THE ROGUE

ASSEMBLY AND INSTALLATION

INSTRUCTIONS

TM

GRAND RAPIDS

TM

WESTERN SALES AND MANUFACTURING PLANT

06-676 S.R. SMITH, LLC 2006 MAY07-

CORPORATE HEADQUARTERS

P.O. Box 400 ? 1017 SW Berg Parkway

Canby, Oregon 97013

(503) 266-2231 ? (503) 266-4334

www.srsmith.com

Table of Contents

Topic Page #

Introduction………………………………………………………….. 2

Applicable Standards and Codes…………………………………. 2

Assembly and Installation………………………………………….. 2

Drawings…………………………………………………………….. 2

Parts List …………………………………………………………….. 3

Slide Deck Anchor Flange Kit……………………………………… 4

Tools Required For Assembly List………………………………… 5

Left Curve Footprint………………………………………………… 5

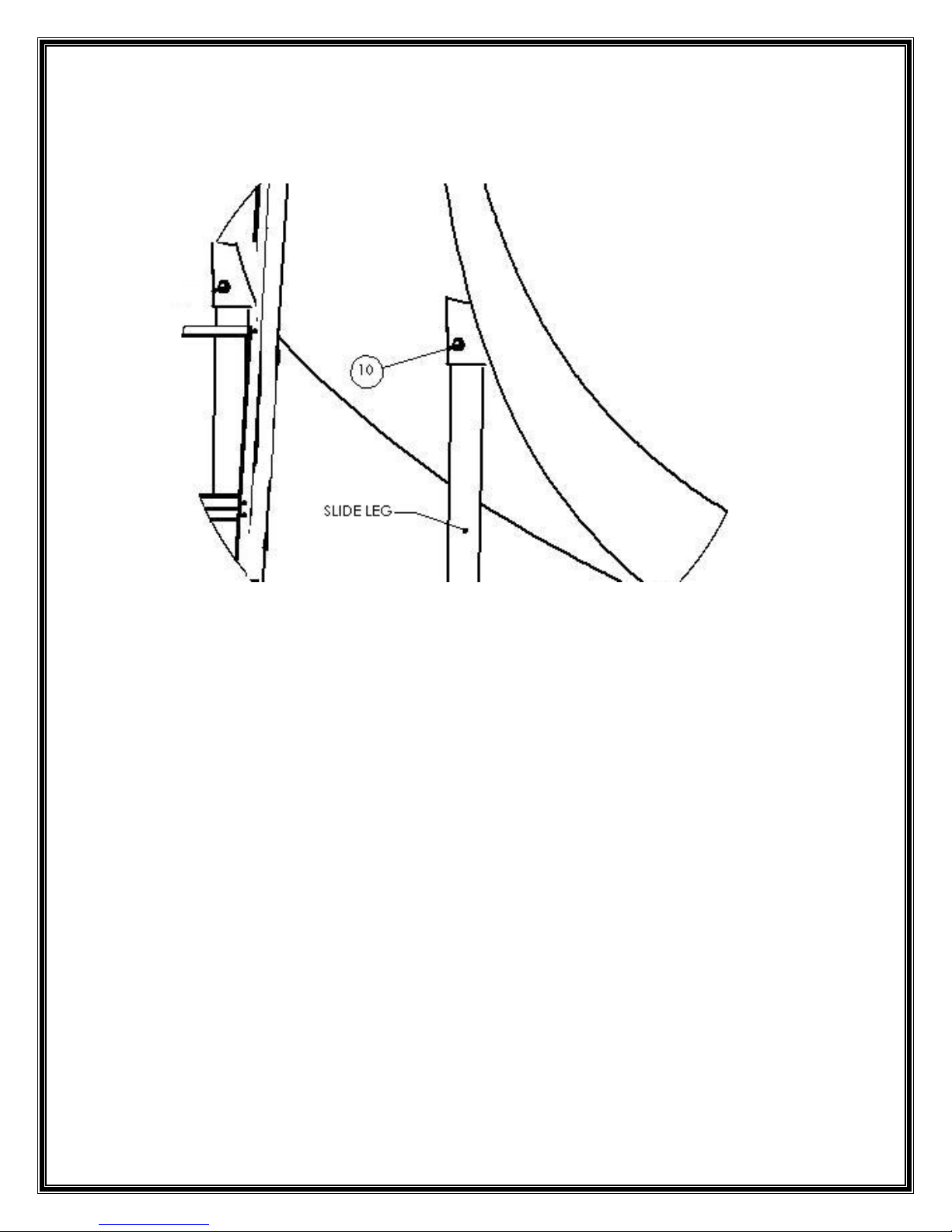

Right Curve Footprint………………………………………………. 6

Left Curve Slide with Flush Deck Mounting……………………… 6

Assembly Instructions for In-Deck Mounting…………………….. 7

Assembly Instructions for Flush Deck Mounting………………… 17

Manufacturer’s Placement Instructions…………………………… 18

Electrical Bonding…………………………………………………… 20

Installed Slide’s Structural & Installation Checklist……………… 20

INTRODUCTION

S.R. Smith RogueTMGrand RapidsTMare manufactured for installation and use on

residential in ground swimming pools only. S.R. Smith RogueTM Grand RapidsTM is

NEVER to be installed and used on public in ground pools, aboveground pools, on

ground pools, houseboats, boat docks, floating docks or platforms.

APPLICABLE STANDARDS AND CODES

1. All S.R. Smith RogueTM Grand RapidsTM are manufactured in accordance with

Consumer Products Safety Commission STANDARD FOR SWIMMING POOL SLIDES, 16 CFR

Ch. 11 Part 1207 (latest edition).

2. Installer must comply with all applicable governmental and building codes.

ASSEMBLY AND INSTALLATION

All S.R. Smith RogueTM Grand RapidsTM are inspected prior to shipment from the

