Page 1

AN2267

Application note

Implementation of current regulator for BLDC

motor control with ST7FMC

Introduction

A conventional method of controlling BLDC motors is to implement an inner current loop for

torque / current control. Reference to this inner loop is provided either by an outer speed

loop or by some other means based on application requirement. The linearity of inner

current / torque loop is greatly affected by the faithfulness of current feedback. In the first

section, an outline to various approaches for obtaining current feedback is presented and

analyzed with the limitations of each. In the subsequent sections, a presentation is given of

a simple, linear and cost effective approach of implementing the inner current loop by

sampling the DC link current at the mid-point of PWM “on time” with ST7FMC. Experimental

results are also discussed.

An accompanying software file is available with this application note and can be downloaded

from www.st.com/mcu

June 2006 Rev 1 1/19

www.st.com

Page 2

Contents AN2267

Contents

1 Outline to various approaches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2 Obtaining the average current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3 BLDC motor control using ST7FMC . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

4 Implementation using ST7FMC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

5 Results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

6 Conclusion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

7 References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Appendix A Sampling inner current loop procedure . . . . . . . . . . . . . . . . . . . . . 14

Appendix B Event U interrupt service routine . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Appendix C ST7MC 3-phase motor control schematics . . . . . . . . . . . . . . . . . . . 16

2/19

Page 3

AN2267 Outline to various approaches

1 Outline to various approaches

A BLDC motor driven in a conventional 6-step method greatly resembles a brushed DC

motor. Hence, one may choose to regulate the average DC link current. But this actually

results in constant power operation for the motor because at constant DC link voltage, if the

average link current is regulated at a certain value, it effectively regulates the power at that

point for any variation in motor load, and the average load current / motor torque varies

inversely with speed depending on the load. Any effort to compensate the average DC link

current data with the duty cycle to obtain average phase current will be impaired by a filter

time constant, rendering this option ineffective.

Since the DC link current does not reveal winding currents during PWM “off time”, one may

choose to monitor all 3 winding currents and build a regulator. But this requires two current

sensors to monitor any two phase currents, while the third phase current can be

reconstructed from these two. However, the cost of these sensors makes this option

expensive.

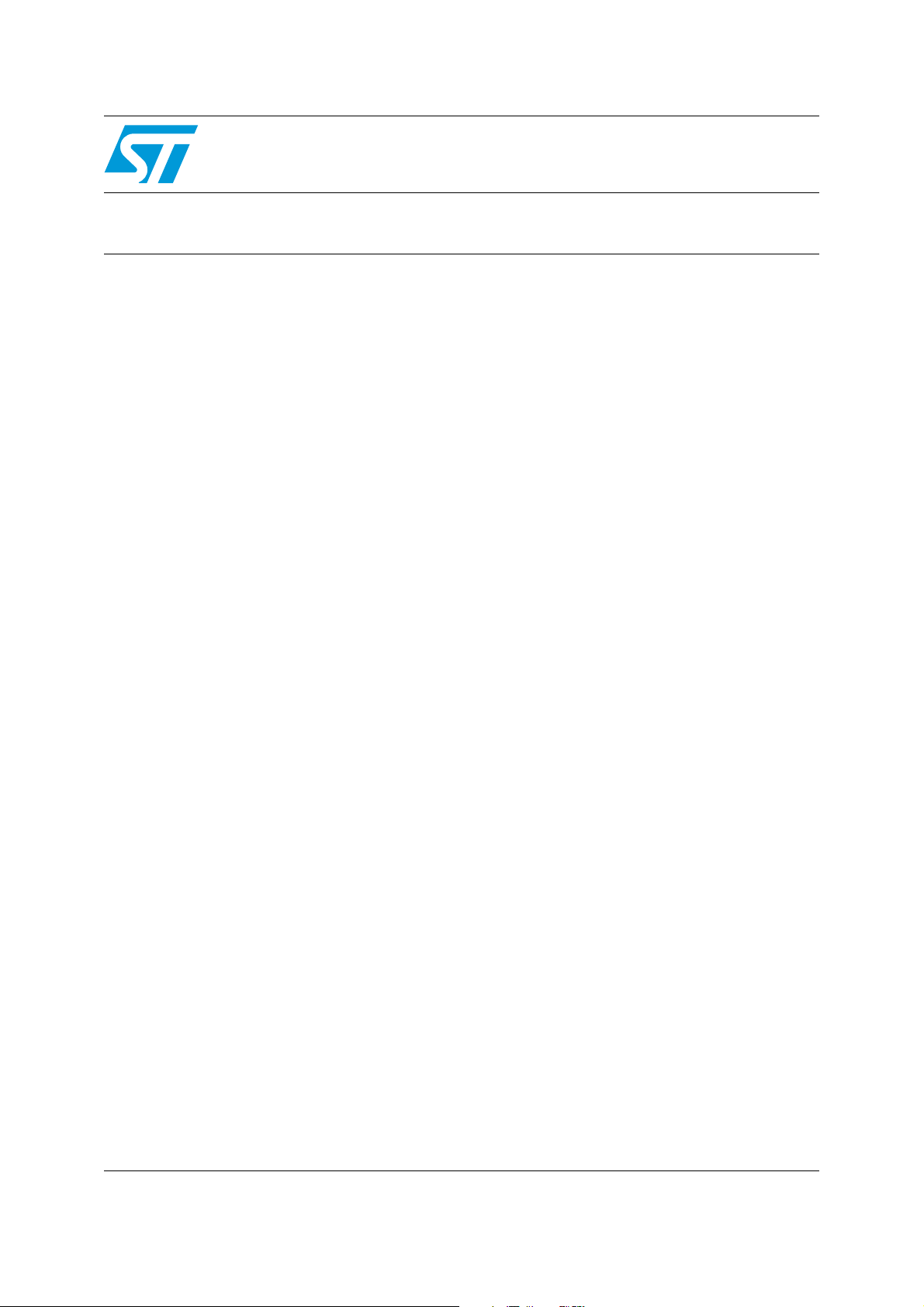

A third option would then be to regulate the peak current per PWM period. Though it is

inexpensive and easy to implement, it is not exactly linear. During PWM on time, at lower

duty cycles, when both speed and BEMF are small, the phase current rises much faster

than at higher duty cycles when the speed and BEMF are large. The same peak currents

per PWM period represent different average currents at different duty cycles. An intuitive

geometric approach will reveal this as shown in Figure 1. A typical variation in average

current vs duty cycle at a given peak current reference is shown in Figure 2.

