Page 1

Introduction

High brightness LEDs are becoming a prominent source of light and often have better efficiency

and reliability than conventional light sources. While LEDs can operate from an energy source

as simple as a battery and resistor, most applications require an efficient energy source not

only for the reduction of losses, but also to maintain the brightness of the LED itself. For

applications that are powered from low voltage AC sources typically used in landscape lighting

or low voltage DC sources that may be used in automotive applications or to meet safety

requirements, high efficiency DC-DC converters configured for constant output current provide

a high efficiency driver that can operate over a relatively wide range of input voltages to drive

series strings of one to several LEDs

This application note describes a DC-DC converter circuit that can easily be configured to dri ve

LEDs at several different output currents and can be configured for either AC or DC input. The

circuit uses the L5973D monolithic step down converter configured to drive a series string of

LEDs in a constant current mode.

AN2259

APPLICATION NOT E

High intensity LED driver using the L5970D/L5973D

L5970D is a step down monolithic power switching regulator capable of delivering 1A while the

L5973D is able to deliver 2A at output voltages from 1.25V to 35V. Both devices use internal PChannel D-MOS transistors (with typical R

minimize the size of external components. An internal oscillator fixes the switching frequency

at 250kHz.

The brightness of the LED (Light Emitting Diode), or light intensity as measured in Lumens, is

proportional to the forward current flowing through the LED. Since the forward voltage drop of

the LED can vary from device to device it is important to drive the LEDs with a constant current

driver to be able to get good matching of the light output, especially when they are located side

by side where variations in light intensity are quickly noticed. A typical way to drive LEDs in the

constant current mode is to use a DC-DC converter configured to give a constant current

output. The circuit shown in Figure 7. uses the L5973D in a constant current configuration to

drive LEDs

of 250mΩ) as the switching element to

DS(on)

Rev 1.0

AN2259/1105 1/38

www.st.com

38

Page 2

AN2259

Figure 1. Board Layout

2/38

Page 3

AN2259

Contents

1 DESCRIPTION OF BOARD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2 INPUT CAPACITOR SELECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3 CURRENT FEEDBACK LOOP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4 INDUCTOR SELECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

5 BOARD LAYOUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

6 REFERENCE DESIGN VERSIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

7 REVISION HISTORY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

3/38

Page 4

AN2259

Figures

Figure 1. Board Layout. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

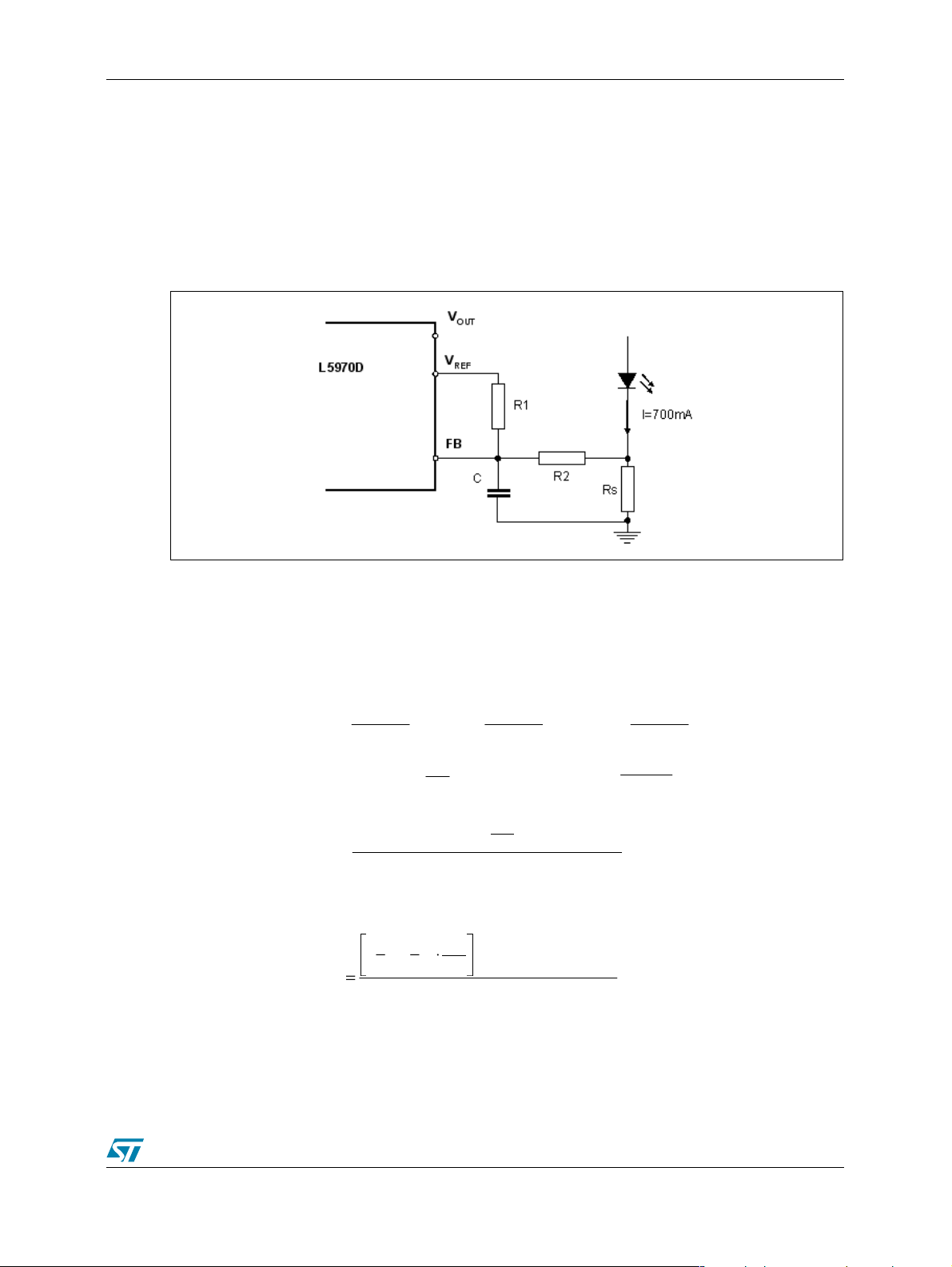

Figure 2. Current feedback . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

