Page 1

AN2208

APPLICATION NOTE

Designing Industrial Applications with

VN808/VN340SP High-side Drivers

Introduction

This application note describes the functions of VN808/VN340SP high-side drivers in industrial

applications. The VN340SP and VN808 are monolithic devices based on VIPower technology. With

primary application requirements being safety and reliability , this application note co v ers the v arious tests

used to ensure compliance with international electromagnetic compatibility (EMC) specifications as well

as other requirements.

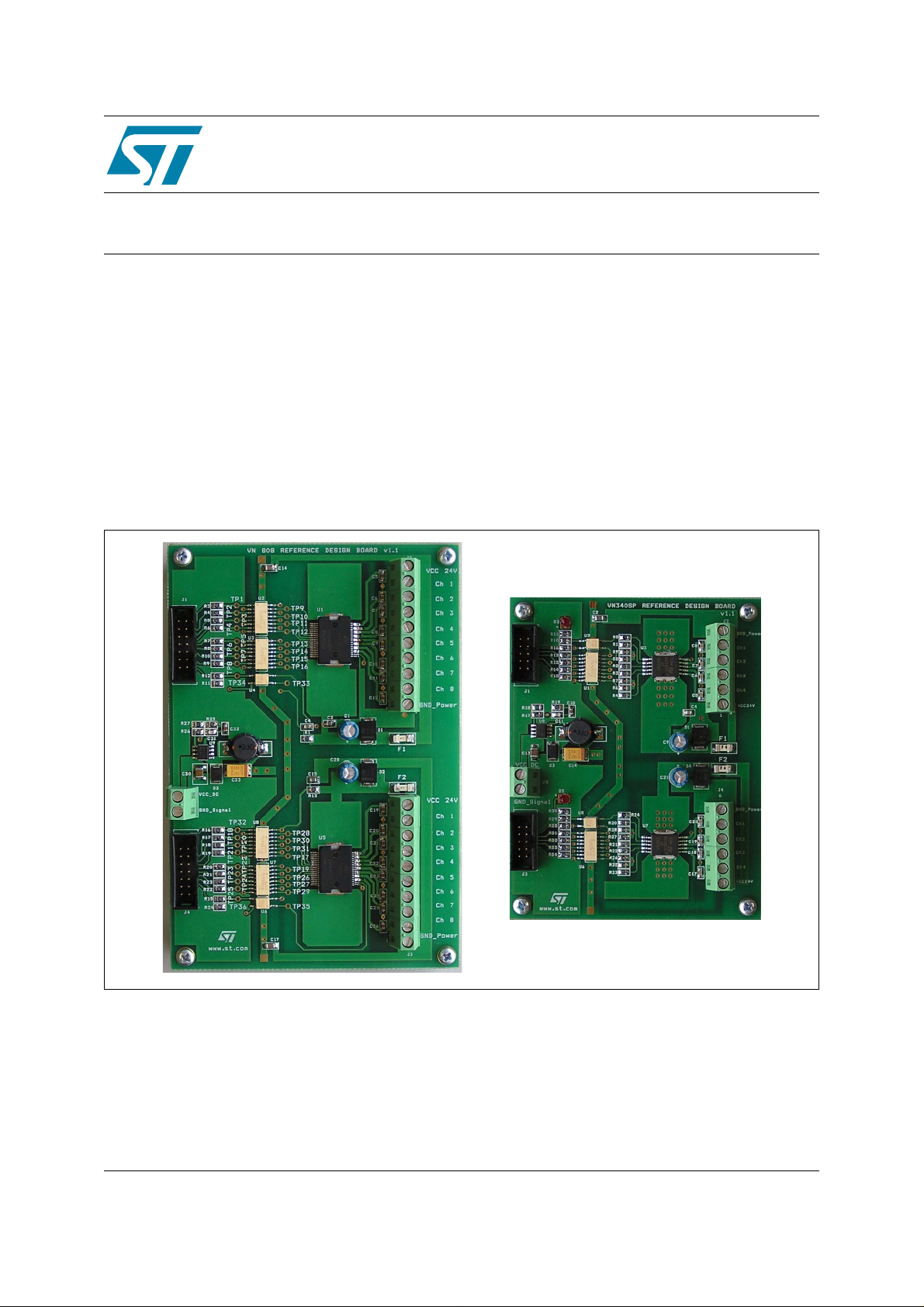

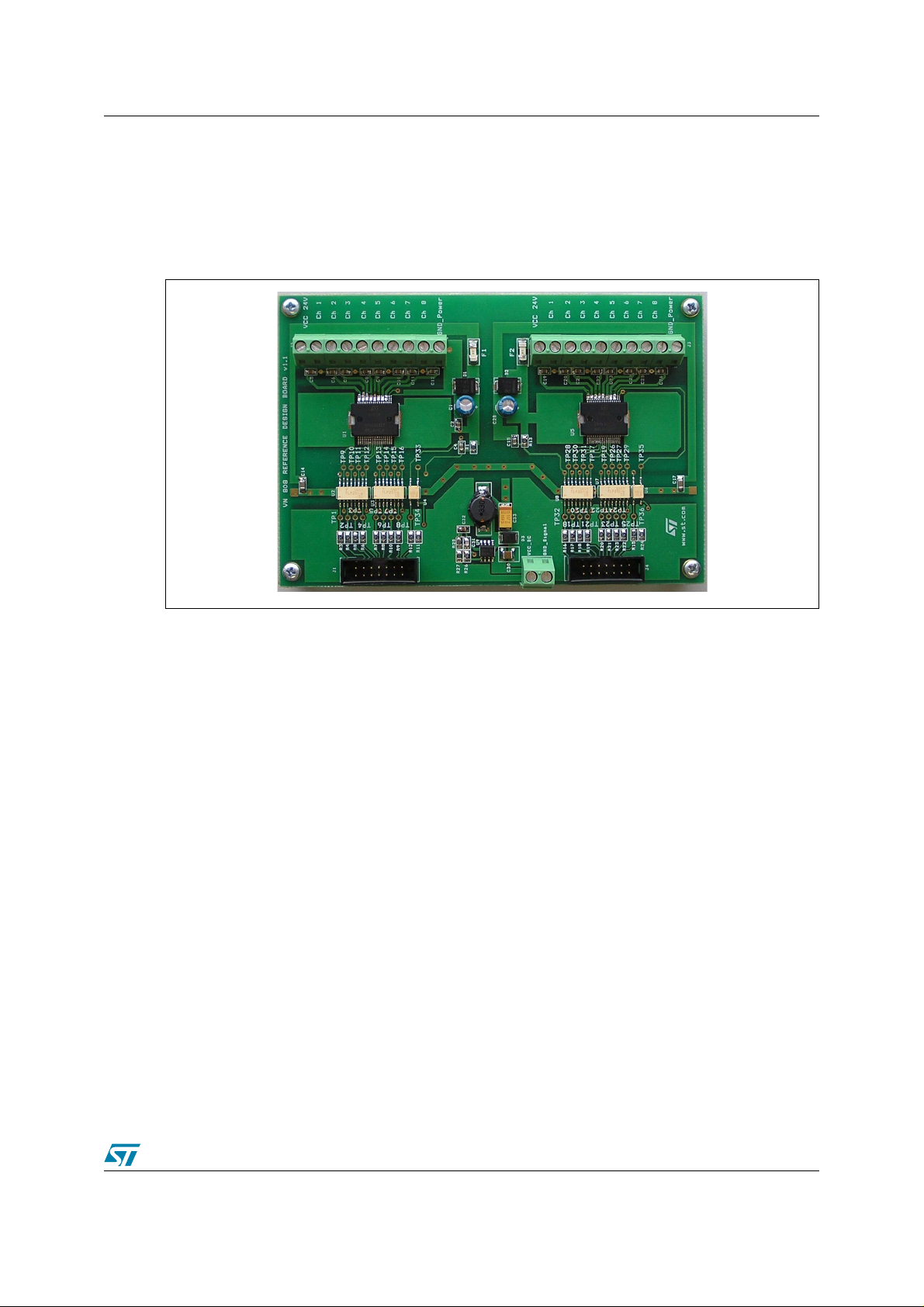

VN808/VN340SP high-side drivers are teste d mounted on their respecti ve ref eren ce design board (RDB).

Note: Additional information concerning the L5970D DC/DC converter, based on BCD technology, is

included in Section Appendix C: L5970D DC/DC converter on page 46.

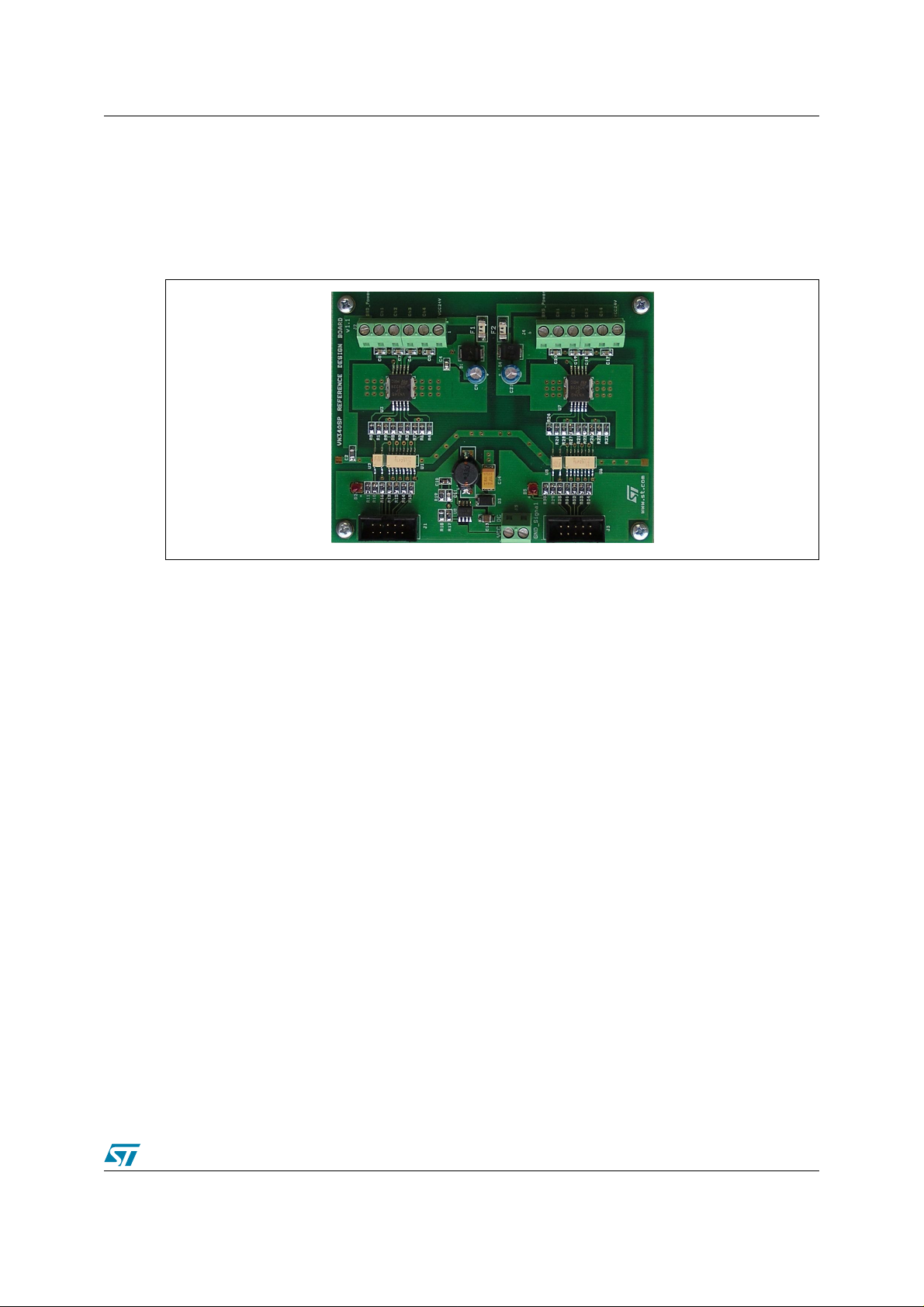

Figure 1. VN808 and VN340SP reference design boards

Rev. 1

September 2005 1/51

http:/www.st.com

1

Page 2

AN2208

Contents

1 High-side driver description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2 VN808 reference design board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.1 Circuit description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.2 Surge suppression . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.3 Isolation recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.4 Heatsink recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.5 Schematic diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3 VN340SP reference design board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.1 Circuit description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.2 Schematic diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4 Load switching tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5 Thermal stress tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

