Page 1

AN2383

Application note

A single plate induction cooker

with the ST7FLITE09Y0

Introduction

This application note describes an induction cooking design which can be used to evaluate

ST components or to get started quickly with your own induction cooking development

project.

Induction cooking is not a radically new invention; it has been widely used all around the

world. With recent improvements in technology and the consequent reduction of component

costs, Induction cooking equipment is now more affordable than ever.

The design provides an opportunity to understand how an induction cooker works and to

make an in-depth examination of the various blocks and parts of this type of cooking

application such as the driving topology, how the resonant tank works, how the pot gets hot

and how to remove it safely from the cooking element.

The design is entirely controlled by a simple ST7FLITE09Y0 8-bit microcontroller, which

provides the PWM driving signals, communicates information to the user interface, and

drives the fan and relay control to the plate feedback.

September 2009 Doc ID 12433 Rev 3 1/39

www.st.com

Page 2

Contents AN2383

Contents

1 Induction heating basics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2 Block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3 Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.1 Mains, DC link voltage and zero voltage switching . . . . . . . . . . . . . . . . . . . 8

3.2 Isolated power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.3 Power stage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.4 Feedbacks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.5 MCU pin configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4 How the system works . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.1 Standby (system off) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.2 System on . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.3 Safety relay and fan management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5 Measurements at 50 Hz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.1 Standby (system off) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.2 Powering the plate (without pot) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.3 Powering the plate (with pot) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.4 Working level 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.5 Working level 9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.6 Real-time current adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.7 Removing the pot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

6 Measurements at PWM frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.1 Powering the plate (with pot) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.2 Working level 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

6.3 Working level 9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

6.4 Current waveform at 50 Hz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

7 Alarm management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

2/39 Doc ID 12433 Rev 3

Page 3

AN2383 Contents

8 User interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

8.1 Keyboard schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

8.2 Display schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

9 Software management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

10 Thermal conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

11 Bill of material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

12 Demonstration board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

13 References and related materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

14 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Doc ID 12433 Rev 3 3/39

Page 4

List of tables AN2383

List of tables

Table 1. Bill of material (part 1 of 3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Table 2. Bill of material (part 2 of 3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Table 3. Bill of material (part 3 of 3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Table 4. Document revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

4/39 Doc ID 12433 Rev 3

Page 5

AN2383 List of figures

List of figures

Figure 1. Induction cooking design block diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Figure 2. Mains and +325 volt DC link . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Figure 3. Isolated power supply, 5 and 15 volt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Figure 4. L6384 IGBT driver and power stage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Figure 5. Current peak, current phase and alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Figure 6. MCU pin configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Figure 7. System in standby mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 8. Plate power-on (without pot on the plate) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 9. Plate power-on (with pot on the plate) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 10. System working at level 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Figure 11. System working at level 9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 12. Plate power-on (with pot on the plate) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 13. System working at level 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Figure 14. System working at level 9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Figure 15. Current waveform at 50 Hz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Figure 16. The analog keyboard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Figure 17. Display circuitry. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Figure 18. The six most important software events . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Figure 19. Demonstration board photo (no cooking plate connected) . . . . . . . . . . . . . . . . . . . . . . . . . 34

Figure 20. User interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Figure 21. Resonant capacitors (in blue) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Figure 22. Reverse angle. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Doc ID 12433 Rev 3 5/39

Page 6

Induction heating basics AN2383

1 Induction heating basics

Put simply, an induction cooking element (what on a gas stove would be called a "burner") is

a special kind of transformer. When a good-sized piece of magnetically conducting material

such as, for example, a cast-iron frying pan, is placed in the magnetic field created by the

cooking element, the field transfers ("induces") energy into the metal. That transferred

energy causes the metal - the cooking vessel - to become hot.

By controlling the intensity of the magnetic field, we can control the amount of heat being

generated in the cooking vessel and we can change that amount instantaneously.

Induction cooking has several advantages over traditional methods of cooking:

● Speed: conductive heat transfer to the food is very direct because the cookware is

heated uniformly and from within. Induction cooking is even faster than gas cooking

● Safety: there are no open flames. This reduces the chances of fire and the cold stove

top is also more child safe

● Efficiency: around 90%. Heat is generated directly in the pot, while for electric and gas

the efficiency is around 65% and 55% respectively due to heat transfer loss.

Induction cooking functions based on the principle of the series L-C resonant circuit, where

the inductance L is the cooking element itself.

By changing the switching frequency of the high voltage half-bridge driver, the alternating

current flowing through the cooking element changes its value. The intensity of the magnetic

field and therefore the heating energy can be controlled this way.

6/39 Doc ID 12433 Rev 3

Page 7

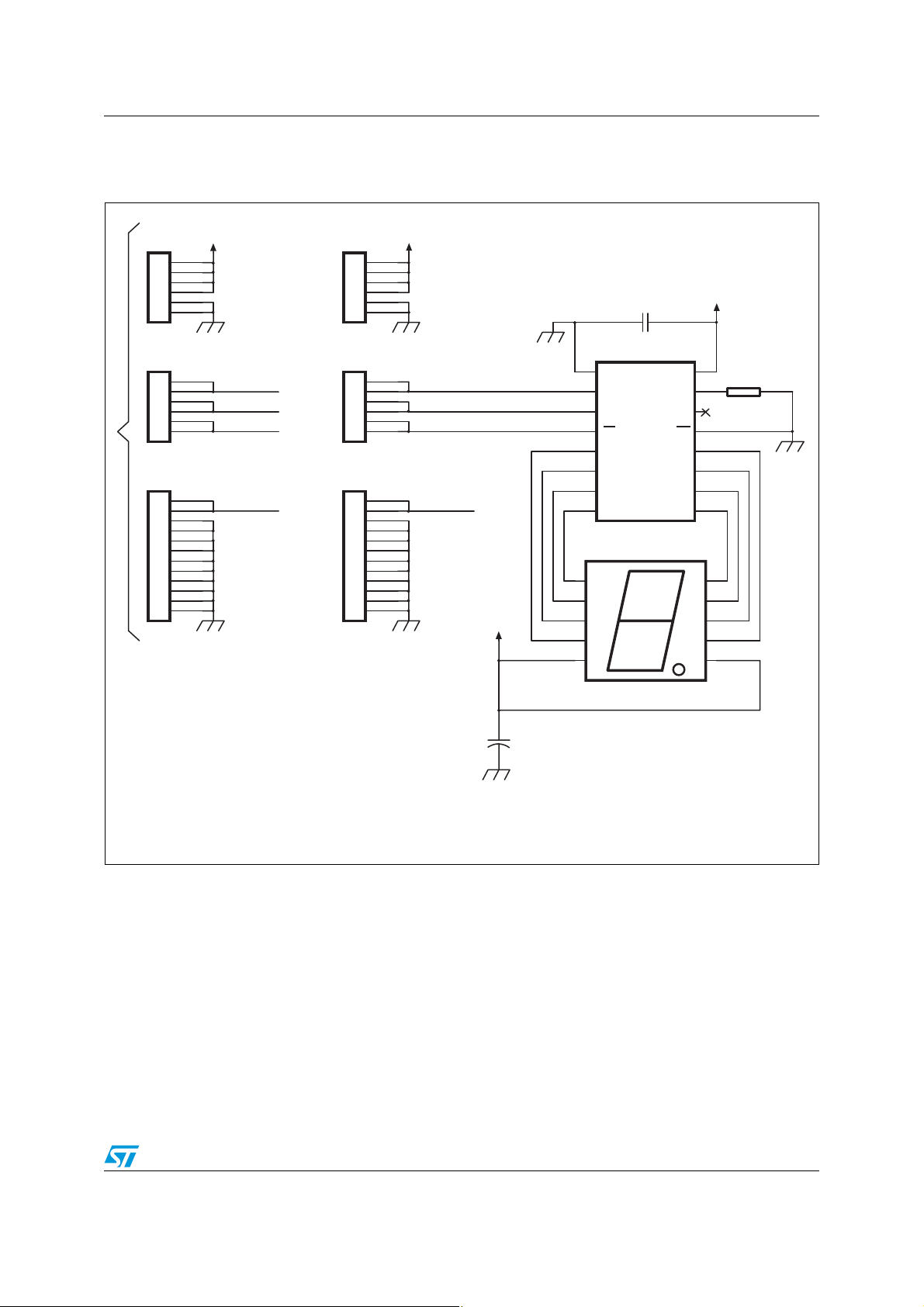

AN2383 Block diagram

2 Block diagram

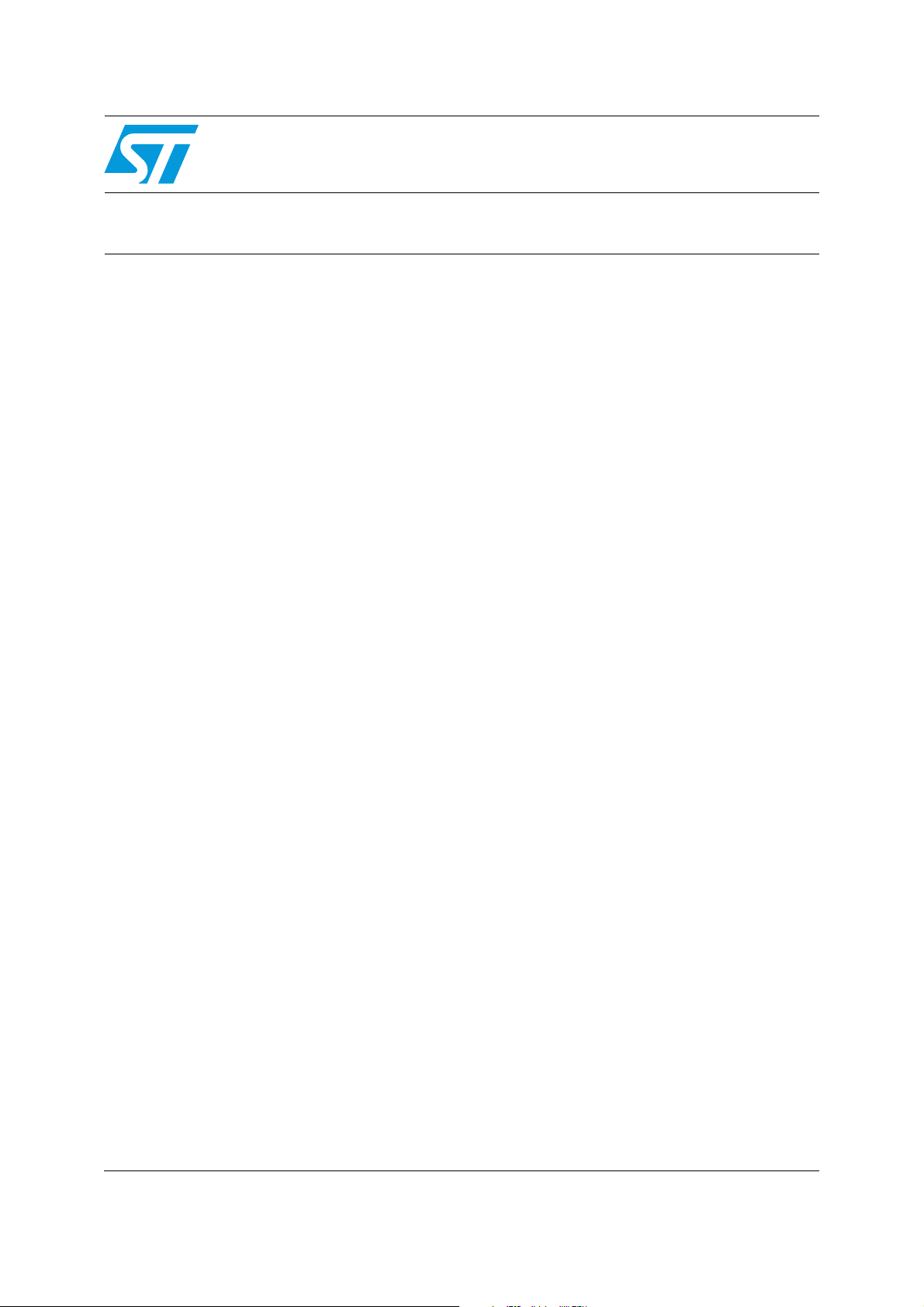

Figure 1. Induction cooking design block diagram

USER INTERFACE FAN

PLATE

DRIVER 2x IGBTs

MCU

ST7LITE

RELAY

POWER

SUPPLY

5 / 15V

PLATE FEEDBACK

AI12605

The induction cooking design consists of a small number of simple blocks.

