S.R. Smith Frontier II User Manual

1/2 METER

FRONTIER II

JUMP STAND W/JIG

STEEL STAND COMPLETE

6’ 68-209-586 |

8’ 68-209-588 |

CAUTION

CAUTION

ALL MINIMUM WATER ENVELOPE DIMENSIONS FOR RESIDENTIAL INGROUND SWIMMING POOLS MUST MEET THE ANSI/NSPI-5 2003 AMERICAN NATIONAL STANDARD FOR RESIDENTIAL INGROUND SWIMMING POOLS (REFERENCED THROUGHOUT THESE ASSEMBLY AND INSTALLATION INSTRUCTIONS AS “ANSI/NSP-5 2003”). COMPLY WITH LOCAL GOVERNMENT REGULATIONS IF THEY EXCEED ANSI/NSPI STANDARDS.

All diving boards and related equipment are manufactured for inground swimming pools ONLY. The S.R. Smith Frontier II Jump Stands are designed to be easily transported and installed. Follow all instructions carefully and inspect closely to assure proper and safe installation.

PROPER INSTALLATION CANNOT BE OVERSTATED. IMPROPER INSTALLATION VOIDS S.R. SMITH’S WARRANTY AND MAY AFFECT THE SAFETY OF THE USER.

ASSEMBLY AND INSTALLATION INSTRUCTIONS

– PLEASE READ CAREFULLY –

WESTERN SALES AND MANUFACTURING PLANT

CORPORATE HEADQUARTERS

P.O. Box 400 • 1017 S.W. Berg Parkway

Canby, Oregon 97013

Phone (503) 266-2231 • Fax (503) 266-4334

EASTERN MANUFACTURING PLANT

105 Challenger Drive

Portland, Tennessee 37148

Phone (615) 325-0770 • Fax (615) 325-0775

www.srsmith.com

ATTENTION!

THESE INSTRUCTIONS MUST REMAIN WITH STAND OWNER

06-305 |

AUG06 |

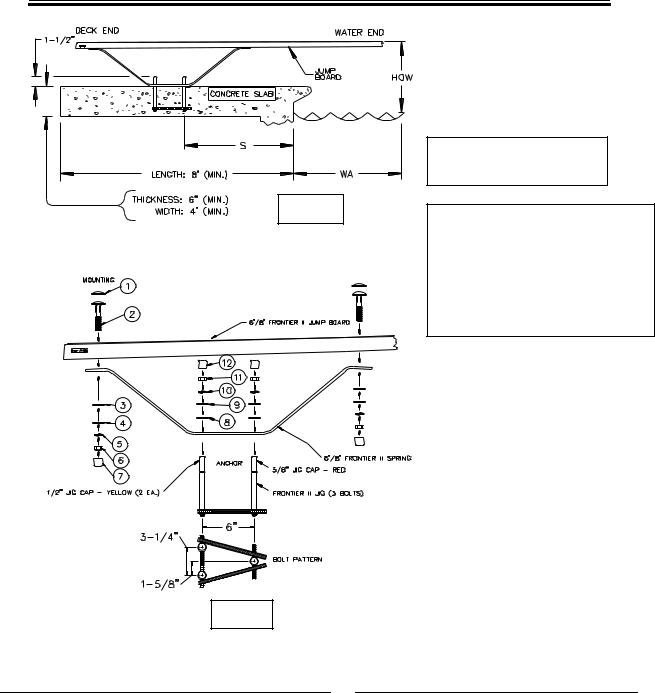

1/2 METER FRONTIER II JUMP STAND For 6’ and 8’ Frontier II Jump Boards

TIGHTENING SCHEDULE

SECURE BOARD TO STAND WITH

MOUNTING HEX NUTS

FIBERGLASS: 20-25 FT-LBS.

SECURE STAND TO JIG WITH: ANCHOR HEX NUTS

40-50 FT-LBS.

S.R. SMITH CANNOT GUARANTEE

CUSTOMER’S CONCRETE OR

THICKNESS

FIG. 1 |

IMPORTANT NOTICE: |

|

|

|

IT IS NECESSARY TO USE AN |

|

ANTI-SEIZE COMPOUND ON |

|

ALL STAINLESS STEEL |

|

HARDWARE. FAILURE TO USE |

|

ANTI-SEIZE COMPOUND MAY |

|

RESULT IN GALLING AND |

|

SEIZING OF THE HARDWARE. |

FIG.2

FRONTIER II MOUNTING

BOLT KIT (69-209-032-SS)

1.STEP BOLT HEAD CAP – WHITE RUBBER (3 EA.)

