Contents

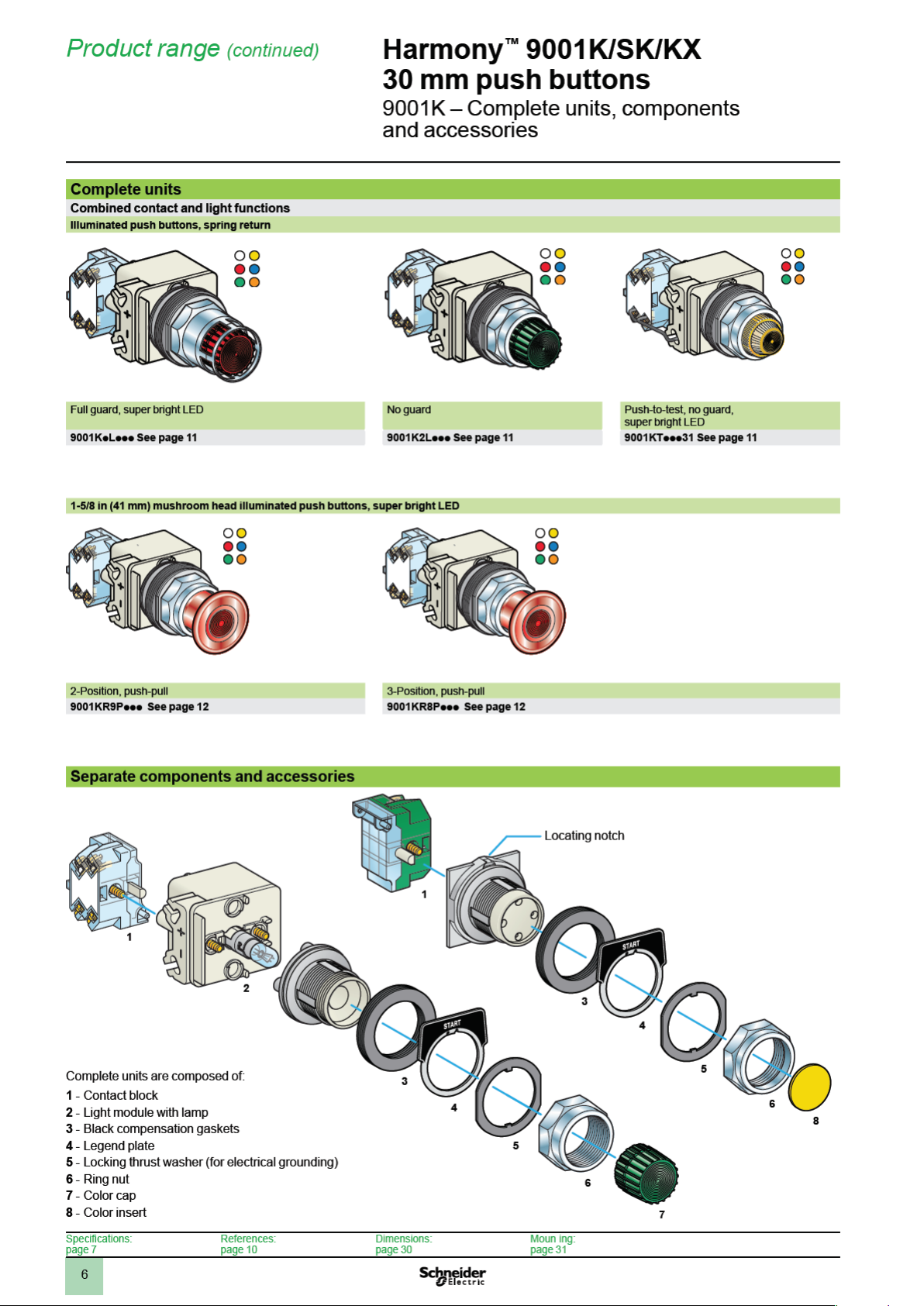

Harmony™ 9001K/SK/KX

30 mm push buttons

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

9001K heavy-duty operators with chrome-plated bezels:

