Page 1

Application Note

STPM01 Programmable, Single-Phase

Energy Metering IC External Circuits

Introduction

The STPM01 is implemented in an advanced 0.35µm BCD6 technology. It is designed for

active, reactive, and apparent energy measurement, including Root Mean Square (V

and I

This application note describes the STPM01 external circuits which are comprised of:

● a cry sta l os c illator,

● a power supply circuit,

● a voltage sensing circuit, and

● two current sensing circuits.

Note: This document should be used in conjunction with the STPM01 datasheet.

), instantaneous, and harmonic voltage and current.

RMS

AN2317

RMS

April 2006 Rev 1 1/27

www.st.com

Page 2

Contents AN2317 - Application

Contents

1 External Circuit Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.1 Current Sensing Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.1.1 Primary Current Sensing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.1.2 Secondary current sensing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.2 Anti-aliasing Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.3 Voltage Sensing Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

1.4 Crosstalk Cancellation Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

1.5 Capacitive Power Supply Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

1.5.1 Varistor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

1.5.2 Capacitive Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

1.5.3 EMC Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

1.6 Clock Generation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2 Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

2/27

Page 3

AN2317 - Application List of Figures

List of Figures

Figure 1. STPM01 External Circuit Schematics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Figure 2. Primary Current Sensing Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Figure 3. Current Sense Transformer-to-Power Line Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Figure 4. Shunt Module-to-Power Line Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Figure 5. Anti-aliasing Filter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Figure 6. Anti-aliasing Effect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Figure 7. Anti-aliasing Filter Magnitude Response . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Figure 8. Anti-aliasing Filter Phase Response. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Figure 9. Voltage Sensing Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 10. Crosstalk Network. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 11. Capacitive power supply (with EMC Filter). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Figure 12. Capacitive Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 13. Internal RC Recommended Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Figure 14. Quartz Recommended Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Figure 15. External Clock Source Recommended Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3/27

Page 4

External Circuit Design AN2317 - Application

1 External Circuit Design

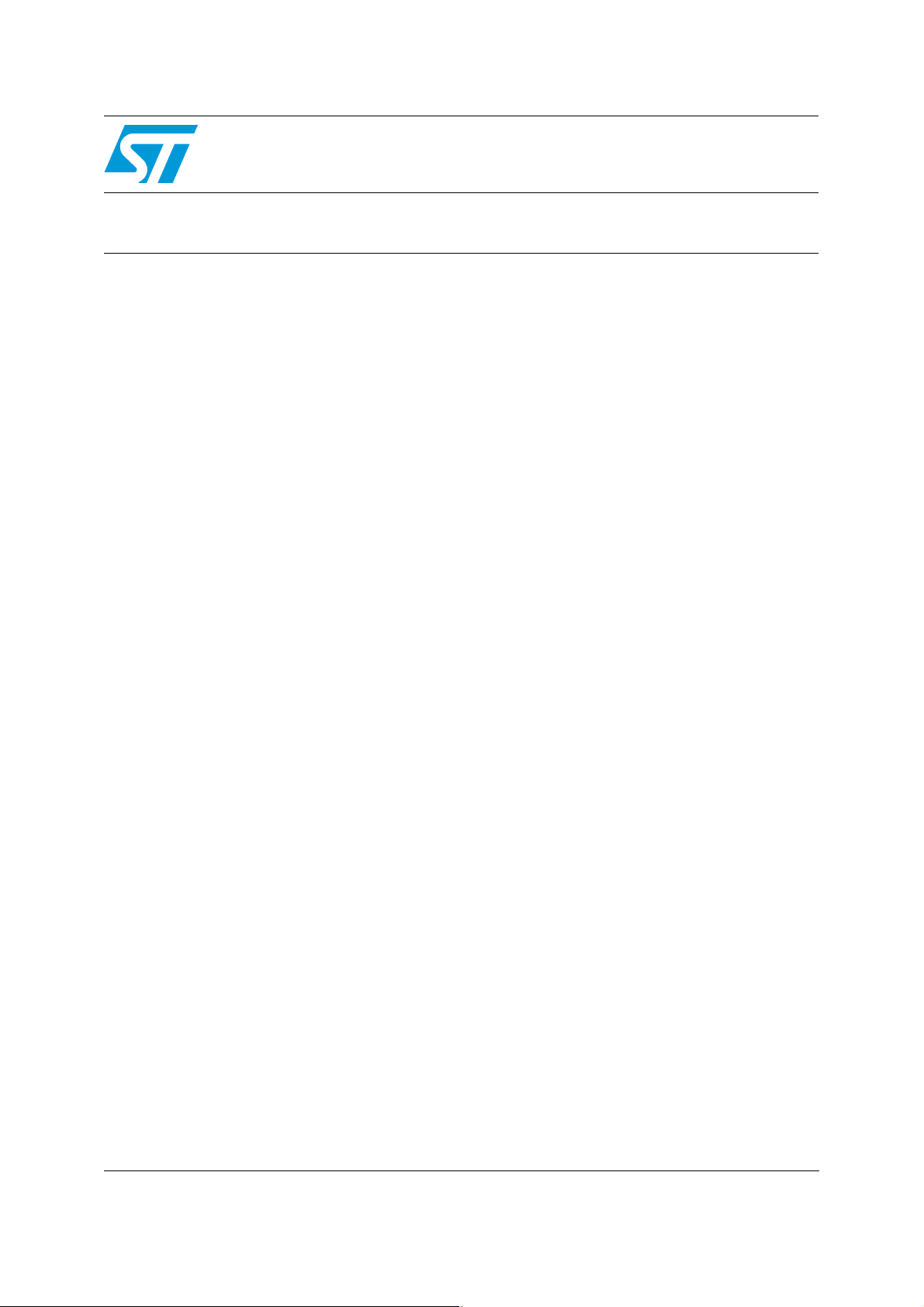

Figure 1 on page 5

shows an implementation example of the STPM01 in a simple Stepper

Counter Connector design. The main external circuits include:

● a

Current Sensing Circuit

● an

● a

● a

● a

Anti-aliasing Filter on page 11

Voltage Sensing Circuit on page 15

Capacitive Power Supply Circuit on page 18

Clock Generation on page 24

,

,

,

, and

(RC oscillator, quartz, or external clock).

4/27

Page 5

AN2317 - Application External Circuit Design

Figure 1. ST PM01 External Circuit Sc hema t ic s

D2

12121212

1

33.0R

R22

R21

2

22

Q3

3

BC8578

112

C3

C2

1.0N

1.0N

221

CURRENT SENSING

W3

VODNIK

W4

VODNIK

1

1K

2

11

Q4

BC8578

3

12

1

C16

2

R23

47K

21

C6

1MYC71MY

12

2

D1

1N4148

1

VDD

4121

TR1

12

E4622/X503

4121

TR2

12

E4622/X503

1

1

F

1

V4

510V

2

12

N

1

W6

1MY

VODNIK

1

W5

VODNIK

1

2

C5

C4

1.0N

1

R2

12

1.0k

R5

30.1R

R1

12 12

1.0k

ANTI-ALIASING FILTER

R3

12

1.0k

R6

30.1R

R4

12

1.0k

12

L6

220MYH

L3

220MYH

R24

21 21 2

82R

1

C14

1.0N

2

1

1N4148D31N4148D41N4148D51N4148

C17

2

D6

1MY

VDDA

C8

10N

10N

1

SRD 200mcd

2

1

R20

2.4K

2

20

1

2

4

5

6

8

7

9

10

1

C18

2

U1

STPM01E

LED

MON

MOP

VDD

VSS

VCC

VDDA

VOIP

IIP1

IIN1

10N

SDA

SCL

SCS

SYN

CLKOUT

CLKIN

VIN

IIN2

IIP2

1

C19

2

D7 SRD 200mcd

19

18

3

15

17

16

14

13

VIP

12

11

10N

2

1

12121

R19

2.4K

R13

2M

10N

12

2M

C11

1

2

C9

R14

4.7my

R8

261K

12

12

261K

R10

261K

R7

12

475R

R11

12

R9

150K

C20

12

220N

C1

470N

D11

21

1

DIF60

D10

DIF60

2

C15

+

VDD

121

D12

1000M

2

VDD

2

1

D8 SRD 200mcd

D9 SRD 200mcd

R18

R17

2.4K

C10

1

10N

R12

12

2.21k

W1

VODNIK

1

W2

5.6V

VODNIK

1

PI

G08 10-2V

1

3

5

VDDA

7

2

9

1

2.4K

2

12

2

1

4194.304kHz

C12

2

CRYSTAL OR RTC

OSCILLATOR

2

VOLTAGE SENSING

CAPACITIVE POWER SUPPLY

15P

2

4

6

8

10

R15

1M

Y1

1

1

C13

2

AI12296

SBG

SDA

SCL

SCS

SYN

15P

5/27

Page 6

External Circuit Design AN2317 - Application

1.1 Current Sensing Circuit

The STPM01 has two external current sensing circuits (see

1. Primar y channe l, and

2. Secondary channel.

1.1.1 Primary Current Sensing

The primary channel uses a current transformer to couple the mains current (see

The Burden resistor is used to produce a voltage between V

filter (LPF) is used to filter out the high frequency interference and has little influence on the

voltage drop between V

Figure 2. Pr imary Curr ent S ens i ng Ci rcui t

I1

IN1

I2

and V

.

IP1

Burden Resistor LPF

R2

12

1.0k

6.8R

R1

12

1.0k

R23

1R

1

R25

2

1

2

Figure 1 on page 5

IN1

and V

1

C9

2

. The Low-pass

IP1

VIN1

+

U0

10N

–

VIP1

AI12297

):

Figure 2

).

6/27

Page 7

AN2317 - Application External Circuit Design

Primary current sensing is calculated as follows:

Equation 1

N

1

------ -

I

2

⋅=

I

1

N

2

Equation 2

U

0UAI2

R23R25⋅

------- ----------- ----------- ---

⋅

+

R

23R25

N

------ --

N

1

2

I

⋅⋅==≈

1

R23R25⋅

------ ----------- ----------- ----

+

R

23R25

Assuming I

, the calculation will proceed as:

1PEAK

Equation 3

I

1PEAK

-----------------I

2PEAK

N

2000

2

=

=

------ -

------------ -

N

1

1

Equation 4

I

I

2PEAK

1PEAK

------------------ 3 m A==

2000

Equation 5

R23R25⋅

U

0PEAKUAPEAKI2PEAK

The maximum differential input voltage between V

------------------------- -

⋅ 2.6mV===

+

R

23R25

and V

IN1

is dependent on the

IP1

Programmable Gain Amplifier (PGA) selection. For the purposes of this application, use 8x

as the gain value, then U

0PEAK

= 0.15V.