factory. Proper assembly and installation is mandatory. Improper assembly and

installation voids S.R. Smith’s warranty and may affect the safety of the user. S.R.

Smith cannot and does not guarantee customer’s concrete deck.

All drawings in these Assembly and Installation Instructions are for illustration purposes

only and are NOT TO SCALE.

DRAWINGS

2

PARTS LIST

Before getting started check to make sure that all of the parts listed below arrived with

your new S.R. Smith Rogue

TM

Grand Rapids

TM

slide.

Ref # * PART # DESCRIPTION QTY

1 05-765 PVC 90 Elbow ST SCH 40 MTXT 1 ea.

2 05-766 PVC Ball Valve SCH 80 SXS 1 ea.

3 05-769 PVC Union SCH 40 1” SXS 1 ea.

4 05-767 Plastic Pipe Clamp for 1” SCH 40 6 ea.

5 5-371 Self Tapping Screw #10-16 x 1” S/S 6 ea.

6 05-668 Vinyl Cap .172 ID x .5 LG. 6 ea.

7 05-772 PVC Thread Adapter SCH 40 SPG X MPT 1” 1ea.

8 05-771-1 PVC Spa Hose 1” ID x 1.125” OD (Not Shown) 8 ft.

9 01-210 Aluminum Ladder Spacer 2 ea.

10 05-31-110 5/16” x 1” Hex Washer Head Tek Screw 4 ea.

11 05-14-101 5/16 “ x 1” Lag Screw C/S 2 ea.

12 05-14-102 5/16” x 7/8” Flat Washer 2 ea.

13 05-622 5/16” x 3/4" Black Rubber Washer 2 ea.

14 05-31-151 ¼-20 x 6” Carriage Bolt S/S 4 ea.

15 05-31-149 ¼-20 x 8” Carriage Bolt S/S 2 ea.

16 6-121 Nylon Tube Connector 6 ea.

17 6-123 Nylon Handrail Connector 6 ea.

18 01-212 Aluminum Handrail Spacer 6 ea.

19 5-149 ¼” Lock Washer S/S 8 ea.

20 5-137 ¼-20 Hex Nut S/S 8 ea.

21 5-14-111 1/4 x 5/8 Flat Washer 8 ea.

22 05-14-124 ¼” x ½” Sheet Metal Screw (Not Shown) 5 ea.

23 05-143 ¼” x ¾” Flat Washer C/S (Not Shown) 5 ea.

SLIDE DECK ANCHOR FLANGE KIT

(OPTIONAL – FOR FLUSH DECK MOUNTING)

24 ** Deck Anchor Flange

25 04-14-111 1/4 X 5/8 Flat Washer 8 ea.

