Sri 210D User Manual

HPLC

Model 210D

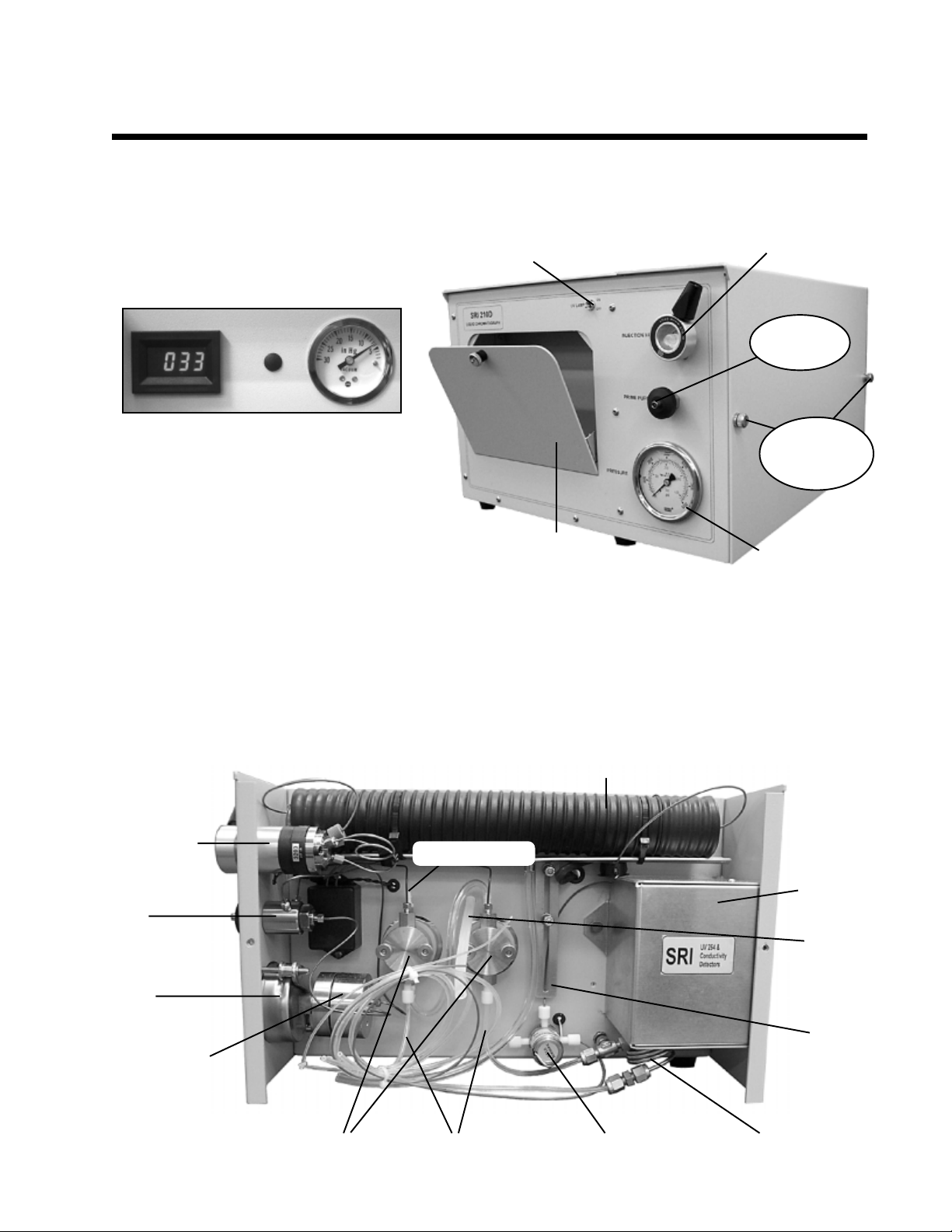

1. Overview

The Model 210D front panel houses the UV detector lamp switch, Rheodyne injection valve, prime/purge