6 Electromagnetic compatibility (EMC) tests . . . . . . . . . . . . . . . . . . . . . . . . 22

6.1 Terminology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

6.2 List of EMC test equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

6.3 Requested test levels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

6.3.1 IEC 61000-4-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

6.3.2 IEC 61000-4-5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

6.3.3 IEC 61000-4-6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

6.4 IEC 61000-4-4 EFT test setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

6.4.1 Power supply tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

6.4.2 Input port tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

6.4.3 Output port tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6.5 IEC 61000-4-5 surge test setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

6.5.1 Power supply tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

6.5.2 Output port tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

6.6 IEC 61000-4-6 conducted immunity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

6.6.1 Power supply tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

2/51

Page 3

AN2208

6.6.2 Input port tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

6.6.3 Output port tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

7 Test results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

7.1 VN808 HSD test results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

7.1.1 Load switching test results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

7.1.2 Thermal stress test results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

7.1.3 EMC test results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

7.2 VN340SP HSD test results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

7.2.1 Load switching test results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

7.2.2 Thermal stress test results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

7.2.3 EMC test results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Appendix A VN808 reference design board (RDB) . . . . . . . . . . . . . . . . . . . . . . . 42

A.1 VN808 RDB bill of materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

A.2 Recommended VN808 PCB Layout. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Appendix B VN340SP reference design board (RDB). . . . . . . . . . . . . . . . . . . . . 44

B.1 VN340SP RDB bill of materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

B.2 Recommended VN340SP RDB PCB layout . . . . . . . . . . . . . . . . . . . . . . . . . 45

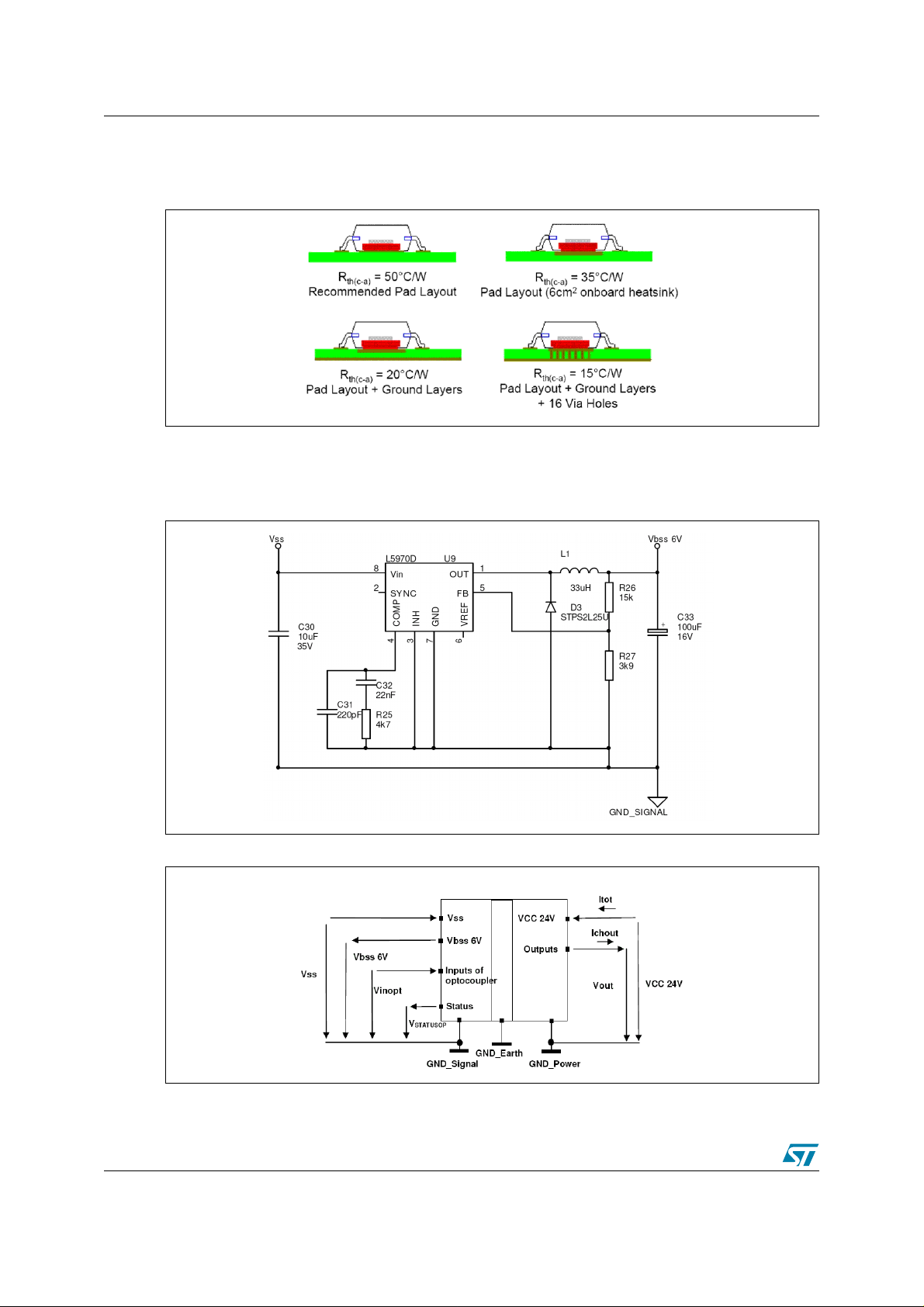

Appendix C L5970D DC/DC converter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

C.1 Functional description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

C.2 L5970D layout recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

C.3 L5970D DC/DC converter load test results . . . . . . . . . . . . . . . . . . . . . . . . . . 48

8 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

3/51

Page 4

AN2208

List of figures

Figure 1. VN808 and VN340SP reference design boards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

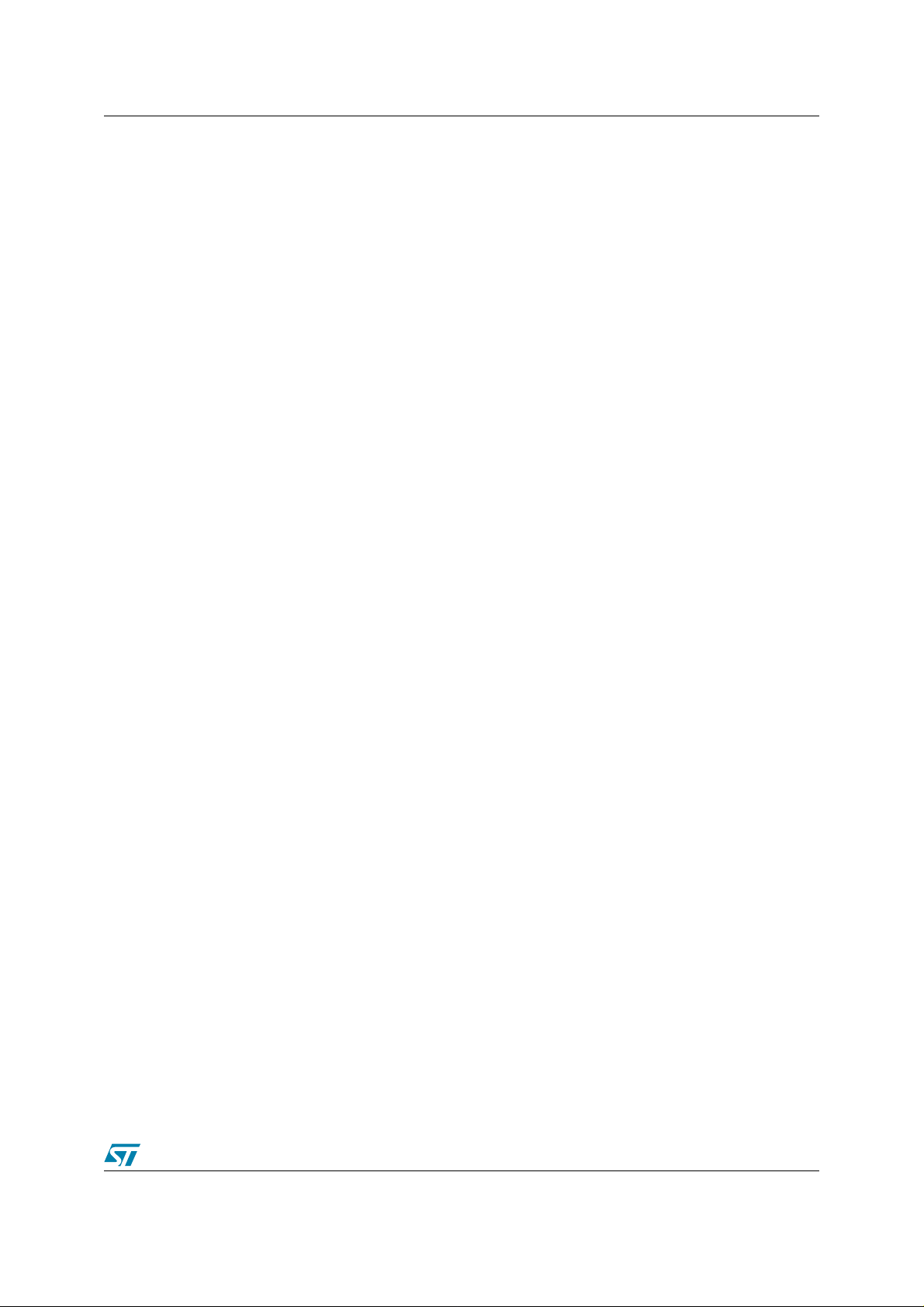

Figure 2. VN808 block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Figure 3. VN340SP block diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Figure 4. VN808 reference design board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Figure 5. Surge Suppression Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

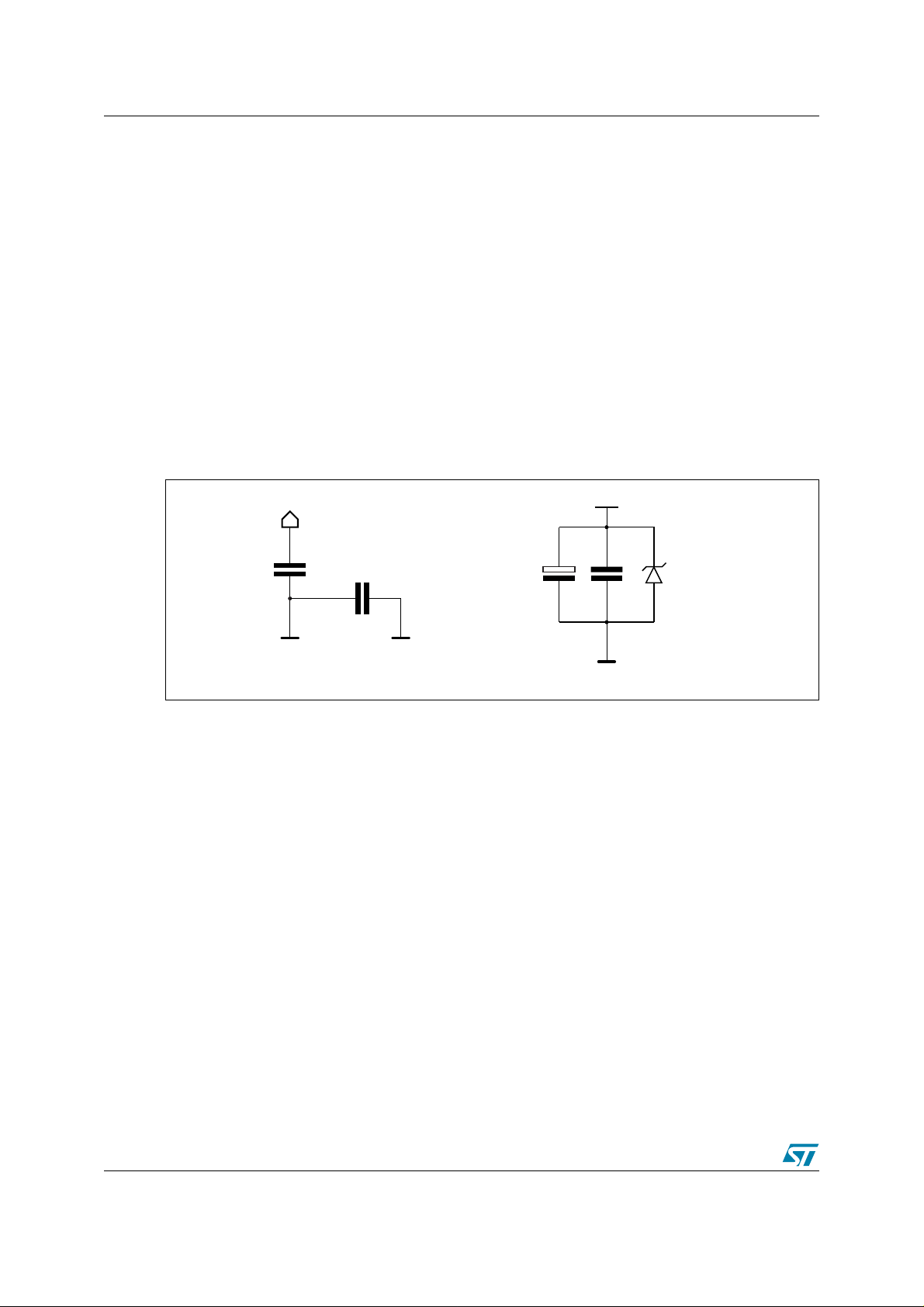

Figure 6. Typical input/status isolation by optocouplers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Figure 7. Burst pulse affecting one input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