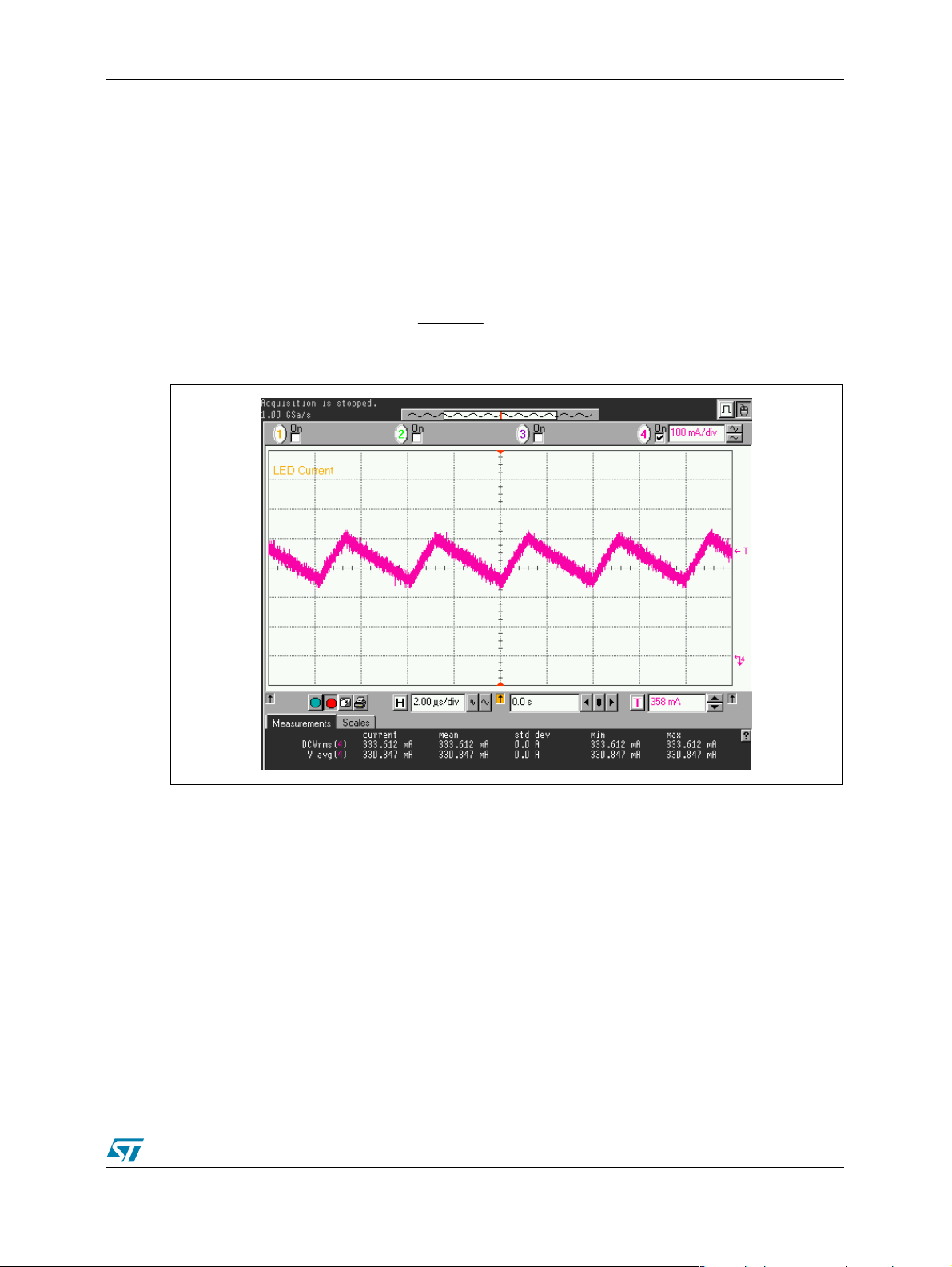

Figure 3. Ripple Current (One 1W LED). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

