Page 1

AN2288

Application note

Single-phase energy meter with tamper detection

based on ST7FLITE2x

Introduction

This application note describes the design for a single-phase power / energy meter with

tamper detection. The design measures active power, voltage, current, power factor and line

frequency in a single-phase distribution environment and displays active energy, voltage,

current, power factor, line frequency, current date and time. It differs from ordinary singlephase meters in that it uses two current transformers (CT) to measure active power in both

live and neutral wires. This enables the meter to detect, signal, and continue to measure the

active energy consumed reliably even when subject to external tamper attempts.

ST7FLITE20 is the microcontroller used to perform all the measurements in the meter. As

the ST7FLITE30 is pin-to-pin compatible with ST7FLITE20, the ST7LITE30 can also be

used in this application (replacing the ST7LITE20) but a revalidation is required for finding

the accuracy class of the meter.

The active energy consumed is available in the form of frequency-modulated pulse outputs

and the accumulated active energy on an LCD display module. Additional features for both

consumer types can also be incorporated. These include multiple tariff rates and improved

communications, through which meter readings can be taken with less time and with higher

accuracy.

May 2006 Rev 1 1/29

www.st.com

Page 2

Contents AN2288

Contents

1 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3 Theory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.1 Analog front end . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4 Meter hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.1 Main blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.1.1 5V power supply block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.1.2 2.5V reference block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.1.3 Current transformer block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.1.4 Voltage divider block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.1.5 Tamper detection block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.1.6 Gain switching block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.1.7 EEPROM block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.1.8 RTC block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.1.9 LCD module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.1.10 In-Circuit Programming block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.1.11 Calibration through PC GUI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.1.12 Microcontroller block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5 Software routines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.1 Initialization routine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.2 Main routine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.3 Lite timer time base2 interrupt routine . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5.4 SPI interrupt routine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.5 AVD interrupt routine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.6 External interrupt routine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.7 ART timer input capture interrupt routine . . . . . . . . . . . . . . . . . . . . . . . . . 23

6 Results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

6.1 Load tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

6.2 Voltage tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

2/29

Page 3

AN2288 Contents

6.3 Frequency tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

7 Conclusions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

8 Calibration coefficients . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

9 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

3/29

Page 4

Features AN2288

1 Features

● Cost-Effective and Flexible Single-Phase Energy Meter

● ASSP is not used; microcontroller is doing all the measurements and calculations

● Fulfils IEC 61036:1996 + A1: 2000, Static meter for active energy (classes 1 and 2) for

Ib=10A and Imax=55A

● Meter starts at few mA

● Detects, Signals and Continues to Measure Accurately under tamper Condition

● Compact design with Internal Flash memory, SRAM and external EEPROM

● External EEPROM used to store calibration parameters, tampering information and

accumulated kWh. This is more secure than using internal EEPROM, as it keeps the

data away from the risk being lost on a burnt microcontroller.

● Flexibility to use External or Internal EEPROM by changing only the sales type to

ST7FLITE29 (embedded with 256 bytes of EEPROM) without changing the hardware

design

● Gain multipliers (Operation Amplifier) are used for wider range of load with Ib=10A and

Imax=5.5Ib

● Large line voltage operable range from 140V to 300V

● Active power, current, voltage, power factor and line frequency measurements

● RTC for displaying current date and time

● LCD module for display accumulated kWh, Vrms, Irms, power factor, line frequency,

current date and time

● Secure and reprogrammable Flash memory enables flexible firmware updates up to

10k cycles

● Adjustable Active Energy Pulse Output goes up to 32 000 Impulses/kWh

● Large Compensation of Phase difference generated by CTs by hardware (increasing or

decreasing capacitor values at current channel)

● One-Time, Quick, and Accurate Digital Calibration gives added benefits like more

accurate calibration and no need for Trimming external components

4/29

Page 5

AN2288 Overview

2 Overview

Power meters / Energy Meters are also known as kiloWatt-hour meters. As per definition,

energy consumed is a measure of work that is done over a known time period. Suppose, a

heater of 2kW is ON for half an hour, the consumed energy will be 2000W * 1800s =

3 600 000W-s (Watt-second), which is 1kWh.

The Active Energy Pulse output of 50% duty cycle is an indication of active power

consumed, as measured by the power meter. If the active power is higher, the frequency of

the pulse will also be higher. The pulse count gives the active energy measured by the

meter. The greater the number of pulse counts, the greater the amount of consumed active

energy. The pulse output frequency is easily configurable by software. The current software

has 3,200 impulses per kiloWatt-hour.

All the measurements can be calibrated by software, so there is no need for any trimming

components. With the firmware, phase difference created between voltage and current due

to current transformer can also be compensated. Because only one ADC is used to convert

both analog voltage and current signal into digital form and there is no dual sampling feature

available in the ST7FLITE20 microcontroller, the shift error (the sampling difference

between voltage and current) can also be compensated by the firmware. The calibration

procedure can be automated, which removes the time-consuming manual trimming required

in traditional, electromechanical meters. Digital calibration is fast and efficient, reducing the

overall production time and cost. Calibration coefficients, accumulated kWh and tampering

information are safely stored on the external EEPROM. This is more secure than internal

EEPROM since data would be lost in the event of a burnt microcontroller. Internal EEPROM

can be used in place of external EEPROM by changing only the microcontroller (without any

change in hardware design), if the consumer or supplier prefers.

