Page 1

AN2321

Application note

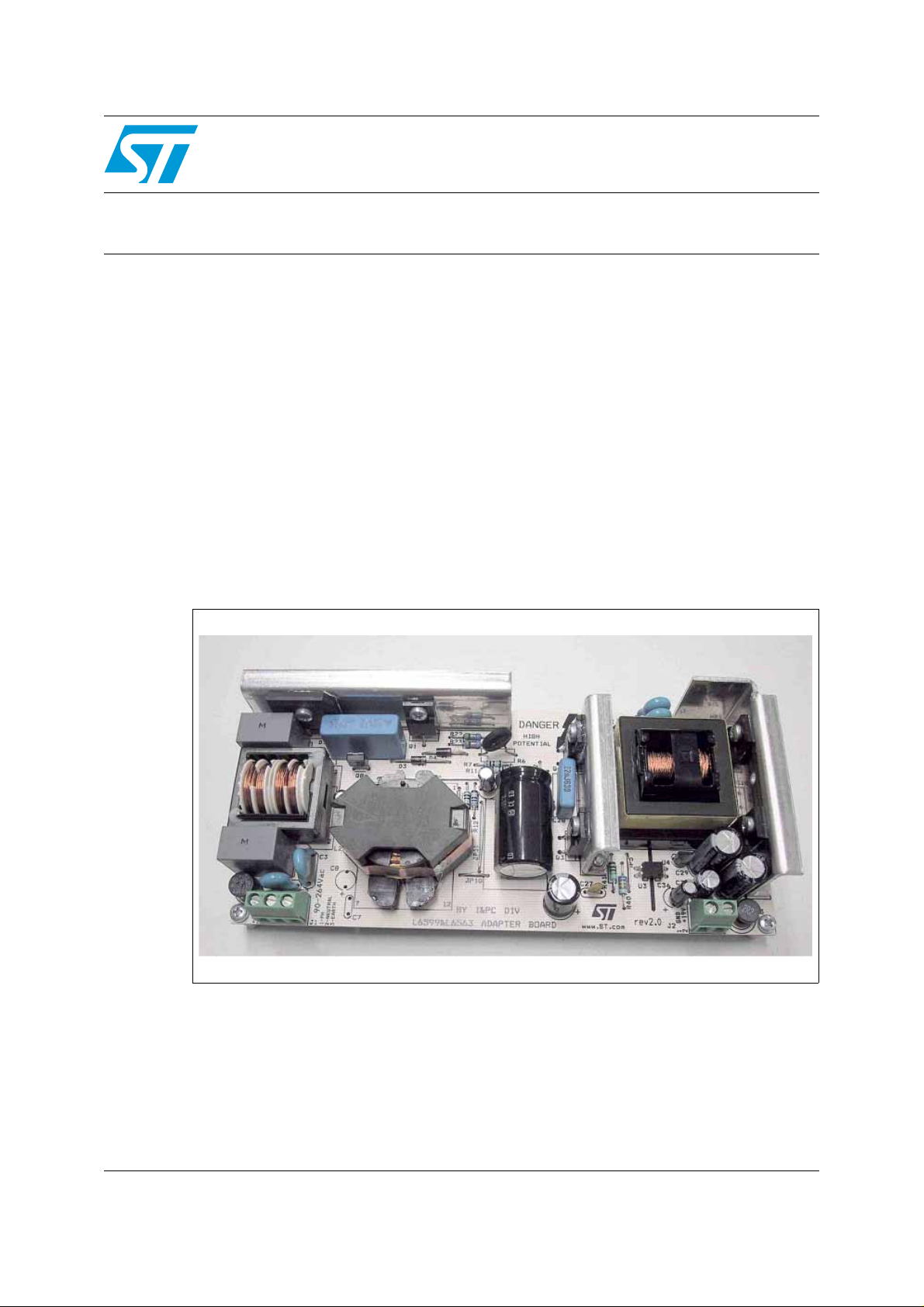

Reference design: high performance, L6599-based HB-LLC

adapter with PFC for laptop computers

Introduction

This note describes the performances of a 90 W, wide-range mains, power-factor-corrected

AC-DC adapter reference board. Its electrical specification is tailored on a typical hi-end

portable computer power adapter. The peculiarities of this design are the very low no-load

input consumption (<0.4 W) and the very high global efficiency.

The architecture is based on a two-st age approach: a front -end PFC pre-regulato r based on

the L6563 TM PFC controller and a downstream multi-resonant half-bridge converter that

makes use of the new L6599 resonant controller. The Standby function of the L6599,

pushing the DCDC converter upon recognition of a light load to work in burst mode and the

logic dedicated to stop the PFC stage allows meeting the severe no-load consumption

requirement.

The PFC TM operation and the top-level efficiency performance of the HB-LLC topology

provide also a very good overall efficiency of the circuit.

L6599 & L6563 90W - adapter demo-board (EVAL6599-90W)

May 2007 Rev 2 1/29

www.st.com

Page 2

Contents AN2321

Contents

1 Main characteristics and circuit description . . . . . . . . . . . . . . . . . . . . . 5

2 Test results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1 Efficiency measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.2 Resonant stage operating waveforms . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.3 Stand-by & no load power consumption . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.4 Short circuit protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.5 Over voltage protections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.6 Start-up sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3 Thermal tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4 Conducted emission pre-compliance test . . . . . . . . . . . . . . . . . . . . . . 17

5 Bill of material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

6 PFC coil specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

6.1 Electrical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

6.2 Mechanical aspect and pin numbering . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

7 Resonant power transformer specification . . . . . . . . . . . . . . . . . . . . . 25

7.1 Electrical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

7.2 Mechanical aspect and Pin numbering . . . . . . . . . . . . . . . . . . . . . . . . . . 26

8 PCB lay-out . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

9 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

2/29

Page 3

AN2321 List of tables

List of tables

Table 1. Efficiency measurements - Vin=115 Vac . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Table 2. Efficiency measurements - Vin=230 Vac . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Table 3. Stand-by consumption - Vin=115 Vac . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Table 4. Stand-by consumption - Vin=230 Vac . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Table 5. Temperature of measured points @115 Vac - full load . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Table 6. Temperature of measured points @230 Vac - full load . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Table 7. Bill of material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Table 8. Winding characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Table 9. Winding characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Table 10. Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

3/29

Page 4

List of figures AN2321

List of figures

Figure 1. Electrical diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Figure 2. Efficiency vs. Pout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Figure 3. Resonant circuit primary side waveforms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Figure 4. Resonant circuit secondary side waveforms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Figure 5. Input power without load vs. mains voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Figure 6. Waveforms at no-load operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Figure 7. Waveforms at no-load operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Figure 8. Load transition 0 ÷ 100% . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Figure 9. Load transition 100% ÷ 0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Figure 10. O/P short circuit waveforms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Figure 11. O/P short circuit waveforms (zoomed) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Figure 12. Start-up @115 Vac - full load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Figure 13. Start-up @115 Vac - full load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Figure 14. Thermal map @115 Vac - full load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 15. Thermal map @230 Vac - full load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 16. CE peak measure at 115 Vac and full load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 17. CE peak measure at 230 Vac and full load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