Figure 1. Peak current regulation at different duty cycles with BEMF load

I

phase

I

peak

I

phase

I

peak

tt

Figure 2. I

vs duty cycle at a given I

ave

I

ave

I

peak

peak

dutycycle

00.51.0

3/19

Page 4

Obtaining the average current AN2267

2 Obtaining the average current

For linear torque control, it is important that we sample the average phase current as

feedback to the current regulator. It is best to get this information from the DC link current

using only a shunt resistor because of its low cost and simplicity. However, the DC link

current is not continuous and is present only during PWM on time. As a simple model for

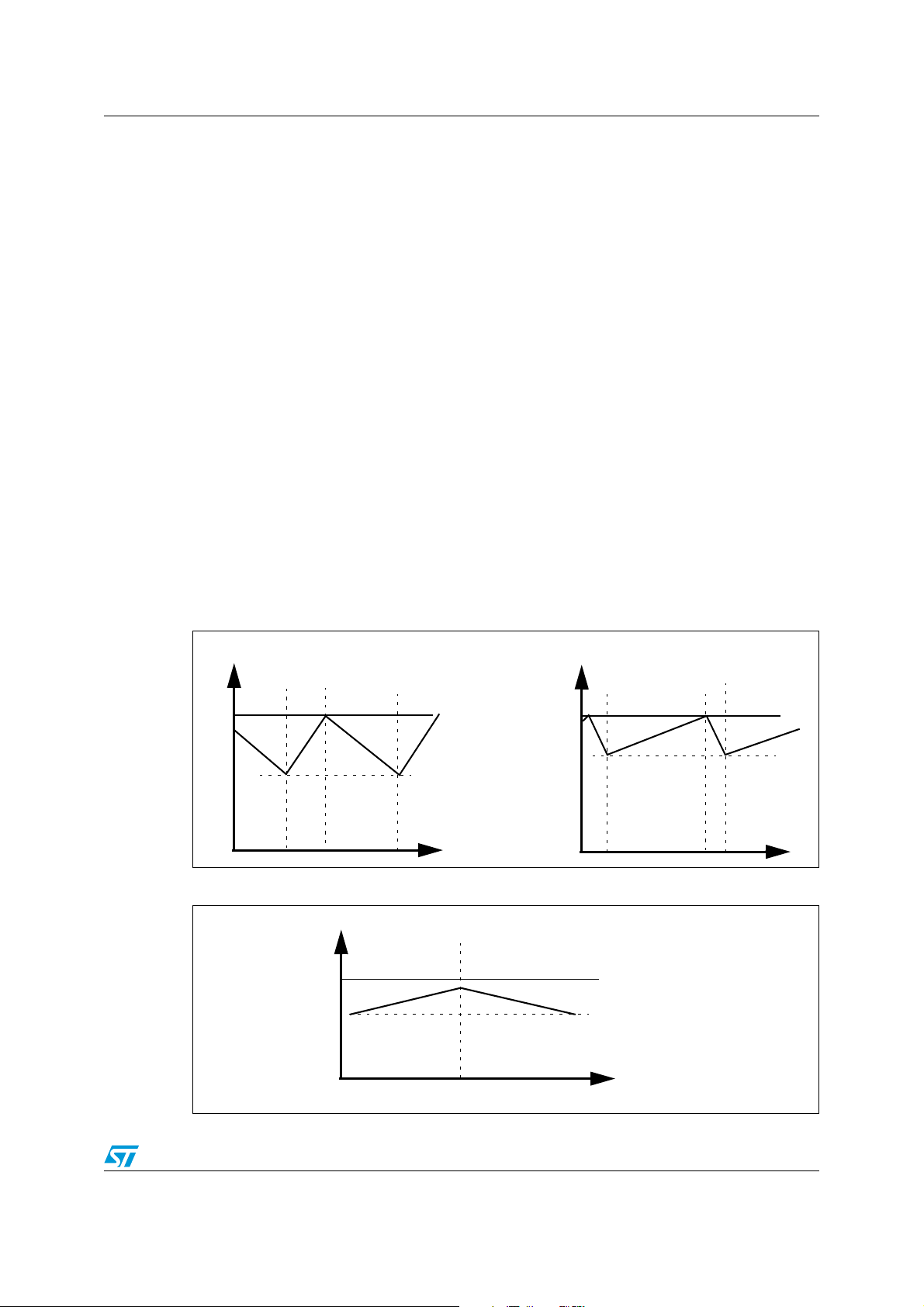

current control, assume a simple buck converter feeding an RL load as shown in Figure 3.

Figure 3. Buck converter feeding an RL load

PWM

CONTROL

SW1

1

BT1

2

R1

D1

V

L

R

sh

I

sh

I

L

L1

The switching frequency, PWM on time and load inductance are such that the load current is

continuous. Figure 4 shows the load voltage, load current and DC link current waveforms. A

close look at the load current waveform reveals that its average value is equal to its

instantaneous value during the middle of PWM on time or off time. Since the load current

flows through the DC link during PWM on time, sampling the DC link current during the

middle of PWM on time gives the average load current.

