Page 1

AN2316

Application Note

Improved ST7LITE05 AC Chopper Driver Solution

Introduction

This application note presents an AC motor or load circuital solution improvement of

efficiency over the one discussed in a previously published application note, AN1255.

Above all, this solution does not have limits on where it may be applied, embracing all types

of AC asynchronous monophase motor applications (e.g. refrigerators, hydraulic pumps,

fans, and lamps).

Due to the increasing electric pollution of the environment, European standards impose

restrictions on Electromagnetic Compatibility (EMC). The proliferation of non-linear loads

and the consequential increase in harmonics pollution in power distribution lines have

induced various technical committees to establish maximum limits on the harmonic content

produced by all industrial and domestic devices. Manufacturers of these devices are

required to conform to this new standard and develop products which function with new

operational characteristics.

The most common method used to vary the AC monophase motor voltage is a TRIACbased phase angle partialization technique. Although this is a simple, low-cost solution that

has been used for several years, it is problematic because of the excessive harmonic

distortion which reduces the efficiency of the entire system. These systems typically include

a complex inverter drive which is quite expensive, and, while they can solve the load’s

harmonic content problems, they do not address those same problems in the electric lines.

March 2006 Rev 1 1/24

www.st.com

Page 2

Contents AN2316 - Application Note

Contents

1 STEVAL-IHM006V1 Circuit Description . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2 EMC Precompliance Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.1 Electrical Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.2 EM C D ouble-Filter Bill of Mater ials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3 Safety and Operating Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.1 STEVAL-IHM006V1 Board Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.2 Environmental Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.3 Mandatory Checks Before Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.4 Start-up Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4 ST7FLITE05 Software Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.1 Peripheral Initialization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.2 Firmware Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.3 Development Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5 Library Source Cod e . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.1 Software downloa ds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.2 File Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

6 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2/24

Page 3

AN2316 - Application Note List of Figures

List of Figures

Figure 1. Two-Switch Drive Motor Schematic (ST patented). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Figure 2. Basic Working Principal Illustration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Figure 3. System Waveforms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Figure 4. EMC Measure ment Schematic. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Figure 5. EM C Double -Filter Stage Schem atic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Figu r e 6 . 20kH z Switc h in g F r e quen c y EMC An a lysi s . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Figu r e 7 . 35kH z Switc h in g F r e quen c y EMC An a lysi s . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Figure 8. STEVAL-IHM0 06V1 Board Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 9. ST7FLITE05 Flow Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 10. Softec STVD7 v3.10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 11. ST7 Visual Programm er . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3/24

Page 4

STEVAL-IHM006V1 Circuit Description AN2316 - Application Note

1 STEVAL-IHM006 V1 Circuit Description

This ST-patented solution uses a working switch mode to solve third harmonic problems.

The base circuit can be viewed as a mains vol tage double-chopper without any preliminar y

AC/DC conversion type (see

Note: The AC chopper STEVAL-IHM006V 1 provides customers with a demo that regulates the

voltage in AC motors or loads of up to 300W. This allows the user to demonstrate smooth,

silent, and efficient regulation with respect to TRIAC solutions.

The double-chopper is a device which energizes the load beginning from any level of the

sinusoidal voltage wave and demagne tizes the load with a freewheeling current system,

thereby obtaining voltage and current regulation of the load.

Starting from a perfect sinusoidal-shaped mains curve, the regulated current is also

sinusoidal for all the power levels that the user desires to transfer to the load. By neglecting

the electronic device losses, the circuit incoming power S is equa l to the outgoing power:

Equation 1

SV

Figure 1 on page 6

AC RMS()IAC RMS()

⋅

=

V

).

⋅=

LOAD RMS()

I

LOAD RMS()

where,

V

AC(RMS)

I

AC(RMS)

V

LOAD(RMS)

I

LOAD(RMS)

The I

= Root Mean Squared (RMS) Mains Volt age,

= RMS Input Current,

= RMS Load Voltage, and

= RMS Output Current.

AC(RMS)

and I

LOAD(RMS)

currents are related as follows:

Equation 2

I

LOAD RMS()

------ ----------- ----------- ---------- -

I

AC RMS()

V

AC RMS()

=

------ ------------ ----------- ----------- --

V

LOAD RMS()

The circuit operates as a converter, particularly as an AC/AC converter or transformer. It has

no limitation in terms of load impedance since it works with both, inductive and ohmic loads,

with notable angles between the current and the vol tag e.