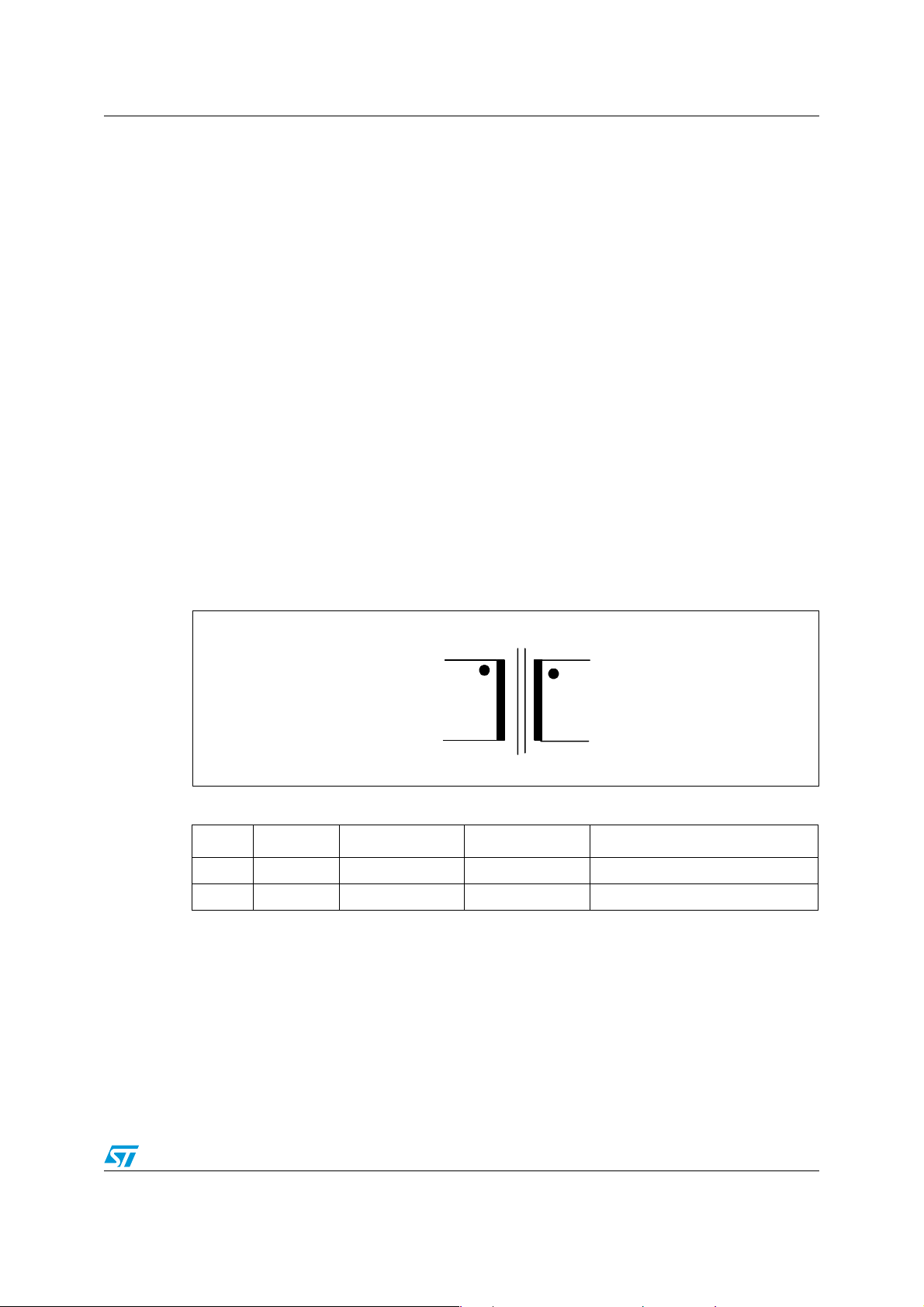

Figure 18. Electrical diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Figure 19. Bottom view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Figure 20. Electrical diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Figure 21. Pin lay-out, top view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Figure 22. Thru-hole component placing and top silk screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Figure 23. SMT component placing and bottom silk screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Figure 24. Copper tracks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4/29

Page 5

AN2321 Main characteristics and circuit description

1 Main characteristics and circuit description

The main characteristics of the SMPS are listed here below:

● Universal inpu t mains range: 90÷264 Vac - frequency 45 to 65 Hz

● Output v oltage: 19 V@4.7 A continuous operation

● Mains harmonics: Compliance with EN61000-3-2 specifications

● Standby mains consumption: Typ. 0.4 W @230 Vac; Max 0.5 W @265 Vac

● Overall efficiency: better than 90%

● EMI: Compliance with EN55022-class B specifications

● Safety: Compliance with EN60950 specifications

● Low profile design: 25 mm maximum height

● PCB single layer: 78x174 mm, mixed PTH/SMT technologies

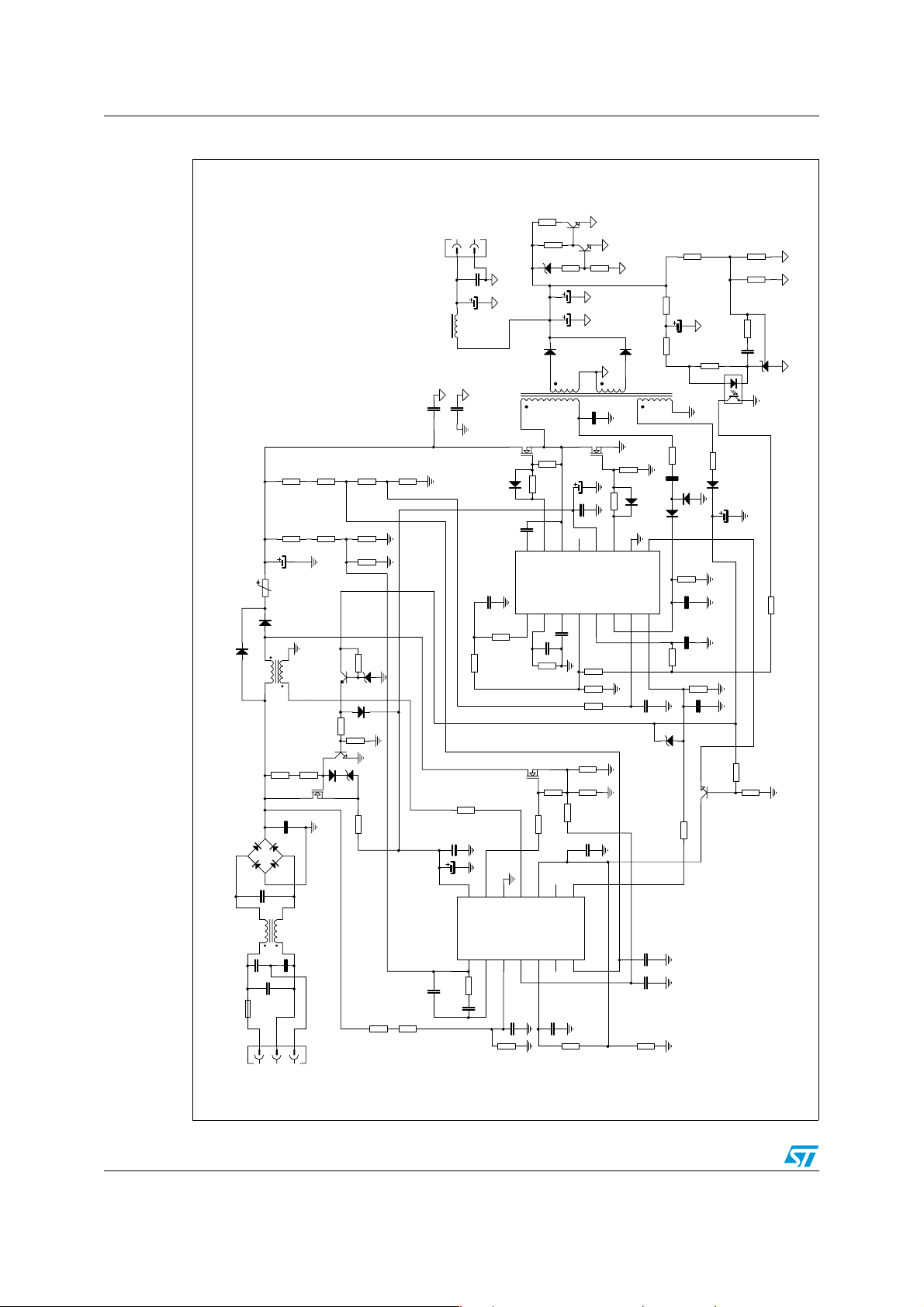

The circuit consists of two stages: a front - end PF C imp l eme nt ing the L65 63 and a r eson ant

DC/DC converter based on the new resonant controller, the L6599. The Power Factor

Corrected (PFC) stage delivers a stable 400 VDC and provides for the reduction of the

mains harmonic, allowing to meet European standard EN61000-3-2. The controller is the

L6563 (U1), working in transition mode and integrating all functions needed to control the

PFC and interface the downstream resonant converter. The power stage of the PFC is a

conventional boost converter, connected to the output of the rectifier bridge. It includes coil

L2, diode D4 and capacitor C9. The boost s witch is re presented by the po w er MOSFET Q1.

The L2 secondary winding (pins 8-10) is dedicated to provide to the L6563 the information

about the PFC coil core demagnetization, necessary to the controller for the TM operation.

The divider R1, R2 and R14 provides to the L6563 the information of the instantaneous

voltage that is used to modulate the boost current, and to derive some further information

like the average value of the AC line, used by the V

function keeps the ou tput voltage almost independent of the mains on e . The divide r R7, R8 ,

R9, R10 detects the output voltage . The second divider R11, R12, R13 and R28 protects the

circuit in case of voltage loop fail. The second stage is a resonant converter, half bridge

topology, working in ZVS. The controller is the new L6599, incorporating the necessary

functions to drive properly the Half-bridge by a 50 percent fixed duty cycle with dead-time,

working with variable frequency.

(voltage feed-forward) function. This

FF

The main features of the L6599 are a non-linear soft-start, a new current protection pin

(ISEN, pin 6) that programs the hiccup mode timing, a dedicat ed pin for sequencing or

brown-out (LINE) and a stand-by pin (STBY) for burst mode operation at light load. The

transformer uses the integrated magnetic approach, incorporating the resonant series

inductance. Thus, no any external additional coil is needed for the resonance. The

transformer configuration chosen for the secondary winding is centre tap, using two

Schottky rectifiers, type STPS10L60FP. The feedback loop is implemented by means of a

typical circuit using a TL431 modifying the current in t he optocoupler diode . The optocoupler

transistor modulates the current from pin 4, so the frequency will change accordingly, thus

achieving the output voltage regulation. Resistor R34 sets the maximum operating

frequency and the load at which the controller starts to work in Burst mod e. In case of a

short circuit, the current into the primary winding is detected by the lossless circuit R41,

C27, D11, D10, R39, and C25 and it is fed into the pin 6. In case of o v erload, th e v oltage on

pin #6 will overpass an internal threshold that will trigger a protection sequence via pin #2,

keeping the current flo wing in the circuit at a safe lev el. In case of output v oltage loo p f ailure,

the intervention of the zener diode connected to pin #8 (DIS) will activate the latched

protection of the L6599. The DIS pin can be also activated by the L6563 via the

PWM_LATCH pin in case of PFC loop failure.