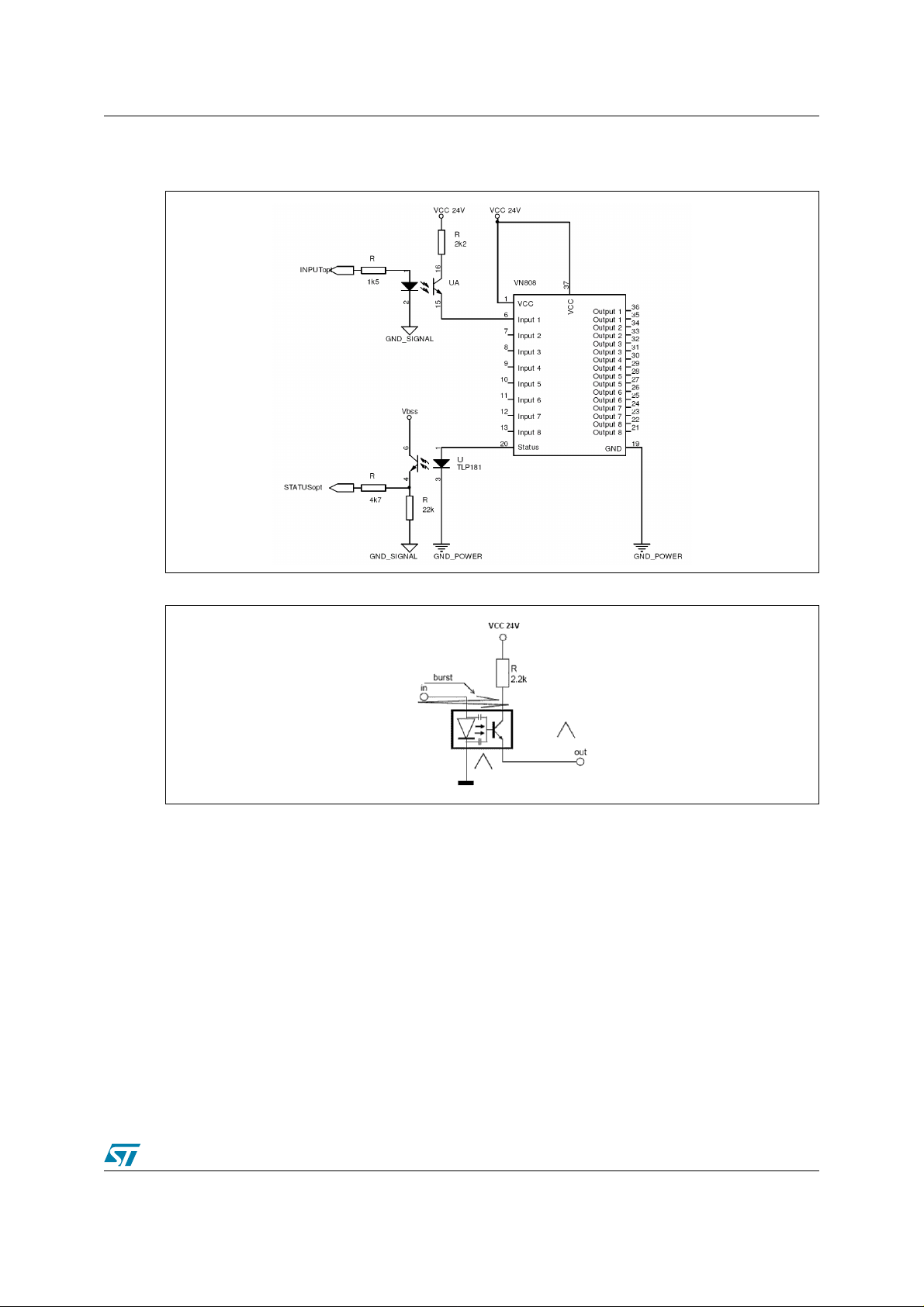

Figure 8. Recommended layout for High Power Dissipation capability . . . . . . . . . . . . . . . . . . . . . . . 12

Figure 9. DC/DC part of the application circuit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Figure 10. Current and voltage conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Figure 11. Complete application circuit with VN808 and L5970D devices. . . . . . . . . . . . . . . . . . . . . . 13

Figure 12. Switching part of the application circuit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Figure 13. VN340SP reference design board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 14. Switching part of the application circuit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 15. Complete application circuit with VN340SP and L5970D devices . . . . . . . . . . . . . . . . . . . 17

Figure 16. Description of the switching inductor loads. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Figure 17. IPS simplified structure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 18. Simplified thermal models. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 19. Power supply tests (IEC 61000-4-4). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Figure 20. Switch diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Figure 21. Test on input ports (IEC 61000-4-4) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Figure 22. Output port tests (IEC 61000-4-4) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Figure 23. Power supply tests (IEC 61000-4-5). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Figure 24. Test on Output Ports (IEC 61000-4-5) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Figure 25. Power supply tests (IEC 61000-4-6). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Figure 26. Input port tests (IEC 61000-4-6) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Figure 27. Output port tests (IEC 61000-4-6) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Figure 28. VN808 Waveforms (Part 1). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Figure 29. VN808 Waveforms (Part 2). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Figure 30. GND_Power disconnection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Figure 31. Switching lamps: VCC = 24V, f = 0.5 Hz, Wave1 = VINOPT,

Wave2 = VOUT, Wave4 = ICH1OUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Figure 32. Waveform tOFF inductor load: VCC = 24V, L = 130mH, RLOAD = 63W,

tOFF = 1.2101 ms, Wave2 = VOUT, Wave1 = VINOPT, Wave4 = ICH1OUT . . . . . . . . . . 32

Figure 33. Waveform switching inductive load: VCC = 24V, L = 130mH, RLOAD = 48W,

f = 0.5Hz, Wave2 = VOUT, Wave1 = VINOPT, Wave4 = ICH1OUT . . . . . . . . . . . . . . . . . 33

Figure 34. Switching with short circuit: VCC = 24V, f = 0.5Hz, Wave2 = VSTATUSOPT,

Wave1 = VINOPT, Wave4 = ICH1OUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Figure 35. Time delay between VINOPT and VOUT: VCC = 24V, Load = Lamp,

Wave2 = VOUT, Wave3 = VINOPT, Dt = 58.462 µs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Figure 36. GND_Power disconnection for VN808: VCC = 25V, Load = Lamp,

Wave1 = VCC, Wave2 = VOUT, Wave3 = GND of power supply . . . . . . . . . . . . . . . . . . . 33

Figure 37. Waveform ITOT and VINOPT during the test with short circuit VCC = 28V,

TA = 85°C, Wave4 = ITOT, Wave1 = VINOPT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Figure 38. Waveform on ITOT and VINOPT during the test with short circuit VCC = 28V,

TA = –25°C, Wave4 = ITOT, Wave1 = VINOPT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Figure 39. Case temperature dependency vs. current ITOT (TA = 25°C and VCC = 24 V) . . . . . . . . 34

Figure 40. Burst applied on the power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

4/51

Page 5

AN2208

Figure 41. Burst applied on the output channel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Figure 42. Positive surge applied on power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Figure 43. Negative surge applied on power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Figure 44. Switching lamps: Vcc = 24V, f = 0.5Hz, Wave3 = VINOPT,

Wave2 = VOUT, Wave4 = ICH1OUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Figure 45. Waveform tOFF inductor load: Vcc = 24V, L = 130mH, RLOAD = 60W,

tOFF = 1.2276ms, Wave2 = VOUT, Wave3 = VINOPT, Wave4 = ICH1OUT. . . . . . . . . . . 38

Figure 46. Time delay between VINOPT and VOUT: Vcc = 24V, Load = Lamp,

Wave2 = VOUT, Wave3 = VINOPT, Dt = 139µs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Figure 47. Switching with short circuit: Vcc = 24V, f = 0.5Hz, Wave2 = VSTATUSOPT,

Wave3 = VINOPT, Wave4 = ICH1OUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Figure 48. Waveform switching inductive load: Vcc = 24V, L = 130mH, RLOAD = 48W,

f = 0.5Hz, Wave2 = VOUT, Wave3 = VINOPT, Wave4 = ICH1OUT . . . . . . . . . . . . . . . . . 39

Figure 49. Switching with short circuit: Vcc = 24V, f = 0.5Hz, Wave2 = VSTATUSOPT,

Wave3 = VINOPT, Wave4 = ICH1OUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Figure 50. Waveform ITOT and VSTATUSOPT during the test with short circuit:

Vcc = 28V, TA = 85°C, Wave4 = ITOT, Wave1 = VSTATUSOPT . . . . . . . . . . . . . . . . . . . 39

Figure 51. Waveform on ITOT and VSTATUSOPT during the test with short circuit:

Vcc = 28V, TA = –25°C, Wave4 = ITOT, Wave1 = VSTATUSOPT . . . . . . . . . . . . . . . . . . 39

Figure 52. VN808 RDB PCB layout (top and bottom) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Figure 53. VN808 RDB PCB layout (component side) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Figure 54. VN340SP RDB PCB layout (Top side) and (Bottom side) . . . . . . . . . . . . . . . . . . . . . . . . . 45

Figure 55. VN340SP RDB PCB layout (component side) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Figure 56. L5970D block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Figure 57. L5970 DC/DC converter layout example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Figure 58. Efficiency vs. output current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Figure 59. Output voltage stability of L5970D, Vss = 24 V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Figure 60. Voltage ripple on capacitor C30, IOUTDC = 0.4A, Vss = 24V . . . . . . . . . . . . . . . . . . . . . . 49

Figure 61. Waveform on coil L1, IOUTDC = 0.4A, Vss = 24V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Figure 62. Voltage ripple on capacitor C33, Vss = 24V, IOUTDC = 0.4 A. . . . . . . . . . . . . . . . . . . . . . 49

Figure 63. Waveform on coil L1, without load, Vss = 24V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

5/51

Page 6

AN2208

List of tables

Table 1. VN808 and VN340SP main characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Table 2. EMC industrial compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Table 3. Abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Table 4. Equipment list for EMC tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Table 5. Abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Table 6. EMC test IEC 61000-4-4 EFT test results (VN808 RDB) . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Table 7. EMC test IEC61000-4-5 surge test results (VN808 RDB) . . . . . . . . . . . . . . . . . . . . . . . . . 36

Table 8. EMC test IEC 61000-4-6 conducted immunity test results (VN808 RDB) . . . . . . . . . . . . . 37

Table 9. EMC test IEC 61000-4-4 EFT test results (VN340SP RDB). . . . . . . . . . . . . . . . . . . . . . . . 40

Table 10. EMC test IEC61000-4-5 surge test results (VN340SP RDB) . . . . . . . . . . . . . . . . . . . . . . . 40

Table 11. EMC test IEC 61000-4-6 conducted immunity test results (VN340SP RDB) . . . . . . . . . . . 41

Table 12. VN808 RDB bill of materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Table 13. VN340SP RDB bill of materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

6/51

Page 7

AN2208 1 High-side driver description

1 High-side driver description

The VN808 (Figure 2) is a high-side driver (HSD) us ed to driv e eight ind epend ent l oads . Act ive

current limitation combined with thermal shutdown and automatic restart functions protect the

device against ov erload. A thermal case substrat e protection is implemented to prot ect the FRx

substrate under short circuit and worst case ambient conditions in terms of reliability. The

device automatically turns off when the ground pin is disconnected. The VN340SP and VN808

are especially suitable for use with programmable logic controllers (PLC) in industrial

applications.