Figure 4. Buck Converter - Waveforms

V

I

L

I

L(ave

I

S

4/19

T

o

T

off

Page 5

AN2267 BLDC motor control using ST7FMC

(

g

C

g

d

3 BLDC motor control using ST7FMC

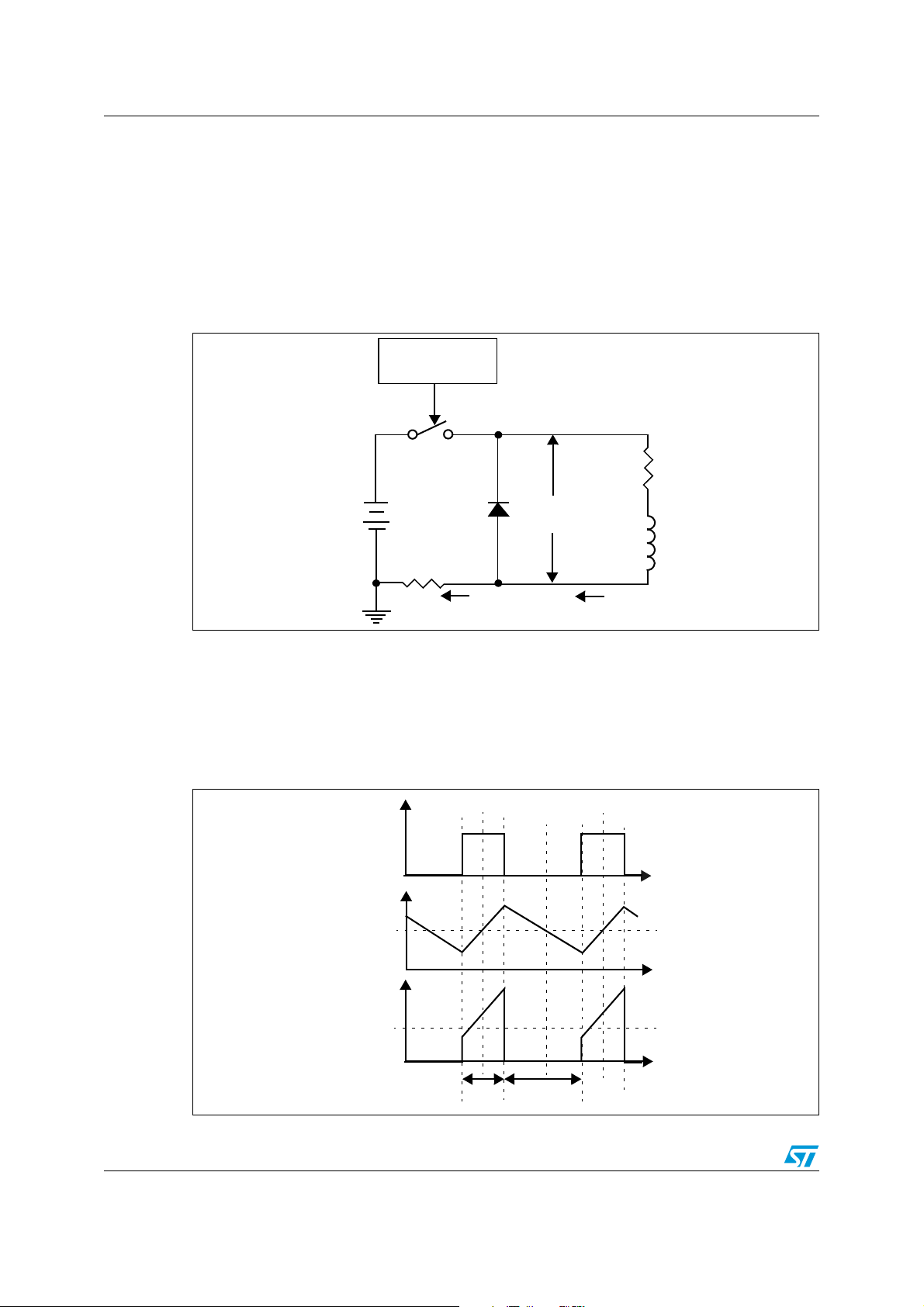

The main feature of ST7FMC is its powerful motor control macro cell, capable of generating

control signals to drive a sensorless or sensored 3 phase BLDC or AC motor.

STMicroelectronics application notes AN1946 [1] and AN2030 [2] explain, in detail, the

procedure to control a 3 phase BLDC motor using ST7FMC.

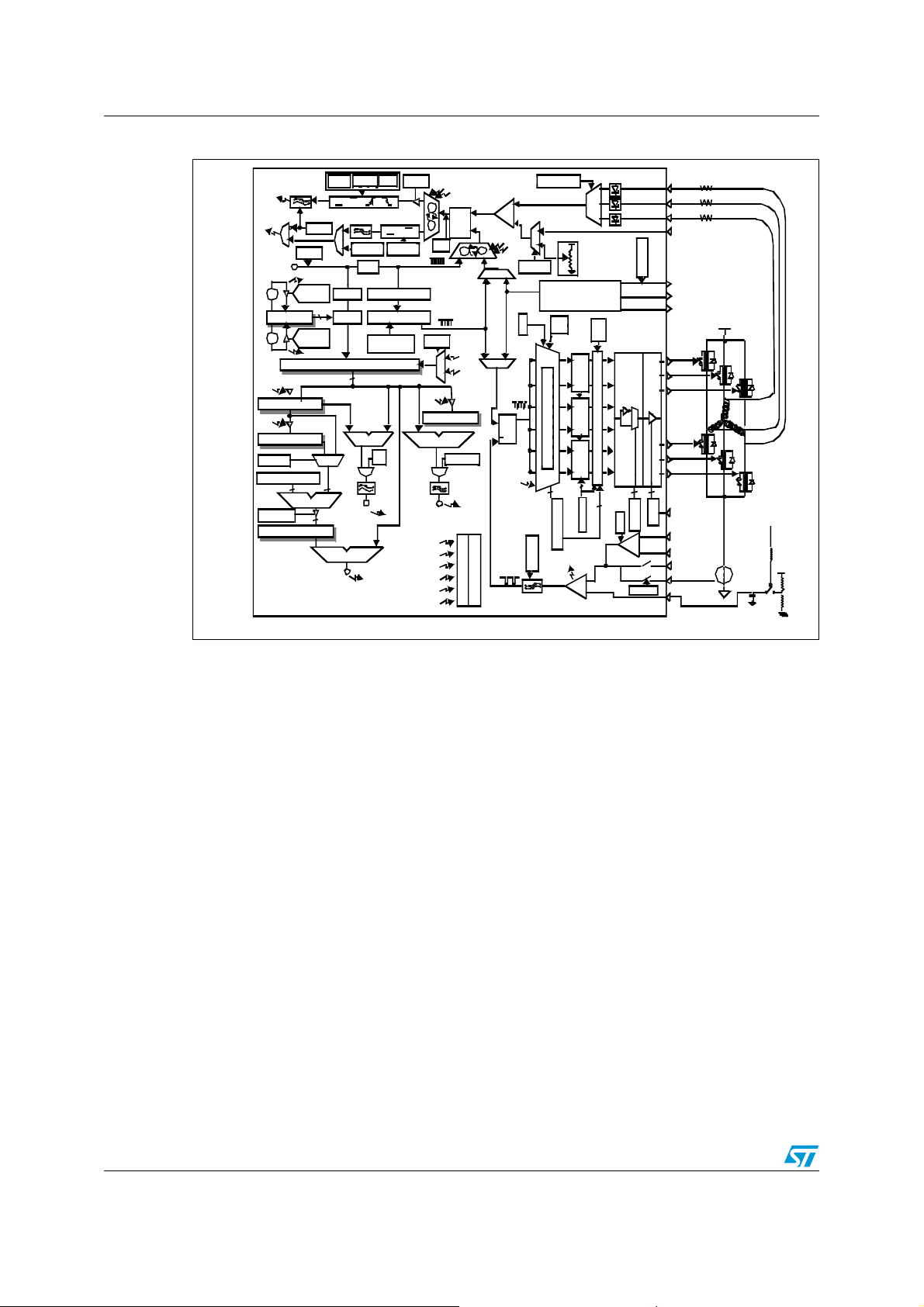

Figure 5 shows the simplified block diagram of the hardware motor control macro cell. The

macrocell has multiple timers performing various functions in parallel to generate control

pulses for the motor. An auto scalable 8-bit timer (MTIM) monitors the time difference

between successive phase back EMF zero crossings (Z events) of the motor. When a Z

event occurs, the timer value is captured into MZREG and the timer restarts counting from

zero, and, the previous content of MZREG is transferred to MZPRV. This timer is a part of

what is called DELAY MANAGER that, based on this time difference and a delay coefficient

(MWGHT), identifies the timing for next phase commutation instant (C events). All in

parallel, a 12-bit free running counter generates the PWM carrier for inverter switching.