26 05-14-117 1/4-20 UNC Hex Nylon Locking Nut 4 ea.

27 05-14-123 1/4-20 UNC x 2-3/4 Hex Head Cap Screw 4 ea.

28 05-161 5/16-18 UNC x 2-1/4 Stud W/ Nut and Flat Washer 20 ea.

29 06-622 Anchor Flange Installation Instructions 1 ea.

30 01-500 3/8” O.D. Aluminum Bushing 4 ea.

31 5-306 5/16” lock Washer Split, S/S 20ea.

* Ref #s are shown as (#__ ) in these ASSEMBLY AND INSTALLATION INSTRUCTIONS

** Deck anchor flanges are available in plastic (05-623) or aluminum (75-209-5000).

3

28

28

31

30

27

25

25

26

SLIDE LEG

TOOLS REQUIRED FOR SLIDE ASSEMBLY

• PVC glue

• Silicon sealant

• Hand drill with Phillips bit

• Ratchet with 7/16”, 1/2" and 3/8” sockets

• 7/16” wrench

• 1/2” wrench

• Hammer drill with 1/4" masonry bit

• Small Level

FIGURE 3

5

:

LEFT CURVE FOOTPRINT

The purpose of this footprint is to serve as a GUIDELINE ONLY for approximate

placement of the slide relative to the pool’s edge. The actual dimensions after

installation may vary according to the slope of the deck and the angle that the slide is

oriented relative to the pool wall. YOU MUST FOLLOW THE INSTALLATION

INSTRUCTIONS AS PRINTED IN THIS MANUAL.

NOTE: All dimensions are

measured from the left side of

the ladder foot (0”, 0”)

RIGHT CURVE FOOTPRINT

The purpose of this footprint is to serve

as a GUIDELINE ONLY for approximate

placement of the slide relative to the

pool’s edge.

The actual dimensions after installation

may vary according to the slope of the

deck and the angle that the slide is

oriented relative to the pool wall.

YOU MUST FOLLOW THE

INSTALLATION INSTRUCTIONS AS

PRINTED IN THIS MANUAL.

FIGURE 4

LEFT CURVE SLIDE WITH FLUSH DECK MOUNTING

The purpose of this side view is to serve as a

GUIDELINE ONLY

the slide relative to the deck. The actual

dimensions after installation may vary

according to the slope of the deck and

the angle that the slide is oriented

relative to the pool wall. When installing

the slide in the deck, these dimensions

will be reduced by at least 3-1/8 inches.

HEIGHT ABOVE DECK LEVEL OF:

(A) Bottom of first ladder step: 11-1/2” 11-5/8”

(B) Top runway surface: 78-3/8” 78-1/2”

(C) Top runway side rail: 83-3/4” 83-3/4”

(D) Top of handrail: 94-3/4” 94-3/4”

(E) Exit runway surface: 12-7/8” 14”

(F) Bottom of slide at exit end: 11-1/8” 11-7/8”

for approximate placement of

FIGURE 5

LEFT CURVE RIGHT CURVE

6

ASSEMBLY INSTRUCTIONS FOR IN-DECK MOUNTING

1) Place the slide runway upside down on a surface that will not scratch the slide.

2) Open the ladder and parts carton and locate the ladder and the 4 legs.

3) Insert the top of the slide ladder all the way into the two sockets in the slide.

NOTE: The top of the ladder is the end with the side rails cut square. See

Figure 7.

4) Insert the slide legs into the leg sockets of the slide. The shorter legs go into the

sockets on the inside curve of the slide. Be sure to insert the end of the legs that

do not have the pre-drilled holes into the leg sockets. Do not attach the legs

permanently at this point. See Figure 8.

Figure 8

Figure 7

7

5) Carefully turn the slide with the legs and ladder upright for setup. It will be

necessary for two people to perform this to avoid damage to the slide and the

legs. If necessary use something such as tape to temporarily hold the legs in

place while turning the slide over.

6) Place the slide at the desired location relative to the pool wall. See

MANUFACTURER’S PLACEMENT INSTRUCTIONS on pages 18 & 19.

7) Ensure that the exit runway surface does not exceed 20 inches above the water

surface, nor less than 8 inches above the deck/coping surface (see Figure 26 on

page 18). The exit runway surface is measured at the point of transition between

the runway and the beginning of the exit end radius.

