Page 1

AN2349

Application note

Simple cost-effective PFC using Bipolar Transistors

for low-to-medium power HF Ballasts

Introduction

This note deals with the implementation of a Power Factor Correction (PFC) in a

Discontinuous-mode Boost Converter where a PFC stage is achieved with a power bipolar

transistor driven in self oscillating configuration. The new solution proposed exploits the

physical relation (t

(PWM) signal in a Boost Converter.

, IC) of any bipolar transistor to achieve the Pulse Width Modulation

S

June 2006 Rev 1 1/30

www.st.com

Page 2

Contents AN2349

Contents

1 PFC solutions for low-medium power HF Ballasts . . . . . . . . . . . . . . . . 5

1.1 Application description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2 Feedback block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3 Selection of boost output inductor L1 . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.1 Selection of boost output capacitor C4 . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4 PFC driving network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.1 Feed-Back block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5 T Transformer and L1 inductor specifications . . . . . . . . . . . . . . . . . . 23

5.1 220V design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.2 120V design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

6 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

2/30

Page 3

AN2349 List of tables

List of tables

Table 1. 40W Demoboard 220V bill of materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Table 2. 40W Demoboard 120V bill of materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Table 3. Document revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

3/30

Page 4

List of figures AN2349

List of figures

Figure 1. Valley Fill circuit schematic diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Figure 2. Valley Fll input current waveform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Figure 3. Active PFC with IC and MOSFET in boost topology. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Figure 4. Base schematic of Bipolar PFC in HF ballast voltage Fed . . . . . . . . . . . . . . . . . . . . . . . . . 6

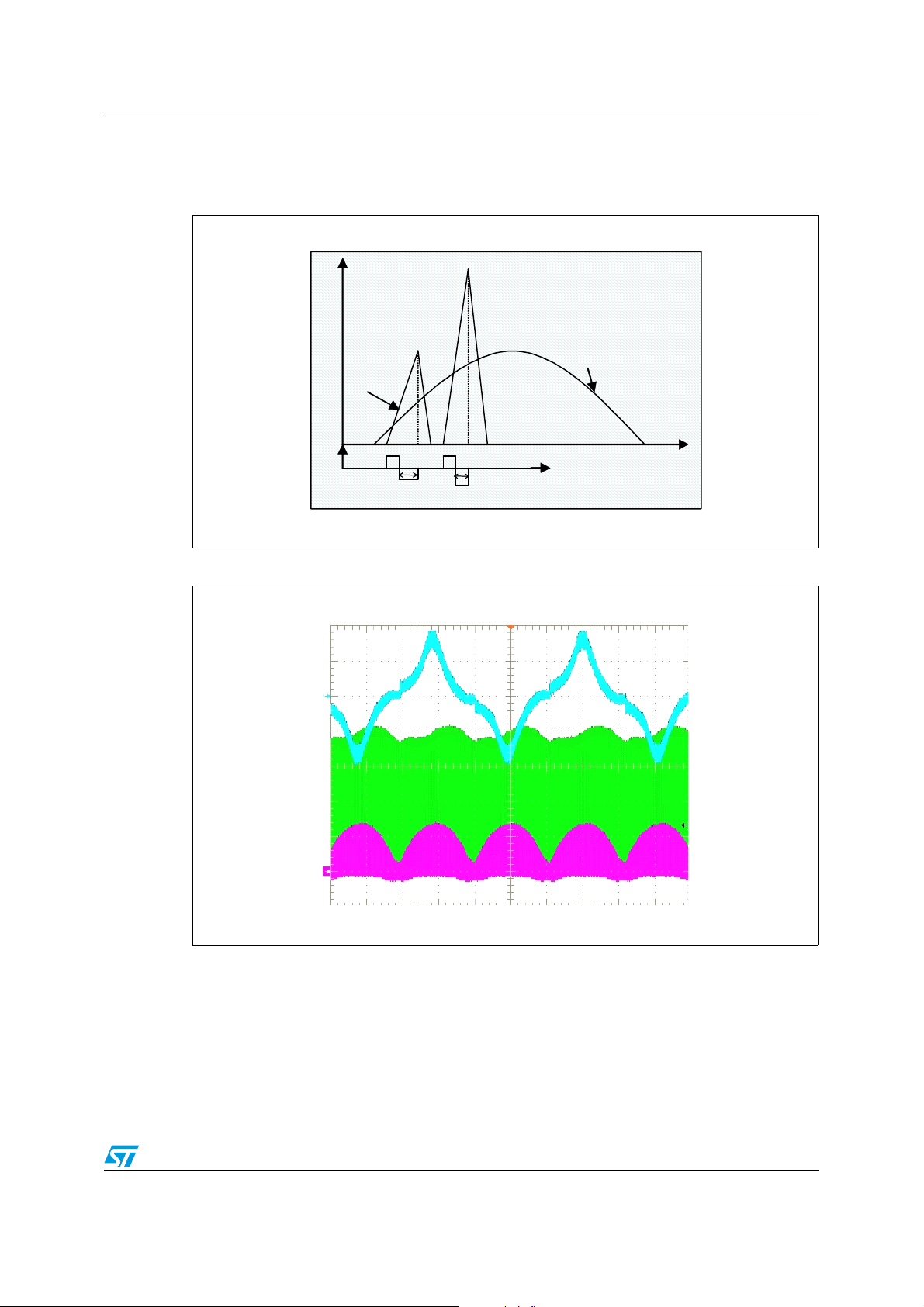

Figure 5. Ts modulation in bipolar PFC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Figure 6. Imain achieved using the basic Bipolar PFC shown in Figure 4 . . . . . . . . . . . . . . . . . . . . . . 7

