Page 1

AN2359

Application note

Double output Buck-Boost converter with VIPerX2A

Introduction

This paper introduces two off-line non-insulated SMPS double outputs in Buck–Boost

configuration based on VIPerX2A family The power supplies are operated in wide input

voltage range, i.e. 88 to 265VAC. They can supply small loads, such as a microcontroller,

triacs, display and peripherals in the industrial segment and home appliance. In the

applications where a double output is required, two different solutions can be used. The first

one regards an insulated converter topology, with second output generated by means of

one winding on the magnetic core of the inductor with a proper turns ratio. Nevertheless,

this solution is expensive in terms of transformer and can be used for medium and high

current or insulated applications. For low power and low cost applications, a non-insulated

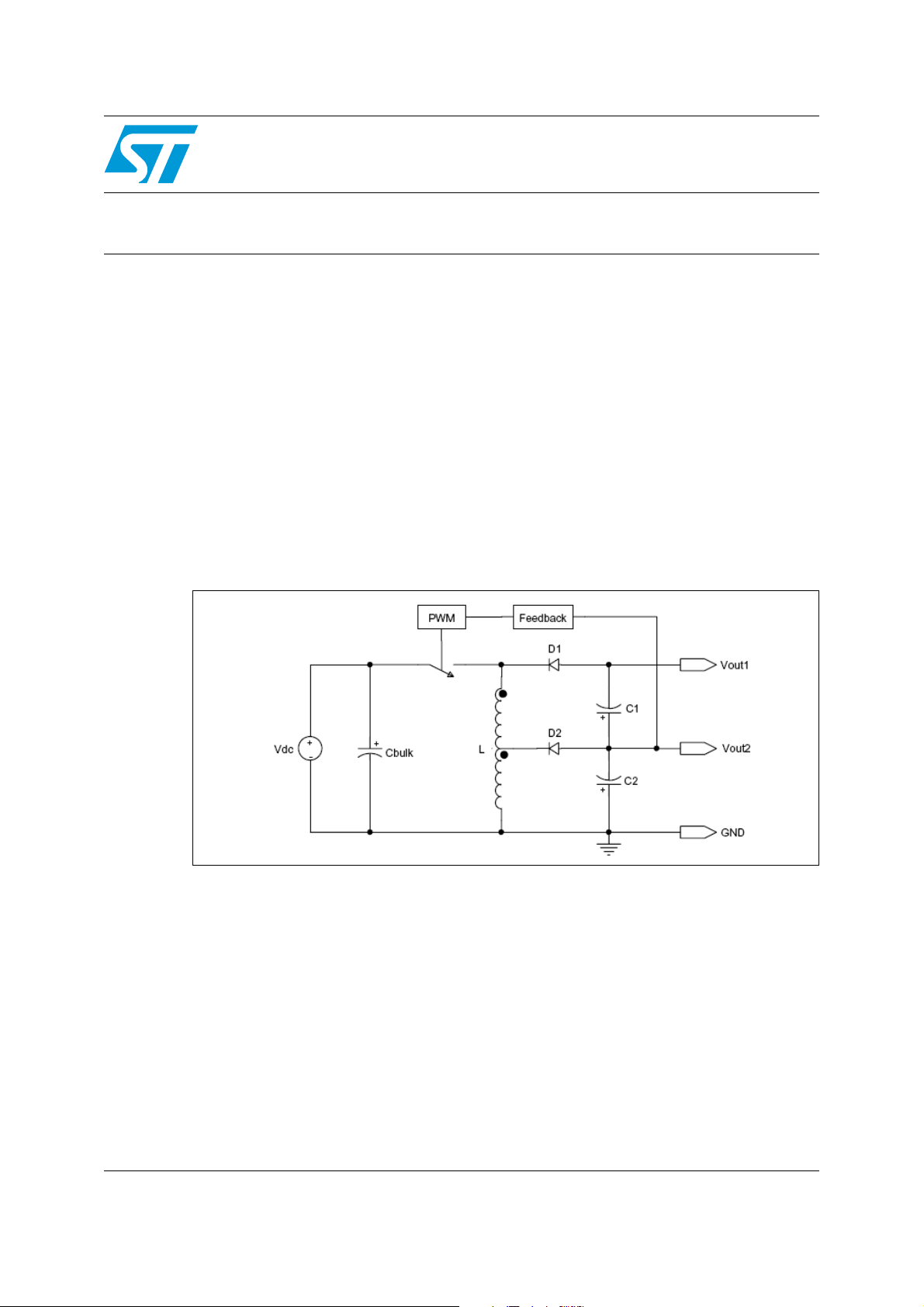

converter topology can be used. The proposed topology, based on Buck-Boost converter, is

used to supply negative output voltage referred to neutral in all those applications where the

galvanic insulation is not required. The principle schematic is shown in figure below.