Product range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

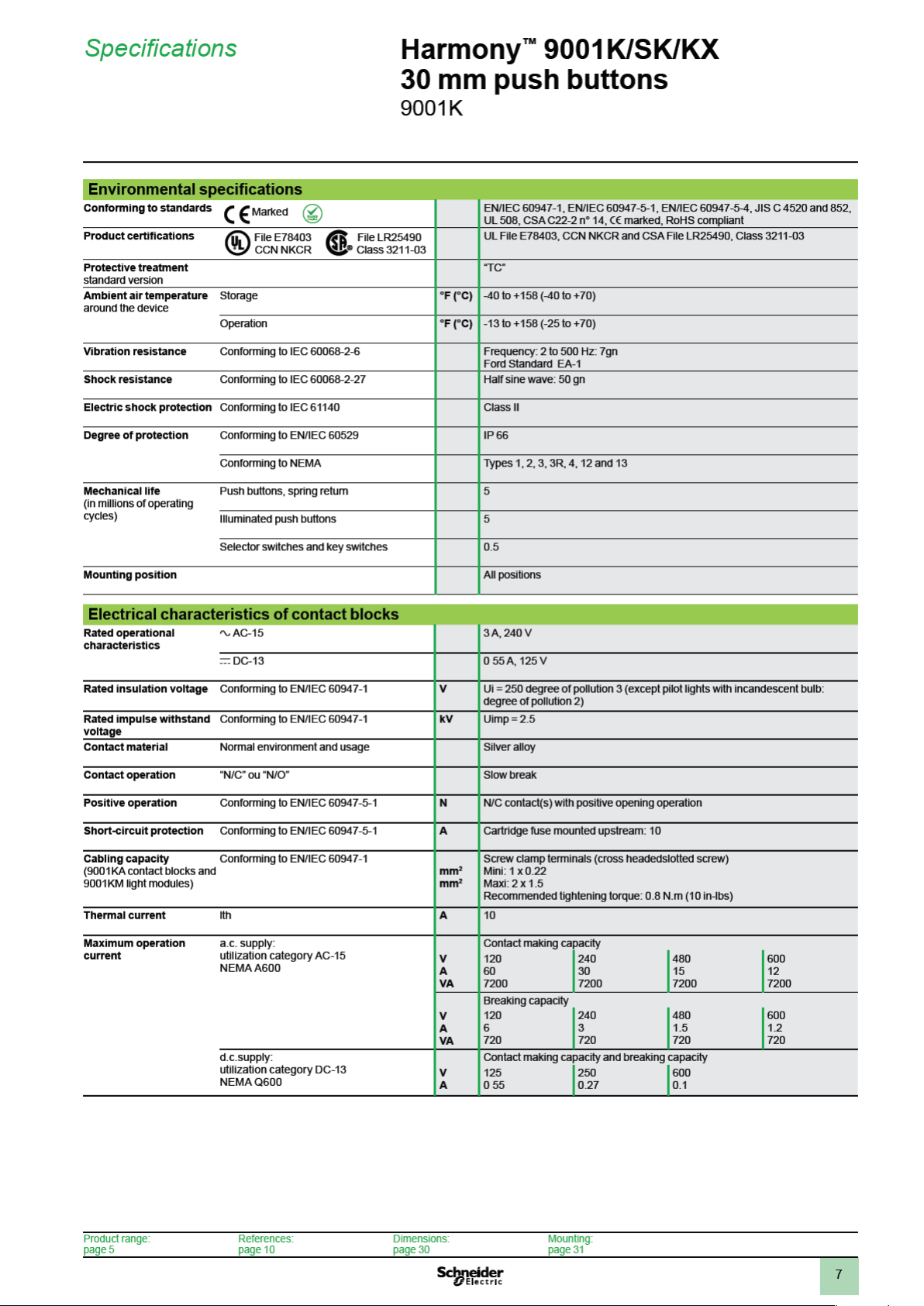

Specications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

References

v

Push buttons and mushroom operators

v

Multi-function operators

v

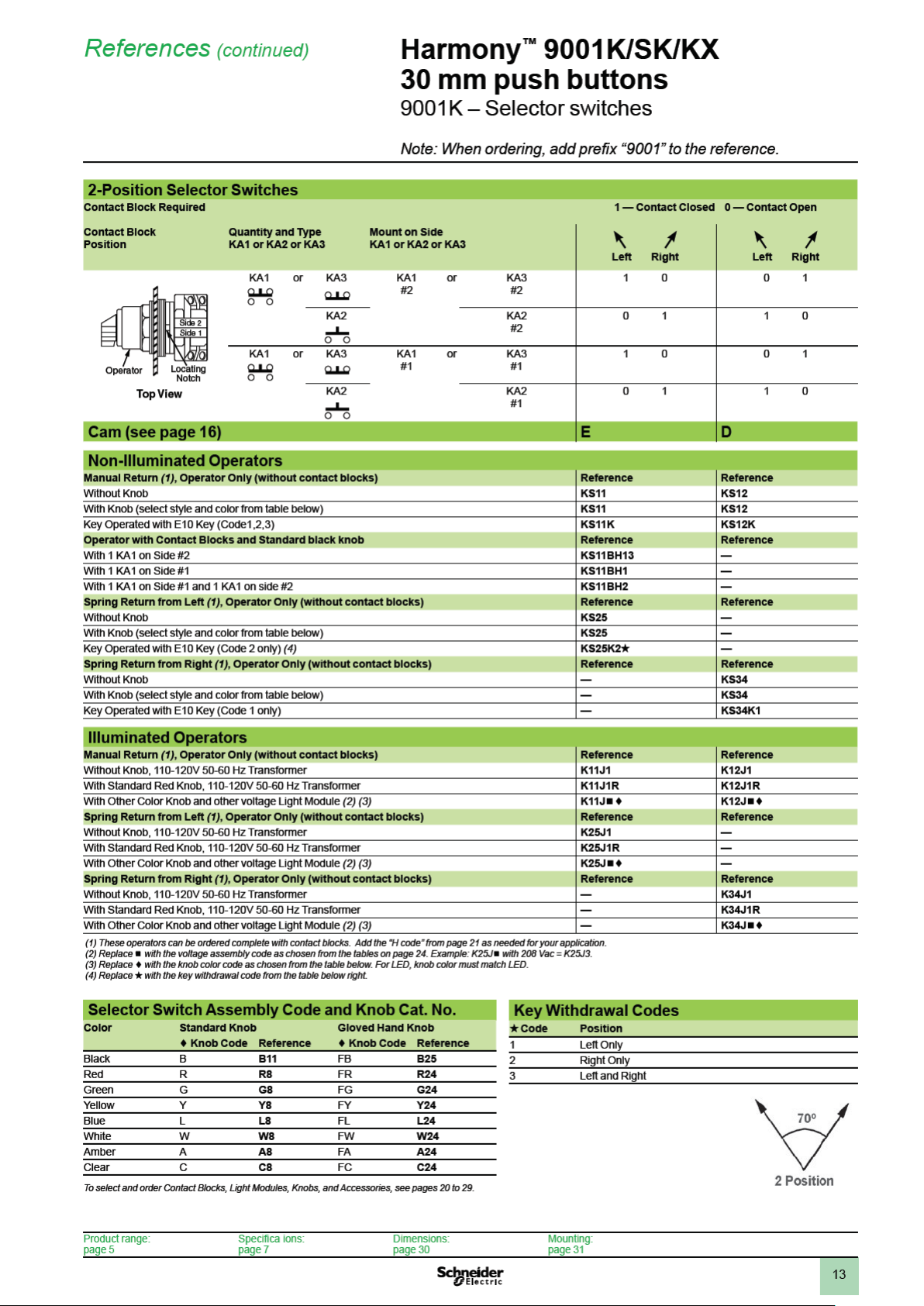

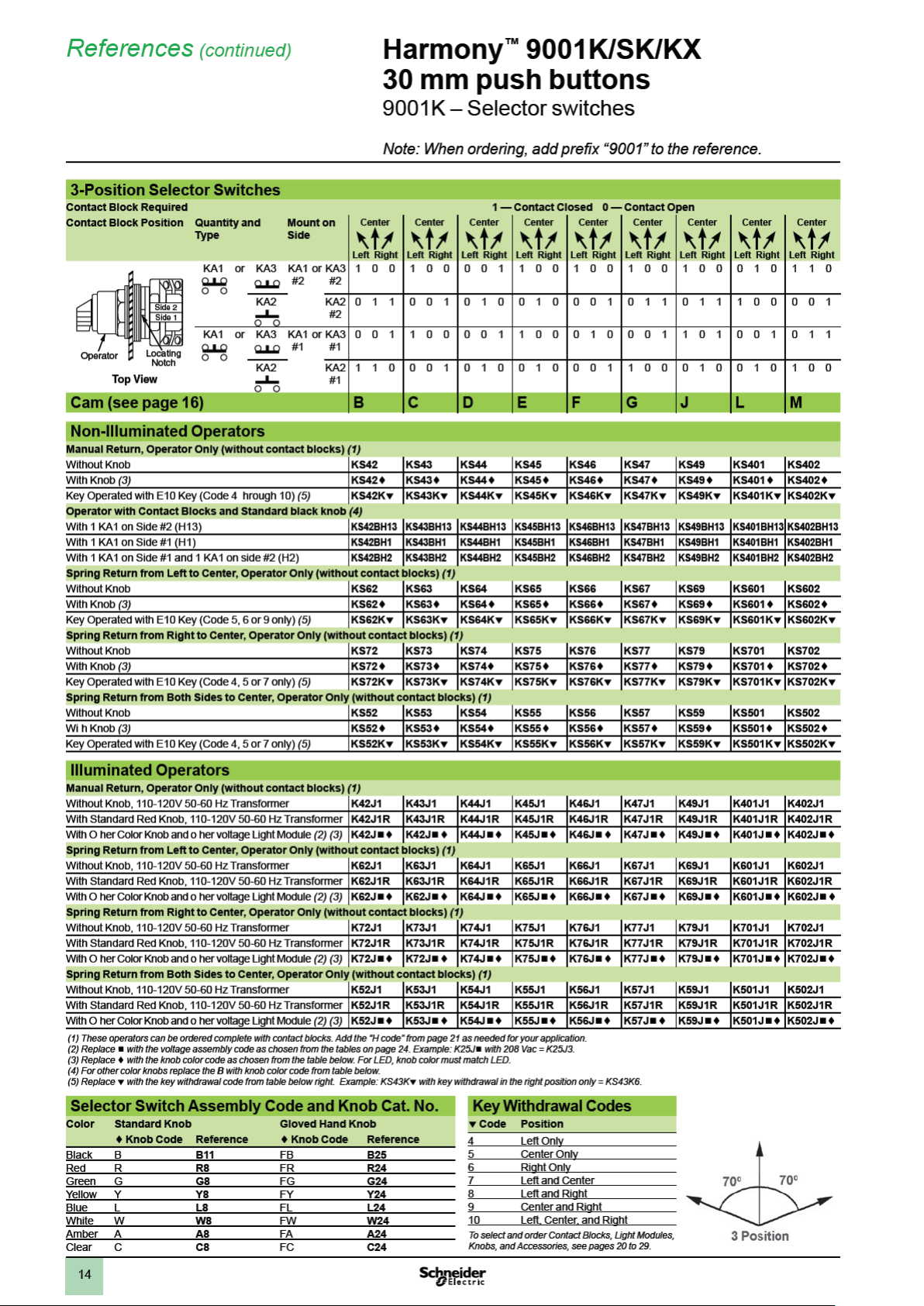

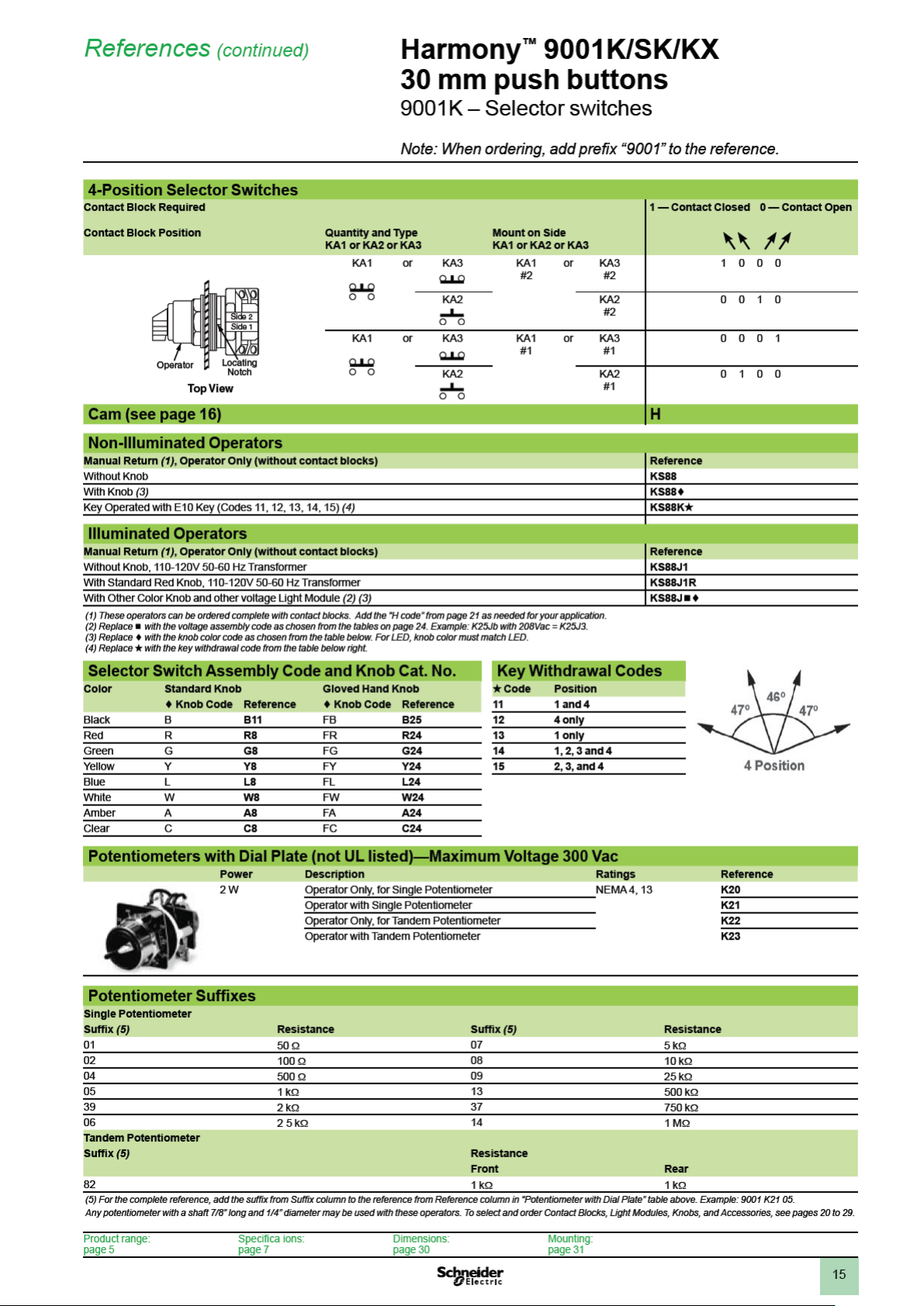

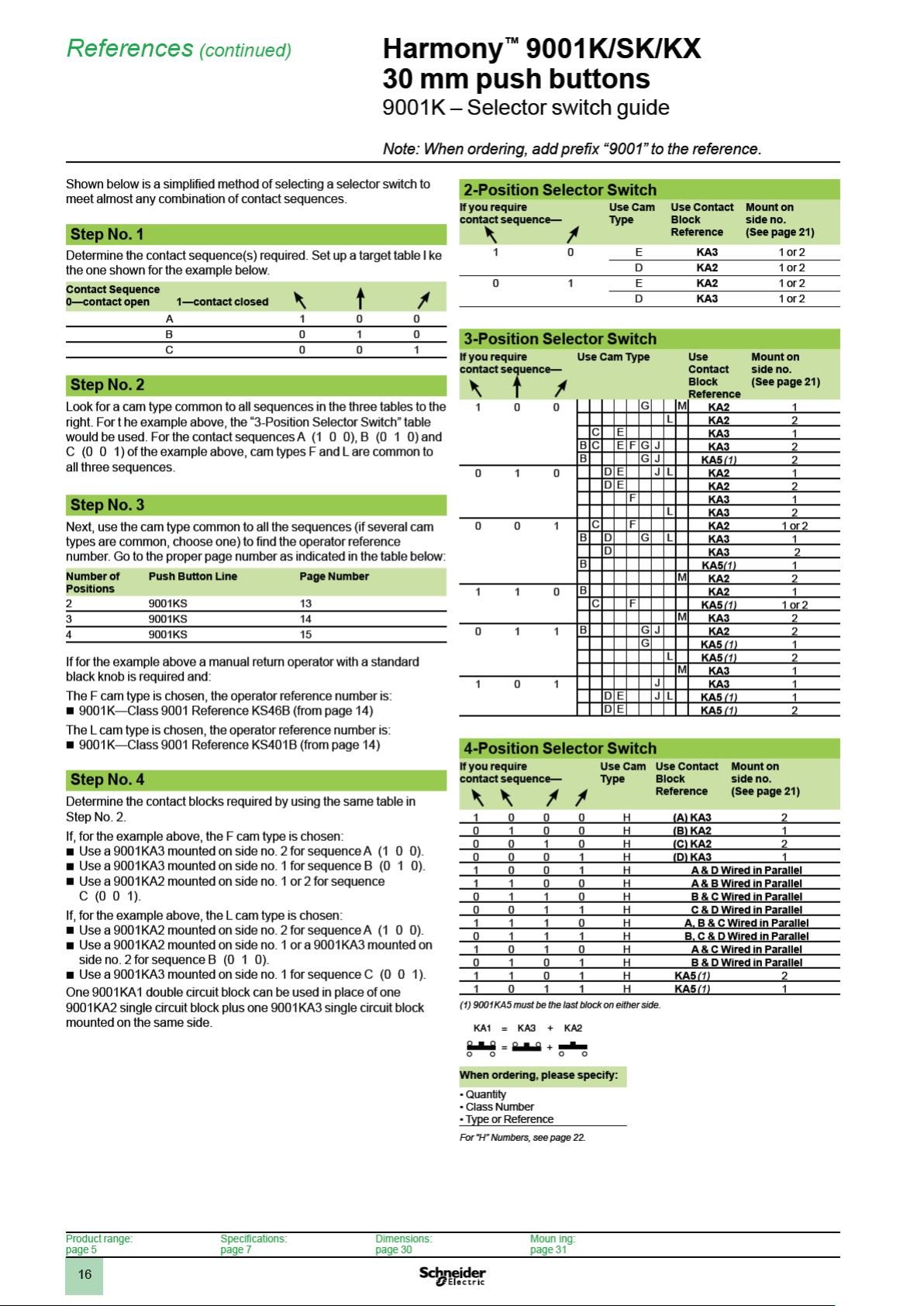

Selector switches

v

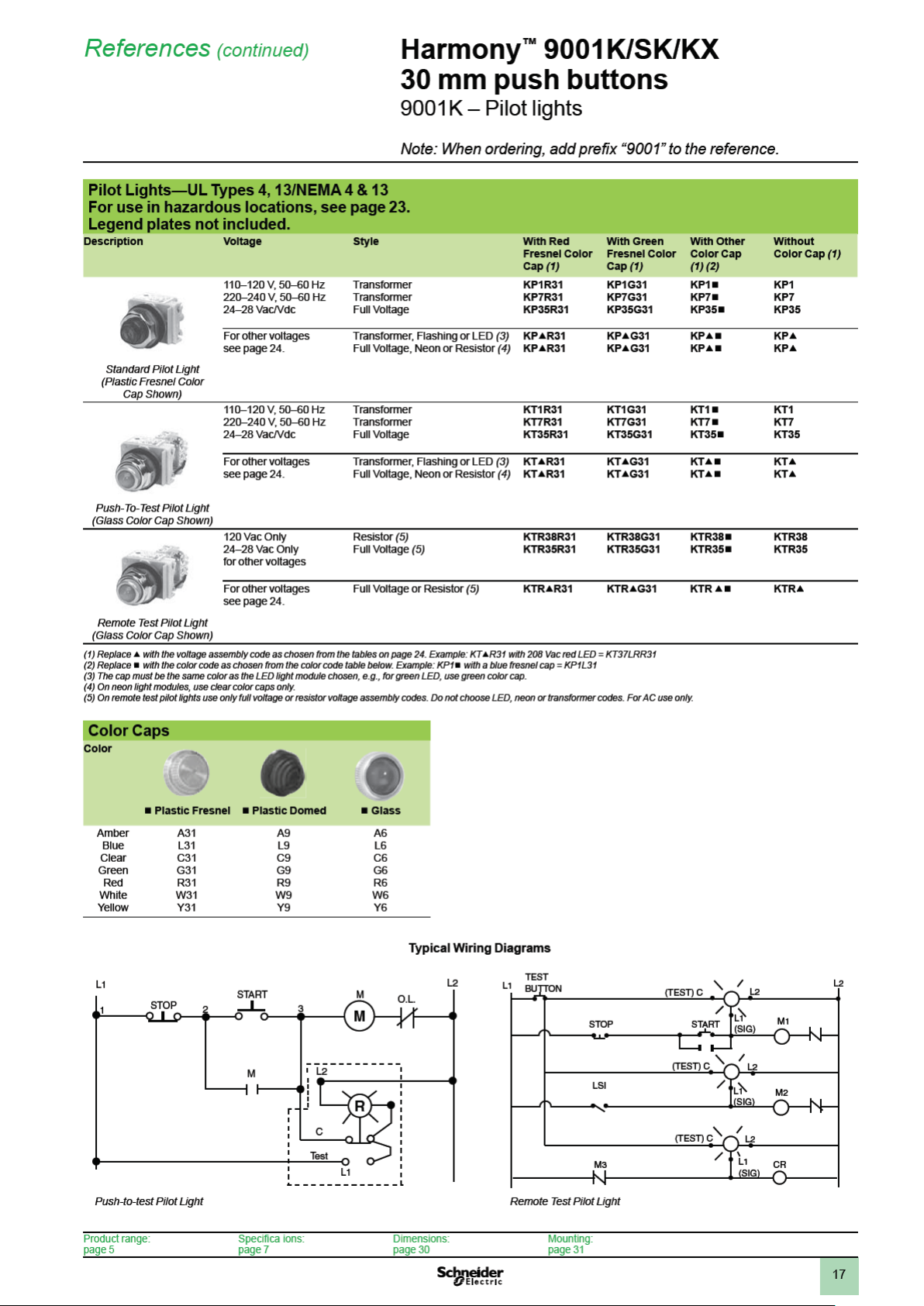

Pilot lights

v

Specialty operators

v

Contact blocks

v

Light modules

v

Legend plates

v

Accessories

v

Replacement parts

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

......................................24

......................................25

.......................................27

...............................12

...................................13

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

...................................29

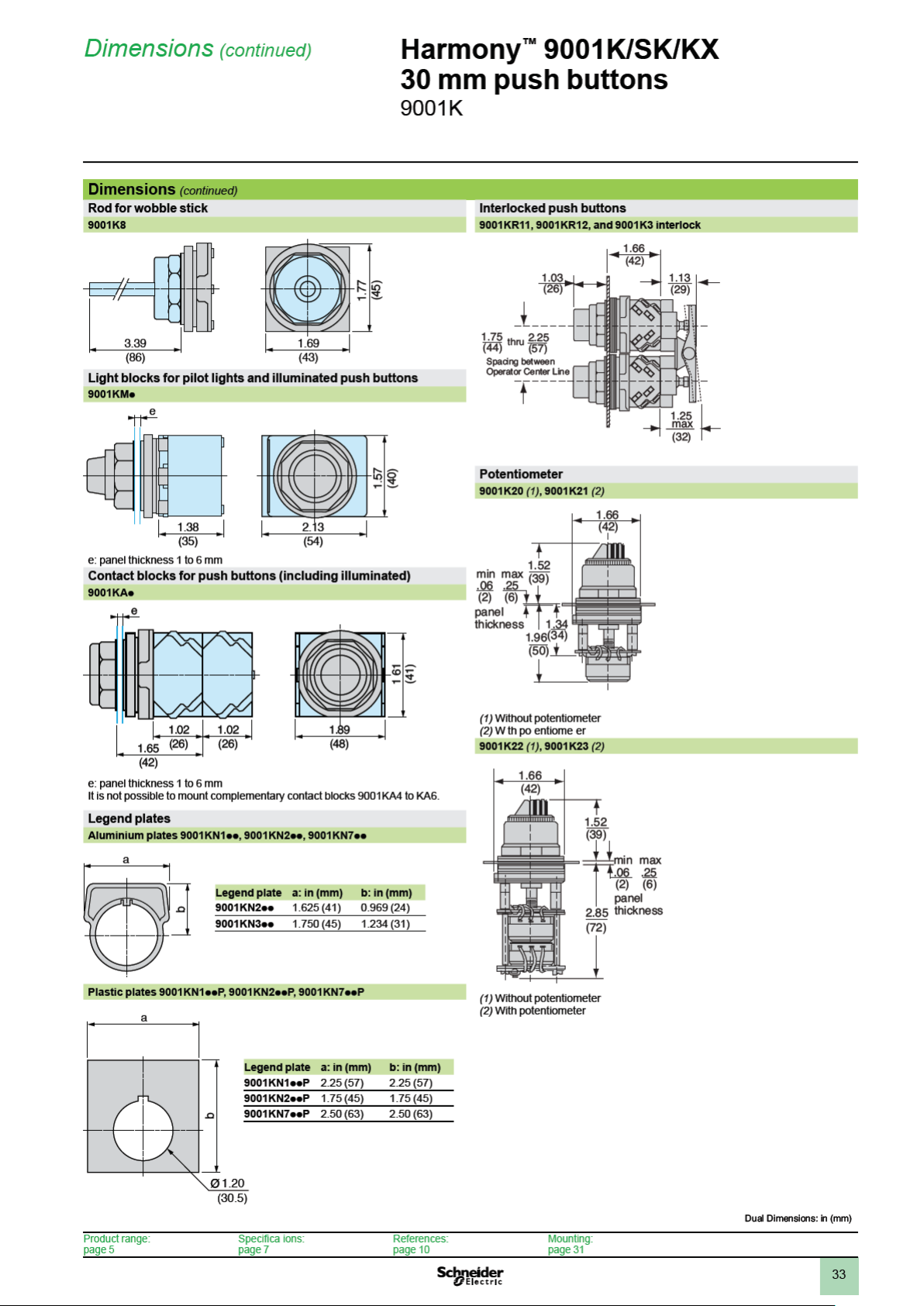

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

.....................10

9001SK corrosion-resistant operators with black plastic bezels:

Product range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Specications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