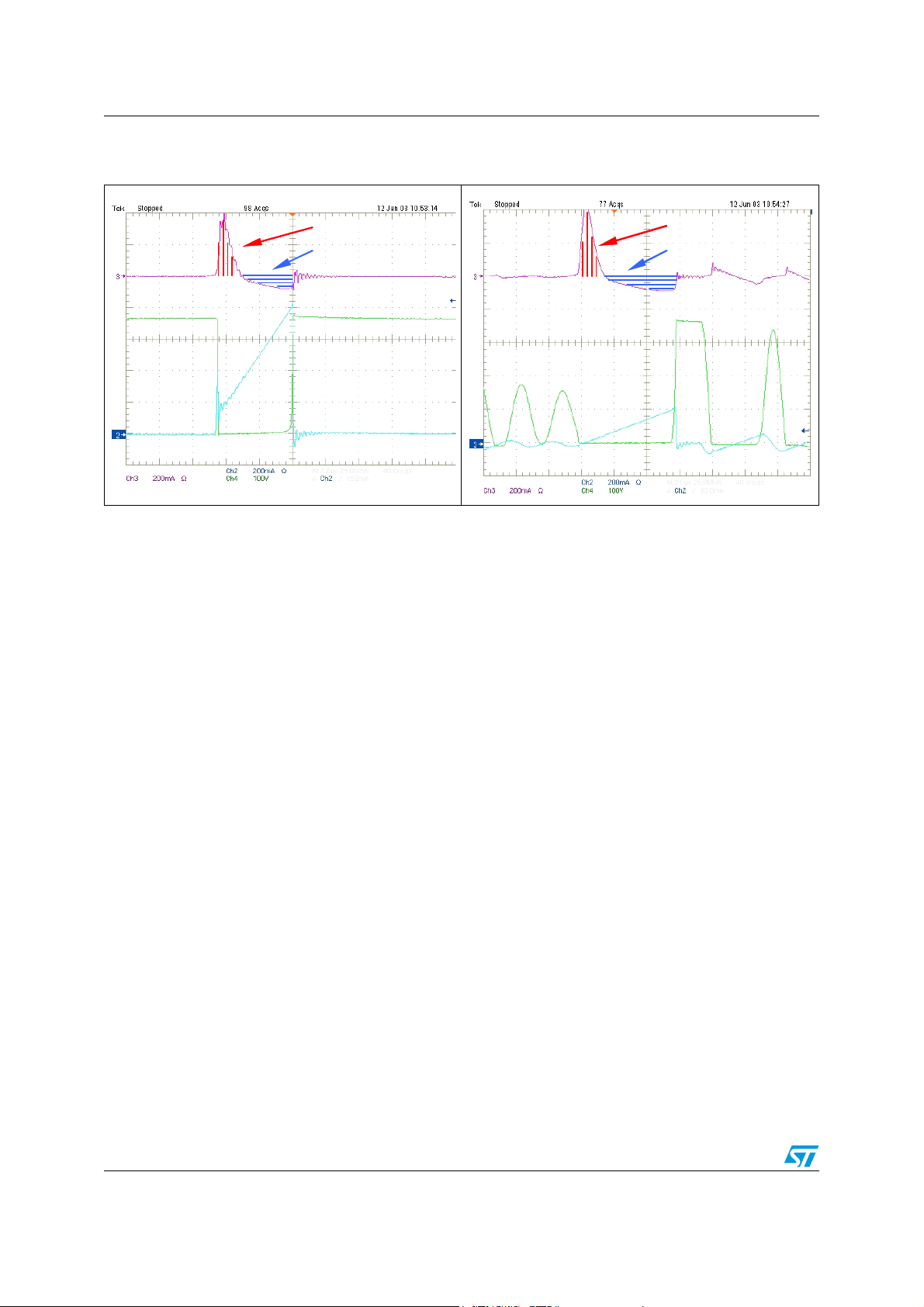

Figure 7. Detail of storage time value and Ic in t2 istant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Figure 8. Detail of storage time value and Ic in t1 istant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

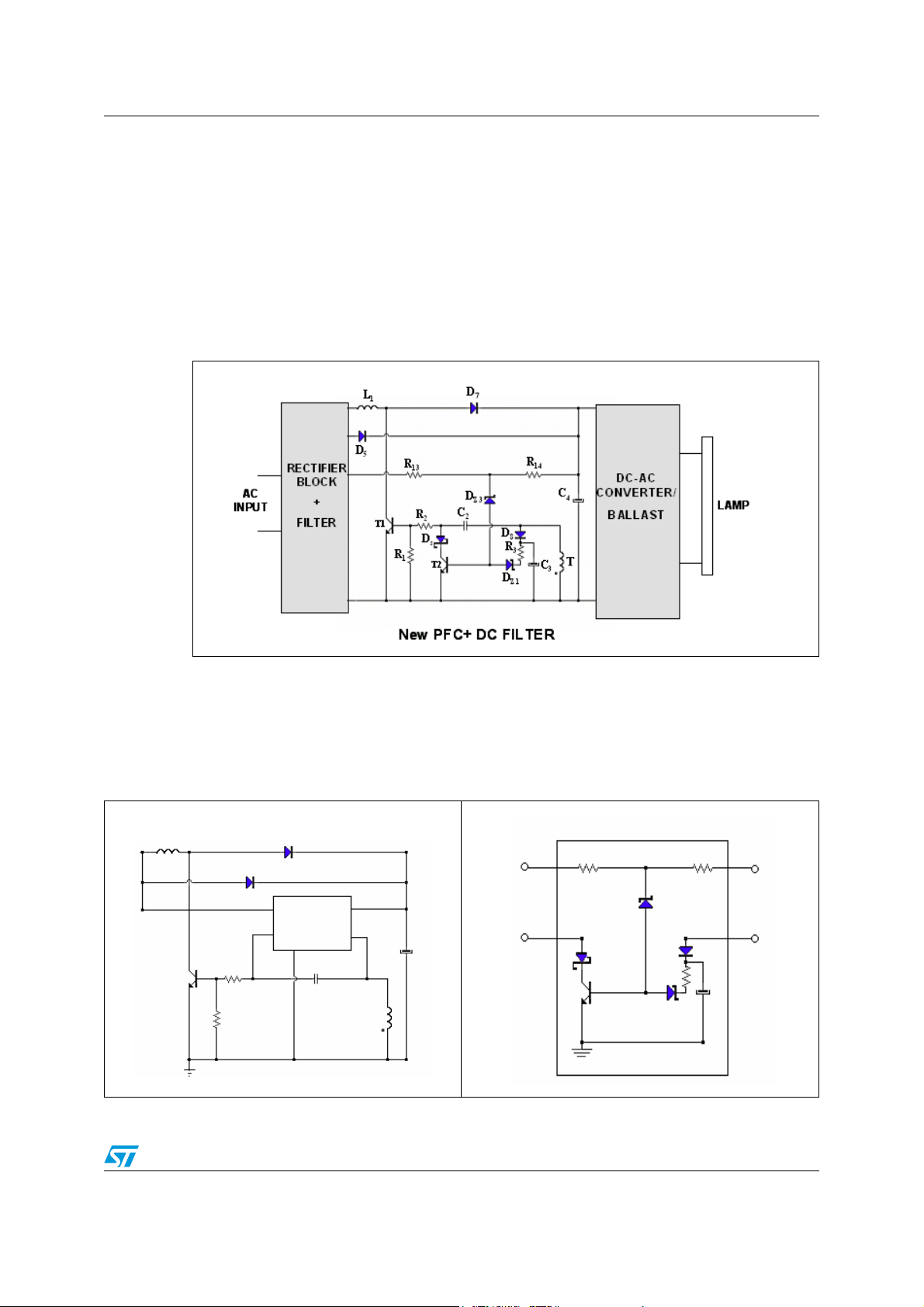

Figure 9. Complete electrical schematic of the Bipolar PFC in HF Ballast . . . . . . . . . . . . . . . . . . . . . 9

Figure 10. PFC stage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Figure 11. Feed-back block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Figure 12. PFC waveforms with Feedback block working . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Figure 13. Imain achieved by the proposed bipolar PFC solution . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Figure 14. Detail of Storage time value in t2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Figure 15. Detail of storage time value in t1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Figure 16. Pre-heating @ 220V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Figure 17. Current on the electrolytic capacitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Figure 18. Inductor current with di/dt>0 and transformer voltage shape . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 19. Inductor current with di/dt=0 and transformer voltage shape . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 20. Inductor current with di/dt<0 and transformer voltage shape . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 21. Transformer Vout shape and base current shape . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 22. Collector current and base current shape. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 23. Detail of T1 total charge during Ton . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 24. 40W demoboard electrical schematic. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Figure 25. 40W demoboard PCB layout and mounting components. . . . . . . . . . . . . . . . . . . . . . . . . . 25

4/30

Page 5

AN2349 PFC solutions for low-medium power HF Ballasts

1 PFC solutions for low-medium power HF Ballasts

The Valley Fill circuit is an example of a low-cost passive PFC available on the market.