Proposed double output Buck-Boost topology

V

is provided using the classic Buck-Boost configurations, while V

OUT1

thanks to an intermediate tap on the inductor.

Compared to other already proposed solutions, the second output is obtained thanks to an

intermediate tap on a low cost inductor. This configuration limits the parasitic capacitive

effect between the two winding and improves the regulation at open load.

Further advantage is related to the regulation feedback connected on V

regulation, it is possible to cover those applications where a low tolerance and low voltage is

required (i.e. a microcontroller) and a high tolerance and high voltage is required for the

auxiliary circuit (drivers, relays…).

December 2006 Rev 1 1/18

is obtained

OUT2

. Thanks to this

OUT2

www.st.com

Page 2

Contents AN2359

Contents

1 VIPerX2 description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2 Output voltage selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3 Application example nº 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.1 Experimental results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.2 Thermal measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4 Application example nº 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.1 Experimental results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5 Layout considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

6 Conclusions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

7 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2/18

Page 3

AN2359 List of figures

List of figures

Figure 1. Converter schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Figure 2. Typical waveforms at 88V

Figure 3. Typical waveforms at 88V

Figure 4. Typical waveforms at 265V

Figure 5. Typical waveforms at 265V

Figure 6. Commutation at full load: 88V

Figure 7. Commutation at full load: 265V

Figure 8. Output ripple voltage at full load: 88V

Figure 9. Output ripple voltage at full load: 265V

Figure 10. Turn on losses measurement at full load: 88V

Figure 11. Turn on losses measurement at full load: 265V

Figure 12. VIPer22A Thermal profile: at V

Figure 13. VIPer22A Thermal profile: at V

Figure 14. VIPer22A temperature at maximum load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Figure 15. Converter schematic. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Figure 16. Typical waveforms at 300V

Figure 17. Typical waveforms at 300V

Figure 18. PCB Layout (not in scale). Option nº 1: -12V output voltage . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 19. PCB Layout (not in scale). Option nº 2: -24V output voltage . . . . . . . . . . . . . . . . . . . . . . . 16