4/24

Page 5

AN2316 - Application Note STEVAL-IHM006V1 Circuit Description

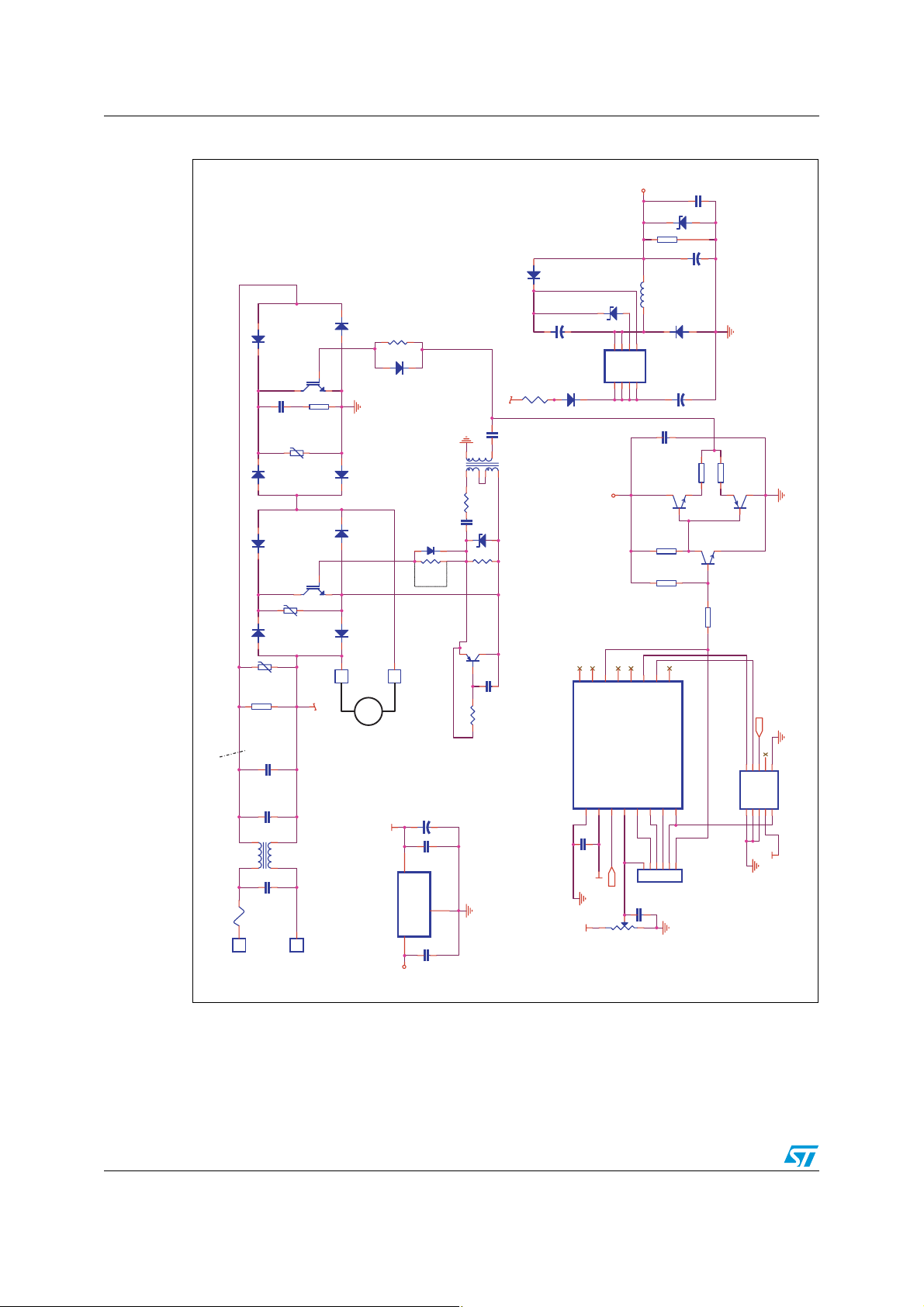

The circuit is based on the fo llowing parts (see

● IGBT Z1

Figure 1

):

Together with diodes D1, D2, D5, and D6, it performs current freewheeling (only for

inductive load).

● IGBT Z2

Together with diodes D3, D4, D7, and D8, it is the main switch through which the load is

energized.

● Pulse Transformer T1

It allows the signal derived from the PWM generator to be transferred to the Z1 gate.

This component electrically insulates the input from the output’s entry signal and phase

inversion.

● PWM generator

This is provided by the ST7Lite05 microcontroller.

5/24

Page 6

STEVAL-IHM006V1 Circuit Description AN2316 - Application Note

Figure 1. Two-Switch Dri ve Mo t or S che m at i c (S T patented )