The isolated power supply is obtained directly from the mains, 220 V AC 50 Hz. 15 volts are

used to supply the IGBT driver, fan, relay and feedback circuitry, while 5 volts are needed to

supply the rest of the ICs, including the MCU.

The ST7FLITE09Y0 microcontroller controls the whole process and communicates with the

user interface (buttons and display), drives the fan and the relay, receives feedback from the

cooking element (referred to in this document as “plate” for simplicity) and generates the

PWM signal to drive the IGBTs.

Doc ID 12433 Rev 3 7/39

Page 8

Schematic AN2383

3 Schematic

Although the schematic is not very complex, this section presents the different parts as

separate topics:

● Mains, DC link and zero voltage switching

● Isolated power supply

● Power stage

● Feedbacks

● MCU pin configuration

The user interface schematic is not presented in this section. It is discussed and analyzed in

Section 8.

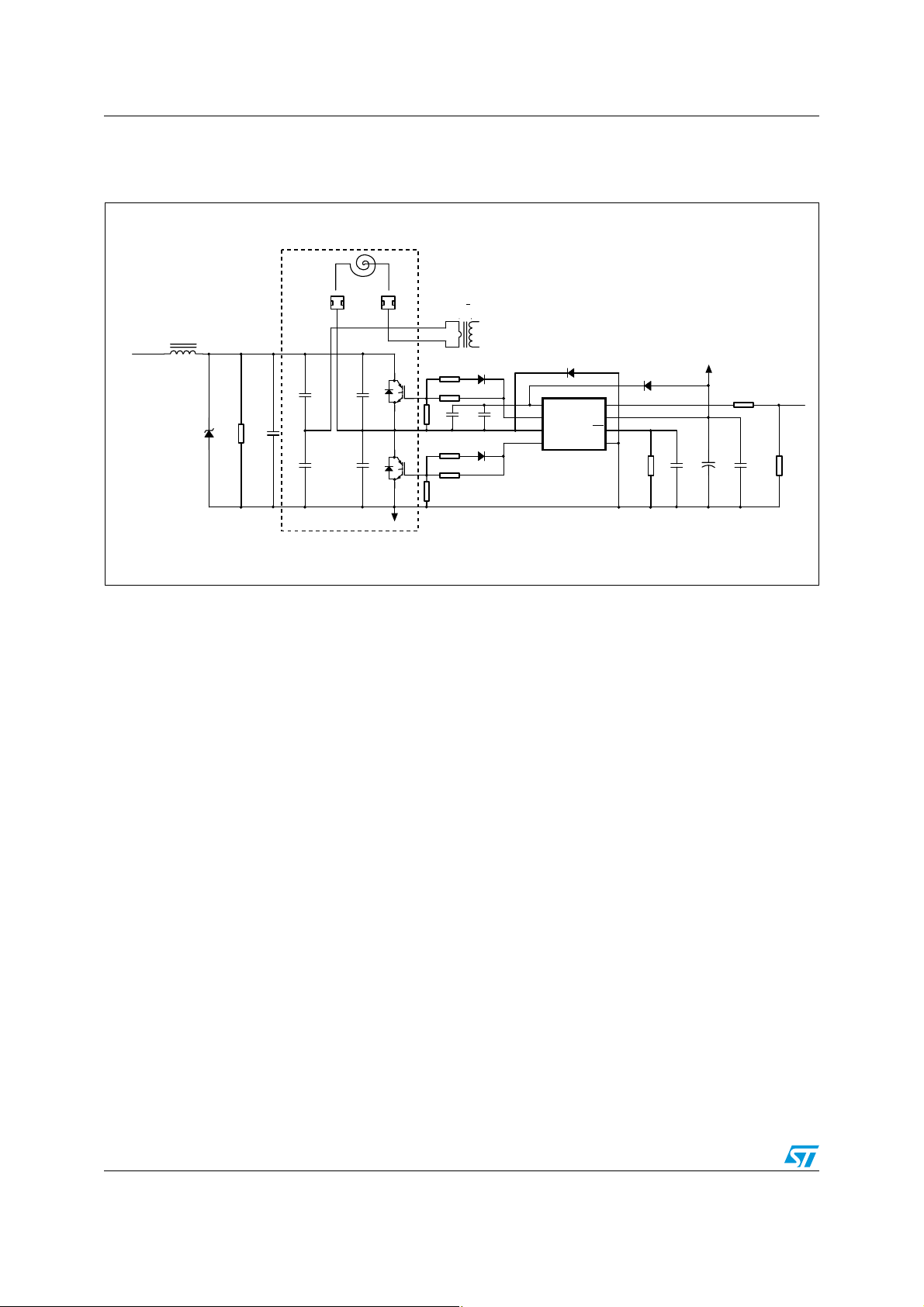

3.1 Mains, DC link voltage and zero voltage switching

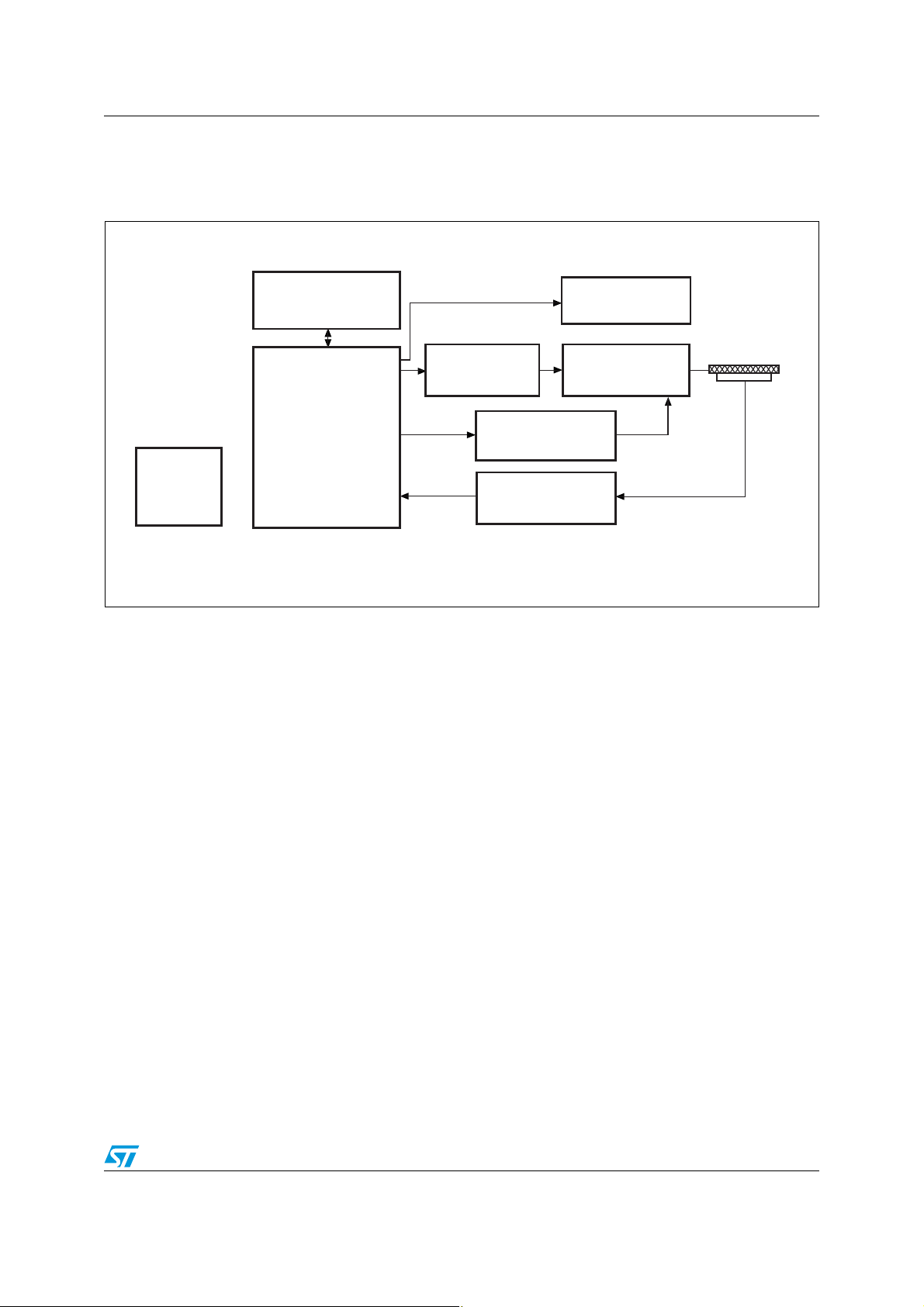

Figure 2. Mains and +325 volt DC link

FST1

FST2

LI N E

NEUTRAL

1

2

C1

1µF

275V X2

1

2

FS T3

EAR TH

1

2

RV1

460V

124

R1

470K

1W

L1

TDK_TF 2510H

AC N

C2

C4

3n3 Y1

3

C3

3n3 Y1

RELAY

1µF

275V X2

AC L

R2

4K7

C5

1µF

275V X2

RL1 12V

16A 250VAC

R3

10K

2

7

+15V

3

6

1

8

1N4 007

Q3

BC 337

D1

R4

8K2

4

5

DL1

LED

470K

RV2

275V

R5

1W

~

+

270K

D2

~

25A

R8

R9

8K2

R6

220K

R7

220K

+325V

R10

4K7

C6

22nF

TP1 4

VLINK

R11

4K3

R12

4K3

R13

4K3

R14

4K3

ACL

R15

4K3

50Hz

R17

4K3

D13

1N4007

2

PC817

R16

2K2

1

ISO2

4

+5V

3

TP17

The mains is filtered and is not applied directly to the power diode bridge: for safety reasons,

it goes through a relay. This means that the DC link voltage is not applied to the IGBT while

the system is off.

The 14 V DC relay is driven by the MCU through a classic NPN transistor. An LED is also

present.

When the system is on - and the AC line is applied to the power diode bridge - the IGBTs

are supplied with +325 V. The resistive divider sends an image of the DC link voltage to the

MCU (label VLINK). The last part of the schematic is an isolated zero voltage switching

(ZVS): a square waveform at 50 Hz synchronized with the mains (label 50 Hz).

