Page 1

AN2323

Application note

Calibration procedure for STEVAL-IPE007V1

single-phase energy meter based on ST7FLite2x

Introduction

This application note describes the calibration procedure for STEVAL-IPE007V1, a singlephase power / energy meter with tamper detection.

Calibration is performed to minimize measurement errors and to increase the accuracy of

the meter.

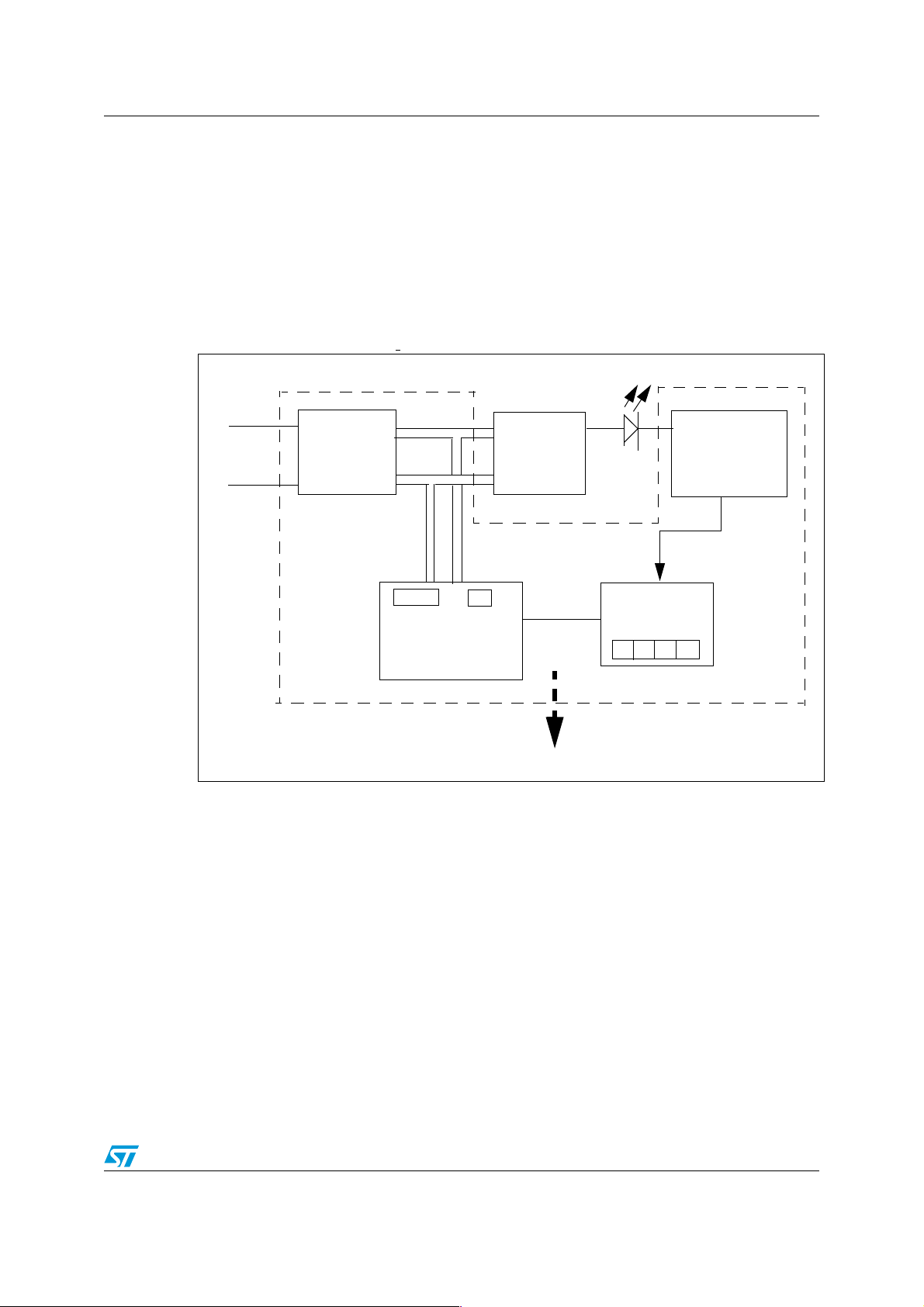

Figure 1. STEVAL-IPE007V1 energy meter

July 2006 Rev 2 1/14

www.st.com

Page 2

Contents AN2323

Contents

1 Calibration procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.1 Hardware set-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.2 Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.2.1 Using firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.2.2 Using the energy meter-GUI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2/14