References

v

Push buttons and mushroom operators

v

Multi-function operators

v

Selector switches

v

Pilot lights

v

Specialty operators

v

Contact blocks

v

Light modules

v

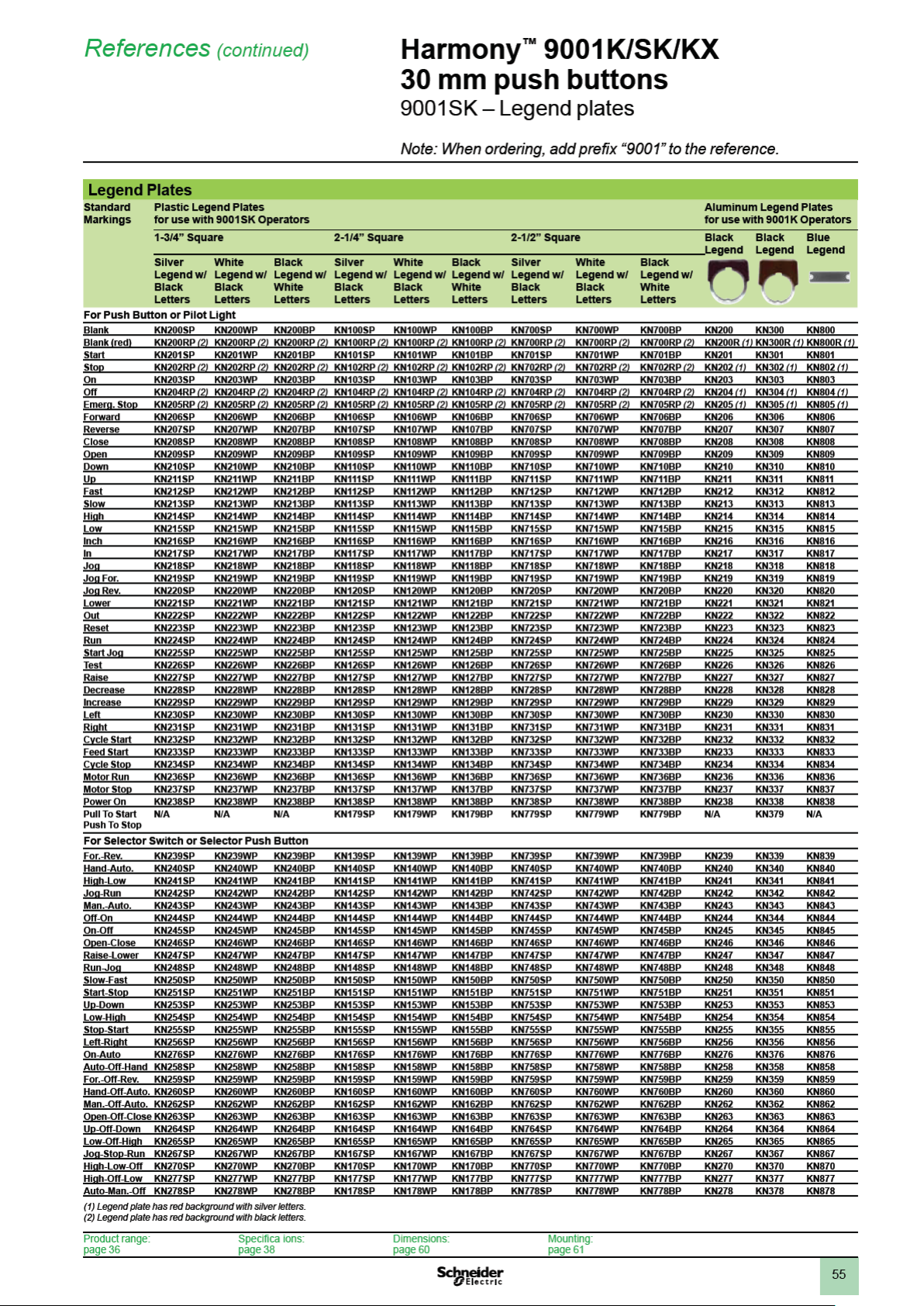

Legend plates

v

Accessories

v

Replacement parts

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

......................................54

......................................55

.......................................57

...............................43

...................................44

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

...................................59

.....................41

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

9001KX multi-function operators with chrome-plated

square-head bezels:

Product range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Specications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

References

v

Push buttons with contacts

v

Push buttons without contacts

v

Selector switches

v

Contact blocks

v

Pilot lights

v

Legend plates

v

Accessories

...................................72

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

......................................74

.......................................75

.............................70

...........................71

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Index ..............................................78

3

8

Specications (continued)

Harmony™ 9001K/SK/KX

30 mm push buttons

9001K

Basic Operators

(For Color Caps, Mushroom Buttons, Knobs, Se lector Switch Cams, Contact Blocks, Light Modules and Legend Plates, see page 21.)

Description UL Types/NEMA Types

4, 13

Non Illuminated Push Button (Full Guard) 9001KR1

Non Illuminated Push Button (Extended Guard) 9001KR2

Non Illuminated Push Button (No Guard) 9001KR3

Non Illuminated Push Button (Mushroom Button/screw on) 9001KR20

Non Illuminated Dual Push Button (Momentary) 9001KR6

Non Illuminated Dual Push Button (Momentary Interlocked) 9001KR67

Non Illuminated Dual Push Button (Maintained Interlocked) 9001KR7

Momentary Pull - Maintained Neutral - Momentary Push 9001KR8 (1) (4)

Maintained Pull - Maintained Push 9001KR9 (1) (4)

lluminated Push Button (Full Guard - Plastic Top) 9001K1L (2)

lluminated Push Button and Push-to-test (No Guard) 9001K2L (2) (3)

lluminated Push Button (Full Guard - Metal Top) 9001K3L (2)

Standard Pilot Light 9001KP

2-Position Selector Switch 9001KS1 (1), 9001KS2 (1), 9001KS3 (1)

3-Position Selector Switch 9001KS4 (1), 9001KS5 (1), 9001KS6 (1), 9001KS7 (1)

4-Position Selector Switch 9001KS8 (1)

Trigger-Action Emergency Stop 9001KR16 (1)

(1) Operator can be converted to an illuminated operator by removing the liner (6509704901) and adding a light module.

(2) Operator can be converted to a non-illuminated operator by adding liner (6509704901).

(3) Operator includes jumper wires for push-to-test conversion.

(4) These operators can be supplied with 1-3/8" or 2-1/4" dia. mushroom buttons. For 1-3/8" Add •20 to reference number. The • refers to the color chosen - see page 10.

For 2-1/4": Add •21 to reference number. The • refers to the color chosen - see page 10. Voids UL and NEMA Type 6 Rating.

Non Hazardous Locations:

File

CCN

E42259

NKCR

File

Class

LR25490

3211 03

Marking

Hazardous Locations (Reed contact blocks, see page 23):

File

CCN

E10054

NOIV

File

Class

LR26817

3218 02

Marking

Product range:

page 5

References:

page 10

Dimensions:

page 30

Moun ing:

page 31

9

Specications (continued)

Harmony™ 9001K/SK/KX

30 mm push buttons

9001K

9001K Operator Materials:

Push Button and Push-to-test Pilot Light

(9001KR and 9001KT)

Gasket – Nitrile

Seal – Nitrile

Seal Cap – Amorphous Acetal

Decorative Ring – Polyester Film

Compensating Washer – Polypropylene

Lock Ring – Amorphous Nylon

Stem – Thermoplastic Polyester

Base Cap – Thermoplastic Polyester

Knob – Polycarbonate

Liner – Polypropylene

Hold Down Spring for 9001K-15 – Neoprene

Operator Base – Zinc

Operator Base (9001KR8) – Polyester

Return Spring – Music Wire or Stainless Steel (9001KT only)

Ring Nuts – Aluminum or Zinc

Springkeeper – Steel

Locking Thrust Washer – Zinc

Color Insert – Polyethylene

Boots – Silicone

Selector Switch (9001KS)

Gasket – Nitrile

Seal – Nitrile

Bearing Washer – Polyester Film

Compensating Washer – Polypropylene

Cam Follower – Delrin 100

Liner – Polypropylene

Knob – Polycarbonate

Cam Carrier – Amorphous Nylon

Cam Rotor – Celenex 3300

Cam Prole– Delrin 100

Operator Base – Zinc

Detent Spring – Stainless Steel

Ring Nuts – Aluminum or Zinc

Seal keeper – Stainless Steel

Locking Thrust Washer – Zinc

Contact Block And Light Module Materials:

Contact Block (9001KA)

Housing – Amorphous Nylon

Contact Slider – Phenolic, Nylon or Acetal

Terminal – Steel

Saddle Clamp – Steel

Spring – Stainless Steel

Contacts – Silver and Copper

Blade – Beryllium Copper

Mounting Screw – Steel

Label – Paper

Light Module (9001KM)

Housing – Thermoplastic Polyester

Socket – Steel

Terminal – Steel with Tin Plate

Saddle Clamp – Steel

Translating Pin – Polycarbonate

Transformer – Thermoplastic Polyester, Steel, Copper,

Polyvinyl Chloride, Polytetrauorethylene,

Acetate, Paper

Lamp Spring – Tin Plated Music Wire

Pilot Light (9001KP)

Gasket – Nitrile

Compensating Washer – Polypropylene

Lens – Glass or Polycarbonate

Light Module Housing – Thermoplastic Polyester

Operator Base – Zinc

Glass Lens Ring – Anodized Aluminum

Product range:

page 5

References:

page 10

Dimensions:

page 30

Mounting:

page 31

10

References

Harmony™ 9001K/SK/KX

30 mm push buttons

9001K – Push buttons and mushroom operators

Note: When ordering, add prex “9001” to the reference.

Non-Illuminated Momentary Push Button Operators

For use in hazardous locations, see page 23.

Contact blocks and legend plate not included unless otherwise noted.

Description Color Operator with 1 N.O.

Full Guard Black KR1BH13 KR1BH5 KR1BH6 KR1B

Red KR1RH13 KR1RH5 KR1RH6 KR1R

Green KR1GH13 KR1GH5 KR1GH6 KR1G

9001KR1B

No Guard Black KR3BH13 KR3BH5 KR3BH6 KR3B

9001KR3B

Extended Guard Black KR2BH13 KR2BH5 KR2BH6 KR2B

9001KR2B

1-3/8 in (35 mm)

Diameter

Mushroom Button

9001KR4B

1-1/2 in (40 mm)

Diameter

Mushroom Button

9001KR24BM

2-1/4 in (57 mm)

Diameter

Mushroom Button

9001KR5B

2-3/8 in (60 mm)

Diameter

Mushroom Button

9001KR25BM

(1) The universal push button operators contain one each of the following color inserts: black, red, green, yellow, orange, blue and white.

(2) Replace b with the color code as chosen from the color code table below.

(3) Knob has the words “Emergency Stop” in raised letters highlighted in white for readability.

(4) Replace d with the color code as chosen from the color code table below.

Universal (1) KR1UH13 KR1UH5 KR1UH6 KR1U

Other (2) KR1bH13 KR1bH5 KR1bH6 KR1b

Red KR3RH13 KR3RH5 KR3RH6 KR3R

Green KR3GH13 KR3GH5 KR3GH6 KR3G

Universal (1) KR3UH13 KR3UH5 KR3UH6 KR3U

Other (2) KR3bH13 KR3bH5 KR3bH6 KR3b

Red KR2RH13 KR2RH5 KR2RH6 KR2R

Green KR2GH13 KR2GH5 KR2GH6 KR2G

Universal (1) KR2UH13 KR2UH5 KR2UH6 KR2U

Other (2) KR2bH13 KR2bH5 KR2bH6 KR2b

Snap-In Plastic Mushroom Button

Black KR4BH13 KR4BH5 KR4BH6 KR4B

Red KR4RH13 KR4RH5 KR4RH6 KR4R

Red (3) KR4R05H13 KR4R05H5 KR4R05H6 KR4R05

Green KR4GH13 KR4GH5 KR4GH6 KR4G

Other (4) KR4dH13 KR4dH5 KR4dH6 KR4d

Screw-On Plastic Mushroom Button with Set Screw

Black KR24BH13 KR24BH5 KR24BH6 KR24B

Red KR24RH13 KR24RH5 KR24RH6 KR24R

Green KR24GH13 KR24GH5 KR24GH6 KR24G

Other (4) KR24dH13 KR24dH5 KR24dH6 KR24d

Screw-in Metal Mushroom Button with Set Screw

Black — — — KR24BM

Red — — — KR24RM

Green — — — KR24GM

Snap-In Plastic Mushroom Button

Black KR5BH13 KR5BH5 KR5BH6 KR5B

Red KR5RH13 KR5RH5 KR5RH6 KR5R

Red (3) KR5R05H13 KR5R05H5 KR5R05H6 KR5R05

Green KR5GH13 KR5GH5 KR5GH6 KR5G

Other (4) KR5dH13 KR5dH5 KR5dH6 KR5d

Screw-On Plastic Mushroom Button with Set Screw

Black KR25BH13 KR25BH5 KR25BH6 KR25B

Red KR25RH13 KR25RH5 KR25RH6 KR25R

Green KR25GH13 KR25GH5 KR25GH6 KR25G

Other (4) KR25dH13 KR25dH5 KR25dH6 KR25d

Screw-in Metal Mushroom Button with Set Screw

Black — — — KR25BM

Red — — — KR25RM

Green — — — KR25GM

and 1 N.C. Contact

(KA1)

Operator with

1 N.O. Contact (KA2)

Operator with

1 N.C. Contact (KA3)

Operator Only

with No Contacts

Color Codes

Color KR1, 2, 3

Blue

Yellow

White

Orange

Gray

To select and order Contact Blocks, Light Modules, Knobs, and

Accessories, see pages 20 to 29.

Product range:

page 5

Place Color Code

in Reference b

L

Y

W

S

E

KR4, 5, 24, 25

Place Color Code

in Reference d

L

Y

—

S

—

Specications:

page 7

Dimensions:

page 30

Moun ing:

page 31

11

References (continued)

Harmony™ 9001K/SK/KX

30 mm push buttons

9001K – Push buttons and mushroom operators

Note: When ordering, add prex “9001” to the reference.

Illuminated Momentary Push Button Operators

For use in hazardous locations, see page 23.

Legend plate and contact block not included unless otherwise noted.

Description Voltage

Full Guard

Illuminated

Push Button

Clear Plas ic

Top

9001K1L1

Full Guard

Illuminated

Push Button

Metal Top

9001K3L1

No Guard

Illuminated

Push Button

9001K2L1

1-3/8 in

(35 mm)

Illuminated

Screw-On

Plastic

Mushroom

(no Set Screw)

9001K2LR20

2-1/4 in

(57 mm)

Illuminated

Screw-On

Plastic

Mushroom

(no Set Screw)

9001K2LR21

(1) These operators can be ordered complete with contact blocks. For maximum block usage, see page 22. Add the “H”

number chosen from page 22 to the end of the operator reference number and add the cost of the “H” number to the operator cost.

(2) Replace b with the voltage assembly code as chosen from the tables on page 24. Example: K2Lb with 240 Vac/Vdc = K2L25

(3) On neon light modules, use clear color caps only.

(4) The cap must be the same color as the LED light module chosen, e.g., for red LED, use red color cap.

(5) Replace e with the color code as chosen from the color cap table below. Example: K2L25e with a blue 13⁄8 mushroom button = K2L25L20

(6) The only difference between a no guard (K2L) operator and mushroom button operator is the color cap.

and

Frequency

110–120 V, 50–60 Hz Transformer K1L1RH13 K1L1GH13 K1L1e

220–240 V, 50–60 Hz Transformer K1L7RH13 K1L7GH13 K1L7e

24–28 Vac/Vdc Full Voltage K1L35RH13 K1L35GH13 K1L35e

For other voltages (2) Transformer or Flashing K1LbRH13 K1LbGH13 K1Lbe

110–120 V, 50–60 Hz Transformer K3L1RH13 K3L1GH13 K3L1e

220–240 V, 50–60 Hz Transformer K3L7RH13 K3L7GH13 K3L7e

24–28 Vac/Vdc Full Voltage K3L35RH13 K3L35GH13 K3L35e

For other voltages (2) Transformer or Flashing K3LbRH13 K3LbGH13 K3Lbe

110–120 V, 50–60 Hz Transformer K2L1RH13 K2L1GH13 K2L1e

220–240 V, 50–60 Hz Transformer K2L7RH13 K2L7GH13 K2L7e

24–28 Vac/Vdc Full Voltage K2L35RH13 K2L35GH13 K2L35e

For other voltages (2) Transformer or Flashing K2LbRH13 K2LbGH13 K2Lbe

110–120 V, 50–60 Hz Transformer K2L1R20H13 K2L1G20H13 Order K2Lbe above

220–240 V, 50–60 Hz Transformer K2L7R20H13 K2L7G20H13

24–28 Vac/Vdc Full Voltage K2L35R20H13 K2L35G20H13

For other voltages (2) Transformer or Flashing K2LbR20H13 K2LbG20H13

110–120 V, 50–60 Hz Transformer K2L1R21H13 K2L1G21H13 Order K2Lbe above

220–240 V, 50–60 Hz Transformer K2L7R21H13 K2L7G21H13

24–28 Vac/Vdc Full Voltage K2L35R21H13 K2L35G21H13

For other voltages (2) Transformer or Flashing K2LbR21H13 K2LbG21H13

Style With Red Color

Cap and 1 N.O.

and 1 N.C.