The most important part of the meter is the firmware which includes tampering detection

functionality in a single-phase meter. The firmware can be modified and updated at any time

by using In-Circuit Programming, even when the meter is installed and running. The

firmware is entirely written in C except some time critical routines which are written in

assembly, which makes modifications easy to implement.

5/29

Page 6

Theory AN2288

3 Theory

The main objective of this application note is to demonstrate that a low cost energy meter

can be implemented without use of an external dedicated device (ASSP). Only a single 10bit SAR ADC is used to perform voltage and current measurements. The ADC on

ST7FLITE20 device accepts input from 0 to Vdd. Since the Vdd is +5V, the operable range

of the ADC is 0 to +5V. Since the ADC is operable in the positive range only, the AC input

signals of voltage and current have to shifted up and centered around +2.5V. This is

achieved by biasing one end of the secondaries of current transformers and one end of

potential divider with +2.5V. The input waveform of current and voltage to ADC is shown in

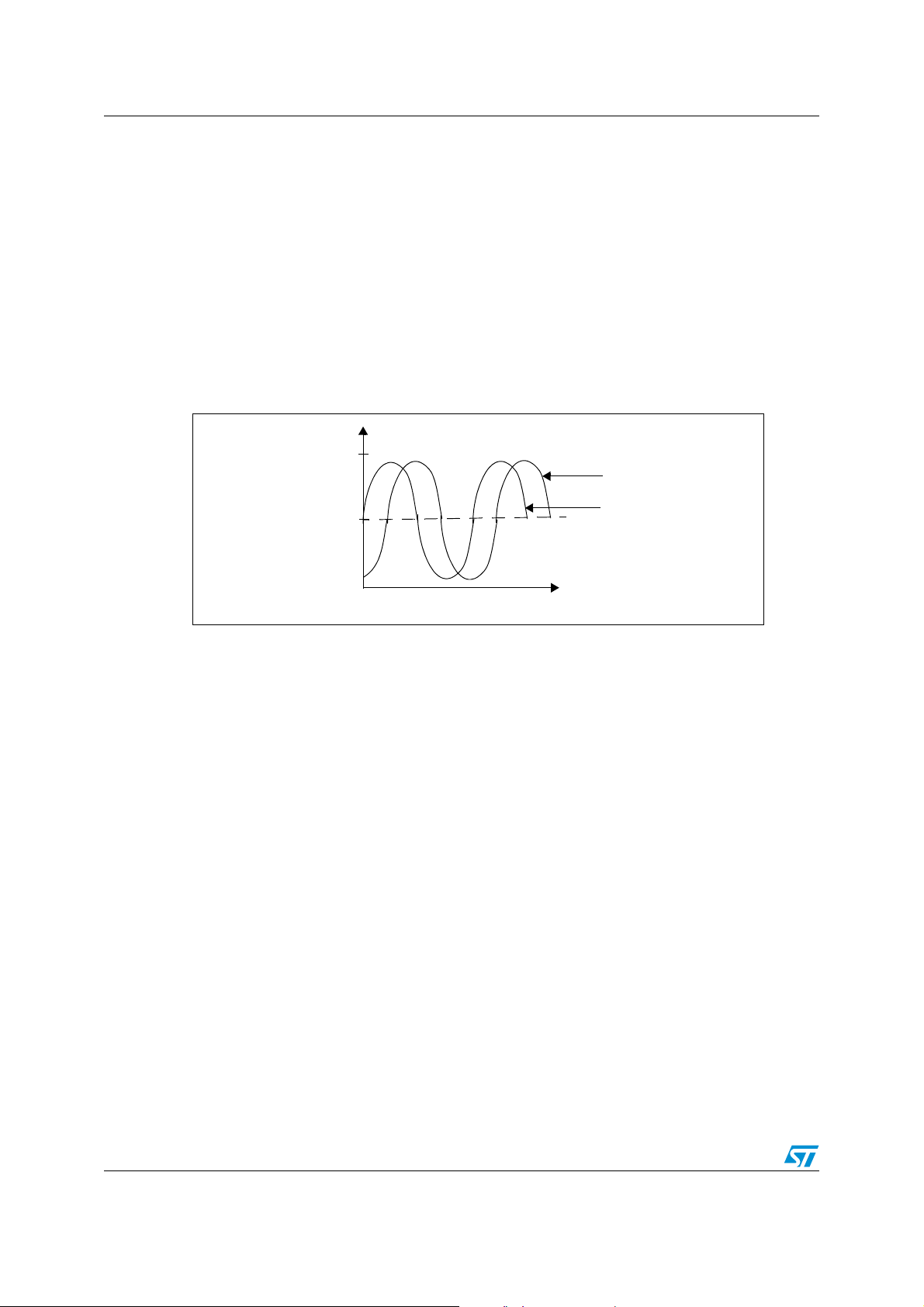

figure1.