The VN340SP (Figure 3) is used to drive four independent resistive, capacitive and inductive

loads in high-side configurations. Active current limitation prevents the system power supply

from dropping in the event of a short load. A built-in thermal shutdown circuit protects the chip

from high temperatures and short circuits. Each I/O is pulled down when an over-temperature

condition of the relative channel is detected and restarts after reaching the lower thermal

threshold. The system oscillates depending on the thermal impedance of the application.

Table 1. VN808 and VN340SP main characteristics

VN340SP HSD VN808 HSD

Output current per channel 0.5A at 24V

Built-in current limiter

Short-load and overtemperature (Junction)

protection

Under-voltage shutdown

Open-drain diagnostic output Status output current 2 to 4 mA

DC supply voltage 36V DC supply voltage 45V

V e ry low stand-by current

Short-load and overtemperature (Junction and

Case) protection

7/51

Page 8

1 High-side driver description AN2208

Figure 2. VN808 block diagram

INPUT 1

INPUT 2

INPUT 3

INPUT 4

INPUT 5

INPUT 6

INPUT 7

LOGIC CONTROL

INPUT 8

STATUS

Figure 3. VN340SP block diagram

I/O1

I/O2

I/O3

I/O4

DIAG

GROUND

Overtemp 1

Overtemp 2

Overtemp 3

Overtemp 4

UNDERVOLTAGE DETECTION

CLAMP POWER

CURRENT LIMITER

JUNCTION TEMP. DETECTION

Same struct ure f or al l channels

CASE TEMP. DETECTION

V

CC

Undervoltage

Control

Logic

Driver 1

I Limit 1

Driver 2

I Limit 2

Driver 3

I Limit 3

Driver 4

I Limit 4

V

CC

CLAMP

VCC

GND

OUTPUT 1

OUTPUT 2

OUTPUT 3

OUTPUT 4

OUTPUT 5

OUTPUT 6

OUTPUT 7

OUTPUT 8

Ai11606

OUTPUT 1

OUTPUT 2

OUTPUT 3

OUTPUT 4

8/51

SC07950

Page 9

AN2208 2 VN808 reference design board

2 VN808 reference design board

This is a practical example how the VN808 high-side driver (HSD) can be used in applications

for an industrial environment.

Figure 4. VN808 reference design board

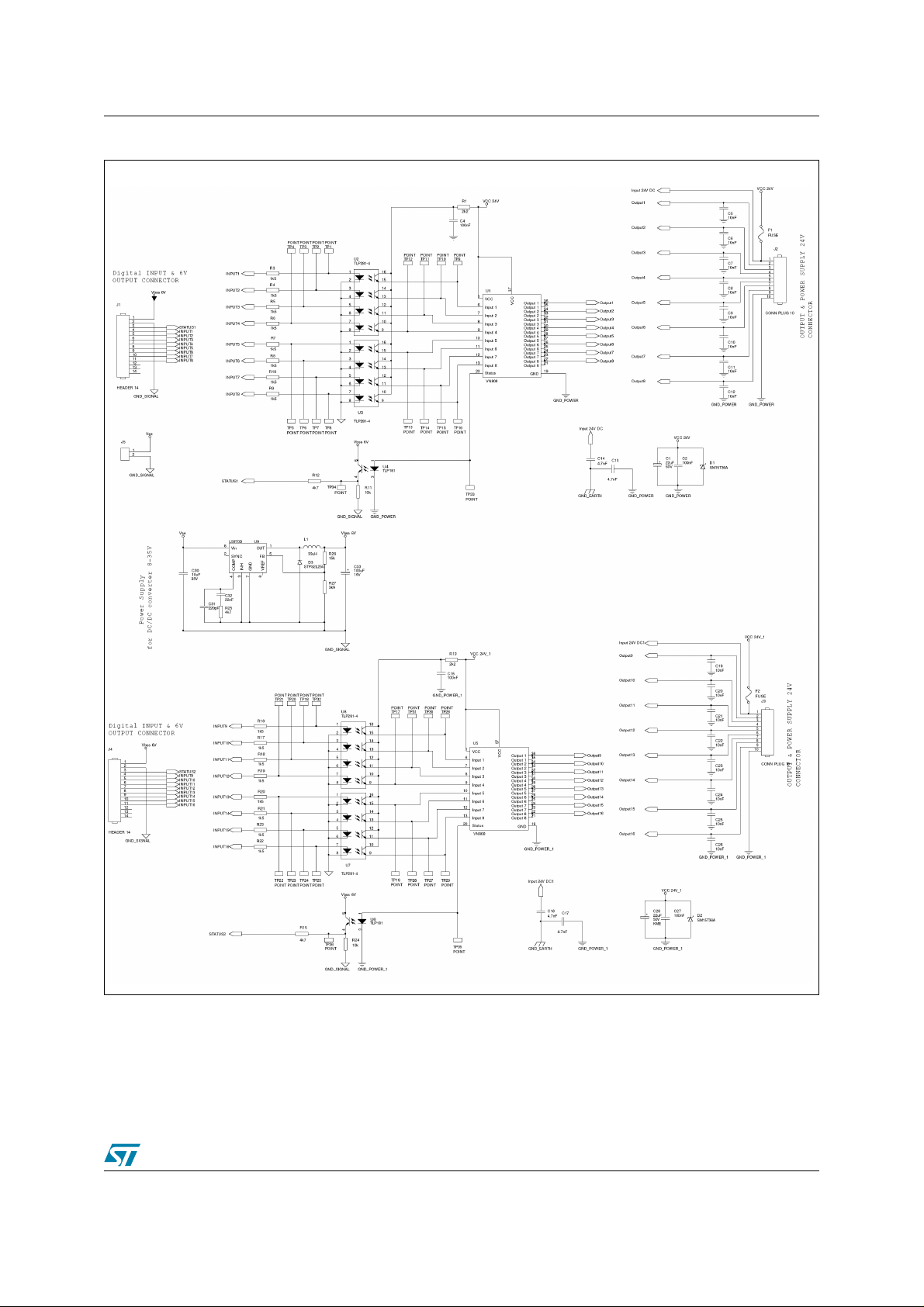

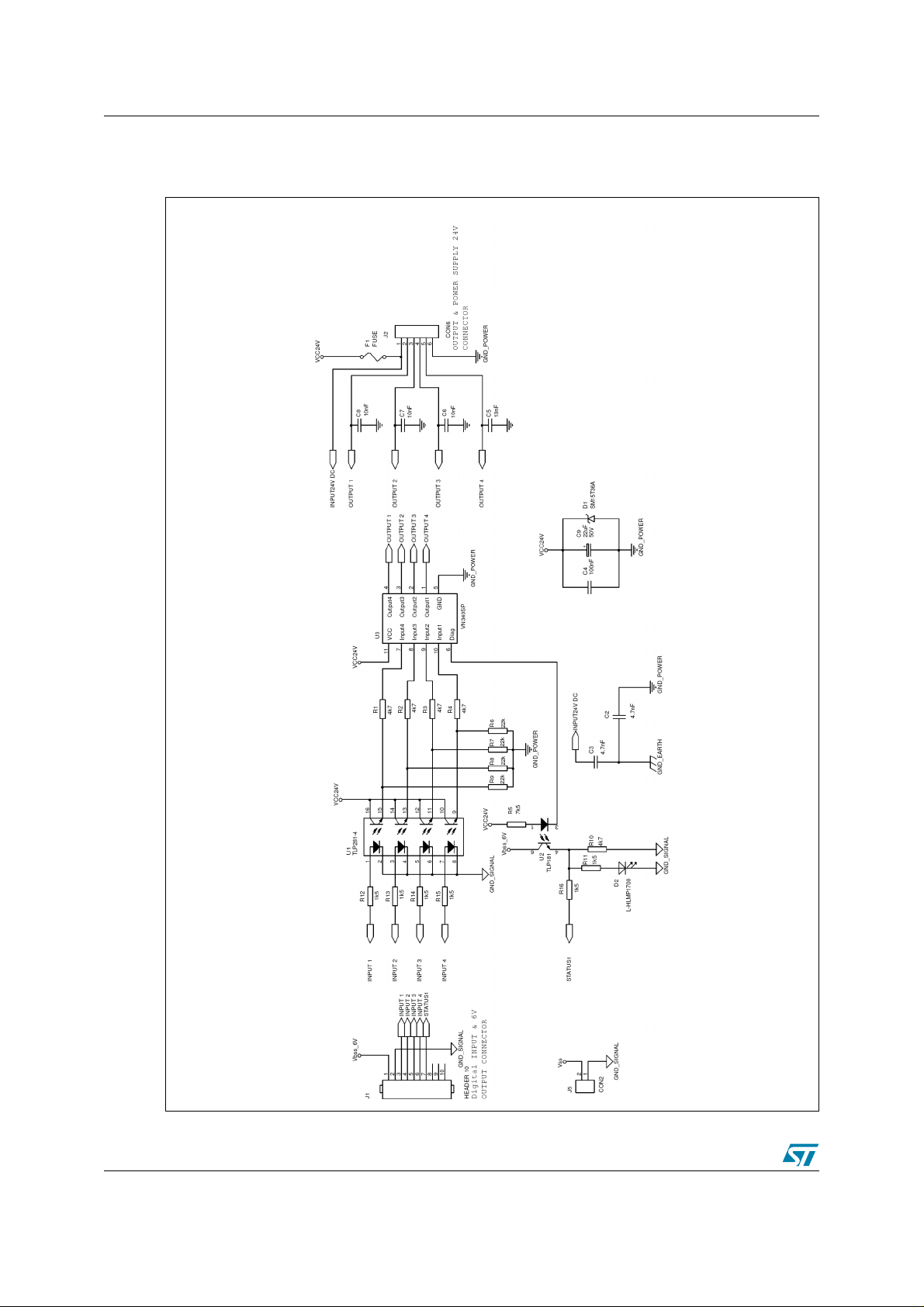

2.1 Circuit description

In order to protect the high-side driver (HSD) from the harsh industrial conditions of power

supply lines, usually optocouplers and Transil diodes are used to separate the ap plic at ion

control circuits from the power supply. Figure 11 shows a complete schematic diagram of the

VN808 reference design board.

The VN808 reference design board uses multi-channel TLP281-4 and TLP181 optocouplers.

The TLP281-4 and TLP181 are small and thin couplers, suitable for surfa ce-mounted

assemblies that consist of a photo transistor optically coupled to a gallium-arsenide infrared

emitting diode. The isolation voltage for this type of optocoupler is 2500 V

The clamping function of Transil diodes protect the HSD against transient overvoltages. The

reference design board is assembled with uni-directional SM15TXXA Transil diodes because

they protect the HSD against both positi ve and negative surge pulses. For more information

about SM15TXXA Transil diodes from STMicroelectronics, please refer to the SM15T36A

Datasheet av ailable at www.st.com.

Refer to Section A.2: Recommended VN808 PCB Layout on page 43 for more information

about designing boards to improve EMC immunity and performance in industrial environments.

2.2 Surge suppression

When designing your application, VCC and ground lines should lay on top of ea ch other,

minimizing the closed loop area and increasing the ability of the application to reject

RMS

.

9/51

Page 10

2 VN808 reference design board AN2208

environmental noise. Figure 5 shows a surge suppression block using a un i-directional

SM15T36A Transil diode.

The Transil diode provides overvoltage protection for the HSD. The SM15T36A has a peak

pulse power dissipation of 1500 W, stand-off voltage of 36 V and breakdown voltage of 37.8 V.

Depending on the application, a Transil diode with a different v a lue (for example, betw een 2 8 V

and 40 V) may be used.

An electrolytic capacitor (C1) must be placed immedi a tely afte r th e sur g e sup p re ssio n block.

The size of the electrolytic capacitor is selected based on the slope of the output current, the

impedance of the complex power supply cables, as well as the maximum allowed voltage drop

across the device . The C1 v a lue is ge ner ally 25 µF per chip. For more inf ormation about th e C1

value, please refer to Application Note AN1351: VIPower and BCDMultipower: Making life

easier with ST's high-side drivers.

A low ESR SMD capacitor (C2) must be placed as close as possib le to the HSD in order to f ilter

the power supply line for electromagnetic compatibility concerns. The suggested C2 value is

100 nF.