Figure 5. Simplified block diagram of Motor control Macro cell for BLDC motors

or SPEED MEASURE UNIT (not

WEIGH

DELAY = WEIGHT x

MEASUREMENT

WINDOW

GENERATOR

PWM

12-bit

Phase

Phase V

Phase W

[Z] : Back EMF Zero-crossin

: Time elapsed between two consecutive Z

Z

n

[C] : Commutation

: Time delayed after Z event to generate C

n

(I): Current

e

(V): Volta

DELAY

(I

CAPTURE

(V

Phase

CURRENT

VOLTAGE

MOD

(V

MTI

TIME

=

COMMUTE

PCN

BEMF ZERO-CROSSING

BEMF=

[Z

TACH

Encoder

INPUT DETECTION

P

H

A

U, V,

Phase

CFAV

CHANNEL

12-bit THREE-PHASE

PWM GENERATOR

Vre

OAON

MCI

MCI

MCI

Ex

In

+

-

AD

MCO

MCO

MCO

MCO

MCO

MCO

NMCE

MCAO

MCAO

MCCRE

C

MCPWM

MCPWM

MCPWM

MCVRE

MCAOZ/

MCCFI

(V

Vd

I

R

3

5/19

Page 6

BLDC motor control using ST7FMC AN2267

Figure 6. Motor Control Macro cell - BLDC motor control configuration

HV

C

C

ext

Board + Motor

MCPWMU / V/ W

V

DD

(I)

R

(V)

R

1ext

2ext

Microcontroll er

Z

H

D

H

Fcpu

+1

ST3-0 bits

-1

Z

H

MZREG Reg [ Zn]

Z

S,H

MZP RV Reg [Z

DCB bit

MWGHT R eg [a

SWA bi t

MCOMP Reg [C

EF[2: 0]

Filte r / D

SR bit

X T16 bi t

+

R

MTIM

= FFh?

MZREG

< 55h?

-

R

MTIM [8-bit Up Counter]

]

n-1

]

n+1

A x B / 256

n+1

+

-

S,H

D

S,H

D

V

REF

VR2- 0

SR b it

S,H

Filt er / PWM

Reg

MPHST

CFF[2:0] bit

ISn bit

12- bit P WM ge nera tor

n

bits

OS

MREF

3

n

6 6

Reg

Ch0Ch1Ch2Ch3Ch4

Dead

Time

Dead

Time

High Frequency Chopper

Dead

Time

Ch5

8

2

6

PCN bi t =0

DTG register

MPAR Reg

+

CL

-

x6 x6

AO bit

+

-

CFA V bi t

MCIA

MCIB

MCIC

MCVREF

MPWME Reg

MCPWMU

MCPWMV

MCPWMW

MCO0

MCO2

MCO4

MCO1

MCO3

MCO5

1

NM CE S

MOE bi t

MPOL Reg

MCAOP

MCAON

MCAOZ

MCCFI

MCCREF

B

A

A

CP Bn bit

1 / 2

1 / 2

nn-1

88

Compare

EF[2:0]

Filter / C

Rat i o

ck

C

HDMn bit

1 / 4

8

Compare

S,H

ororor

SA3- 0 &

OT1-0 bits

SZn

bit

Z

S

PZ bit

1 ¾ 1/128

Filter / C

EF[2 :0]

or

CP Bn bit

1 /20

REO bi t

cl r

D

S,H

C

2

1

SPLG

SWA bi t

1

0

D

H

MDREG Reg [ Dn]

Com p a re

SDMn bit

EF[2:0 ]

F ilter / C

CL

-/+

R

E

Z

S,H

D

S,H

C

S,H

S,H

DQ

CP

C

2

1

V

I

Com p ar e U

Z

V

I

C

H

SQ

R

D

S

MISR R eg

MI MR Reg

ZVD bit

4

8

]

A PWM output is generated as a result of comparison between this carrier and a compare

register (MCPUH:MCPUL) that carries pulse width (duty cycle) information. This PWM

signal is directed to one of the six inverter switches by a CHANNEL MANAGER that acts as

a traffic diverter on the PWM output. The channel manager also selects a complementary

switch, as programmed by the user, which together with the switch receiving PWM will force

current into the motor windings. Based on the motor terminal voltages or Hall sensor

outputs, an analog block identifies the motor phase BEMF Z events and captures the

contents of MTIM timer into MZREG and the previous value of MZREG into MZPRV and this

cycle repeats all over again.

6/19

Page 7

AN2267 Implementation using ST7FMC

4 Implementation using ST7FMC

A typical schematic block diagram of ST7FMC based sensorless control of BLDC motor [2]

is shown in Figure 7. Refer to Appendix C on page 16 for a complete schematic of the

experimental hardware. This schematic resembles the motor control starter kit schematic

from Softec Microsystems, with matching I/O assignments wherever possible.