valve, pressure gauge, and the storage

compartment. In the storage compartment

are the LED display for the column

temperature, and the vacuum degas pressure

UV detector

lamp switch

Rheodyne 7725i injection valve

Prime/purge

valve

gauge (shown above). An accessories kit is

included with your 210D. In the kit are two

Column

compartment

thumbscrews

PEEK finger tight nuts (Alltech part # 32233)

for column connection, a spare 1/16”

stainless steel fitting (Valco part ZN1) and

ferrule (Valco part ZF1S6), a flange fitting

Storage

compartment

Pressure gauge

(Upchurch part 203X) and ferrule

(Upchurch part 240X) for the solvent recycle valve, a 20mL priming syringe (Sigma Aldrich part Z248037),

and a 100µL glass injection syringe (SGE part 005300).

On the right hand side of the 210D is the column compartment, which gives you access to the column heater,

pump head(s), solvent recycle valve, and the detector housing. Open the column compartment by loosening

the two captive thumbscrews and lifting off the cover. Use the picture below to familiarize yourself with the

interior of the column compartment.

Column heater

Rheodyne 7725i

injection valve

with a 20µL

sample loop

Prime/purge

valve

Pump outlet line

UV and

Conductivity

detectors

Pressure

gauge

Pulse damper

Vacuum

de-gas

outlet

Vertical

slide

Pump inlet linesPump heads

Solvent recycle valve

Vacuum de-gas coil

HPLC

Model 210D

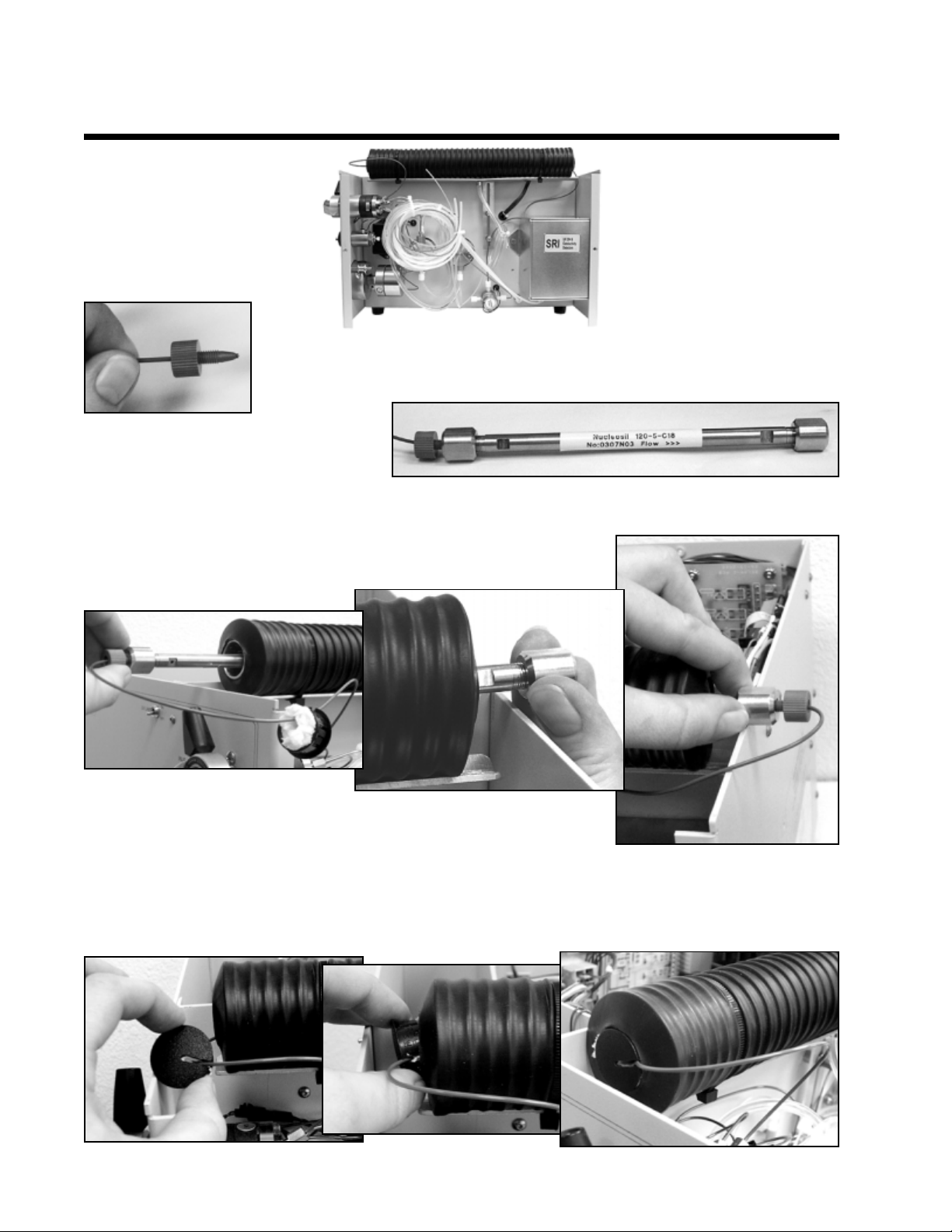

2. Installing a Column

Slide the column heater up.

Install the column of your choice using the included PEEK finger tight nuts. Slide the

nuts onto the PEEK tubing, letting about 1mm of PEEK tubing protrude.

Secure one nut to the column.

Slide the column through the column heater so you can reach the other end,

and attach the second nut. Roughly center the column in the column heater.

Slide the column heater up

on its aluminum slider.

Replace the black column heater end caps, which have notches in them for the PEEK tubing. Pack in any

loose insulation. When you have replaced both end caps as shown below, slide the column heater back down

into the operating position.