Figure 1. Valley Fill circuit schematic diagram

DC-AC

DC-AC

DC-AC

DC-AC

CONVERTER/

CONVERTER/

CONVERTER/

AC

AC

AC

AC

INPUT

INPUT

INPUT

INPUT

RECTIFIER+PFC+DC

RECTIFIER+PFC+DC

RECTIFIER+PFC+DC

RECTIFIER+PFC+DC

FILTER BLOCK

FILTER BLOCK

FILTER BLOCK

FILTER BLOCK

Figure 2. Valley Fll input current waveform

CONVERTER/

BALLAST

BALLAST

BALLAST

BALLAST

LAMP

LAMP

LAMP

LAMP

The capacitors are charged in serie, and discharged, via the two diodes, in parallel. Current

is drawn from the line from 30° to 150°, and then from 210° to 330°. Discontinuities occur

from 150° to 210° and from 330° to 360°, and then the cycle repeats itself.

Disadvantages of this PFC solution are spikes on input current waveform and large zero

current gaps between the half sinusoidal wave and the next one (meaning a lower power

factor and high input current distortion), and high ripple in the DC output voltage that causes

poor performance in High Power Lamps. On the other hand, high performances can be

achieved by IC driver optimized for controlling PFC regulators in boost topology as shown in

Figure 3.

5/30

Page 6

PFC solutions for low-medium power HF Ballasts AN2349

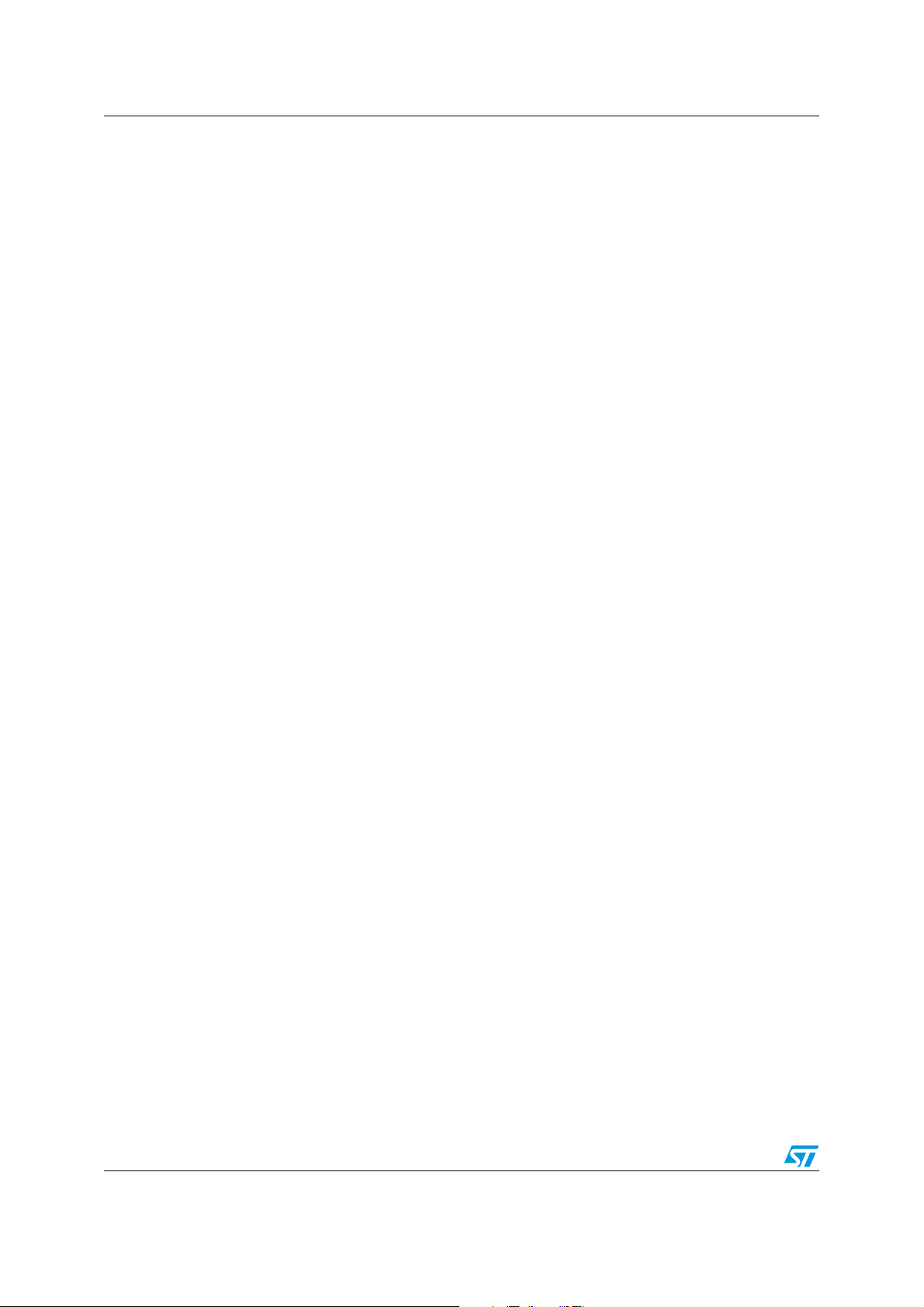

Figure 3. Active PFC with IC and MOSFET in boost topology

The proposed Bipolar PFC solution targets the low-cost HF Ballast market up to 80 W as it

provides a simple cost-effective solution without sacrificing THD and PF levels. It does not

need any ICs to achieve the PWM signal since it uses just a power bipolar transistor and a

closed-loop feedback that performs the duty cycle modulation and a satisfactory output

power regulation.

1.1 Application description

The active PFC solution with Bipolar transistor adopts the Boost topology working in

Discontinuous Conduction mode. This is the most simple and cost-effective solution for

220V and 120V mains and low\medium power.