Figure 7. Schematic block diagram of ST7FMC based sensorless control of BLDC

motor

V

V

CC

Speed Ref

AINy

MCO0

MCO1

MCO2

MCO3

MCO4

MCO5

Shut Down

dclink

BLDC

AINx

PE0

PE1

PE2

MCIA

MCIB

MCIC

V

CC

Max Current

ST7FMC

Limit

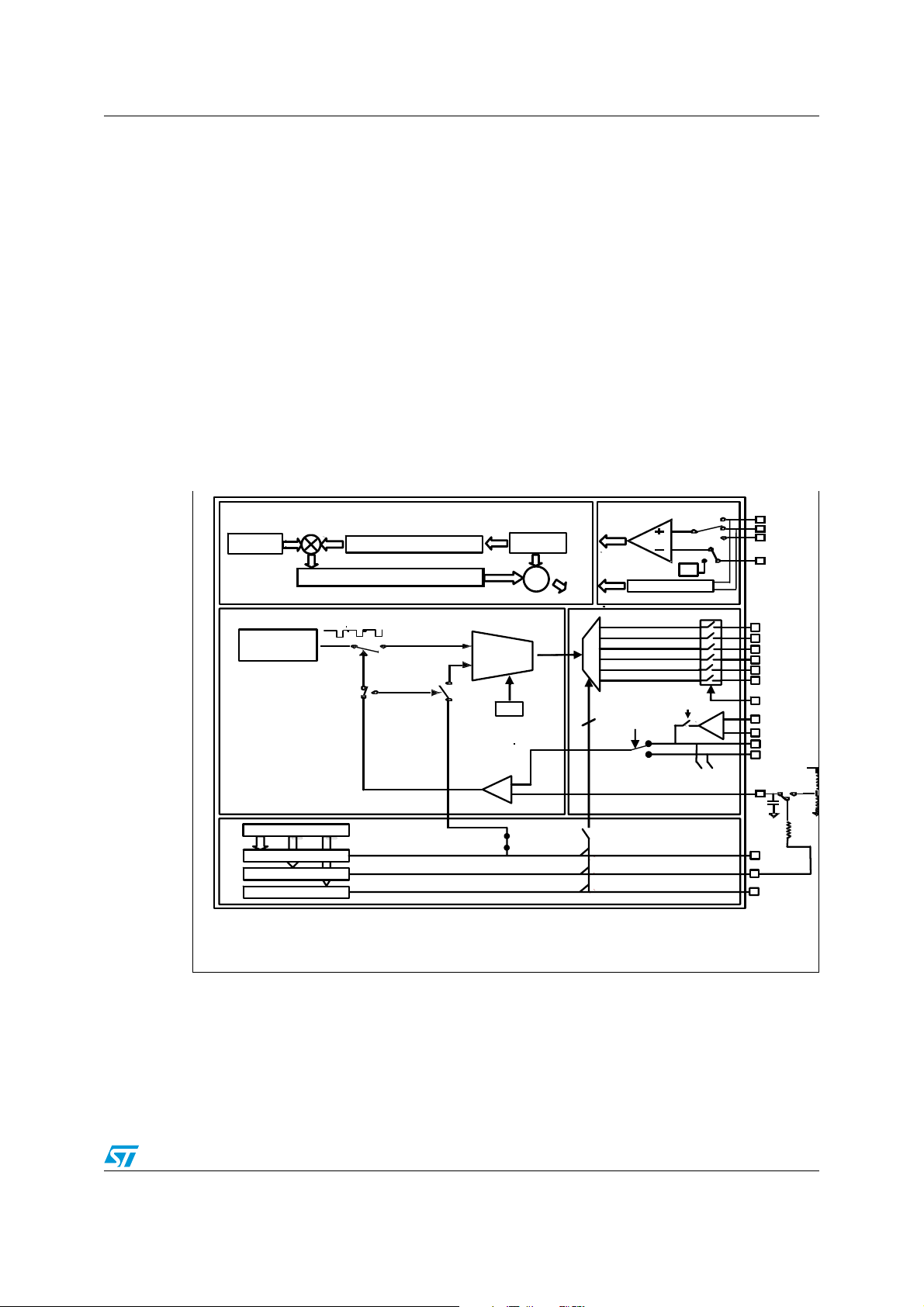

Figure 8a shows the PWM carrier configured in center aligned mode, where the counter

counts up to a maximum value (as defined by MCP0) and starts counting down to zero and

repeats this cycle again. (See Appendix A for information on setting the PWM frequency).

The PWM generator is set to generate a duty cycle update interrupt (U event) upon

completion of every N carrier cycles as specified by MREP register. (See Appendix A for

information on setting the periodicity of this interrupt). The timing of the U event or interrupt

is positioned as shown in Figure 8a. The carrier is compared with MCPU and PWM pulses

are generated as shown in Figure 8b. Due to the application of PWM voltage on motor

windings, a current flows in its windings as shown in Figure 8c.

7/19

Page 8

Implementation using ST7FMC AN2267

Figure 8. PWM on time midpoint identification and control

MCP0

U event

Carrier

U event

Ref

Fig 8a

t

Fig 8b

PWM

t

Fig 8c

Current

t

Fig 8d

U ISR

t

T

From Figure 8a and Figure 8b, it is clear that the U event takes place at the center of PWM

on time. Based on the previous discussions, this is the right instant to read the

instantaneous DC link current in order to get the average phase current value. Hence the

interrupt associated with U event should be set to the highest priority and the very first

instruction in this Interrupt Service Routine (ISR) should read the DC link current value. In

any case, there is an interrupt latency time of approximately 3-4µs, which is also the typical

conversion time of on-chip Analog to Digital Converter (ADC). If the current feedback analog

input channel was previously selected and set for sampling continuously, then, when the first

instruction in U event interrupt subroutine reads the ADC data register, it will aptly hold the

DC link current value fairly close to that during the middle of PWM on time.

8/19

Page 9

AN2267 Implementation using ST7FMC

Figure 9. Update (U) event interrupt subroutine flow chart

Start U

Read current feedback

Set U ISR priority lower if required

Read other Analog inputs

Current loop PI regulator

Dutycycle update

Set ADC Channel back to Sample current feedback

Restore ISR priority to the highest

End U

The flowchart in Figure 9 shows the actions within the U event interrupt service routine. To

coordinate the reading of any other analog inputs to the ADC, it is recommended that they

are all read within this U event subroutine after the DC link current read. However, before

returning from the interrupt, it is important to restore the ADC to sample the DC link current

channel again so that on re-entry in the next U event, the DC link current value can be read

from ADC right away. If required, interrupt priority of this routine can be lowered after

reading the current value upon entry, but should be restored to the highest value before

returning for obvious reasons.

Refer to the accompanying file for a complete listing of the code and experimental

workspace.