Figure 1. AC input signals to ADC

V

Vdd

Voltage Waveform

Vdd/2

t

Current Waveform

Four ADC input channels are used, three for current and one for voltage measurement. One

of the current channels is multiplexed with two current gain factors x128 and x512. The

sampling rate for each channel is 5kHz. This higher rate of sampling is there to reduce the

quantization noise. The active energy consumed is calculated based on instantaneous value

of power. The sampling rate is 5kHz, so, with a 50Hz sinewave the number of samples per

cycle is 100. The sampling time is 200µs. After every 200µs, one current and voltage sample

is taken and multiplied to get an instantaneous power sample. The discrete summation of

these power samples over time gives the active energy.

When the phase difference between voltage and current is 0, the active power will be at the

maximum which is equal to total power, and the reactive power will be 0.

If v(t) = Vsin(ωt) and i(t) = Isin(ωt - φ), the instantaneous power:

VI 2⁄() φ()cos 2ωt φ–()cos–()=

Pt() vt() it()×=

After averaging, we get cos(2ωt - φ)=0 for a cycle of sinewave. So, the theoretical average

power (P) is VIcos(φ)/2. If ik and vk are respectively the instantaneous values of the current

and the voltage, the discrete formula of average power with regular, simultaneous, voltage

and current samples is:

N-1

1N⁄()vk ik×

=

P

d

∑

K=0

6/29

Page 7

AN2288 Theory

So, the average active energy over a time period with N samples is:

sampling

N-1

∑

K=0

vk ik×

Edt

=

There is delay (δ) between each voltage and current sample, due to this the real phase shift

angle (α) between v(t) and i(t) is different than theoretical phase shift angle (φ). So, there is

a discrete error (ε

):

d

P

P ε

+=

d

ε

d

=

VI×

-------------

2N×

d

N-1

K=0

∑

2α 2Kωt φ–+()cos

The average ε

will be 0. So, Ed = E.

d

There is also error due to non-simultaneous sampling, which is shift error (ε

The total active energy including not simultaneous sampling will be:

3.1 Analog front end

The ADC used in this application is only one 10-bit SAR ADC for current as well as voltage

sampling. The voltage is reduced by potential divider and lifted up by Vdd/2 (e.g. 2.5V) and

then given to one of the ADC channels of ST7Lite20 microcontroller to get the digital

converted value after every 200us. The Lite2 timer RTC2 interrupt is used to get 200us.

The current value is measured using a current transformer with a 1:5000 turn ratio and with

36 Ohm shunt resistance. The voltage induced across the current transformer is lifted up by

3V

/4 (e.g. 3.75V) to make the induced voltage unipolar (because the microcontroller

DD

works in one direction only). Two analog switches are used for tampering detection

phenomena. The output of both switches are connected, but the inputs are different, one

from phase line and the other one from neutral line. The output goes to gain multipliers e.g.

operational amplifiers. There are four gain multipliers implemented by three operation

amplifiers and with one analog switch. The gain factors are x2, x8, x32 and x128. The x32

and x128 are multiplexed using one op-amp and one analog switch. The output of the gain

multipliers goes to the ADC channels of the microcontroller. The active channel for current is

selected based on current range.

ε

P

P

E

ns

ns

ns

ns

VI×

-----------

δφ()sin

2

P εnsε

++=

P ε

+=

ns

E

ε

+=

d

∑

):