Equation 6

U

APEAK

U

0PEAK

0.15V==

Equation 7

Equation 8

Equation 9

I

2PEAK

I

1PEAK

I

1RMS

R

+

23R25

2000I

I

1PEAK

------------------

------------------------- -

⋅ 172mA==

⋅

R

23R25

2PEAK

344A==

243A==

U

APEAK

2

7/27

Page 8

External Circuit Design AN2317 - Application

The primary current sensing circuit can be connected to mains as follows (see

Figure 3

):

1. The hot line voltage wire must be connected to pin F of the module.

Normally, this wire is also connected to the hot line current wire. However, during

production or to verify phases, this wire may be connected to some other line voltage

source.

2. The neutral line voltage wire must be connected to pin N of the module.

This wire is also connected to the neutral line current wire.

3. The hot line current wire must be placed through the current transformer TR1 hole

(becoming the hot load wire).

2

Use insulated 4mm

copper wire.

4. The neutral line current wire must be placed through the current transformer TR2 hole.

2

Use insulated 4mm

copper wire.

Figure 3. Current Sense Transformer-to-Power Line Connections

Neutral Line

Hot Line

FN

TR2 TR1

Neutral Load

Hot Load

W6

W5

Comp side

*

P1

AI12298

8/27

Page 9

AN2317 - Application External Circuit Design

1.1.2 Secondary current sens ing

The secondary channel uses shunt resistor structure (see

Figure 4

). The 420µW shunt

resistor is used to maximize the use of the dynamic range of the current sensing circuit.

However, there are some important conside rations when selecting a shunt structure for

energy metering applications.

● The power dissipation in the shunt must be minimized.

The maximum rated current for this design element is 20A, so the maximum power

dissipated in the shunt is calculated as follows:

2

20A()

● The higher power dissipation may make it difficult to manage the thermal issues.

420μΩ 168mW=×

Although the shunt is manufactured from manganin material, which is an alloy with a

low thermal resistance, an apparent error may occur when it reaches a high

temperature.

● The shunt should be able to resist the shortage of the phase circuit.

This reduces the shunt resistance is much as possible.

The design values used are:

– Mains voltage = 220V

RMS

,

– Ib = 2A, and

– Shunt resistance = 420µΩ.

The remaining design elements calculated from these values are as follows:

– Voltage across shunt:

2A 420μΩ 0. 00084 V=×

– Mains power dissipation:

– Error:

1.68 10

3–

× 0.44 103–× 100percent 0.0004percent=×⁄

220V 2A 0.44kW=×

9/27

Page 10

External Circuit Design AN2317 - Application

The secondary current sensing circuit can be connected to the mains as shown in

Figure 4

1. The hot line voltage wire must be connected to pin N of the module.

Normally, this wire is also connected to the hot line current wire. However, during

production or to verify phases, this wire may be connected to some other line voltage

source.

2. The neutral line voltage wire must be connected to pin F of the module.

This wire is also connected to the neutral line current wire, which passes by the

module.

3. The hot line current wire must be connected to the Shunt pole which is close to pin N of

the module.

2

Use insulated 4mm

copper wire.

4. The hot load current wire must be connected to the Shunt pole which is close to the

edge of the module.

2

Use insulated 4mm

copper wire.

Figure 4. Shunt Module-to-Power Line Connections

Neutral

Hot Line

FN

Comp side

Shunt

*

P1

Hot Load

W6

W5

LED

NLC

TPR

DIR

AI12299

:

10/27

Page 11

AN2317 - Application External Circuit Design

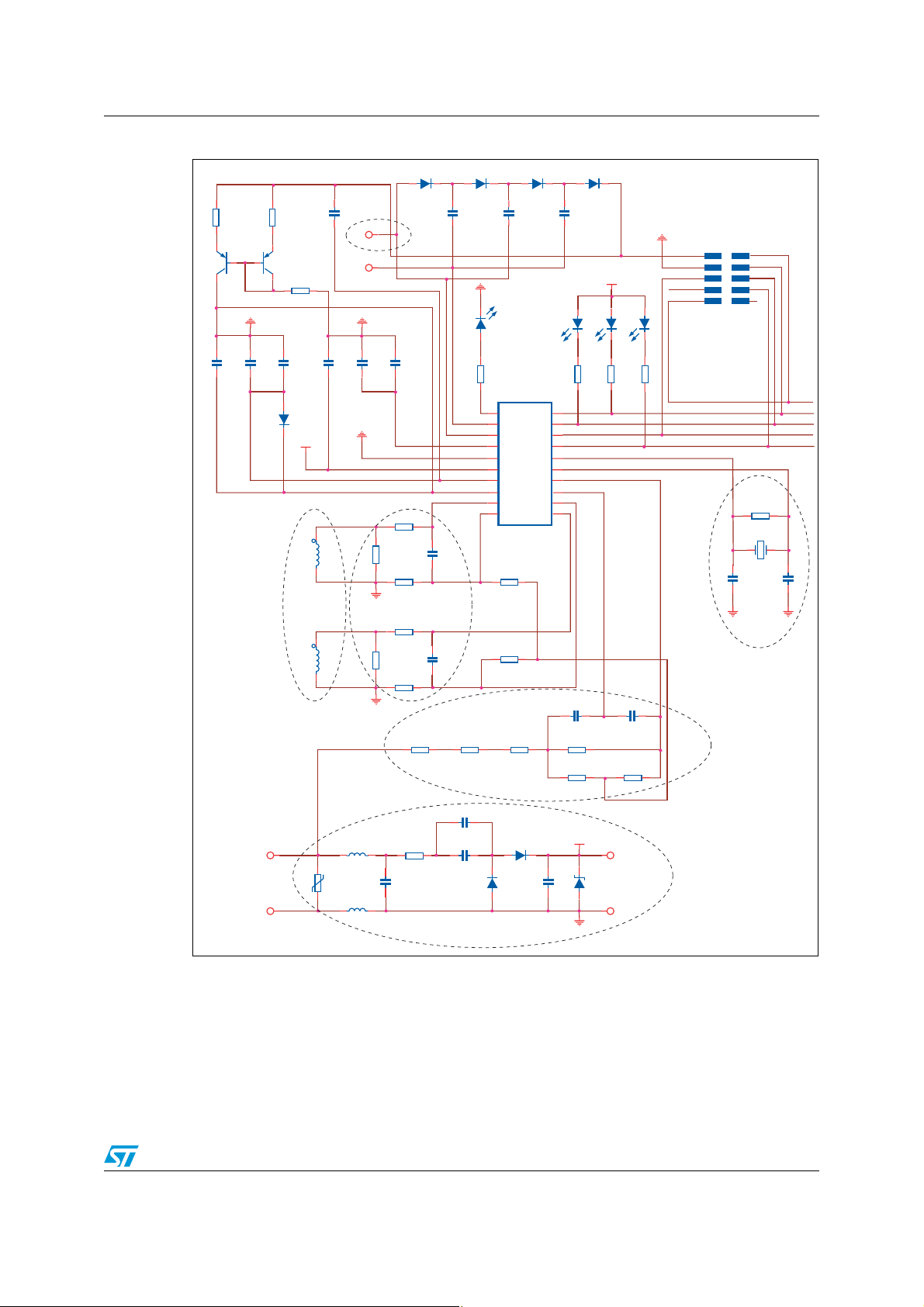

1.2 Anti-aliasing Filter

The anti-aliasing filter (

Figure 5

) is a low-pass filter. It reduces high frequency levels which

may cause distortion due to the sampling (aliasing) that occurs before the analog inputs of

an analog-to-digital converter (ADC) are introduced into the application (see

Figure 6

).

Filtering is easily implemented with a resistor-capacitor (RC) single-pole circuit which

obtains an attenuation of –20dB/dec.

Figure 5. Anti-aliasing Filter

R

U

C

U

I

R

C

O

AI12900

Figure 6. Anti-aliasing Effect

0

Image

Frequencies

2

450

Frequency - kHz

900

AI12901

11/27

Page 12

External Circuit Design AN2317 - Application

The anti-aliasing filter magnitude and phase response can be calculated as follows:

Equation 10

1

U

A

O

------- -

u

U

I

-------- jωc

------------------- 1

R

-------- -+

jωc

------------------------ -== =

1jωRC+

1

Note: The cutoff frequency is expressed as:

So

Equation 10

f

p

can be changed to:

1

--------2πτ

1

--------------- -==

2πRC

Equation 11

u

1j

f

--- -

⋅+

f

p

1

------------------- -

==

A

1

------------------- -

1j

⋅+

f

--- f

p

Equation 12

1

----------------------

A

=

u

1

+

f

⎛⎞

----

⎝⎠

f

p

2

The phase is expressed as:

Equation 13

In the module:

3

R = 2 • 10

KΩ and

C = 10nF, so then

ϕ arc–

1

--------------- - 7961.8Hz==

f

p

2πRC

f

----tan=

f

p

12/27

Page 13

AN2317 - Application External Circuit Design

According to

Equation 12

response can be seen in

● When f = 50Hz:

Equation 14

and

Equation 15

● When f = 60Hz:

Equation 16

and

Equation 17

and

Equation 13 on page 12

Figure 7

and

Figure 8 on page 14

ϕ 0.35

ϕ 0.43

, the filter’s magnitude and phase

.

°

–=

A

1≈

u

°

–=

1≈

A

u

Assume that the current lags the voltage by a phase angle, δ. After an anti-aliasing filter, a

phase error (ϕ) is introduced into the STPM01. The power factor (PF) error is calculated as:

Equation 18

δcos δϕ+()cos–

error

-----------------------------------------------

PF

δcos

100percent⋅=

When,

δ = –60° (PF = –0.5), and

f = 50Hz,

according to

Equation 14

, a phase error, ϕ = –0.35° has occurred:

Equation 19

°

–()cos–

100percent 1percent=⋅=

error

60–°()cos 60°– 0.35

----------------------------------------------------------------------------------

PF

60–°()cos

This indicates that even a small phase error will translate into a significant measurement

error at a low power factor. Thus correct phase matc hing is required in this situation.