Figure 5. Surge Suppression Block

24V DC Input

C14

4.7 nF

GND_EARTH GND_POWER

C13

4.7 nF

2.3 Isolation recommendations

Industrial environments require good isolation between digital and power supply parts.

Optocouplers are widely used and multi-channel optocouplers represent a very attractive

solution. Figure 6 shows a schematic diagram with optocouplers connected to ground.

Although optocouplers are good isolators, they may lower the category of the Electrical Fast

Transients (EFT) immunity tests as the primary and secondary sides of the optocouplers may

still have parasitic capacitance “bonding” to each other, even though they are isolated. This

parasitic capacitance may inject a current through the base emitter junction of the

phototransistor when one half of the optocoupler is “tight” due to fast voltage transients with

respect to the other side as shown in Figure 7.

C1

22 µF

50V

VCC 24V

+

C2

100 nF

GND_POWER

D1

SM15T36A

Ai11615

If an optocoupler is used in an emitter-follower configuration, as in most industrial applications,

a high emitter voltage sig nal ma y b e induced b y applying EFTs e ven after opening the collector

termination. An efficient way to prevent this high emitter voltage signal is to provide a

conducting plane connected to gro und on both the top and bo ttom la y ers of th e PCB (under the

optocouplers) as shown in Figure 52: VN808 RDB PCB layout (top and bottom).

10/51

Page 11

AN2208 2 VN808 reference design board

Figure 6. Typical input/status isolation by optocouplers

Figure 7. Burst pulse affecting one input

2.4 Heatsink recommendations

Depending on ambient thermal conditions, HSD’s with a PowerSO10/SO36 package require

external cooling as the copper bott om p lat e of t he PSO-Package, u sed to maint ain t he ju nctio n

temperature during inductive switching, acts as a thermal capacitor.

11/51

Page 12

2 VN808 reference design board AN2208

The VN808 reference board is designed with an onboard heatsink capability (minimum heat

sink area is 6 cm²). The recommended layout for Power SO packages is shown in Fig ure 8.

Figure 8. Recommended layout for High Power Dissipation capability

2.5 Schematic diagrams

Figure 9. DC/DC part of the application circuit

Figure 10. Current and voltage conventions

12/51

Page 13

AN2208 2 VN808 reference design board

Figure 11. Complete application circuit with VN808 and L5970D devices

13/51

Page 14

2 VN808 reference design board AN2208

Figure 12. Switching part of the application circuit

14/51

Page 15

AN2208 3 VN340SP reference design board

3 VN340SP reference design board

This is a practical example how the VN340SP high-side driver (HSD) can be used in

applications for an industrial environment.

Figure 13. VN340SP reference design board

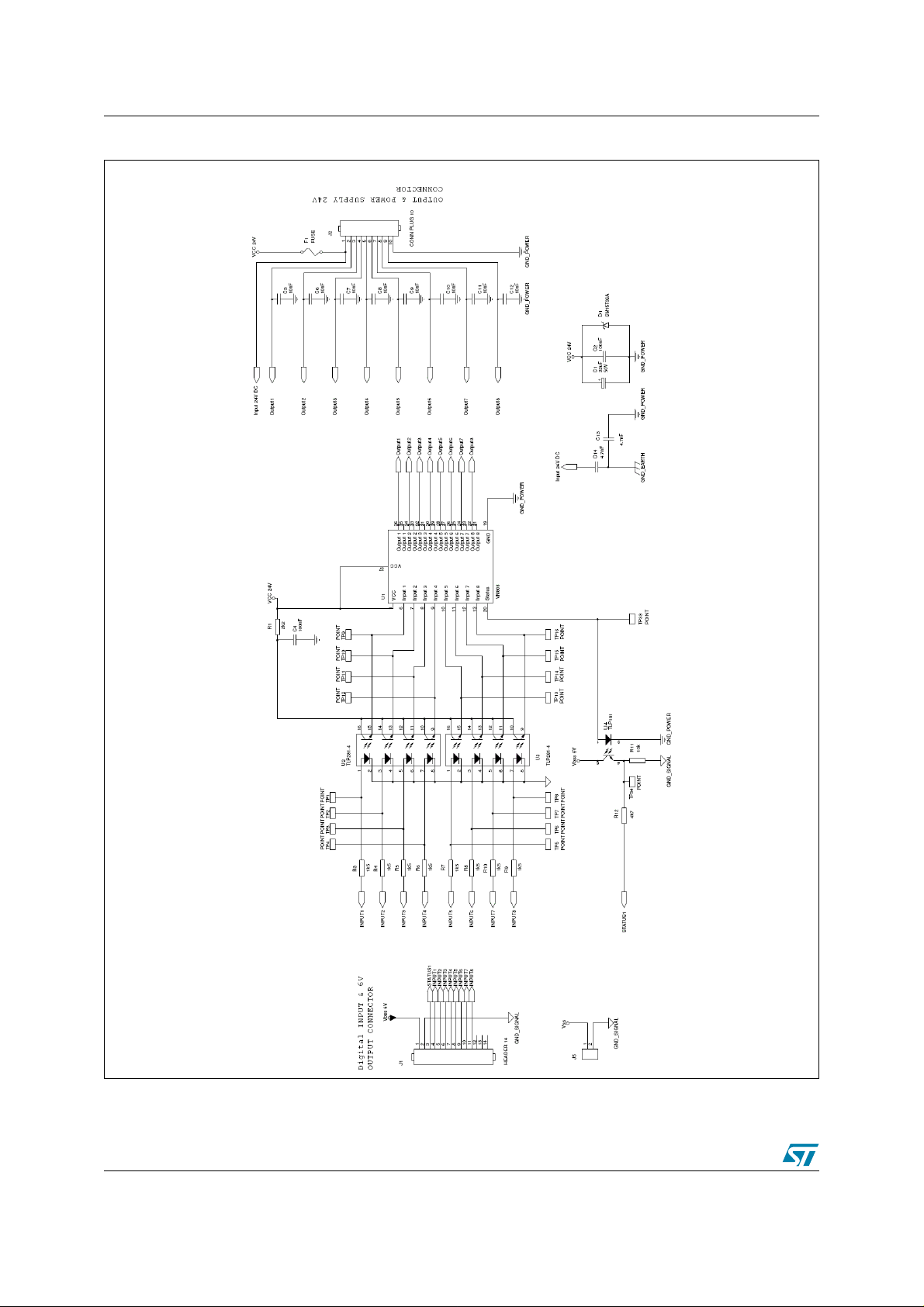

3.1 Circuit description

The application described below is very similar to that of the VN808 reference design board;

only the type of HSD and the optocoupler inter-co nn e ctio n is different. Figure 15 shows a

complete schematic diagram of the VN340SP reference design board. The optocouplers and

Transil diodes are the same as those used in the VN808 reference design board.

15/51

Page 16

3 VN340SP reference design board AN2208

3.2 Schematic diagrams

Figure 14. Switching part of the application circuit

16/51

Page 17

AN2208 3 VN340SP reference design board

Figure 15. Complete application circuit with VN340SP and L5970D devices

17/51

Page 18

4 Load switching tests AN2208

4 Load switching tests

Many differen t types of loads can be found in an industrial environment. Typical loads have

inductive or resistive characteristics. Applications compliant with UL 508 (48Ω and 1.15H)

specifications are generally considered as the worst case.

A basic description of typical switching inductor loads is given in Figure 16. The supply voltage

is nominally 24V but can rise up to 30.5V. In this application, 24V filament lamps are used with

130mH/48Ω inductors as the loads. The V

The V

switch off the circuit, the bigger | V

voltage value decides the t

CLAMP

CLAMP

Figure 16. Description of the switching inductor loads

supply condition is between 18.5V and 28. 5V DC .

CC

demagnetization duration: the faster you want to

OFF

| compared with | VCC| has to be.

Note: Typical V

STMicroelectronics’ Intelligent Powe r Switches (IPSs) provide a “fast demagnetization” output

structure, an integrated solution for fast switch-off of inductive loads.

IPSs are basically a Zener diode with a 52V breakdown (approx.) and high power dissipation

capability connected between an output and V

the output voltage is then clamped at V

supply voltage.

The integrated clamping structure saves on components and space. Internal demagnetization

can be used only if thermal behavior and load conditions are well known to designers.

Therefore a detailed analysis of thermal behavior related to inductive load switching is

mandatory to prevent improper utilization of the IPSs.

VINx Load x

VINx Load x

VINx Load x

VN808

VINx

L

V

OUT

R

value for VN808 is 52V.

CLAMP

V

IN

V

V

OUT

V

I

OUT

= VCC - 52, and is therefore dependent on the

OUT

I

OUT

as shown in Figure 17. In most applications,

CC

t

OFF

I

O

CC

CLAMP

Ai11608

18/51

Page 19

AN2208 4 Load switching tests

Figure 17. IPS simplified structure

VCC

ZD1

50V

High Side Switch

S1

GND

The parameters are given by the following formulas:

E

OFF

t

OFF

V

CLAMP

---------------------

R

LOAD

L

----------------- -

R

LOAD

•=

-------------------------------------- -+

ln•=

1

V

CLAMPVCC

LV

•

CC

-------------------- V

R

LOAD

P

t

OFF

CLAMPVCC

E

OFF

------------- -=

t

OFF

For example for VN808:

Where, I

V

CLAMP

t

= 1.6 ms

OFF

E

= 21 mJ per channel

OFF

= 0.5 A, L = 130 mH, f = 0.5 Hz, VCC = 24 V and V

OUT

- VCC = 28 V and R

LOAD

P

= 48 Ω

t

OFF

4

21mJ

---------------- -

• 52.5W==

1.6ms

OUT

V

CC

–

–()t

Ai11609

•()–

OFF

CLAMP

= 52 V

Note: For more information about switching inductor loads, see Application Note AN1351.

19/51

Page 20

5 Thermal stress tests AN2208

5 Thermal stress tests

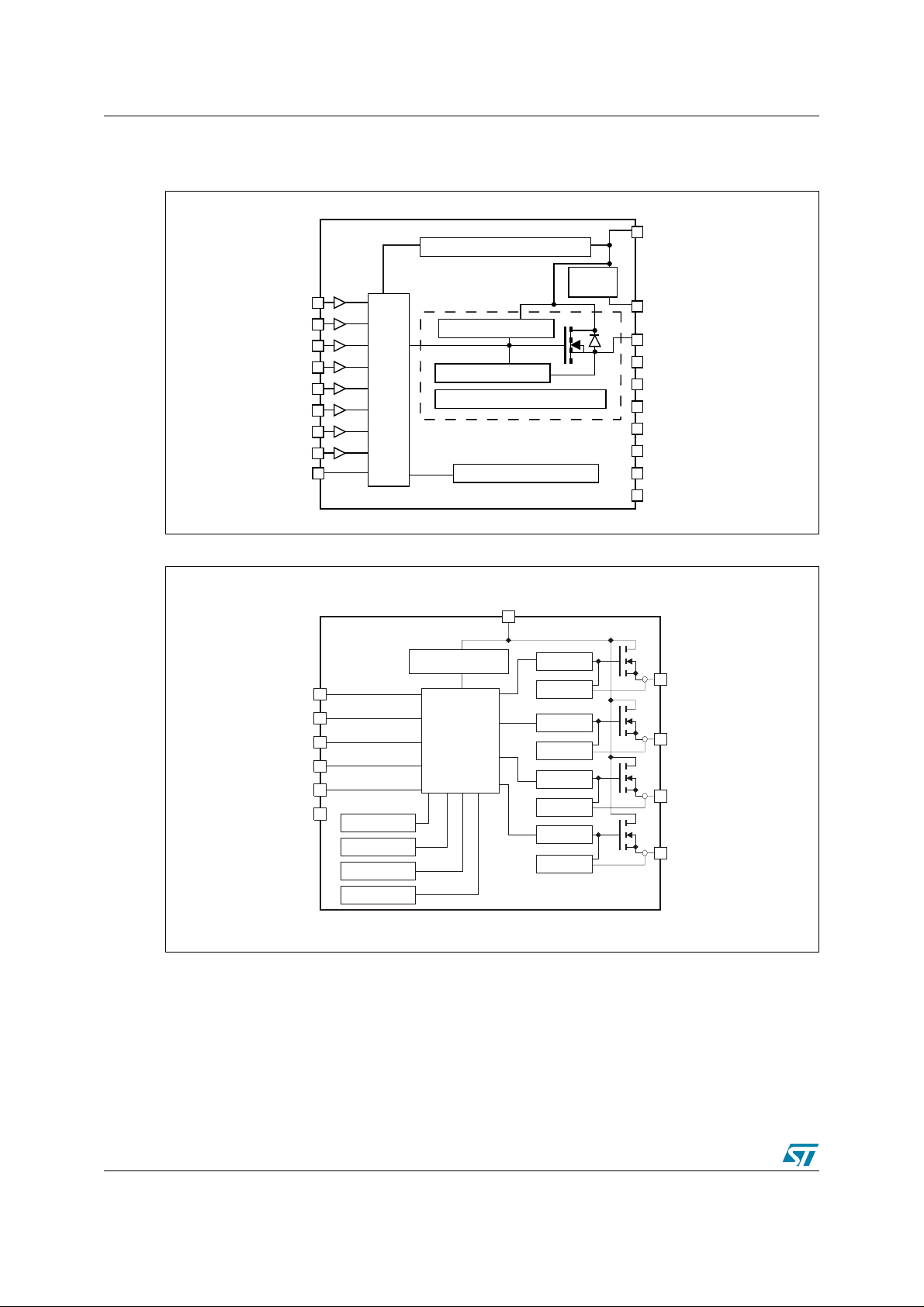

The thermal model of a generic Intelligent Power Switch (IPS) can be exemplified as shown in

Figure 18. R

resistance, whereas C

package itself.