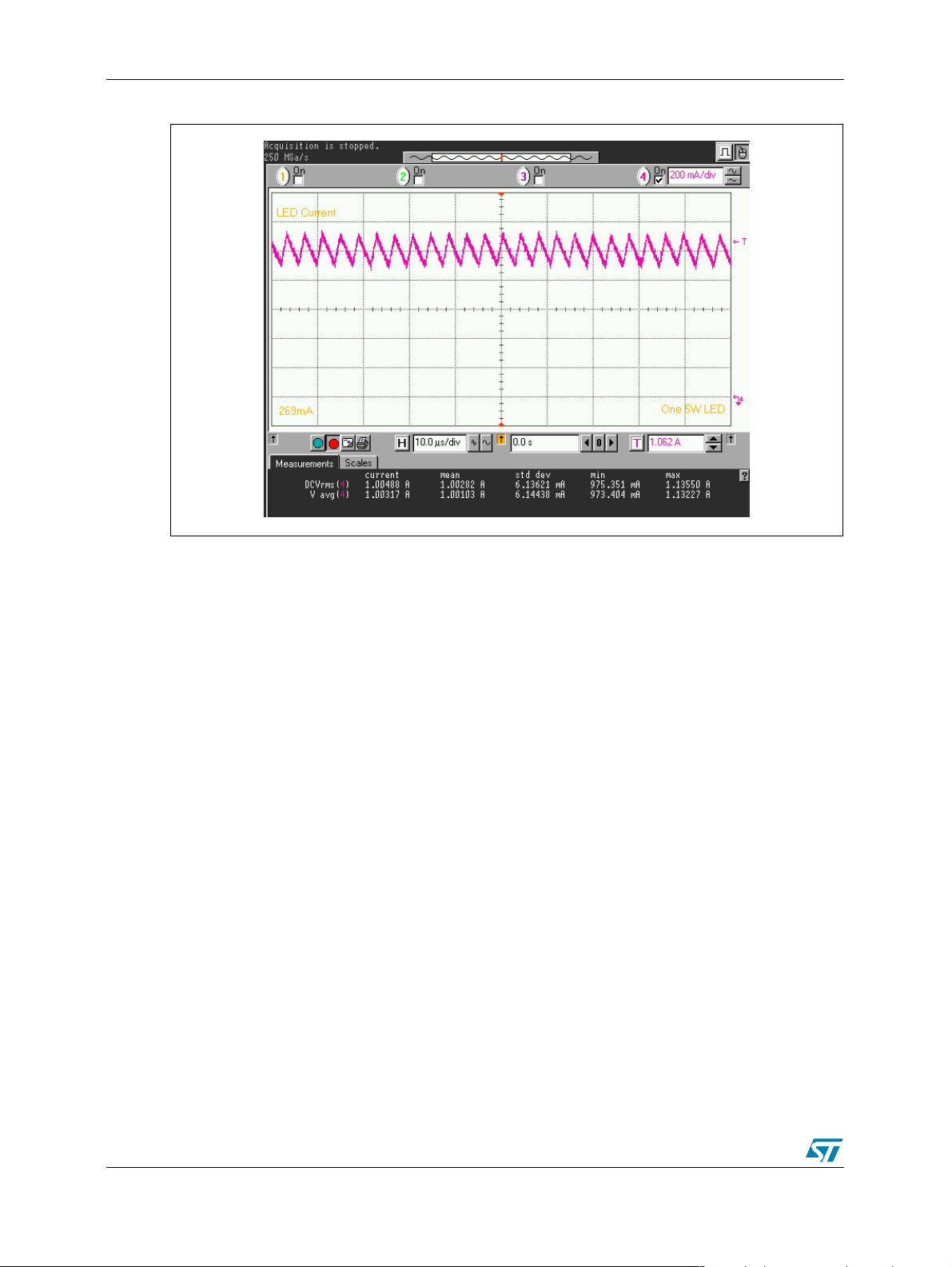

Figure 4. Ripple current (One 5W LED). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Figu r e 5 . T o p side of Boar d ( n o t in sca le) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Figu r e 6 . Botto m side of Bo ard (no t in sca le) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Figure 7. Board Schematic. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Figure 8. 12Vac Input 1W LED Driver Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Figure 9. 12Vac Input 3W LED Driver Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 10. 12Vac Input 5W LED Driver Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Figure 11. 6 to 12Vdc Input 1W LED Driver Schematic . . . . . . . . . . . . . . . . . . . . . . . 24

Figure 12. 6 to 12Vdc Input 3W LED Driver Schematic . . . . . . . . . . . . . . . . . . . . . . . 26

Figure 13. 6 to 12Vdc Input 5W LED Driver Schematic . . . . . . . . . . . . . . . . . . . . . . . 28

Figure 14. 6 to 24Vdc Input 1W LED Driver Schematic . . . . . . . . . . . . . . . . . . . . . . . 30

Figure 15. 6 to 24Vdc Input 3W LED Driver Schematic . . . . . . . . . . . . . . . . . . . . . . . 32

Figure 16. 6 to 24Vdc Input 5W LED Driver Schematic . . . . . . . . . . . . . . . . . . . . . . . 34

4/38

Page 5

AN2259

Tables

Table 1. Bill of Mata r ials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Table 2. Components Changes For Different Configuration. . . . . . . . . . . . . . . . . . 16

Table 3. 12Vac Input 1W LED Driver Bill of Materials. . . . . . . . . . . . . . . . . . . . . . . 19

Table 4. 12Vac Input 3W LED Driver Bill of Materials. . . . . . . . . . . . . . . . . . . . . . . 21

Table 5. 12Vac Input 5W LED Driver Bill of Materials. . . . . . . . . . . . . . . . . . . . . . . 23

Table 6. 6 to 12Vdc Inp ut 1W LED Driv e r Bill of Mater ia ls . . . . . . . . . . . . . . . . . . . 25

Table 7. 6 to 12Vdc Inp ut 3W LED Driv e r Bill of Mater ia ls . . . . . . . . . . . . . . . . . . . 27

Table 8. 6 to 12Vdc Inp ut 5W LED Driv e r Bill of Mater ia ls . . . . . . . . . . . . . . . . . . . 29

Table 9. 6 to 24Vdc Inp ut 1W LED Driv e r Bill of Mater ia ls . . . . . . . . . . . . . . . . . . . 31

Table 10. 6 to 24Vdc Inp ut 3W LED Driv e r Bill of Mater ia ls . . . . . . . . . . . . . . . . . . . 33

Table 11. 6 to 24Vdc Inp ut 5W LED Driv e r Bill of Mater ia ls . . . . . . . . . . . . . . . . . . . 35

5/38

Page 6

1 DESCRIPTION OF BOARD AN2259

1 DESCRIPTION OF BOARD

The evaluation board shown in F igure 1. was designed so that it can be configured to accept

several different input voltages that are common for automotive and lighting applications. The

most common input voltages are 12V ac, 12Vdc (for automotive) and 24Vdc. The board also

allows the user to select the output current using the jumpers J2 and J4 on the board without

having to change any components on the evaluation board. The standard configuration of the

board includes a full wave bridge rectifier that is required for an AC input

6/38

Page 7

AN2259 2 INPUT CAPACITOR SELECTION

Vin

o

D

I

n

V

)

2

2

C

2 INPUT CAPACITOR SELECTION

For DC input, the input capacitor, C1, is selected based on its ripple current rating for the

capacitor. The ripple current is calculated based on its duty cycle as outlined below.

V

=

Where D = duty cycle

Vo = output voltage

Vin = input voltage

The RMS current through the capacitor therefore is:

22

DD2

⋅

ripple

µ= efficiency

DIo

−=

+

2

η

η

For an AC input voltage, the input capacitor is selected primarily to have enough capacity to

supply the LED between the peaks of the AC input. The capacitor must be selected so that the

minimum voltage at the input to the L5973D is maintained during each half cycle of the AC

input.