+15V

C15

0.1µF

D15

18V

R10

12K 1/4W

D11

STTH108

D13

15V

R7

NTC22

12

CONTROL

V

+

C10

10µF 25V

t°

D12

STTH108

U3

123

+15V

45

S

S

FB

VDD

DDD

D

678

D4

D8

STTH306

R3

470-1/4W

STTH306

1

Z2

STGP7NB60HD

2

3

R2

C2

3.3nF

5.6-1/4W

D3

D2

250V10L

STTH306

RV3

D7

D6

STTH306

1

Z1

STGP7NB60HD

2

3

STTH306

STTH306

D9

1N4148

NOT ASSEMBLED

pulse transformer

C3

0.1µF-100V

D16 1N4148

R15

1.2k

C4

0.1µF-100V

T1

17

294

5

0

R4

D10

18V

R5

270K

PHASE

RS-196-375

L1 1mH

D14

STTH108

VIPer12A DIP

+

C12

0.1µF

Q1

BC547

R9

2.2K

R8

470K

+

C14

C13

1µF-450V

R11 15

Q2

10µF 25V

R13 0

BC547

Q3

BC557

S 1

1

Line filter

F1

1

J1

D1

R1

4

T2

3

5 A

STTH306

250V14L

220K 1/2W

C1

C17

1

2

C16

MAINS

320VAC

RV2

250V10L

RV1

1µF 250VAC

100nF x 2

phase

100nF x 2

1

J2

PHASE

D5

J3

PHASE

STTH306

1

M

AC

ASYNCHRONOUS

1

J4

MOTOR

+5V

1

OUT

IN

U1

L78L05A/TO92

3

+15V

NOT ASSEMBLED

C5

47µF-25V

+

C7

0.1µF

GND

2

C6

0.1µF

BC557

321

Q5

C18

100pF

R14 R

NOT ASSEMBLED

NOT ASSEMBLED

16151413121110

PA1

PA3

PA4

PA0/LTIC

PA2/ATPWM0

VSS

VDD

RESET

U4

SS/AIN0/PB0

1234567

AIN0

C25

100nF

+5V

RESET

+5V

R6

22K

9

PA7

PA5/ICCDATA

PA6/MCO/ICCCLK

MISO/AIN2/PB2

MOSI/AIN3/PB3

SCK/AIN1/PB1

8

1

C8

0.1µF

R12 10K

CLKIN/AIN4/PB4

ST7LITE09

65432

J10

CON6_0

246

13579

JP1

AI12268

RESET

8

10

+5V

CON10A

6/24

Page 7

AN2316 - Application Note STEVAL-IHM006V1 Circuit Description

In order to avoid short-circuiting the mains through switches Z1 and Z2, they must work in a

complementary manner. When Z1 is ON, Z2 must be OFF and vice-versa.

For example, if the line vol tage at J1 i s posi tiv e wi th respect to J2, and the PWM signal goes

from high-to-low, Z2 switches ON with a delay inserted by its own gate capacitance and by

resistor R3 so the load is energized. In the meantime, Z1 swit ches OFF instant aneously.

Note: In this condition, if the current is positive (i.e. it goes into J1 and comes out from J2), it will

flow through D4, Z2, D7, and the load. Conversely, if the current is negative, it will be going

out from J1 and closing through the load, D3, Z2, and D8.

As is the case with the current, when the PWM goes from low-to-high, Z2 is turned OFF

instantaneously , while Z1 is switched ON with a delay. This enables a freewheeling current

to flow through Z1.

Given these relationships, if “δ” is the duty cycle (see

is may be expressed as:

Equation 3

V

t() δ VACt()⋅δV

LOAD

where,

= Load voltage,

V

LOAD

= Mains voltage, and

V

AC

= Maximum sinusoida l vo l t age.

V

MAX

The load current may be expressed as:

Equation 4

I

LOAD

t()

1

-- -

δ

IAC⋅ t()

1

-- -

I

MAX

δ

where,

I

= Load current,

LOAD

= Input current,

I

AC

= Maximum current value, and

I

MAX

ϕ = the angle between the current and voltage.