: open load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

AC

: full load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

AC

: open load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

AC

: full load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

AC

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

AC

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

AC

= 88VAC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

IN

= 265VAC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

IN

and full load: commutation . . . . . . . . . . . . . . . . . . . . . . . . . 15

DC

and full load: detail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

DC

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

AC

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

AC

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

AC

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

AC

3/18

Page 4

List of tables AN2359

List of tables

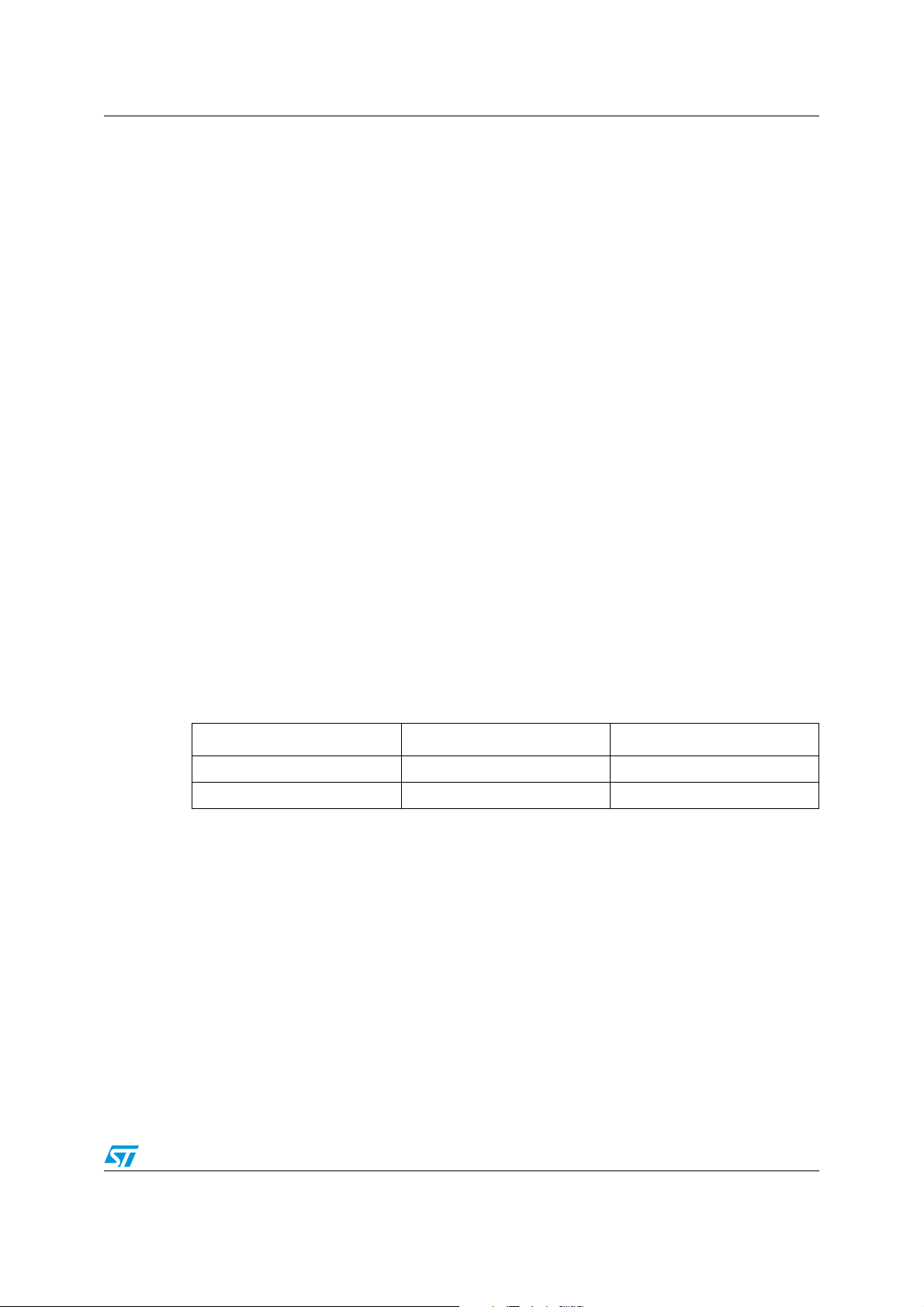

Table 1. Proposed converters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Table 2. SMPS specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Table 3. Component list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Table 4. Circuit characterization - V

Table 5. Circuit characterization - V

Table 6. Circuit characterization - V

Table 7. SMPS specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Table 8. Component list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Table 9. Experimental results - V

Table 10. Experimental results - V

Table 11. Experimental results - V

Table 12. Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

= 120VDC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

IN

= 320VDC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

IN

= 374VDC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

IN

=120VDC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

IN

=320VDC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

IN

=374VDC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

IN

4/18

Page 5

AN2359 VIPerX2 description

1 VIPerX2 description

The proposed converters are based on The VIPerX2A family, which is a range of smart

power devices with current mode PWM controller, start-up circuit and protections integrated

in a monolithic chip using VIPower M0 Technology.

The VIPerX2A family includes:

– VIPer12, with a 0.4A peak drain current limitation and 730V breakdown voltage;

– VIPer22, with a 0.7A peak drain current limitation and 730V breakdown voltage.

The switching frequency is internally fixed at 60kHz by the integrated oscillator of the

VIPerX2.

The internal control circuit offers the following benefits:

– Large input voltage range on the V DD pin accommodates changes in supply

voltage;

– Automatic burst mode in low load condition;

– Overload protection in hiccup mode.

The feedback pin FB is sensitive to current and controls the operation of the device.

2 Output voltage selection

Two converters with different output voltage are introduced in this paper. The main

specifications are listed in Table 1.

Table 1. Proposed converters

Output 1 Output 2 P

-12V/150mA -5V/300mA 3.3W

-24V/100mA -5V/300mA 3.9W

As already discussed, V

This imposes, for the two solutions, a different design of the output inductor in terms of turns

ratio, i.e. n=1.4 for the –12V solution, against n=3.8 for the –24V solution (even if it could be

necessary to tune the turn ratio for proper output voltage).

Some disadvantage are related to the –12V solution:

– The parasitic capacitance effect between the two windings is increased, compared

to the second one. This will bring about higher switching losses in turn-on (see

Figure 10. and Figure 11.) and, consequently, a worsening in terms of efficiency;

– A higher voltage diode is needed to supply the VIPer;

– The peak current is twice higher, giving less output power margin for a given I

Therefore, a –24V/-5V solution can be suitably used for all those applications where

efficiency and cost are important and, in general, in all the designs where a –24V output

voltage does not impact on the cost of the relays and drivers.

is obtained by means of an intermediate tap on the inductor.

OUT2

OUT(MAX)

DLIM

.

5/18

Page 6

Application example nº 1 AN2359

Instead, the -12V/-5V solution can be used all those times where it is not possible to change

the auxiliary supply voltage.