5/29

Page 6

Main characteristics and circuit description AN2321

Figure 1. Electrical diagram

+19V

RTN

J2

1

2

C32

100N

C31

L3

2u2

100uF-35V YXF

C21

C20

2N2 - Y1

R11

3M0

R12

3M0

R13

5K1

R28

27K

R7

1M0

R8

1M0

R10

15K

R9

82K

C9

R6

NTC_1 0R S23 6

47uF-450V

D4

STTH2L06

D3

1N4005

2-35

L2

86A-5158C

810

R3

2M4

D1

GBU4J

C5

470N-400V

R69

4K7

D20

BZV55- B15

Q9

BC847C

D7

LL4148

R70

100K

R71

Q10

R4

2M4

Q8

6K8

BC847C

D16

D17

BZV55 -B1 2

LL4148

STQ1HNK60R

R20

10K

2N2 - Y1

C18

2u2-6.3V

R44

2K7

R101

R19

56K

C39

100N

R66

2K2

Q6

BC847C

Q5

BC847C

R65

+19V@4.7A

D18

U2

*

39R

47K

D15

BZV5 5-C18

R56

1K8

R62

4K7

470uF-35V YXF

C30

470uF-35V YXF

C29

STPS10L60FP

D12

13

14

2

Q3

STP9NK50Z

LL4148

C19

100N

16

VBOOT

L6599D

CSS

1

Q1

4

C26

R58

100K

10uF-50V

R25

56R

13

14

15

NC

OUT

HVG

CF

DELAY

3

2

4

C45

220NF

C17

470PF

R24

1M0

R31

R30

STP12 NM50 FP

R46

100K

R27

470R

R21

39R

D13

STPS10L60FP

11

12

5

C28

22N

R59

100K

Q4

STP9N K50Z

R38

56R

C40

100N

D19

11

10

12

VCC

LVG

GND

LINE

STBY5RFmin

ISEN

7

6

R34

3K3

15K

10R

R23

R22

C43

0R47

0R47

C16

2N2

R49

39K

R43

51R

C36

1uF-50V

R42

5K6

T1

86A-5166A

6

R41

100R

C27

220PF

D10

LL4148

LL4148

4N7

D11

LL4148

9

R39

130R

PFC_STOP

C25

DIS

8

100N

C44

3N9

R32

47R

D8

BZV55 -B2 4

R29

1K0

R47

1K0

12

43

R60

10K

C23

10N

Q2

BC847C

R51

120K

R50

6K2

R48

47K

C34

220N

U4

TL431AIZ

U3

SFH617A-2

R40

6R8

D9

LL4148

220uF-35V

C24

R35

0R0

R37

100K

R52

6K8

C15

C4

470N-X2

L1

86A-5163

C3

C2

2N2

F1

FUSE 4A

1

J1

INPUT CONN.

2N2

C1

470N-X2

2

3

R1

1M0R21M2

90-264Vr ms

10uF-50V

U1

L6563

C14

100N

6/29

14

VCC

INV

1

C13

1uF

11

13

12

GD

ZCD

RUN

GND

MULT

COMP

3

2

R18

56K

PWM_STOP

PWM_LATCH

C10

PFC_OK

VFF5CS

TBO

4

C11

R14

18K

7

6

C12

470N

10N

150K

R15

22N

C22

220PF

R26

240K

*: R101 MOUNTED BY REWORKING

8

10

9

Page 7

AN2321 Test results

2 Test results

2.1 Efficiency measurements

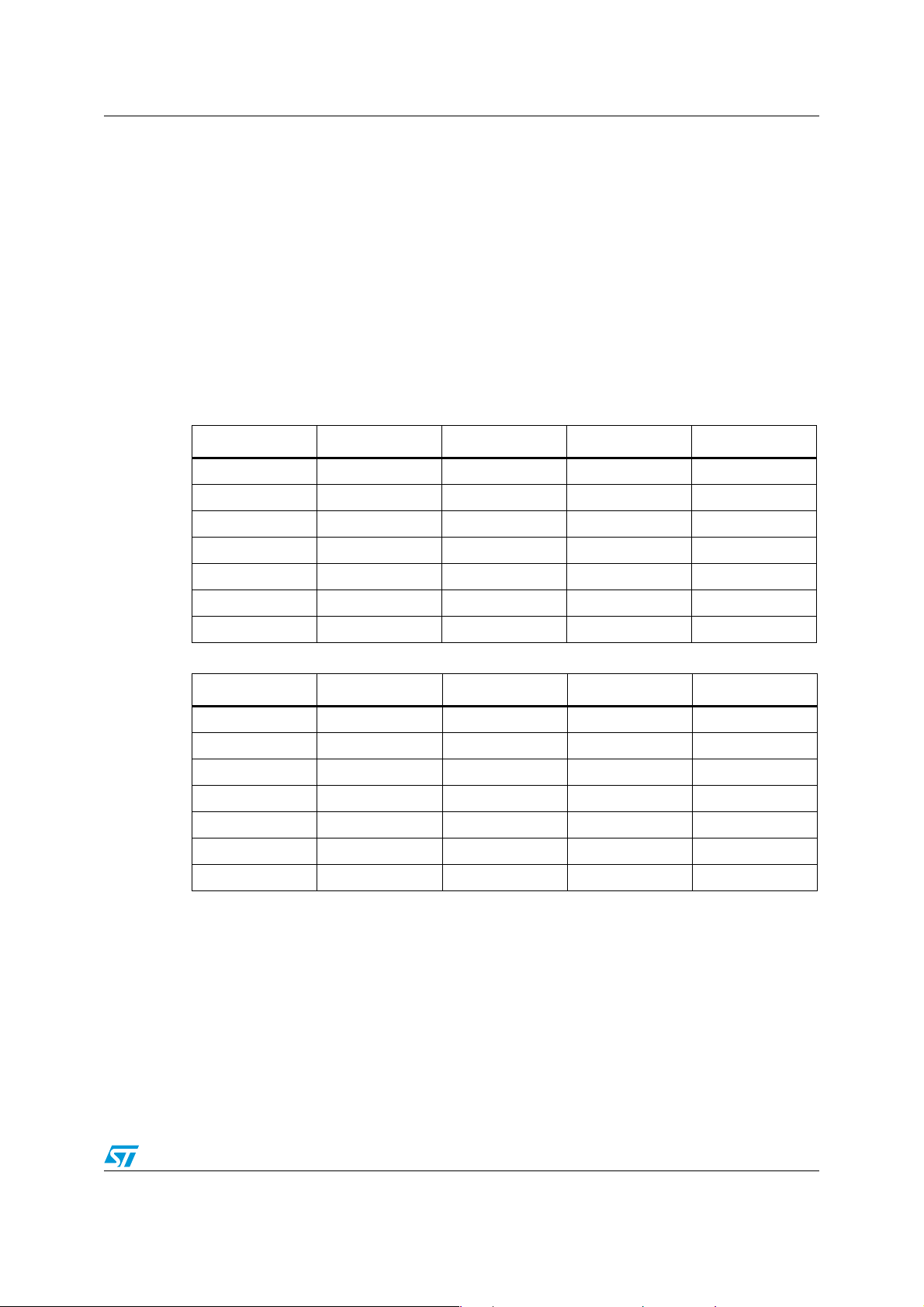

Table 1 and Table 2 show the output voltage measurements at nominal mains with different

load conditions. Efficiency is then calcu lated . For all measurements, both at full load and no

load operation, the input pow er has been mea sured b y a digita l po wer meter, Yokogawa WT-

210. Particular attention has to be paid when measuring input power at full load in order to

avoid measurem ent errors due to the voltage drop on cables and connections. Therefore

please connect the WT210 voltmeter termination to the board inpu t connector . F or the same

reason please measure the output voltage at the output connector or use th e r emot e d etect

option of your active load for a correct voltage measurement.

Table 1. Efficiency measurements -

Vout [V] Iout [A] Pout [W] Pin [W] Efficiency (%)

18.95 4.71 89.25 99.13 90.04

18.95 3.72 70.49 78.00 90.38

18.97 2.7 51.22 56.55 90.57

18.98 1.71 32.46 36.00 90.16

18.99 1.0 18.99 21.70 87.51

18.99 0.5 9.50 11.30 84.03

Vin=115 Vac

19.00 0.25 4.75 5.86 81.06

Table 2. Efficiency measurements - Vin=230 Vac

Vout [V] Iout [A] Pout [W] Pin [W] Efficiency (%)

18.95 4.71 89.25 97.23 91.80

18.96 3.72 70.53 76.74 91.91

18.97 2.7 51.22 55.85 91.71

18.98 1.71 32.46 35.57 91.24

18.99 1.0 18.99 21.30 89.15

19.00 0.5 9.50 10.87 87.40

19.00 0.25 4.75 5.77 82.32

In Table 1, Table 2 and Figure 2, the overall circuit efficiency is measured at different loads,

powering the board at the tw o nominal input mains v oltages. The measures hav e been do ne

after 30 minutes of warm-up at maximum load. The high efficiency of the PFC working in

transition mode and the very high efficiency of the resonant stage w orking in ZVS , provides

for an overall efficiency better than 90%. This is a significant high number for a two-stage

converter delivering an output current of 4.7 amps, especially at low input mains voltage

where the PFC conduction losses increase. Even at lower loads, the efficiency remains still

high.