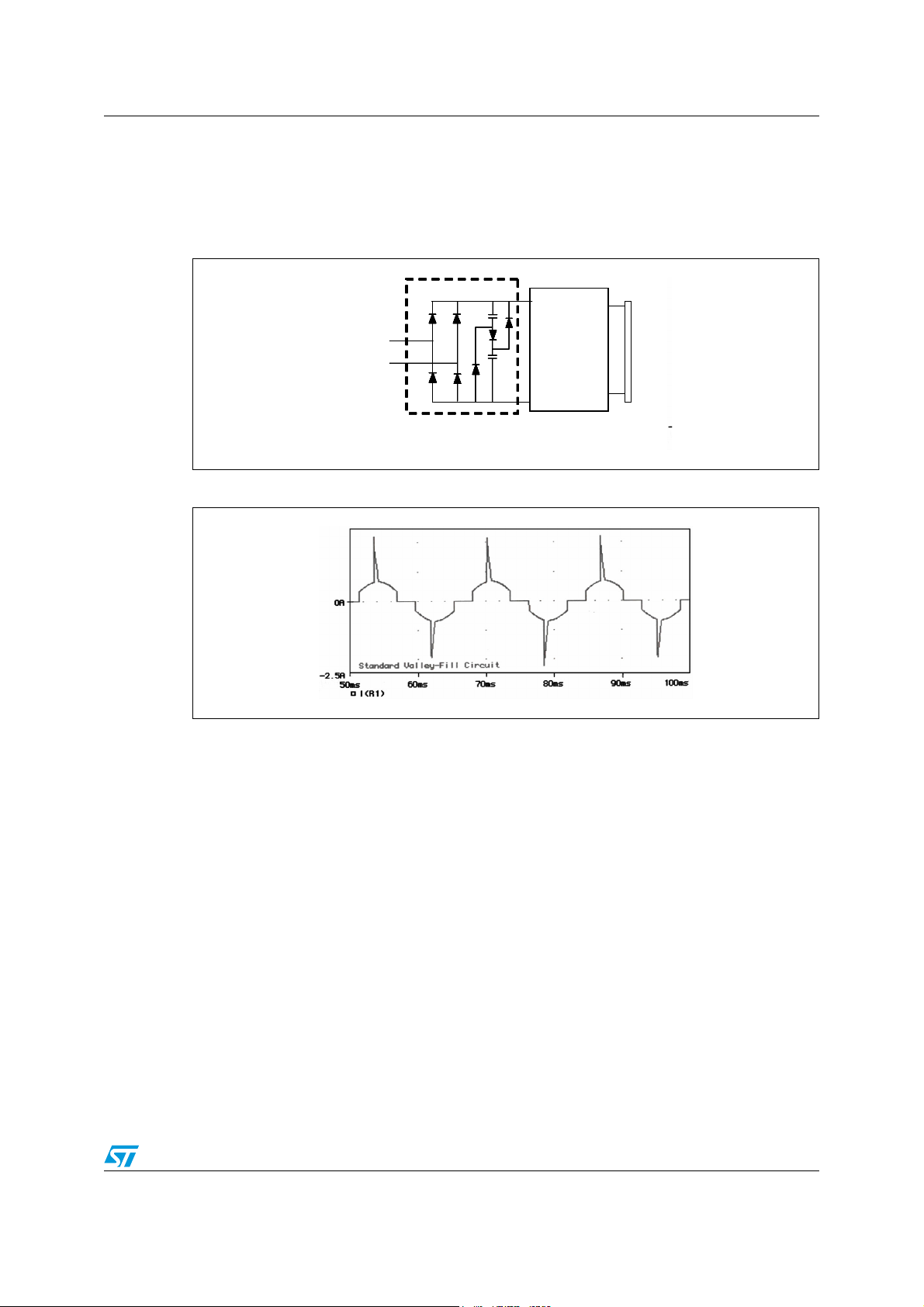

Figure 4. Base schematic of Bipolar PFC in HF ballast voltage Fed

No IC is used to generate a PWM signal, but the physical relation (t

, IC) of any power

S

bipolar transistor is exploited when the base current IB value is kept constant.

Figure 5 shows two different storage time values at two different input V

bipolar reaches a higher saturation level than in t

The overall switch on time is given by the sum of "I

therefore, if the "I

time" is constant, the duty cycle changes according to the ts

BON

modulation. This natural duty cycle variation generates an appropriate PWM signal to

6/30

, and this means tS1>tS2.

2

time" plus the storage time,

BON

AC

values: in t1 the

Page 7

AN2349 PFC solutions for low-medium power HF Ballasts

AV

control the PFC stage and reduces the Imain distortion achieving a THD in the range of

about 30%, with a shape of the current drawn from the main as shown in Figure 6.

Figure 5. Ts modulation in bipolar PFC

I

IN

IIN

IL=I

c

t

I

B

s1

t

s2

t

t

Figure 6. Imain achieved using the basic Bipolar PFC shown in Figure 4

Imain

Vce

Ic

Figure 7 and Figure 8 show in a real situation, what has been explained before.

7/30

Page 8

PFC solutions for low-medium power HF Ballasts AN2349

Figure 7. Detail of storage time value and Ic

istant

in t

2

Injected charges

Injected charges

Storage time

Storage time

Ib

Ib

Vce

Vce

Ic

Ic

The PWM signal acts on T1 bipolar transistor base through an auxiliary winding T on the

transformer normally used in the ballast.

Figure 8. Detail of storage time value and Ic

in t1 istant

Injected charges

Injected charges

Storage time

Storage time

Ib

Ib

Vce

Vce

Ic

Ic

8/30

Page 9

AN2349 Feedback block

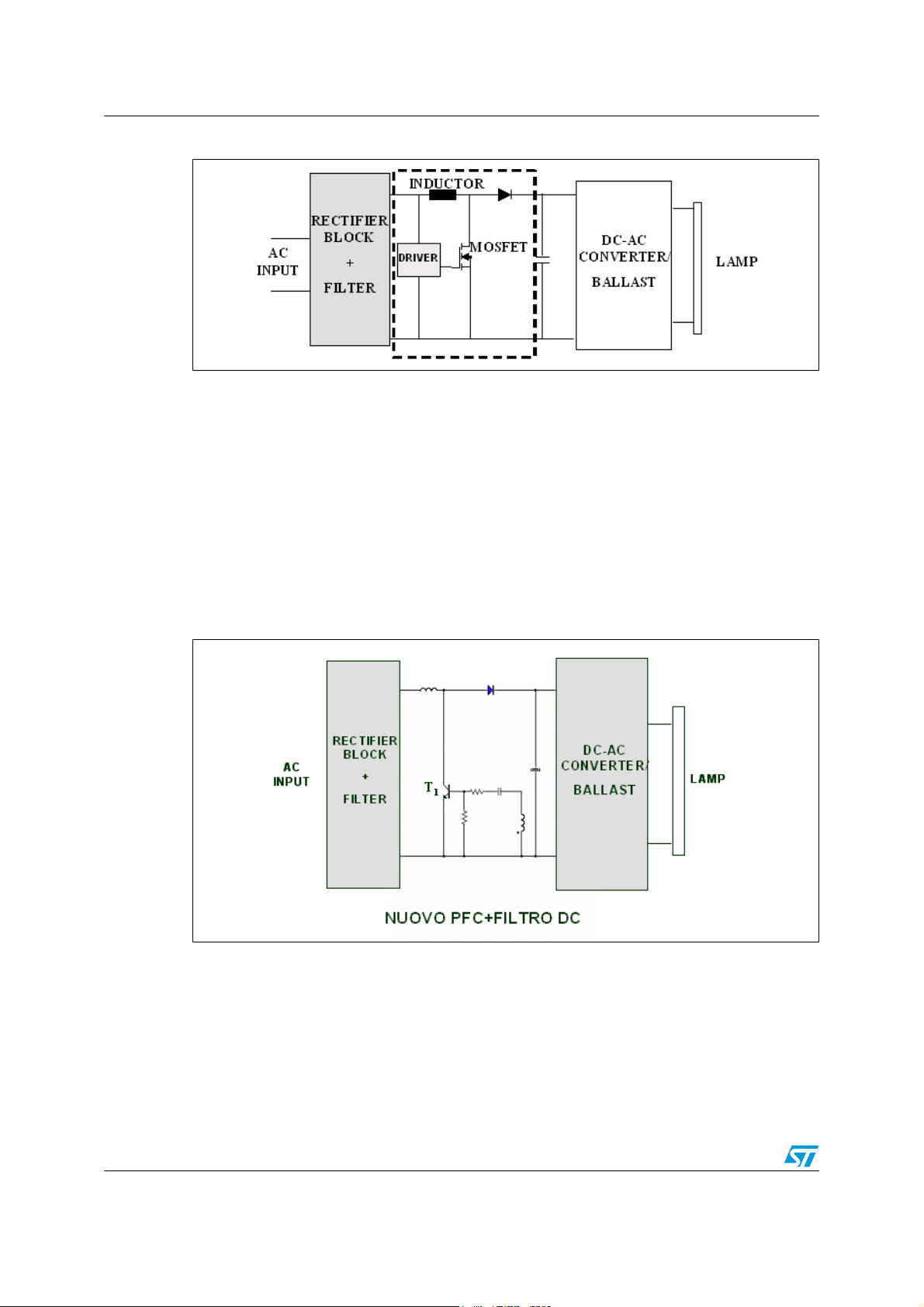

2 Feedback block

The duty cycle modulation performed by the Basic Solution shown in Figure 4 is not enough

effective to achieve high THD values and no protection task can be implemented against

overoload or high VAC values.