Page 3

AN2323 Calibration procedure

1 Calibration procedure

The procedure for meter calibration is explained below by firstly giving an overview of the

hardware set-up, and then by describing how to connect a calibration board and energy

meter GUI to update the firmware of the board.

1.1 Hardware set-up

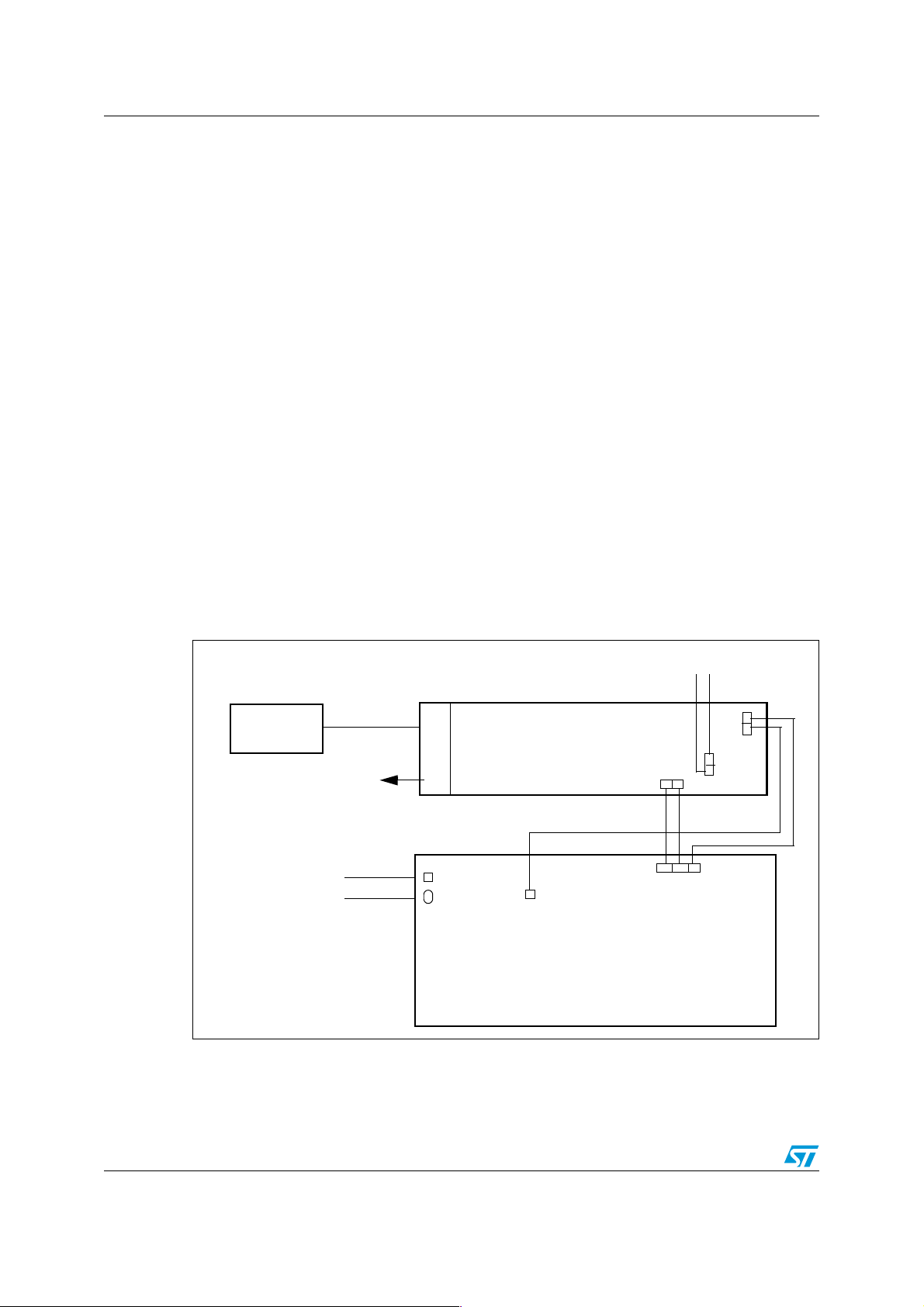

Figure 2. Wiring Diagram

voltage

220 V

Input

AC Source &

phantom load

current

Energy

Meter

Sensor

Reference

Meter

Phantom Load Equipment

● AC Source and Phantom Load: As shown in Figure 2, this provides the AC source

and serves as a virtual load providing the current and voltage ratings as per the circuit

requirements.

● Energy Meter: The required voltage and current of the energy meter input is provided

by the phantom load. The basic current of this meter is 10 A with a maximum current

rating is 50 A. Operating voltage is 140 to 280 V.

As can be seen in the block diagram, there is an LED called the pulse count LED drawn

at the output of the meter. It glows at the rate of 3200 imp/kWh.

● Sensor: The sensor detects the current pulses of the pulse count LED and thereby

shows the error on the error calculator screen. As can be seen from the block diagram,

the sensor is connected to the error calculator.

● Reference Meter: This acts as a reference to the various measurements made with

the energy meter. The meter constant and the pulse count can be set with the help of

the reference meter. The meter constant is initially set to 3200 imp/kWh and the pulse

count is set according to the current at which the error is to be measured. For example,

Error

Calculator

3/14

Page 4

Calibration procedure AN2323

if the pulse count is set to 15, this means that after 15 current pulses, the error