ns

N1–

δ

--- -

+=

∑

N

K0=

d

d

2α 2Kωt φ–+()cos

7/29

Page 8

Theory AN2288

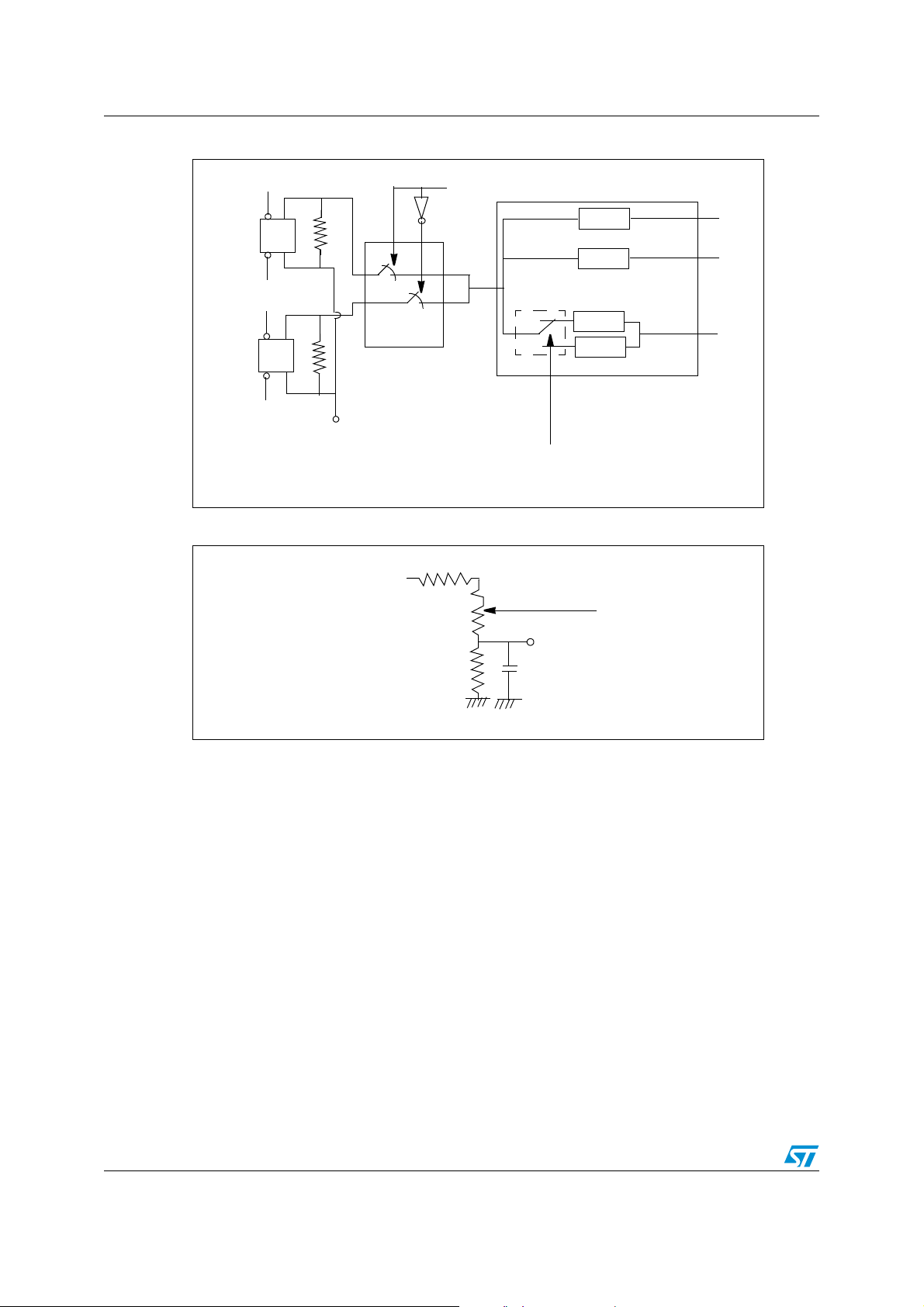

Figure 2. Analog Front End (AFE) for current

Phase In

Phase Out

Neutral In

Neutral Out

Current Transformer

36 Ohm

36 Ohm

analog switches

+3.75V

Control by MCU

Figure 3. Analog Front End for voltage

Phase

x2

x8

x32

x128

analog switch

Gain multipliers

Controlled by MCU

To MCU ADC

To MCU ADC

+3.75V

8/29

Page 9

AN2288 Meter hardware

4 Meter hardware

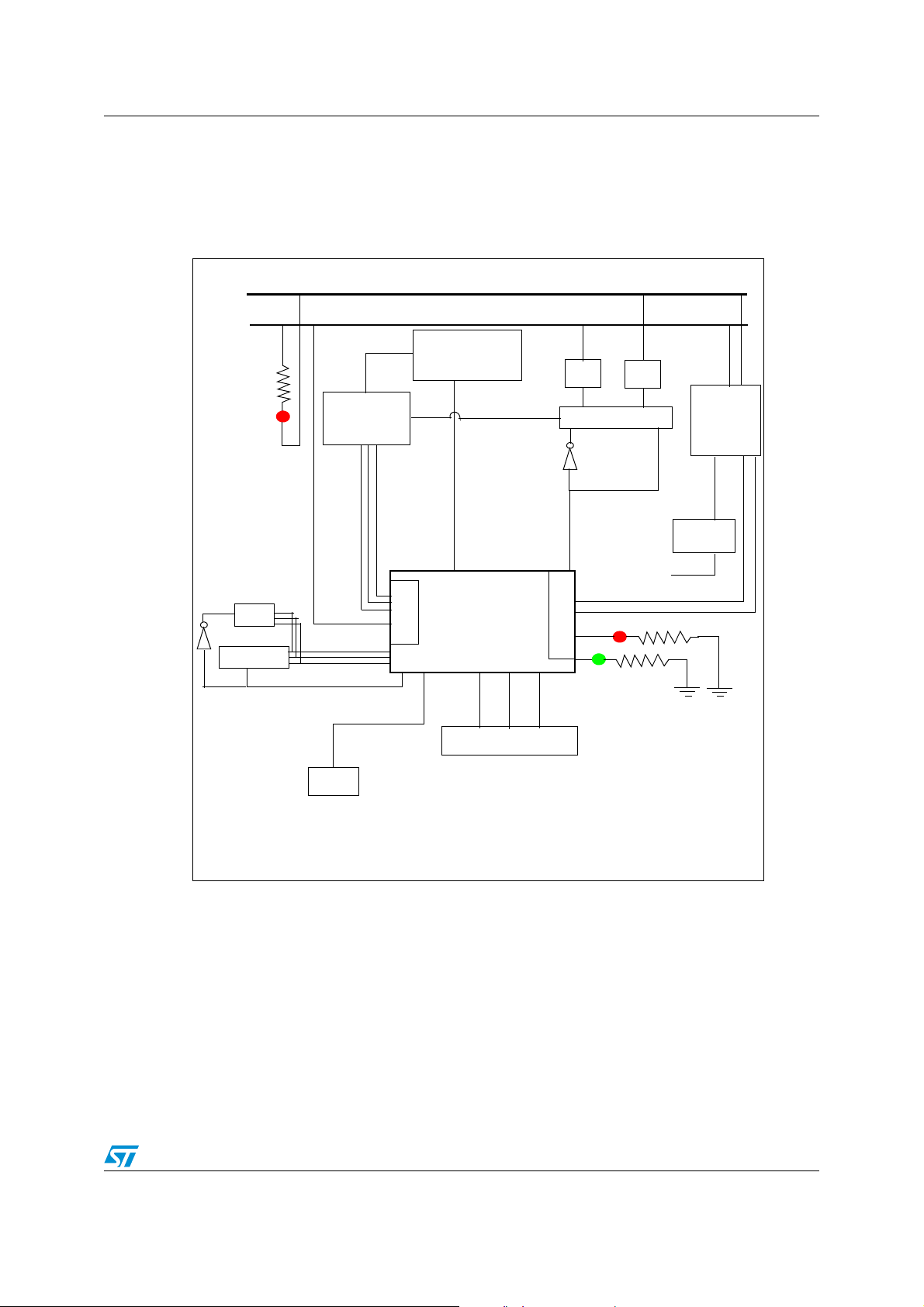

The block diagram of meter hardware is shown below:

Figure 4. Energy meter block diagram

Neutral line

Phase line

Power LED

RTC

EEPROM

EEPROM/RTC

Op-Amps for

gain x2, x8,

x32 & x128

Phase voltage

SPI

ICP

Analog switch for

gain factor b/w

x32 & X128

Control for

switching

between x32

& x\128

ST7FLITE20

ADC

control for switching

between CTs

LCD module

CT

Analog switches

Power supply

CT

Used for

reference

Tamper LED

Energy pulse

output LED

AC to DC

capacitive

power supply (5V)

3.75V

Voltage

follower

CT = Current Transformer

ICP = In-Circuit Programming

9/29

Page 10

Meter hardware AN2288

4.1 Main blocks

These are the main blocks in the Meter:

● 5V Power supply block

● 3.75V reference block

● Current Transformer block

● Voltage divider block

● Tamper detection block

● Gain switching block

● EEPROM block

● RTC block

● LCD Module

● In-Circuit Programming block

● Calibration through PC GUI

● Microcontroller block

4.1.1 5V power supply block

The 5V capacitive power supply is based on full-wave rectification. The positive half wave is

used to charge the capacitor and as well as negative half wave of sinewave is also used to

charge the capacitor in the same direction. The zener diode (ZD1) tells to which voltage the

C3 is charged. Voltage regulator U1 utilizes the energy stored in C3 to produce a stable

output voltage. Resistor R1 controls the charge and discharge of C1 and also limits the

current flow through zener diode ZD1. Two inductors (L1 and L2) are used to reduce the