3 Application example nº 1

The first application example is a 3.3W double output Buck-Boost converter. The

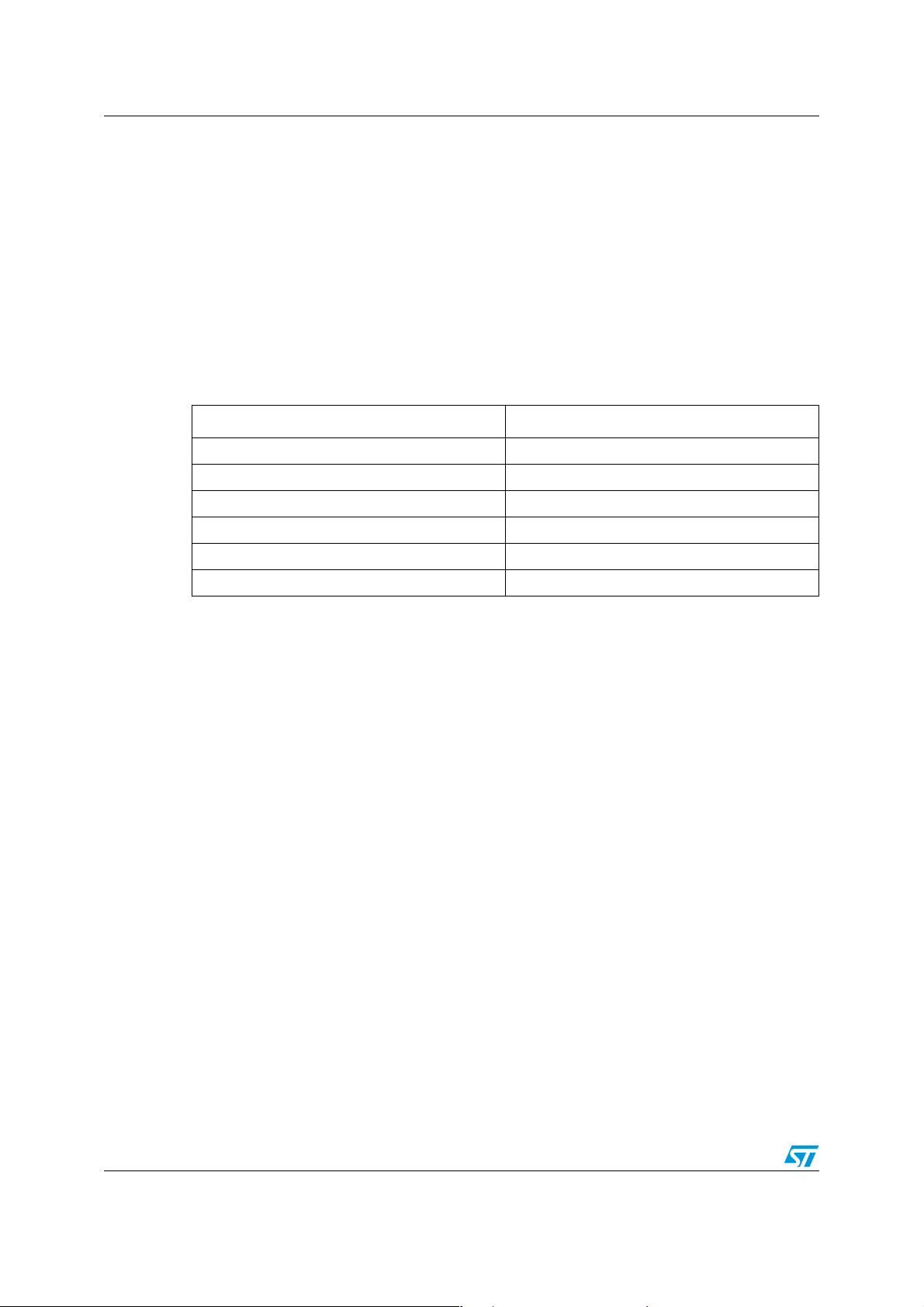

specifications are listed in Table 2.

The schematic of the circuit is shown in Figure 1. and the component list is shown in Table 3.

Table 2. SMPS specifications

Specification Value

Input voltage range, V

Output voltage V

Output voltage V

Maximum output current I

Maximum output current I

Maximum output power 3.3W

IN

OUT1

OUT2

OUT1

OUT2

The input voltage can range from 88V

to 265VAC. The input section consists in a resistor

AC

88 - 265V

-12V

-5V

150mA

300mA

AC

as a fuse, a single input rectifier diode and an input C-L-C filter. Such a filter provides both

DC voltage stabilization and EMI filtering. The C

SN-RSN

leg across D1 helps the further

reducing of the conducted emissions.

The regulation feedback is connected to V

zener diode D

precision depends on D

, in order to provide an output voltage with tight regulation range (the output

Z2

tolerance). V

Z2

OUT1

by means of the PNP transistor Q1 and

OUT2

is obtained thanks to the turns ratio of the

transformer.

The output inductor is wound in a TDK drum ferrite core (SRW0913 type), with an

intermediate tap for V

● L

● N

● N

= 420µH;

1-3

= 70 turns;

1-2

= 62 turns.

2-3

Optional bleeder resistors, R

. The specifications are the following:

OUT2

and Rb2, can be connected to the outputs in order to improve

b1

the regulation.

In particular, R

is full loaded and V

6/18

has to be chosen in order to avoid the overvoltage on V

b1

is in no load condition.