Vi

peak ⋅=

2

If the application is driving only one LED, the Vmin is determined by the minimum operating

voltage specification for the L5973D (4.4V). When driving more than one LED in series, the

minimum input voltage is determined by the output voltage and the minimum differential input to

output voltage for the regulator (the drop out voltage). In this case V

+ V

DO

= (x * Vf) + (I

min

out

* R

sense

Where: x = number of LED in series

= forward voltage of one LED

V

f

= LED drive current

I

o

= Drop out voltage

V

DO

The capacitor can then be selected using the equation:

−

3

⋅⋅⋅

=

1

Vpeak

(

VoIo105

1

⋅−⋅⋅η

22

minV

)

The ripple current rating will have two parts where in the low frequency range, the capacitor will

be charged by 120Hz while at the high frequency range the capacitor is discharged by 250kHz.

For the low frequency part, it is approximately the same as the input RMS current and the

power factor is approximately 0.7 for a full wave rectifier.

7/38

Page 8

2 INPUT CAPACITOR SELECTION AN2259

7.

I

Io

I

Vav

D

2

n

V

Io

I

I

⋅

in

=

For the high frequency part (ignoring output current ripple), we have:

VoIo

⋅η⋅

0Vin

ripple

Dav

⋅

−=

η

where Dav is the average duty cycle.

We will use the average duty cycle assuming that the voltage on the capacitor changes from

the peak to the minimum voltage linearly.

av =

ripple

Vo

Dav

av

=

⋅

−=

+

η

The equivalent series resistance of an aluminum capacitor has different frequency

characteristics. There is a coefficient associated with different frequencies. Typically, for 120Hz,

Kfl=1; for frequency greater than 10 kHz, Kfh=1.5.

Iin

cap

Therefore, the ripple current rating of the capacitor has to be greater than Icap

=

Kfl

Iripple

+

Kfh

22

DavDav2

+

DavDav2

⋅

2

η

+

mi

VVpeak

22

⋅

2

η

22

8/38

Page 9

AN2259 3 CURRENT FEEDBACK LOOP

2R1

R

2

2R1

R

2R1

R

V

2

1

R

V

Rs

e

I

Rs

2

I

Rs

2

I

3 CURRENT FEEDBACK LOOP

To drive LEDs in a constant current mode, the feedback for the regulator is taken by sensing

the voltage drop across the current sense resistor, Rs, as shown in Figure 2. The voltage

divider between the sense resistor and the feedback pin (R

feedback pin so that it equals the internal reference voltage at the desired current level.

Figure 2. Current feedback

and R2) scales the voltage at the

1

In order to get Io = 350 mA, the values of R1, R2 and Rs are selected based on the following

values.

Vref = 3.3V ; Vfb = 1.235V ; Ifb_bias = 2.5 10

Vsense=Rs.Io

Using the superposition method:

2R

fb

Vref

⋅=

Vsense

+

2R

sense ⋅−⋅−−=

o

=

Since Vref

Therefore, the equation can be simplified to:

and Vfb come from same band gap, they are directly correlated. K=Vref/Vfb=2.672.

o

=

For 350mA output the selected values are:

)VfbVref(Vfb

)1K(1

⋅−−

-6

A ; Rs=0.68Ω

1R

⋅+

bias_Ifb

+

Rbias_Ifb

2R

)VfbVref(Vfb

o =

Rbias_Ifb

⋅−⋅−−

⋅+

Vsens

R1R

⋅

+

1R

2R

1R

⋅−⋅

Rbias_IfbVfb

R1 = 2.74k

R2 =1.30k

Rs = 0.68

Ω,

Ω and

Ω.

9/38

Page 10

3 CURRENT FEEDBACK LOOP AN2259

For an output current of 700mA the value of Rs would be 0.34Ω. If R1 and R2 are small

enough, the effect of the bias current can be ignored.

On the evaluation board, the value of Rs is selected by jumpers J2 and J4. When both J2 and

J4 are open, the output current is set to 350mA. Inserting each jumper connects a 0.68

resistor in parallel with the 0.68

Ω Rs. With J2 shorted, the output current will be set to 700mA

Ω

and the output current becomes 1A with both J2 and J4 shorted.

10/38

Page 11

AN2259 4 INDUCTOR SELECTION

n

ax

Im

4 INDUCTOR SELECTION

The output inductor is selected to limit the ripple current in the LEDs.

For example, for a given DC input voltage and an output current of 350mA, the peak current

can be fixed to 500mA. This implies a

For an output current of 700mA, the peak current can be fixed to1000mA. This implies a

∆Imax= 600mA

Lmin=

Figure 3. Ripple Current (One 1W LED)

∆Imax = 300mA.

VoVin

−

⋅

To

∆

Figure 3. shows the ripple current measured with one 1W LED (warm white) at the output with

12Vac input. The measured ripple current is 180mA.

11/38

Page 12

4 INDUCTOR SELECTION AN2259

Figure 4. Ripple current (One 5W LED)

Figure 4. shows the ripple current driving one 5W LED at 1.05 A from a 12Vac input. The input

current is 269mA.

12/38

Page 13

AN2259 5 BOARD LAYOUT

5 BOARD LAYOUT

The layout for the evaluation board is shown below in Figure 5. and Figure 6. The area within

the circle in the center of the board illustrates the required area for the final application. The

components outside of the circle are connectors for convenience and the auxiliary devices that

allow the current to be selected on this board without changing the resistor values. Obviously

the final application would use a single resistor for R

Figure 5. Top side of Board (not in scale)

that is optimized for the application.

S

Figure 6. Bottom side of Board (not in scale)