Figure 2 on page 8

MAX

ωt()sin⋅⋅==

ωt ϕ+()sin⋅⋅==

), the load voltage

7/24

Page 8

STEVAL-IHM006V1 Circuit Description AN2316 - Application Note

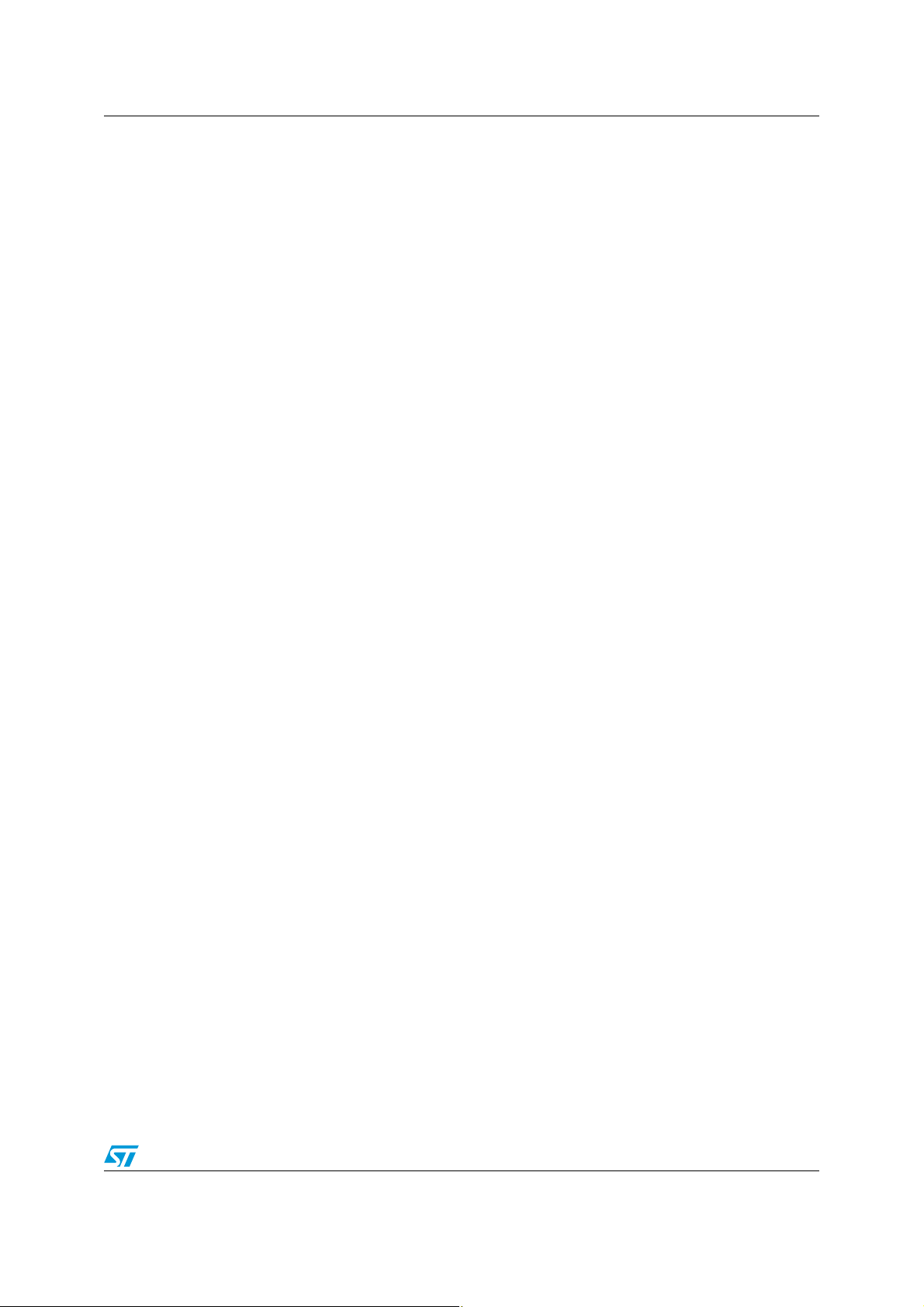

The relationships expressed in

Equation 3

and

Equation 4

, and

Figure 2

show that it is

possible to control power fed to the load by changing the PWM signal duty cycle.

Note: The load is assumed to be inductive so the high frequency harmonics are filtered in the

current waveform (see Figure 3 on page 9 for system wavefor m deta ils).

Figure 2. Basic Working Principal Illustration

Bi-directional PWM Chopping

V

line

Load Current

t

duty cycle

Duty Cycle Increase

t

AI12267

8/24

Page 9

AN2316 - Application Note STEVAL-IHM006V1 Circuit Description

Figure 3. System Waveforms

VAC, I

LOAD

V

CONTROL

V

G1

VAC

I

LOAD

t

a

t

b

tON

tOFF

V

G2

tS

Current in

point i1

Current in

Z1 switch

Legend:

a = line voltage and load cur rent

b = PWM control signal generated by the ST7Lite05 microcontroller

c, d = Z1 and Z2 gate signals

e = section S1 current (see

Figure 1 on page 6

)

c

t

t

d

t

e

t

f

AI12269

f = current through switch Z2

9/24

Page 10

EMC Precompliance Measurement AN2316 - Application Note

2 EMC Precompliance Measurement

Electromagnetic Compatibility (EMC) measurement requires us e of the Line Impedance

Stabilization Network (LISN).The LISN operates as a filter between the line and test board,

providing clean energy to the syst em under test. It collects al l the emissions coming from the

systems under test (>9kHz) and sends the noise to the EMC analyzer (see

Figure 4. EMC Measurement Schematic

AC-Chopper Board

Load

Figure 4

).

Insulation

Transformer

LISN

EMC Analyzer

AI12289

Caution: For safety reasons, an insulated 1:1 transformer is used to avoid a possible ground current

loop.

Table 1. AC Chopper EMC Limits

Description

(1)

Limit Line Frequency Range

EN55014 Conducted <700W, Motors, Quasi-pe ak 150kHz to 30MHz

EN55014 Conducted <700W, Motors, Average 150kHz to 30MHz

1. EMC AC chopper measurem ent at 20kHz switching frequency (CISPR-14), per EN55014 standard.

2. Instrument used: E7400 Agilent Technology

(2)

10/24

Page 11

AN2316 - Application Note EMC Precompliance Measurement

2.1 Electrical Conditions

● V

●

● Motor voltage = 230V

●

= 230V

INPUT

AC

Motor type = Asynchronous with capacitor

AC

Motor current =1.5A

The on-board EMC filter is not optimized for every kind of load, so users need to consider

that the included filter might be inadequate for certain applications.