OUT1

OUT1

when V

OUT2

Page 7

AN2359 Application example nº 1

Figure 1. Converter schematic

Table 3. Component list

Reference Value Description

R

R

R

SN

b1

C

D

D

FUSE

, R

R

2

R

3

, R

C

SN

, C

1

C

3

C

4

C

5

C

6

C

7

C

8

D

1

, D

2

, D

4

D

Z1

D

Z2

Q

1

L

1

1

b2

2

3

5

22Ω, 1/2W Metallic oxide resistor

1.2KΩ, 1/4W Resistor

22Ω, 1/2W Resistor

68Ω, 1/4W Resistor

Optional resistor

0.1µF, 400V Polyester capacitor

10µF, 400V Electrolytic capacitor

10µF, 50V Electrolytic capacitor

22nF, 35V Ceramic capacitor

0.47µF, 50V Electrolytic capacitor

4.7µF, 50V Electrolytic capacitor

220µF, 16V Electrolytic capacitor

470µF, 16V Electrolytic capacitor

Diode 1N4007

Diode BA157

Diode STTH106 (ultrafast)

Diode Zener 6.8V

Diode Zener 4.3V

PNP transistor BC558

470µH Axial inductor

7/18

Page 8

Application example nº 1 AN2359

Table 3. Component list (continued)

Reference Value Description

L

2

IC STMicroelectronics VIPer22ADIP

(Read sec. 5)

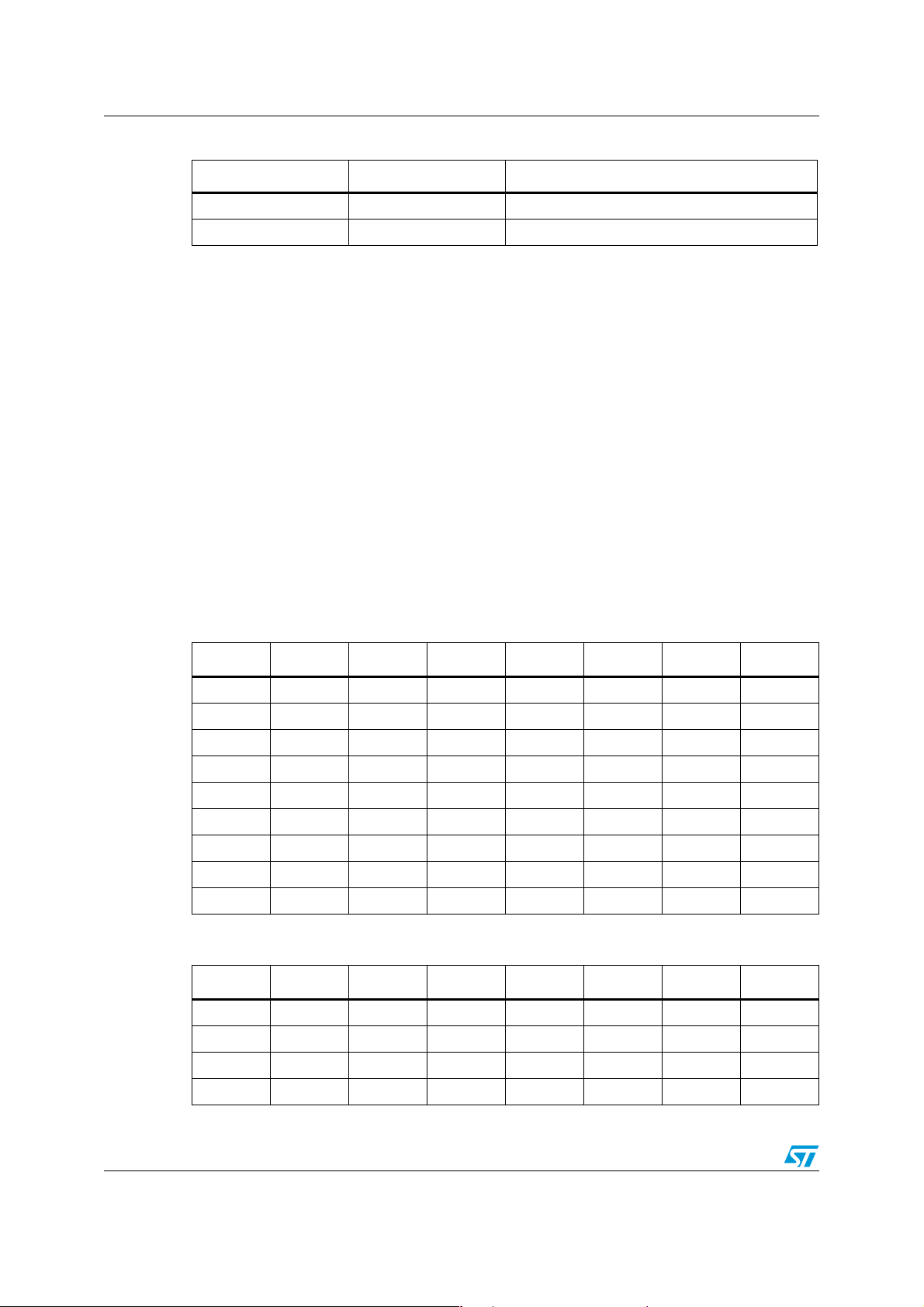

3.1 Experimental results

The power supply has been characterized in terms of line and load regulation. The

efficiency measurements have been taken using a DC power source and a

milliamperometer, in order to have higher accuracy than in AC measurements. In Tab le