noise in power supply.

Figure 5. Capacitive power supply

Phase line

L1

C4

Neutral line

L2

R1

R2

4.1.2 2.5V reference block

A potential divider is used to get a 3.75V reference. As some current (I2) flows towards the

voltage follower (refer to Figure 6), the current through R5 is higher than that through R6. If

R5=R6, there is a voltage drop of R5*I2 in the reference. This voltage drop is variable, which

depends on the current flow through reference I2. If I2 is negligible and constant, this

3.75Vref will be ~3.75 and constant. So, a voltage follower is used to get ~3.75V constant

reference.

C1

C2

D4

D1

D2

D3

R3

ZD1

C5

C3

5V

L7805

C6

10/29

Page 11

AN2288 Meter hardware

Figure 6. 2.5V reference circuit

5V

R5

R6

I1+I2

I2

3.75V - R5*I2

I1

4.1.3 Current transformer block

The current transformer used has a turn ratio of 1:5000 and ~350 Ohm resistance, the shunt

resistance used is 36 Ohms (refer fig. 2), so, the effective resistance will be:

R

shunt

After multiplication of secondary current with R

be:

V

V

is multiplied with gain stage to give actual value to input to microcontroller ADC. The

shunt

minimum multiplication factor is x2. The MAX current is chosen such that the operational

amplifier should not saturate. So, with x2 the max value of V

350 36×

---------------------- - 32.64E==

350 36+

55A

shunt

------------ -

5000

-

3.75Vref

× 359mV==

R

shunt

+

, the voltage V

shunt

AIN

is:

3.75V

for max current will

shunt

V

AIN

The peak to peak voltage is 2.03V. There is safe margin of ~0.47V for a gain factor of x2.

4.1.4 Voltage divider block

The voltage is reduced using a potentiometer and referenced at 3.75V.

Figure 7. Voltage divider circuit

Phase

Neutral line

R28

R29

R31

MAX()359m V 2× 2× 1.015V==

R30

C12

R26

Analog input to ADC

C20

2.5V

11/29

Page 12

Meter hardware AN2288

4.1.5 Tamper detection block

Two analog switches and one control pin with one fast switching transistor is used to detect

tampering.