9/19

Page 10

Results AN2267

ω

ω

5 Results

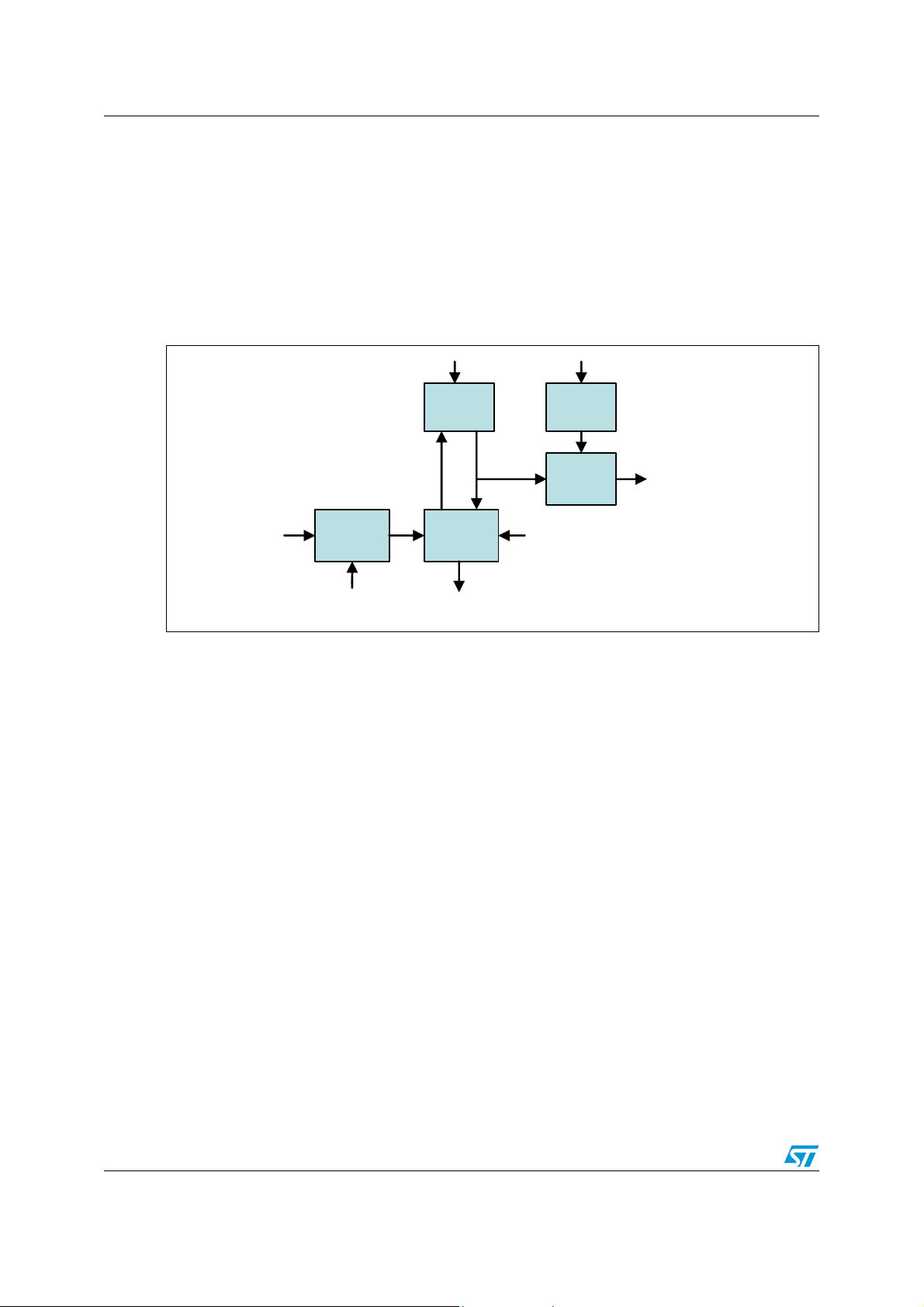

Experimental implementation of this scheme yielded satisfactory results. A closed loop

regulator for BLDC motor control with inner current and outer speed loops as shown in

Figure 10 was implemented. Current loop sampling time of 500µs and speed loop sampling

time of 2ms was chosen. The amount of computing time required within a 2ms time window

to execute through a full cycle of control loop and all motor control ISRs at an electrical

frequency of 200Hz is less than 1ms. The important waveforms obtained are shown in

figures 11 and 12. Figure 11 shows the convergence of reference and actual phase current

values at the instant of occurrence of U event which is the feedback sampling instant. Notice

that the U event occurs during the middle of PWM ON time. Figure 12 shows the tight

control of motor average phase current for a given current reference.

Figure 10. Closed loop current and speed control - block diagram

ST7FMC controller

PI reg

+

-

I*

+

-

Vdclink

PI reg

duty

BLDC

Speed

estimator

10/19

Page 11

AN2267 Results

Figure 11. DC link current sampling at U event and closed loop convergence

Figure 12. Tight control of average phase current vs reference

11/19

Page 12

Conclusion AN2267

6 Conclusion

The experiments performed based on the described method gave fairly linear current

control. One limitation of this sampling method is when the motor current becomes

discontinuous, in which case the actual average current is less than the instantaneous value

at the mid point of PWM on time, and correcting this error is quite cumbersome.

12/19

Page 13

AN2267 References

7 References

[1]. STMicroelectronics AN1946 - Sensorless BLDC motor control and BEMF sampling

methods with ST7MC

[2]. STMicroelectronics AN2030 - Back EMF detection during PWM on time by ST7MC

13/19

Page 14

Sampling inner current loop procedure AN2267

p

Appendix A Sampling inner current loop procedure

Procedure to set carrier frequency (Fpwm) and periodicity of U event (TU) for sampling inner

current loop:

Chosen F

where,

F

pwm

pwm

= F

= 16KHz

/ (Prescaler . 2 . MCP0)

mtc

F

mtc

Prescaler Up/ Down

MPCR

PCP[2:0]

Given F

and choosing Prescaler = 1,

then,

Choosing TU = 500µS

where,

= 16MHz,

mtc

MCP0 = 500

TU = Tpwm . (MREP + 1) / 2

UU

MCP0 MREP

counter

F

wm

Repeat

Counter

MPCR

CMS = 1

U

Substituting for TU and T

pwm

,

MREP = 15

14/19

Page 15

AN2267 Event U interrupt service routine

Appendix B Event U interrupt service routine

/***************************************************

Motor control - Event U interrupt service routine

***************************************************/

@interrupt @nosvf void mtcU_CL_SO_ISR(void)

{

if (bitTest_TRUE(MISR, PUI) ) // check for U event presence

{

/* === Current loop PI Controller begins here === */

currentFb = (ADCDRMSB << 2) + ADCDRLSB; // get new value of currentFb

piconCur(); // call current loop PI regulator

to get new dutycycle

MCPUL = PIconCur.byte.b2; // update MCPUH :MCPUL with new dutycycle

MCPUH = PIconCur.byte.b3;

/* === Current Loop PI controller ends here === */

// Read potentiometer to get latest speed reference

getADC_10bit (speedRef , SPEED_REF_CHNL);

if (speedRef > SPEED_REF_MAX)

speedRef = SPEED_REF_MAX;

// Current Feedback measurement setup for next cycle

ADCCSR = ADON + CURRENT_FDBK_CHNL;

ADCDRMSB; // to clear EOC of prev conv

MISR = 0xff - PUI; //reset IT flag

}

return;