Contact (KA1) (2)

Full Voltage K1LbRH13 K1LbGH13 K1Lbe

Resistor or Neon (3) K1LbRH13 K1LbGH13 K1Lbe

LED (4) K1LbRH13 K1LbGH13 K1Lbe

Full Voltage K3LbRH13 K3LbGH13 K3Lbe

Resistor or Neon (3) K3LbRH13 K3LbGH13 K3Lbe

LED (4) K3LbRH13 K3LbGH13 K3Lbe

Full Voltage K2LbRH13 K2LbGH13 K2Lbe

Resistor or Neon (3) K2LbRH13 K2LbGH13 K2Lbe

LED (4) K2LbRH13 K2LbGH13 K2Lbe

Full Voltage K2LbR20H13 K2LbG20H13

Resistor or Neon (3) K2LbR20H13 K2LbG20H13

LED (4) K2LbR20H13 K2LbG20H13

Full Voltage K2LbR21H13 K2LbG21H13

Resistor or Neon (3) K2LbR21H13 K2LbG21H13

LED (4) K2LbR21H13 K2LbG21H13

With Green Color

Cap and 1 N.O.

and 1 N.C.

Contact (KA1) (2)

With Other Color

Cap Without

Contact Block

(1) (2) (5)

(6)

(6)

Color Caps

Color Color Codes

e K1L, K2L, K3L e 1-3/8 in

Red

Green

Blue

Yellow

White

Clear

Amber

To select and order Contact Blocks, Light Modules, Knobs, and Accessories, see pages 20 to 29.

Product range:

page 5

R

G

L

Y

W

C

A

Mushroom

R20

G20

L20

Y20

W20

C20

A20

Specica ions:

page 7

e 2-1/4 in

Mushroom

R21

G21

L21

Y21

W21

C21

A21

Dimensions:

page 30

Mounting:

page 31

19

Emergency Break-Glass

Operator 9001K15

Rocker Arm Operating Lever

9001K50

References (continued)

Time Delay Push Button

Push-on Push-off Module

9001K85

Illuminated and Non-Illuminated Dual Operators

Meets UL Type 13/NEMA 13 and UL Type 6/NEMA 6, which UL and NEMA consider an

equivalent to UL Type 4/NEMA 4. For use in hazardous locations, see page 23.

Legend plate and contact blocks not included unless otherwise noted.

Description Color With 2 N.O.

Momentary

Dual

Function

9001KR7U

9001KR11U

Momentary

Interlocked

Dual Function

Maintained

Interlocked

Dual Function

Description Color Contacts (KA1) Without

Both Buttons

Maintained Interlocked

Assembly

One Button Momentary

One Button Maintained

Interlocked Assembly

(1) Universal for KR6, KR67, KR7 includes 2 inserts each of black, red and green.

(2) Replace b with one color for each button. R = red, G = green, B = Black. Example: A KR6 with left button red and right button black = KR6RB

(3) Universal for KR11, KR12 includes 2 each of black, red, green, yellow, orange, blue, white.

(4) Replace d with one color for each button. B = black, R = red, G = green, L = blue, Y = yellow, W = white, S = orange, E = gray.

Example: A KR11 with top button gray and bottom button orange = KR11ES

Harmony™ 9001K/SK/KX

30 mm push buttons

9001K – Specialty operators

Note: When ordering, add prex “9001” to the reference.

Universal (1)

Green-Red

Other (2)

Universal (1)

Green-Red

Other (2)

Universal (1)

Green-Red

Other (2)

Universal (3)

Other (4)

Universal (3)

Other (4)

Contacts (2 KA2)

KR6UH7

KR6GRH7

KR6bH7

KR67UH7

KR67GRH7

KR67bH7

KR7UH7

KR7GRH7

KR7bH7

— KR11UH1

— KR12UH1H1

With 1 N.O. &

1 N.C. Contact

(KA2, KA3)

KR6UH37

KR6GRH37

KR6bH37

KR67UH37

KR67GRH37

KR67bH37

KR7UH37

KR7GRH37

KR7bH37

KR11dH1

KR12dH1H1

Without

Contacts

KR6U

KR6GR

KR6b

KR67U

KR67GR

KR67b

KR7U

KR7GR

KR7b

Contacts

KR11U

KR11d

KR12U

KR12d

Emergency Break-Glass

Operator— UL 4, 13/NEMA 4, 13

Reference

K15

Operator is held in a depressed position by a

glass disc. When the glass disc is broken with the

hammer, button returns to a normal extended

position. Package of 5 discs included with

operator.

Rocker Arm Operating Lever

Reference

K50

Allows two standard push buttons to be operated

independently of each other. Order push buttons

and legend plates from pages 10, 11, 25, and 26

(please specify which marking is to be inverted).

9001K15 Replacement Parts

Description Reference

Yellow bumper 3105211101

Hammer and chain 3105206750

Lower ring nut 6512232801

Top ring nut 9001K40

Package of 5 replacement discs 9001K57

Clip to hold hammer 2540902240

Alternate Action—Push-on, Push-off Module

Reference

K85

Wobble stick

For easy operation of any

standard push button.

Reference

K8

Time Delay Push Button—UL Types 4, 13/NEMA 4, 13

Description

(Off - Delay)

Timed Contact

1 N.O. and 1 N.C.

Reference (All Colors)

Full Guard Extended Guard No Guard

KRD1UH1 KRD2UH1 KRD3UH1

KRD1UH2 KRD2UH2 KRD3UH2

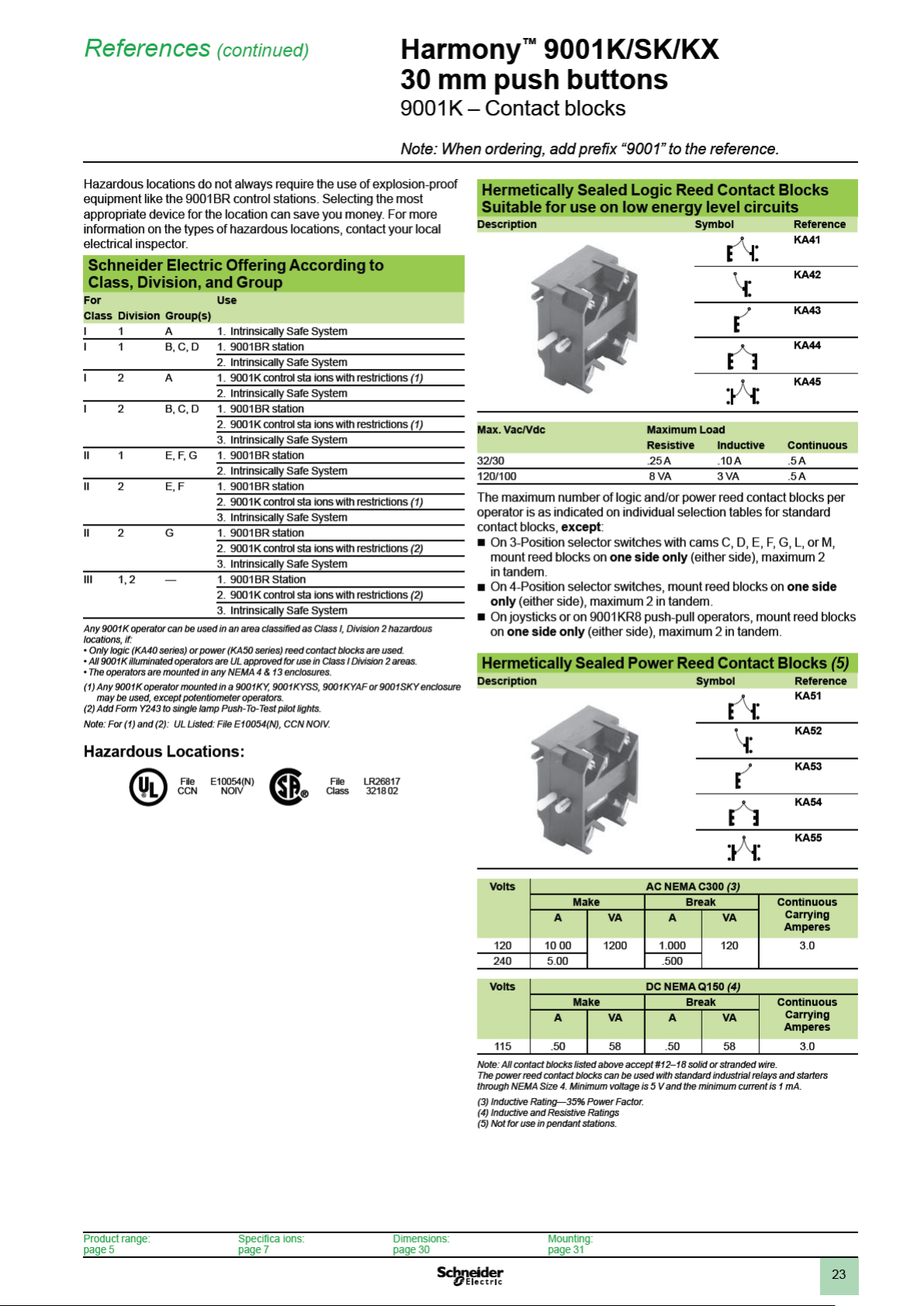

This module can be added to standard 9001K,

9001KX, 9001SK or 9001T momentary push

button operators. Contact blocks mounted

behind this module (maximum of 2) are held in

the depressed position when the operator is

pressed once, and released to their normal

position when the operator is pressed again.

For a N.C. circuit, use a 9001KA3 or the N.C.

contact of either a 9001KA1 or 9001KA4. For a

N.O. circuit, use the N.O. contact of either a

9001KA4 or 9001KA6.

Product range:

page 5

Timed Contact

2 N.O. and 2 N.C.

Timing period is adjustable from 0.1 second to 60 seconds and begins after button has been released. Devices include a pack of

seven color inserts for color coding the push button. See page 28 for Universal color insert. Contacts are quick make-quick break.

Note: When mounted in top or bottom hole of a 9001K enclosure, device requires one additional space below or above operator.

When mounted other than in top or bottom hole, device may require two additional spaces, one above and one below operator.

Closing plates must be installed on unused holes.

Specica ions:

page 7

Dimensions:

page 30

Mounting:

page 31

27

KU1

KU17

KU37

KU27

References (continued)

Harmony™ 9001K/SK/KX

30 mm push buttons

9001K – Accessories

Note: When ordering, add prex “9001” to the reference.

Padlock Attachments

Used On Description Reference

Non-illuminated

push button —

Standard or

mushroom (KR4,

KR5 mushroom

buttons only).

Non-illuminated

push buttons with or

without protective

boots.

Non-illuminated

push buttons with or

without protective

boots.

Non-illuminated

push buttons, cover

type attachment.

KR, SKR

Push buttons, cover

type attachment.

Push-pull operator

and illuminated push

buttons. KR8, KR9

Holds button in

depressed position

and can be

padlocked.

Holds button in

depressed position

when padlocked.

Holds button in

depressed position

when padlocked.

Attachment can be

padlocked. Does not

hold button in

depressed position.

Spring loaded cover

cannot be

padlocked. Does not

hold button in

depressed position.

Holds button in

depressed position

and can be

padlocked.

K4

K5

K97

K6

K60

K62

Padlock Attachments

Used On Description Reference

Selector switches

and potentiometers

(will not work with

gloved-hand knob).

Selector switches

and potentiometers

(will not work with

gloved-hand knob).

Illuminated push

buttons (with or

without guard) and

key operated push

buttons.

Illuminated push

buttons (with or

without guard) and

key operated push

buttons.

Maintained

push-pull operators

using 1.375 in dia.

mushroom buttons

(-20 series as shown

on page 28).

Cover type

attachment that can

be padlocked to

keep unauthorized

personnel from

tampering with the

operator.

Same as 9001K7

but with spring

loaded lockout

cover.

Cover type

attachment that can

be padlocked to

keep unauthorized

personnel from

tampering with the

operator.

Same as 9001K108

but with spring

loaded lockout

cover.

Cover type

attachment that

holds mushroom

button in depressed

position and can be

padlocked.

K7

K107

K108

K109

K110

Protective Boots

KR11U and KR12U

Interlocked

Assembly

9001KR9

Push-pull

operators—

Non-Illuminated

and Illuminated

Holds maintained

button in depressed

position and can be

padlocked.

Holds button in

depressed position.

Can be padlocked.

K96

K162

Mushroom Button Guards

Aluminum Mushroom Guard

for 1.375 in Mushroom Button

Operator (KR4, KR24)

Reference Reference Used On Reference Used On

K48 K56a (1) KR4 K68 KR5

(1) Replace a with B=Black, G=Green, R=Red or Y=Yellow.

(2) Replace b with R=Red or Y=Yellow. The mushroom guard has nger holes for

push-pull operators.

Product range:

page 5

Yellow Plastic Extended

Mushroom Guard for 1.375 in

and 1.625 in Mushroom

Button Operators

K56bM (2) KR8, KR9 K685 KR25

Specica ions:

page 7

Aluminum Mushroom Guard

for 2.25 in Mushroom Button

Operator

Dimensions:

page 30

These 9001KU protective boots are recommended for very dirty environments or severe hose

down, but they are not required for UL Type 4 rating on the 9001K operators. The 9001K1

wrench (see page 29) is required for installation of these boots.

For Non-Illuminated

Push Buttons (3)

Color Reference Standard knob selector switch KU17

Black KU1 Gloved-hand cap for use on standard

Red KU2

Blue KU3

Brown KU4 Standard pilot light and maintained

Green KU5

Yellow KU6

Clear KU7 Push-to-test and illuminated push

Clear KU8

(Provides Full Guard) Illuminated push button with guard KU47

(3) Use KU27 for maintained contact push buttons.

Clear Color for Reference

KU18

knob selector switch

KU27

contact push buttons

KU37

button without guard

Closing Plates

Round (1-1/2 in Dia.)

Description Reference

Gray K51 (4)

Black K52 (4)

(4) Meets UL and NEMA 1, 2, 3, 4, 4X, 6, 12 and 13.

Mounting:

page 31

29

References (continued)

Harmony™ 9001K/SK/KX

30 mm push buttons

9001K – Replacement parts

Ring Nuts

Used On Reference

K1L 9001K44

K30-K37 9001K45

K70-K73 9001K45

K20, K21, K22, K23 9001K45

K20, K21, K22, K23 (1) 9001K46

K2L 9001K49

K3L (complete) 9001K111

K3L (metal top only) 6515802701

KP, KTR 9001K41

KR1 9001K41

KR11 9001K42

KR12 (1) 9001K42

KR12 (2) 9001K41

KR13, 14, 15 9001K55

KR2 9001K42

KR20 9001K49

KR24 9001K49

KR25 9001K49

KR3 9001K40

KR4 9001K41

KR5 9001K41

KR6 9001K47

KR67 9001K47

KR7 9001K47

KR8 9001K58

KR9 9001K41

KS 9001K45

KS (3) 9001K46

KT 9001K49

(1) Maintained button of two button operator.