13/27

Page 14

External Circuit Design AN2317 - Application

Figure 7. Anti-aliasing Filter Magnitude Response

0

–20

–40

Decibels (dB)

–60

1000 10000 100000 100000010010

Frequency (Hz)

Figure 8. Anti-aliasing Filter Phase Response

0

–20

–40

–60

Degrees (°)

–80

–100

1000 10000 100000 100000010010

Frequency (Hz)

AI12902

AI12903

14/27

Page 15

AN2317 - Application External Circuit Design

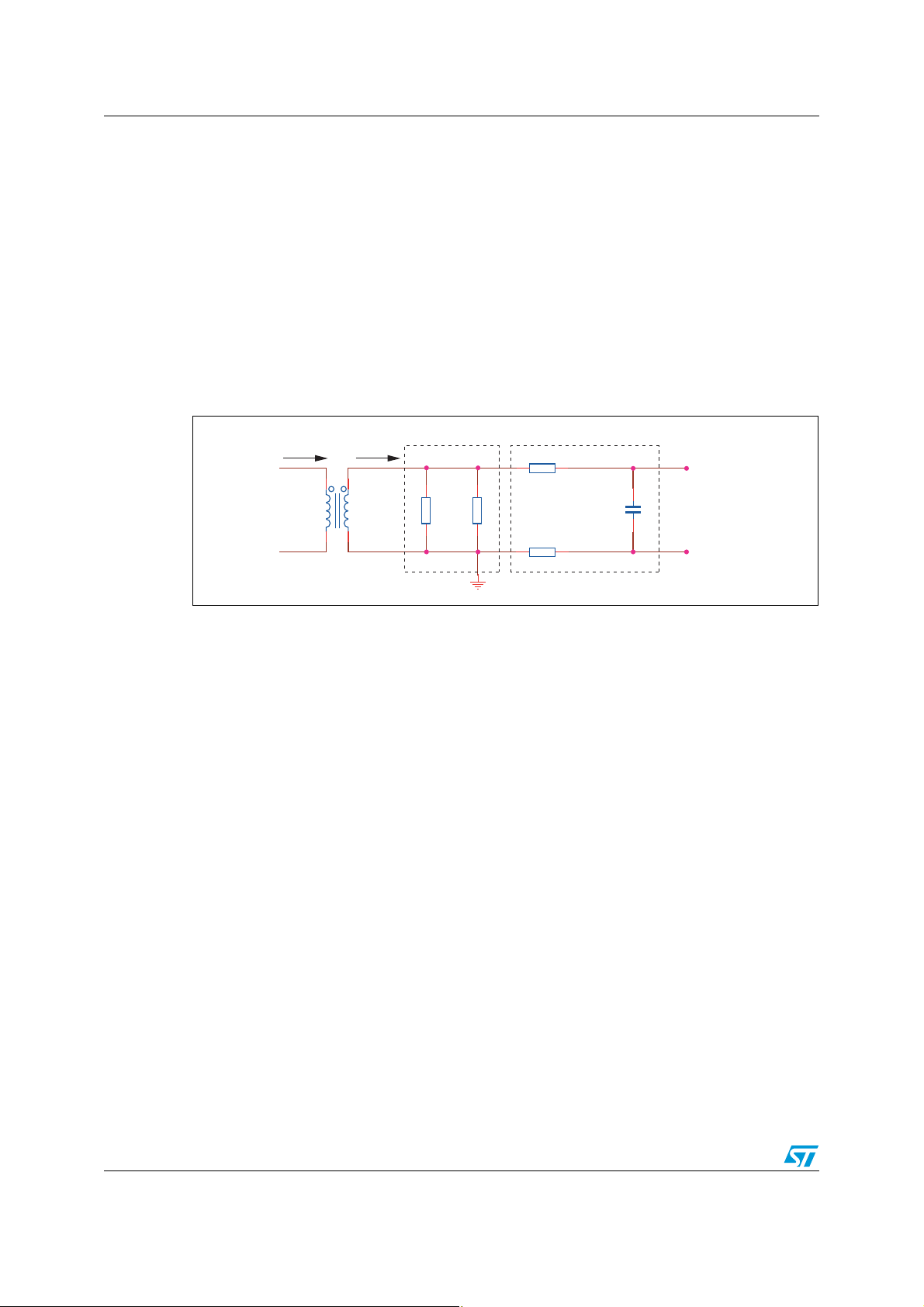

1.3 Voltage Sensing Circuit

The STPM01 normally uses a resistor divider as voltage input channel (see

783kΩ resistor is separated into three 261kΩ, in-series resistors (see

Figure 9

). The

Figure 1 on page 5

),

which ensure that a high voltage transient will not bypass the resistor. These three resistors

also reduce the potential across the resistors, thereby decreasing the possibility of arcing.

The following resistors are used as the resistor divider when the mains voltage is present:

● R‘ = 783KΩ, and

● R

C11 and (R

created by the circuit from migrating onto the Line or Neutral busses (see

through

=475Ω.

5

+ R15) create a filter which prevents Electromagnetic Interference (EMI)

19

Equation 24 on page 16

Equation 20

).

Figure 9. Voltage Sensin g Circui t

L2

1m

R'

783k

Z2

R'

783k

R5

475

R6

475

Z1

R19

42.2k

C11

22n

R15

100

V1

V2

AI12904

15/27

Page 16

External Circuit Design AN2317 - Application

Equation 20

Z

R

1

+()42.3KΩ==

19R15

Equation 21

Z

R5R6+()Z1⋅

------------------------------------ 930Ω==

2

++

R

5R6Z1

Equation 22

Z

2

-----2

U

1

U2–

----------------------

2R′ Z

+

V

mains

2

⎧

V

⎪

mains

=⋅==

⎨

⎪

V

mains

⎩

110 2V U10.046V=,=

220 2V U10.092V=,=

Equation 23

Z

2

----- 2

U

U1U2–

0

------------------ -

Z

-------

+

R′

2

V

mains

2

⎧

V

⎪

mains

=⋅==

⎨

⎪

V

mains

⎩

110 2V U00.092V=,=

220 2V U00.185V=,=

Z1 has little influence on the U

, thus:

0

Equation 24

R

5

-------------------

U

≈

0

R′ R5+

Note: For a specific U0, choose an appropriate combination of resistors (R5 and R’) to get that

particular U

value.