8/39 Doc ID 12433 Rev 3

AI12612

Page 9

AN2383 Schematic

3.2 Isolated power supply

Figure 3. Isolated power supply, 5 and 15 volt

AC L

AC N

L3

330µH

D15

PKC-13 6

8

~

2

V

DD

FB

Source11Source2

U4

VIPer2 2A

F

~

D16

1,5A

+

+C23

+C22

10µF

10µF

400V

400V

–

R29

10

4

Drain15Drain26Drain37Drain4

3

+C25

10µF

35V

D14

BAR4 6

C40

22nF

T1

TRONIC

348

2

1

C4 1

2n2 Y

1 2

ISO1

5

815

U5

TL431I

43

D10

STPS2H100

R38

1K

R39

1K

C24

100nF

R47

24K

R46

4K7

R48

4K7

R30

n.c.

+15V

+

TP 15

C26

330µF

35V

+15V+15V

+

U6

L7805CV

VIN1

C27

330nF

C38

100µF

35V

GND

2

V

OUT

C28

100 nF

C29

10µF

16V

AI12611

An isolated power supply is connected immediately after the mains filtering, without passing

through the safety relay. A VIPer22A and a simple voltage regulator provide 15 and 5 volts

respectively. The power supply ground is isolated from the system ground.

+5V

TP 16

3

+

Doc ID 12433 Rev 3 9/39

Page 10

Schematic AN2383

3.3 Power stage

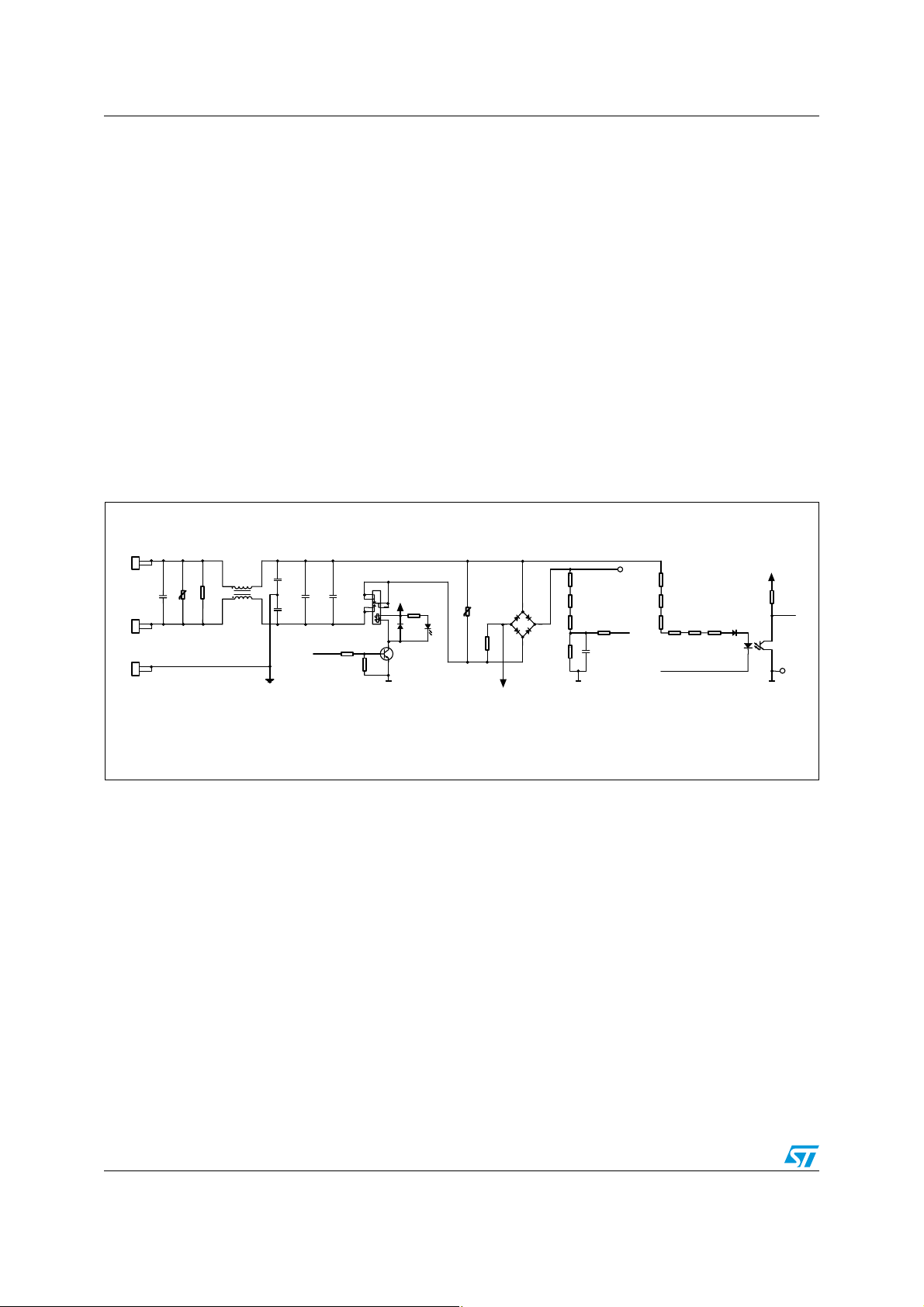

Figure 4. L6384 IGBT driver and power stage

PLATE

Q1

Q2

T2

TDKCT034

1:20

41

32

R22

11R

R2147R

C36

47nF

R25

11R

R24

47R

0

D8

STTH102

C15

1µF

D9

STTH102

8

7

6

5

V

BOOT

HVG

V

OUT

LVG

D17

STTH102

V

CC

DT/SD

GND

U2

L6384

+15V

D18

ST TH102

1

IN

2

3

4

R26

220K

C16

2n2

R27

PWM0

1K

C17

+

10µF

35V

C37

47nF

R28

4K7

AI12613

+325V

L2

80µH

TR1

1.5KE

R19

470K

1W

C10

3µF

400V

FST4

SCREW

C11

680n

800V

C12

680nF

800V

1

C13

33nF

800V

C14

33nF

800V

FST5

SCREW

40NC60V D

STGY

40NC60VD

STGY

1

R20

10K

R23

10K

The +325 V DC link voltage is applied through a filter to the upper-side IGBT only when the

safety relay is closed and the system is on. Components inside the dotted rectangle are the

core part of the power stage: the L-C resonant tank is obtained by the plate (represented in

the schematic by a spiral) and the capacitors on the left side. The resonant capacitor has

been divided in two identical capacitors, so that the amount of current flowing through each

capacitor is reduced by half, while the voltage to the capacitors remains the same.

A current transformer has been placed in series with the plate in order to provide plate

feedback information to the MCU.

The IGBTs are driven by high frequency complementary square waves with 50% duty cycle.

The PWM0 signal applied to the driver input pin is generated directly by the MCU. The

frequency varies in a range between 19 kHz and 60 kHz.

For more information regarding the dead time, charging pump capacitor and driving

topology, please refer to the L6384 datasheet.