13/38

Page 14

5 BOARD LAYOUT AN2259

Figure 7. Board Sche matic

14/38

Page 15

AN2259 5 BOARD LAYOUT

Table 1. Bill of Matarials

Qty

1 C1 1200uF/35V elect rolytic EEU-FC1V22L Panasonic Radial TH

1 C2 220pF/50V ceramic SMD

1 C3 22nF/50V ceram ic SMD

1 C4 22nF/50V ceram ic SMD

1 C5 4.7nF/50V ceramic SMD

Part

Reference

Part Description Mfg P/N Mfg Geometry Mounting

D2 D4 D5

5

D6 D7

1J1

1 J2 Current Select Ju mper 22-28-8020 Molex TH

1 J3 St ackable Receptacle 535676-5 Tyc o TH

1 J4 Current Select Jumper 22-28-8020 Molex 6 Pin TH

1 L1 Inductor DO3316P-683 Coilcraft SMD

1 Q1 PNP Transistor MMBT3906 STMicroelectronics SOT23 SMD

1 Rs 0.68ohms 1% 1/4W 2010 SMD

1 Rs2 0.68ohms 1% 1/4W 2010 SMD

1 Rs3 0.68ohms 1% 1/4W 2010 SMD

1 R1 2.74kohms 1% 1/8W 0805 SMD

1 R2 1.30kohms 1% 1/8W 0805 SMD

1 R3 4.7kohms 5% 1/8W 0805 SMD

1 R4 240kohms 5% 1/8W 0805 SMD

1 U1 Step-down controller L5973D STMicroelectronics SO8 SMD

Low Drop Power

Schottky R e ctifie r

Phoenix 2 Pin

Connector

STPS2L40U STMicroelectronics SMB SMD

MKDSN1.5/2 Phoenix Contact TH

15/38

Page 16

6 REFERENCE DESIGN VERSIONS AN2259

6 REFERENCE DESIGN VERSIONS

The evaluation board is designed to display the full functionality of L5973D as a LED driver to

drive one to three 1W, 3W as well as 5W LEDs at 12Vac input. The components selected for

the demo board are optimized for 5W LED driver application. Based on this circuit, there are

nine different configurations with different input voltages and output power levels that could be

derived by making minor components changes to the evaluation board. Table 1. shows the

component changes needed in order to obtain each configuration. The final schematics and bill

of materials for each configuration are shown in the subsequent pages. The 6 to 12 Vdc input

configuration was designed for automotive applications that must survive a reverse battery

condition. In this case one of the rectifiers remains on the board to provide protection against

reversing the power supply leads.

Table 2. Components Changes For Different Configuration

LED Driver U1 D4 D5 D6 D7

12Vac

1W LED

12Vac

3W LED

12Vac

5W LED

6-12Vdc

1W LED

6-12Vdc

3W LED

6-12Vdc

5W LED

6-24Vdc

1W LED

6-24Vdc

3W LED

6-24Vdc

5W LED

L5970D STPS1L40A STPS1L40A STPS1L40A STPS1L40A

L5973D STPS2L40U STPS2L40U STPS2L40U STPS2L40U

L5973D STPS2L40U STPS2L40U STPS2L40U STPS2L40U

L5970D Not used Not used STPS1L40A Jumper wire

L5973D Not used Not used STPS2L40U Jumper wire

L5973D Not used Not used STPS2L40U Jumper wire

L5970D Not used Not used Jumper wire Jumper wire

L5973D Not used Not used Jumper wire Jumper wire

L5973D Not used Not used Jumper wire Jumper wire

16/38

Page 17

AN2259 6 REFERENCE DESIGN VERSIONS

Table 2. (Continued)

C1 R2 Rs L1 D2

680uF/35V 1.30k 1% 0.68 47uH STPS1L40A

1200uF/35V 1.33k 1% 0.33 33uH STPS2L40U

1200uF/35V 1.30k 1% 0.24 68uH STPS2L40U

27uF/50V 1.30k 1% 0.68 47uH STPS1L40A

68uF/50V 1.33k 1% 0.33 33uH STPS2L40U

100uF/50V 1.30k 1% 0.24 68uH STPS2L40U

22uF/35V 1.30k 1% 0.68 100uH STPS1L40A

68uF/35V 1.33k 1% 0.33 100uH STPS2L40U

100uF/35V 1.30k 1% 0.24 100uH STPS2L40U

17/38

Page 18

6 REFERENCE DESIGN VERSIONS AN2259

V

V

Figure 8. 12Vac Input 1W LED Driver Schematic

J4

J3

LED+

1

47uH

L1

D2

2.74K

1/8W

R1

1 2

5

6

1

OUT

VREF

LED-

1

STPS1L40A

1 2

R2

FB

GND

7

1.30K

1 2

Rs

0.68

12

1/8W

C4

22nf

R4

240K

1/8W

1 2

1/4W

13

C5

4.7nf

2

Q1

L5970D

U1

VCC

2

8

C1

680uF

D6

D4

J1

in-

INH

3

SYNC

COMP

4

35V

+

STPS 1L40A

1 2

STP S1L40A

1 2

1

R3

4.7K

22nf

220pf

1/8W

D5

STPS 1L40A

D7

STP S1L40A

1

in+

C3

C2

MMBT3906

1 2

1 2

Minimum input voltage for 3 LEDs : 10VAC

Minimum input voltage for 2 LEDs : 7.5VAC

Minimum input voltage for 1 LED : 5VAC

Note:

1 2

J2

18/38

Page 19

AN2259 6 REFERENCE DESIGN VERSIONS

Table 3. 12Vac Input 1W LED Driver Bill of Materials

Qty Reference

Part

Description

Mfg P/N Mfg Geometry Mtg

1C1

1C2

2C3, C4

1C5

D2, D4, D5,

5

1 L1 47uH Inductor DO3308P-473 Coilcraft 9.4mmx12.95mm SMD

1 Q1 PNP Transistor MMBT3906 STMicroelectronics SOT-23 SMD

1 Rs 0.68 Ohm 1% 1206 SMD

1 R1 2.74k 1% 0805 SMD

1 R2 1.30k 1% 0805 SMD

1 R3 4.7k 5% 0805 SMD

1 R4 240k 5% 0805 SMD

1U1

D6, D7

680uF/35V

Electrolytic

220pF/50V

Ceramic

22nF/50V

Ceramic

4.7nF/50V

Ceramic

Schottky Diode

1A/40V

Step-down

controller

EEU-FC1V681 Panasonic Radial TH

SMD

SMD

SMD

STPS1L40A STMicroelectronics SMA SMD

L5970D STMicroelectronics 0SO8 SMD

19/38

Page 20

6 REFERENCE DESIGN VERSIONS AN2259

V

V

Figure 9. 12Vac Input 3W LED Driver Schematic

J4

STPS2L40U

LED-

1

1.33K

1 2

R2

1 2

R4

Rs

0.33

12

1/8W

C4

22nf

240K

1/8W

1 2

1/2W

C5

4.7nf

J3

LED+

1

33uH

L1

D2

2.74K

1/8W

R1

1 2

6

1

OUT

L5973D

U1

VCC

8

J1

5

FB

VREF

GND

7

INH

3

SYNC

COMP

2

4

35V

C1

1200uF

+

D6

STPS2L40U

1 2

D4

STPS2L40U

1 2

1

in-

R3

4.7K

220pf

1/8W

22nf

1 2

D5

STPS2L40U

1 2

D7

STPS2L40U

1 2

1

J2

in+

C3

C2

MMBT3906

2

13

Q1

Note:

Minimum input voltage for 2 LEDs : 8VAC

Minimum input voltage for 1 LED : 5VAC

Minimum input voltage for 3 LEDs : 10.5VAC

20/38

Page 21

AN2259 6 REFERENCE DESIGN VERSIONS

Table 4. 12Vac Input 3W LED Driver Bill of Materials

Qty Reference

Part

Description

Mfg P/N Mfg Geometry Mtg

1C1

1C2

2C3, C4

1C5

D2, D4, D5,

5

1 L1 33uH Inductor DO3308P-333 Coilcraft 9.4mmx12.95mm SMD

1 Q1 PNP Transistor MMBT3906 STMicroelectronics SOT-23 SMD

1 Rs 0.33 Ohm 1%

1 R1 2.74k 1% 0805 SMD

1 R2 1.33k 1% 0805 SMD

1 R3 4.7k 5% 0805 SMD

1 R4 240k 5% 0805 SMD

1U1

D6, D7

1200uF/35V

Electrolytic

220pF/50V

Ceramic

22nF/50V

Ceramic

4.7nF/50V

Ceramic

Schottky Di ode

2A/40V

Step-down

controller

EEU-

FC1V122L

STPS2L40U STMicroelectronics SMB SMD

CRL2010-FW-

R330E

L5973D STMicroelectronics SO8 SMD

Panasonic Radial TH

SMD

SMD

SMD

Bourns 2010 SMD

21/38

Page 22

6 REFERENCE DESIGN VERSIONS AN2259

Figure 10. 12Vac Input 5W LED Driver Schematic

L5973D

U1

J3

LED +

CON1

1

68uH

L1 DO3316P-683

R1

1

6

OUT

VREF

VCC

2

8

LED -

J4

CON1

1

D2

STPS2L40U

2.74K

1/8W

5

FB

SYNC

COMP

4

R2

1 2

GND

7

INH

3

R3

C3

22nF

4.7k

1/8W

Rs

0. 2 4 O h m

1/4W

1 2

1.30K

1/8W

C4

22nf

240k

1/8W

R4

1 2

C5

4.7nf

2

13

Q1

MMBT3906

C2

35V

+

STPS2H10 0U

STPS2H100U

Vin -

220pf

D5

STPS2H10 0U

D7

STPS2H100U

1

Vcc

C1

1200uF

D6

D4

1

J1

CON1

22/38

J2

Vin +

CON1

Note:

Minimum input voltage for 1 LED: 5Vac

Minimum input voltage for 2 LEDs: 8Vac

Minimum input voltage for 3 LEDs: 10.5Vac

Page 23

AN2259 6 REFERENCE DESIGN VERSIONS

Table 5. 12Vac Input 5W LED Driver Bill of Materials

Qty Reference

Part

Description

Mfg P/N Mfg Geometry Mtg

1C1

1C2

2C3, C4

1C5

D2, D4, D5,

5

1 L1 68uH Inductor DO3316P-683 Coilcraft 9.4mmx12.95mm SMD

1 Q1 PNP Transistor MMBT3906 STMicroelectronics SOT-23 SMD

1 Rs 0.24 Ohm 1%

1 R1 2.74k 1% 0805 SMD

1 R2 1.30k 1% 0805 SMD

1 R3 4.7k 5% 0805 SMD

1 R4 240k 5% 0805 SMD

1U1

D6, D7

1200uF/35V

Electrolytic

220pF/50V

Ceramic

22nF/50V

Ceramic

4.7nF/50V

Ceramic

Schottky Di ode

2A/40V

Step-down

controller

EEU-

FC1V122L

STPS2L40U STMicroelectronics SMB SMD

CRL2010-FW-

R240E

L5973D STMicroelectronics SO8 SMD

Panasonic Radial TH

SMD

SMD

SMD

Bourns 2010 SMD

23/38

Page 24

6 REFERENCE DESIGN VERSIONS AN2259

J

V

J

V

Figure 11. 6 to 12Vdc Input 1W LED Driver Schematic

J3

1

47uH

L1

2.74K

R1

1

OUT

L5970D

U1

VCC

8

J4

LED+

D2

1/8W

1 2

6

5

VREF

SYNC

2

4

FB

COMP

LED-

1

STPS1L40A

1 2

GND

INH

C3

1.30K

R2

7

3

R3

4.7K

22nf

1 2

R4

1/8W

1 2

Rs

0.68

12

1/8W

C4

22nf

240K

1/8W

1 2

MMBT390 6

1/4W

2

13

Q1

C5

4.7nf

C2

220pf

50V

C1

27uF

+

D6

STPS1L40A

1 2

1

in+

2

24/38

D7 Jumper

1 2

1

in-

1

Page 25

AN2259 6 REFERENCE DESIGN VERSIONS

Table 6. 6 to 12Vdc Input 1W LED Driver Bill of Materials

Qty Reference

Part

Description

Mfg P/N Mfg Geometry Mtg

1C1

1C2

2C3, C4

1C5

2D2, D6

1D7

1 L1 47uH Inductor DO3308P-473 Coilcraft 9.4mmx12.95mm SMD

1 Q1 PNP Transistor MMBT3906 STMicroelectronics SOT-23 SMD

1 Rs 0.68 Ohm 1% 1206 SMD

1 R1 2.74k 1% 0805 SMD

1 R2 1.30k 5% 0805 SMD

1 R3 4.7k 5% 0805 SMD

1 R4 240k 5% 0805 SMD

1U1

27uF/50V

Electrolytic

220pF/50V

Ceramic

22nF/50V

Ceramic

4.7nF/50V

Ceramic

Schottky Di ode

1A/40V

Jumper at D7

position

Step-down

controller

EEU-

FC1H270

STPS1L40A STMicroelectronics SMA SMD

L5970D STMicroelectronics SO8 SMD

Panasonic Radial TH

SMD

SMD

SMD

SMD

25/38

Page 26

6 REFERENCE DESIGN VERSIONS AN2259

J

V

Figure 12. 6 to 12Vdc Input 3W LED Driver Schematic

J4

STPS2L40U

FB

LED-

1

1 2

GND

1.33K

R2

7

1 2

R4

Rs

0.33

12

1/8W

C4

22nf

240K

1/8W

1 2

1/2W

2

13

Q1

C5

4.7nf

J3

LED+

1

33uH

L1

D2

2.74K

1/8W

R1

1 2

6

1

OUT

5

VREF

L5973D

U1

D6

2

INH

3

SYNC

VCC

8

C6

1 2

1

COMP

2

4

50V

68uF

+

STPS2L40U

in+

C3

C2

220pf

22nf

R3

4.7K

1/8W

D7 Jumper

J1

MMBT3906

1 2

1 2

1

Vin-

26/38

Page 27

AN2259 6 REFERENCE DESIGN VERSIONS

Table 7. 6 to 12Vdc Input 3W LED Driver Bill of Materials

Qty Reference

Part

Description

Mfg P/N Mfg Geometry Mtg

1C1

1C2

2C3, C4

1C5

2D2, D6

1D7

1 L1 33uH Inductor DO3308P-333 Coilcraft 9.4mmx12.95mm SMD

1 Q1 PNP Transistor MMBT3906 STMicroelectronics SOT-23 SMD

1 Rs 0.33 Ohm 1%

1 R1 2.74k 1% 0805 SMD

1 R2 1.33k 1% 0805 SMD

1 R3 4.7k 5% 0805 SMD

1 R4 240k 5% 0805 SMD

68uF/50V

Electrolytic

220pF/50V

Ceramic

22nF/50V

Ceramic

4.7nF/50V

Ceramic

Schottky Di ode

2A/40V

Jumper at D7

position

EEU-

FC1H680

STPS2L40U STMicroelectronics SMB SMD

CRL2010-FW-

R330E

Panasonic Radial D8mm TH

805 SMD

805 SMD

805 SMD

SMD

Bourns 2010 SMD

1U1

Step-down

controller

L5973D STMicroelectronics SO8 SMD

27/38

Page 28

6 REFERENCE DESIGN VERSIONS AN2259

Figure 13. 6 to 12Vdc Input 5W LED Driver Schematic

LED -

LED +

J4

1

Rs

0.24Ohm

1/4W

1 2

J3

1

L5973D

U1

L1 DO3316P-683

68uH

D2

STPS2L40U

R1

2.74K

1/8W

6

VREF

C1

5

FB

SYNC

COMP

2

4

50V

100uF

+

1

OUT

VCC

8

Vcc

Vcc

1 2

GND

INH

7

3

C3

22nF

C2

R2

R3

220pF

4.7k

1/8W

1.30K

1/8W

C4

R4

240k

22nF

1/8W

1 2

2

13

Q1

MMBT3906

C5

4.7nF

D6

STPS2H100U

1

J2

CON1

Vin +

28/38

D7 Jumper

J1

1 2

1

CON1

Vin -

Page 29

AN2259 6 REFERENCE DESIGN VERSIONS

Table 8. 6 to 12Vdc Input 5W LED Driver Bill of Materials

Qty Reference

Part

Description

Mfg P/N Mfg Geometry Mtg

1C1

1C2

2C3, C4

1C5

2D2, D6

1D7

1 L1 68uH Inductor DO3316P-683 Coilcraft 9.4mmx12.95mm SMD

1 Q1 PNP Transistor MMBT3906 STMicroelectronics SOT-23 SMD

1 Rs 0.24 Ohm 1%

1 R1 2.74k 1% 0805 SMD

1 R2 1.30k 1% 0805 SMD

1 R3 4.7k 5% 0805 SMD

1 R4 240k 5% 0805 SMD

100uF/50V

Electrolytic

220pF/50V

Ceramic

22nF/50V

Ceramic

4.7nF/50V

Ceramic

Schottky Di ode

2A/40V

Jumper at D7

position

EEU-

FC1H101

STPS2L40U STMicroelectronics SMB SMD

CRL2010-FW-

R240E

Panasonic Radial D8mm TH

805 SMD

805 SMD

805 SMD

SMD

Bourns 2010 SMD

1U1

Step-down

controller

L5973D STMicroelectronics SO8 SMD

29/38

Page 30

6 REFERENCE DESIGN VERSIONS AN2259

J

V

J

V

Figure 14. 6 to 24Vdc Input 1W LED Driver Schematic

J3

L5970D

U1

J4

LED+

1

100uH

L1

D2

2.74K

1/8W

R1

1 2

1

OUT

VCC

8

5

6

FB

VREF

SYNC

COMP

2

4

1

STPS1L40A

1 2

GND

INH

C3

7

3

22nf

LED-

Rs

0.68

1/4W

12

1.30K

1/8W

R2

C4

22nf

1 2

R4

240K

R3