calculator shows the deviation of the energy meter from the reference meter.

● Error Calculator: As the name suggests, this calculates the error and shows the value

on its screen. The Error is the deviation of the energy meter from the reference meter.

1.2 Calibration

There are two methods of meter calibration

● Using Firmware: This uses firmware and a calibration board linked to a PC, and

through the use of an Energy Meter GUI, calibrates the Energy Meter board. Before

doing this, the micro should have code inside. Refer to Section 1.2.1 on page 4.

● Using Energy Meter GUI: This method uses only a calibration board linked to a PC

and through the use of an Energy Meter GUI, calibrates the Energy Meter board.

Before doing this, the micro should have code inside. Refer to Section 1.2.2 on page 7.

1.2.1 Using firmware

Here, the firmware is used for calibration of the energy meter. The various steps to follow are

as follows:

1. First of all, the energy meter calibration board is connected with the PC Energy Meter

GUI using a serial cable. Then, the energy meter calibration board must be connected

to the meter. The connection diagram of the calibration board with the energy meter

and the PC is shown in Figure 3 below:

Figure 3. Connection diagram of calibration board with energy meter and PC

5V DC

Power Supply

PC

Serial

Cable

Serial

Calibration

Board

TDO RDI

GND1

GND2

V2

V1

Port

220V

TDO RDI GND

AC

Supply

V1

Energy Meter

2. A 5V DC supply should be connected to the GND2 and V2 pins of the calibration board.

For the calibration mode, a switch is provided on the energy meter which must be

4/14

Page 5

AN2323 Calibration procedure

pressed within 30 seconds of the supply of power to the unit. The energy meter then

switches into calibration mode.