8) Ensure that the ladder is not twisted relative to the slide.

9) Insert 3/8” diameter rebar (not provided) into the holes located at the bottom of

each leg making sure that the rebar will be a minimum of three inches (3”) below

the deck surface.

10) Install electrical bonding as local code specifies (see

ELECTRICAL BONDING page

20).

11) Secure the ladder so that the ladder steps are level, from side to side, and the

ladder is slopped 15 degrees from vertical.

12) Apply a small amount of silicon sealant to the male thread side of the (#1) PVC

90° Elbow. Thread the elbow into the fitting in the bottom of the slide as shown

below. Tighten until the elbow is snug and in the orientation shown in Figure 9.

Figure 9

8

13) Apply PVC glue to the male slip end of the (#7) PVC Thread Adapter and insert

into one side of the (#3) PVC Union. Be sure to push the thread adapter as far

as it will go into the union. See Figure 10.

Figure 10

14) Apply a small amount of silicon sealant to the male thread side of the (#3) PVC

Union. Thread the PVC Union into the elbow from step 12 and hand tighten until

snug. See Figure 11.

Figure 11

9

15) Apply PVC glue to the inside of the slip end of the PVC Union. Insert the (#8)

PVC Spa Hose into the union as shown below in Figure 12.

16) Use a drill with a Phillips bit to fasten the (#4) Plastic Pipe Clamp to the ladder

as shown below in Figure 13a. The hose clamp should be attached with the

clamp aligned with the bottom of the step, See Figure 13b. Place (#6) Vinyl Cap

over visible portion of screw. Repeat this step for each tread on ladder.

Figure 12

Figure 13a

Figure 13b

10

17) Starting with the top hose clamp, insert the PVC hose into the clamps as shown

below in Figure 14. The clamps automatically tighten when pressure is applied

pushing the hose into the clamps.

Figure 14

18) Apply PVC glue to one socket of the (#2) PVC Ball Valve and insert the PVC

hose into the valve as shown in Figure 15. Allow the glue sufficient time to dry.

The final step is joining the PVC Ball Valve to the water source.

Figure 15

11

12

Garden Hose Adapter Installation Instructions

If connecting the RogueTMGrand RapidsTMwater system to the pool plumbing system is

not an option you may connect the water system to a garden hose by following the

steps outlined below.

A.) Make sure that the RogueTMGrand

RapidsTMwater system has been

properly assembled as explained in

the RogueTMGrand Rapids

TM

Installation Instructions. Next, apply

PVC glue around the end of the

garden hose adapter indicated by the

arrow in Figure 16.

B.) After the glue is applied quickly

insert the PVC fitting into one end of

PVC ball valve as shown in Figure 17.

C.) The final step is to thread a garden

hose into the PVC garden hose

adapter.

Figure 16

Figure 17

Figure 16

Figure 17

19) Adjust the top runway of the slide so that it is level, from side to side and

lengthwise as shown below in Figure 18.

Figure 18

20) Underneath the top portion of the slide, on the inside flat surface next to the

ladder socket, use the existing holes as a template to drill a 1/4-inch hole through

each ladder side rail as shown below in Figure 19.

Figure 19

13

21) To secure the ladder to the slide screw into the previously drilled holes (one per

side rail) a (#11) 5/16” x 1” lag screw, a (#12) 5/16” x 7/8” flat washer and a (#13)

5/16” x 3/4" rubber washer tightening to 8 ft.-lbs of torque. See Figure 20.

CAUTION: DO NOT OVER TIGHTEN.

Figure 20

22) Level as close as possible the exit runway surface horizontally from side to side,

approximately 9” up from the exit end, using a small level as shown in Figure 21.

Figure 21

14

23) If necessary the legs can be adjusted up and down within the leg sockets to help

adjust for level. Once the slide is properly leveled the legs shall be permanently

attached by drilling a 1/4" hole into each leg using the hole on the leg socket as a

guide and fastening with a (#10) 5/16” Hex Head Washer Tek Head Screw. See

Figure 22.

Figure 22

24) Disassemble each handrail as shown in Figure 23. Insert the two handrails into

the holes on the top of the slide runway rails, and secure each using a (#21) Flat

Washer, a (#19) Lock Washer, and a (#20) Hex Nut.