10/39 Doc ID 12433 Rev 3

Page 11

AN2383 Schematic

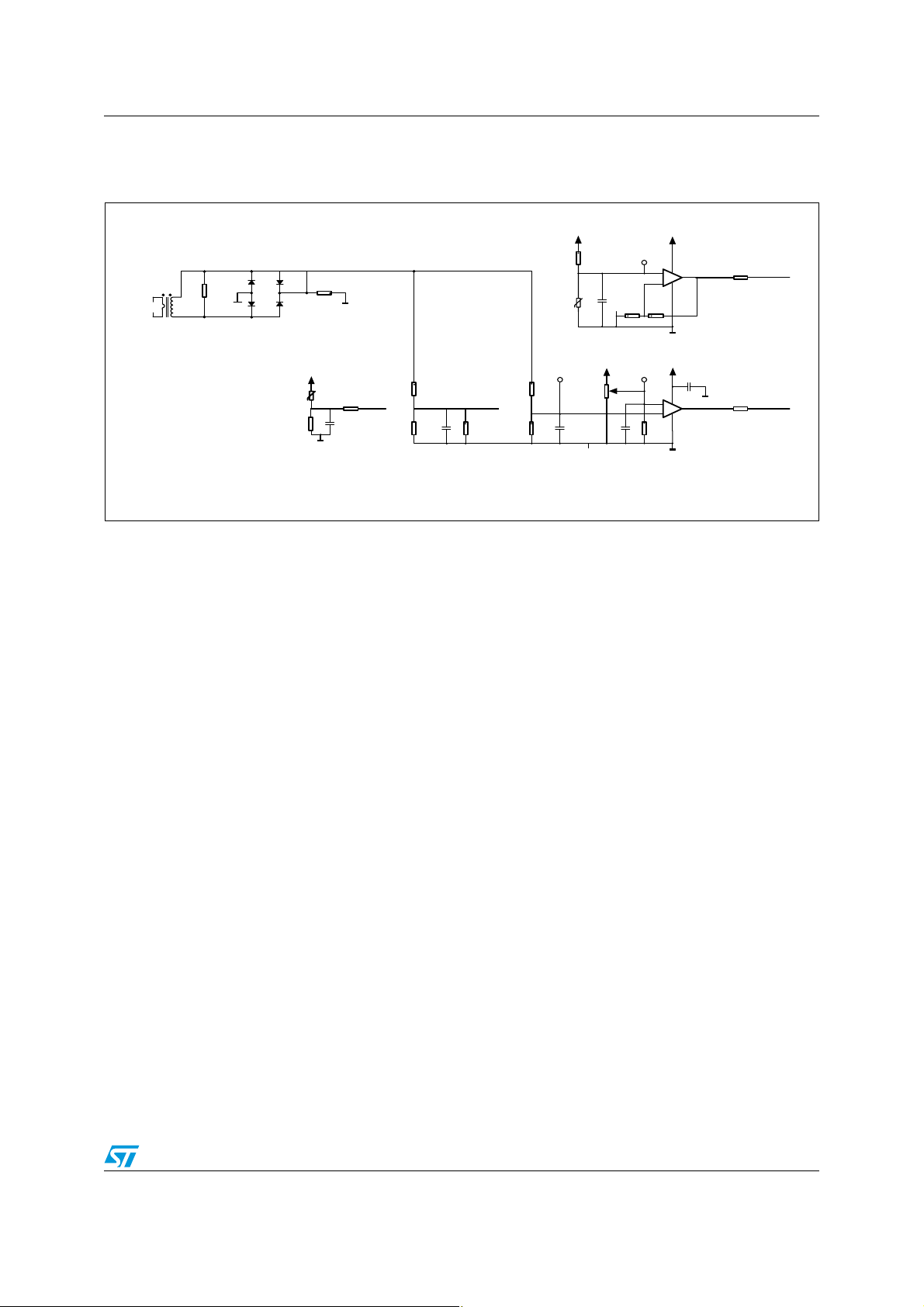

3.4 Feedbacks

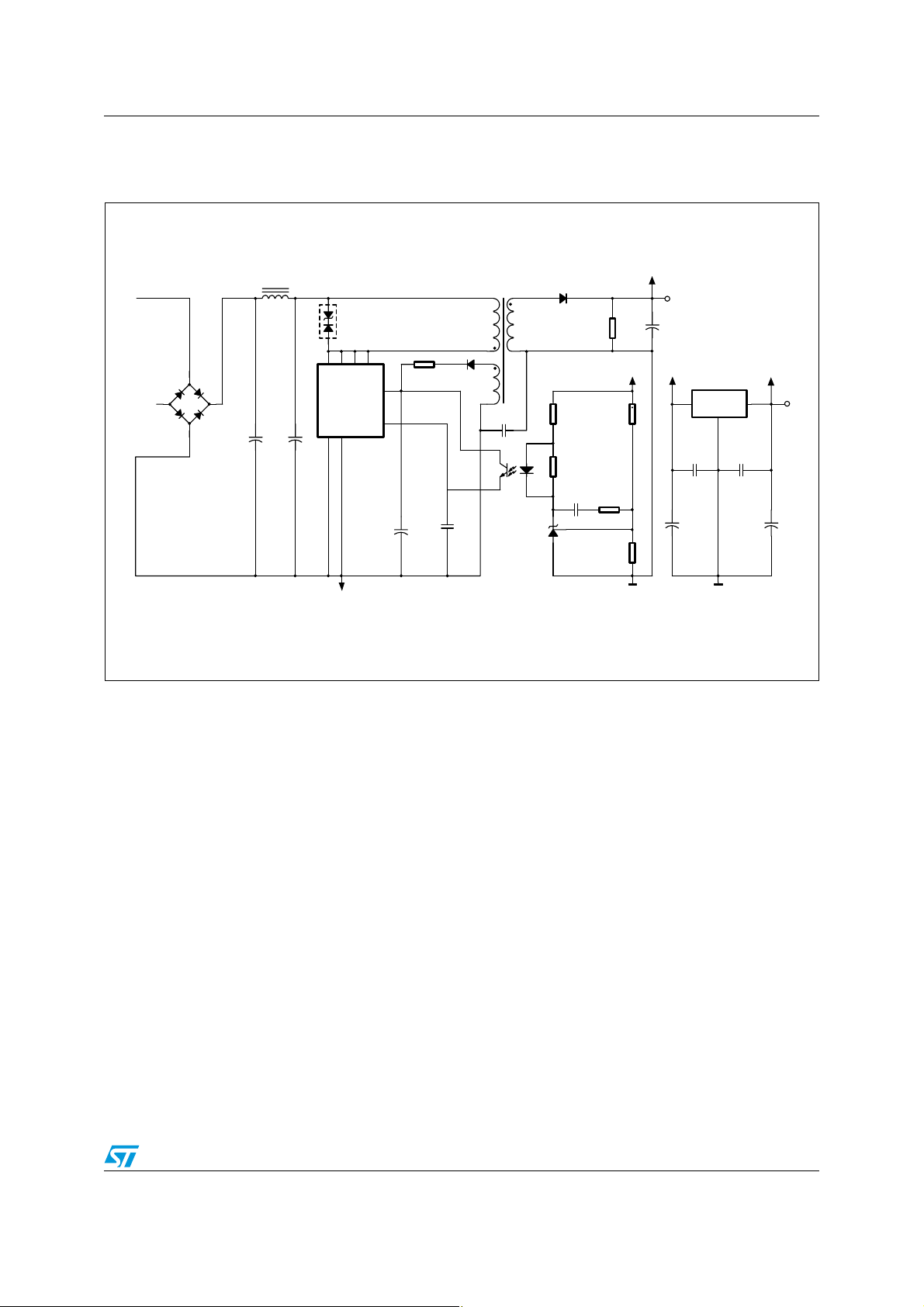

Figure 5. Current peak, current phase and alarm

T2

03

K_

TD CT 4

1:200

41

32

TP19

TP18

C20

22nF

R44

1M

TH1

110

+15V

8

5

+

7

6

–

4

LM

U3B

Temperature control

for plate

PT1000 sensors

+15V

C21

100nF

8

3

1

+

2

–

U3A

4

LM 258

Alarm management

258

R37

10K

R45

12K

TMP2

with

ALARM

AI12610

R18

100R

D4

STTH102

D6

D7

STTH102

D5

STTH102

NTC4

47K

R69

100K

STTH102

+5V

R68

1K

C44

10nF

R31

33R

1W

R32

2K7

TMP1

R33

n.c.

C18

22nF

I-CTRL

R34

1K8

R35

2K2

R36

4K7

R41

100K

NTC2

PT1000

TP20

+15V

C19

22nF

C31

100nF

PT1

50K

R40

62K

+15V

Feedback signals are output by the current transformer placed in series with the plate, and

temperature sensors.

The most important feedback is the current signal (label I-CTRL), which sends the MCU an

image of the current flowing through the plate. This signal is used to monitor the current and

set it in accordance with the selected working level.

In addition, the signal coming from the current transformer is sent to an operational

amplifier. If for any reason the current increases too much, exceeding the alarm threshold

set by the potentiometer, the MCU immediately takes action to prevent damage to the power

stage.

A NTC has been glued to the heatsink between the IGBTs. The signal is sent to the MCU to

monitor the heatsink temperature and drive the fan accordingly. In the same way, a PT1000

is placed in the middle of the plate to monitor the plate temperature. The signal is amplified

and sent to the MCU for processing.

Waveforms and a description of how these signals interact with the MCU are given in

Section 5: Measurements at 50 Hz.

Doc ID 12433 Rev 3 11/39

Page 12

Schematic AN2383

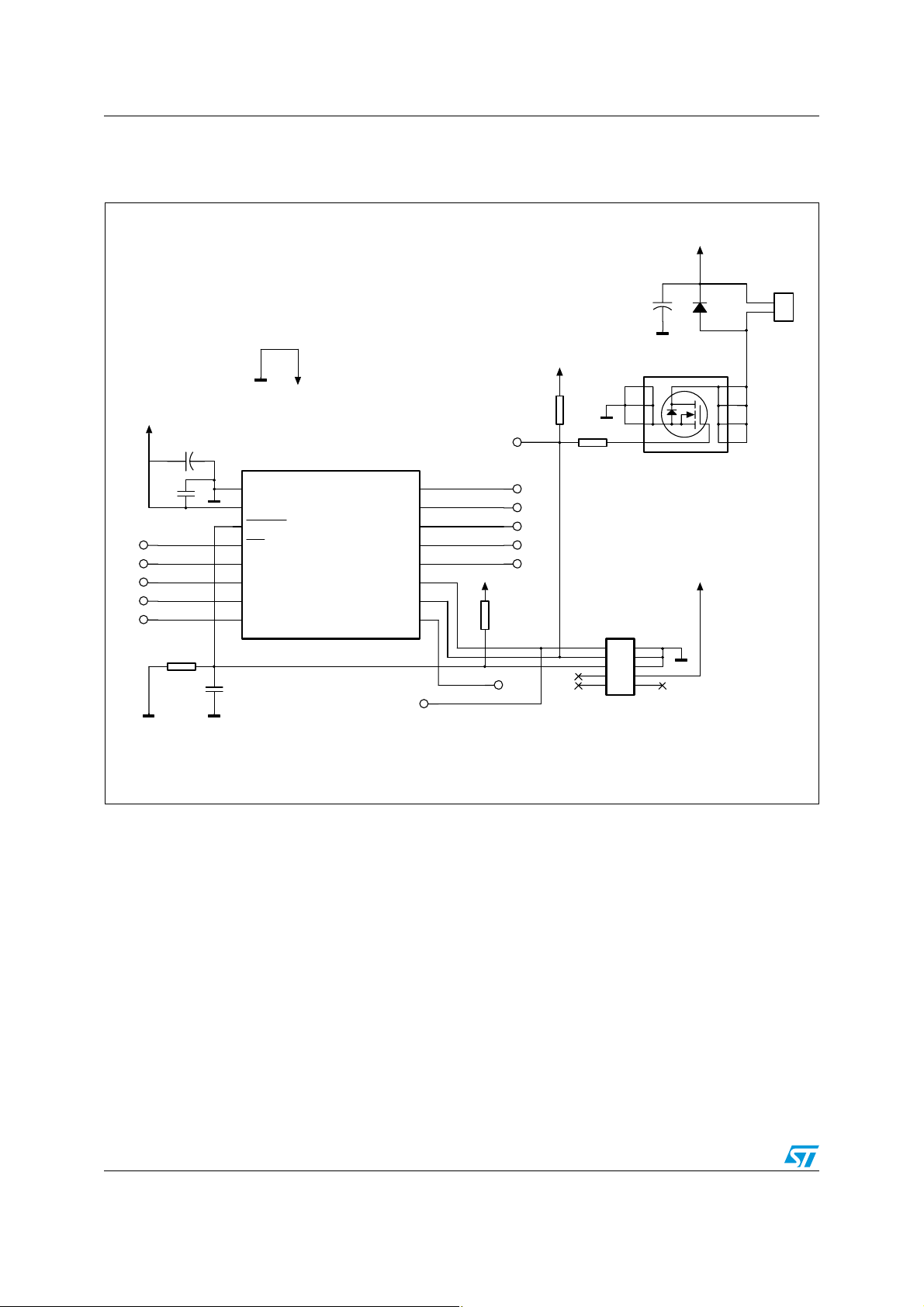

3.5 MCU pin configuration

Figure 6. MCU pin configuration

+15V

J8

C30

100µF

35V

+

D3

1N4007

1

2

FAN

+5V

C35

220µF

16V

+

C8

100nF

I-CTRL

TP1

KEYS

TP2

TMP1

TP3

TMP2

TP4

VLINK

TP5

R51

1M

Reset Pin Hints:

R51 is mandatory if re sidual voltage is still on Reset Pin.

R52 is not mandatory, its functionality has to be checked dur ing tests .

U1

ST 7F LITE 09

1

V

S

S

2

V

DD

3

RESET

4

SS/ AIN0/PB0

5

SCK/AIN1/PB1

6

MISO/A IN 2/PB 2

7

MOSI/A IN3/ PB3

8

CLKI N/AI N4 /PB4

C9

10 nF

ExternalI nterrupt request:

PA0 - 16 - ei0 - AL ARM

PA7 - 9 - ei1 - 50Hz

PA7

TP11

16

15

14

13

12

11

10

9

ei1

PA0 (HS)/LTIC

PA1 (HS)

PA 2 (HS)/ATPWMO

PA 3 (HS)

PA 4 (HS)

PA 5 (HS)/ICCDATA

PA6/MCO/ICCCLK

ei0

50Hz

RELAY

ALARM

DATA

PWM0

SCLK

/LE

+5V

R52

10K

TP12

TP13

TP6

TP7

TP8

TP9

TP10

+5V

R50

10K

R49

100

J7

CON10A

I CC Programmer

Q5

STS5NF60L

1

2 7

3

4

Fan control

+5V

12

34

56

78

910

8

6

5

AI12608

The ST7FLITE09Y0 microcontroller controls the whole induction cooking system. It can be

in-circuit programmed (ICP) via a standard 10-pin connector.

Starting from the left, going clockwise, the first input is the VLINK. It comes from the power

diode bridge and is an image of the DC link voltage applied to the upper side IGBT. Read as

analog input, this signal is used by the MCU to detect when a pot is placed on the plate or

when it has been removed.

TMP1 and TMP2 provide the MCU with the temperature information coming from the

heatsink and plate, respectively.