7/29

Page 8

Test results AN2321

Figure 2. Efficiency vs. Pout

Effi ci en cy v s P out

Eff. @115Vac

Eff. @230Vac

O/P P o wer

Efficiency

94.00

92.00

90.00

88.00

86.00

84.00

82.00

80.00

78.00

76.00

74.00

89 71 51 32 19 10 5

The global efficiency at full load has been measured with good results even at the limits of

the input voltage range :

Vin = 90Vac - full load

Pin = 100.5 W

Efficiency = 88.9%

Vin = 264 Vac - Full load

Pin = 96.3 W

Efficiency = 92.6%

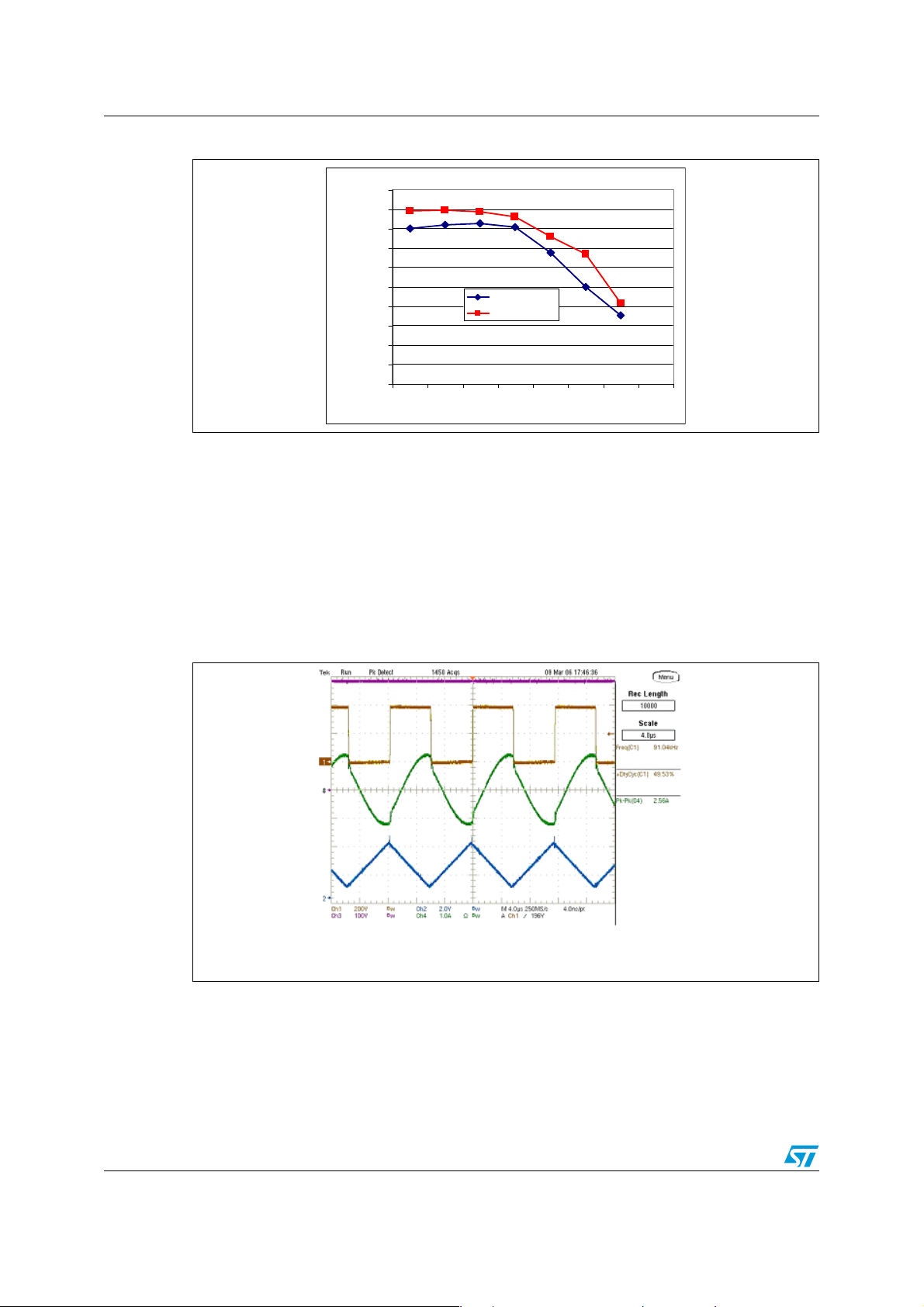

2.2 Resonant stage operating waveforms

Figure 3. Resonant circuit primary side waveforms

CH1: L6599 - V

CH2: L6599 - V

(HB voltage)

PIN14

(CF)

PIN3

CH3: +400 V PFC Output voltage

CH4: T1 primary winding current

In Figure 3 are reported some waveforms during steady state operation of the circuit at full

load. The CH2 waveform is the oscillator signal at pin #3 of the L6599, while the CH3

waveform is the PFC output voltage , po wering th e resonant stage . The CH1 tra ce is the ha lf

bridge waveform, driving the resonant circuit. In the picture it is not obvious, but the

switching frequency is normally slightly modulated following the PFC 100 Hz ripple that is

rejected by the resonant control circuitry. The switching frequency has been chosen around

90 kHz, in order to have a good trade off between transformer losses and its dimensions.

8/29

Page 9

AN2321 Test results

The transformer primary current wave shape is the CH4 trace. As shown, it is almost

sinusoidal, because the operating frequency is slightly above the resonance of the leakage

inductance and the resonant capacitor (C28).

In this condition, the circuit has a good margin for ZVS operations providing good efficiency

and the almost sinusoidal wave shape provides for an extremely low EMI generation.

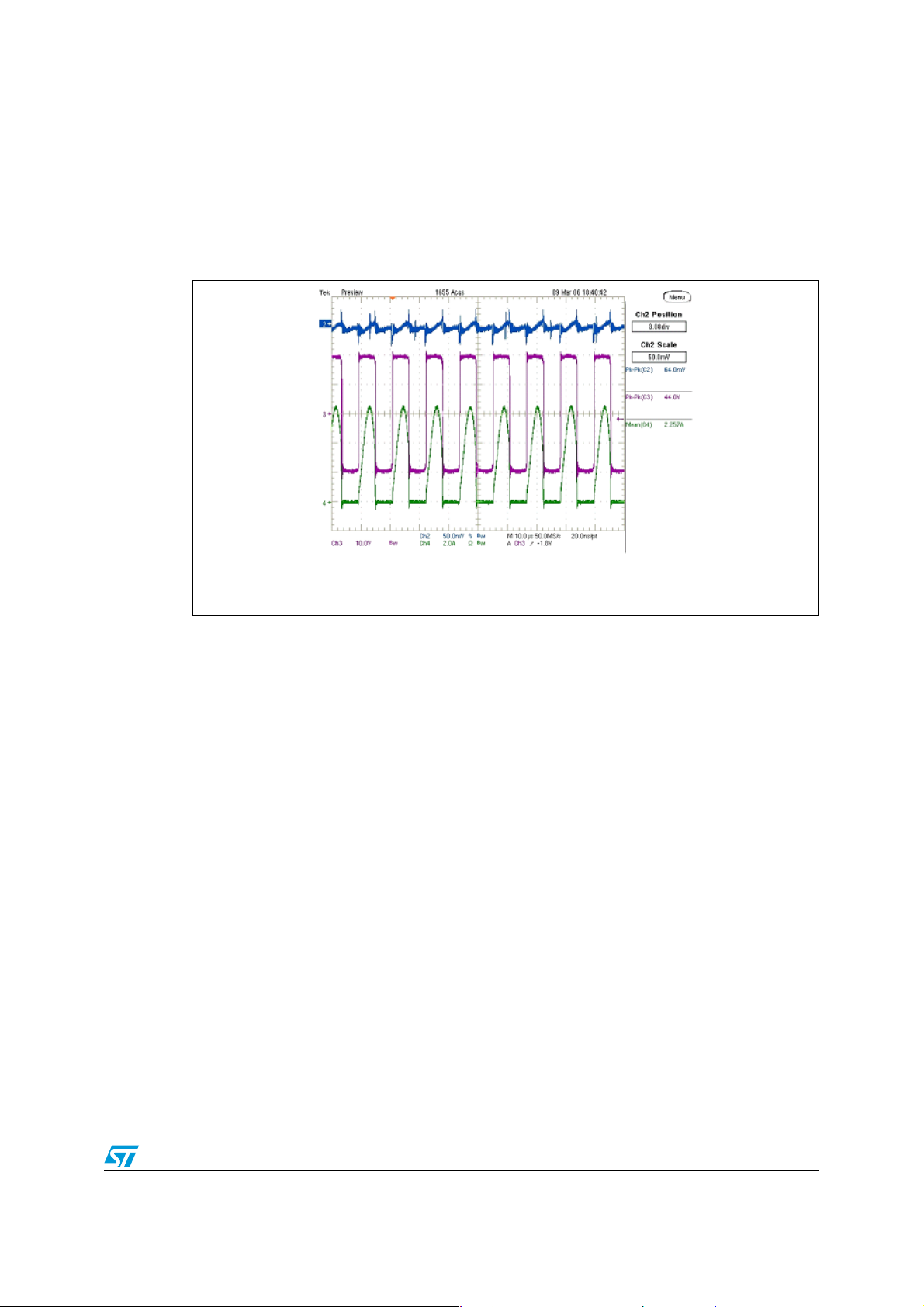

Figure 4. Resonant circuit secondary side waveforms

CH2: +19V Output voltage ripple and noise

CH3: D12 rectifiers anode voltage

CH4: D12 rectifiers current

In Figure 4 are represented some waveforms relevant to the secondary side: the rectifiers

reverse voltage is measured by CH3 and the peak to peak value is indicated on the right of

the picture. It is a bit higher than the theoretical value that would be 2(V

about 40 V. It is possible to observe a small ringing on the bottom side of the waveform,

responsible for this difference. The channel CH4 (green in the picture) shows the current in

the diode D12, equal to that one flowing in D13. Even this current shape is almost a sine

wave, its average value is half of the output current. The ripple and noise on the output

voltage is measured by CH2.

Thanks to the advantages of the resonant converter, the high frequency ripple and noise of

the output voltage is o nly 100mV (0.52%) including spik es, whi le the resi dual ripple at mains

frequency is 130 mV at maximum load and any line condition.

2.3 Stand-by & no load power consumption

The board is specifically designed for li ght load and zero load operation, like during

operation with load disconnected. The result s are reported in the diagram of Figure 5, he re

following. As high lighted in the diagram of Figure 4, the input power at no load is always

below 0.4 W for any input mains voltage. Thanks to the L6599 stand-by function, at light load

conditions both the resonant converter and the PFC work skipping switching cycles,

according to the load. In fact, the L6599 via the PFC_ST OP pin (#9) stops the operation of

the L6563 during the burst mode off-time.