25) Starting with the top handrail spacer, align the top hole in the handrail with the

top hole in the ladder side rail. Next, assemble the handrail spacer parts (#16),

(#17) and (#18) in the order shown in Figure 23 and align it between the handrail

and ladder top holes. Next, insert the (#15) 1/4-20 x 8” Carriage Bolt through the

handrail and the handrail spacer parts. The (#9) Ladder spacer is to be placed in

between the front and back sides of the ladder side rail such that the (#15)

Carriage Bolt holds it in place after it is pushed completely through the ladder

side rail, see Figure 24. Secure the (#15) Carriage bolt using a (#21) Flat

Washer, a (#19) Lock Washer, and a (#20) Hex Nut in the order shown in Figure

23. Finally, place a (#6) Vinyl Bolt Cap over the exposed threaded end of the

bolt.

26) For the remaining two ladder spacer s, align parts (#16), (#17) and (#18)

between the hole in the handrail and the hole in the ladder as in step 24. Use a

(#14) 1/4-20 x 6” Carriage Bolt along with a (#21) Flat Washer, a (#19) Lock

Washer, and a (#20) Hex Nut to fasten the parts together as shown in Figures 23

and 24. Again, place a (#6) Vinyl Bolt Cap over the exposed threaded ends of

the bolts.

15

`

Figure 23

Figure 24

16

27) After connecting the water hose to ladder water connection, turn on water slowly to

check for leaks.

28) Secure the slide, so that it will not move during the concrete pour, to ensure that the

settings remain the same.

29) SUGGESTION: To ensure easy removal of concrete from legs and ladder, wax or

wrap with wax paper approximately 12 inches above deck level.

30) Proceed with pouring the concrete deck and finish as desired. Let concrete cure 24

hours before using slide.

ASSEMBLY INSTRUCTIONS FOR FLUSH DECK MOUNTING

The following instructions are for mounting a slide on an existing deck.

1) Follow the steps listed on the previous page for in-deck mounting, as they are the

same with the exception of the attachment of the deck anchor flanges. NOTE: Rebar

will not be used.

2) Place a deck anchor flange over each end of the slide legs.

3) Using the four holes on each flange as a template (see Figure 25 below), drill four

5/16” holes per flange 1-3/8” deep. CAUTION: Do not drill holes larger than 5/16”.

Maintain drill hole straight and perpendicular for proper holding strength of anchor

stud.

4) Raise the flange up the leg and secure in place while using a hammer to drive the

(#28) 5/16”-18UNC x 2-1/4” Anchor Stud, with a (#28) 5/16” Hex Nut on top, into the

hole leaving 7/8 of an inch of the stud above the deck. Then tighten the nut until it is

flush with the deck. Then, tighten the nut approximately three turns to set the anchor

stud. Finally, remove the nuts.

5) Secure the four flanges with (#28)

5/16” Flat Washers, (#31) 5/16" Lock

Washers and the (#28) 5/16"–18UNC

Hex Nuts.

6) Using the two holes on each ladder

feet as templates, drill holes 5/16"

diameter by 1-3/4 inches deep and

secure (#28) Anchor Studs as

described in 3 & 4 above.

7) Secure the two ladder feet with (#28)

5/16” Flat Washers, (#31) lock

washers, and the (#28) hex nuts. Be

sure that the ladder maintains 15

degrees from vertical.

Figure 25

17

8) Drill a 1/4" diameter hole into the slide leg through the 3/8” diameter hole in the

flange. Insert the (#30) 3/8” O.D. Aluminum Bushing into the hole in the deck flange

and push in until it contacts the slide leg. Now insert the (#27) 1/4"-20UNC x 2-3/4”

Hex Head Cap Screws and (#25) 1/4" x 5/8” Flat Washers through the bushing and in

about a 1/2" into the hole in the slide leg. With the cap screw in position, drill a 1/4"

hole into the slide leg through the 5/16” diameter hole in the opposite side of the deck

flange. Take care not to run the drill bit into the 1/4" bolt. Push the cap screw

completely through the slide leg. Install the (#25) 1/4" x 5/8” Flat Washers and (#26)

1/4"-20UNC Hex Lock Nuts (see Figure 25).

MANUFACTURER’S PLACEMENT INSTRUCTIONS

1) The critical dimensions for placement of the slide are as shown in Figures 26 and 27.