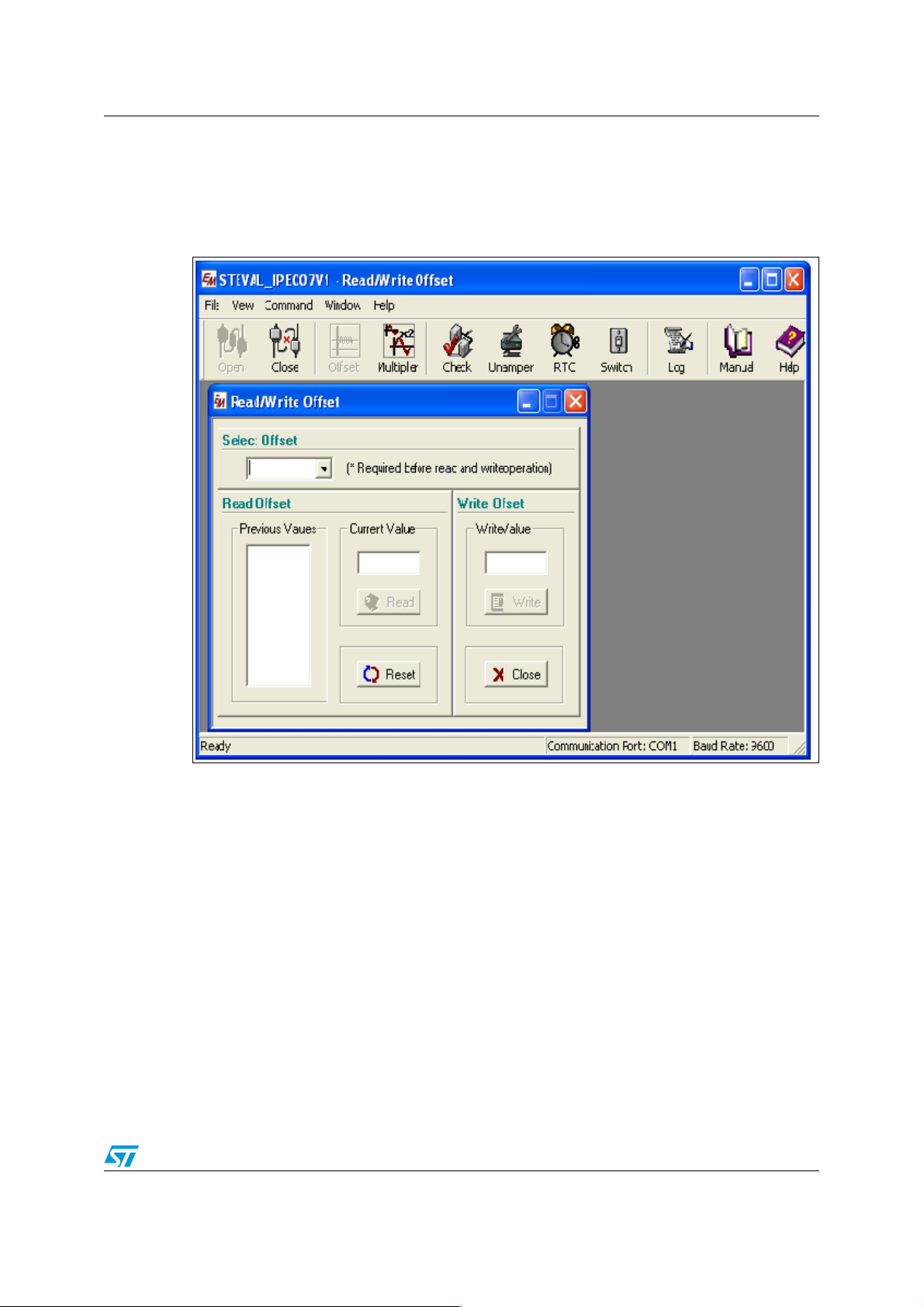

3. Then, on the PC, it is necessary to open the Energy Meter GUI V1.x.x. This shown in

Figure 4 below:

Figure 4. Energy meter GUI

To operate the Energy Meter GUI:

4. First press Open, a window appears in which the baud rate should be selected as 9600

and COM port as COM1. Then, press the calibration switch on the energy meter and

click on the Check icon (upper middle), shown in Figure 4. With successful

communication, the message ‘Device is connected’ appears and voltage/current

offsets can be read. Otherwise, check the connections between the energy

meter/calibration board/PC and repeat the earlier steps.