OUT+VF

), hence

9/29

Page 10

Test results AN2321

Figure 5. Input power without load vs. mains voltage

Pin vs. Vac @ no- l oad

0.5

0.4

0.3

0.2

Input power

0.1

0

90Vac 115Vac 230Vac 265Vac

Pin= [W]

0.4 0.28 0.34 0.37

Mains voltage

The result is visible in Figure 6: the two converters are now working for a very short time, the

output voltage is perf ectly regula ted at its nominal v alue , with just a negligib le residual ripple

over imposed (~14 0mV). Thanks to the burst mode and the reduced number of switching

cycles the relevant losses are drastically reduced, therefore input power drawn from the

mains is very low . How e v er , if the ou tput v oltage has a sudden load change , both con v erters

are ready to react immediately, thus avoiding output v oltage drops. In Figure 7 the details of

the wav eforms captured in Figure 6 show some details during the switching period and

additionally, the L6563 RUN pin (#10) signal is captured. This pin is connected to the

PFC_STOP pin (#9) of the L6599 and enables the operation of the PFC during the burst

pulse of the resonant.

Figure 6. Waveforms at no-load operation Figure 7. Waveforms at no-load operation

CH1: L6599 - V

CH2: +19 V Output voltage

(HB voltage)

PIN14

CH3: +400 V PFC Output voltage

CH4: Q1-Drain voltage

Table 3 and Table 4 report the measurements of the input power during operation as a

function of the output power. Even with reduced load operation, the burst mode functio nality

allows to work with good circuit efficiency.

10/29

CH1: L6599 - V

CH2: L6563 - V

CH3: +400 V PCF Output voltage

(HB voltage)

PIN14

(RUN pin)

PIN10

CH4: Q1 - Drain voltage

Page 11

AN2321 Test results

Table 3. Stand-by consumption - Vin=115 Vac

Vout [V] Iout [mA] Pout [W] Pin [W]

19.01 80 1.5 3

19.01 53 1 2

19.01 27 0.5 1.08

19.01 13 0.25 0.66

Table 4. Stand-by consumption - Vin=230 Vac

Vout [V] Iout [mA] Pout [W] Pin [W]

19.01 80 1.5 2.4

19.01 53 1 1.68

19.01 27 0.5 1

19.01 13 0.25 0.67

Figure 8 shows the waveforms of the outpu t v oltage and current during a load v ariation from

0 to 100%. During operation at zero load, the circuit is w orking in burst mode as described

before then, as soon as the load incr eases it works in continuous switching operation. As

shown, due to the fact that the PFC is always operating, the circuit response is fast enough

to avoid outp ut vo ltage dips . In Figure 9, the opposite load transition is ch eck e d (100% to 0 ).

Even in this case the tr ansition in clean and doesn 't show any prob lem f or th e output v olt age

regulation.

Thus, it is clear that the proposed architecture is the most suitable for power su pply

operating with strong load variation without any problem related to the load regulation.

Figure 8. Load transition 0 ÷ 100% Figure 9. Load transition 100% ÷ 0

CH3: +19 V Output voltage

CH4: +19 V Output current

CH3: +19 V Output voltage

CH4: +19 V Output current

11/29

Page 12

Test results AN2321

2.4 Short circuit protection

The L6599 is equipped with a current sensing input (pin #6, ISEN) and a dedicated over

current management system. The current flowing in the circuit is detected and the signal is

fed into the ISEN pin. It is internally connected to the input of a first comparator, referenced

to 0.8 V, and to that of a second comparator referenced to 1.5 V. If the voltage externally

applied to the pin by either circuit in Figure 8 exceeds 0.8 V, the first comparator is tripped

causing an internal switch to be turne d on and dis c ha r ging th e sof t- s ta rt capacitor CSS.

Under output short circuit, this operation results in a nearly constant peak primary current.

With the L6599 the designer can progra m externally the maximum time (TSH) that the

converter is allowed to run overloaded or under short circuit conditions. Overloads or short

circuits lasting less than TSH will not cause any other action, hence providing the system

with immunity to short duration phenomena. If, instead, TSH is exceeded, an overload

protection (OLP) procedure is activated that shuts down the L6599 and, in case of

continuous overload/short circuit, results in continuous intermittent operation with a userdefined duty cycle. This function is realized with the pin DELAY (#2), by means of a

capacitor C45 and the parallel resistor R24 connected to ground. As the voltage on the

ISEN pin exceeds 0.8V t he first OCP comparator, in addition to discharging CSS, turns on

an internal current generator that via the DELA Y pin charges C45. As the voltage on C45 is

3.5 V, the L6599 sto p s switching and the PFC_STOP pin is pulled low. Also the internal

generator is turned off, so that C45 will now be slowly discharged by R24. The IC will restart

when the voltage on C45 will be less than 0.3 V. Additionally, if the voltage on the ISEN pin

reaches 1.5 V for any reason (e.g. transformer saturation), the second comparator will be

triggered, the L6599 will shutdown and the operation will be resumed after an on-off cycle.

Figure 10. O/P short circuit waveforms Figure 11. O/P short circuit waveforms

(zoomed)

CH1: L6599 - V

CH2: L6599 - V

CH3: L6599 - V

CH4: Output current

#14 (HB voltage)

PIN

#2 (DELAY)

PIN

#6 (ISEN)

PIN

The L6599 short circuit protection sequence described above is visib le in the Figure 10. The

on/off operation is controlled by the voltage on pin #2 (DELAY), providing for the hiccup

mode of the circuit.

Thanks to this control pin, the designer can select the hiccup mode timing and th us keep the

average output current at a safe lev el. Please note on the picture left side the very low mean

current flowing in the shorted output, less than 0.3 A. A better detail of the waveforms can

12/29

CH2: L6599 - V

CH3: L6599 - V

CH4: Output current

PIN

PIN

#2 (DELAY)

#6 (ISEN)

Page 13

AN2321 Test results

be appreciated in Figure 11 where it is possible to recognize the oper ation phases

described above.

2.5 Over voltage protections

Both circuit stages, PFC and resonant, are equipped with their own over voltage protection.

The PFC controller L6563 is internally equipped with a dynamic and a static over voltage

protection circuit detecting the error amp lifie r via th e voltage divider de d icat ed to th e

feedback loop to detect the PFC output voltage. In case the internal threshold is exceeded,

the IC limits the voltage to a programmable, safe value. Moreover , in the L6563 there is an

additional protection against loop failures using an additional divider (R11, R12, R13, R28)

connected to a dedicated pin (PFC_OK, #7) protecting the circuit in case of loop failures,

disconnection or deviation from the nominal value of the feedback loop divider. Hence the

PFC output voltage is always under control and in case a fault condition is detected the

PFC_OK circuitry will latch the L6563 operations and, by means of the PWM_LATCH pin

(#8) it will latch the L6599 as well via the pin #8 (DIS).

The pin DIS is also used to protect the resonant stage against over voltage or loop

disconnections. In fact, the zener diode D8 connected to pin DIS detects the voltage and in

case of open loop it will conduct and voltage on pin DIS will exceed the internal threshold.

Then the IC will be immediately shut down and its consumption reduced at a low value. This

state will be latched and will be necessary to let the voltage on the Vcc pin go below the

UVLO threshold to reset the latch and restart the IC operation.

2.6 Start-up sequence

Figure 12. Start-up @115 Vac - full load Figure 13. Start-up @115 Vac - full load

CH1: L6599 - V

CH2: Vcc voltage

CH3: +19 V Output voltage

CH4: +400 V PFC Output voltage

(HB voltage)

PIN14

Figure 12 shows the wavef orms during the start at 90 V a c and full load . It is possib le t o note

the sequence of the two sta ges: at po wer on the L6563 and L6599 Vcc v o ltages increase up

to the turn-on thresholds of the two ICs. The PFC starts and its output voltage increases

from the mains rectified voltage to its nominal value, with a small ov ershoot. In the meantime

the L6599 is kept inactive by the LINE pin (#7) until the PFC voltage reaches the threshold

CH1: L6599 - V

CH2: L6599 - V

CH3: +19 V Output voltage

CH4: Resonant capacitor C28 current

(HB voltage)

PIN14

(SS)

PIN2

13/29

Page 14

Test results AN2321

set by the divider R11, R12, R13, R28. As so on as it reaches th e L6599 LINE pin th reshold,

the resonant starts to operate. Hence the output voltage rises according to the soft-start and

reaches the nominal level. This sequence provides for the advantages of a perfect

sequencing of the circuit at start-up with the PFC acting as master and avoids complex

additional circuitry for the correct start-up of the circuit in all conditio ns. T he circuit has been

tested in all line and load conditions showing a correct start-up sequence. The used hi gh

voltage start-up circuit used avoids useless po wer dissipation during light load operation and

provides for an almost constant wake-up time of the circuit.

In Figure 13, the L6599 start-up sequence is analyzed: as soon as the LINE pin (#7)

enables the operation of the L65 99 co nverter's soft start-up sequence is triggered therefore

initially, the capacitor C18 is totally discharged, and the resistor R44 is effectively in parallel

to R24 thus the resulting initial frequency is determined by R

and R

SS

only, since the

Fmin

optocoupler's phototransistor is off ( as long as the output v oltage is not too f ar a wa y from the

regulated value). C18 is progressively charged until its voltage reaches the reference

voltage (2 V) and, consequently, the current through R44 goes to zero.

During this frequency sweep the operating frequency will decrease follo wing the exponential

charge of C18 that will count balance the non-linear frequency dependence of the tank

circuit. As a result, the average input current will smoothly increase , without the peaking that

occurs with linear frequency sweep, and the output voltage will reach the regulated value

with almost no overshoot as the waveforms in the picture.

14/29

Page 15

AN2321 Thermal tests

3 Thermal tests

In order to check the design reliability, a thermal mapping by means of an IR Camera was

done. Here below the thermal measures of the board, component side, at nominal input

voltage are shown. Some pointers visible on the pictures have been placed across key

components or components showing high temperature. The correlation between

measurement points and components is indicated below, for both diagrams.