0

16/27

Page 17

AN2317 - Application External Circuit Design

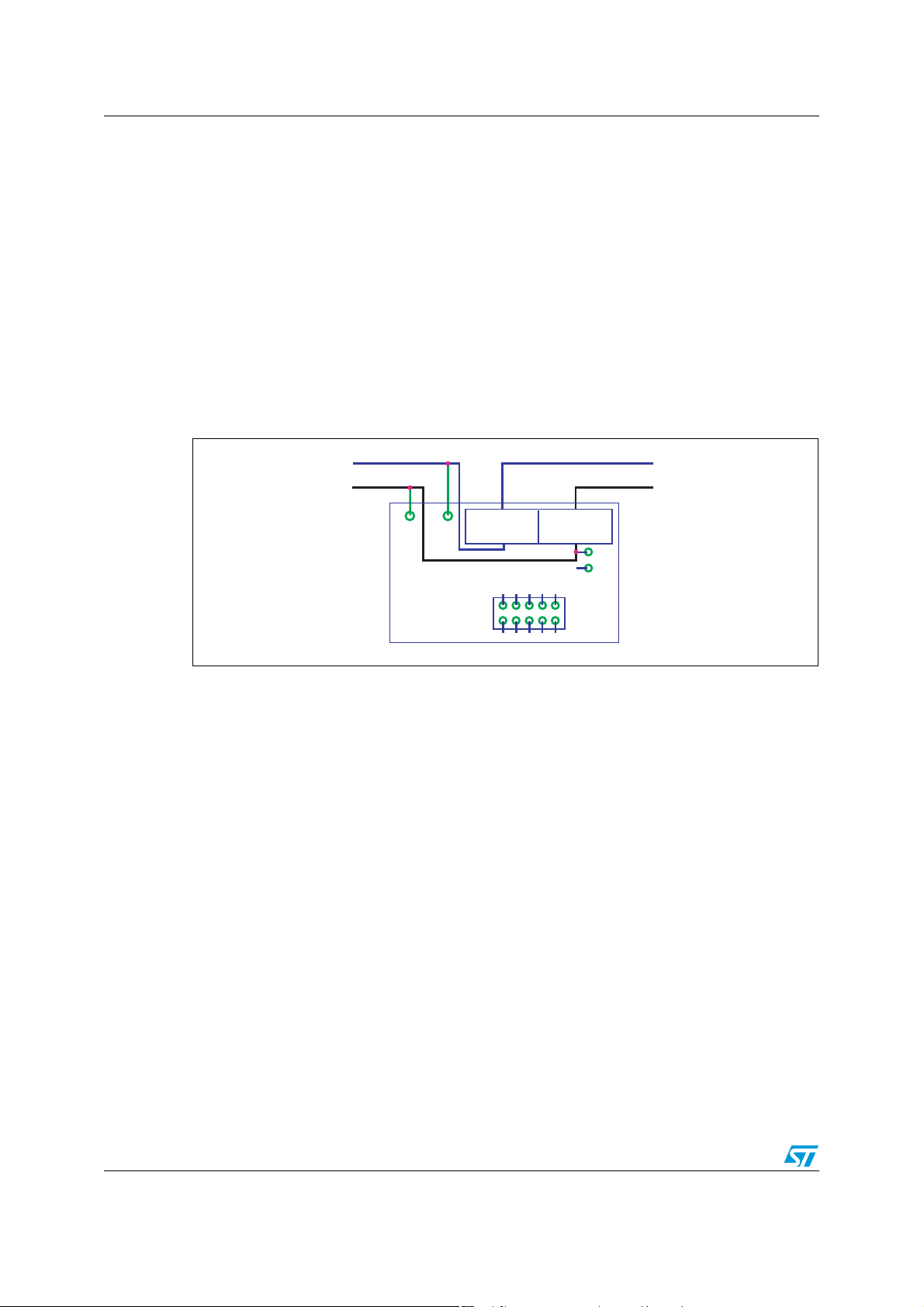

1.4 Crosstalk Cancellation Network

The voltage front end handles voltages of considerable amplitude, which makes it a

potential source of noise. Disturbances are readily emitted into current measurement

circuitry where it will interfere with the actual signal to be measured. Typically, this shows as

a non-linear error at small signal amplitudes and non-unity power factors.

At unity power factor, voltage and current signals are in phase and crosstalk between

voltage and current channels merely appears as a gain error, which can be calibrated.

When voltage and current are not in phase, crosstalk will have a non-linear effect on the

measurements, which cannot be calibrated.

Crosstalk is minimized by means of good PCB planning and the proper use of filter

components in the crosstalk network. Recommended filter components are shown in

Figure 10

input. This prevents crosstalking within the STPM01. The signal subtraction is calculated in

Equation 25

Equation 25

. The network subtracts a signal proportional to the voltage input from the current

and

Equation 26

V

.