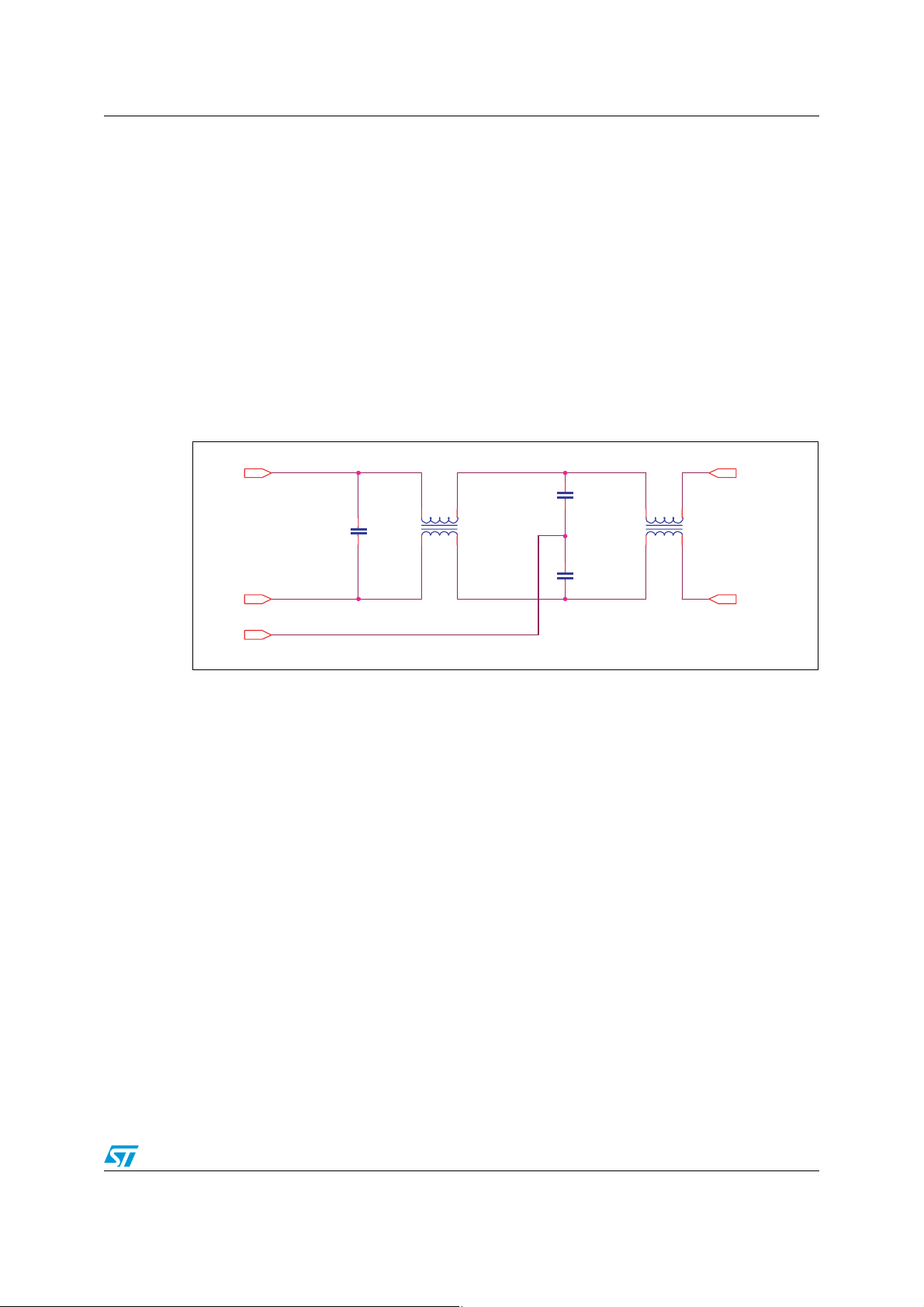

A double-filter stage ( see

Figure 5

) is required to obtain good EMC results (acceptable EMC

level) without the included filter (T2, C16, and C17), use the recommended filter mentioned

in

Figure 5

. The measured results are shown in

Figure 6

and

Figure 7 on page 12

.

Note: In order for the f ilter to be effective, the motor case must be connected to the earth-ground.

Figure 5. EMC Double-Filter Stage Schematic

Mains

Mains

0.47µF 230VAC

Common mode filter 10mH

X2

C1

2.2nF 400VAC

T1

5

1

8

4

2.2nF 400VAC

Y2

Y2

Common mode filter 111µH

C2

5

1

C3

P

T2

8

To the AC-Chopper

4

Circuit

N

EARTH GROUND

2.2 EMC Double-Filter Bill of Materials

C1 = 0.47µF 230VAC X2

C2 = C3 = 2.2nF 230V

T1 = 10mH common mode filter (to be designed in terms of current, depending on the final

load to be driven). For this application, the type used is TDK 103Y1R2X3X.