2.1/2” X 3” LG. STEP BOLT – S/S (3 EA.)

3.1/2” X 1-1/2” ROUND NYLON WASHER (3 EA.)

4.1/2” X 1-3/8” FLAT WASHER S/S (3 EA.)

5.1/2” LOCK WASHER S/S (3 EA.)

6.1/2” HEX NUT S/S (3 EA.)

7.1/2” WHITE PLASTIC NUT CAP (3 EA.)

FRONTIER II SPRING

ANCHOR BOLT KIT (69-209-033-SS)

8.5/8” X 1-3/4” NYLON PROTECTIVE WASHER (3 EA.)

9.5/8” X 1-3/4” FLAT WASHER S/S (3 EA.)

10.5/8” LOCK WASHER S/S (3 EA.)

11.5/8” HEX NUT S/S (3 EA.)

12.5/8” WHITE RUBBER NUT CAP (3 EA.)

2

FRONTIER II JUMP STAND

INSTALLATION CHART

Refer to Fig.1

Frontier II |

Jump |

ANSI/NSPI-5 |

Distance For Setting |

Min. Overhang |

Max. Height of Board |

|

Stand with |

Board |

2003 |

Front Bolt of Jig From |

± 3” |

Above Water |

|

|

Length |

Pool Type |

Water’s Edge |

|

|

|

|

|

|

“S” |

“WA*” |

“HOW” |

|

|

6’ |

I or II |

26” |

18” |

20” |

|

|

6’ |

III |

20” |

24” |

26” |

|

FRONTIER II |

8’ |

III |

34” |

24” |

26” |

|

6’ |

IV |

14” |

30” |

30” |

||

|

||||||

|

8’ |

IV |

28” |

30” |

30” |

|

|

8’ |

V |

22” |

36” |

40” |

|

|

|

|

|

|

|

IMPORTANT: The distance for setting the front bolt of the jig “S” from the waters edge is valid only if the minimum water depth is maintained at the tip of the board noted at point A in ANSI/NSPI-5 2003, Figure 3 and Table 1. If minimum water depth is not maintained the distance “S” must be adjusted accordingly.

*WA DIMENSION IS VALID ONLY IN CONJUNCTION WITH MIN. DEPTH AT POINT A (SEE ANSI/NSPI-5 2003 FIGURE 3 AND TABLE 1) FOR POOL TYPE.

NOTE: When coping is used do not set front bolts of jig closer than 3" from the back edge of coping.

INSTALLATION INSTRUCTIONS

BE SURE CONCRETE DECK SURROUNDING ANCHOR JIG COMPLIES WITH MINIMUM DIMENSIONS AS SHOWN IN FIG. 1 FOR POOL TYPE AND BOARD TO BE USED.

1.READ CAREFULLY the following, and pages A through E, which have been extracted from ANSI/NSPI-5 2003 and pay particular attention to Figure 3 and Table 1 set forth therein.

2.The Frontier II three-bolt jig should be set in accordance with the INSTALLATION CHART above and Fig. 1, with the "RED" capped bolt closest to the pool. This will give the desired minimum overhang. Board must be placed at deep end of pool on centerline.

CAUTION: Before pouring concrete around jig, check the bolt pattern of jig to Fig. 2. It is possible that they have become misaligned through shipping and handling.

3.Make sure bolts project out of concrete 1-1/2" with ample concrete depth below jig. Refer to Fig. 1 for minimum deck thickness, width and length.

4.When finishing deck surface, maintain a LEVEL DECK SURFACE where jig bolts project out so that the stand makes uniform contact with deck.

5.Before mounting stand, chisel away any excess concrete that may have built up around jig bolts and remove the red and yellow bolt caps.

6.Place stand over jig bolts and secure according to Fig. 2. Tighten ANCHOR hex nuts. Tighten all MOUNTING and ANCHOR hex nuts according to the TIGHTENING SCHEDULE in Fig. 1.

7.With Frontier II stand properly secured, select board size according to INSTALLATION CHART above. Take the White Rubber Step Bolt Caps and pullover the heads of the 1/2" x 3" long Step Bolts. When inserting Step Bolts through the board holes, tap with a rubber mallet in order to obtain a snug fit. Secure Frontier II jump board to stand according to Fig. 2 and tighten MOUNTING hex nuts.

8.The top surface of the diving board shall be level from side to side.

ONLY ONE PERSON ON A JUMP BOARD AT A

TIME, WITH A MAXIMUM WEIGHT OF 250 LBS.

3

Loading...

Loading...