Figure 14. Thermal map @115 Vac - full load

Table 5. Temperature of measured points @115 Va c - full load

Points - ref. Temp

A - D1 59.1 °C

B - Q1 54.0 °C

C - D4 67.6 °C

D - R6 85.8 °C

E - L2 45.7 °C

F - Q4 46.2 °C

G - Q3 46.5 °C

H - T1

CORE

I - T1

PR

J - T1

SEC

K - D12 62.8 °C

L - D13 62.8 °C

61.8 °C

67.2 °C

67.4 °C

T

AMB

=27°C

15/29

Page 16

Thermal tests AN2321

Figure 15. Thermal map @230 Vac - full load

T

=27°C

AMB

Table 6. Temperature of measured points @230Vac - full load

Points - ref. Temp

A - D1 45.9 °C

B - Q1 44.3 °C

C - D4 59.0 °C

D - R6 72.4 °C

E - L2 43.7 °C

F - Q4 46.8 °C

G - Q3 46.5 °C

H - T1

I - T1

J - T1

CORE

PR

SEC

63.7 °C

67.9 °C

69.5 °C

K - D12 64.8 °C

L - D13 64.9 °C

All other components of the board are working within the temperature limits, assuring a

reliable long term operation of the power supply.

16/29

Page 17

AN2321 Conducted emission pre-compliance test

4 Conducted emission pre-compliance test

The limits indicated on both diagrams at 115 Vac and 230 Vac comply with EN55022 ClassB specifications. The values are measured in peak detection mode.

Figure 16. CE peak measure at 115 Vac and full load

115Vac

FULL LOAD

Figure 17. CE peak measure at 230 Vac and full load

230 Vac

FULL LOAD

17/29

Page 18

Bill of material AN2321

5 Bill of material

Table 7. Bill of material

Res.

des.

C1 470N-X2 X2 FILM CAPACITOR - R46-I 3470--M1- RUBYCON

C1 470N-X2 X2 FILM CAPACITOR - R46-I 3470--M1- ARCOTRONICS

C10 22N 50 V CERCAP - GENERAL PURPOSE AVX

C11 10N 50 V CERCAP - GENERAL PURPOSE AVX

C12 470N 25 V CERCAP - GENERAL PURPOSE AVX

C13 1uF 25 V CERCAP - GENERAL PURPOSE AVX

C14 100N 50 V CERCAP - GENERAL PURPOSE AVX

C15 10uF-50V ALUMINIUM ELCAP - YXF SERIES - 105 °C RUBYCON

C16 2N2 50 V CERCAP - GENERAL PURPOSE AVX

C17 470PF 50 V - 5% - C0G - CERCAP AVX

C18 2 µF2-6.3 V 25 V CERCAP - GENERAL PURPOSE AVX

C19 100N 50 V CERCAP - GENERAL PURPOSE AVX

C2 2N2 Y1 SAFETY CAP. MURATA

C20 2 N2 - Y1 DE1E3KX222M - Y1 SAFETY CAP. MURATA

C21 2 N2 - Y1 DE1E3KX222M - Y1 SAFETY CAP. MURATA

C22 220PF 50 V CERCAP - GENERAL PURPOSE AVX

C23 10N 50 V CERCAP - GENERAL PURPOSE AVX

C24 220 µF-35 V ALUMINIUM ELCAP - YXF SERIES - 105 °C RUBYCON

Part type/

part value

Description Supplier

C25 100N 50 V CERCAP - GENERAL PURPOSE AVX

C26 10 µF-50 V A LUMINIUM ELCAP - YXF SERIES - 105 °C RUBYCON

C27 220PF 500 V CERCAP - 5MQ221KAAAA AVX

C28 22N 630 V - PHE450MA5220JR05 EVOX-RIFA

C29 470 µF-35 V YXF ALUMINIUM ELCAP - YXF SERIES - 105 °C RUBYCON

C3 2N2 Y1 SAFETY CAP. MURATA

C30 470 µF-35 V YXF ALUMINIUM ELCAP - YXF SERIES - 105 °C RUBYCON

C31 100 µF-35 V YXF ALUMINIUM ELCAP - YXF SERIES - 105 °C RUBYCON

C32 100N 50 V CERCAP - GENERAL PURPOSE AVX

C34 220N 50 V CERCAP - GENERAL PURPOSE AVX

C36 1 µF-50 V ALUMINIUM ELCAP - YXF SERIES - 105 °C RUBYCON

C39 100N 50 V CERCAP - GENERAL PURPOSE AVX

C4 470N-X2 X2 FILM CAPACITOR - R46-I 3470--M1- ARCOTRONICS

C40 100N 50 V CERCAP - GENERAL PURPOSE AVX

18/29

Page 19

AN2321 Bill of material

Table 7. Bill of material (continued)

Res.

des.

C43 4N7 50V CERCAP - GENERAL PURPOSE AVX

C44 3N9 50V CERCAP - GENERAL PURPOSE AVX

C45 220NF 25V CERCAP - GENERAL PURPOSE AVX

C5 470N-400 V PHE426KD6470JR06L2 - POLYPROP. FILM CAP EVOX-RIFA

C9 47 µF-450 V ALUMINIUM ELCAP - ED SERIES - 105°C PANASONIC

D1 GBU4J SINGLE PHASE BRIDGE RECTIFIER VISHAY

D10 LL4148 FAST SWITCHING DIODE VISHAY

D11 LL4148 FAST SWITCHING DIODE VISHAY

D12 STPS10L60FP POWER SCHOTTKY RECTIFIER STMicroelectronics

D13 STPS10L60FP POWER SCHOTTKY RECTIFIER STMicroelectronics

D15 BZV55-C18 ZENER DIODE VISHAY

D16 LL4148 FAST SWITCHING DIODE VISHAY

D17 BZV55-C12 ZENER DIODE VISHAY

D18 LL4148 FAST SWITCHING DIODE VISHAY

D19 LL4148 FAST SWITCHING DIODE VISHAY

D20 BZV55-B15 ZENER DIODE VISHAY

D3 1N4005 GENERAL PURPOSE RECTIFIER VISHAY

Part type/

part value

Description Supplier

D4 STTH2L06 ULTRAFAST HIGH VOLTAGE RECTIFIER STMicroelectronics

D7 LL4148 FAST SWITCHING DIODE VISHAY

D8 BZV55-B24 ZENER DIODE VISHAY

D9 LL4148 FAST SWITCHING DIODE VISHAY

F1 FUSE 4A FUSE T4A - TIME DELAY WICHMANN

HS1 HEAT SINK FOR D1&Q1 DWG

HS2 HEAT SINK FOR Q3&Q4 DWG

HS3 HEAT SINK FOR D12&D13 DWG

J1 MKDS 1,5/ 3-5,08 PCB TERM. BLOCK, SCREW CONN.- 3 W. PHOENIX CONTACT

J2 MKDS 1,5/ 2-5,08 PCB TERM. BLOCK, SCREW CONN.- 2 W. PHOENIX CONTACT

L1 86A-5163 INPUT EMI FILTER DELTA ELECTRONICS

L2 86A-5158C PFC INDUCTOR DELTA ELECTRONICS

L3 RFB0807-2R2 2u2 - RADIAL INDUCTOR COILCRAFT

Q1 STP12NM50FP N-CHANNEL POWER MOSFET STMicroelectronics

Q10 BC847C NPN SMALL SIGNAL BJT STMicroelectronics

Q2 BC847C NPN SMALL SIGNAL BJT STMicroelectronics

Q3 STP9NK50ZFP N-CHANNEL POWER MOSFET STMicroelectronics

19/29

Page 20

Bill of material AN2321

Table 7. Bill of material (continued)

Res.

des.