Figure 18. Simplified thermal models

thJC

and R

represent the junction-to-case and the case-to-ambient thermal

thCA

is the predominant thermal capacitance and is basically related to the

thC

VN340 (4-channel IPS)

R

= 1.33˚ C/W R

th1

T

J1

T

J2

T

J3

T

J4

= 1.67˚ C/W

th2

C

thC

T

C

VN808 (8-channel IPS)

R

= 1.9˚ C/W R

th1

T

J1

T

J2

T

J3

T

J8

= 1.1˚ C/W

th2

C

thC

T

Note: Case thermal time co n st an t of 48 ms with out exter n al co olin g.

R

= R

thJC

th2+Rth1

If Nb = 8, R

If Nb = 4, R

/Nb of channels

= 1.34°C/W

thJC

= 2°C/W

thJC

The aim of the designer will be to provide the lowest possible junction–ambient thermal

impedance, in order to minimize the chip temperature jump-up.

16 mJ/K

C

36 mJ/K

R

thCA

T

A

R

thCA

T

A

Ai11610

Example VN808:

I = 0.5 A, L = 130 mH, f = 0.5 Hz, T

= 60°C, Duty cycle = 0.5, VCC = 24 V,

A

8 channels active, 4 chann els working at the same time.

Conduction losses:

Losses due to I

(supply current): 24V* 12mA(max.) = 288 mW

SON

PowerMOS losses at ON State: 280 mΩ(max.)*(0.5)^2*0.5*8 = 280 mW

Switching losses:

Switching losses are due to inductance discharge:

P

DOFF

= 8* E

*F = 8* 21mJ * 0.5 = 84 mW

OFF

Total losses and Junction temperature:

Total power losses = 652 mW (0.652 W)

20/51

Page 21

AN2208 5 Thermal stress tests

If the PSO36 is on FR4, R

t

= 1.6 ms << 48 ms (constant time of the PSO36)

OFF

T

= TA + Pmean* R

C

thCA

= 50°C/W

thCA

TC = 60°C +34 °C = 94°C

T

JMax

during t

= 94 + (1.1 + (1.9/4))*52 = 175°C

OFF

21/51

Page 22

6 Electromagnetic compatibility (EMC) tests AN2208

6 Electromagnetic compatibility (EMC) tests

The VN808 and VN340SP reference design boards pass t he f ollo wing indu strial tests. (Re f er to

specific product datasheet for electrostatic discharge (ESD) characteristics).

Table 2. EMC industrial compliance

IEC Specification Description

61000-4-4 Electric Fast Transients (EFT)

61000-4-5 Surge protection

61000-4-6 Immunity to conducted disturbances

6.1 Terminology

Table 3. Abbreviations

Abbreviations

CC Current Clamp

CCC Capacitive Coupling Clamp

CDN Coupling/Decoupling Network

DN Decoupling Network

EFT Electric Fast Transients

EFT Generator Generator with CDN according IEC 61000-4-4

ESD Electrostatic Discharge

EUT Equipment Under Test

HSD High-side Driver

IPS Intelligent Power Switch

PE Protected Earth (metal plane)

Signal Generator Wave generator with power amplifier according IEC 61000-4-6

Surge Generator Generator with CDN according IEC 61000-4-5

Description

22/51

Page 23

AN2208 6 Electromagnetic compatibility (EMC) tests

6.2 List of EMC test equipment

Table 4. Equipment list for EMC tests

Equipment Description

Surge Generator EM Test Surge generator VCS 500 with CDN

EFT Generator EM Test EFT 800 EFT/burst generator with CDN

CC EMC Partner CN-EFT 1000 Capacitive coupling clamp

Pow er Supply

Decoupling network Trennstelltrafo LTS 606 for separation from the mains

Loads

Signal Generator

CDN

Attenuator EM TEST ATT6/75

Multimeter FLUKE 189

Oscilloscope LECROY LT 374M

Current Probe LECROY AP015

Wood table 1-meter high

Metal plane Size in proportion to wood table and test setup

Wood isolation 0.1-meter thick

PCE A1200 40 30 DC power supply 40V/30A

Toellner TOE 8733

Osram 8x lamps 24V/15W

8x Inductor 130mH/48Ω

Agilent 33220A

PMM 3000 according IEC 61000-4-6

EMC Partner CDN-1000 KIT for surge test

EMC Partner CN-EFT-1000

FCC-M3-16A for IEC 61000-4-6

FCC F-120-9A Current Injection Probe for IEC 61000-4-6

6.3 Requested test levels

6.3.1 IEC 61000-4-4

● Polarity: positive/negative

● Test voltage: Level 4 (4 kV)

● Burst duration: 15ms±20% at 5 kHz

● Burst period: 300 ms±20%

● Duration time: 60 seconds (min.)

● Applied to: Input/Output ports and Supply lines

6.3.2 IEC 61000-4-5

● Polarity: positive/negative

● Test voltage: Level 3 (2 kV)

● Number of Discharges: 5

● Repetition Rate: 1 per min.

● Applied to: Output ports and Supply lines (all combinations)

23/51

Page 24

6 Electromagnetic compatibility (EMC) tests AN2208

6.3.3 IEC 61000-4-6

● Test voltage: Level 3 (10 V)

● Frequency range: 150 kHz to 80MHz

● Modulation: 80% dept h by AM 1 kHz

● Frequency step: 1%

● Dwell Time 100 ms

● Applied to: Input/Output ports and Supply lines

6.4 IEC 61000-4-4 EFT test setup

The reference design boards are tested on input/output ports and power supply lines. The test

voltage is applied from the EFT generator to the EUT via a capacitive coupling clamp. The test

setup and test voltage waveform comply with IEC 61000-4-4 specification s. The capacitive

coupling clamp is connected by a high-voltage coaxial cable to the generator as close as

possible to the EUT.

6.4.1 Power supply tests

Figure 19 illustrates the power supply test setup. A capacitive coupling clamp applies the test

voltage (max. 4 kV) to the power supply lines. A decoupling network (DN) protects the power

supply against the test voltage.

EUT test conditions:

Input port ON/OFF and f

Input port wave form: Square 0/5V; f = 1 Hz

Figure 19. Power supply tests (IEC 61000-4-4)

6.4.2 Input port tests

Figure 21 illustrates the input port test setup. The RDB input ports are tested by first switching

them to ground and then to the 5V supply using the battery-power ed s witch sho wn in Figure 20

to increase protection.

OPER

= 1 Hz

Maximum test voltage must not exceed 4 kV.

24/51

Page 25

AN2208 6 Electromagnetic compatibility (EMC) tests

Figure 20. Switch diagram

V

PP

Input

OPT

Figure 21. Test on input ports (IEC 61000-4-4)

6.4.3 Output port tests

Figure 22 illustrates the output port test setup. The capacitive coupling clamp is the

recommended method for coupling the generator source voltage into the output ports. All

auxiliary devices are placed on the wood isolation board (0.1-meter thick). The test is

performed while the HSD output port is switched On/Off at 1 Hz.

GND

Ai11611

Maximum test voltage must not exceed 4 kV.

25/51

Page 26

6 Electromagnetic compatibility (EMC) tests AN2208

Figure 22. Output port tests (IEC 61000-4-4)

6.5 IEC 61000-4-5 surge test setup

Section 5 of the IEC 61000-4 specification concerns the immunity requirements, test methods,

and range of recommended test levels for equipmen t to unidirectional surges caused by

overvoltages from switching and lightning transients. The reference design boards are tested

on the power supply lines and output port.

6.5.1 Power supply tests

Figure 23 illustrates the power supply test setup. The reference design boards are tested with

different coupling modes:

● Line-to-line coupling mode with source impedance 42Ω (meaning V

GND_Power on the board, both polarities)

● Line-to-PE coupling mode with sou rce i mpedan ce 42Ω (meaning V

GND_earth on the board, both polarities)

● Output to GND_Power with source impedance 42Ω

● Output to V

● Output to Protect Earth with source impedance 42Ω

24V with source impedance 42Ω

CC

24V and

CC

24V/GND_Pow er to

CC

26/51

Page 27

AN2208 6 Electromagnetic compatibility (EMC) tests

The maximum surge voltage may not exceed 2kV for line-to-line coupling mode and 2kV for

line-to-PE coupling mode. The test is performed while the HSD output port is switched On/Off

at 1Hz. The maximum length of the cables between the EUT and CDN is 2 meters.

Figure 23. Power supply tests (IEC 61000-4-5)

6.5.2 Output port tests

Figure 24 illustrates the output port test setup. The maximum surge voltage and coupling mode

is same as with the power supply tests. The test is performed while the HSD output port is

switched On/Off with both polarities. The output lines are tested between V

Figure 24. Test on Output Ports (IEC 61000-4-5)

/GND and PE.

CC

6.6 IEC 61000-4-6 conducted immunity

The reference design boards are t ested on the Input/Output ports and P ow er supply lines with a

maximum voltage of 10 V

frequency swe eps from 150 kHz up to 80 MHz with a 80% amplitude modulation at 1 kHz of the

same signal. The EUT clearance from all metallic objects must be at least 0.5 meters.

. The test signal is basically a sinusoidal waveform, whose

RMS

27/51

Page 28

6 Electromagnetic compatibility (EMC) tests AN2208

6.6.1 Power supply tests

Figure 25 illustrates the power supply test setup. The test voltage is applied by coupling

decoupling networks CDN. The maximum voltage is 10 V

EUT and CDN is 0.3 meters. All Auxiliary Units (AU) such as power supplies switching devices

must be placed on the wood isolation.

Figure 25. Power supply tests (IEC 61000-4-6)

. The maximum distance between

RMS

6.6.2 Input port tests

Figure 26 illustrates the input port test setup. The test voltage from the signal generator to the

EUT is applied by the current clamp. This device establishes inductive coupling to the cable

connected to the EUT. The maximum distance between the EUT and t he CC is 0.3 meters . The

test is performed while the HSD input port is switched On/Off at 1Hz .

Figure 26. Input port tests (IEC 61000-4-6)

6.6.3 Output port tests

Figure 27 illustrates the output port test setup. The power supply must be protected to

disturbance signal by a decoupling network. The current clamp is used as the coupling device

28/51

Page 29

AN2208 6 Electromagnetic compatibility (EMC) tests

for the signal generator. The test is performed while the HSD output port is switched On/Off at

1Hz.

Figure 27. Output port tests (IEC 61000-4-6)

29/51

Page 30

7 Test results AN2208

7 Test results

The following abbreviations are used in this section.

Table 5. Abbreviations

Symbol Parameter

V

V

V

T

A

T

T

T

TC

T

T

IN

OUT

STAT

JSD

R

CSD

CR

j

Input Voltage

Output Voltage

Voltage on STATUS pin

Ambient temperature

Junction shut-down temperature

Junction Reset temperature

Case shut-down temperature

Case operating temperature

Case reset temperature

Junction operating temperature

7.1 VN808 HSD test results

The typical behavior of the VN808 HSD according the datasheet is shown in Figure 28 and

Figure 29.