(2) Momentary button of two button operator.

(3) Secondary ring nut (holds knob on selector switch or potentiometer).

Replacement Lamps For Series A–F (black)

Light Modules

Light

Module Reference

KM1 GE44 (4) —

KM2 GE1490 2550101003

KM3 GE44 (4) —

KM4 GE1490 2550101003

KM5 GE44 (4) —

KM6 GE44 (4) —

KM7 GE44 (4) —

KM8 GE44 (4) —

KM9 GE755 2550101020

KM11 CMDK1A5 2550105014

KM12 CMDK1A5 2550105014

KM13 CMDK1A5 2550105014

KM14 CMDK1A5 2550105014

KM15 CMDK1A5 2550105014

KM21 SYL12PSB 2550105003

KM22 SYL12PSB 2550105003

KM23 SYL28PSB 2550105008

KM25 SYL120PSB 2550105005

KM31 SYL6PSB 2550105007

KM32 SYL12PSB 2550105003

KM34 SYL24PSB 2550105004

KM35 SYL28PSB 2550105008

KM36 SYL48PSB 2550105009

KM37 SYL60PSB 2550105010

KM38 SYL120PSB 2550105005

(4) GE44 and GE755 are interchangeable (GE755 gives longer life). If a GE44 lamp is

ordered, a GE755 (2550101020) will be substituted. For a replacement lamp in a current

series light module see the light module listing on page 24.

Product range:

page 5

Lamp Number

(ANSI)

Specica ions:

page 7

Schneider Electric

Replacement Lamp Reference

Dimensions:

page 30

Repair Parts

Description Reference

E10 Key

Gray cap for KR11 or KR12

Clear plas ic top (only) for 9001K44 Ring Nut

Gasket for 9001K Push-pull Knob

Gasket for Plastic Illuminated Lens

Gasket for 9001K selector switch knob

Black Compensating Gasket (9001K Operators)

Liner for Non-Illuminated Operators

Locking Thrust Washer

Nylon Spacer

Push-pull Mushroom Adapter (5)

Rubber Boot for Joystick

Knob on Joysticks without latch

Knob for SK Potentiometer

Fingersafe Cover for 9001KM

(5) Allows Type -20 and -21 mushroom color caps to be used on push-pull operators. Use of

9001K54 voids Type 6 rating.

2941101100

3105217001

4487D63XI

6509701801

6509701901

3105406401

6509702001

6509704901

6512231201

6509705001

9001K54

6512243201

4458D20X3

3105404408

6508804101

KU Replacement Ring Nuts

(Threaded Inside and Out)

Used On Reference

KU1 through KU8, KU27, KU37, KU47 3105204101

KU17, KU18 3105205901

Interlock

For mechanically interlocking two push buttons so that only one

button can be depressed at a time. A K3 attachment is

furnished with the 9001KR11 and KR12 operators. However,

these are maintained operators and the K3 interlock serves to

release one of the buttons when the other is depressed. When

used with momentary contact buttons, the K3 interlock does

not hold the buttons in the depressed position. It simply

prevents pushing both buttons at the same time.

The K3 interlock is mounted behind the operators. Operators

not included.

Reference

9001K3

Screwdriver

Reference

9001K69

Used to tighten mounting screws on contact blocks and light modules.

Wrenches

K95 K1

Where Used Reference

For tightening ring nuts on 22 and 30 mm control units 9001K95

For protective cap kits 9001K1

Mounting:

page 31

39

Specications (continued)

Harmony™ 9001K/SK/KX

30 mm push buttons

9001SK

Basic Operators

(For Color Caps, Mushroom Buttons, Knobs, Se lector Switch Cams, Contact Blocks, Light Modules and Legend Plates, see page 51.)

Description UL Types/NEMA Types

4, 4X, 13

Non Illuminated Push Button (Full Guard) 9001SKR1

Non Illuminated Push Button (Extended Guard) 9001SKR2

Non Illuminated Push Button (No Guard) 9001SKR3

Non Illuminated Push Button (Mushroom Button/screw on) 9001SKR20

Non Illuminated Dual Push Button (Momentary) –

Non Illuminated Dual Push Button (Momentary Interlocked) –

Non Illuminated Dual Push Button (Maintained Interlocked) –

Momentary Pull - Maintained Neutral - Momentary Push 9001SKR8 (1)

Maintained Pull - Maintained Push 9001SKR9 (1)

Illuminated Push Button (Full Guard - Plastic Top) 9001SK1L (2)

Illuminated Push Button and Push-to-test (No Guard) 9001SK2L (2) (3)

Illuminated Push Button (Full Guard - Metal Top) –

Standard Pilot Light 9001SKP

2-Position Selector Switch 9001SKS1 (1), 9001SKS2 (1), 9001SKS3 (1)

3-Position Selector Switch 9001SKS4 (1), 9001SKS5 (1), 9001SKS6 (1), 9001SKS7 (1)

4-Position Selector Switch 9001SKS8 (1)

Trigger-Action Emergency Stop 9001SKR16 (1)

(1) Operator can be converted to an illuminated operator by removing the liner (6509704901) and adding a light module.

(2) Operator can be converted to a non-illuminated operator by adding liner (6509704901).

(3) Operator includes jumper wires for push-to-test conversion.

Non Hazardous Locations:

File

CCN

E42259

NKCR

File

Class

LR25490

3211 03

Marking

Hazardous Locations (Reed contact blocks, see page 53):

File

CCN

E10054

NOIV

File

Class

LR26817

3218 02

Marking

Product range:

page 36

References:

page 41

Dimensions:

page 60

Mounting:

page 61

40

Specications (continued)

Harmony™ 9001K/SK/KX

30 mm push buttons

9001SK

9001SK Operator Materials:

Push Button and Push-to-test Pilot Light

(9001SKR and 9001SKT)

Base – Thermoplastic Polyester

Stem – Acetal (non-illuminated push button)

Thermoplastic Polyester (illuminated push button

and push-to-test pilot light)

Seal – Nitrile

Gasket – Nitrile

Spring – 302 Stainless Steel

Spring Support – CRS

Lock Ring – Nylon

Trim Washer – Polypropylene

Locking Thrust Washer – Thermoplastic Polyester

Ring Nut – Thermoplastic Polyester

Color Insert – Polyethylene (non-illuminated push button)

Color Cap – Polycarbonate (illuminated push button and

push-to-test pilot light)

Mushroom Button – Acetal (non-illuminated push button)

Polycarbonate (illuminated push button)

Liner – Polypropylene (non-illuminated push button)

Selector Switch (9001SKS)

Base – Thermoplastic Polyester

Seal – Nitrile

Gasket – Nitrile

Seal Keeper – 302 Stainless Steel

Spring – 302 Stainless Steel

Cam Follower – Delrin 100

Bearing Washer – Polyester Film

Cam Carrier – Trogamid

Cam Prole – Delrin 100

Liner – Polypropylene (non-illuminated only)

Knob – Polycarbonate

Trim Washer – Polypropylene

Locking Thrust Washer – Thermoplastic Polyester

Spring Support – CRS

Pilot Light (9001SKP)

Gasket – Nitrile

Base – Thermoplastic Polyester

Trim Washer – Polypropylene

Locking Thrust Washer – Thermoplastic Polyester

Ring Nut – Thermoplastic Polyester

Color Cap – Polycarbonate

Contact Block And Light Module Materials:

Contact Block (9001KA)

Housing – Amorphous Nylon

Contact Slider – Phenolic, Nylon or Acetal

Terminal – Steel

Saddle Clamp – Steel

Spring – Stainless Steel

Contacts – Silver and Copper

Blade – Beryllium Copper

Mounting Screw – Steel

Label – Paper

Light Module (9001KM)

Housing – Thermoplastic Polyester

Socket – Steel

Terminal – Steel with Tin Plate

Saddle Clamp – Steel

Translating Pin – Polycarbonate

Transformer – Thermoplastic Polyester, Steel, Copper,

Polyvinyl Chloride, Polytetrauorethylene,

Acetate, Paper

Lamp Spring – Tin Plated Music Wire

Product range:

page 36

References:

page 41

Dimensions:

page 60

Moun ing:

page 61

41

References (continued)

Harmony™ 9001K/SK/KX

30 mm push buttons

9001SK – Push buttons and mushroom operators

Note: When ordering, add prex “9001” to the reference.

Non-Illuminated Momentary Push Button Operators—UL Types 4, 4X, 13/NEMA 4, 4X, 13

For use in hazardous locations, see page 53.

Contact blocks and legend plate not included unless otherwise noted.

Description Color Operator with

Black SKR1BH13 SKR1BH5 SKR1BH6 SKR1B

Red SKR1RH13 SKR1RH5 SKR1RH6 SKR1R

Green SKR1GH13 SKR1GH5 SKR1GH6 SKR1G

Universal (1) SKR1UH13 SKR1UH5 SKR1UH6 SKR1U

9001SKR1B

Full Guard

9001SKR3B

No Guard

9001SKR2B

Extended Guard

9001SKR4B

1-3/8 in (35 mm)

Mushroom Button

9001SKR5

2-1/4 in (57 mm)

Mushroom Button

Other (2) SKR1bH13 SKR1bH5 SKR1bH6 SKR1b

Black SKR3BH13 SKR3BH5 SKR3BH6 SKR3B

Red SKR3RH13 SKR3RH5 SKR3RH6 SKR3R

Green SKR3GH13 SKR3GH5 SKR3GH6 SKR3G

Universal (1) SKR3UH13 SKR3UH5 SKR3UH6 SKR3U

Other (2) SKR3bH13 SKR3bH5 SKR3bH6 SKR3b

Black SKR2BH13 SKR2BH5 SKR2BH6 SKR2B

Red SKR2RH13 SKR2RH5 SKR2RH6 SKR2R

Green SKR2GH13 SKR2GH5 SKR2GH6 SKR2G

Universal (1) SKR2UH13 SKR2UH5 SKR2UH6 SKR2U

Other (2) SKR2b SKR2bH5 SKR2bH6 SKR2b

Snap-In Mushroom Button

Black SKR4BH13 SKR4BH5 SKR4BH6 SKR4B

Red SKR4RH13 SKR4RH5 SKR4RH6 SKR4R

Red (3) SKR4R05H13 SKR4R05H5 SKR4R05H6 SKR4R05

Green SKR4GH13 SKR4GH5 SKR4GH6 SKR4G

Other (4) SKR4dH13 SKR4dH5 SKR4dH6 SKR4d

Screw-On Mushroom Button with Set Screw Security

Black SKR24BH13 SKR24BH5 SKR24BH6 SKR24B

Red SKR24RH13 SKR24RH5 SKR24RH6 SKR24R

Green SKR24GH13 SKR24GH5 SKR24GH6 SKR24G

Other (4) SKR24dH13 SKR24dH5 SKR24dH6 SKR24d

Snap-In Mushroom Button

Black SKR5BH13 SKR5BH5 SKR5BH6 SKR5B

Red SKR5RH13 SKR5RH5 SKR5RH6 SKR5R

Red (3) SKR5R05H13 SKR5R05H5 SKR5R05H6 SKR5R05

Green SKR5GH13 SKR5GH5 SKR5GH6 SKR5G

Other (4) SKR5dH13 SKR5dH5 SKR5dH6 SKR5d

Screw-On Mushroom Button with Set Screw Security

Black SKR25BH13 SKR25BH5 SKR25BH6 SKR25B

Red SKR25RH13 SKR25RH5 SKR25RH6 SKR25R

Green SKR25GH13 SKR25GH5 SKR25GH6 SKR25G

Other (4) SKR25dH13 SKR25dH5 SKR25dH6 SKR25d

1 N.O. and

1 N.C. Contact

(KA1)

Operator with

1 N.O. Contact

(KA2)

Operator with

1 N.C. Contact

(KA3)

Operator Only

No Contacts (5)

Color Codes

Color b SKR1, 2, 3 Place Color Code in Reference d SKR4, 5, 24, 25 Place Color Code in Reference

Blue L L

Yellow Y Y

White W —

Orange S S

Gray E —

(1) The universal push button operators contain one each of the following color inserts: black, red, green, yellow, orange, blue and white.

(2) Replace b with the color code as chosen from the color code table above.

(3) Knob has the words “Emergency Stop” in raised letters highlighted in white for readability.

(4) Replace d with the color code as chosen from the color code table above

(5) These operators can be ordered complete with contact blocks. For maximum block usage, see page 51. Add the “H” number chosen from

page 51 to the end of the operator reference number and add the cost of the “H” number to the operator cost.

To select and order Contact Blocks, Light Modules, Knobs, and Accessories, see pages 50 to 59.

Product range:

page 36

Specica ions:

page 38

Dimensions:

page 60

Mounting:

page 61

42

References (continued)

Illuminated Push Button Operators—UL Types 4, 4X, 13/NEMA 4, 4X, 13

For use in hazardous locations, see page 53.

Legend plate not included unless otherwise noted.

Description Voltage and

Full Guard

Illuminated

Push Button

9001SK1L1

Harmony™ 9001K/SK/KX

30 mm push buttons

9001SK – Push buttons and mushroom operators

Note: When ordering, add prex “9001” to the reference.

Frequency

110–120 V, 50–60 Hz Transformer SK1L1RH13 SK1L1GH13 SK1L1

220–240 V, 50–60 Hz Transformer SK1L7RH13 SK1L7GH13 SK1L7

24–28 Vac/Vdc Full Voltage SK1L35RH13 SK1L35GH13 SK1L35

For other voltages (2) Transformer, Flashing SK1LbRH13 SK1LbGH13 SK1Le

Style With Red Color

Cap and 1 N.O.

and 1 N.C.

Contact (KA1)

Full Voltage SK1LbRH13 SK1LbGH13 SK1Le

Resistor, Neon (3) SK1LbRH13 SK1LbGH13 SK1Le

LED SK1LbRH13 SK1LbGH13 SK1Le (4)

With Green

Color Cap and

1 N.O.and 1 N.C.

Contact (KA1)

With Other

Color Cap

Without

Contact

Blocks (1) (5)

9001SK2L1

9001SK2L1R20

9001SK2L1R21

No Guard

Illuminated

Push Button

1-3/8 in

(35 mm)

Illuminated

Mushroom

2-1/4 in

(57 mm)

Illuminated

Mushroom

(1) These operators can be ordered complete with contact blocks. For maximum block usage, see page 51. Add the “H” number chosen from

page 51 to the end of the operator reference number and add the cost of the “H” number to the operator cost.

(2) Replace b with the voltage assembly code as chosen from the tables on page 54. EXAMPLE: SK2Lb with 240 Vac/Vdc = SK2L25.

(3) On neon light modules, use clear color caps only.

(4) The cap must be the same color as the LED light module chosen e.g., for red LED, use red color cap.

(5) Replace e with the color code as chosen from the color code table below. EXAMPLE: SK2L35e with a blue 1-3/8 in mushroom button =

SK2L35L20.

(6) The only difference between a no guard (SK2L) operator and mushroom button operator is the color cap.