Q4 STP9NK50ZFP N-CHANNEL POWER MOSFET STMicroelectronics

Q5 BC847C NPN SMALL SIGNAL BJT STMicroelectronics

Q6 BC847C NPN SMALL SIGNAL BJT STMicroelectronics

Q8 STQ1HNK60R N-CHANNEL POWER MOSFET STMicroelectronics

Q9 BC847C NPN SMALL SIGNAL BJT STMicroelectronics

R1 1M0 SMD STANDARD FILM RES - 1/4 W - 5% - 250ppm/°C BC COMPONENTS

R10 15K SMD STANDARD FILM RES - 1/8 W - 1% - 100ppm/°C BC COMPONENTS

R11 3M0 MBB0207 AXIAL FILM RES - 0.4 W - 1% - 50ppm/°C BC COMPONENTS

R12 3M0 MBB0207 AXIAL FILM RES - 0.4 W - 1% - 50ppm/°C BC COMPONENTS

R13 8K2 SMD STANDARD FILM RES - 1/8 W - 1% - 100ppm/°C BC COMPONENTS

R14 18K SMD STANDARD FILM RES - 1/4 W - 5% - 250ppm/°C BC COMPONENTS

R15 150K SMD STANDARD FILM RES - 1/8 W - 5% - 250ppm/°C BC COMPONENTS

R18 56K SMD STANDARD FILM RES - 1/8 W - 5% - 250ppm/°C BC COMPONENTS

R19 56K SMD STANDARD FILM RES - 1/8 W - 5% - 250ppm/°C BC COMPONENTS

R2 1M2 SMD STANDARD FILM RES - 1/4 W - 5% - 250ppm/°C BC COMPONENTS

R20 10K SMD STANDARD FILM RES - 1/4 W - 5% - 250ppm/°C BC COMPONENTS

R21 39R SMD STANDARD FILM RES - 1/4 W - 5% - 250ppm/°C BC COMPONENTS

Part type/

part value

Description Supplier

R22 0R47

R23 0R47

R24 1M0 SMD STANDARD FILM RES - 1/4 W - 5% - 250ppm/°C BC COMPONENTS

R25 56R SMD STANDARD FILM RES - 1/8 W - 5% - 250ppm/°C BC COMPONENTS

R26 240K SMD STANDARD FILM RES - 1/8 W - 5% - 250ppm/°C BC COMPONENTS

R27 470R SMD STANDARD FILM RES - 1/4 W - 5% - 250ppm/°C BC COMPONENTS

R28 24K9 SMD STANDARD FILM RES - 1/8 W - 1% - 100ppm/°C BC COMPONENTS

R29 1K0 SMD STANDARD FILM RES - 1/4 W - 5% - 250ppm/°C BC COMPONENTS

R3 2M4 SMD STANDARD FILM RES - 1/4 W - 5% - 250ppm/°C BC COMPONENTS

R30 10R SMD STANDARD FILM RES - 1/8 W - 5% - 250ppm/°C BC COMPONENTS

R31 15K SMD STANDARD FILM RES - 1/8 W - 1% - 100ppm/°C BC COMPONENTS

R32 47R SMD STANDARD FILM RES - 1/4 W - 5% - 250ppm/°C BC COMPONENTS

R34 3K3 SMD STANDARD FILM RES - 1/4 W - 5% - 250ppm/°C BC COMPONENTS

R35 0R0 SMD STANDARD FILM RES - 1/8 W - 5% - 250ppm/°C BC COMPONENTS

R37 100K SMD STANDARD FILM RES - 1/4 W - 5% - 250ppm/°C BC COMPONENTS

R38 56R SMD STANDARD FILM RES - 1/8 W - 5% - 250ppm/°C BC COMPONENTS

SFR25 AXIAL STAND. FILM RES - 0.4 W - 5% 250ppm/°C

SFR25 AXIAL STAND. FILM RES - 0.4 W - 5% 250ppm/°C

BC COMPONENTS

BC COMPONENTS

20/29

Page 21

AN2321 Bill of material

Table 7. Bill of material (continued)

Res.

des.

R39 130R SMD STANDARD FILM RES - 1/4 W - 5% - 250ppm/°C BC COMPONENTS

R4 2M4 SMD STANDARD FILM RES - 1/4 W - 5% - 250ppm/°C BC COMPONENTS

R40 6R8

R41 100R

R42 5K6 SMD STANDARD FILM RES - 1/4 W - 5% - 250ppm/°C BC COMPONENTS

R43 51R SMD STANDARD FILM RES - 1/8 W - 5% - 250ppm/°C BC COMPONENTS

R44 2K7 SMD STANDARD FILM RES - 1/4 W - 5% - 250ppm/°C BC COMPONENTS

R46 100K SMD STANDARD FILM RES - 1/8 W - 5% - 250ppm/°C BC COMPONENTS

R47 1K0 SMD STANDARD FILM RES - 1/8 W - 5% - 250ppm/°C BC COMPONENTS

R48 47K SMD STANDARD FILM RES - 1/8 W - 5% - 250ppm/°C BC COMPONENTS

R49 39K SMD STANDARD FILM RES - 1/4 W - 5% - 250ppm/°C BC COMPONENTS

R50 6K2 SMD STANDARD FILM RES - 1/8 W - 1% - 100ppm/°C BC COMPONENTS

R51 120K SMD STANDARD FILM RES - 1/8 W - 1% - 100ppm/°C BC COMPONENTS

R52 6K8 SMD STANDARD FILM RES - 1/4 W - 5% - 250ppm/°C BC COMPONENTS

R53 0R0 0R0 JUMPER BC COMPONENTS

Part type/

part value

Description Supplier

SFR25 AXIAL STAND. FILM RES - 0.4 W - 5% 250ppm/°C

SFR25 AXIAL STAND. FILM RES - 0.4 W - 5% 250ppm/°C

BC COMPONENTS

BC COMPONENTS

R54 0R0 0R0 JUMPER BC COMPONENTS

R55 0R0 0R0 JUMPER BC COMPONENTS

R56 1K8 SMD STANDARD FILM RES - 1/8 W - 5% - 250ppm/°C BC COMPONENTS

R57 0R0 0R0 JUMPER BC COMPONENTS

R58 100K SMD STANDARD FILM RES - 1/8 W - 5% - 250ppm/°C BC COMPONENTS

R59 100K SMD STANDARD FILM RES - 1/8 W - 5% - 250ppm/°C BC COMPONENTS

R6 NTC_10R S236 NTC RESISTOR P/N B57236S0100M000 EPCOS

R60 10K SMD STANDARD FILM RES - 1/4 W - 5% - 250ppm/°C BC COMPONENTS

R62 4K7 SMD STANDARD FILM RES - 1/8 W - 5% - 250ppm/°C BC COMPONENTS

R65 47K SMD STANDARD FILM RES - 1/8 W - 5% - 250ppm/°C BC COMPONENTS

R66 2K2 SMD STANDARD FILM RES - 1/4 W - 5% - 250ppm/°C BC COMPONENTS

R69 4K7 SMD STANDARD FILM RES - 1/8 W - 5% - 250ppm/°C BC COMPONENTS

R7 1M0 MBB0207 AXIAL FILM RES - 0.4 W - 1% - 50ppm/°C BC COMPONENTS

R70 100K SMD STANDARD FILM RES - 1/8 W - 5% - 250ppm/°C BC COMPONENTS

R71 12K SMD STANDARD FILM RES - 1/4 W - 1% - 100ppm/°C BC COMPONENTS

R72 0R0 0R0 JUMPER BC COMPONENTS

R8 1M0 MBB0207 AXIAL FILM RES - 0.4 W - 1% - 50ppm/°C BC COMPONENTS

R9 82K SMD STANDARD FILM RES - 1/8 W - 1% - 100ppm/°C BC COMPONENTS

21/29

Page 22

Bill of material AN2321

Table 7. Bill of material (continued)

Res.

des.

R101

(1)

Part type/

part value

Description Supplier

39R SMD STANDARD FILM RES - 1/8 W - 5% - 250ppm/°C BC COMPONENTS

T1 86A-5166A RESONANT POWER TRANSFORMER DELTA ELECTRONICS

U1 L6563 TRANSITION-MODE PFC CONTROLLER STMicroelectronics

U2 L6599D HIGH VOLTAGE RESONANT CONTROLLER STMicroelectronics

U3 SFH617A-2 OPTOCOUPLER INFINEON

U4 TL431AIZ PROGRAMMABLE SHUNT VOLTAGE REFERENCE STMicroelectronics

1. R101 mounted by reworking on PCB

22/29

Page 23

AN2321 PFC coil specification

6 PFC coil specification

● Application type: consumer, IT

● Transformer type: open

● Coil former: vertical type, 6+6 pins

● Max. temp. rise: 45 °C

● Max. operating ambient temp.: 60 °C

● Mains insulation: N.A.

6.1 Electrical characteristics

● Converter topology: boost, transition mode

● Core type: RM14 - PC40 or equivalent

● Min. operating frequency: 20 kHz

● Primary inductance: 700 µH ±10% @1 kHz - 0.25 V (see Note 1)

● Peak primary current: 5 Apk

● RMS primary current: 1.8 A r ms

Note: 1 Measured between pins #2 & #5

Figure 18. Electrical diagram

Table 8. Winding characteristics

Pins Winding RMS current Number of turns Wire type

5 - 2 PRIMARY 1.8 A

8 - 11 AUX

1. Auxiliary winding is wound on top of primary winding

(1)

RMS

0.05 A

PRIM.