T2 = 111µH common mode filter (to be designed in terms of current, depending on the final

load to be driven).

AC

Y2

AI12290

11/24

Page 12

EMC Precompliance Measurement AN2316 - Application Note

Figure 6. 20kHz Switching Frequency EMC Analysis

Mkr1 15.08MHz

21.44dBµV

1

Ref 75dBµV

Peak

Log

10

dB/

W1 S2

S3 FC

AA

#Atten 10dB

Start 150kHz

Res BW 9kHz

VBW 30kHz

Figure 7. 35kHz Switching Frequency EMC Analysis

Ref 75dBµV #Atten 10dB

Peak

Log

10

dB/

W1 S2

S3 FC

AA

Start 150kHz

Res BW 9kHz VBW 30kHz

Sweep 881.3ms (1515pts)

Stop 30MHz

AI12291

Mkr1 15.08MHz

25.42dBµV

1

Stop 30MHz

Sweep 881.3ms (1515pts)

AI12292

12/24

Page 13

AN2316 - Application Note Safety and Operating Instructions

3 Safety and Operating Instructions

Note: Please read this section before attempting any operation with this manual.

The AC chopper board is designed for demonstration purpos es only, and shall not be used

for electrical installation or machinery. The technical data, as well as information concerning

the power supply conditions shall be taken from the documentation and strictly observed.

The AC chopper driver poses several inherent hazards dur ing installation and operation,

including bare wires and hot surfaces. All operations involving transportation, installation

and use, as well as maintenance are to be carried out by skilled technical personnel

(national accident prevention rules must be observed). For the purposes of these basic

safety instructions, “skilled technical personnel” are defined as suitably qualified people who

are familiar with the installa ti o n, use , and maint e nance of po we r electro n i c syste m s.

Danger: There is danger of serious personal injury and damage to

property, if the Kit or its components are improperly used or

installed incorrectly.

3.1 STEVAL-IHM006V1 Board Installation

The installation and cooling of the demo board shall be in accordance with the specifications

and the targeted application.

● The motor drive converters shall be protected against excessive strain. In particular, no

components are to be bent, or isolating distances altered during the course of

transportation or handling.

● No physical contact shall be made with electronic components and contacts.

● The boards contain electrostatically sensitive components that are prone to damage

through improper use. Electrical components must not be mechanically damaged or

destroyed (to avoid potential health risks).

Warning: Applicable national accident prevention rules must be

followed when working on the main power supply with a

motor or AC load.

Note: Do NOT expose the kit to ambient temperatures of over 35°C, as this may harm the

components or reduce their lifetimes.

13/24

Page 14

Safety and Operating Instructions AN2316 - Application Note

3.2 Environmental Considerations

The STEVAL-I HM0 06V 1 AC chopper demo board must only be used in a power laboratory.

The high voltage used in any AC drive system presents a se rious shock hazard. A complete

laboratory setup consists of:

● an isolated AC power supply,

● the STEVAL-IHM 006V1 demo board,

● an AC Induction motor, and

● an isolated (laboratory) power supply for +15V (as needed).

The Kit is not electrically isolated from the AC input. The microprocessor is grounded

without insulation with respect to the mains so that it and the associated circuitry are hot.

They MUST therefore be isolated from user controls and serial interfaces.

Note: Any measurement equipment must be isolated from the main power supply before powering

up the motor drive. To use an oscilloscope with the Kit, it is safer to isolate the AC supply

AND the oscilloscope. This prevent s a shock occurring as a result of touching any SINGLE

point in the circuit, but does NOT prevent shocks when touching TWO or MORE points in

the circuit.

An isolated AC power supply can be constructed using an isolation transformer and a

variable transformer. A schematic of this AC power supply may be found in the Application

Note, “AN438, TRIAC + M icroc ontrolle r: Safety Precautions for Development Tools”.

(Although this Application Note was written for TRIACs, the isolation constraints still apply

for fast -switching semiconductor devices such as IGBTs).

Note: Isolating the application rather than the oscilloscope is highly recommended in any case.

3.3 Mandatory Checks Before Operation

The following ver ificat ions must be performed before operating the demo board:

● The motor load is connected and earth-grounded,

● there is no metal part on, below , or around the PC boards, and there are no unintended

earth/ground loops caused by peripheral (e.g. test) equipment (e.g. PC or

oscilloscope), and

● the motor and mechanical load are safely housed so that rotating parts cannot be

inadvertently accessed and cause injury (e.g., loose clothing, long hair).

Warning: The high voltage levels used to operate the motor drive could

present a serious electrical shock hazard. This demo board

must be used only in a power laboratory only by engineers

and technicians who are experienced in power electronics

technology.

14/24

Page 15

AN2316 - Application Note Safety and Operating Instructions

3.4 Start-up Procedure

1. Connect the AC m otor or AC load on the board to connectors J3 and J4 (see

Sequencing is arbitrary.