KEYS is an analog input read by the internal A/D converter of the MCU, and is connected to

the keyboard in the user interface. The keyboard features 3 buttons. In order to save MCU

pins, a smart schematic has been adopted, so that just one input pin is needed to read all

the keys.

The I-CTRL feedback is processed as analog input. It is an image of the current flowing

through the plate.

12/39 Doc ID 12433 Rev 3

Page 13

AN2383 Schematic

ALARM has to be sent to the MCU as fast as possible, therefore this input has been

configured as an external interrupt. As soon as an alarm occurs, the MCU immediately

starts the alarm management routine so it can rapidly take the necessary actions.

DATA, SCLK and /LE are used to drive the 8-bit constant current LED sink driver present in

the user interface board. In this way, the MCU can address a 7-segment display using only 3

pins.

PWM0 generates a PWM signal with a 50% duty cycle. It is sent directly to the IGBT driver.

Depending on the working level (and therefore on the power required), the frequency of the

square waveform varies in a range between 19 and 60 kHz.

RELAY and FAN drive the safety relay in the mains circuitry and the fan, respectively. The

fan is used to cool the heatsink next to the IGBTs and the power diode bridge.

The last pin, 50 Hz, is configured as an external interrupt. It is synchronized with the voltage

mains and, every 10 ms, it captures the moment when the AC voltage crosses zero.

Doc ID 12433 Rev 3 13/39

Page 14

How the system works AN2383

4 How the system works

4.1 Standby (system off)

As soon as the induction cooking system is plugged into the mains, the system is running

and the MCU goes into standby mode, or put simply, “system off”.

No controls or actions are taken, only the keyboard is scanned to capture a “button pressed”

event. The display shows "-".

In this status, putting or removing a pot from the plate has no impact on the system

functionality. The safety relay contacts are open, so no DC link voltage is applied to the

resonant tank.

4.2 System on

The system is turned on by pressing the on-off button (the first on the left in the user

interface).

Each time it is switched on the induction cooking system performs a sequence: safety relay

first, then plate power-on. The safety relay contacts close, which applies the DC link voltage

to the resonant tank.

At this point, the system temporarily powers-on the plate: a 60 kHz PWM signal is applied to

the half-bridge driver for half a second. During this time, if a pot is placed on the plate, or it is

there already, the system moves to the lowest operating power level, shown as "1" in the

user interface display. If however, no pot is detected on the plate, the system stops the PWM

signal. Another power-on sequence is performed after 10 seconds. After 5 unsuccessful

power-on sequences, the system goes back to standby mode.

When the PWM signal is applied to the half-bridge driver, the decimal point in the user

interface display turns on.

Once a pot is detected, the user can move through 9 working power levels by pressing the

buttons on the user interface. 1 is the lowest level, and 9 is the maximum.

4.3 Safety relay and fan management

The safety relay prevents the DC link voltage from being applied to the resonant tank when

the system is off. The relay contacts are connected in series with the plate, and they close

when the system is turned on. To prevent oscillation or undesired relay commutations, an

anti-bounce software routine is implemented. The relay turns off when the system turns off.

The fan helps the heatsink dissipate the heat while the system is working. It is turned on as

soon as the heatsink temperature reaches 55 °C. The fan stays on for at least one minute,

whether the system is on or in standby mode.

14/39 Doc ID 12433 Rev 3

Page 15

AN2383 Measurements at 50 Hz

5 Measurements at 50 Hz

The following oscilloscope waveform readings have been taken during the different

operating phases. These signals are synchronized with the voltage mains, therefore running

at 50 Hz frequency.

5.1 Standby (system off)

Figure 7. System in standby mode

MAINS

ZVS

VLINK

I - CTRL

In standby mode, the zero voltage crossing signal is the only active one. The square wave is

sent to the MCU and used to synchronize all the events. VLINK, an image of the DC link

voltage (not yet applied to the plate), is constant. No current flows through the plate.

Doc ID 12433 Rev 3 15/39

Page 16

Measurements at 50 Hz AN2383

5.2 Powering the plate (without pot)

Figure 8. Plate power-on (without pot on the plate)

MAINS

ZVS

VLINK

PDT

I - CTRL

The DC link voltage is applied to the plate and the PWM signal is applied to the half-bridge

driver for half a second. Due to the resonant tank consumption, a voltage drop appears on

the VLINK signal. The voltage drop is read by the MCU to detect if a pot is present on the

plate.

No pot is on the plate, so the voltage drop is not big enough to exceed the pot detection

threshold (PDT), set by software at 500 mV. The PWM signal is stopped, and the powering

sequence is repeated after a break of 10 seconds.

Powering the plate continuously in order to detect a pot would result in an increase in power

consumption. However, no parts would burn or be damaged. The break of 10 seconds

between one powering sequence and another reduces power consumption while keeping

full functionality and pot control.

16/39 Doc ID 12433 Rev 3

Page 17

AN2383 Measurements at 50 Hz

5.3 Powering the plate (with pot)

Figure 9. Plate power-on (with pot on the plate)

MAINS

ZVS

VLINK

PDT

I - CTRL

The DC link voltage is applied to the plate and the PWM signal is applied to the half-bridge

driver for half a second. Due to the resonant tank consumption, a voltage drop appears on

the VLINK signal. The voltage drop is read by the MCU to detect if a pot is present on the

plate.

In this case, the pot is on the plate and the voltage drop is high enough to exceed the pot

detection threshold (PDT), set by software at 500 mV. A certain current is now flowing

through the plate.

The pot is detected, so the system can move to the first working level: level 1.

The waveform shown in Figure 9 was taken while a 22 cm-diameter iron pot filled with water

was placed on the plate.

Doc ID 12433 Rev 3 17/39

Page 18

Measurements at 50 Hz AN2383

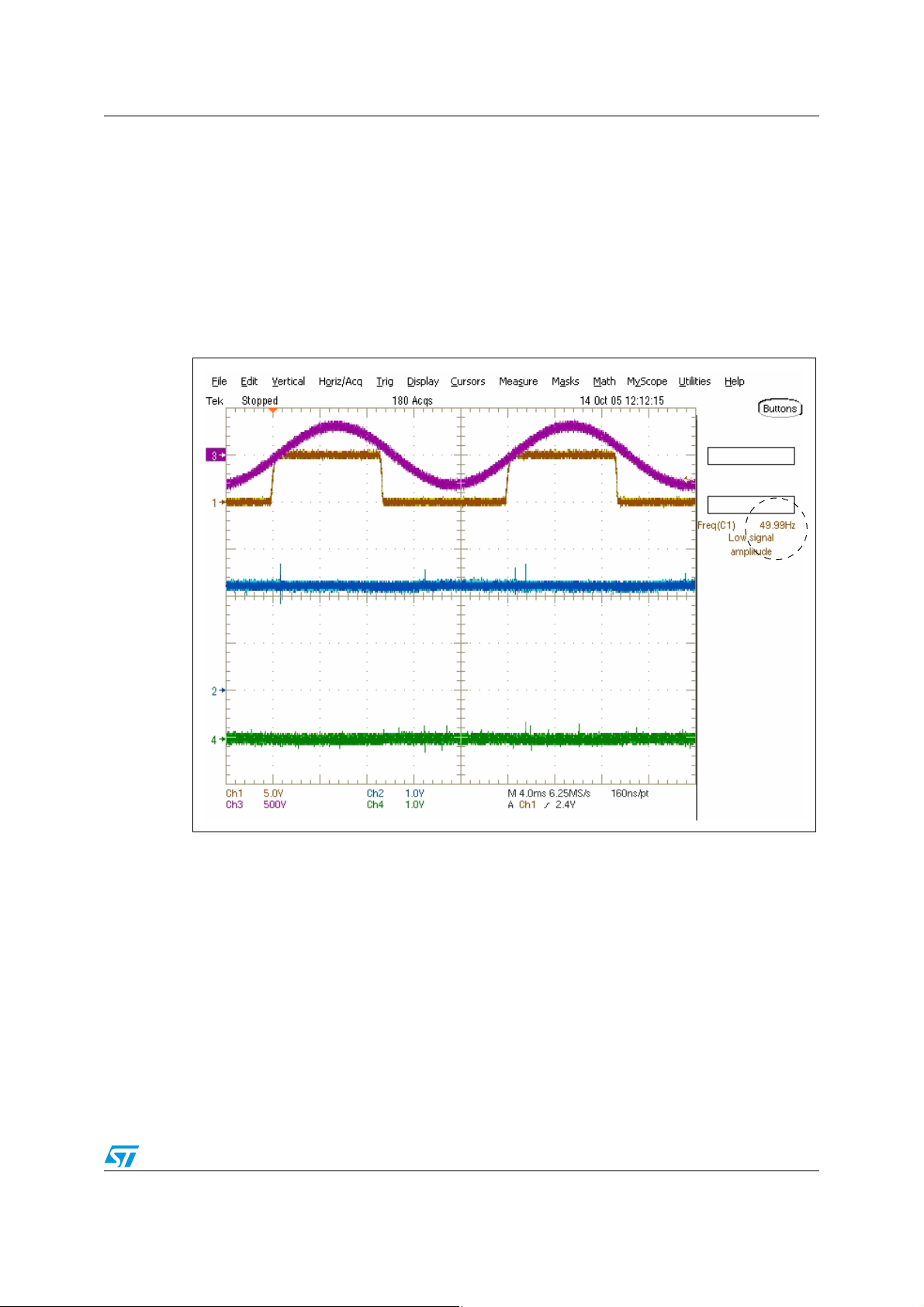

5.4 Working level 1

Figure 10. System working at level 1

MAINS

ZVS

VLINK

I - CTRL

As soon as the pot is detected, the system moves to level 1, the lowest power working level.

The PWM signal applied changes accordingly. The lower the working level, the higher the

PWM frequency applied to the half-bridge driver, and vice-versa.

I-CTRL signal is an image of the current flowing through the plate and is sent to the MCU by

the current transformer placed in series with the plate.

With the system working properly, there must be a certain current flowing through the plate,

as the I-CTRL waveform shows in Figure 10. Even if we are talking about current, the

waveform unit is expressed in volts and processed by the MCU as a voltage level.

The waveform shown in Figure 10 was taken while a 22 cm-diameter iron pot filled with

water was placed on the plate.

18/39 Doc ID 12433 Rev 3

Page 19

AN2383 Measurements at 50 Hz

5.5 Working level 9

Figure 11. System working at level 9

MAINS

ZVS

VLINK

At level 9, the system delivers the maximum output power. I-CTRL rises accordingly.

The waveform shown in Figure 11 was taken while a 22 cm-diameter iron pot filled with

water was placed on the plate.

5.6 Real-time current adjustment

As seen, the induction cooking system works on the principle of a series L-C resonant

circuit. When the size of L and C are set, the resonant frequency is set as well.

Unfortunately, this value does not depend only on the resonant tank. In fact, the size and

material of the pot affect the resonant frequency too. This causes the system to have an

oscillating resonant frequency strongly dependent on the type of pot placed on the plate at

different times.

Therefore the 9 working levels cannot be based on constant frequency levels. The PWM

frequency must be adjusted to the selected level in order to work with the pot placed on the

plate at that moment.

So each working level does not work on a constant PWM frequency, but a constant current.

By reading the I-CTRL feedback signal, the MCU smoothly adjusts the PWM frequency in

order to keep the current constant for the selected working level. Each level has a

corresponding constant value of current.