A negative feedback network has been introduced to further control the duty cycle

modulation by modifying the total Q

Chapter Figure 9. on page 9 shows the complete solution of the proposed PFC stage.

Figure 9. Complete electrical schematic of the Bipolar PFC in HF Ballast

charge which is injected into the T1 base.

on

The feed-back block in Figure 11 changes the T

amplitude and duration through the intervention of the transistor T

proposed network by the T

duty cycle of the main switch (T

conduction reduces the base current permitting to reduce the

2

) performing a further THD correction and output power

1

charge by modifying both the I

1 QON

. In particular the

2

regulation.

Figure 10. PFC stage Figure 11. Feed-back block

D7

D5

D5

D7

Feed-Back

Feed-Back

Block

Block

C2

C2

Input 2

Input 2

Input 3

Input 3

T

T

C4

C4

Input 1

Input 1

Output

Output

R13

R13

Ds D8

Ds D8

T

T

2

2

Dz3

Dz3

Dz1

Dz1

L1

L1

Input 1

Input 1

Output

Output

T

T

1

1

R2

R2

R1

R1

R3

R3

R14

R14

C3

C3

Input 2

Input 2

Input 3

Input 3

BON

9/30

Page 10

Feedback block AN2349

The network D8, R3, DZ1, and C3 in Figure 11 ensures the switch protection during start-up

thanks to a smart combination of three input signals.

1. Input 1 comes from the Main Voltage and it'is used to limit the amount of the distortion

improving the THD.

2. Input 2 comes from PFC Vout : it'is used to further regulate the power factor and to

regulate the PFC Vout against supply voltage variations.

3. Input 3 signal is a voltage proportional to the pre-heating current during start up and it'

is used. to protect the power switch against over voltage . The Output signal is the base

current driving the T

The transistor T

during its On-state modifies the natural modulation imposed by the storage

2

time variation of the transistor T

● It reduces the time constant during the charge of the capacitor C

time length of the On base current of T

●

It shunts part of the same current to ground thus reducing its amplitude.

main switch.

1

since:

1

thus reducing the

2

1

The combination of the previous two effects implies a reduction of the duty cycle of the

transistor T

The schottky diode Ds in series with the collector of the transistor T

current on the transistor itself ensures a low voltage drop during T

helping to correct the THD and the power factor level .

1

by blocking any reverse

2

on state.

2

The steady state waveforms associated to the new proposed circuit are below reported in

Figure 16.

Figure 12. PFC waveforms with Feedback

block working

Figure 13. Imain achieved by the proposed

bipolar PFC solution

Imain

Imain

Vce

Vce

Ic

Ic

Components values of the Feedback block have been chosen to achieve a base current

modulation that allows obtaining a constant collector current in the range of V

sen ωt with

M

30° ≤ωt≤ 150°.

Waveforms reported in Figure 13 shows now a quasi-sinusoidal behavior of the current

drawn from the main, while the blue waveform in Figure 12 shows the T

1 IBON

modulation

performed by the negative feedback.

10/30

Page 11

AN2349 Feedback block

The overall storage time modulation achieved by the Bipolar PFC working with the negative

feedback network is evident in Figure 14 and Figure 15 showing real values of storage time

detected on the oscilloscope at t

Figure 14. Detail of Storage time value in t

Injected charges

Injected charges

Storage time

Storage time

and t2 instances.

1

Figure 15. Detail of storage time value in t1

2

Injected charges

Injected charges

Storage time

Storage time

Figure 16 shows the pre-heating and start-up phase waveforms.

Figure 16. Pre-heating @ 220V

VceIcVce

Ic

11/30

Page 12

Selection of boost output inductor L1 AN2349

3 Selection of boost output inductor L

The boost output inductor L1 is calculated in the peak of sinusoidal voltage at maximum

instantaneous input power in order to obtain the minimum I

discontinuous mode operation. This calculation is made considering a working operation at

constant current peak I

, due to the base current modulation, and fixing a working switching

P

frequency. Supposed a purely resistive load it is:

Equation 1

V

MIM

------------------------ -==

2

where V

PV

is the maximum input main voltage and IM is the maximum input main current.

M

•

effIeff

Then from Equation 1,

Equation 2

• 2P=

V

MIM

Now considered the total energy stored by the inductor in the period at the maximum input

main voltage:

Equation 3

2P

2PT

-------==

f

sw

where T is the period and f

E

TOT

is the working switching frequency.

SW

But the total energy stored by the inductor in the period is, also, the sum of two contributes,

the first LI

2

/2, due to the inductor L1 charge and the other one, VMIptB/2, due to the

P

discharge of the same via the main voltage, then equalizing the two terms we obtain:

value assuring the

P

•()

1

Equation 4

2P

---------

f

SW

where I

is the peak of the working switching current at maximum voltage VM and tB is the

P

inductor discharge time that is:

Equation 5

with V

Substituting t

imposed at 390V and it is the PFC output voltage.

out

in Equation 4:

B

Equation 6

2P

---------

f

SW

LI

-----------

2

2

P

•

V

MIP

------------------ -

2

calculated in the max point of the sinusoid, in general for 30°≤ ωt ≤150° it can be can

written:

12/30

2

V

LI

-----------

2

t

-------------------------=

B

V

•

MIp

P

----------------------- -+=

LI

P

–

outVM

LI

P

-------------------------

V

–

outVM

• t

2

B

2

LI

-----------

=+=

V

P

-------------------------

2

V

outVM

out

–

Page 13

AN2349 Selection of boost output inductor L1

tAt

Equation 7

2P t()

--------------

f

SW

LI

-----------

2

2

P

senωtIP•

V

M

---------------------------------- -

2

-----------------------------------------

•

V

outVM

where according to the working operation, LI

LI

P

senωt–

2

/2 is the constant term, while the other one

P

LI

-----------

2

2

P

•=+=

V

out

-----------------------------------------

V

outVM

senωt–

contains the sinusoidal modulation of the main current with 30°<ωt<150°.

In order to calculate I

, you consider the instantaneous Max Power in a 50 Hz period:

P

Equation 8

PMVMIM•=

is also the medium value of the peak of the working switching current in the period T

but I

M

corresponding to the max point of the Main Voltage V

.