2. Connect the current probe on one motor line in order to monitor motor current on the

oscilloscope.

3. Apply the heat sink spreader (not included in the STEVAL-IHM006V1) on the two

IGBTs using the appropriate insulation foil.

4. Set the potentiometer R6 in arbitrary position. This changes the main switch Z2 duty

cycle.

5. Apply the main voltage supply to connectors 230V

6. Rotate potentiometer P2 Clockwise (CW) to begin increasing the motor load voltage.

The resulting current wavefor m should remain fairly sinusoidal.

Warning: The entire circuit board and motor output terminals are

always “hot” with respect to earth ground, even when the

drive is in a stopped condition.

Figure 8. STEVAL-IHM006V1 Boa rd Layout

J1 and J2.

AC

Figure 8

).

15/24

Page 16

ST7FLITE05 Software Description AN2316 - Application Note

4 ST7FLITE05 Software Description

The ST7FLITE05 firmware allows designers to generate the PWM signal required to drive

the STEVAL-IHM006V1 AC chopper Z1 and Z2 IGBTs (see

the Softec STVD7 Toolset v3.10 and 16K limited free version of Cosmic Compiler v4.5c.

The system may be customized by setting parameters in the “Param.h” header file,

including:

● switching frequencies,

● maximum and minimum applicable duty cycle, and

● related hysteresis.

Figure 9. ST7 F LI TE 0 5 Fl ow D iagram

Begin

Peripherals

Initialization

Wait for hardware

start-up

Figure 9

). It was de v e l oped wi th

Output_status =

PWMOutput_L

Output_status =

PWMOutput_H

A/D conversion

for potentiometer

reading

Output_status = PWM_ON Output_status = PWMOutput_L Output_status = PWMOutput_H

Covered

value ≤ higher limit +

hysteresis?

YesYes

Output_status =

PWM_ON

Yes

Converted

value ≤ lower

limit?

No

Converted

value ≥ upper

limit?

No

Covered

value ≥ lower limit –

hysteresis?

Output_status =

From_L_to_ON

NoNoYes

AI12294

16/24

Page 17

AN2316 - Application Note ST7FLITE05 Software Description

4.1 Peripheral Initialization

The peripherals are initialized. After initialization, the firmware waits 255ms for the hardware

to be start up. The potentiometer is read, and the digital values are used to compute those

to be loaded into the successive DCR registers. Initialization activities include the following:

4.1.1 Auto-reload Timer (AT) Configuration

The 12-bit AT is configured in PWM mode so that the ATR registers contain the auto-reload

value used to set the PWM frequency.

4.1.2 PWM Duty Cycle, Overflow and Compare Interrupts

The PWM frequency and the DCR registers contain the val ue which sets the PWM duty

cycle.

Furtherm ore, the PWM output on the AT PW 0 pin is enabled by setting the OE0 Bit in the

PWMCR register, and both, the overflow and compare interrupts have been enabled.

Note: In order to guarantee the proper operation of the overall system, using very high and very

low duty cycle values are di scouraged.

If the duty cycle exceeds a higher threshold, the PWM must be sw itched of f and the

microcontroller pin must be kept continuously in logic high state. The PWM output is

enabled again only if the user turns the potentiometer so the corresponding duty cycle is

below the higher threshold minus hysteresis (see Figure 9 on page 16).

If the duty cycle goes below a lower th reshold, the PWM must be switched off and the

microcontroller pin must kept continuously in logic low state. The PWM output is enabled

again only if the duty cycle related to the potentiometer position goes above the lower

threshold plus hysteresis (see Figure 9).

4.1.3 ST7LITE Timer

The 8-bit LITE Timer is configured so that an ove rflow event (and the related interrupt)

occurs every millisecond. This allows users to have a time base at their disposal to

implement, for example, the soft variation of the PWM duty cycle.

4.1.4 Channel 0 A/D Conversion

The 8-bit A/D conversion of Channel 0 is enabled at the f

/2 frequency.

cpu

17/24

Page 18

ST7FLITE05 Software Description AN2316 - Application Note

4.2 Firmware Configuration

The user-modifiable parameters are defined in “Param.h” header file, part icular ly:

4.2.1 Switching Frequency

#define PWM_FREQUENCY Fx0kHz

Use F20kHz, or F40kHz to set the respective 20kHz or 40kHz frequencies (see

Section 4.1.1 on page 17

4.2.2 Maximum Duty Cycle

#define MAX_DUTY 90 //in percentage

Use the PWM frequency and the DCR register values to set the duty cycle (see

Section 4.1.2

).

4.2.3 Minimum Duty Cycle

#define MIN_DUTY 10 //in percentage

Use the PWM frequency and the DCR register values to set the duty cycle (see

Section 4.1.2

).

).

4.2.4 Hysteresis

#define HYSTERESIS 5 //in percentage

Use the PWM frequency and the DCR register values to set hysteresis (see

Section 4.1.2

).