Figure 28. VN808 Waveforms (Part 1)

V

IN

V

OUT

V

STAT

V

CC

V

IN

V

OUT

V

USD

Normal Operation

Undervoltage

V

USDhyst

V

STAT

30/51

Undefined

Ai11622

Page 31

AN2208 7 Test results

Figure 29. VN808 Waveforms (Part 2)

Hard Short Circuit

> T

T

J

TSD

T

TSD

T

R

T

CSD

T

CR

V

V

T

V

IN1

OUT1

STAT

V

I

OUT2

T

IN2

J1

C

T

J1

T

C

V

IN1

V

OUT1

V

STAT

7.1.1 Load switching test results

Test conditions: T

Switching loads: Lamp 24V, 15W; Inductor L = 130 mH, R

In the event of GND_Pow er disconnection, the device turns off immediately. The test was

performed with different V

Test Results: The VN808 HSD worked properly during the test.

= 25° C, VCC = 24 V, f = 0.5 Hz

AMB

values.

CC

Overload Condition

> T

T

C

CSD

LOAD

= 48Ω

Ai11623

T

TSD

T

R

T

CSD

T

CR

31/51

Page 32

7 Test results AN2208

The waveform after GND_Power disconnection is shown in Figure 30 with the following

conditions: Power supply = 24V, Load = 24V /15W lamp, and HSD input = ON.

If the HSD input is OFF, then the output will still switch OFF after GND_Power disconnection.

Figure 30. GND_Power disconnection

V

CC24

Output 1

Load

V

OUT

Switch

Figure 31. Switching lamps: V

0.5 Hz, Wave1 = V

Wave2 = V

, Wave4 = I

OUT

= 24V, f =

CC

INOPT

,

CH1OUT

GND_Power

Figure 32. Waveform t

Ai11624

inductor load: VCC =

OFF

24V, L = 130mH, R

t

= 1.2101 ms, Wave2 = V

OFF

Wave1 = V

INOPT

LOAD

, Wave4 = I

= 63Ω,

OUT

CH1OUT

,

32/51

Page 33

AN2208 7 Test results

Figure 33. Waveform switching inductive load:

V

= 24V, L = 130mH, R

CC

f = 0.5Hz, Wave2 = V

V

INOPT

, Wave4 = I

OUT

CH1OUT

Figure 35. Time delay between V

: VCC = 24V, Load = Lamp,

V

OUT

Wave2 = V

, Wave3 = V

OUT

INOPT

= 48Ω,

LOAD

, Wave1 =

and

, ∆t =

INOPT

58.462 µs

Figure 34. Switching with short circuit: VCC =

24V, f = 0.5Hz, Wave2 = V

Wave1 = V

INOPT

, Wave4 = I

STATUSOPT

CH1OUT

Figure 36. GND_Power dis connection for

VN808: V

Wave1 = V

= 25V, Load = Lamp,

CC

, Wave2 = V

CC

OUT

,

Wave3 = GND of power supply

,

7.1.2 Thermal stress test results

1. All channels shorted: f

2. All channels shorted: f

3. All channels shorted: f

Test Results: The case temperature with 8 channels shorted oscillates between 116 and

119°C with an ambient temperature of 25°C. The case temperature increases to between 116

and 121°C with an ambient temperature of 85°C.

SWITCH

SWITCH

SWITCH

Ground Disconnection

= 0.5 Hz, VCC = 28V, duration 72 hours, TA = 25°C.

= 0.5 Hz, VCC = 28V, duration 8 hours, TA = 85°C.

= 0.5 Hz, VCC = 28V, duration 8 hours, TA = –25°C.

33/51

Page 34

7 Test results AN2208

Figure 37 and Figure 38 illustrate thermal behavior by showing the w aveform of I

HSD during the short circuit with different ambient temperature. The input is switched at 1 Hz.

The thermal shutdown is active and the output channel is switched off because it is shorted.

The maximum case temperature with maximum current I

(without short circuit) as shown in Figure 39.

Figure 37. Waveform I

the test with short circuit V

= 85°C, Wave4 = I

T

A

Wave1 = V

TOT

INOPT

and V

INOPT

TOT

during

,

CC

= 28V,

is 42°C during normal operation

TOT

Figure 38. Waveform on I

the test with short circuit V

= –25°C, Wave4 = I

T

A

Wave1 = V

INOPT

TOT

and V

TOT

current to

TOT

INOPT

CC

,

during

= 28V,

Figure 39. Case temperature dependency vs. current I

(TA = 25°C and VCC = 24 V)

TOT

Note: The temperature measured in thermal chamber using the FLUKE 189 multimeter and thermo-

coupler. No airflow present during the test.

34/51

Page 35

AN2208 7 Test results

7.1.3 EMC test results

IEC 61000-4-4 EFT test

The VN808 reference design board is tested according IEC 61000-4-4 for ±4kV level. Table 6

lists test results. Waveforms of bursts injected during the tests are shown in Figure 40 and

Figure 41.

The test lasted approximately 1 minute with ±4 kV and a repetition rate of 5 kHz. During the

tests, all channels were switched.

Test result: The VN808 HSD worked properly during the test.

Table 6. EMC test IEC 61000-4-4 EFT test results (VN808 RDB)

IEC 61000-4-4 Burst test Test Condition VN808 RDB 1/2 VN808 RDB 2/2

Input ON ±4kV OK ±4kV OK

Power supply

Output

Input

Input OFF ±4kV OK ±4kV OK

Switch @ 1Hz ±4kV OK ±4kV OK

Input ON ±4kV OK ±4kV OK

Input OFF ±4kV OK ±4kV OK

Switch @ 1Hz ±4kV OK ±4kV OK

Input ON ±4kV OK ±4kV OK

Input OFF ±4kV OK ±4kV OK

Figure 40. Burst applied on the power supply Figure 41. Burst applied on the output channel

IEC 61000-4-5 surge test

A coupling decoupling network with a 42 Ω impedance was used when pe rforming the test. The

test was executed with ±2kV.

When testing power supply lines , a ll channels w ere switched. When testing the output channel,

only the tested channel was switched.

A 4.7nF 500V capacitor was placed between the power supply and the earth protection.

35/51

Page 36

7 Test results AN2208

Figure 42 and Figure 43 illustrate active Transil protection. The pulse from generator was

applied on the power supply an d the Transil diode limited the voltage fr om 2kV to appro ximate ly

50V. The test contained five positive and five negative discharges with each polarity. Repetition

rate was 1 discharge per minute.

Test result: The VN808 HSD worked properly during the test.

Table 7. EMC test IEC61000-4-5 surge test res u lts (VN808 RDB)

IEC 61000-4-5 Surge Test Test Condition VN808 RDB 1/2 VN808 RDB 2/2

Power supply V

to Earth

V

CC

GND to Earth

Output of the RDB to V

Output of the RDB to GND_Power

Output of the RDB to Earth

to GND_Power

CC

CC

Input ON ±2kV OK ±2kV OK

Input OFF ±2kV OK ±2kV OK

Input ON ±2kV OK ±2kV OK

Input OFF ±2kV OK ±2kV OK

Input ON ±2kV OK ±2kV OK

Input OFF ±2kV OK ±2kV OK

Input ON ±2kV OK ±2kV OK

Input OFF ±2kV OK ±2kV OK

Input ON ± 2kV OK ± 2kV OK

Input OFF ± 2kV OK ± 2kV OK

Input ON ± 2kV OK ± 2kV OK

Input OFF ± 2kV OK ± 2kV OK

Figure 42. Positive surge applied on power

supply

IEC61000-4-6 conducted immunity

This is the most difficult test and requires the use of a coupling decoupling network for power

supply lines and special current clamp for output and data lines. The test was executed with

Level 3 (10V) compliance. Table 8 lists test results.

Figure 43. Negative surge applied on power

supply

36/51

Page 37

AN2208 7 Test results

If input lines are grounded, the optocoupler will switch on during the test because the inducted

voltage is too high. This is a normal reaction and when the test fin ish es, the optocoupler works

normally.

Test result: The VN808 HSD worked properly during the test.

Table 8. EMC test IEC 61000-4-6 conducted immunity test results (VN808 RDB)

IEC 61000-4-6 Test Condition VN808 RDB 1/2 VN808 RDB 2/2

Input ON 10V OK 10V OK

Power supply

Output

Input

Note: B means a temporary degradation or loss of function or performance, with an automatic return

to normal operation.

Input OFF 10V OK 10V OK

Switch @ 1Hz 10V OK 10V OK

Input ON 10V OK 10V OK

Input OFF 10V OK 10V OK

Switch @ 1Hz 10V OK 10V OK

Input ON 10V OK 10V OK

Input OFF 10V OK B 10V OK B

Switch @ 1Hz 10V OK 10V OK

7.2 VN340SP HSD test results

7.2.1 Load switching test results

Test conditions: T

Switching loads: Lamp = 24V, 15W; Inductor L = 130 mH, R

Test result: The VN340SP HSD worked properly during the test.

Figure 44 to Figure 49 show the waveforms during the load switching tests.

If input is ON, the output will switch off immediately if GND_Power is disconnected. If the input

is OFF, the output remains OFF.

7.2.2 Thermal stress test results

1. All channels shorted: f

2. All channels shorted: f

3. All channels shorted: f

Test result: The VN340SP HSD worked properly during the test.

The maximum temperature with 4 channels shorted is 156°C with an ambient temperature of

25°C and 159°C with an ambient temperature of 85°C. Figure 50 and Figure 51 show behavior

during the thermal stress tests.

= 25° C, VCC = 24 V, f = 0.5 Hz

AMB

SWITCH

SWITCH

SWITCH

= 0.5 Hz, VCC = 28V, duration 72 hours, TA = 25°C.

= 0.5 Hz, VCC = 28V, duration 8 hours, TA = 85°C.

= 0.5 Hz, VCC = 28V, duration 8 hours, TA = –25°C.

LOAD

= 48Ω

37/51

Page 38

7 Test results AN2208

The input was switched at 1 Hz. The thermal shutdown is shown in the figures below.

Figure 44. Switching lamps: V

0.5Hz, Wave3 = V

Wave2 = V

OUT

CC

INOPT

, Wave4 = I

Figure 46. Time delay between V

: VCC = 24V, Load = Lamp,

V

OUT

Wave2 = V

, Wave3 = V

OUT

139µs

= 24V, f =

,

CH1OUT

and

INOPT

, ∆t =

INOPT

Figure 45. Waveform t

inductor load: VCC =

OFF

24V, L = 130mH, R

= 1.2276ms, Wa ve2 = V

t

OFF

Wave3 = V

INOPT

, Wave4 = I

Figure 47. Switching with short circuit: V

24V, f = 0.5Hz, Wave2 = V

Wave3 = V

INOPT

, Wave4 = I

LOAD

= 60Ω,

OUT

CH1OUT

STATUSOPT

CH1OUT

,

CC

=

,

38/51

Page 39

AN2208 7 Test results

Figure 48. Waveform switching inductive load:

V

= 24V, L = 130mH, R

CC

f = 0.5Hz, Wave2 = V

V

INOPT

, Wave4 = I

Figure 50. Waveform I

TOT

CH1OUT

and V

OUT

STATUSOPT

= 48Ω,

LOAD

, Wave3 =

during the test with shor t ci rcuit:

= 28V, TA = 85°C, Wave4 = I

V

CC

Wave1 = V

STATUSOPT

TOT

,

Figure 49. Switching with short circuit: V

24V, f = 0.5Hz, Wave2 = V

Wave3 = V

INOPT

Figure 51. Waveform on I

, Wave4 = I

and V

TOT

STATUSOPT

CH1OUT

STATUSOPT

during the test with short circuit:

= 28V, TA = –25°C, Wave4 = I

V

CC

Wave1 = V

STATUSOPT

CC

=

TOT

,

,

Note: The temperature measured in thermal chamber using a FLUKE 189 multimeter and thermo-

coupler.

7.2.3 EMC test results

IEC 61000-4-4 EFT test results

The VN340SP HSD is tested according IEC 61000-4-4 Level 4 (4kV). Power supply and input/

output ports are tested while all other channels are active. Table 9 lists test results.

39/51

Page 40

7 Test results AN2208

Test result: The VN340SP HSD worked properly during the test.

Table 9. EMC test IEC 61000-4-4 EFT test results (VN340SP RDB)

IEC 61000-4-4 Burst Test Test Condition RDB VN340SP 1/2 RDB VN340SP 2/2

Input ON ±4kV OK ±4kV OK

Power supply

Output

Input

Input OFF ±4kV OK ±4kV OK

Switch @ 1Hz ±4kV OK ±4kV OK

Input ON ±4kV OK ±4kV OK

Input OFF ±4kV OK ±4kV OK

Switch @ 1Hz ±4kV OK ±4kV OK

Input ON ±4kV OK ±4kV OK

Input OFF ±4kV OK ±4kV OK

IEC 61000-4-5 surge test results

The board was tested with 42Ω coupling/decoupling network. All channels were active during

the test. Different combinations of channel activity were also tested. Table 10 lists test results.