5. The voltage/current offsets can now be read:

a) First, read the voltage offset. To do this, click on Offset icon (right side of close

icon). On the window that appears, click on the Select icon. Four gain multipliers

and a 220V reading are displayed. To read the voltage offset, click on 220V.

Press the calibration switch of the energy meter again and click on the Read icon

(bottom left) of the GUI. Offset values appear in the “Previous Values” column

5/14

Page 6

Calibration procedure AN2323

(bottom left) as shown in Figure 4. Select a value that appears most frequently.

This value is to be taken as the voltage offset.

b) Now read the current offsets at 0.5A, 2A, 8A, 32A in the same manner as

described above. Here, select the gain multipliers for reading the offsets as shown

in Ta bl e 1 below:

Table 1. Gain multipliers used when reading current offsets

Current Ratings Gain Multipliers

0.5A X128

2A X32

8A X8

32A X2

6. After taking offsets, enter these values into the init_EEPROM[ ] array which is used in

the firmware.

For example, if the offset obtained for 0.5A is 02FF, then the user has to enter this in the

following manner:

0x02,0xFF and the location where the user has to write the offset is shown in Tab le 2

below:

Table 2. Byte locations used when entering the offset values

Current Ratings Byte location in init_EEPROM[ ] array

0.5A 12th and 13th byte

2A 10th and 11th byte

8A 8th and 9th byte

32A 6th and 7th byte

220V 14th and 15th byte

The first byte of this array must also be changed to make the calibrated offset values

effective.

7. Now compile the code and update the firmware in the microcontroller.

8. After doing this, the error must be checked at 32A, 8A, 2A and 0.5A.

This is done by connecting the energy meter to the AC mains and the reference meter.

The goal is to minimize the error for each current rating.

The procedure for doing this is given below:

– Each current value mentioned above has a pre-stored calibration constant in the

init_EEPROM[ ] array. Their locations are shown inTa bl e 3 below:

Table 3. Pre-stored calibration constant byte locations

Current Ratings Byte location in init_EEPROM[ ] array

0.5A 28th-31st

2A 24th-27th

8A 20th-23rd

32A 16th-19th

– The pre-stored bytes have to be grouped together for the corresponding current

6/14

Page 7

AN2323 Calibration procedure

rating.

For example, for 0.5 A, we have the following four bytes in init_EEPROM[ ] array.

0x23, 0x45, 0xFD, 0xAE

These are written as follows: 0x2345FDAE.

– Similarly, the bytes for the other three current values should be grouped. These

pre-stored calibration constants should be modified according to the errors

obtained for each current value. The procedure for doing this is explained with the

help of an example.

Suppose the error is +x% for the calibration constant of 2345FDAE, for example,

0.5A.

– First, 2345FDAE should be changed to a decimal value.

The decimal value for this is 591789486.

– Now, add the error to it as shown: 591789486 + (591789486 * x%)

That is, 591789486 (1 + x%).

– After this, the final value obtained should be changed back to its hexadecimal

equivalent.

– Now, if the error is -x%, then we have to only change the sign as shown below:

591789486 (1 - x%).

– The value finally obtained should again be changed to hexadecimal format.

We have perform the above procedure for all the four values of current.

– After doing this, we have to write the corrected calibration constants at their

respective locations in the init_EEPROM[ ] array as shown above in Tab l e 2.

This completes the procedure for minimizing the errors for meter calibration.

9. Finally, the first byte value of init_EEPROM[ ] has to be changed in order to make the

modified information effective. Following a compile operation, the firmware in the

microcontroller can be updated.

This completes the calibration procedure.

1.2.2 Using the energy meter-GUI

The second method for meter calibration is using the energy meter GUI.

In addition to calibration, other tasks can performed with the PC-GUI such as untampering

the meter, setting the RTC and switching the meter in the calibration mode.

Functional description

The functional description of the PC-GUI is given below.

7/14

Page 8

Calibration procedure AN2323

Figure 5. Energy meter GUI

1. Open: This selects the connection properties. When clicked (upper left corner), a

window appears as shown below.