110–120 V, 50–60 Hz Transformer SK2L1RH13 SK2L1GH13 SK2L1

220–240 V, 50–60 Hz Transformer SK2L7RH13 SK2L7GH13 SK2L7

24–28 Vac/Vdc Full Voltage SK2L35RH13 SK2L35GH13 SK2L35

For other voltages (2) Transformer, Flashing SK2LbRH13 SK2LbGH13 SK2Le

Full Voltage SK2LbRH13 SK2LbGH13 SK2Le

Resistor, Neon (3) SK2LbRH13 SK2LbGH13 SK2Le

LED SK2LbRH13 SK2LbGH13 SK2Le (4)

110–120 V, 50–60 Hz Transformer SK2L1R20H13 SK2L1G20H13 Order

220–240 V, 50–60 Hz Transformer SK2L7R20H13 SK2L7G20H13

24–28 Vac/Vdc Full Voltage SK2L35R20H13 SK2L35G20H13

For other voltages (2) Transformer, Flashing SK2LbR20H13 SK2LbG20H13

Full Voltage SK2LbR20H13 SK2LbG20H13

Resistor, Neon (3) SK2LbR20H13 SK2LbG20H13

LED SK2LbR20H13 SK2LbG20H13

110–120 V, 50–60 Hz Transformer SK2L1R21H13 SK2L1G21H13 Order

220–240 V, 50–60 Hz Transformer SK2L7R21H13 SK2L7G21H13

24–28 Vac/Vdc Full Voltage SK2L35R21H13 SK2L35G21H13

For other voltages (2) Transformer, Flashing SK2LbR21H13 SK2LbG21H13

Full Voltage SK2LbR21H13 SK2LbG21H13

Resistor, Neon (3) SK2LbR21H13 SK2LbG21H13

LED SK2LbR21H13 SK2LbG21H13

SK2Le (4) (6)

SK2Le (4) (6)

Product range:

page 36

Color Caps

Color Color Codes

SK1L/SK2L 1-3/8 in (35 mm) Mushroom 2-1/4 in (57 mm) Mushroom

Red R R20 R21

Green G G20 G21

Blue L L20 L21

Yellow Y Y20 Y21

White W W20 W21

Clear C C20 C21

Amber A A20 A21

To select and order Contact Blocks, Light Modules, Knobs, and Accessories, see pages 50 to 59.

Specications:

page 38

Dimensions:

page 60

Moun ing:

page 61

49

References (continued)

Specialty Operators—UL Types 4, 4X, 13/NEMA 4, 4X, 13

For use in hazardous locations, see page 53.

Legend plate and contact blocks not included unless otherwise noted.

Interlocked Assembly Description Color Contacts Without Contacts

9001SKR11U

(1) Universal for SKR11,12 includes 2 each of black, red, green, yellow, orange, blue, white.

(2) Replace b with the color code as chosen from the following: B = black, R = red, G = green, L = blue, Y = yellow, W = white, S = orange, E = gray.

Example: An SKR11 with top button gray and bottom button orange = SKR11ES

Harmony™ 9001K/SK/KX

30 mm push buttons

9001SK – Specialty operators

Note: When ordering, add prex “9001” to the reference.

Interlocked Assembly

Both Buttons Maintained

Interlocked Assembly

One Button Momentary

Interlocked Assembly

One Button Maintained

Universal (1) SKR11UH1 SKR11U

Other (2) SKR11bH1 SKR11b

Universal (1) SKR12UH1H1 SKR12U

Other (2) SKR12bH1H1 SKR12b

Product range:

page 36

Specica ions:

page 38

Dimensions:

page 60

Mounting:

page 61

57

KU1

KU17

KU37

KU27

References (continued)

Harmony™ 9001K/SK/KX

30 mm push buttons

9001SK – Accessories

Note: When ordering, add prex “9001” to the reference.

Padlock Attachments

Used On Description Reference

Non-illuminated

push button —

Standard or

mushroom (KR4,

KR5 mushroom

buttons only).

Non-illuminated

push buttons with

or without

protective boots.

Non-illuminated

push buttons with

or without

protective boots.

Non-illuminated

push buttons,

cover type

attachment. KR,

SKR

Push buttons,

cover type

attachment.

Push-pull operator

and illuminated

push buttons. KR8,

KR9

Holds button in

depressed position

and can be

padlocked.

Holds button in

depressed position

when padlocked.

Holds button in

depressed position

when padlocked.

Attachment can be

padlocked. Does

not hold button in

depressed position.

Spring loaded

cover cannot be

padlocked. Does

not hold button in

depressed position.

Holds button in

depressed position

and can be

padlocked.

K4

K5

K97

K6

K60

K62

Padlock Attachments

Used On Description Reference

Selector switches

and potentiometers

(will not work with

gloved-hand knob).

Selector switches

and potentiometers

(will not work with

gloved-hand knob).

Illuminated push

buttons (with or

without guard) and

key operated push

buttons.

Illuminated push

buttons (with or

without guard) and

key operated push

buttons.

Maintained

push-pull operators

using 1.375 in dia.

mushroom buttons

(-20 series as

shown on page 58).

Cover type

attachment that can

be padlocked to

keep unauthorized

personnel from

tampering with the

operator.

Same as 9001K7

but with spring

loaded lockout

cover.

Cover type

attachment that can

be padlocked to

keep unauthorized

personnel from

tampering with the

operator.

Same as 9001K108

but with spring

loaded lockout

cover.

Cover type

attachment that

holds mushroom

button in depressed

posi ion and can be

padlocked.

K7

K107

K108

K109

K110

Protective Boots

KR11U and

KR12U

Interlocked

Assembly

9001SKR9

Push-pull

operators—

Non-Illuminated

and Illuminated

Holds maintained

button in

depressed position

and can be

padlocked.

Holds button in

depressed position.

Can be padlocked.

Mushroom Button Guards

Aluminum Mushroom Guard

for 1.375 in Mushroom Button

Operator (KR4, KR24)

Reference Reference Used On

K48 K56a (1) SKR4

(1) Replace a with B=Black, G=Green, R=Red or Y=Yellow.

(2) Replace b with R=Red or Y=Yellow. The mushroom guard has nger holes for

push-pull operators.

Product range:

page 36

Yellow Plastic Extended

Mushroom Guard for 1.375 in

and 1.625 in Mushroom

Button Operators

K56bM (2) SKR8, SKR9

Specica ions:

page 38

Aluminum Mushroom Guard

for 2.25 in Mushroom Button

Operator

Dimensions:

page 60

K96

K162

These 9001KU protective boots are recommended for very dirty environments or severe

hose down, but they are not required for UL Type 4 or 4X rating on the 9001SK operators.

The 9001K1 wrench (see page 59) is required for installation of these boots.

For Non-Illuminated

Push Buttons (3)

Color Reference Standard knob selector switch KU17

Black KU1 Gloved-hand cap for use on standard

Red KU2

Blue KU3

Brown KU4 Standard pilot light and maintained

Green KU5

Yellow KU6

Clear KU7 Push-to-test and illuminated push

Clear KU8

(Provides Full Guard) Illuminated push button with guard KU47

(3) Use KU27 for maintained contact push buttons.

Clear Color for Reference

KU18

knob selector switch

KU27

contact push buttons

KU37

button without guard

Closing Plates

Round (1-1/2 in Dia.)

Description Reference

Gray K51 (4)

Black K52 (4)

(4) Meets UL and NEMA 1, 2, 3, 4, 4X, 6, 12 and 13.

Mounting:

page 61

59

References (continued)

Harmony™ 9001K/SK/KX

30 mm push buttons

9001SK – Replacement parts

Ring Nuts

Used On Reference

SK1L 9001SK44

— —

— —

SK20, SK21, SK22, SK23 9001SK45

SK20, SK21, SK22, SK23 (3) 9001SK46

SK2L 9001SK49

— —

— —

SKP, SKTR 9001SK41

SKR1 9001SK41

SKR11 9001SK42

SKR12 (1) 9001SK42

SKR12 (2) 9001SK41

— —

SKR2 9001SK42

— —

— —

SKR25 9001SK49

SKR3 9001SK40

SKR4 9001SK41

SKR5 9001SK41

— —

— —

— —

SKR8 6509704401

SKR9 9001SK41

SKS 9001SK45

SKS (3)

SKRU11

SKRU1,2,3,4,5,10

SKT 9001SK49

(1) Maintained button of two button operator.

(2) Momentary button of two button operator.

(3) Secondary ring nut (holds knob on selector switch or potentiometer).

9001SK46

9001SK41

9001SK40

Replacement Lamps For Series A–F (black)

Light Modules

Light

Module Reference

KM1 GE44 (4) —

KM2 GE1490 2550101003

KM3 GE44 (4) —

KM4 GE1490 2550101003

KM5 GE44 (4) —

KM6 GE44 (4) —

KM7 GE44 (4) —

KM8 GE44 (4) —

KM9 GE755 2550101020

KM11 CMDK1A5 2550105014

KM12 CMDK1A5 2550105014

KM13 CMDK1A5 2550105014

KM14 CMDK1A5 2550105014

KM15 CMDK1A5 2550105014

KM21 SYL12PSB 2550105003

KM22 SYL12PSB 2550105003

KM23 SYL28PSB 2550105008

KM25 SYL120PSB 2550105005

KM31 SYL6PSB 2550105007

KM32 SYL12PSB 2550105003

KM34 SYL24PSB 2550105004

KM35 SYL28PSB 2550105008

KM36 SYL48PSB 2550105009

KM37 SYL60PSB 2550105010

KM38 SYL120PSB 2550105005

(4) GE44 and GE755 are interchangeable (GE755 gives longer life). If a GE44 lamp is

ordered, a GE755 (2550101020) will be substituted. For a replacement lamp in a current

series light module see the light module listing on page 54.

Product range:

page 36

Lamp Number

(ANSI)

Specica ions:

page 38

Schneider Electric

Replacement Lamp Reference

Dimensions:

page 60

Repair Parts

Description Reference

E10 Key

Gray cap for 9001SKR11, or 9001SKR12

Clear plas ic top (only) for 9001SK44 Ring Nut

Gasket for 9001K and 9001SK Push-pull Knob

Gasket for Plastic Illuminated Lens

Gasket for 9001SK selector switch knob

Black Compensating Gasket

Liner for Non-Illuminated Operators

Locking Thrust Washer

Nylon Spacer

Locking Thrust Washer (Std. 9001SK Operator)

Push-pull Mushroom Adapter (5)

Rubber Boot for Joystick

Knob on Joysticks without latch

Knob for SK Potentiometer

Fingersafe Cover for 9001KM

(5) Allows Type -20 and -21 mushroom color caps to be used on push-pull operators. Use of

9001K54 voids Type 6 rating.

2941101100

3105217001

4487D63XI

6509701801

6509701901

3105406401

6509702001

6509704901

6512231201

6509705001

6512240601

9001K54

6512243201

4458D20X3

3105404408

6508804101

KU Replacement Ring Nuts

(Threaded Inside and Out)

Used On Reference

KU1 through KU8, KU27, KU37, KU47 3105204101

KU17, KU18 3105205901

Interlock

For mechanically interlocking two push buttons so that only one

button can be depressed at a time. A K3 attachment is

furnished with the 9001SKR11,SKR12, SKRU1 and SKRU11

operators. However, these are maintained operators and the

K3 interlock serves to release one of the buttons when the

other is depressed. When used with momentary contact

buttons, the K3 interlock does not hold the buttons in the

depressed position. It simply prevents pushing both buttons at

the same time.

The K3 interlock is mounted behind the operators. Operators

not included.

Reference

9001K3

Screwdriver

Reference

9001K69

Used to tighten mounting screws on contact blocks and light modules.

Wrenches

K95 K1

Where Used Reference

For tightening ring nuts on 22 and 30 mm control units 9001K95

For protective cap kits 9001K1

Mounting:

page 61

69

Specications (continued)

Harmony™ 9001K/SK/KX

30 mm push buttons

9001KX

9001KX Operator Materials

Single Push Button (KXRA, KXRB, KXRN, KXRP, KXTA)

Gasket – Nitrile

Locking Head – ZAMAC #3

Screws – Steel

Terminals – Steel

Button – Polycarbonate

Seal – Nitrile

Seal Retainer – Steel

Bezel – Zinc

Stem – Polycarbonate

Stem Cover – Polycarbonate

Legend Insert – Polyester

Return-Spring – Music Wire

Ring Nut – Zinc or Aluminum

Adaptor – Zinc

Adaptor Mounting Clip – Music Wire

Liner – Nylon

Dual Push Button

(Non-Illuminated and Illuminated)

(KXRC, KXRD, KXRE, KXRF, KXRG, KXRH, KXRJ, KXRK, KXRL,

KXRM, KXTC)

Gasket – Nitrile

Seal – Nitrile

Seal Retainer – Brass

Bezel – Zinc

Button Stem – Stainless Steel

Button – Polycarbonate

Button Cover – Polycarbonate

Legend Insert – Polyester

Lamp Cover – Polycarbonate

Lens Retainer – Polycarbonate

Lens – Polycarbonate

Return-Spring – Music Wire

Ring Nut – Zinc or Aluminum

Adaptor – Zinc

Adaptor Mounting Clip – Music Wire

Liner – Nylon

Retainer Ring – Steel

Interlock Pad – Polyester

Interlock – Sintered Steel

Interlock – Nylon (KXRD)

Pin – Steel (KXRE, KXRF)

Detent Bearing – Steel (KXRE, KXRF)

Detent Spring – Music Wire (KXRE, KXRF)

Interlock – Steel (KXRM)

Bafe – Steel

Locking Head – ZAMAC #3

Screws – Steel

Stem – Polycarbonate

Stem Cover – Polycarbonate

Terminals – Steel

Selector Switch

(Non-Illuminated and Illuminated) (KXS)

Gasket – Nitrile

Seal – Nitrile

Seal Retainer – Steel

Return Spring – Music Wire

Cam Rotor – Celenex 3300

Cam Follower – Delrin 100

Cam Carrier – Trogamid

Cam Prole – Delrin 100

Bearing – Polyester

Bezel – Zinc

Knob – Polycarbonate or Nylon

Knob Ring Nut – Polycarbonate

Knob Seal – Nitrile

Legend Plate – ABS

Plug Insert – Polyester

Key Plug – Zinc, Brass, Music Wire

Key – Brass

Locking Head – Zinc

Locking Head Seal – Nitrile

Insert – Zinc

Adaptor – Zinc

Adaptor Mounting Clip – Music Wire

Liner – Nylon

Ring Nut – Zinc or Aluminum

Terminals – Steel

Screws – Steel

Product range:

page 66

References:

page 70

Dimensions:

page 76

Contact Block (9001KA)

Housing– Amorphous Nylon

Contact Slider– Nylon or Acetal

Terminal– Steel

Saddle Clamp– Steel

Spring– Steel

Contacts– Silver and Copper

Blade– Beryllium Copper

Label– Paper

Shrouds– Delrin 507

Lockout– 410 Stainless Steel

Closing Plate– ZAMAC #3

Boots– Neoprene

Potentiometer (KXBA, KXBB, KXBC, KXBD):

Pot – Clarostat Types J and EJ

Operator – ZAMAC #3

Legend Plate – ABS

Knob – Polycarbonate

Printed circuit board – Phenolic

Cam Rotor – Polyester

Cam – Acetal

Cam Carrier – Nylon

Adaptor – ZAMAC #3

Adaptor Spring – Square Music Wire

Spacer – F ber Board

Gasket – Buna N

Terminal – Brass

Screws – Steel

Bezel – Zinc

Locking Head – ZAMAC #3

Legend Inserts (KXN100, KXN200, KXN300, KXN400, KXN500)

– 0.005 Thk. Matte Polyester

Legend Plates (KXN-600, KXN-700) – ABS

Pilot Light (KXPA, KXPB, KXPC, KXTE)

O-Ring – Nitrile

Bezel – Zinc

Button – Polycarbonate

Button Cover – Polycarbonate

Button Stem – Polycarbonate

Screws – Steel

Terminals – Steel

Lens Assembly – Polycarbonate

Bafe – Steel

Ring Nut – Zinc or Aluminum

Adaptor – Zinc

Adaptor Mounting Clip – Music Wire

Light Module (Single Lamp KM)

Housing – Thermoplastic Polyester

Socket – Steel

Terminal – Steel with Tin Plate

Saddle Clamp – Steel

Translating Pin – Polycarbonate

Transformer – Thermoplastic Polyester, Steel, Copper,

Polyvinyl Chloride, Polytetrauoroeth ylene, Acetate, Paper

Lamp Spring – Tin Plated Music Wire

Light Module (2 Lamp KXAKM2)

Adaptor Screw – Steel

Housing – Thermoplastic Polyester

Lamp Terminal – Copper

Terminal – Steel

Saddle Clamp – Steel

Contact Spring – Copper

Translating Pin – Polycarbonate

Transformer – Thermoplastic Polyester, Steel, Copper, Polyvinyl

Chloride, Polytetrauoroeth ylene, Acetate, Paper

Light Module (4 Lamp KXAKM4)

Housing – Thermoplastic Polyester

Lamp Terminal – Copper

Adaptor Screw – Steel

Terminal – Steel

Saddle Clamp – Steel

Transformer – Nylon, Steel, Copper, Polyvinyl Chloride,

Polytetrauoroethylene, Acetate, Paper

70

References (continued)

1

2

1

2

3

Pilot Light at

110–120 V, 50–60 Hz

Transformer

1

2

3

4

Pilot Lights at

110–120 V, 50–60 Hz

Transformer

Push Buttons—Single, with Contacts

Description Button Color Legend Marking Contacts Voltage Reference

NonIlluminated

Illuminated Amber blank 1 N/O + 1 N/C 24 KXRB34AH1

Push Buttons—Dual, with Contacts

Description Top Button (#1) Lower Button (#2) Contacts Reference

Momentary Start (Green) Stop (Red) 2 N/O + 2 N/C KXRC111

Momentary Start (Green) Stop (Red) 1 N/O, 1 N/C KXRC136

Momentary Up (Green) Down (Green) 2 N/O KXRD140

Momentary blank (Blue) blank (Blue) 2 N/O KXRDLLH7

Maintained (1) Start (Green) Stop (Red) 1 N/O + 1 N/C KXRE115

Maintained (1) On (Blue) (2) Off (Blue) (2) 3 C/O KXRELLH3

Maintained (1) On (Blue) (2) Off (Blue) (2) 3 C/O KXRELLH3

Maintained (1) On (Blue) (2) Off (Blue) (2) 2 N/O + 2 N/C KXRELLH2

Harmony™ 9001K/SK/KX

30 mm push buttons

9001KX – Push buttons with contacts

Note: When ordering, add prex “9001” to the reference.