Figure 8. Tamper detection circuit

5V

Control signal from MCU

Voltage out from phase CT

To gain multiplier

Voltage out from Neutral CT

analog switches

4.1.6 Gain switching block

Gain multipliers are used to get the large load range with Ib=10A and Imax=55A. In this

application, there are four gain multipliers x2, x8, x32 and x128. A particular gain factor is

actively used by the microcontroller, depending on the signal strength. For the lowest signal

strength x128 gain factor is used. The operational amplifiers are used in non-inverting

mode.

Gain 1

⎛⎞

=

⎝⎠

R

F

------ -+

R

1

where RF is negative feedback resistance

is resistance at inverting terminal of Op-amp

R

1

The exact gain factors are:

x2 1

x8 1

x32 1

x128 1

------------- -+

⎝⎠

470E

1.5K

⎛⎞

------------- -+

⎝⎠

220E

16K 51K

⎛⎞

-------------------------- -+

⎝⎠

51K

⎛⎞

------------- -+

⎝⎠

390E

||

390E

2==

7.818==

32.23==

131.77==

470E

⎛⎞

When the voltage after x2 multiplier decreases below ~2.03Vp-p/4(=~0.508V), the gain

factor will change to x8 or when the voltage after x8 multiplier increases after ~2.03V, the

gain factor will change to x2. There is some hysteresis also implemented for this. So, when

upper half of sinewave after x2 decreases below ~0.508V/2 (= ~0.254V), the active gain

12/29

Page 13

AN2288 Meter hardware

factor will change to x8 or when upper half of sinewave after x8 increases after 1.015V, the

active gain factor will change to x2. The Irms will be:

2Irms× R

----------------------------------------------------------------- - 0.253V=

5000

shunt

x2×()×

The same logic applies with the x8 voltage multiplier. Below ~0.508V, the gain factor

increases to x32. At this level, when the voltage increases higher than 2.03V, the gain factor

drops back to x8. The Irms can be calculated (using just the upper half of the sinewave):

Irms

13.7 7.818×

-------------------------------- - 3.32A==

32.23

The same logic applies with the x32 voltage multiplier. Below ~0.508V, the gain factor

increases to x128. At this level, when the voltage increases higher than 2.03V, the gain

factor drops back to x32. The Irms can be calculated (using just the upper half of the

sinewave):

Irms

3.32 32.23×

-------------------------------- - 0.81A==

131.77

13/29

Page 14

Meter hardware AN2288

Figure 9. Gain switching circuit

3.75V

R8

R9

From Analog switch

3.75V

R7

R14

3.75V

From Analog switch

-

+

-

+

R13

Analog input to ADC

x 2

R10

Analog input to ADC

x 8

Microcontroller

Controlled by MCU

R12

R11

-

x32 or

x128

From Analog switch

+

4.1.7 EEPROM block

After power up, the accumulated kWh data, tampering information and calibration

parameters are read by the microcontroller and stored in the form of RAM variables. When

the meter is tampered, the tampering information (meter is tampered and tampered

channel) will be stored in the EEPROM immediately. When power goes off, the accumulated

kWh data will be stored in the EEPROM.

14/29

Analog input to ADC

C39

Page 15

AN2288 Meter hardware

Figure 10. EEPROM circuit

4.1.8 RTC block

RTC block is used to show current date and time. When power goes down, RTC will be

entered in low power mode and then power will be given by rechargeable battery of 3.6V, so

that internal RTC registers gets updated according to the real time. When power goes up,

supply is given by Vcc and battery charging is started.

Figure 11. RTC circuit

3.6V

M95010

V

BAT

M41T94

NS

Q

C

D

NS

SDO

SCL

Selection of Chip

Selection of Chip

PA0

MISO

SCK

MOSI

Microcontroller

SPI

PA0

MISO

SCK

GND

4.1.9 LCD module

GDM093 module is used to display accumulated kWh, instantaneous rms voltage,

instantaneous rms current, instantaneous power factor and line frequency. This LCD module

uses HT1621 controller. This module has 18X4 segment.

SDI

MOSI

Microcontroller

SPI

15/29

Page 16

Meter hardware AN2288

Figure 12. LCD circuit

NCS

NWR

DATA

5V

PA3

PA2

PA1

Microcontroller

4.1.10 In-Circuit Programming block

By using In-Circuit Programming, the microcontroller can be programmed even when the

meter is installed and running. There are only five pins used from the 10-pin HE10 ICC

connector. One oscillator pin is also optional. In all, there are only four mandatory pins.

Figure 13. ICP connector

1

10-pin

HE120

5V

OSC

connector

9

10

2

ICCDATA

ICCCLK

RESET

16/29

Page 17

AN2288 Meter hardware

4.1.11 Calibration through PC GUI

Calibration of the meter and initialization of the RTC can be done using the PC GUI. To enter

calibration mode the user has to press switch S1 within 30 seconds of power-on of the

meter.

Figure 14. Calibration mode

PA2

S1

4.1.12 Microcontroller block

The microcontroller is the heart of the energy meter, it does all the calculations and

measurements. Only a 20-pin package is used. Refer to Figure 4 for more details.