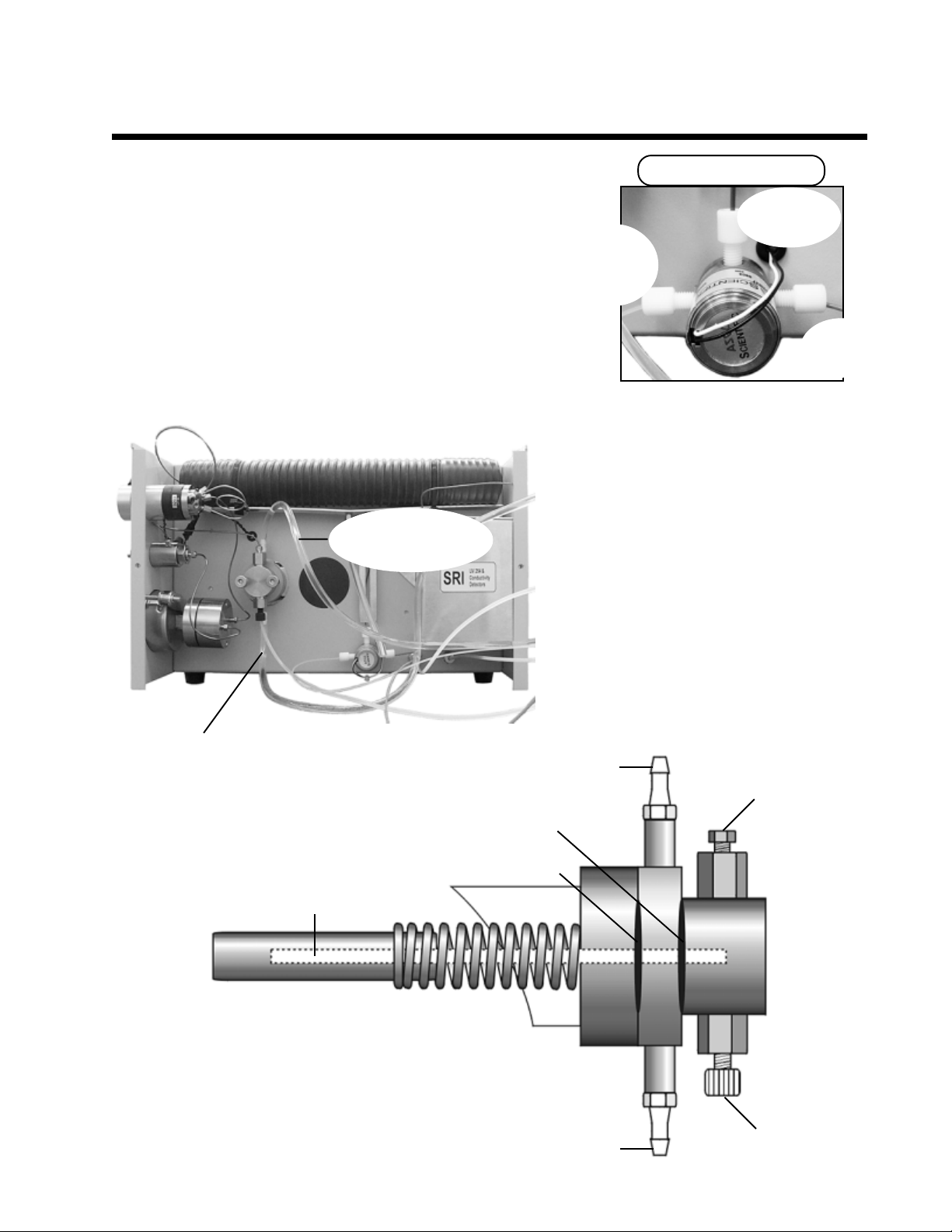

3. Solvent Set-up

The pump heads each have an 1/8” Teflon solvent inlet line. Place

the ends of these lines in your solvent bottle. The solvent recycle

valve has two outlet lines. The 1/16” clear line is recycled solvent.

Put it into the solvent bottle, or into its own container if you wish

to keep it separate from your fresh solvent. Place the end of the

1/16” green line into a waste bottle. A simplified way to remember:

all the clear lines go to the solvent bottle. In default mode, the

solvent recycling valve sends the effluent out the clear tube; when

activated, it directs the effluent out the green waste tube.

1/4” tygon tubing

piston flush inlet line

HPLC

Model 210D

Solvent recycle valve

Blue = in

from column

Clear =

recycled

solvent out

Green =

to waste

The 1/4” Tygon tubing attached to the pump

head(s) is the piston flush line. Piston flushing

helps keep the high pressure seal(s) clean,

minimizing wear and tear from crystallized and

abrasive buffer deposits that leak through the

seal, and would otherwise dry on the piston.

There are inlet and outlet lines for piston

flushing. Place the ends of both into a bottle

containing at least 50% organic solvent (usually

diluted with deionized water). Binary gradient

pump head piston flush lines are daisy chained,

and share the same in and out lines.

Piston flush

outlet line

210D pump, side view:

It is possible for solvent to leak past

the high pressure seal with the back

and forth thrusting of the piston.