RMS

5

8

AUX

2

53 STRANDED 7 x φ 0.28 mm – G2

4 SPACED φ 0.28 mm – G2

11

23/29

Page 24

PFC coil specification AN2321

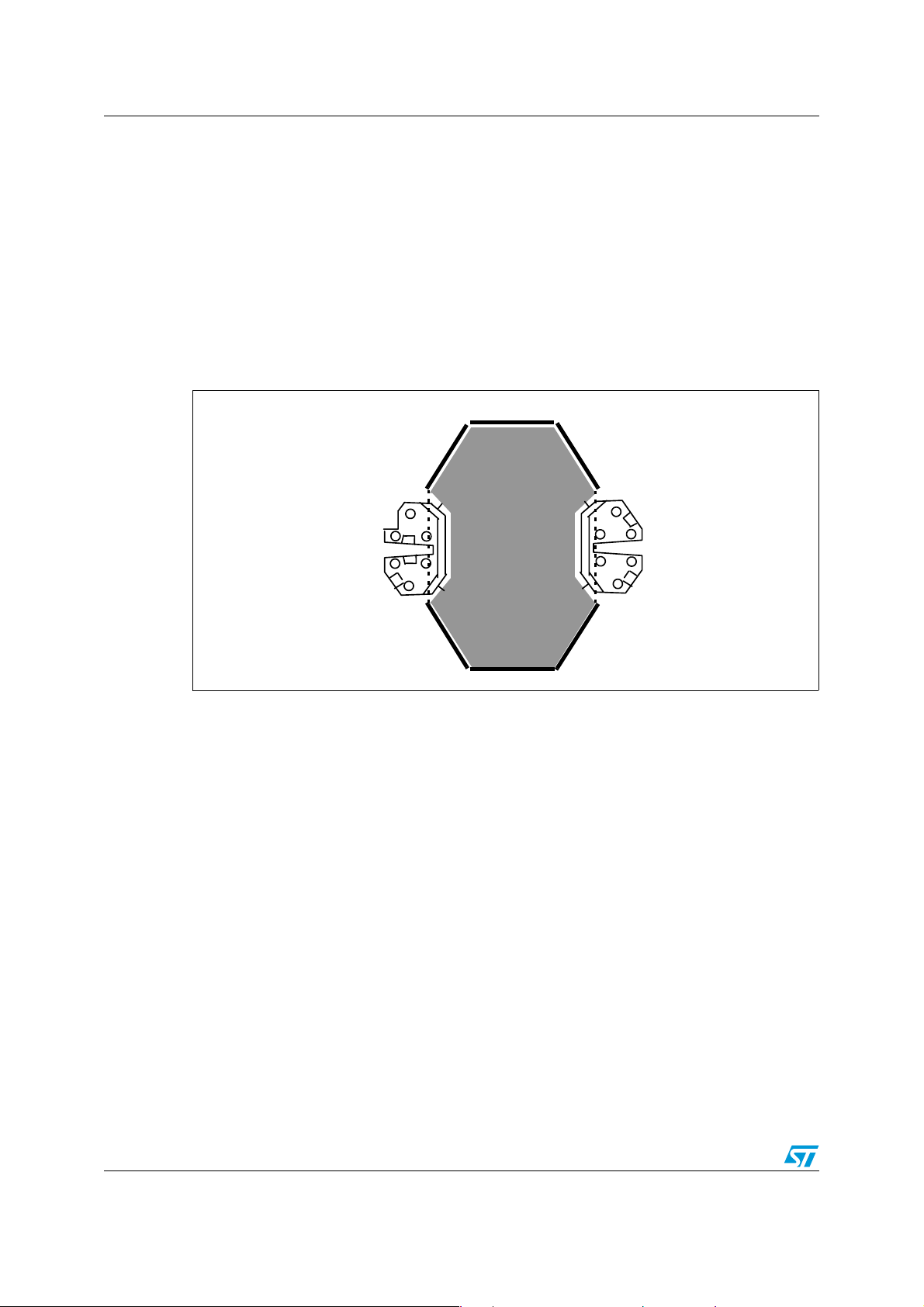

6.2 Mechanical aspect and pin numbering

● Maximum height from PCB: 22 mm

● Coil former type: vertical, 6+6 pins

● Pin distance: 5.08 mm

● Pins #1, 3, 4, 6, 7, 10, 12 are removed - Pin 9 is for polarity key.

● External copper shield: Bare, wound around the ferrite core and including the winding

and coil former. Height is 7 mm. Connected by a solid wire soldered to pin 11.

● Manufacturer: DELTA ELECTRONICS

● P/N: 86A - 5158C

Figure 19. Bottom view

2

x

x

x

x

5

8

x

9

x

x

10

11

24/29

Page 25

AN2321 Resonant power transformer specification

7 Resonant power transformer specification

● Application type: consumer, IT

● Transformer type: open

● Coil former: Horizontal type, 7+7 pins, 2 Slots

● Max. temp. rise: 45 °C

● Max. operating ambient temp.: 60 °C

● Mains insulation: Compliance with EN60950

7.1 Electrical characteristics

● Converter topology: half-bridge, resonant

● Core type: ER35 - PC40 or equivalent

● Min. operating frequency: 60 kHz

● Typical operating frequency: 100 kHz

● Primary inductance: 810 µH ±10% @1 kHz - 0.25 V (see Note 1)

● Leakage inductance: 200 µH ±10% @1 kHz - 0.25 V (see Note 1 and Note 2)

Note: 1 Measured between pins 1-4.

2 Measured between pins 1-4 with ONLY a secondary winding shorted.

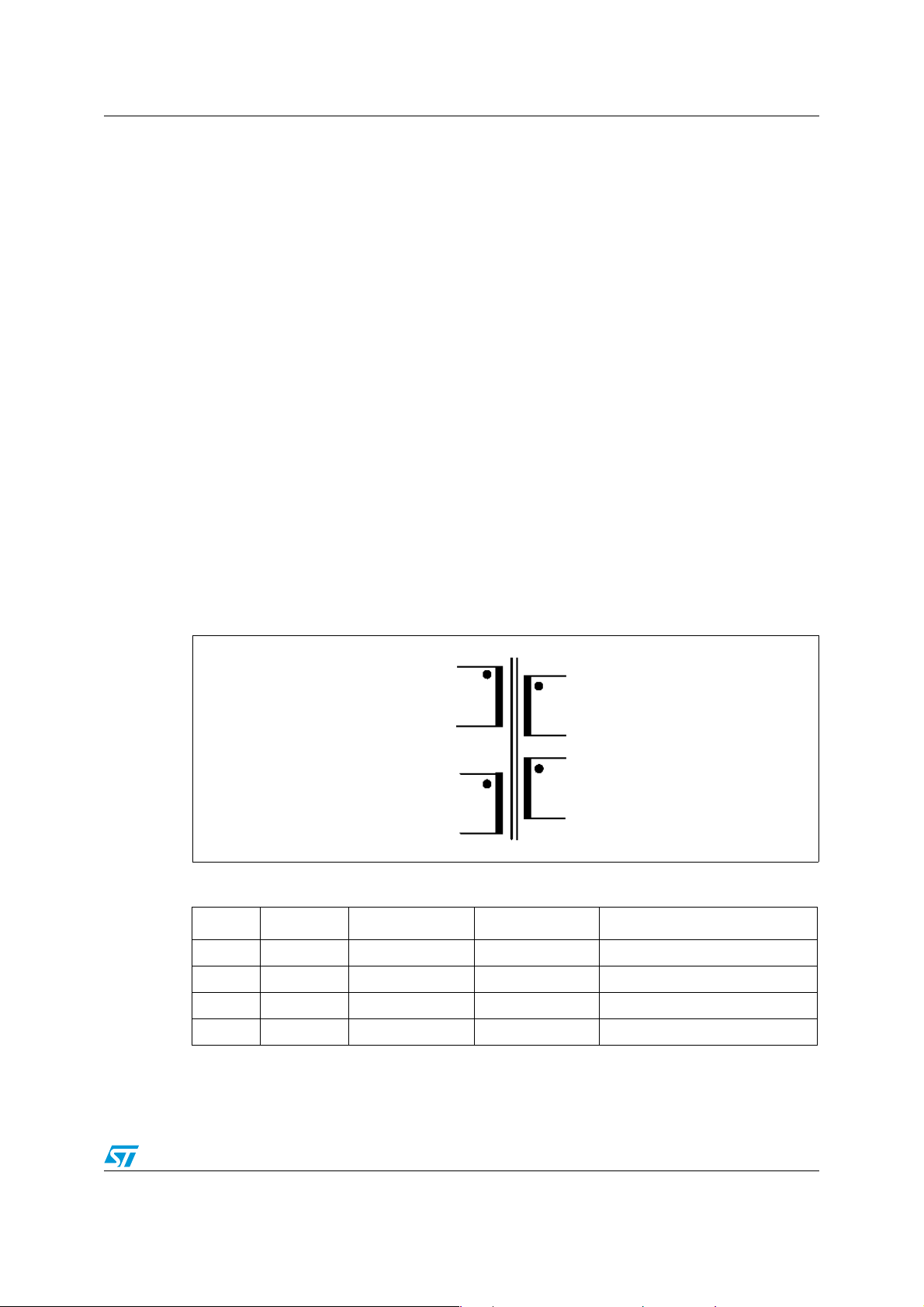

Figure 20. Electrical diagram

Table 9. Winding characteristics

Pins Winding RMS current Number of turns Wire type

2 - 4 PRIMARY 1 A

14 - 13 SEC. A

12 - 11 SEC. B

5-6 AUX

1. Secondary windings A and B must be wound in parallel

2. Auxiliary winding is wound on top of primary winding

(1)

(2)

(2)

4 A

4 A

0.05 A

RMS

RMS

RMS

RMS

PRIM.

AUX.

2

14

SEC. A

4

13

12

5

SEC. B

11

6

60 MULTISTRAND -0.12x12-G2

6 MULTISTRAND -0.20x20-G2

6 MULTISTRAND -0.20x20-G2

5 SPACED 0.22-G2

25/29

Page 26

Resonant power transformer specification AN2321

7.2 Mechanical aspect and Pin numbering

● Maximum height from PCB: 22 mm

● Coil former type: horizontal, 7+7 Pins (Pins 1 and 7 are removed)

● Pin distance: 5 mm

● Row distance: 30 mm

● Manufacturer: DELTA ELECTRONICS

● P/N: 86A-5166A

Figure 21. Pin lay-out, top view

1

7

14

8

26/29

Page 27

AN2321 PCB lay-out

8 PCB lay-out

Figure 22. Thru-hole component placing and top silk screen

Figure 23. SMT component placing and bottom silk screen

Figure 24. Copper tracks

27/29

Page 28

Revision history AN2321

9 Revision history

Table 10. Revision history

Date Re vision Changes

01-Aug-2006 1 Initial release.

15-May-2007 2

– Figure 1 changed

– Minor text changes

28/29

Page 29

AN2321

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely res ponsibl e fo r the c hoic e, se lecti on an d use o f the S T prod ucts and s ervi ces d escr ibed he rein , and ST as sumes no

liability whatsoever relati ng to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third pa rty p ro duc ts or se rv ices it sh all n ot be deem ed a lice ns e gr ant by ST fo r t he use of su ch thi r d party products

or services, or any intellectua l property c ontained the rein or consi dered as a warr anty coverin g the use in any manner whats oever of suc h

third party products or servi ces or any intellectual propert y contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICUL AR PURPOS E (AND THEIR EQUIVALE NTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZED ST REPRESENTATIVE, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJ URY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST fo r the ST pro duct or serv ice describe d herein and shall not cr eate or exten d in any manne r whatsoever , any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in vari ous countries.

Information in this document su persedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2007 STMicroelectronics - All rights reserved

STMicroelectronics group of compan ie s

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - Fran ce - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

29/29

Loading...

Loading...