data

Figure 29. DEVICE3 TVTC - comparison between simulated and measured data

Also in this case, the simulated data and the measured data are close to each other.

26/30

Page 27

AN2386 Conclusions

4 Conclusions

This paper has studied the effect of the temperature on the MOSFET threshold voltage and

its thermal coefficient. In particular, a mathematical model for both parameters was

achieved and a comparison with real measurement was performed considering three low

voltage power MOSFET devices by ST; DEVICE1, DEVICE2 and DEVICE3. The simulated

and real data obtained for all the devices under test are quite close and, thus confirming the

validation of the theory.

The model has highlighted that, in order to decreases in absolute value TVTC to avoid

thermal run-away of the device, the thickness oxide, silicon and the gate doping

concentration must be decreased. However, minimizing TVTC and obtaining a standard

threshold voltage device can't be done by decreasing the three parameters together, they

must be rearranged as in the example shown in Figure 23. and Figure 24. of this article.

Another important result shown in this paper regards the example of the device DEVICE3.

In this case, the higher total charge concentration in the channel involves a band-gap

narrowing that increases in absolute value TVTC and makes the device more thermally

instable.

27/30

Page 28

References AN2386

5 References

● Introduction on semiconductor materials

– Au. Tyagi - Ed. Wiley&Sons

● Atlas User's Manual Vol.I - February 2000

– Silvaco International

● Mutual Compensation of Mobility and Threshold Voltage Temperature Effects with

Applications in CMOS Circuit

– Au. I.M. Filanovsky A. Allam Ed. IEEE Vol. 48 No. 7, July 2001

28/30

Page 29

AN2386 Revision history

6 Revision history

Table 3. Revision history

Date Revision Changes

13-Jun-2006 1 Initial release.

29/30

Page 30

AN2386

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZE REPRESENTATIVE OF ST, ST PRODUCTS ARE NOT DESIGNED,

AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING APPLICATIONS,

NOR IN PRODUCTS OR SYSTEMS, WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY, DEATH, OR

SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2006 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

30/30

Loading...

Loading...