M

Equation 9

+

B

--------------- -

•=

2T

is the L1 discharge time.

out-VM

where t

I

MIP

=LIP/VM is the L1 charge time and tB=LIP/V

A

Now from Equation 9:

Equation 10

2T

M

--------------- -

•=

t

+

AtB

IPI

Substituting Equation 10 in Equation 7 and resolving by L:

Equation 11

2

where t

t

+

P

AtB

--- -

L

/T is chosen equal to 0.70 in order to ensure that the circuit remains in the

A+tB

--------------- -

•

f

T

--------

•

I

V

1

-------------------------

•=

2

M

discontinuous mode leaving a dead-time of 0.3T.

3.1 Selection of boost output capacitor C

The PFC works to obtain a sinusoidal Main Current. Therefore the capacitor C4 will charge

with a rectified current at double half-wave shape, as shown in Figure 17. This current shape

will generate on the electrolytic capacitor an almost continuous voltage with a ripple value

depending on the same capacitor value. In order to calculate the capacitor C4, the current

flowing on the electrolytic capacitor can be asssumed as thoroughly the sum of two

contributions, one due to a continuous component and other one due to an alternate

component, as shown in Figure 17. The alternate component will have double frequency

respect to the main frequency.

–

outVM

V

out

4

13/30

Page 14

Selection of boost output inductor L1 AN2349

Figure 17. Current on the electrolytic capacitor

I

I

|IMsenωt|

|IMsenωt|

I

I

= 2*IM/π

= 2*IM/π

DC

DC

I

I

AC

AC

IM –2*IM/π

IM –2*IM/π

π

π

I

I

M

M

2π

2π

T

T

T

T

Thus for 0<ωt<Π:

Equation 12

IMωtsin I

+≅

DCIAC

where I

, the continuous component, is the mean value of IM sinωt :

DC

Equation 13

π

and I

I

M

I

DC

is the alternate component with double frequency and out of phase of π/2 respect to

AC

-----

=

∫

ωt • t

π

0

2I

-------- -=dsin

M

π

the main one that is:

Equation 14

I

I

AC

M

2I

-------- -–

M

sin=

π

π

2ωt–

-- -–

2

Now substituting Equation 13 and Equation 14 into Equation 12, we have:

Equation 15

I

ωtsin

M

V

The peak ripple voltage is:

M

RIPPLE

2I

M

-------- - I

π

2I

M

---------–

M

sin+≅

π

π

2ωt–

-- -–

2

Equation 16

V

PP

RIPPLE

V

M

RIPPLE

V

M

But is the alternate voltage on the capacitor due to the I

RIPPLE

----------------------- -=

2

AC

Equation 17

V

M

RIPPLE

14/30

2I

M

I

-------- -–

M

XC•=

π

Page 15

AN2349 Selection of boost output inductor L1

V

V

where from Equation 17, the IM-2IM/π is the max amplitude of the alternate current IAC on

the electrolytic capacitor, while X

electrolytic capacitor, with f

*

is the capacitive reactance XC=ωC

C

=2f

main(fmain

=50/60Hz).

=2πf* of the

OUT

Equalizing Equation 16 and Equation 17 you have

Equation 18

PP

RIPPLE

----------------------- -

2

=

2I

M

I

-------- -–

M

2πf• C

π

OUT

and resolving by C:

Equation 19

OUT

----------------------- -

4πf

C

where is the peak to peak ripple voltage and from Equation

2 I

V

=2*P/VM.

M

PP

RIPPLE

v

DC

MAXVDC

OUT

–=

out

MIN

PP

RIPPLE

1

-----

•=

I

M

15/30

Page 16

PFC driving network AN2349

4 PFC driving network

The network composed by the capacitor and resistor in series to the base of the power

bipolar transistor T1 are chosen in order to fix the duty-cycle at level less than 50% in the

max point of the main sinusoid and they determine the conduction time of the device, while

the base-emitter resistor has the function to regulate the capacitor discharge during the off

state of the device and to define the duty-cycle. The bipolar transistor used as switching is

driven in a self-oscillating configuration taking the signal in order to polarize its base through

an auxiliary winding on the transformer normally used in the ballast. This signal can assume

three different shapes depending on the signal shape on the ballast due to the di/dt

variation of the Ballast inductor current. The inductor current is the sum of the Transistor

Collector Current, Diode Current and Snubber Capacitor Current.

1. End collector current with di/dt>0

Figure 18. Inductor current with di/dt>0 and transformer voltage shape

I

I

CT1 I

CT1 I

I

I

D1

D1

+

+

A

A

V

V

A

A

di/dt

di/dt

B

B

+

+

D2

D2

I

I

CT2

CT2ICT2

I

I

T2

T2

I

I

L

L

I

I

T1

T1

V

V

B

B

T

T/2

T/2

T

2. End collector current with di/dt= 0

Figure 19. Inductor current with di/dt=0 and transformer voltage shape

I

I

D2

T/2

T/2

D2

I

I

CT2

CT2

I

I

T2

T2

I

I

L

L

I

I

T1

T1

T

T

I

I

CT1

CT1

di/dt

di/dt

I

I

D1

D1

A

A

+

+

V

V

A

A

= 0

= 0

B

B

V

V

B

B

16/30

Page 17

AN2349 PFC driving network

3. End collector current with di/dt < 0

Figure 20. Inductor current with di/dt<0 and transformer voltage shape

The first condition is considered for our reference design, di/dt > 0, and in particular the

slope on the point A has a di/dt value four times larger than the slope of the point B.

Figure 21 shows the output voltage of the transformer where the V

larger than the V

Figure 21. Transformer V

value.

B

shape and base current shape

out

value is four times

A

17/30

Page 18

PFC driving network AN2349

The output voltage VT of the transformer at the initial instant is:

Equation 20

V

V

V

V

T

C

0

2.5V= V

V

C

where is the initial capacitor voltage, is the resistor R

the T

0

BE voltage.

1

R

0

2

BEVA

R

2

=++=

voltage and VBE is

2

The shape of the transformer voltage in a half period T/2 is:

Equation 21

VAVB–()t•

VTt() V

After the initial instant, the capacitor begins to charge and, as soon as V

current I

B

considering this instant t

V

R

and are equal to zero and the storage time of the device is beginning, so

2

that is you have:

2

t

I

BON

---------------------------------–=

A

T

---

2

(t)=VT(t) the base

C

Equation 22

VTt2() V

where V

capacitor voltage, and vc(t

V

= 0.2V is base-emitter voltage when IB is equal to zero and taking in consideration that

BE

), voltage on the capacitor C2, is the sum of two terms , that is the initial

C(t2

) , that is the voltage variation due to the charge of the capacitor,

2

BEVCt2

() VBEV

vCt2()++=+=

C

0

V

C

0

there are charges stored into the base of the transistor.

Equalizing the two expressions 21 and 22 at this instant, you obtain:

Equation 23

VAVB–()t2•

by considering V

=4VB≅ 6V, VB=1.5V and t2=.

A

In order to calculate t

----------------------------------- -

V

A

t

I

= you have:

BON

2

T

---

2

V

t

I

BON

BEVC

vCt2()++=–

0

Equation 24

LI

p

tAt

calculated when the collector current I

base current I

is without modulation yet (as shown in Figure 22).

b

I

BON

(for ωt=30°) reaches its maximum value and the

C

t

ST

----------------------- -=+=

VMsenωt

18/30

Page 19

AN2349 PFC driving network

Figure 22. Collector current and base current shape

t

Since v

)=Q/C=Ib

c(t2

*t2 /2C having imposed that at the instant =tST=t

peak

I

BON

2

Equation 25

Ib

•

peakt2

C

---------------------------=

()•

2v

ct2

where it has been imposed Ib

V

Now from Equation 20 can be calculated:

R

2

=0.75*Ip=0.53mA.

peak

Equation 26

V

where V

Then, since , R

=1V is the base-emitter voltage of the device at the working current.