4.,Table 5. and Table 6. the experimental results are shown. It is then possible to observe

the efficiency decreases, at same output power, when V

explained with an increase of the parasitic capacitance effect between the windings. These

measurements have been performed without bleeder resistors. Consequently, an

overvoltage occurs on V

can be avoided adding a 3.3KW resistor as a bleeder, with only a slight reduction of the

efficiency. In Figure 2., Figure 3., Figure 4., Figure 5., Figure 6., and Figure 7. typical

waveforms at minimum and maximum input voltage are shown. Figure 8. and Figure 9.

shows the output ripple voltage at full load at minimum and maximum input voltage. In

Figure 10. and Figure 11. turn-on losses measurements are shown in the same previous

conditions. It is important to point out that a lot of power is dissipated in turn-on, due to the

parasitic capacitance of the inductor.

Table 4. Circuit characterization - VIN = 120V

I

[mA] I

OUT1

OUT2

[mA] V

OUT1

OUT1

is more loaded. This can be

OUT2

when it is in no load condition and V

DC

[V] V

[V] IIN [mA] PIN [W] P

OUT2

is full loaded. This

OUT2

[W]

OUT

η [%]

0 0 12.00 5.01 1.08 0.129 0 0

0 150 14.73 4.99 9.71 1.16 0.784 67.58

0 300 16.04 4.97 18.33 2.20 1.49 67.70

75 0 10.51 5.00 8.86 1.06 0.788 74.30

75 150 11.15 4.97 17.60 2.11 1.58 74.80

75 300 11.32 4.95 27.10 3.25 2.33 71.70

150 0 10.40 4.99 16.81 2.02 1.56 77.20

150 150 10.95 4.95 26.40 3.17 2.38 75.00

150 300 11.14 4.92 36.60 4.40 3.15 71.50

Table 5. Circuit characterization - VIN = 320V

I

[mA] I

OUT1

0 0 11.77 5.04 0.47 0.15 0.00 0.00

0 150 15.56 5.02 3.89 1.24 0.75 60.49

0 300 16.26 5.01 7.25 2.32 1.50 64.78

75 0 10.55 5.02 3.55 1.14 0.79 69.65

OUT2

[mA] V

OUT1

[V] V

[V] IIN [mA] PIN [W] P

OUT2

DC

OUT

[W]

η [%]

8/18

Page 9

AN2359 Application example nº 1

Table 5. Circuit characterization - VIN = 320V

I

OUT1

[mA] I

OUT2

[mA] V

OUT1

[V] V

[V] IIN [mA] PIN [W] P

OUT2

DC

OUT

[W]

75 150 11.23 5.01 7.01 2.24 1.59 71.05

75 300 11.37 4.99 10.53 3.37 2.35 69.73

150 0 10.4 5.01 6.7 2.14 1.56 72.76

150 150 11.01 5 10.38 3.32 2.40 72.30

150 300 12.21 4.98 14.44 4.62 3.33 71.97

Table 6. Circuit characterization - VIN = 374V

I

OUT1

[mA] I

OUT2

[mA] V

OUT1

[V] V

[V] IIN [mA] PIN [W] P

OUT2

DC

OUT

[W]

0 0 11.74 5.06 0.44 0.16 0.00 0.00

0 150 15.77 5.02 3.39 1.27 0.75 59.39

0 300 16.51 5 6.38 2.39 1.50 62.86

75 0 10.54 5.02 3.09 1.16 0.79 68.40

75 150 11.26 5.01 6.18 2.31 1.60 69.05

75 300 11.41 5 9.36 3.50 2.36 67.29

150 0 10.4 5.01 5.92 2.21 1.56 70.46

η [%]

η [%]

150 150 11.05 5.01 9.26 3.46 2.41 69.56

150 300 11.2 4.98 12.74 4.76 3.17 66.61

Figure 2. Typical waveforms at 88VAC: open

load

Ch1 Freq - 2.38kHz

Ch2 Max - 228mA

Figure 3. Typical waveforms at 88VAC: full

load

Ch1 Freq - 59.61kHz

Ch2 Max - 572mA

9/18

Page 10

Application example nº 1 AN2359

Figure 4. Typical waveforms at 265VAC: open

Figure 6. Commutation at full load: 88V

load

Ch1 Freq - 2.39kHz

Ch2 Max - 428mA

Ch1 Freq - 103V

AC

A

m

2

6

5

-

x

a

M

2

h

C

Figure 5. Typical waveforms at 265VAC: full

load

Ch1 Freq - 59.65kHz

Ch2 Max - 532mA

Figure 7. Commutation at full load: 265V

V

x

a

-

h

M

C

A

m

0

3

5

-

x

a

M

2

h

C

1

6

3

6

AC

Figure 8. Output ripple voltage at full load:

88V

10/18

AC

Ch1 Pk-Pk - 90mV

Ch3 Pk-Pk - 80mV

Figure 9. Output ripple voltage at full load:

265V

AC

Ch1 Pk-Pk - 108mV

Ch3 Pk-Pk - 82mV

Page 11

AN2359 Application example nº 1

Figure 10. Turn on losses measurement at full

load: 88V

AC

M1 Area 2.92µWs

3.2 Thermal measurements

In this application, the main thermal issues are related to parasitic capacitance effects that

can lead to higher power dissipation in the device and then higher working temperature. In

order to evaluate the case temperature of the VIPer in the entire input voltage range, a

thermal mapping by means of an IR Camera was done at ambient temperature and full load.

In Figure 12. and Figure 13. the thermal profile of the device at minimum and maximum

input voltage range respectively is shown. It is important to highlight that at low line the

conduction losses are predominant, instead at high input voltage the switch losses became

not negligible, due to parasitic capacitance of the inductor. This is point out in Figure 14.

Figure 11. Turn on losses measurement at full

load: 265V

M1 Area 10.07µWs

AC

Figure 12. VIPer22A Thermal profile: at VIN=

88V

T

CASE(MAX)

AC

=53.3°C

Figure 13. VIPer22A Thermal profile: at VIN=

265V

AC

T

CASE(MAX)

=67.3°C

11/18

Page 12

Application example nº 2 AN2359

Figure 14. VIPer22A temperature at maximum load

4 Application example nº 2

In this second example, the Buck-Boost is modified in order to have –24V/-5Voutputs

voltages in a 4W application. In Table 7. the main specifications of the power supply are

listed. The schematic of the circuit and the component list are shown in Figure 15. and in

Table 8. respectively.

Table 7. SMPS specifications

Specification Value

Input voltage range, V

Output voltage V

Output voltage V

Maximum output current I

Maximum output current I

Maximum output power 4W

The –24V output voltage allows to supply the VIPer directly from the feedback path, saving

the cost of a high voltage diode. Even in this case, the feedback regulation is connected to

V

by means of Q1 transistor and DZ1 zener diode. The output inductor, with

OUT2

intermediate tap for V

, is provided by PULSE (PFM0250 type) with the following

OUT2

features:

● L

● N

● R

● R

= 510µH ±10%;

1-3

/ N

1-3

1-2

2-3

= 3.81 ± 2%;

2-3

= 560mW (max);

260ΩW (max).

IN

OUT1

OUT2

OUT1

OUT2

88 - 265V

-24V

-5V

100mA

300mA

AC

12/18

Page 13

AN2359 Application example nº 2

Also bleeder resistors or zener diodes may be mandatory at no load in order to improve the

regulation and avoid output overvoltage.

Figure 15. Converter schematic

Table 8. Component list

Reference Value Description

R

R

R

C

D

2

FUSE

, R

SN

R

2

R

3

, R

b1

b2

C

SN

, C

1

2

C

3

C

4

C

6

C

7

C

8

D

1

, D4, D

D

Z1

D

Z2

Q

1

L

1

1

5

22Ω, 1/2W Metallic oxide resistor

1.2KΩ, 1/4W Resistor

22Ω, 1/4W Resistor

100Ω, 1/4W Resistor

0.1µF, 400V Polyester capacitor

10µF, 400V Electrolytic capacitor

33µF, 25V Electrolytic capacitor

47nF, 35V Ceramic capacitor

22µF, 16V Electrolytic capacitor

470µF, 25V Electrolytic capacitor

100µF, 16V Electrolytic capacitor

Diode BYT11-400 (ultrafast)

PNP transistor BC327

470µH Axial inductor

Optional resistor

Diode 1N4007

Diode Zener 18V

Diode Zener 4.3V

13/18

Page 14

Application example nº 2 AN2359

Table 8. Component list (continued)

Reference Value Description

L

2

(Read sec. 6) Pulse PFM0250

IC STMicroelectronics

4.1 Experimental results

In Table 9., Tab l e 10 . and Ta b l e 11 . the measures performed on the proposed converter are

listed. In Figure 16. and Figure 17. typical waveforms at 300V

The converter performs well in terms of line and load regulation. The –5V output shows a

±5% of precision. V

performance too, even if an overvoltage occurs on V

V

is full loaded. This can be avoided connecting an appropriate bleeder resistor on

OUT2

V

. The efficiency measurements show a better behavior compared to the –12V

OUT1

solution. This can be explained because, in this configuration, the turn-on losses are lower

compared to the –12V solution.