Green Start 1 N/O — KXRA133

Red Stop 1 N/C — KXRA134

Amber blank 2 N/O + 2 N/C — KXRAAH2

Green blank 2 N/O + 2 N/C — KXRAGH2

Blue blank 2 N/O + 2 N/C — KXRALH2

Green blank 1 N/O + 1 N/C 24 KXRB34GH1

Red blank 1 N/O + 1 N/C 24 KXRB34RH1

Amber blank 1 N/O + 1 N/C 110/120 KXRB1AH1

Green blank 1 N/O + 1 N/C 110/120 KXRB1GH1

Red blank 1 N/O + 1 N/C 110/120 KXRB1RH1

Push Buttons—Dual with One Pilot Light and Contacts

Description Top Button (#1) Middle Lens (#2) Lower Button (#3) Contacts Voltage Reference

Momentary Start (Green) On (Red) Stop (Red) 2 N/O + 2 N/C 110/120 KXRG117

Momentary Start (Green) On (Red) Stop (Red) 1 N/O, 1 N/C 110/120 KXRG137

Maintained (1) Start (Green) On (Red) Stop (Red) 1 N/O + 1 N/C 110/120 KXRJ119

Push Buttons—Dual with Two Pilot Lights and Contacts

Description Top Button

Momentary Start (Green) On (Red) Off (Green) Stop (Red) 2 N/O + 2 N/C 110/120 KXRL121

Momentary Start (Green) On (Red) Off (Green) Stop (Red) 1 N/O,

Momentary Start (Green) On (Red) Off (Green) Stop (Red) 2 N/O + 2 N/C 24 KXRL34GRGRH2

Momentary Start (Green) On (Red) Off (Green) Stop (Red) 1 N/O,

(1) Maintained operators are mechanically interlocked.

(2) Text is vertical.

(#1)

Left Lens

(#2)

Right Lens

(#3)

Lower Button

(#4)

Contacts Voltage Reference

110/120 KXRL138

1 N/C

24 KXRL34GRGRH37

1 N/C

Product range:

page 66

Specications:

page 67

Dimensions:

page 76

71

References (continued)

1

2

1

2

3

1

2

3

4

Push Buttons—without Contacts (1)

Push Button Action Lens Color (1) Lens Color (2) Reference

Single Push Button

Non-Illuminated Momentary Amber — KXRAA

Illuminated 24 V Momentary Amber — KXRB35A

Illuminated 110/120 V Momentary Amber — KXRB38A

Dual Push Button

Non-Illuminated Momentary +

Harmony™ 9001K/SK/KX

30 mm push buttons

9001KX – Push buttons without contacts

Note: When ordering, add prex “9001” to the reference.

Green — KXRAG

Blue — KXRAL

Red — KXRAR

White — KXRAW

Green — KXRB35G

Blue — KXRB35L

Red — KXRB35R

White — KXRB35W

Green — KXRB38G

Blue — KXRB38L

Red — KXRB38R

White — KXRB38W

Interlock

Maintained +

Interlock

Green Red KXRCGR

White White KXRCWW

Green Green KXRCGG

Green Red KXREGR

White White KXREWW

Green Green KXREGG

Dual Push Button with Pilot Light—without Contacts (1)

Action Voltage Lens Color (1) Lens Color (2) Lens Color (3) Lens Color (4) Reference

With One Pilot Light

Momentary 24 Vac/dc Red White Green — KXRG35RWG

24 Vac/dc Green White Green — KXRG35GWG

110/120 Vac/dc Red White Green — KXRG38RWG

110/120 Vac/dc Green White Green — KXRG38GWG

Momentary +

Interlock

Maintained +

Interlock

With Two Pilot Lights

Momentary 24 Vac/dc Red White White Green KXRL35RWWG

Momentary +

Interlock

(1) Order contacts separately (see page 73). For accessories, see page 74.

24 Vac/dc Red White Green — KXRH35RWG

24 Vac/dc Green White Green — KXRH354GWG

110/120 Vac/dc Red White Green — KXRH38RWG

110/120 Vac/dc Green White Green — KXRH38GWG

24 Vac/dc Red White Green — KXRJ35RWG

24 Vac/dc Green White Green — KXRJ35GWG

110/120 Vac/dc Red White Green — KXRJ38RWG

110/120 Vac/dc Green White Green — KXRJ38GWG

24 Vac/dc Red Red Green Green KXRL35GGRR

110/120 Vac/dc Red White White Green KXRL38RWWG

110/120 Vac/dc Red Red Green Green KXRL38GGRR

24 Vac/dc Red White White Green KXRM35RWWG

24 Vac/dc Red Red Green Green KXRM35RRGG

110/120 Vac/dc Red White White Green KXRM38RWWG

110/120 Vac/dc Red Red Green Green KXRM38RRGG

Product range:

page 66

Specica ions:

page 67

Dimensions:

page 76

72

References (continued)

Selector Switches—with Contacts

Description Legend Knob Contacts Reference

2-Position, maintained Off-On Black 1 0 KXSA125

2-Position, maintained Off-On Black 1 0 KXSA139

3-Position, maintained Hand-Off-Auto Black 1 0 0 KXSD126

Selector Switches—without Contacts (1)

Description Voltage Knob Color Reference

2-Position, Maintained Non-Illuminated — Black KXSAEB

3-Position, Maintained Non-Illuminated — Black KXSDCB

4-Position, Maintained Non-Illuminated — Black KXSHHB

(1) Order contacts separately (see table below).

Harmony™ 9001K/SK/KX

30 mm push buttons

9001KX – Selector switches, contact blocks

Note: When ordering, add prex “9001” to the reference.

0 1

0 0 1

Illuminated 24 Vac/dc Red KXSJE35R

Illuminated 24 Vac/dc Green KXSJE35G

Illuminated 24 Vac/dc White KXSJE35W

Illuminated 120 Vac/dc Red KXSJE38R

Illuminated 120 Vac/dc Green KXSJE38G

Illuminated 120 Vac/dc White KXSJE38W

Key (Withdraw L) — N/A KXSRE1

Key (Withdraw R) — N/A KXSRE2

Key (Withdraw Bo h) — N/A KXSRE3

Key (Withdraw C) — N/A KXSVC5

Key (Withdraw All) — N/A KXSVC10

Contact Blocks—Purchase Separately

Description Reference Description Reference

Clear Cover 1 N/O, 1 N/C KA1 Clear Cover 1 N/C, 1 N/O

(Early Make)

Green Cover 1 N/O KA2 Red Cover 1 N/C (Late

Break)

Red Cover 1 N/C KA3 Green Cover 1 N/O (Early

Make)