R15

R15

---------------------------- R19 R15+

V

VCI

R15

---------- R19

⋅≅⋅=

V

VCI

Equation 26

R1

V

CCI

R1

------------------------R21 R1+

V

R15

R1

---------- R21

⋅≅⋅

V

R15

---------- R21

R15

---------- R19

V

≅⋅⋅==

VCI

1.18e6–V

VCI

Note: This network must be applied to every STPM 01 design, from the voltage channel to each

current channel.

Figure 10. Crosstalk Network

+

R19

42.2k

R21

2M

R1

1k

V

CCI

Current

Channel

Input

AI12908

–

+

Voltage

Channel

–

V

VCI

Input

R15

100

17/27

Page 18

External Circuit Design AN2317 - Application

1.5 Capacitive Power Supply Circuit

The capacitive power supply circuit is shown in

● a varistor,

● the capacitive power supply , and

● the Electromagnetic Compatibility (EMC) filter.

Figure 11. Capacitive power supply (with EMC Filter)

LINE

NEUTRAL

1.5.1 Varistor

The varistor is a surge protection device that is connected directly across the AC input.

When a power surge or voltage spike exceeding a specified voltage (varistor voltage) is

sensed, the varistor's resistance rapidly decreases, creating an instant shunt path for the

overvoltage, thereby saving the sensitive control panel components. The varistor and the

line fuse are subject to damage or weakened because the shunt path creates a short circuit.

Transient

Protection

RV1

510V

Figure 10

Filter 1 Filter 2

L1

220m

C1

1n

L2

220m

Current

Limiter

82R

R1

Voltage

Divider

C2

470n

DIF60

and includes:

D1

DIF60

D2

C3

1000m

VDD

2

D3

5.1V

1

GND

AI12909

An essential point of varistor selection is t hat t he varistor can handle the peak pulse current,

which is 110% of the maximum current at which the varistor voltage does not change. If the

peak pulse current rating is insufficient, then the varistor may be damaged. The main

voltage is 220V

, and sometimes the maximum will r eac h 265V

RMS

K10*300V varistor is chosen for this application.

18/27

.Thus, an MOKS

RMS

Page 19

AN2317 - Application External Circuit Design

1.5.2 Capacitive Power Supply

There are several ways to convert AC voltage into the DC voltage required by STPM01.

Traditionally, this is done with a transformer and rectifier circuit. There is also switching

power supply solution. However , these two solutions are expensive and take up a

considerable amount of PCB space.

To provide a low-cost, alternative solution, a transformerless power supply can be used (see

Figure 12

Figure 12. Capacitive Power Supply

).

LINE

UIN

R1

82R

C2

470n

IIN

D2

DIF60

D1

DIF60

C3

1000m

VDD

2

D3

5.1V

1

NEUTRAL

GND

AI12914

19/27

Page 20

External Circuit Design AN2317 - Application

The input current (IIN) is limited by R1 and the capacitive reactance of C2 (see

and

Equation 29

), and is expressed as:

Equation 27

V

I

IN

IN R MS()

------------------------ -=

X

+

C2R1

where,

X

= C2 reactance.

C2

Note: R1 is used to limit inrush current, but it dissipates power.

By adding a low-cost half-wave rectifier, current is allowed to be supplied by the source

during the positive half, where,

● V

= RMS voltage of the half-wave AC wav eform, and is expressed as follows:

INRMS

Equation 28

V

1

PEAKVZ

-- -

V

IN RMS()

------------------------------ -

⋅=

2

2

where,

= mains peak voltage (i.e. United States = 115V/60Hz and

V

PEAK

Europe = 220V /50Hz ), and

= the voltage drop across D1 and D3.

V

Z

● X

= Capacitor reactance, and is expressed as:

C2

Equation 28

–

Equation 29

1

----------------=

2πfC

2

with those in

Equation 28

and

Equation

By substituting the values expressed in

29

, the results are as follows:

X

C2

Equation 27

Equation 30

I

----------------------------------------

IN

22X

V

PEAKVZ

C2R1

–

+()

2V

----------------------------------------==

22X

–

mainsVZ

+()

C2R1

Assuming that the voltage drop across each diode is 0.7V, then the total voltage drop is

expressed as:

Equation 31

V

Z

V

D1VD3

5 0.7 2 6.4V=⋅+=+=

20/27

Page 21

AN2317 - Application External Circuit Design

When these application parameters are considered:

= 220VAC,

V

mains

f = 50Hz, and

= 6.4V (see

V

Z

Equation 31

), the calculated IIN would be:

Equation 32

I

15.7mA=

IN

Selecting components in the circuit is a critical consideration. As a general rule, components

should be sized at twice the maximum power calculated for each device.

For example, by using the I

value in

IN

Equation 32

and VDD = 5V to choose an appropriate

Zener diode, the results required to make the selection are expressed as follows:

Equation 33

2

V

DDIIN

R10.02W=⋅=

and

Equation 34

P

D3

VD3I

IN

5.1 0.0157 0.08W=⋅=⋅=

Thus, a ZMM SOD 80*5.1V G Zener Diode is used.

21/27

Page 22

External Circuit Design AN2317 - Application

1.5.3 EMC Filter

EMC has become an important power supply parameter. In order to deal with common and

differential mode noise, a two-part AC filter is added (see

● Differential filter (Filter 1)

Inductors L

, and C1 represent a differential filter for DM (differential mode) noise

1/L2

trying to enter the power supply. DM noise is produced by current flowing along either

the Line or Neutral conductor, and returning by the respective other. This produces a

noise voltage between the Line and Neutral conductors.