Table 9. Experimental results - VIN=120V

I

[mA] I

OUT1

0 0 24.09 5.096 0.986 0.1972 0 0.00

10 30 23.87 5.098 3.643 0.7286 0.39164 53.75

50 150 23.97 5.087 13.33 2.666 1.96155 73.58

80 240 24.05 5.075 20.5 4.1 3.142 76.63

100 300 24.06 5.069 25.68 5.136 3.9267 76.45

OUT2

[mA] V

, obtained by means of the turns ratio of the inductor, shows good

OUT1

OUT1

[V] V

when it is in no load condition and

OUT1

DC

[V] IIN[mA] PIN[W] P

OUT2

are shown.

DC

[W] η[%]

OUT

0 300 41.54 5.02 12.74 2.55 1.51 59.11

100 0 21.82 5.083 13.74 2.75 2.18 79.40

Table 10. Experimental results - VIN=320V

I

[mA] I

OUT1

0 0 24.1 5.098 0.666 0.20 0.00 0.00

10 30 23.9 5.094 2.435 0.73 0.39 53.64

50 150 23.96 5.091 9.182 2.75 1.96 71.21

80 240 24.03 5.079 13.85 4.16 3.14 75.60

100 300 24.03 5.068 17.17 5.15 3.92 76.17

0 300 41.14 5.025 8.684 2.61 1.51 57.87

100 0 21.89 5.096 9.41 2.82 2.19 77.54

14/18

OUT2

[mA] V

OUT1

[V] V

OUT2

DC

[V] IIN[mA] PIN[W] P

[W] η[%]

OUT

Page 15

AN2359 Layout considerations

Table 11. Experimental results - V

I

[mA] I

OUT1

0 0 24.16 5.098 0.513 0.21 0.00 0.00

10 30 23.99 5.094 1.852 0.74 0.39 53.01

50 150 24 5.094 7.04 2.82 1.96 69.75

80 240 24.03 5.085 10.66 4.26 3.14 73.71

100 300 24.028 5.071 13.14 5.26 3.92 74.66

0 300 41 5.03 6.68 2.67 1.51 56.47

100 0 21.93 5.1 7.221 2.89 2.19 75.92

OUT2

[mA] V

OUT1

[V] V

IN

OUT2

Figure 16. Typical waveforms at 300VDC and

full load: commutation

=374V

DC

[V] IIN[mA] PIN[W] P

[W] η[%]

OUT

Figure 17. Typical waveforms at 300VDC and

full load: detail

5 Layout considerations

A proper PCB layout is essential for correct operation of any switch-mode converter and the

same basic rules have to be taken into account in order to optimize the current path,

especially in high current path routing.

Since EMI issues are related to layout, the current loop area has to be minimized. Moreover,

the control ground path has to be separated from power ground, in order to avoid any noise

interference between the control section and the power section.

All the traces carrying high currents have to be as short as possible, in order to minimize the

resistive and inductive effect.

A particular care has to be taken into account regarding the optimal routing of the input EMI

filter path and the correct placement of any single component (L

bulk capacitors, trace as short as possible…).

–R1 very close to input

1

15/18

Page 16

Layout considerations AN2359

Finally, dissipating copper area on the VIPer drain and diodes pins have to be provided, in

order to increase the power dissipation capability and, consequently, reduce the devices

temperature.

The circuit layout is shown in figure 12 for the –12V configuration and in figure 13 for the –

24V configuration. The PCB is the same and includes the options for the two configurations.

Figure 18. PCB Layout (not in scale). Option nº 1: -12V output voltage

Figure 19. PCB Layout (not in scale). Option nº 2: -24V output voltage

16/18

Page 17

AN2359 Conclusions

6 Conclusions

Two low cost double outputs Buck-Boost converters have been proposed based on

STMicroelectronics VIPer22A.

Thanks to the regulation feedback connected to –5V output, the converters can be suitably

used to supply a microcontroller or applications where a high output voltage tolerance is

required.

Instead, the -12V or-24V output voltage, achieved by the output inductor turns ratio, can be

used for the auxiliary circuits where a lower tolerance can be accepted.

In particular, the –24V option can be preferred because it guarantees a higher efficiency

(due to lower turn- on losses) and allows to save the cost of a high voltage diode compared

to the –12V solution.

On the other side, the –12V solution has to be used in many applications when it is not

possible to change the auxiliary supply voltage from –12V to –24V.

The same topology can be used for lower power range, replacing the VIPer22 with the

VIPer12.

In this case the device can deliver up to about 2.2W.

7 Revision history

Table 12. Revision history

Date Revision Changes

04-Dec-2006 1 Initial release

17/18

Page 18

AN2359

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZED ST REPRESENTATIVE, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2006 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

18/18

Loading...

Loading...