A 4.7nF 500V capacitor was placed between the power supply and earth protection.

Test result: The VN340SP HSD worked properly during the test.

Table 10. EMC test IEC61000-4-5 surge test results (VN340SP RDB)

IEC 61000-4-5 Surge Test Test Condition VN340SP RDB 1/2 VN340SP RDB 2/2

Power supply V

GND:_Power

to Earth

V

CC

GND to Earth

Output of the RDB to V

Output of the RDB to

GND_Power

Output of the RDB to Earth

CC

to

CC

Input ON ±2kV OK ±2kV OK

Input OFF ±2kV OK ±2kV OK

Input ON ±2kV OK ±2kV OK

Input OFF ±2kV OK ±2kV OK

Input ON ±2kV OK ±2kV OK

Input OFF ±2kV OK ±2kV OK

Input ON ±2kV OK ±2kV OK

Input OFF ±2kV OK ±2kV OK

Input ON ±2kV OK ±2kV OK

Input OFF ±2kV OK ±2kV OK

Input ON ±2kV OK ±2kV OK

Input OFF ±2kV OK ±2kV OK

IEC61000-4-6 conducted immunity test results

The test was executed according the standard with required levels. Table 11 lists test results.

Test results: Loss of function was observed during the test on output lines when HSD input

was OFF. Lamps shone little bit. (Normal behavior: Lamps switched OFF.)

40/51

Page 41

AN2208 7 Test results

Loss of function was observed during the test on input lines, but is considered as normal

behavior because the conducted voltage was too high and optocoupler input channels were

switched.

Table 11. EMC test IEC 61000-4-6 conducted immunity test results (VN340SP RDB)

IEC 61000-4-6 Test Condition VN340SP RDB 1/2 VN340SP RDB 2/2

Input ON 10V OK 10V OK

Power supply

Output of the RDB

Input of the RDB

Note: B means a temporary degradation or loss of function or performance, with an automatic return

to normal operation.

Input OFF 10V OK 10V OK

Switch @ 1Hz 10V OK 10V OK

Input ON 10V OK 10V OK

Input OFF 10V OK B 10V OK B

Switch @ 1Hz 10V OK 10V OK

Input ON 10V OK 10V OK

Input OFF 10V OK B 10V OK B

Switch @ 1Hz 10V OK 10V OK

41/51

Page 42

7 Test results AN2208

Appendix A VN808 reference design board (RDB)

A.1 VN808 RDB bill of materials

The list of parts for the VN808 Reference Design Board is provided in Table 12.

Table 12. VN808 RDB bill of materials

Item Quantity Reference Value Note

1 16 C5, C6, C7, C8, C9, C10, C11, C12 10nF

C19, C20, C21, C22, C23, C24, C25, C26

2 4 C14, C13, C18, C17 4.7nF 500V SMD 1206

3 4 C2, C4, C15, C27 100nF 50V SMD 0805

4 2 C1, C28 22uF/50V

5 1 C30 10µF/35V ceramic

6 1 C33 100µF/16V tantalum

7 1 C31 220pF

8 1 C32 22nF

9 2 D1, D2 SM15T36A

10 1 D3 STPS2L25U

11 2 J1, J4 Headers 2line 14pin

12 2 J2, J3 Terminal bloc k 5,08 mm

13 1 L1 33µH/2A

14 2 R1, R13 2k2

15 16 R3, R4, R5, R6, R7, R8, R9, R10 1k5

R16, R17, R18, R19, R20, R21, R22,

R23

16 1 R26 15K

17 3 R12, R15, R25 4k7

18 1 R27 3k9

19 1 R11, R24 10k

20 1 J5 Terminal block 5.08mm

21 4 U2, U3, U7, U8 TLP281-4

22 2 U1, U5 VN808

23 2 U4, U6 TLP181

24 1 U9 L5970

25 2 F1, F2 7A

42/51

Page 43

AN2208 7 Test results

A.2 Recommended VN808 PCB Layout

The PCB layout is very important in order to operate the devices in the worst condition and

under EMC immunity.

Figure 52. VN808 RDB PCB layout (top and bottom)

Figure 53. VN808 RDB PCB layout (component side)

43/51

Page 44

7 Test results AN2208

Appendix B VN340SP reference design board (RDB)

B.1 VN340SP RDB bill of materials

The list of parts for the VN340SP Reference Design Boa rd is provided in Table 13.

Table 13. VN340SP RDB bill of materials

Item Quantity Reference Part Note

1 4 C2, C3, C12, C15 10nF

2 2 C4, C16 100nF 50V 0805

3 8 C5, C6, C7, C8, C17, C18, C19, C20 4n7 500V 1206

4 2 C9, C21 22µF

5 1 C10 22nF

6 1 C11 220pF

7 1 C13 10uF/35V Ceramic

8 1 C14 100uF/16V Tantalum

9 2 D1, D4 SM15T36A

10 1 D3 STPS2L25U

11 2 D2, D5 L-HLMP1700

12 1 J5 Terminal Block 5.08mm

13 2 J1, J3 HEADER 2 line 10 pin

14 2 J2, J4 Terminal Block 5.08mm

15 1 L1 33uH/2A

16 13

17 2 R5, R24 7k5

18 8 R6, R7, R8, R9, R25, R26, R27, R28, 22k

19 10

20 1 R17 15k

21 1 R18 3k9

22 2 F1, F2 Fuse 4A

23 2 U1, U6 TLP281-4

24 2 U2, U5 TLP181

25 2 U3, U7 VN340SP

26 1 U8 L5970D

R1, R2, R3, R4, R19, R10, R20, R21, R22, R23,

R29,

R11, R12, R13, R14, R15, R30, R31, R32, R33,

R34, R16, R35

4k7

1k5

44/51

Page 45

AN2208 7 Test results

B.2 Recommended VN340SP RDB PCB layout

Figure 54. VN340SP RDB PCB layout (Top side) and (Bottom side)

Figure 55. VN340SP RDB PCB layout (component side)

45/51

Page 46

7 Test results AN2208

Appendix C L5970D DC/DC converter

C.1 Functional description

The L5970D (Figure 56) is a step-down power regulator capable of delivering output voltages

from 1.235 to 35V (up to 1A). The operat ing input v oltage r anges from 4.4 to 36V. It is designed

in BCD5 technology and the power switching element is a P-Channel D-MOS power transistor.

An internal oscillator sets the switching frequency at 250 kHz, minimizing the LC output filter.

The L5970D is used for supplying optocouplers and other applications.

Figure 56. L5970D block diagram

VCC

+

-

VOLTAGE

MONITOR

PWM

THERMAL

SHUTDOWN

SUPPLY

1.235V 3.5V

PEAK TO PEAK

CURRENT LIMIT

DCkQ

FREQUENCY

SHIFTER

DRIVER

V

REF

BUFFER

LPDMOS

POWER

OUTGND

V

Ai11607

REF

INH

COMP

SYNC

TRIMMING

INHIBIT

E/A

1.235V

-

+

OSCILLATOR

FB

The VN808 and VN340SP reference design boards use the L5970D DC/DC Converter for the

power supplies f or the data parts. With an output v olt age of 6V and ou tput cu rrent up to 1A, the

L5970D is an attractive and simp le solution.

The main internal blocks are shown in Figure 56 where is reported the device block diagram.

They are:

● A voltage regu lator that supp lies the internal circuitry. From this regulator a 3.3V reference

voltage is externally available.

● A voltage moni tor circuit that checks the input and internal voltages.

● A fully integrated sawtooth oscillator whose frequency is 250 kHz ±5%, including also the

voltage feed forward function and an input/output synchronization pin.

● Two embedded current limitations circuitries which control the current that flows through

the power switch. The Pulse by Pulse Current Limit forces the power switch OFF cycle by

cycle if the current reaches an internal threshold, while the Frequency Shifter reduces the

switching frequency in order to strongly reduce the duty cycle.

● A transconductance error amplifier.

● A pulse width modulator (PWM) comparator and the relative logic circuitry necessary to

drive the internal power.

● A high-side driver for the internal P-MOS switch.

● An inhibitor block for stand-by operation.

● A circuit to provide the thermal protection function.

46/51

Page 47

AN2208 7 Test results

The output voltage can be adjustab le b y v oltage divider. In Figure 9 can be seen voltage di vider

by resistors R26 and R27. The value of resistor R26 is equal to:

–

V

OUTVFB

R26 R27

=

------------------------------ -

V

FB

Note: V

= 1.235 V

FB

For more information and technical data about L5970D, refer to the L5970D datasheet.

C.2 L5970D layout recommendations

A optimized layout is on of the key f actors to operate the DC/DC converter. It redu ce noise an d

interference. P ower-ge nerating portions of the lay out are the main cause of n oise, theref ore, the

high switching current loop areas, should be kept as small as possible as well as lead lengths

has to be kept short as possible.

High impedance paths (in particular the feedbac k connections) are susceptible to interference

and so they should be as far as possible from the high current paths.

Below there is a layout example on Figure 57. The input and output loops ar e minimized to

avoid radiation and high frequency resonance problems. The feedback pin connections to the

external divider are ve ry close to the device to a v oid pic k up noise. Mo reov er the GND pin of the

device is connected to the ground plane directly with VIA on the bottom side of the PCB.

Figure 57. L5970 DC/DC converter layout example

47/51

Page 48

7 Test results AN2208

C.3 L5970D DC/DC converter load test results

Table 14. L5970D electrical characteristics

Symbol Parameter Min. Typ. Max. Unit

V

SS

I

QOP

I

OUTDC

f

S

d Duty cycle 0 100 %

TA

P

TOTDC

The DC/DC converter was tested with a constant output current with resistive load.

The Waveform on coil L1 has to be clear without overshot (see Figure 61., Figure 63.).

Input/output voltage ripple depends on ESR capacitor values.

Operating input voltage 6.6 35 V

Total operating quiescent current 2.4 5 mA

Maximum limiting current 1.0 1.4 A

Switching frequency 243 250 kHz

Operating Temperature Range –25 to 85°C °C

Power dissipation at Tamb = 60°C 0.75 W

Only low ESR capacitors have been used on V

and V

SS

OUT

.

Test conditions

● Resistive load = 12Ω.

● Input voltages V

● Output volt age V

● Output current I

● Ambient Temperature (T

Test results: If output current is increase up to 1.4 A, then the current limiter will be active.

Output voltage ripple can be seen in Figure 62. The maximum value of ripple is 93 mV. The

efficiency measurement results are shown in Figure 58.

Figure 58. Efficie n cy vs. ou t pu t cur r e nt

= 8, 12, and 24V.

SS

= 5V

BSS

= 0.4A

OUTDC

) = 25°C

A

48/51

Page 49

AN2208 7 Test results

Figure 59. Output voltage stability of L5970D, VSS = 24 V

Figure 60. Voltage ripple on capacitor C30,

I

= 0.4A, VSS = 24V

OUTDC

Figure 62. Voltage ripple on capacitor C33,

V

= 24V, I

SS

OUTDC

= 0.4 A

Figure 61. Waveform on coil L1, I

0.4A, V

= 24V

SS

OUTDC

Figure 63. Waveform on coil L1, without

load, VSS = 24V

=

49/51

Page 50

8 Revision history AN2208

8 Revision history

Date Revision Changes

16-Sept-2005 1.0 Initial release.

50/51

Page 51

AN2208

Information furnished is believed to be accurate and reliable. However, STMicroelectronics assumes no responsibility for the consequences

of use of such information nor fo r any infringement of p atents or other righ ts of third parties w hich may result from its use. No license is g ranted

by implication or otherwise under any pa tent or paten t right s of ST Microel ect ronics . Spec ifica tions me ntio ned i n this pu blicat ion are subject

to change without notice. This publication supersedes and replaces all information previously supplied. STMicroelectronics products are not

authorized for use as critica l components in life support devices or systems without express written approval of STMicroelectronics.

The ST logo is a registered trademark of STMicroelectronics.

All other names are the property of t heir respective owners

© 2005 STMicroelectronics - All rights reserved

STMicroelectronics group of compan ie s

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Ho ng Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

51/51

Loading...

Loading...