The filter will be designed for at least 10 times the line frequency, thereby resulting in a

frequency of 600Hz. The indication is then, that the cutoff frequency (f

below 600Hz.

Capacitor C

is X Class capacitor, used to reduce differential noise. To ensure that C1

1

does not fail because of the surge or short circuit current, it must be able to withstand

twice the mains voltage value. Keeping this requirement in mind, f

follows:

Equation 35

f

C

---------------------------------------------- -7.59Hz=≈

2π L

1

+()C1⋅

1L2

Figure 11 on page 18

) must not be

C

is calculated as

C

).

Note: Generally, a specific fC value is chosen, then the inductors are tuned to that value.

22/27

Page 23

AN2317 - Application External Circuit Design

● Capacitor filter (C

Capacitor C

requirements expressed in

, Filter 2)

3

is used as a filter. Considering load RL, the size of C3 must satisfy the

3

Equation 36

:

Equation 36

RLC1525∼()T=

In fact, considering that the charge stored in the capacitor is:

Equation 37

TQ=

I

L

where,

I

= the load current, and

L

T = the AC sine wave period, and

the output ripple voltage is expressed as:

Equation 38

Q

ΔV

----=

C

then the capacitor C value can be calculated by using a fixed voltage ripple value:

Equation 39

I

T

L

ΔV

--------=

C

then, fixing our ripple to ΔV=200mV we can calculate C value accordingly.

For the purposes of this application, C is calculated as follows:

Equation 40

10mA

-------------------------------------- 1000μF==

C

200m V 50Hz

The STPM01 power supply (V

CC

seems to be enough to change the D3 diode (see

⋅

) configuration range is from 3.3V to 6V. While it

Equation 34

selected ZMM SOD 80*5.1V G Zener Diode, if the output current is too high, then the

C

value must be reduced.

2

Note: Usually it is not necessary to use resistor R1 in the circuit.

) from the previously

23/27

Page 24

External Circuit Design AN2317 - Application

1.6 Clock Generation

All of the STPM01 internal timing is based on the CLKOUT oscillation signal. This signal can

be generated in three different ways:

● RC (see

This oscillator mode can be selected using the RC configuration bit. If RC = 1, then the

STPM01 will r un usi ng the RC os cillat or. A resistor connected between CLKIN and

Ground will set the RC current.

Note: For 4MHz operation, the suggested settling resistor is 12k.

● Quartz (see

The oscillator will work with an external crystal.

Figure 13. Internal RC Recommended Connections

Figure 13

Figure 14

)

)

V

CLKINCLK

SS

OUT

12k

Figure 14. Quartz Recommended Connections

V

CLKINCLK

SS

1M

4194MHz

AI12915

OUT

15pF15pF

AI12916

24/27

Page 25

AN2317 - Application External Circuit Design

● External Clock (see

Figure 15

)

The clock generator is powered from analog supply, and is responsible for two tasks:

a) to retard the turning on of some of the function blocks after Po wer-on Reset (POR)

in order to help smooth start the external power supply circuitry and keep all major

loads off of the circuit, and

b) to provide all necessary clocks for the analog and digital parts. Two nominal

frequency ranges are expected,(1) from 4.000MHz to 4.194MHz, or (2) from

8.000MHz to 8.192MHz.

Figure 15. External Clock Source Recommended Connections

V

CLKINCLK

SS

OUT

–

AI12917

25/27

Page 26

Revision History AN2317 - Application

2 Revision History

Table 1. Document revision history

Date Revision Changes

14-Apr-2006 1 Initial release.

26/27

Page 27

AN2317 - Application

y

y

Please Read Caref u ll y:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at an

time, with out notice.

All ST products are sold pursuant t o ST’s terms and conditio ns of sale.

Purchase rs are solely responsible f or the ch oi ce, selec tion and us e of the ST products and services des cribed he rei n, and S T assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party produ ct s or servic es it shall n ot be deeme d a license grant by ST for the use of such thir d party pro ducts

or services , or any intel lec tual pro per ty cont aine d ther ein or con sidere d as a warra nty c overi ng th e use i n any mann er w hats oever of such

third party products or services or any intellec tual prope rt y contained t herein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPRO VED IN W RITING B Y AN AUTHORIZE REPRESE NTATIVE O F ST, ST PRODU CTS ARE N OT DESI GNED,

AUTHOR I Z ED OR WARRANTED F OR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR L IF E SUSTAINING APP L ICATIONS,

NOR IN PRODUCTS OR SYSTEMS, WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY, DEATH, OR

SEVERE PROPERTY O R ENVIRONMENTAL DAMAGE.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warran ty gr anted by ST fo r the ST produc t or se rvice d es cribed he rein and shall not c reat e o r extend in a ny mann er wha tsoe ver, an

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various c ountries.

Information in this do cument super sedes and replaces all inf ormation pr eviously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2006 STMi croelectronics - All ri ghts reserved

STMicroelectron ics group of co m panies

Austra l i a - Be l gi um - Brazil - Canada - Chi na - Czech Republic - Finl and - Franc e - Germany - Ho ng Kong - India - Israel - It al y - Japan -

Malaysi a - M al ta - Morocco - Singapore - Spain - Sweden - Swit zerland - Un i ted Kingdom - Uni ted States of America

www.st.com

27/27

Loading...

Loading...