A. The slide exit runway surface shall not exceed twenty inches (20”) above the

water surface and not less than eight inches (8”) above the deck/coping surface

(see Figure 26).

B. The slide shall be positioned so that all water flowing off the runway exit drops

into the pool.

C. The minimum depth of water below the exit lip of the slide shall be three feet (3’)

and increases to four feet six inches (4’-6”) at Pt. A which is a distance of four

feet six inches (4’-6”) from the exit lip of the slide. (See Figure 26).

D. A minimum depth of four feet six inches (4’-6”) shall be maintained at a distance

of nine feet (9’) along the extended centerline of the slide from Pt.A. (See Figure

26).

2) A minimum clearance area in front of the slide shall be

maintained away from the coping, another slide, a diving board or a

rope and float line. (See Figure 29)

A. The minimum clearance distance on either side of the

extended centerline of the slide runway shall not be less

than three feet six inches (3’-6”) at a point no less than two

feet six inches (2’-6”) from the exit of the slide and extending

a distance of thirteen feet six inches (13’-6”) in front of the

slide. (See Figure 27)

Figure 26

Figure 27

18

B. The minimum clearance area in front of a diving board is a minimum distance of

three feet six inches (3’-6”) on either side of the board’s centerline. Pt.C extends

a minimum distance of “C” from the tip end of the board. The width distance “W”

on either side of Pt.C is given in CHART 1 and shown in Figure 28.

CHART 1

BOARD MINIMUM CLEARANCE AREA

POOL TYPE “C” DIMENSION “W” DIMENSION

I 14’-6” 5’-0”

II 14’-6” 6’-0”

III 16’-6” 6’-0”

IV 18’-6” 7’-6”

V 21’-0” 7’-6”

See Article 5 contained in ANSI/NSPI-5 2003 STANDARD

FOR RESIDENTIAL INGROUND SWIMMING POOLS and

refer to Figure 3 and Table 1 for Minimum Water Envelope

Dimensions AB, BC and Width at Point C.

“C” DIMENSION FOR BOARD = AB + BC

“W”

DIMENSION FOR BOARD = WIDTH AT PT.C

Figure 28

C. The minimum clearance area of a slide or diving board shall not intersect any

coping or rope and float line. (See Figure29) The minimum clearance area of a

slide or diving board may intersect each other provided that they are not used

simultaneously.

Figure 29

19

ELECTRICAL BONDING

If electrical bonding is required by the local governmental regulations, it shall be done in

accordance with Article No. 680 of the current National Electrical Code or the local

Code, whichever has jurisdiction. Five (#20) 1/4" x 1/2" Sheet Metal Screws and five

(#21) 1/4" x 3/4" Flat Washers are provided for this purpose. Secure one per slide leg

and one per ladder.

INSTALLED SLIDES’ STRUCTURAL & INSTALLATION CHECKLIST

1) Inspect the runway for visible cracks or tears.

2) Inspect the slide for sharp edges, protrusions, cracks or tears.

3) Inspect all attachment flanges for loose or corroded fasteners.

4) Inspect all ladder tread or step-attachment points for evidence of shear, bending

yield, or fatigue in the ladder steps, rails, or attachments means. Yield is

evidenced by crystallization or fine cracking of the ladder tread and/or surface.

5) Inspect the ladder handrails for rigidity and attachment. (Can they be pulled out

of their sockets?)

6) Measure the following dimensions and compare with the Manufacturer’s

Placement Instructions on pages 18 and 19. Also review the ANSI/NSPI-5 2003

STANDARD FOR RESIDENTIAL INGROUND SWIMMING POOLS.

• Measure the depth of water in front of the slide exit. (4-1/2’ min. depth 41/2’ from exit end of slide.)

• Measure the height of the slide runway exit above the water. (20” max.)

• Measure the distance between the slide centerline and the edge of other

pool equipment.

7) Observe the position of the exit of the slide as shown in Figures 26, 27 and 28 on

pages 18 and 19.

IMPORTANT

PERSONALLY GIVE TO SLIDE OWNER THE ROGUETM GRAND RAPIDSTM

OWNER’S MANUAL, THE WARRANTY CARD AND ANSWER ALL QUESTIONS.

20

Loading...

Loading...