}

15/19

Page 16

ST7MC 3-phase motor control schematics AN2267

Appendix C ST7MC 3-phase motor control schematics

Figure 13. Schematic 1 of 3

of

33Tuesday, January 03, 2006

33Tuesday, January 03, 2006

33Tuesday, January 03, 2006

1

C28

0.1uF

C28

SW DIP-2

SW DIP-2

R52

10K

R52

10K

TP1TP1

1

29

30

32

39

40

MCCREF / PC4

MCPWMV / PC6

PF1 / MCZEM / AIN9

PF0 / MCDEM / AIN8

AIN6 / MCCFI1 / OAZ

OSC15OSC2

6

Y1

16.00MHzY116.00MHz

Ceramic

resonator

PB2PB2

12

C360.1uF C360.1uF

12

R68

R68

470K

470K

+5V

0.1uF

SW6

SW6

+5V

5K

RV45KRV4

Idc1

VcVbVa

Vref

26

20

17

18

19

MCIB / PB2

MCIC / PB3

MCVREF / PB0

AIN5 / MCCFI0 / PC1

(HS) PC025ARTIC2 / PA615ARTCLK / (HS)PA4

13

60

SW1

SW4

SW2

SW3

+5V

2

1

P8P8

R80

10K

R80

10K

C470.1uF C470.1uF

CHBLSHUTDOWN

CL

(HS)MCO53(HS)MCO42(HS)MCO31(HS)MCO264(HS)MCO163(HS)MCO0

MCIA / PB1

AIN0 / PWM0 / PA3

AIN1 / ARTIC1 / PA5

PE5 /

12

14

Temprtr

C38

0.1uF

C38

0.1uF

Vdclink

RV3

RV1

RV2

12

R75

R75

100E

100E

C C

+5V

0.1uF

0.1uF

62

16

Idc

2

3

4

5

R54

10K

R54

10K

R64

R64

12

SIG20

SIG21

J3

ICC Interface

D D

R50

R50

10K

10K

12

10K

10K

R72

R72

CON10AJ3CON10A

1 2

U2

U2

J1J1

1 2

10K

10K

C32

C32

Vpp/

50

61

12

10K

10K

R73

R73

3 4

5 6

7 8

9 10

+5V

R51

R51

22pF

22pF

27

PD5/AIN15 / ICCDATA

49

51K

51K

28

OAP / PC2

OAN / PC3

PD4 / EXTCLK_A / AIN14 / ICCCLK

RESET

38

U4

+5V

AHBHAL

4

MCES

AIN2 / PA7

MISO / PB421AIN3 / MOSI / PB5

SIG5

SIG17

GREEN

GREEN

R60

R60

0.1uF

0.1uF

RV3 5KRV3 5K

0.1uF

0.1uF

RV2 5KRV2 5K

0.1uF

0.1uF

RV1 5KRV1 5K

C41

C41

P5

30V

30V

D33

D33

43

NEC2501U4NEC2501

12

R69

200E

R69

200E

RV3

SIG19

+5V

33

52

51

31

PD6(HS) / RDI

PD7(HS) / TDO

MCPWMU / PC5

PC7 / MCPWMW / AIN7

SCK / (HS) PB623AIN4 / SS/(HS)PB7

Vdd_254Vss_253Vss_1

VAREF

22

34

24

+5V

SIG7

SIG6

D26

RED

D26

RED

D27

D27

470E

470E

R61

680E

R61

680E

C44

C44

C43

C43

C42

C42

594837261

D32D32

R57

R57

1K5

1K5

R58

R58

1K5

1K5

D28D28

12

U3

43

R59

R59

2K2

2K2

C34

C34

680pF

680pF

Vdd_18Vdd_037Vss_036Vss_A

7

35

R83

20K

R83

20K

12

R81

20K

R81

20K

12

+5V

R82

20K

R82

20K

12

R74

20K

R74

20K

12

DB9P5DB9

D29D29

8K2

8K2

R62

R62

8K2

8K2

R63

R63

NEC2501U3NEC2501

st72mc_qfp64

st72mc_qfp64

PE0(HS) / OCMP2_B

55

PE1 / OCMP1_B

56

PE2 / ICAP2_B

57

PE3 / ICAP1_B

58

PE4 / EXTCLK_B

59

PD3 / ICAP1_A / AIN13

48

PD2 / ICAP2_A / AIN12

47

PD1(HS) / OCMP1_A

46

PD0 / OCMP2_A / AIN11

45

PF5 (HS)

44

PF4 (HS)