Piston

Piston flush IN

High pressure seal

Low pressure seal

Piston flush OUT

Pump outlet

Pump inlet

HPLC

Model 210D

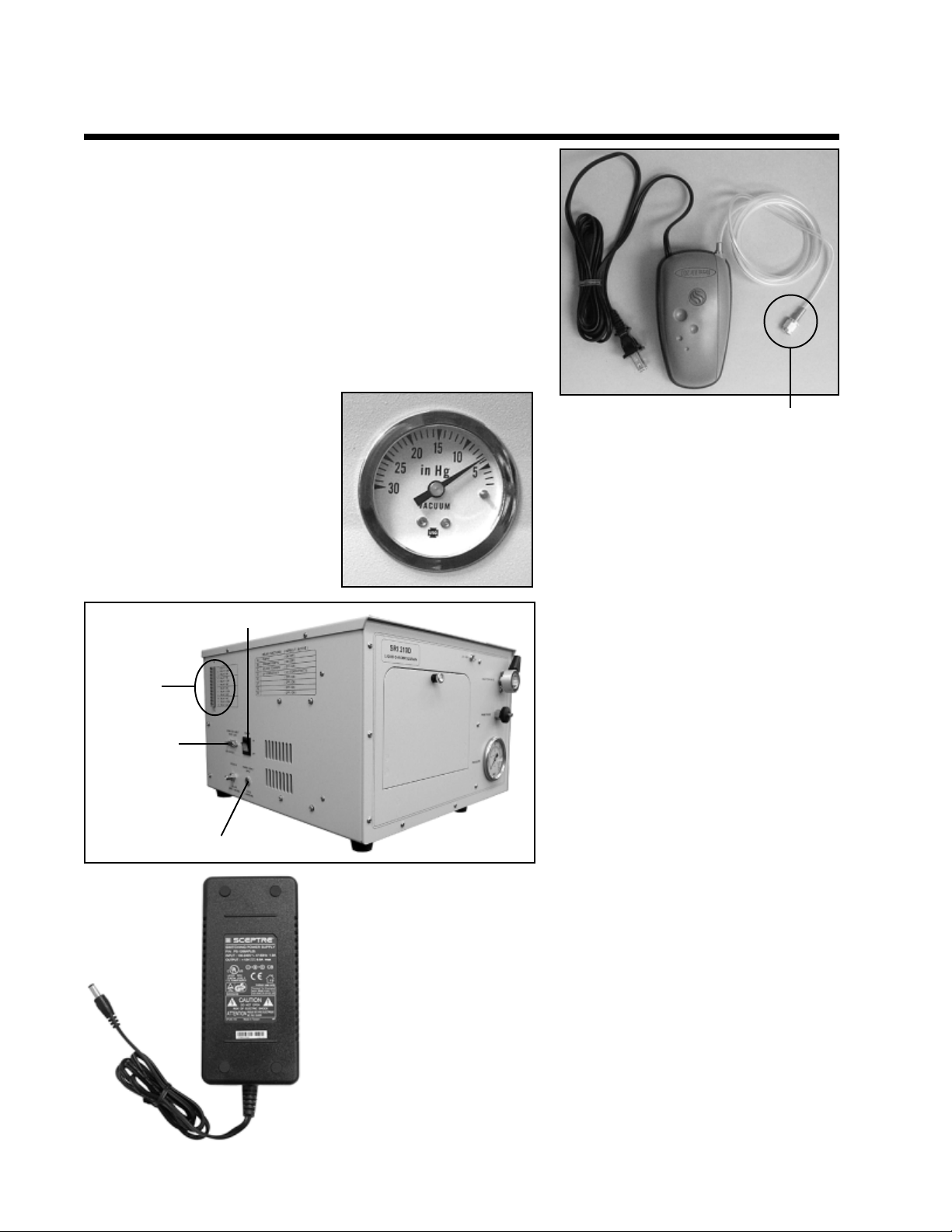

4. Vacuum De-gas

While not all HPLC users degas their solvent, it is a good idea to

do so. The 210D is equipped with an air pump for vacuum

degassing. A length of tygon tubing is provided to connect the

pump to the degas fitting on the left-hand side of the HPLC. The

tubing is equipped with a nut for easy connection to the degas fitting.

With the 210D power ON, connect the pump tubing to the degas

fitting, then plug the pump into a wall outlet. Open the storage

comparment to see the vacuum degas gauge, which should read

7psi with the pump ON and solvent lines attached.

The vacuum degas gauge should

read 7psi during operation.

Simply screw this nut onto the degas fitting

to connect the vacuum pump to the 210D.

Power switch

Access

terminals

Serial or USB

cable to PC

Power supply jack

5. Computer Connection

Connect your 210D to your Windows

TM

computer with the provided serial or USB

cable. The cable connection port is located

on the left-hand side of the 210D.

6. Power Supply

Your 210D comes with a universal (115V or 230V) benchtop 12 volt power

supply (shown at right). Plug the small power source cord into the jack on

the left hand side of the LC. Plug the larger power cord into a wall outlet.

Turn the power ON with the power switch, located above the power supply

jack. The 210D can be powered with any regulated or unregulated voltage

in the range of 11-15 volts at 80 watts (approximately 7 amps), including a

car battery via the cigarette lighter.

Loading...

Loading...