17/29

Page 18

Software routines AN2288

5 Software routines

This section of the application note describe each function contained in the firmware. A

general description and flow diagram are provided for each routine.

5.1 Initialization routine

The two routines are used for initialization. The ASM_init routine is used to initialize the

global variables, which is done using the _stext routine, the auto startup routine. After this

routine the init routine is called which initializes different bool variables, portA register, ADC

bits and SPI.

Figure 15. Initialization routine

Init routine

Initialize 18-bool variables;

Initialize portA;

Call a delay routine to wait for 5V supply to reach to 5V;

Initialize ADC: Amp not selected, calibration OFF, slow bit = 0

Initialize SPI: software slave is used, SPI freq = Fcpu/4, SPI inter-

rupt enabled, read from memory array

5.2 Main routine

The main routine is called after ASM_init (_stext), which called different functions.

ASM_init

Initialize global variables

18/29

Page 19

AN2288 Software routines

Figure 16. Main routine

ASM_init ( )

main

init ( )

PA2 port configured for

calibration mode detection

Enable interrupts

Initialize LCD module

Referesh LCD to make

all segments null

Display kWh, Vrms, Irms, power

factor, line frequency, Current

Date and Time in rolling manner

Anti tampering detection algorithm

to detect whether phase or neutral

line tampering is done or not

Update kWh energy variable to update kWh based on pulses

Gain switching is done based on

current magnitude

19/29

Page 20

Software routines AN2288

5.3 Lite timer time base2 interrupt routine

This routine is the heart of the MCU, which is generated after every 200µs. This means with

a 50Hz sinewave the number of samples per cycle is 100. In this interrupt routine, the

voltage and current samples are taken by changing the active channel for ADC. One current

sample is taken in between the two voltage sample. The two voltage samples are taken to

minimize the error due to a shift in sampling time for voltage and current sample.

Multiplication and accumulation of V*I is done separately for each current gain.

Figure 17. Lite timer interrupt routine

LT_TB2_IT_Routine

no

Is AVDF flag=0 &

AVD_INTERRUPT =

Disabled?

yes

Enable AVD interrupt

Clear TimeBase2

interrupt Flag

EnableInterrupts

Read first Voltage Sample

Read Curent Sample

Read Second Voltage Sample

Average V1 and V2

A

20/29

Page 21

AN2288 Software routines

Figure 18. Lite timer interrupt routine (Cont’d)

A

Find out current peak,

voltage peak, frequency

and power factor

tampering detection by checking at

both phase and neutral current chan-

nel for 6 times after every 500ms

INS_POWER = V * I

TOTAL_POWER [GAIN] +/-=

INS_POWER

Pulse output according to

3200imp/kWh

no

count = 1

Gain_switching++

Data sent to PC GUI as request-

ed for different gain factor

Is count < 100 ?

end

yes

count++

21/29

Page 22

Software routines AN2288

5.4 SPI interrupt routine

This routine is called just after power up of the application. This routine is used to initialize

the EEPROM if the meter is used for the first time or to get the previous accumulated kWh

and tampering information. The one pulse comparison factors and display constants are

also received from EEPROM.

Figure 19. SPI interrupt routine

SPI_IT_Routine_INIT

Disable SPI interrupt

Clears SPI interrupt flag

Read first byte from EEPROM

from address 0x00

temp = Read byte from EEPROM

Read stored calibration fac-

tors and display factors

no

temp!=init_EEPROM

Write new values of different calibra-

tion factors and display factors

Set the Lite timer timebase2 for 200us

interrupt and enable interrupt, ADC on

Is

[0]?

yes

end

22/29

Page 23

AN2288 Software routines

5.5 AVD interrupt routine

This routine is used to store accumulated kWh and tampering information to EEPROM

during power down.

Figure 20. AVD Interrupt power down routine

AVD_Interrupt_Power_Down

Disable AVD interrupt

Write 4-bytes of kWh and

one byte of tampering infor-

mation to EEPROM

end

5.6 External interrupt routine

If the user wants to enter PC calibration mode, he should press the switch within ~30Sec of

start of the application. Application will enter into external interrupt routine by pressing the

external switch. Now external interrupt routine will wait for interrupt coming from PC GUI.

Figure 21. External interrupt routine

External Interrupt

Disable AVD interrupt

Wait for input capture inter-

rupt which is coming from

PC GUI

end

5.7 ART timer input capture interrupt routine

In this application, SCI is simulated using the 12-bit ART TImer. Different commands are

received by software SCI, and a response is sent back to the PC GUI using the ART timer

overflow interrupt.

23/29

Page 24

Results AN2288

6 Results

This section shows the results obtained for the reference design. These results were

obtained at a test house using recognized MTE test equipment. There are three types of

tests performed:

1. Load tests: Voltage and frequency of AC Source is constant, but the load current

varies. These tests are performed for resistive load (unity power factor), 0.5Lag and

0.8Lead.

2. Voltage tests: Frequency of AC source and load current (basic current) is constant, but

the voltage is changed from minimum (140V) to maximum (280V). This test is

performed at UPF, 0.5Lag, 0.8Lag and at 0.8Lead.