Figure 6. Connection properties window

As shown in the figure the COM port is selected as COM1 and baud rate is 9600.

2. Check: The check icon makes sure that the meter is connected with the calibration

board. If connected, the message 'Meter is connected' appears when the check icon is

clicked. Otherwise a warning message is displayed as shown in the figure below.

Figure 7. Window showing that the meter is not connected

Click OK, check the connection, and try again by clicking on the check icon.

Read/write offsets

Once the meter is connected, the offsets should be read and written to EEPROM.

● Click on the Offset icon (upper left on the task bar). A window as shown in figure below

appears.

8/14

Page 9

AN2323 Calibration procedure

Figure 8. Window for reading and writing of offsets

● Four current offsets are available, X128, X32, X8, X2, and one voltage offset for 220V.

Select the required offset from the Select Offset dropdown box as shown in Figure 8.

Corresponding to the selected offset for current, the load current on the phantom load

equipment should be adjusted. Voltage offset is independent of the current value.

Table 4. Current values corresponding to the offsets

Gain Multiplier Current value

X128 0.5A

X32 2A

X8 8A

X2 32A

● Click on the Read icon to read the value for a particular offset. After reading a set of

values, click on the Write icon. If the write operation was successful, the message

shown in Figure 9 is displayed.

Figure 9. Window showing that the offsets have been written successfully

9/14

Page 10

Calibration procedure AN2323

The above procedure should be repeated for each of the five offsets.

This completes the procedure for reading and writing the offsets.

Read/write multiplier factors

The next step of reading and writing the multiplier factors reduces the error percentage.

● Click on the multiplier icon (upper left on the task bar), a multiplier window appears as

shown in figure below.

Figure 10. The multiplier window

Each multiplier factor corresponds to a range of current. This is shown in the table below:

Table 5. Gain multipliers and the corresponding current range

Multiplier factor Current range

X128 0A -> 0.9A

X32 0.9A -> 3.6A

X8 3.6A -> 13.5A

X 2 13.5A -> 60A

● According to the selected multiplier factor, the corresponding current (in mA) and

voltage (V) should be entered in the provided spaces, in the upper-right corner of the

10/14

Page 11

AN2323 Calibration procedure

multiplier window, as shown in Figure 10. These values are those provided by the

phantom load equipment and are also shown in Tab l e 5 above.

One multiplier factor should be taken at a time. Read the offsets by clicking on the

Read icon. After taking a set of readings, click on the Write icon. After a successful

write operation, message appears as shown in Figure 11.

Figure 11. Window showing that the multiplier factors have been written

successfully

This procedure should be repeated for each of the four offsets.

3. Untamper: As the name suggests, this untampers the energy meter from its current

tampered state. A message saying 'Meter successfully untampered' appears on the

screen.

4. RTC (Real Time Clock): This is used for setting the current date and time. Click on the

RTC icon, and a window appears as shown in Figure 12 below:

Figure 12. Window to set current date and time

This window always shows the current date and time. Click OK and the meter is

calibrated with the correct date and time. A message saying 'RTC set successfully'

appears on the screen.

5. Switch: Once clicked, the meter shifts to the normal mode of operation from its current

calibration mode. A message saying 'Electricity meter is switched to normal working

mode' appears.

6. Log: Log file gives the details of the bytes sent and received. It is as shown in figure

below:

11/14

Page 12

Calibration procedure AN2323

Figure 13. Figure 10: Window showing log details

When the user closes the log file, an option comes for saving the file. The user can

save it to the desired location.

12/14

Page 13

AN2323 Revision history

2 Revision history

Table 6. Document revision history

Date Revision Changes

06-Apr-2006 1 Initial release.

Addition of Section 1.2.2: Using the energy meter-GUI on page 7

18-Jul-2006 2

Title of document modified to encompass non-firmware method of

calibration now described

13/14

Page 14

Revision history AN2323

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZED ST REPRESENTATIVE, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2006 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

14/14

Loading...

Loading...