I - CTRL

Doc ID 12433 Rev 3 19/39

Page 20

Measurements at 50 Hz AN2383

5.7 Removing the pot

A pot placed on the plate may be removed at any time, including when the system is

working.

As seen before, the voltage drop present in the VLINK signal determines whether a pot is

placed on the plate or not. The VLINK signal is captured continuously while system is

working.

Lifting the pot up from the plate causes the voltage drop in the VLINK signal to decrease. As

soon as the voltage drop rises over the pot detection threshold (PDT), the MCU recognizes

that the pot has been removed.

The PWM signal is not stopped at once, but smoothly increased until the 50 kHz frequency

is reached, and then stopped. This procedure avoids current spikes on the resonant tank

line and prevents the power stage burning or being damaged.

At this point, the system is still on, without a pot on the plate. The MCU powers on the plate

5 times with a break of 10 seconds between one powering sequence and the other. If no pot

is placed back on the plate during this time, the system returns to standby mode.

This feature is very useful in cases where the user removes the pot and forgets to turn off

the induction cooking system.

20/39 Doc ID 12433 Rev 3

Page 21

AN2383 Measurements at PWM frequency

6 Measurements at PWM frequency

The following scope waveforms were taken during the different working phases. These

signals are synchronized with the PWM signal, therefore running at PWM signal frequency.

The waveforms shown in Figure 12 and Figure 13 were taken while a 22 cm-diameter iron

pot filled with water was placed on the plate.

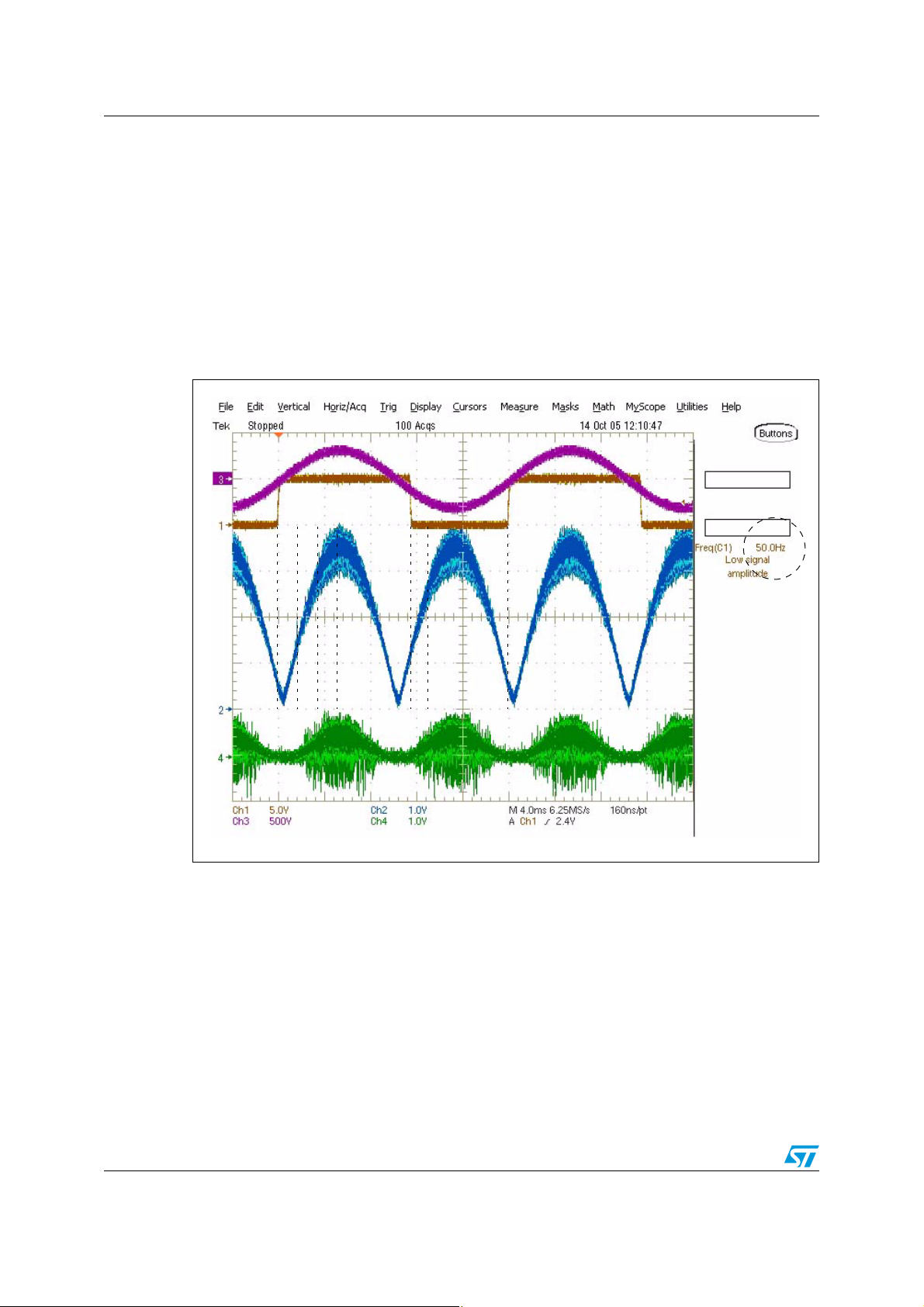

6.1 Powering the plate (with pot)

Figure 12. Plate power-on (with pot on the plate)

PVM

UP-G

LW- G

I - PLATE

The DC link voltage is applied to the plate and the 60 kHz PWM signal with 50% duty cycle

is applied to the half-bridge driver for half a second. UP-G and LW-G are the upper side gate

signal and the lower side gate signal, respectively. Of course they must be complementary

and there must be a certain dead time between the upper gate pulse and the lower one. The

dead time is set by hardware (L6384, resistor on pin 3).

Since the pot is on the plate, a certain current starts to flow through the plate (I-PLATE). The

unit in Figure 12 is expressed in volts, but the current probe connected to the scope is set at

20 amperes per division. This means that at plate power-on the system is already delivering

a 20 ampere peak-to-peak current.

Doc ID 12433 Rev 3 21/39

Page 22

Measurements at PWM frequency AN2383

6.2 Working level 1

Figure 13. System working at level 1

PVM

UP-G

LW-G

I - PLATE

Level 1 is the first and the lowest power working level. The PWM signal frequency,

previously set to 60 kHz, smoothly decreases until the working current for level 1 is reached.

As seen before, the PWM frequency is not constant and is adjusted in real-time to keep the

current level constant. Natural changes such as the iron dilatation or the water warming up,

slightly modify the resonant frequency and therefore the current delivered.

For the 22 cm-diameter iron pot used for the test, level 1 means a PWM frequency of around

48.5 kHz, but variations of several kilohertz are possible and necessary in order to keep the

current level constant.

In this test, level 1 features a 40 ampere peak-to-peak current (I-PLATE, 20 ampere per

division).

22/39 Doc ID 12433 Rev 3

Page 23

AN2383 Measurements at PWM frequency

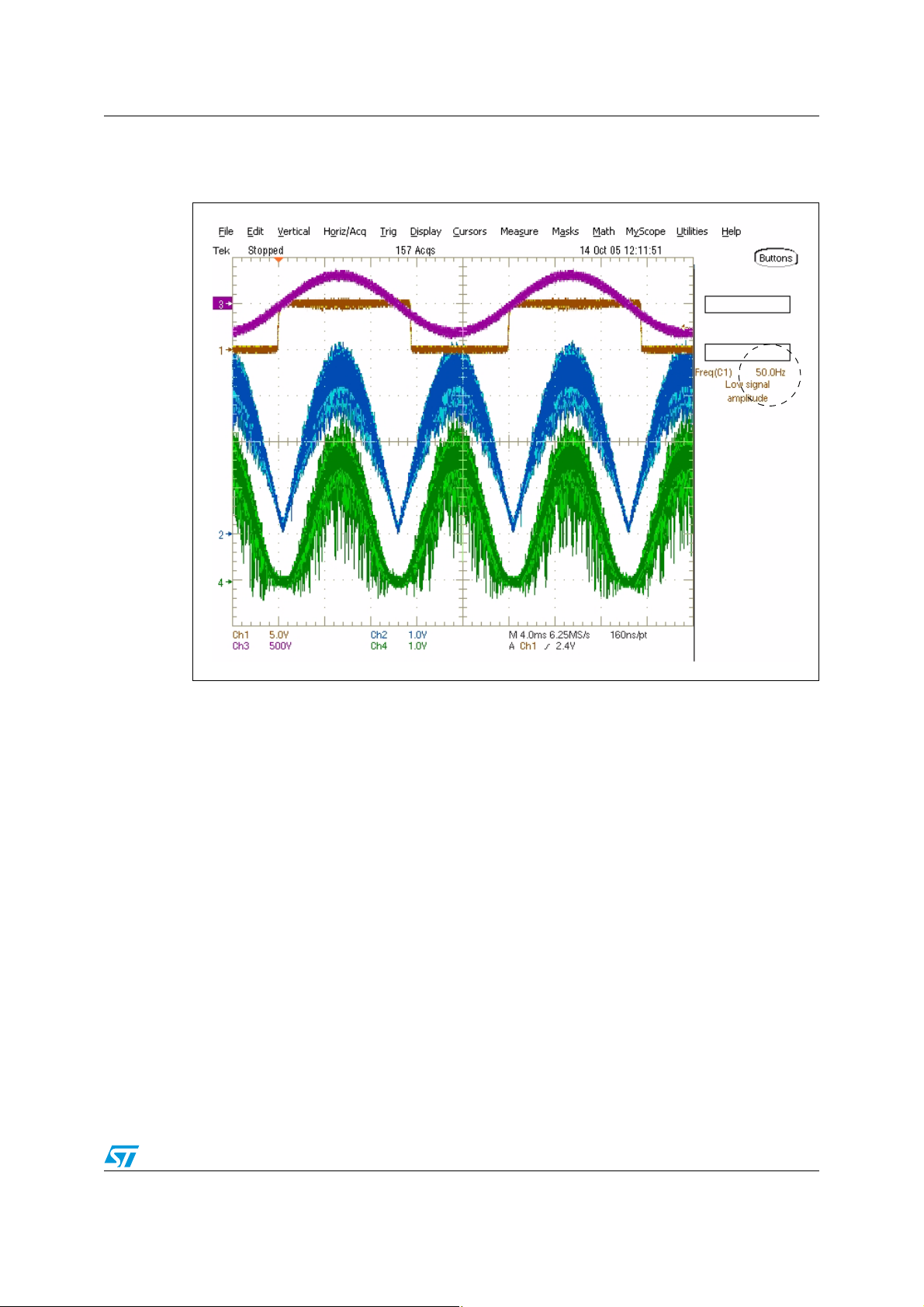

6.3 Working level 9

Figure 14. System working at level 9

PVM

UP-G

LW-G

I - PLATE

Level 9 is the highest working level, with the system delivering maximum output power. To

increase output power, the PWM frequency must be decreased. Moving the working levels

up or down corresponds to a smooth increase or decrease of the PWM frequency, until the

current level for the selected working level is reached.

For the 22 cm-diameter iron pot used for the tests, level 9 means a PWM frequency of

around 25.0 kHz and a corresponding 100 ampere peak-to-peak current (I-PLATE, 50

ampere per division).