BE

V

Ib

R

2

•=

peakR2

VTV

R

2

is determined:

2

VBE––=

C

0

Equation 27

V

R

2

----------------=

R

2

Ib

peak

It has been said that the base-emitter resistor R

has the function to regulate the capacitor

1

discharge during the off state of the device and to define the duty-cycle.

I

The mean current on the R

R1Mean

resistor during the off state of the device:

1

Equation 28

VAVB+

-------------------- - 0.6 V

2

I

R1Mean

where it has been considered a mean value of .

--------------------------------------------------------------=

R

VC0.6 V

+

1R2

•+

C

0

•=

C

0

19/30

Page 20

PFC driving network AN2349

You consider the instant of the main sinusoidal in which the collector current IC (for ωt=30°)

reaches its maximum value and the base current Ib without modulation yet (see Figure 22).

Multiplying this value for T/2, the amount of charge on the capacitor C

during the off state of

2

the device can be calculated:

Equation 29

T

1

Mean

---

=

• Q

2

C2OFF

I

R

this value must be equal at the amount of charge on the same capacitor during the on state

of the device:

Equation 30

I

R1Mean

---

• Q

2

C2ONQTOT

Q

+==

T

T1

2

T

Substituting Equation 28 into Equation 30 you obtain:

Equation 31

VAVB+

-------------------- - 0.6 V

2

--------------------------------------------------------------

Q

where is the total amount of charge on T

collector of T

TOT

T1

.

2

R

In the following picture it has been indicated with Q

base during the turn-on of the device, while the Q

+

1R2

•+

C

0

T

---

• Q

TOT

2

and is the amount of charge on the

1

is the amount of charge during the

2

Q

Q

=+=

T

T1

Q

T

2

the amount of charge provided in the

1

C2ON

2

storage time, thus the total amount of charge is:

Figure 23. Detail of T1 total charge during Ton

where Q

=0.6Q1 due to the recombination of some charges, so substituting in (5.13) it

2

obtains:

Equation 32

Q

TOT

Q10.6Q10.4Q

T1

Equation 33

but

I

t

•

B

I

Peak

------------------------------=

Q

1

BON

2

Substituting Equation 33 into Equation 32 you obtain:

=–=

1

20/30

Page 21

AN2349 PFC driving network

Equation 34

Q

TOT

I

-------------------------------- -

0.4

T1

• 0.42µC==

B

Peak

tIbon•

2

Now, the amount of charge on the collector of T2 is:

Equation 35

I

t

Q

T

2

CT

•=

I

2

BON

with

Equation 36

I

I

CT

2

–=

BpeakIBmin

Now the I

at the instant where the main voltage reaches its max value, v(t)=VM=310V.

Bmin

We consider

Equation 37

di

vt() L

---- -

•=

dt

Equation 38

V

--- -

t

P

cond

L

Resolving Equation 38 by t

cond

II

==

:

Equation 39

IPL•

cond

t

I

BON

Q

TOT

--------------

T1

4.5µs==

V

0.4Q

= Q

1

TOT

T1

t

t

but t

I

=+tST and in this instant =tst=2.25µs

BON

cond

From Equation 32, we already know , where , such to keep

I

=0.7A, in this case is calculated when the base current reaches its minimum value, so

C=IP

knowing the h

h

= 19, we have:

FE

of the device to obtain the saturation at this current value IC, that is

FE

Equation 40

I

C

Q

TOT

Q

Now from , we obtain:

TOT

0.4Q

=

T1

1

---------

t

• 0.15µC≅=

T1

cond

h

FE

Equation 41

But

Equation 42

So

Q

TOT

--------------=

Q

1

0.4

I

•

BONtI

Q

----------------------------- -=

1

BON

2

21/30

Page 22

PFC driving network AN2349

Equation 43

2Q

•

I

BONIBMIN

1

---------------- -==

t

I

BON

From Equation 36, we can obtain

Equation 44

I

CT

Then the amount of charge on the T

I

BpeakIBmin

2

collector is:

2

180mA=–=

Equation 45

Q

I

t

CT

• 0.4µC==

I

2

BON

during the on state of the device is:

2

T

2

So, the total amount of charge on the capacitor C

Equation 46

Q

C2ONQTOT

Q

0.42 0.4 0.82µC=+=+=

T

T1

2

Substituting Equation 46 into Equation 31 and resolving by R

Equation 47

R

1

4.1 Feed-Back block

In order to calculate the two resistors R13 and R14 value in Figure 11 it has been imposed

V

=200V, supposing that this feed-back block acts from this voltage value.

z3

Two instants must be considered:

1. The zener diode doesn't yet conduct for ωt=30°;

2. The zener diode already conducts for ωt=90°.

Therefore the two equations to be considered are:

Equation 48

V

DCoutVZ3

----------------------------------

V

----------------------------------

–

DCoutVZ3

R

14

VAVB+

T

---

-------------------- - 0.6V

2

–

R

14

+

2

ωt30°=()V

V

in

-------------------------------------------------- -

ωt90°=()V

V

in

-------------------------------------------------- -

R

13

1

------------------- -

C

0

ON

Q

C

2

–

Z3

R

13

–

Z3

I

Z3IBONT2

==+

, it can be calculated:

1

R2–=

0=+

where I

current value (I

Equation 48 has to be solved by R

can be calculated knowing the the peak hFE of the T2 device at a minimum

BON T2

=50mA ) (hFE =170).

C

and R14.

13

22/30

Page 23

AN2349 T Transformer and L1 inductor specifications

5 T Transformer and L1 inductor specifications

5.1 220V design

The transformer T has to be choosen as following:

1. The core type is N87-EFD25/13/9 by Epcos

2. The wire gauge used to wind the transformer is 0.28 mm

3. The number of primary winding is 150 turns, the air gap lenght has been chosen in

order to obtain a saturation current of about 1.6A and an inductance value of 2.2mH ±

2.5%

4. The number of secondary winding is 2 turns for each of the two secondaries

The Boost inductor L1 has to be choosen as following:

1. The core type is N27-E20/6 (EF20) by Epcos

2. The number of primary winding is 150 turns, the air gap length has been chosen in

order to obtain a saturation current of about 1.7A and an inductance value of 1.8mH ±

2.5%

3. The wire gauge to wind the transformer is 0.22 mm

5.2 120V design

The transformer T has to be choosen as following:

1. The core type is N87-EFD25/13/9 by Epcos

2. The wire gauge used to wind the transformer is 0.28 mm

3. The number of primary winding is 150 turns, the air gap lenght has been chosen in

order to obtain a saturation current of about 1.7A and an inductance value of 2.1mH ±

2.5%

4. The number of secondary winding is 3 turns in the PFC stage and 2 turns in the

converter stage

The Boost inductor L1 has to be choosen as following:

1. The core type is N27-E20/6 (EF20) by Epcos

2. The number of primary winding is 150 turns, the air gap lenght has been chosen in

order to obtain a saturation current of about 1.7A and an inductance value of 1.5mH ±

2.5%

3. The wire gauge to wind the transformer is 0.22 mm

23/30

Page 24

T Transformer and L1 inductor specifications AN2349

Figure 24. 40W demoboard electrical schematic

24/30

Page 25

AN2349 T Transformer and L1 inductor specifications

Figure 25. 40W demoboard PCB layout and mounting components

Table 1. 40W Demoboard 220V bill of materials

Item Qty Reference Part Description

1 5 D1…D5 1N4007 High Voltage Low frequency Diode

2 1 D6 1N5818 Power schotky diode

3 5 D17,D7, D9,D10,D11 BA159 High Voltage High Frquency diode

4 2 D8, D13 1N4148 Small signal diode

25/30

Page 26

T Transformer and L1 inductor specifications AN2349

Table 1. 40W Demoboard 220V bill of materials (continued)

Item Qty Reference Part Description

5 1 Dz2, 47V Glass zener diode

6 1 Dz1 5.6V Glass zener diode

7 1 L1 1.8mH

8 1 L2 100µH Axial inductor 0.25W

9 1 C1 220nF 400V Medium voltage ceramic capacitor

10 1 C2 470nF 100V Low voltage ceramic capacitor

Mounting type: Through hole.