18/24

Page 19

AN2316 - Application Note ST7FLITE05 Software Description

4.3 Development Tools

This section presents the available materi al that is required to start working with the

ST7FLITE05 and the AC chopper software library.

4.3.1 Integrated Development Environments (IDE)

Different (free) IDE interfaces are available:

● ST’s proprietary STVD7 (free download available at www.st.com), or

● a third party IDE (e.g. Softec Microsys tems' STVD7 for InDART-STX).

The software library presented in this document has been compiled using Cosmic C

compiler (v4.5c), launched with Softec STVD7 v3.10 (see

Figure 10

Note: The 16K limited free version of Cosmic compiler permits users to compile all of the objects

in the software library.

Figure 10. Softec STVD7 v3.10

).

19/24

Page 20

ST7FLITE05 Software Description AN2316 - Application Note

4.3.2 Real-Time Emulators

Two types of real-time development tools are available for debugging applications using

ST7FLITE05:

● Softec In-circuit Debugger (STXF-INDART/USB)

The inDART-STX from Softec Microsystems is both an emulator and a program ming

tool. This is achieved using the in-circuit debugging module embedded on the MCU.

The inDART real-time features include access to working registers and 2 breakpoint

settings. However, trace is not available.

● ST7MDT10-EMU3 Emulator

This fully-featured emulator includes:

– real-time with trace capability,

– performance anal ysis, advanced breakpoints, and

– light logical analyzer capabilities.

It can also be a programming tool when it is used with the ICC ADDON module

(included) which allows users to do STVD7 in-circuit debugging.

20/24

Page 21

AN2316 - Application Note ST7FLITE05 Software Description

4.3.3 Programming Software

In order to program an MCU with the generated .S 19 f ile (compiled output), the ST Visual

Programming software should also be installed (available at www.st.com), and a dedicated

hardware programming interface (e.g. in-circuit programming stick programmer) should be

used. The Visual Programming tool provides an easy way t o erase, program, and verify the

MCU content (see

Note: The inDART-STX from Softec Microsystems is also a programming tool (installation of

DataBlaze Programmer software is required).

Figure 11. ST7 Visual Progra m m er

Figure 11

).

21/24

Page 22

Library Source Code AN2316 - Application Note

5 Library Source Code

5.1 Software downloads

The complete source files are available on t he ST website (www.st.com) as a “zip” file.

Note: Checking for and verify ing the latest library releases as well as release notes before

starting any new development is highly recommended. This helps users stay informed

as to new features which might affect the project.

5.2 File Structure

The unzipped library files produce the following structure:

..\sources

..\Debug

..\Release

5.2.1 .S19 File

To produce the target .S19 file:

1. Open the ST7VD work space “ac-ac20K. stw”.

2. Compile the project by pressing the “Rebuild All” button in the ST7VD development

tool.

5.2.2 Compiler and Linker

Two different sets of compiler and linker options (Debug and Release) can be handled by

the tool, depending on the development stage.

22/24

Page 23

AN2316 - Application Note Revision history

6 Revision history

Table 2. Docu m ent revision histor y

Date Revision Changes

27-Mar-2006 1 Initial release.

23/24

Page 24

AN2316 - Application Note

y

y

Please Read Caref u ll y:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at an

time, with out notice.

All ST products are sold pursuant t o ST’s terms and conditio ns of sale.

Purchase rs are solely responsible f or the ch oi ce, selec tion and us e of the ST products and services des cribed he rei n, and S T assumes no

liability whatsoever relating to the c ho ice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party produ ct s or servic es it shall n ot be deeme d a license grant by ST for the use of such thir d party pro ducts

or services , or any intel lec tual pro per ty cont aine d ther ein or con sidere d as a warra nty c overi ng th e use i n any mann er w hats oever of such

third party products or services or any intellec tual prope rt y contained t herein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT O R OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPRO VED IN W RITING B Y AN AUTHORIZE REPRESE NTATIVE O F ST, ST PRODU CTS ARE N OT DESI GNED,

AUTHOR I Z ED OR WARRANTED F OR USE IN MILITARY, AIR CRAF T , SPACE, LIFE SAV ING, OR LIFE SUSTAINING AP P L ICATIONS,

NOR IN PRODUCTS OR SYSTEMS, WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY, DEATH, OR

SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warran ty gr anted by ST fo r the ST produc t or se rvice d es cribed he rein and shall not c reat e o r extend in a ny mann er wha tsoe ver, an

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various c ountries.

Information in this do cument super sedes and replaces all inf ormation pr eviously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2006 STMi croelectronics - All ri ghts reserved

STMicroelectron ics group of co m panies

Austra l i a - Be l gi um - Brazil - Canada - Chi na - Czech Republic - Finl and - Franc e - Germany - Ho ng Kong - India - Israel - It al y - Japan -

Malaysi a - M al ta - Morocco - Singapore - Spain - Sweden - Swit zerland - Un i ted Kingdom - Uni ted States of America

www.st.com

24/24

Loading...

Loading...