Doc ID 12433 Rev 3 23/39

Page 24

Measurements at PWM frequency AN2383

6.4 Current waveform at 50 Hz

Figure 15. Current waveform at 50 Hz

In the waveforms in Section 6.1 through Section 6.3, the signals were shown at PWM

frequency.

Now, if we keep the system working and increase the scope time scale to observe a 50 Hz

frequency, the shape of the current delivered to the plate is different. As shown in Figure 15,

in phase with the mains, the current peak changes following the 50 Hz frequency, while the

current switching frequency runs at the PWM frequency.

The result is a double wave with a 100 ampere peak-to-peak current (20 ampere per

division).

With a 22 cm-diameter iron pot on the plate, the system delivers about 2500 watts.

24/39 Doc ID 12433 Rev 3

Page 25

AN2383 Alarm management

7 Alarm management

The alarm circuitry is necessary for monitoring any possible malfunctions, and to prevent the

IGBTs, the driver, or any other circuitry from burning or being damaged.

The application described here features 4 different alarms: overtemperature on the heatsink

(H), overtemperature on the plate (t), overcurrent (C) and wrong pot on the plate (P).

An alarm is generated when the heatsink temperature exceeds 115 °C, or when the plate

reaches a temperature of 200 °C.

If for any reason the current flowing through the plate goes over the limit, an alarm occurs.

Similarly, while in the power-on sequence, if a non-magnetically conducting material is

placed on the plate, an alarm occurs. In alarm condition, the PWM frequency is immediately

set to 30 kHz, and then smoothly increased to 50 kHz. The system is put in standby mode

and the display shows which alarm occurred (refer to the letters in brackets).

Doc ID 12433 Rev 3 25/39

Page 26

User interface AN2383

8 User interface

The user interface is implemented on a second PCB vertically soldered on the front side of

the induction cooking application. It features a 3-button keyboard and a 7-segment display.

8.1 Keyboard schematic

Figure 16. The analog keyboard

P1

TACT-2

1 4

2 3

R54

10 K

+5.V

R57

1K

P3

TA CT-2

1 4

2 3

R56

10K

C34

10 nF

R58

1K

KEYS

P2

TA CT-2

R55

10K

14

23

2V62 WHEN P1 PRESSED

5V00 WHEN P2 PRESSED

0V24 WHEN P3 PRESSED

1V78 WHEN NO KEY PRESSED

AI12607

The keyboard is designed with the primary intention of saving MCU pins. The KEYS pin is

directly connected to the analog input pin of the ST7FLITE09Y0.

The keys are placed in parallel with resistors, which means that every time a key is pressed,

it short-circuits its own resistor (P2 two resistors). This causes the voltage on the KEYS pin

to change as shown in Figure 16. Every individual keyboard status has its own related

voltage level.

The analog-to-digital converter of the MCU reads the status of the pin every 20 milliseconds.

Software sets a key-window for each key in the range of 0.5 V. For example, P2 is pressed if

the voltage applied to the KEYS pin is higher than 4.5 V.

If two or even all the keys are pressed together, there is an automatic priority selection.

For example, P2 has the highest priority. This is because this key, when pressed, connects

the KEYS pin directly to +5 V without passing through any resistor.

In addition, if the voltage applied to the KEYS pin does not fit any key-window, the voltage is

ignored and no action is taken.

26/39 Doc ID 12433 Rev 3

Page 27

AN2383 User interface

8.2 Display schematic

Figure 17. Display circuitry

J12

CON6

J13

CON6

J14

CON12

For mechanical robustness only.

+5.V

6

5

4

3

2

1

1

2

3

4

5

6

12

11

10

9

8

7

6

5

4

3

2

1

DATA

SCLK

/LE

KEYS

J9

CON6

J10

CON6

J11

CON12

System Board Connectors

+5.V

6

5

4

3

2

1

1

2

3

4

5

6

12

11

10

9

8

7

6

5

4

3

2

1

DATA

SCLK

/LE

KEYS

+5.V

C32

100nF

U7

STP08CP05

1

GND

2

SDI

3

CLK

4

LE

5

OUT0

6

OUT1

7

OUT2

8

OUT3

DY1

Common Anode Display

9

d

7

c

5

b

4

a

3

A1

R-EXT

SDO

OUT7

OUT6

OUT5

OUT4

+5.V

16

V

DD

OE

dp

A2

R53

10K

15

14

13

12

11

10

9

10

e

2

f

1

g

6

8

+C33

100µF

16V

DISPLAY

AI12606

Although the initial design approach was to implement a user interface with a couple of

classic LEDs, the introduction of an 8-bit constant current LED sink driver in the display

circuitry improved the user interface, while still keeping the number of MCU pins used

relatively low.

The STP08CP05 needs just 3 pins to drive the display properly: DATA, SCLK, and /LE.

The display refreshing frequency is set at 50 Hz. Since the driver keeps the output signals

latched until the next refresh is performed, a lower frequency would not cause any flickering.

The display luminosity is set by an external resistor.

Connectors are duplicated solely for mechanical robustness, left side connectors are

parallel to the right ones.

Doc ID 12433 Rev 3 27/39

Page 28

Software management AN2383

9 Software management

The MCU has to process six types of events: pot-on-plate detection, temperature, keyboard

scan, display refresh and current control. These events are processed every 20

milliseconds; in fact, they are synchronized with the zero voltage switching signal.

The ZVS circuitry generates a square wave with a frequency of 50 Hz. The signal is sent to

the ei1 MCU pin, which is configured as an external interrupt input for both rising and falling

edges. Therefore, an MCU interrupt is generated every time a falling edge or a rising edge

occurs on the pin.

Figure 18. The six most important software events

1

3456

2

The first event, shown in Figure 18 as number 1, takes place as soon as the interrupt

triggered by a rising edge on the ZVS signal occurs. Pot-on-plate detection is performed by

sampling the voltage drop on the VLINK signal during this time.

Before another interrupt occurs, there is still a lot of time to handle three other events.

Events 2 and 3 monitor the temperature of the heatsink and the plate respectively. During

event number 4, the keyboard is scanned to check if a key has been pressed (or released).

A software anti-bounce has been implemented to avoid undesired conditions.

Event number 5 takes place immediately after the interrupt generated by a falling edge of

the ZVS signal occurs. The display refresh routine is performed.

During the last event, number 6, the I-CTRL signal is scanned and compared to the look-up

table that the software refers to for each working level. If any discrepancy appears between

28/39 Doc ID 12433 Rev 3

Page 29

AN2383 Software management

the sampled value and the table, the MCU adjusts the PWM frequency. The adjustment

process is performed step-by-step each period, resulting in a smooth current change.

The dotted lines in Figure 18 indicate the sequence in which the routines are performed, but

not the precise timing.

Events 2 and 3 together last less than 1 ms, and a similar time is needed for event 5.

Doc ID 12433 Rev 3 29/39

Page 30

Thermal conditions AN2383

10 Thermal conditions

The induction cooking system described in this document can deliver up to 2500 W at its

maximum working level.

The IGBTs need to be mounted on a heatsink, as does the power diode bridge.

Tests performed in laboratory conditions demonstrate that even when delivering the

maximum power for a long duration, the temperature of the components does not exceed

the safe working area. The board was placed in an open space without an enclosure.

In a real application, the board would be placed inside a box. And, to save space, the plate

is usually placed over the circuitry. Therefore, the heat dissipated by the heatsink has no

easy way out, and the cooking process worsens the thermal conditions. The heatsink is no

longer sufficient to dissipate the heat. For this reason, a fan is implemented in the system

which is driven directly by the MCU.

Tests have demonstrated that while delivering the maximum power, the temperature

reaches a stable value below 90 °C, which can still be considered safe.

The fan starts as soon as the temperature on the heatsink reaches 55 °C. The fan stays on

for at least one minute, whether the system is on or in standby mode.

Fan management can be modified by software. An NTC mounted directly on the heatsink,

between the IGBTs, improves control efficiency. Working as a thermostat controlled by an

MCU, the sensor turns the fan on or off when necessary.

Any increase in the induction cooking system performance (for example, if higher output

power is required), would result mainly in adapting the cooling system, resizing the heatsink,

using a more powerful fan, or all three.

The system itself is capable of handling up to 3000 watts of power.

30/39 Doc ID 12433 Rev 3

Page 31

AN2383 Bill of material

11 Bill of material

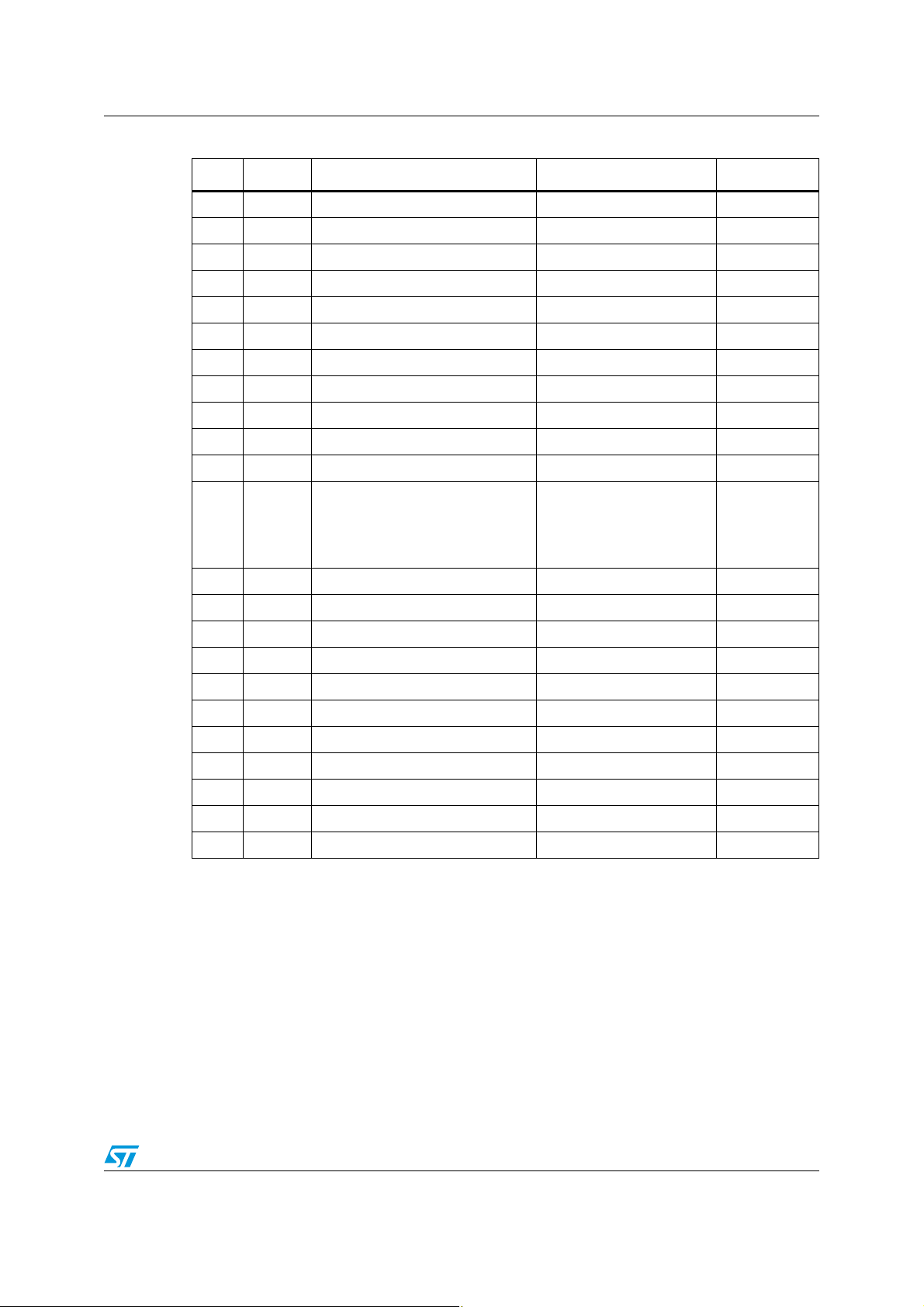

Table 1. Bill of material (part 1 of 3)