Size: 14mm x 22mm. Height: < 18mm

11 1 C3 1µF 63V

Low voltage Radial Electrolytic

capacitor

12 1 C4 22uF 450V High Voltage Electrolytic capacitor

13 1 C5 47nF 63V Low voltage ceramic capacitor

14 2 C6, C7 220nF 100V Low voltage ceramic capacitor

15 1 C8 1.5nF 630V High Voltage ceramic capacitor

16 1 C9 1nF/16V Low voltage ceramic capacitor

17 1 C10 10µF/35V Radial Electrolytic capacitor

18 1 C11 47nF/400V Medium Voltage ceramic capacitor

19` 1 C12 6.8nF/1000V High Voltage ceramic capacitor

20 2 C13, C14,C15 100nF/400V Medium Voltage ceramic capacitor

22 1 R1 82Ω 0.25W 10% Axial Resistor

23 1 R2 4.7Ω 0.25W 10% Axial Resistor

24 1 R3 220Ω 0.25W 10% Axial Resistor

25 2 R5, R7 330KΩ 0.25W 10% Axial Resistor

26 1 R6 220Ω 0.25W 10% Axial Resistor

27 1 R8 1KΩ 0.25W 10% Axial Resistor

28 1 R9 22KΩ 0.25W 10% Axial Resistor

29 1 R10 680KΩ 0.25W 10% Axial Resistor

30 1 R11 56KΩ 0.25W 10% Axial Resistor

31 1 R12 39Ω 0.25W 10% Axial Resistor

32 2 R13, R14 180KΩ 0.25W 10% Axial Resistor

33 1 Rfuse 1Ω 0.25W 10% Axial Resistor

34 1 D16 200V Zener Diode

35 1 D15 100V Zener Diode

36 1 L3 1mH Axial inductor 1W

37 1 SCR X0203NA/X0202NA

38 1 PTC R(25°C)=600Ω Type C884 PTC thermistor, 600Ω

26/30

TO92, V

I

=1.25A

TRMS

DRM/VRMM

=800V;IGT=200 uA,

Page 27

AN2349 T Transformer and L1 inductor specifications

Table 1. 40W Demoboard 220V bill of materials (continued)

Item Qty Reference Part Description

39 1 T

Lp=2.3mH,

Ns=2(PFC),

Ns=2(Half Bridge)

Mounting type: Through hole.

Size: Approx. 25mm x 25mm

Height: 12 mm

40 1 D14 Short circuit

Table 2. 40W Demoboard 120V bill of materials

Item Qty Reference Part Description

1 5 D1…D5 1N4007 High Voltage Low frequency Diode

2 1 D6 1N5818 Power schotky diode

3 5 D7,D9,D10,D11,D14 BA159 High Voltage High Frquency diode

4 2 D8, D13 1N4148 Small signal diode

5 1 Dz2 47V Glass zener diode

6 1 Dz1 7.5V Glass zener diode

7 1 L1 1.5mH

Mounting type: Through hole.

Size: 14mm x 22mm. Height: < 18mm

81L2 120µH Axial inductor 0.25W

9 1 C1 680nF, 250V Medium voltage ceramic capacitor

10 1 C2 680nF 100V Low voltage ceramic capacitor

11 1 C3 1µuF 63V

Low Voltage Radial Electrolytic

capacitor

12 1 C4 22µuF 400V

High Voltage Radial Electrolytic

capacitor

13 1 C5 56nF 63V Low voltage ceramic capacitor

14 2 C6, C7 220nF 100V Low voltage ceramic capacitor

15 1 C8 2.2nF ,630V High Voltage ceramic capacitor

16 1 C9 1nF/16V Low voltage ceramic capacitor

17 1 C10 10uF/35V

Low Voltage Radial Electrolytic

capacitor

18 1 C11 47nF/400V Medium Voltage ceramic capacitor

19` 1 C12 6.8nF/1000V High Voltage ceramic capacitor

20 2 C13, C14 100nF/400V Mediun Voltage ceramic capacitor

21 1 C15 220nF/250V Medium Voltage ceramic capacitor

22 1 R1 22Ω 0.25W 10% Axial Resistor

23 1 R2 6.8Ω 0.25W 10% Axial Resistor

24 1 R3 100Ω 0.25W 10% Axial Resistor

25 1 R4 8.2Ω 0.25W 10% Axial Resistor

26 2 R5, R7 330KΩ 0.25W 10% Axial Resistor

27/30

Page 28

T Transformer and L1 inductor specifications AN2349

Table 2. 40W Demoboard 120V bill of materials (continued)

Item Qty Reference Part Description

27 1 R6 220Ω 0.25W 10% Axial Resistor

28 1 R8 1KΩ 0.25W 10% Axial Resistor

29 1 R9 22KΩ 0.25W 10% Axial Resistor

30 1 R10 680KΩ 0.25W 10% Axial Resistor

31 1 R11 56KΩ 0.25W 10% Axial Resistor

32 1 R12 39Ω 0.25W 10% Axial Resistor

33 1 R13 220KΩ 0.25W 10% Axial Resistor

34 1 R14 68KΩ 0.25 W 10% Axial Resistor

35 1 L ( in place of Rfuse ) 1mH Axial inductor 1W 10%

36 1 D16 130V Zener Diode

37 1 D15 180V Zener Diode

38 1 L3 1mH Axial inductor 1W

39 1 SCR X0203NA/X0202NA

TO92, V

I

=1.25A

TRMS

DRM/VRMM

=800V;IGT=200 uA,

40 1 PTC R(25°C)=600Ω Type C884 PTC thermistor, 600Ω

41 1 T

Lp=2.1mH,

Ns=3(PFC),

Ns=2(Half Bridge)

Mounting type: Through hole.

Size: Approx. 25mm x 25mm

Height: 12mm

42 1 D17 Short circuit

28/30

Page 29

AN2349 Revision history

6 Revision history

Table 3. Document revision history

Date Revision Changes

06-Jun-2006 1 Initial release

29/30

Page 30

AN2349

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZE REPRESENTATIVE OF ST, ST PRODUCTS ARE NOT DESIGNED,

AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING APPLICATIONS,

NOR IN PRODUCTS OR SYSTEMS, WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY, DEATH, OR

SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2006 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

30/30

Loading...

Loading...