3. Frequency tests: Voltage and load current (basic current) is constant, but the

frequency of AC Source is changed from 48Hz to 52Hz. This test is performed at UPF,

0.5Lag, 0.8Lag and at 0.8Lead.

6.1 Load tests

The voltage is 234.5V and the frequency of AC source is 50Hz. Below is the table for the

accuracy Vs. load current.

Table 1. Load current Vs% error

Load current Vs% Error

Load Current [A] UPF (%Error) 0.5 LAG (%Error) 0.8 LEAD (%Error)

53 (5.3Ib) -0.71 -0.58 -0.68

50 (5Ib) -0.34 0.08 -0.55

14 (1.4Ib) -0.22 0.06 -0.54

13 (1.3Ib) -0.14 0.09 -0.42

4 (0.4Ib) -0.11 0.11 -0.41

3 (0.3Ib) -0.04 0.23 -0.28

1 (0.1Ib) -0.24 0.54 -0.35

0.8 (0.08Ib) -0.09 0.62 -0.19

0.5 (0.05Ib) -0.11 -0.74 0.4

0.2 (0.02Ib) 0.19 -0.39 0.79

The % error is within the +-1% error for the range 0.05 Ib < I < 5.5Ib, as required for a class1

meter. Here Imax is 5.5In. The startup current is ~11mA, which is ~0.02% of Imax.

24/29

Page 25

AN2288 Results

6.2 Voltage tests

This test is performed at UPF, 0.5Lag, 0.8Lag and at 0.8Lead. Below is the table for the

accuracy Vs. voltage variation.

Table 2. Voltage vs% error

Voltage Vs% Error

Voltage [V] UPF (%Error) 0.5LAG (%Error) 0.8LAG (%Error)

140 -0.68 -0.35 -0.15 -0.99

280 -0.68 0.0 -0.6 -0.68

6.3 Frequency tests

This test is performed at UPF, 0.5Lag, 0.8Lag and at 0.8Lead.

Table 3. Frequency Vs% Error

Frequency [Hz] UPF (%Error) 0.5LAG (%Error) 0.8LAG (%Error)

48 0.2 0.5 0.48 -0.39

52 0.15 0.2 0.09 -0.23

0.8LEAD

(%Error)

Frequency Vs% Error

0.8LEAD

(%Error)

25/29

Page 26

Conclusions AN2288

7 Conclusions

This electricity meter solution demonstrates that a modular low cost, single chip, digital

energy meter can be implemented with the ST7FLITE20 microcontroller, which is 20-pin

device and has a minimum set of mainly discrete external components. The on-chip 10-bit

ADC with external gain circuits is used instead of a dedicated external measurement IC, to

perform all the voltage, current and energy measurements. The error in measured energy is

within the IEC61036 standard.

The ST7FLITE20 MCU provides a very cost effective solution for a power meter, as it

enables the removal of the dedicated energy measurement device and has a large set of on

chip peripherals like LVD/AVD, Lite Timer, SPI, 10-bit ADC. The other ICs used are L7805

(positive voltage regulator), BC547 (NPN silicon transistor), PN2222A (NPN high speed

switching transistor), TS1854 (Quad rail-to-rail low power operational amplifiers), M95010

(1Kbit serial SPI bus EEPROM) and M41T94 (RTC).

The internal EEPROM of ST7FLITE20 microcontroller can also be used by changing the

sales type of the microcontroller and with some minute firmware changes.

The modular design approach enables the hardware and software to be reused and thus

speed up the design cycle for a power meter development. The schematics, Bill of Materials,

gerber files and software are all available at the ST website.

26/29

Page 27

AN2288 Calibration coefficients

8 Calibration coefficients

There are nine calibration coefficients in all. There are four current offset calibration

parameters, one voltage offset calibration parameter, four one pulse comparison constants

for all the four current gain factors.

27/29

Page 28

Revision history AN2288

9 Revision history

Table 4. Document revision history

Date Revision Changes

23-May-2006 1 Initial release.

28/29

Page 29

AN2288

r

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the right to make changes, corrections,

modifications or improvements, to this document, and the products and services described herein at any time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no liability whatsoever relating to the

choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this document refers to any third party

products or services it shall not be deemed a license grant by ST for the use of such third party products or services, or any intellectual property contained therein or consi dered

as a warranty covering the use in any manner whatsoever of such third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED WARRANTY WITH RESPECT TO THE

USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR

PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL

PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZE REPRESENTATIVE OF ST, ST PRODUCTS ARE NOT DESIGNED, AUTHORIZED OR WARRANTED

FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS, WHERE FAILURE OR

MALFUNCTION MAY RESULT IN PERSONAL INJURY, DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void any warranty granted by ST fo

the ST product or service described herein and shall not create or extend in any manner whatsoever, any liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2006 STMicroelectronics - All rights reserved

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan - Malaysia - Malta - Morocco - Singapore

- Spain - Sweden - Switzerland - United Kingdom - United States of America

STMicroelectronics group of companies

www.st.com

29/29

Loading...

Loading...