Item Quantity Reference Part Supplier

1 2 C30, C38 100 µF 35 V

2 1 C33 100 µF 16 V

3 3 C1, C4, C5 1 µF 275 VAC X2

4 1 C15 1 µF ceramic

5 2 C2, C3, C41 3,3 nF 250 VAC X1 Y1

6 4 C6, C18, C19, C20 22 nF 50 V ceramic

7 6 C8, C21, C24, C28, C31, C32 100 nF 50 V ceramic

8 3 C9, C34, C39 10nF 50 V ceramic

9 1 C10 3 µF 400 V

10 2 C11, C12 680 nF 1000 V

11 2 C13, C14 33nF 1000V

12 1 C16 2,2 nF 50 V ceramic

13 3 C17, C25, C29 10 µF 35 V

14 2 C22, C23 10 µF 400 V

15 1 C26 330 µF 35 V

16 1 C27, C40 330 nF 50 V

17 1 C35 220 µF 16 V

18 2 C36, C37 47 nF 50 V ceramic

19 1 DL1 LED red d. 3

20 1 DY1 Com. anode display

21 2 D1, D3, D13 1N4007

22 1 D2 Diode bridge 25 A

23 8 D4, D5, D6, D7, D8, D9, D17, D18 STTH102 ST

24 1 D10 STPS2H100 ST

25 1 D14 BAT46 ST

26 1 D15 PKC-136 ST

27 1 D16 Diode bridge 1.5 A

28 3 FST1, FST2, FST3 Faston vertical 6.3 mm

29 2 FST4, FST5 Screw

30 8 J1, J2, J4, J5, J9, J10, J12, J13 CON6

31 4 J3, J6, J11, J14 CON12

32 1 J7 CON10A

Doc ID 12433 Rev 3 31/39

Page 32

Bill of material AN2383

Table 2. Bill of material (part 2 of 3)

Item Quantity Reference Part Supplier

33 1 J8 Fan 12 V 1,9 W

34 1 L1 TDK_TF2510H customized TDK

35 1 L2

36 1 L3 330 µH

37 1 NTC1 NTC 47 k

38 1 NTC2 PT1000

39 1 PT1 50 k vertical

40 3 P1, P2, P3 TACT-2 normally open

41 2 Q1, Q2 STGY40NC60VD ST

42 1 Q3 BC337

43 1 Q5 STS5NF60L ST

44 5 R3, R52, R53, R37, R50 10K 5% ¼ W

45 5 R20, R23, R54, R55, R56 10K 1% ½ W metal oxide

80 µH SF1-800Y10A-01PF

TDK

46 1 RL1 12 V (16 A 250 VAC)

47 1 RV1 460 V

48 1 RV2 275 V

49 3 R1, R5, R19 470 k 2 W

50 6 R2, R10, R28, R46, R48 4K 17 5% ¼ W

51 1 R36 4K7 1% ½ W metal oxide

52 1 R4 8K2 5% ¼ W

53 1 R9 8K2 1% ½ W metal oxide

54 3 R11, R12, R13 4K3 1% ½ W metal oxide

55 3 R6, R7, R26 220K 1% ½ W metal oxide

56 1 R8 270K 1% ½ W metal oxide

57 3 R14, R15, R17 4K3 1% ½ W metal oxide

58 1 R16 2K2 5% ¼ W

59 1 R35 2K2 1% ½ W metal oxide

60 1 R18 100R 2W

61 2 R21, R24 47R 1% ½ W metal oxide

62 2 R22, R25, R29 11R 1% ½ W metal oxide

63 5 R27, R38, R39, R43, R58 1K 5% ¼ W

64 1 R57 1K 1% ½ W metal oxide

65 1 R30 n. c.

32/39 Doc ID 12433 Rev 3

Page 33

AN2383 Bill of material

Table 3. Bill of material (part 3 of 3)

Item Quantity Reference Part Supplier

66 1 R31 33R 2W

67 1 R32 2K7 1% ½ W metal oxide

68 1 R33 n. c.

69 1 R34 1K8 1% ½ W metal oxide

70 1 R40 62K 1% ½ W metal oxide

71 2 R41, R42 100K 1% ½ W metal oxide

72 2 R44, R51 1M 1% ½ W metal oxide

73 1 R45 12K 5% ¼ W

74 1 R47 24K 1% ½ W metal oxide

75 1 R49 100 5% ¼ W

76 1 TH1 Thermostat connection

77 19

78 2 ISO1, ISO2 PC817 optocoupler DIP4

79 1 TR1 1.5KE ST

80 1 T1 Customized trafo Tronic (CZ)

81 1 T2 TDK_CT034 TDK

82 1 U1 ST7FLITE09Y0 ST

83 1 U2 L6384 ST

84 1 U3 LM258 ST

85 1 U4 VIPer22A ST

86 1 U5 TL431I ST

87 1 U6 L7805CV ST

88 1 U7 STP08CP05 ST

TP1, TP2, TP3, TP4, TP5, TP6,

TP7, TP8, TP9, TP10, TP11,

TP12, TP13, TP14, TP15, TP16,

TP17, TP18, TP19

Test point

Doc ID 12433 Rev 3 33/39

Page 34

Demonstration board AN2383

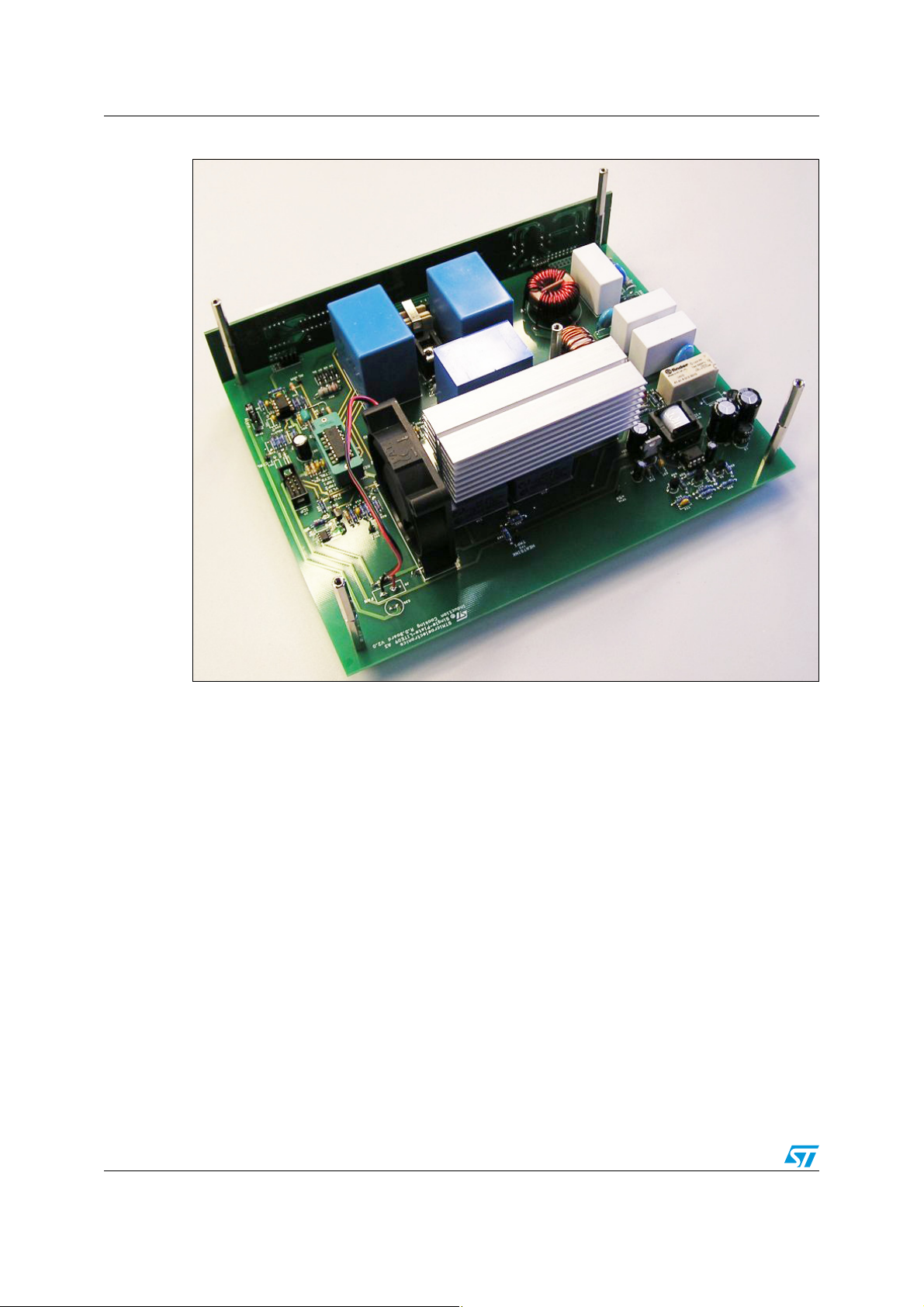

12 Demonstration board

Figure 19. Demonstration board photo (no cooking plate connected)

34/39 Doc ID 12433 Rev 3

Page 35

AN2383 Demonstration board

Figure 20. User interface

Figure 21. Resonant capacitors (in blue)

Doc ID 12433 Rev 3 35/39

Page 36

Demonstration board AN2383

Figure 22. Reverse angle

36/39 Doc ID 12433 Rev 3

Page 37

AN2383 References and related materials

13 References and related materials

For further information related to the basic functionality of each integrated circuit, please

refer to the following documents, which are available at www.st.com:

1. ST7FLITE09Y0 datasheet

2. L6384 datasheet

3. VIPer22A datasheet

4. L7805CV datasheet

5. STGY40NC60VD datasheet

6. LM258 datasheet

7. STS5NF60L datasheet

Doc ID 12433 Rev 3 37/39

Page 38

Revision history AN2383

14 Revision history

Table 4. Document revision history

Date Revision Changes

05-Sep-2006 1 Initial release.

22-Feb-2007 2 Introduction, Section on page 1, updated

Removed demonstration board ordering information.

23-Sep-2009 3

All references to part number STP08C596 have been replaced with

STP08CP05.

Minor text changes.

38/39 Doc ID 12433 Rev 3

Page 39

AN2383

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZED ST REPRESENTATIVE, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2009 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Philippines - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

Doc ID 12433 Rev 3 39/39

Loading...

Loading...