43

PF3 (HS) / BEEP

42

PF2 / MCO / AIN10

41

PWM1 / PA2

11

PWM2 / (HS) PA1

10

PWM3 / PA0

9

SW2

SW3

SW1

B B

PE0

PE1

PE2

SIG13

SIG12

RV1

OVER_temp

SIG18

RV2

2

1

P7P7

OVER_volt

OVER_cur

SIG4

SIG3

C460.1uF C460.1uF

SIG2

R7910K R7910K

SIG1

SIG20

SIG12

SIG4

SIG19

PE2

+5V

+5V

1 2

P9

SW4

0.01uF

0.01uF

C50

C50

1 2

SW9SW9

0.01uF

0.01uF

C48

C48

1 2

SW8SW8

0.01uF

0.01uF

C49

C49

1 2

SW10SW10

0.01uF

0.01uF

C45

C45

1 2

PB3PB3

PE0

3 4

5 6

7 8

9 10

11 12

13 14

15 16

17 18

19 20

21 22

23 24

25 26

27 28

SIG7

SIG21

SIG18

SIG13

PE1

CD4

CD4

CD2

CD2

CD1

CD1

+5V

CD3

CD3

A A

1

ST7MC control of 3 phase motor

ST7MC control of 3 phase motor

ST7MC control of 3 phase motor

<Doc> 3.0

<Doc> 3.0

<Doc> 3.0

B

B

B

Title

Size Document Number Rev

Date: Sheet of

Title

Size Document Number Rev

Date: Sheet of

Title

Size Document Number Rev

Date: Sheet

2

3

SIG3

SIG1

SIG6

4

29 30

31 32

33 34

HEADER34P9HEADER34

SIG2

SIG5

SIG17

0.1uF

0.1uF

0.1uF

0.1uF

5

0.1uF

0.1uF

0.1uF

0.1uF

16/19

Page 17

AN2267 ST7MC 3-phase motor control schematics

Figure 14. Schematic 2 of 3

of

23Tuesday, January 03, 2006

23Tuesday, January 03, 2006

23Tuesday, January 03, 2006

1

2

1

+15V

P3P3

CP3

CP3

1uF/25V

1uF/25V

CP2

CP2

1uF/25V

1uF/25V

CP1

CP1

1uF/25V

1uF/25V

VA_OUT

VB_OUT

P1P1

VC_OUT

213

+15V

Vdc

+15V

+5V

C27 10uF/25VC27 10uF/25V

3

Vo

GND

L7805U1L7805

2

U1

Vi

1

D215VD21

5V

1

<Doc> 3.0

ST7MC control of 3 phase motor

<Doc> 3.0

ST7MC control of 3 phase motor

<Doc> 3.0

ST7MC control of 3 phase motor

B

B

B

Title

Size Document Number Rev

Date: Sheet

Title

Size Document Number Rev

Date: Sheet of

Title

Size Document Number Rev

Date: Sheet of

2

15v REGULATED SUPPLY

3

D23

D23

4

MAIN

RECTIFIER

5

IC4

IC4

STTA106U

STTA106U

1N4148WS

1N4148WS

D22

D22

680uF/200VC1680uF/200V

4

D7

D7

IR8GBU06

IR8GBU06

F1

2

1

P2

L1

AC POWER IN

SW NEU

D25

D25

18V

18V

100uF/25V

100uF/25V

C31

C31

L1

5

6

7

8

DRAIN

DRAIN

SET

RES

SET

RES

-

+

-

+

VIPER12AS

VIPER12AS

4

VDD

VDD

0.23V

0.23V

FB

FB

3

C26

C26

22uF/25V

22uF/25V

D24

D24

15V

15V

C29

C29

22uF/25V

22uF/25V

0.1uF/400VC20.1uF/400V

C2

R1

R19

R19

100K/2WR1100K/2W

13

C1

W1

W1

POWER_JUMPER

POWER_JUMPER

1

-+

-+

3 2

C20

C20

0.1uF/400V

0.1uF/400V

FUSEF1FUSE

HEADER 2P2HEADER 2

1mHL11mH

SOURCE

SOURCE

C30

C30

C9

0.1uF/400VC90.1uF/400V

100K/2W

100K/2W

22nF

22nF

C13

C13

2

1

LINE

D20

D20

STTA106U

STTA106U

R20

R20

0.015E/2W

0.015E/2W

680uF/200V

680uF/200V

FILTER

N

R8

12

1K

AH

22ER822E

OUT

R45

R45

T2

R9

D2 1N4148WSD2 1N4148WS

10

NC11NC

+15V

D11

1N4148WS

D11

1N4148WS

27K

27K

1K

R271KR27

47ER947E

9

LVG

Vprot

OVER_volt

STGP7NB60HDT2STGP7NB60HD

C4

0.01uFC40.01uF

R10

R10

8

GND

7

C15

C15

1K

R301KR30

OVER_cur

22E

22E

0.1uF

0.1uF

Vdc

T3

R11

47E

R11

47E

D3 1N4148WSD3 1N4148WS

0.47uF/50V

0.47uF/50V

C11

C11

Tantalum

14

D9

STTA106UD9STTA106U

VBOOT

LIN1SD2HIN3VCC4DIAG5CIN6GND

IC2 L6386IC2 L6386

+15V

1K

R281KR28

BL

+5V

C25

C25

+5V

Idc1

13

HVG

STGP7NB60HDT3STGP7NB60HD

C5

0.01uFC50.01uF

R291KR29

J2J2

0.01uF

0.01uF

C33

C33

R12

R12

1K

0.1uF

0.1uF

12

OUT

BH

1 2

T4

D4 1N4148WSD4 1N4148WS

22E

22E

R37

R37

Q1

2N4403Q12N4403

7

-

-

6

NC11NC

+15V

R13

47E

R13

47E

9

10

LVG

D12

1N4148WS

D12

1N4148WS

8K2

8K2

R39

10K

R39

10K

1

R46

51K

R46

51K

84

-

-

2

R40

R40

IC5B

IC5B

TS272

TS272

+

+

5

22E

22E

12

OUT

CH

R47

R47

T6

D6 1N4148WSD6 1N4148WS

NC11NC

+15V

D13

D13

27K

27K

NTC

R2

+5V

Temprtr

R17

47E

R17

47E

10

1N4148WS

1N4148WS

1K

R331KR33

C19

C19

10KR210K

STGP7NB60HDT6STGP7NB60HD

2

C8

0.01uFC80.01uF

R18

22E

R18

22E

9

8

LVG

GND

3

7

4

0.1uF

0.1uF

R341KR34

1K

5

STGP7NB60HDT4STGP7NB60HD

C6

0.01uFC60.01uF

R14

22E

R14

22E

8

GND

7

+5V

R482KR48

2K

PB1PB1

12

1K

R381KR38

C17

0.1uF

C17

0.1uF

IC5A

IC5A

TS272

TS272

+

+

3

1K5

1K5

Vdc

T5

R15

47E

R15

47E

C7

D5 1N4148WSD5 1N4148WS

0.47uF/50V

0.47uF/50V

C12

C12

Tantalum

14

13

D10

STTA106U

D10

STTA106U

HVG

VBOOT

LIN1SD2HIN3VCC4DIAG5CIN6GND

IC3 L6386IC3 L6386

+15V

1K

R311KR31

CL

+5V

C18

1nF

C18

1nF

C16

1nF

C16

1nF

C14

1nF

C14

1nF

R491KR49

1K

SHUTDOWN

STGP7NB60HDT5STGP7NB60HD

0.01uFC70.01uF

R16

R16

1K

R321KR32

OVER_temp

STGP7NB60HDT1STGP7NB60HD

Vdc

T1

R7

47ER747E

C3

0.01uFC30.01uF

D1 1N4148WSD1 1N4148WS

C10

C10

0.47uF/50V

0.47uF/50V

Tantalum

14

13

D8

STTA106UD8STTA106U

HVG

VBOOT

LIN1SD2HIN3VCC4DIAG5CIN6GND

IC1 L6386IC1 L6386

+15V

1K

R251KR25

R261KR26

AL

1%

1%

Idc

+5V

D D

C C

B B

A A

17/19

Page 18

ST7MC 3-phase motor control schematics AN2267

Figure 15. Schematic 3 of 3

of

13Tuesday, January 03, 2006

13Tuesday, January 03, 2006

13Tuesday, January 03, 2006

1

P4

2

R56

R56

4K7

4K7

+5V

R55

R55

4K7

4K7

R53

R53

4K7

VA_OUT

VB_OUT

VC_OUT

4K7

HEADER 5P4HEADER 5

12345

0.01uF

0.01uF

C35

C35

+5V

SW4

SW DIP-3

SW4

SW DIP-3

** SW3 and SW5 are fully CLOSED

1

<Doc> 3.0

ST7MC control of 3 phase motor

<Doc> 3.0

ST7MC control of 3 phase motor

<Doc> 3.0

ST7MC control of 3 phase motor

B

B

B

Title

Size Document Number Rev

Date: Sheet of

Title

Size Document Number Rev

Date: Sheet of

Title

Size Document Number Rev

Date: Sheet

2

R35

470E

R35

R5

180K/2WR5180K/2W

R71

47K

R71

SW5

SW DIP-4

SW5

SW3

SW DIP-3

SW3

1N4148WS

1N4148WS

D17

D17

1N4148WS

1N4148WS

D19

D19

1N4148WS

1N4148WS

1N4148WS

1N4148WS

SW2

SW2

SW DIP-3

SW DIP-4

SW DIP-4

D16

D16

D14

1N4148WS

D14

R22

R22

100K/2W

100K/2W

+5V

1N4148WS

D15

1N4148WS

D15

1N4148WS

R441KR44

1K

R431KR43

1K

R421KR42

1K

R411KR41

1K

D18

D18

R4

180K/2WR4180K/2W

3

R3

180K/2WR3180K/2W

4

R61KR6

1K

R241KR24

1K

R231KR23

1K

5

SW DIP-4

SW1

SW1

Vc

47K

R70

47K

R70

47K

R65

47K

R65

47K

VrefVbVa

SW DIP-4

SW DIP-4

C21

C21

0.1uF

0.1uF

C22

C22

0.1uF

0.1uF

C23

C23

0.1uF

0.1uF

C24

C24

0.1uF

0.1uF

SW7

SW7

+5V

SW DIP-2

SW DIP-2

+5V

PE0PE1PE2

R66

R66

470E

VprotVdclink

R36

39K

R36

39K

R21

R21

330K/2W

330K/2W

Vdc

5K

RV55KRV5

+5V

C39

C39

2.2nF

2.2nF

Q2

2N2222Q22N2222

R76

100E

R76

0(NC)

0(NC)

100E

C40

0.1uF

C40

0.1uF

1N4148WS

1N4148WS

D31

R78

R78

2

D31

10K

10K

D30

D30

1N4148WS

1N4148WS

C37

C37

0.1uF

0.1uF

1

10K

10K

R77

R77

10K

10K

R67

R67

P6P6

3

4

5

D D

C C

18/19

B B

A A

Page 19

AN2267

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZE REPRESENTATIVE OF ST, ST PRODUCTS ARE NOT DESIGNED,

AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING APPLICATIONS,

NOR IN PRODUCTS OR SYSTEMS, WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY, DEATH, OR

SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2006 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

19/19

Loading...

Loading...