KA4

KA5

KA6

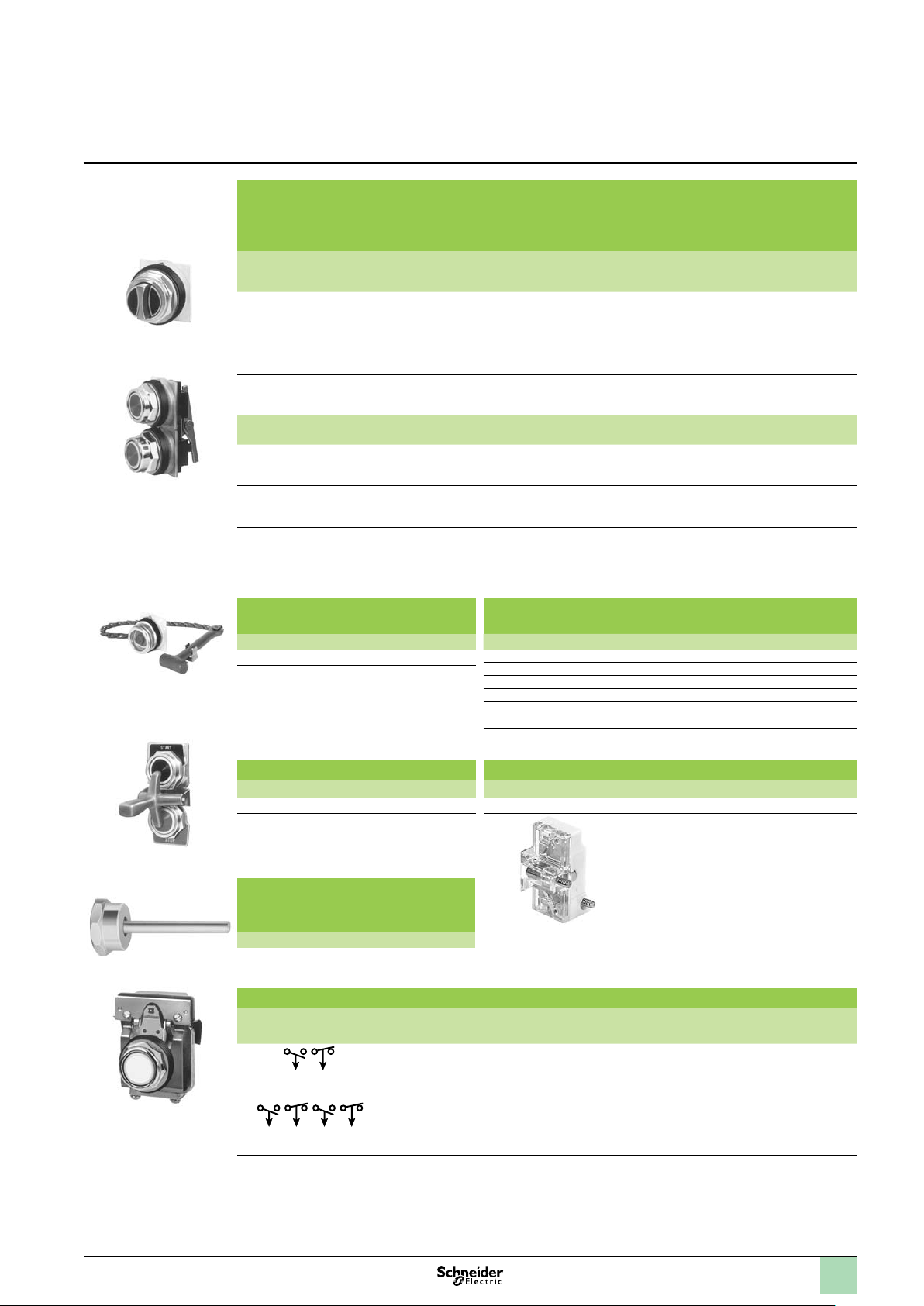

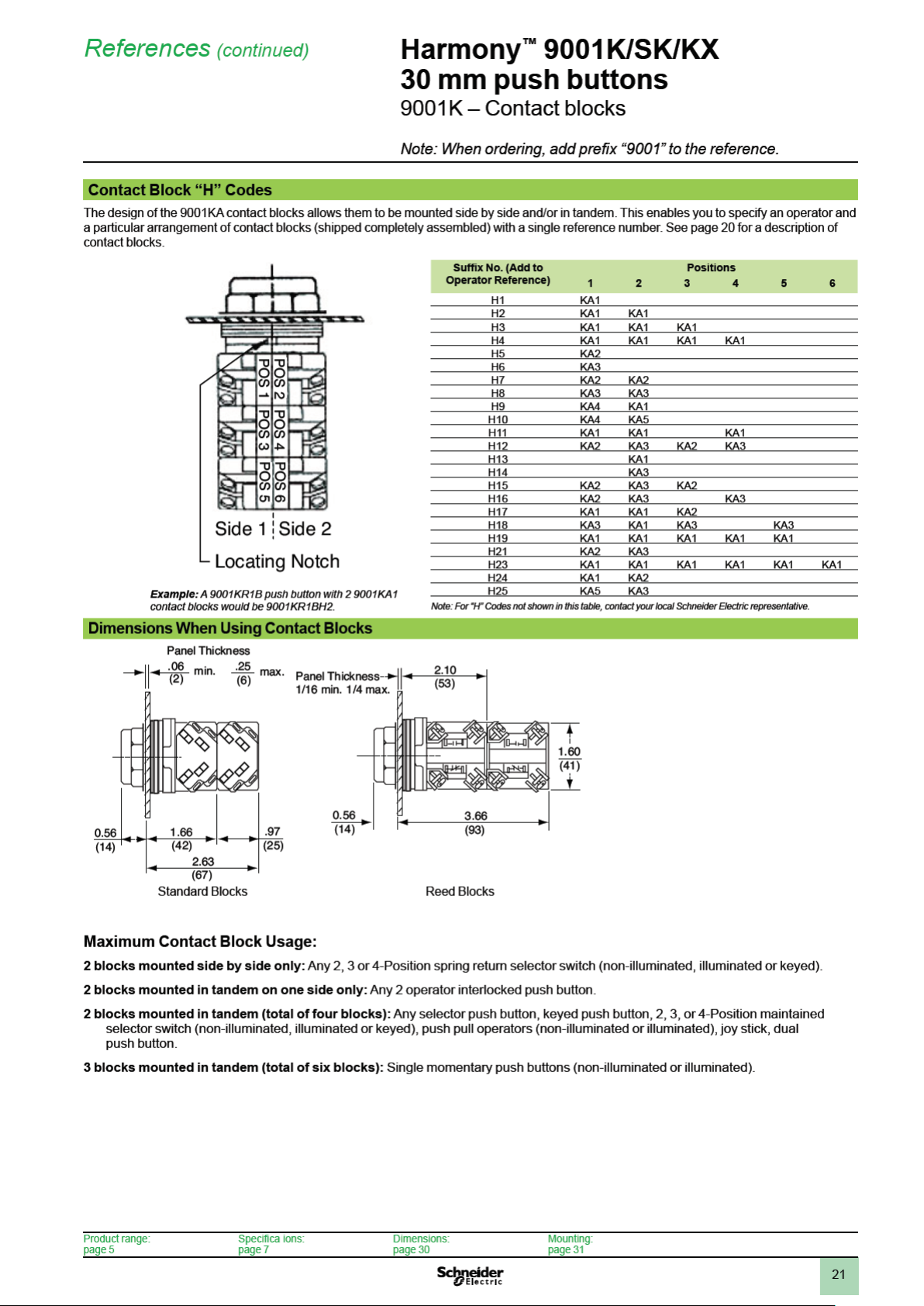

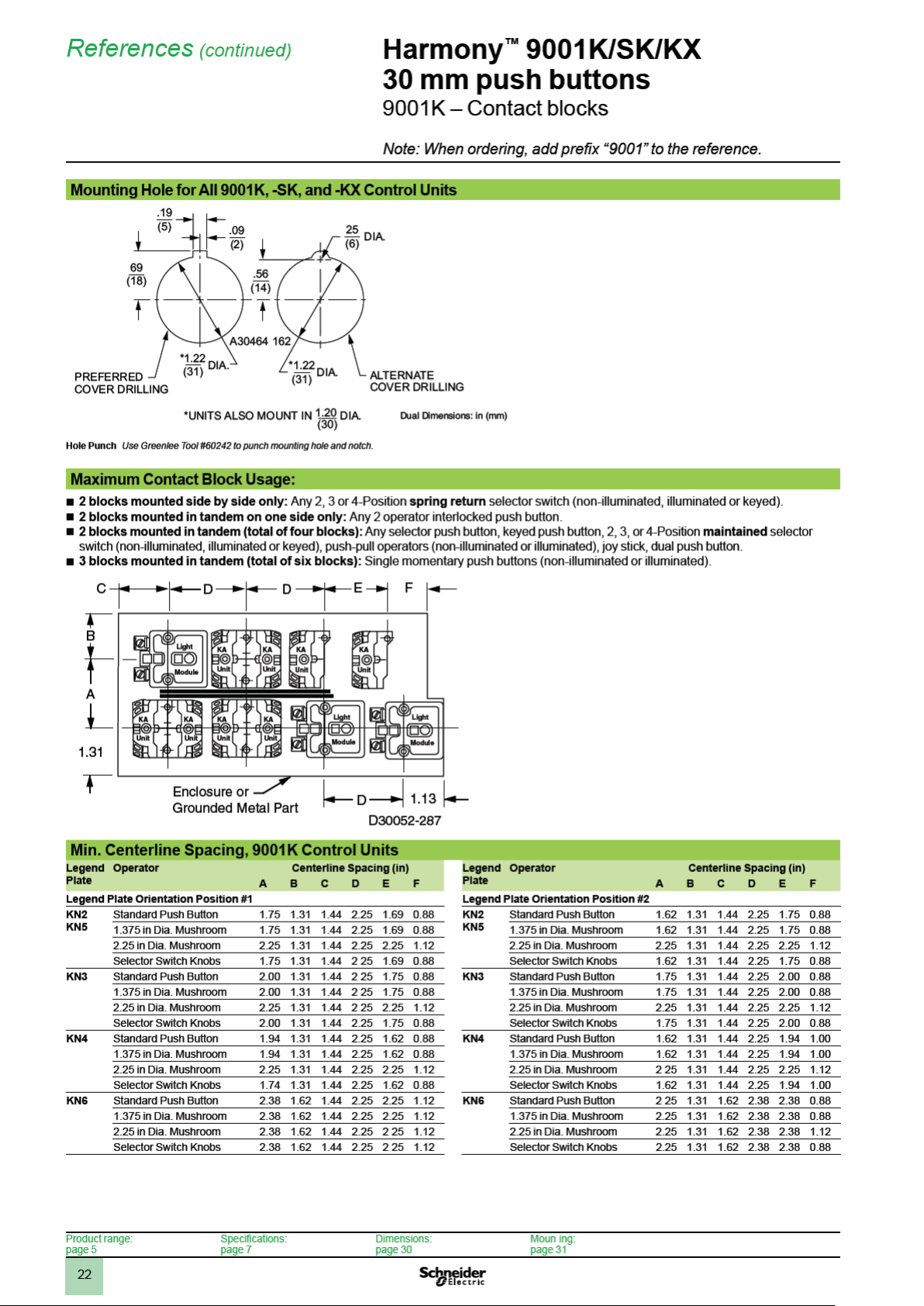

Maximum Contact Block Usage:

2 blocks mounted side by side only: Any 2 or 3-Position spring return selector switch (non-illuminated,

illuminated or keyed).

2 blocks mounted in tandem on one side only: Any 2 operator interlocked push button.

2 blocks mounted in tandem (total of four blocks): Any selector push button, keyed push button,

2 or 3-Position maintained selector switch (non-illuminated, illuminated or keyed), push pull

operators (non-illuminated or illuminated), joy stick, dual push button.

3 blocks mounted in tandem (total of six blocks): Single mo mentary push buttons (non-illuminated

or illuminated).

Product range:

page 66

Potentiometers

Description Power Resistance Reference

Single 2 W

Single 2 W

Single 2 W

Tandem 2 W

Specications:

page 67

Dimensions:

page 76

3.2 kW

5 kW

10 kW

5 kW / 5 kW

KXBB06

KXBB07

KXBB08

KXBD83

73

References (continued)

110–120 V, 50–60 Hz

Transformer

110–120 V, 50–60 Hz.

Transformer

1

2

110–120 V,

50–60 Hz

Transformer

Pilot Lights

Description Voltage Lens 1* Lens 2* Lens 3* Lens 4* Reference

Single 24 Amber KXPA35A

Single 24 Red KXPA35R

Single 24 Green KXPA35G

Single 24 White KXPA35W

Single 110/120 Amber KXPA1A

Single 110/120 Red KXPA1R

Single 110/120 Green KXPA1G

Single 110/120 White KXPA1W

Dual 24 Amber Amber KXPB34AA

Dual 24 Red Red KXPB34RR

Dual 24 Green Green KXPB34GG

Dual 24 White White KXPB34WW

Dual 24 Red Green KXPB34RG

Dual 110/120 Amber Amber KXPB1AA

Dual 110/120 Red Red KXPB1RR

Dual 110/120 Green Green KXPB1GG

Dual 110/120 White White KXPB1WW

Dual 110/120 Red Green KXPB1RG

Quad 24 White Amber Green Red KXPC34WAGR

Quad 110/120 White Amber Green Red KXPC1WAGR

Quad 110/120 White Blue Green Red KXPC1WLGR

* Lenses are blank (no markings)

Harmony™ 9001K/SK/KX

30 mm push buttons

9001KX – Pilot lights

Note: When ordering, add prex “9001” to the reference.

Product range:

page 66

Specica ions:

page 67

Dimensions:

page 76

75

(5)

References (continued)

Harmony™ 9001K/SK/KX

30 mm push buttons

9001KX – Accessories

Note: When ordering, add prex “9001” to the reference.

Closing Plate

UL Types 4, 13/NEMA 4, 13

Square Closing Plate (Chrome Plated)

Same size as KX bezel

Boots

For Use On Reference

All KX**

push buttons and pilot lights

All KX**

selector switches and

potentiometers

Shrouds

Description For Use On Color Reference

Full Shroud All push buttons

and pilot lights

Short Shroud Any KX operator Red KXAK40R

Lamp and Lens Removal Kit

Used to remove lamp and lens on all

illuminated operators and pilot lights.

Reference

KXAK52

KXAKU7

KXAKU17B

Red KXAK41R

Black KXAK41B

Black KXAK40B

Reference

KXALLRT

Button Covers

Description For Use On Color Reference Code

KXPB

KXTD

Includes

2-KXN200

KXTC (Position 1 & 4) Red

Includes

KXN400

KXTC (Position 2 & 3) Red

Includes

KXN500

KXPC Red

Includes

1–KXN100

KXRA

KXRB

Includes

KXN100

KXRN

KXRP

Includes

KXN100

Includes

KXN200

Includes

KXN300

Includes

KXN400

Includes

KXN500

Includes

KXN100

Includes

KXN100

(1) Each KXAC28 includes a clear cover and 1 each of all colors. If the same color is required

for position #1and #2 of the KXPB operator, order 2 of reference KXAC28.

(2) When specifying color codes—the rst will be installed in #1 and the second in #2.

(3) Each KXAC48 includes a clear cover and 1 each of all colors. If the same color is required

for position #1and #2 of the KXPC operator, order 2 of reference KXAC48.

(4) When specifying color codes—the rst will be installed in #1, the second in #2, the third in

#3 and the fourth in #4.

(5) Two required per operator. When ordering an assembled operator—specify two code

numbers.The rst code will be assembled into #1 and the second code will be assembled

into #2.

KXRC

KXRD

KXRE

KXRF

KXRG (Position 2)

KXRH (Position 2)

KXRJ (Position 2)

KXRK (Position 2)

KXRG (Position 1 & 3)

KXRH (Position 1 & 3)

KXRJ (Position 1 & 3)

KXRK (Position 1 & 3)

KXRL (Position 1 & 4)

KXRM (Position 1 & 4)

KXRL (Position 2 & 3)

KXRM (Position 2 & 3)

KXPA Red

KXTA

KXTB

Red

Green

Amber

Blue

White

Green

Amber

Blue

White

Green

Amber

Blue

White

Green

Amber

Blue

White

Red

Green

Amber

Blue

White

Red

Green

Amber

Blue

White

Red

Green

Amber

Blue

White

Red

Green

Amber

Blue

White

Red

Green

Amber

Blue

White

Red

Green

Amber

Blue

White

Green

Amber

Blue

White

Red

Green

Amber

Blue

White

KXAC28 (1)

KXAC28 (1)

KXAC28 (1)

KXAC28 (1)

KXAC28 (1)

KXAR4

KXAG4

KXAA4

KXAL4

KXAW4

KXAR5

KXAG5

KXAA5

KXAL5

KXAW5

KXAC48 (3)

KXAC48 (3)

KXAC48 (3)

KXAC48 (3)

KXAC48 (3)

KXAR1

KXAG1

KXAA1

KXAL1

KXAW1

KXARM1

KXAGM1

KXAAM1

KXALM1

KXAWM1

KXAR2

KXAG2

KXAA2

KXAL2

KXAW2

KXAR3

KXAG3

KXAA3

KXAL3

KXAW3

KXAR4

KXAG4

KXAA4

KXAL4

KXAW4

KXAR5

KXAG5

KXAA5

KXAL5

KXAW5

KXAR8

KXAG8

KXAA8

KXAL8

KXAW8

KXAR1

KXAG1

KXAA1

KXAL1

KXAW1

R (2)

G (2)

A (2)

L (2)

W (2)

R

G

A

L

W

R

G

A

L

W

R (4)

G (4)

A (4)

L (4)

W (4)

R

G

A

L

W

R

G

A

L

W

R

G

A

L

W

R

G

A

L

W

R

G

A

L

W

R

G

A

L

W

R

G

A

L

W

R

G

A

L

W

Product range:

page 66

Specica ions:

page 67

Dimensions:

page 76

78

Index

Harmony™ 9001K/SK/KX

30 mm push buttons

#

2540902240

2550101002

2550101003

2550101013

2550101020

2550101025

2550101027

2550101036

2550101037

2550105003

2550105004

2550105005

2550105007

2550105008

2550105009

2550105010

2550105014

2941101100

3105204101

3105205901

3105206750

3105211101

3105217001

3105404408

3105406401

4458D20X3

4487D63XI

6508804101

6508805201

6508805202

6508805203

6508805204

6508805205

6508805206

6508805210

6508805211

6508805212

6508805213

6508805214

6509701801

6509701901

6509702001

6509704401

6509704901

6509705001

6512231201

6512232801

6512240601

6512243201

6515802701

9001K40

9001K57

A

A20

A21

A22

A24

A31

A6

A7

A8

A9

B

B11

B19

B23

B25

C

C20

C21

C22

C24

C31

C6

C7

C8

C9

24, 54

29, 59

24, 54

24, 29, 54, 59

24, 54

24, 54

24, 54

24, 54

29, 59

29, 59

29, 59

29, 59

29, 59

29, 59

29, 59

29, 59

29, 59

29, 59

29, 59

29, 59

29, 59

29, 59

29, 59

29, 59

29, 59

24, 54

24, 54

24, 54

24, 54

24, 54

24, 54

24, 54

24, 54

24, 54

24, 54

24, 54

29, 59

29, 59

29, 59

29, 59

29, 59

29, 59

29, 59

28, 58

28, 58

28, 58

28, 58

28, 58

28, 58

28, 58

28, 58

28, 58

28, 58

28, 58

28, 58

28, 58

28, 58

28, 58

28, 58

28, 58

28, 58

28, 58

28, 58

28, 58

28, 58

19

19

19

59

19

59

29

19

19

G

G19

G20

G21

G22

G24

G31

G6

G7

G8

G9

K

K1

K107

K108

K109

K110

K111

pp

K11J

K11J1

K11J1R

pp

K12J

K12J1

K12J1R

K13B

K13C

K13D

K13E

K13F

K13G

K13H

K13J

K13L

K13M

K15

K162

K16B

K16G

K16L

K16R

K16R05

K16S

K16Y

K17B

K17G

K17L

K17R

K17R05

K17S

K17Y

K1L

pp

K1L

K1LpGH13

K1LpRH13

p

K1L1

K1L1GH13

K1L1RH13

p

K1L35

K1L35GH13

K1L35RH13

p

K1L7

K1L7GH13

K1L7RH13

pp

K25J

K25J1

K25J1R

K2L

pp

K2L

K2LpG20H13

K2LpG21H13

K2LpGH13

K2LpR20H13

K2LpR21H13

K2LpRH13

p

K2L1

K2L1G20H13

K2L1G21H13

K2L1GH13

28, 58

28, 58

28, 58

28, 58

28, 58

28, 58

28, 58

28, 58

28, 58

28, 58

29, 59

27, 57

27, 57

27, 57

27, 57

28, 58

28, 58

28, 58

28, 58

28, 58

28, 58

28, 58

28, 58

28, 58

28, 58

27, 57

28, 58

28, 58

28, 58

28, 58

28, 58

28, 58

28, 58

28, 58

28, 58

28, 58

28, 58

28, 58

28, 58

28, 58

K2L1R20H13

K2L1R21H13

K2L1RH13

K2L35

K2L35G20H13

K2L35G21H13

K2L35GH13

K2L35R20H13

K2L35R21H13

K2L35RH13

K2L7

K2L7G20H13

K2L7G21H13

K2L7GH13

K2L7R20H13

K2L7R21H13

K2L7RH13

29

K3

13

K30

13

K30H8

13

K31

13

K31H8

13

K32

13

K32H8

K33

K33H8

K34

K34H2

K34J

K34J1

K34J1R

K35

K35H2

K36

19

K36H2

K37

K37H2

K3L

K3L

K3LpGH13

K3LpRH13

K3L1

K3L1GH13

K3L1RH13

K3L35

K3L35GH13

K3L35RH13

K3L7

K3L7GH13

K3L7RH13

21

K4

11

K40

11

K401J

11

K401J1

11

K401J1R

11

K402J

11

K402J1

11

K402J1R

11

K41

11

K42

11

K42J

11

K42J1

11

K42J1R

13

K43J1

13

K43J1R

13

K44

21

K44J

11

K44J1

11

K44J1R

11

K45

11

K45J

11

K45J1

11

K45J1R

11

K46

11

K46J

11

K46J1

11

K46J1R

11

K47

pp

p

pp

p

p

pp

pp

pp

pp

p

p

pp

pp

29, 59

27, 57

11

11

11

11

11

11

11

11

11

11

11

11

11

11

11

11

11

18

18

18

18

18

18

18

18

18

18

13

13

13

18

18

18

18

18

18

21

11

11

11

11

11

11

11

11

11

11

11

11

29

14

14

14

14

14

14

29

29

14

14

14

14