1/8W

1 2

MMBT3906

4.7K

1/8W

1 2

2

13

Q1

C5

4.7nf

C2

220pf

35V

C1

22uF

+

D6 J um per1

1 2

1

in+

2

24V

30/38

D7 J um per

1 2

1

in-

1

Page 31

AN2259 6 REFERENCE DESIGN VERSIONS

Table 9. 6 to 24Vdc Input 1W LED Driver Bill of Materials

Qty Reference

Part

Description

Mfg P/N Mfg Geomet ry Mtg

1C1

1C2

2C3, C4

1C5

1D2

1D7

1D6

1 L1 100uH Inductor DO3308P-104 Coilcraft

1 Q1 PNP Transistor MMBT3906 STMicroelectronics SOT-23 SMD

1 Rs 0. 68 Ohm 1% 1206 SMD

1 R1 2.74k 1% 0805 SMD

1 R2 1.30k 1% 0805 SMD

22uF/35V

Electrolytic

220pF/50V

Ceramic

22nF/50V

Ceramic

4.7nF/50V

Ceramic

Schottky Di ode

1A/40V

Jumper at D7

position

Jumper at D6

position

EEU-

FC1H220

STPS1L40A STMicroelectronics SMA SM D

Panasonic Radial TH

SMD

SMD

SMD

SMD

SMD

9.4mm x

12.95mm

SMD

1 R3 4.7k 5% 0805 SMD

1 R4 240k 5% 0805 SMD

1U1

Step-down

controller

L5970D STMicroelectronics SO8 SMD

31/38

Page 32

6 REFERENCE DESIGN VERSIONS AN2259

J

V

Figure 15. 6 to 24Vdc Input 3W LED Driver Schematic

L5973D

U1

J3

1

100uH

L1

2.74K

R1

1

OUT

VCC

8

J4

LED+

D2

1/8W

1 2

6

5

FB

VREF

SYNC

COMP

2

4

LED-

1

STPS2L40U

1 2

GND

INH

C3

1.33K

R2

7

3

R3

4.7K

22nf

1 2

R4

1/8W

1 2

Rs

0.33

12

1/8W

C4

22nf

240K

1/8W

1 2

MMBT3906

1/2W

2

13

Q1

C5

4.7nf

C2

220pf

35V

C1

68uF

+

D6 J umper

1 2

1

J2

Vin+

24V

32/38

D7 Jumper

1 2

1

in-

1

Page 33

AN2259 6 REFERENCE DESIGN VERSIONS

Table 10. 6 to 24Vdc Input 3W LED Driver Bill of Materials

Qty Reference

Part

Description

Mfg P/N Mfg Geomet ry Mtg

1C1

1C2

2C3, C4

1C5

1D2

1D6

1D7

1 L1 100uH Inductor DO3316P-104 Coilcraft

1 Q1 PNP Transistor MMBT3906 STMicroelectronics SOT-23 SMD

1 Rs 0.33 Ohm 1%

1 R1 2.74k 1% 0805 SMD

1 R2 1.33k 1% 0805 SMD

1 R3 4.7k 5% 0805 SMD

68uF/35V

Electrolytic

220pF/50V

Ceramic

22nF/50V

Ceramic

4.7nF/50V

Ceramic

Schottky Di ode

2A/40V

Jumper at D6

position

Jumper at D7

position

EEU-

FC1V680

STPS2L40U STMicroelectronics SMB SMD

CRL2010-FW-

R330E

Panasonic Radial TH

SMD

SMD

SMD

SMD

SMD

9.4mm x

12.95mm

Bourns 2010 SMD

SMD

1 R4 240k 5% 0805 SMD

1U1

Step-down

controller

L5973D STMicroelectronics SO8 SMD

33/38

Page 34

6 REFERENCE DESIGN VERSIONS AN2259

0.24o

J4

E

D

Figure 16. 6 to 24Vdc Input 5W LED Driver Schematic

L5973D

L1 DO3316P-104

U1

J3

LE

1

L

1

Rs

1/4W

1 2

100uH

R1

D2

2.74K

STPS2L40U

1/8W

R2

1.30K

1/8W

1 2

R4

C4

240k

22nF

1/8W

1 2

C5

4.7nF

1

OU T

VCC

8

5

6

FB

VREF

GND

7

INH

3

SYNC

COMP

2

4

C3

R3

4.7k

1/8W

22nF

2

13

Q1

MMBT3906

VccVcc

Vcc

35V

C1

100uF

+

D6 Jumper

1 2

1

J2

CON1

Vin +

34/38

C2

220pF

D7 Jumper

J1

1 2

1

CON1

Vin -

Page 35

AN2259 6 REFERENCE DESIGN VERSIONS

Table 11. 6 to 24Vdc Input 5W LED Driver Bill of Materials

Qty Reference

Part

Description

Mfg P/N Mfg Geomet ry Mtg

1C1

1C2

2C3, C4

1C5

1D2

1D6

1D7

1 L1 100uH Inductor DO3316P-104 Coilcraft

1 Q1 PNP Transistor MMBT3906 STMicroelectronics SOT-23 SMD

1 Rs 0.24 Ohm 1%

1 R1 2.74k 1% 0805 SMD

1 R2 1.30k 1% 0805 SMD

1 R3 4.7k 5% 0805 SMD

100uF/35V

Electrolytic

220pF/50V

Ceramic

22nF/50V

Ceramic

4.7nF/50V

Ceramic

Schottky Di ode

2A/40V

Jumper at D6

position

Jumper at D7

position

EEU-

FC1V101

STPS2L40U STMicroelectronics SMB SMD

CRL2010-FW-

R240E

Panasonic Radial TH

SMD

SMD

SMD

SMD

SMD

9.4mm x

12.95mm

Bourns 2010 SMD

SMD

1 R4 240k 5% 0805 SMD

1U1

Step-down

controller

L5973D STMicroelectronics SO8 SMD

35/38

Page 36

7 REVISION HISTORY AN2259

7 REVISION HISTORY

Date Revision Changes

04-Nov-2005 1.0 First edition

36/38

Page 37

AN2259 7 REVISION HISTORY

37/38

Page 38

7 REVISION HISTORY AN2259

I

s

o

d

b

ct

t

ot

a

nformation furnished is believed to be accurate and reliable. However, STMicroelectronics assumes no responsibility for the consequence

f use of such information nor for any infringement of patents or other rights of third parties which may result from its use. No license is grante

y implic ation or otherwise under any patent or pat ent rights of STMicroelectronics. Specifications mentioned in thi s publicatio n are sub je

o change without notice. This publication supersedes and replaces all information previously supplied. STMicroelectronics products are n

uthoriz ed for use as critical compo nents in life support devic es or systems without express written approval of STMicroel ectronics.

The ST logo is a registered t rademark of ST M i croelectr oni cs.

All other nam es are the pro perty of their respectiv e owners

Austra l i a - Be l gi um - Brazil - Canada - China - Czech Rep ubl ic - Finlan d - F rance - Germ any - Hong Kon g - India - Israel - Italy - Japan -

Malaysi a - M al ta - Morocco - Singapore - Spain - Swe den - Switze rl and - United Kingdom - United States of America

© 2005 STMi croelectronics - All rights reserved

STMicroelectron ics group of com panies

www.st.com

38/38

Loading...

Loading...