Page 1

Marley NC Class Stainless Crossflow Cooling Tower

/

/

Product Specifications

Page 2

Marley / NC Class Stainless Cooling Tower / Contents

Specifications / Base

Base 4

Thermal Performance 4

Performance Warranty 5

Design Loading 5

Construction 6

Mechanical Equipment 7

Fill, Louvers and Drift Eliminators 8

Hot Water Distribution System 9

Casing, Fan Deck and Fan Cylinder 9

Access 10

Cold Water Collection Basin 10

Specifications / Options

Convenience and Safety Options

Guardrail and Ladder 11

Ladder Extension 11

Ladder Safety Cage 11

Ladder Safety Gate 11

Access Door Platform 12

Plenum Walkway 12

Interior Mechanical Equipment Access Platform 12

2

Control Options

Fan Motor Starter Control Panel 14

Vibration Limit Switch 15

Basin Heater 15

Electric Water Level Control 15

Fan Motor Variable Speed Drive 16

Marley Premium VFD System 17

Miscellaneous Options

Motor Outside of the Airstream 18

Fan Cylinder Extensions 18

Inlet Flow Control Valves 19

Equalizer Flume Weir Gate 19

Sound Control 19

Inlet Sound Attenuators 19

Outlet Sound Attenuators 20

Low Noise Fan 20

Ultra Low-Noise Fan 21

Single Hot Water Inlet Connection 21

Air Inlet Screens 21

High Wind/Seismic Designs 21

Multicell Basin Equalizer Outlets 22

Basin Sweeper Piping 22

Extended Geareducer Lube Line Dipstick 22

Page 3

Marley / NC Class Stainless Cooling Tower

/

3

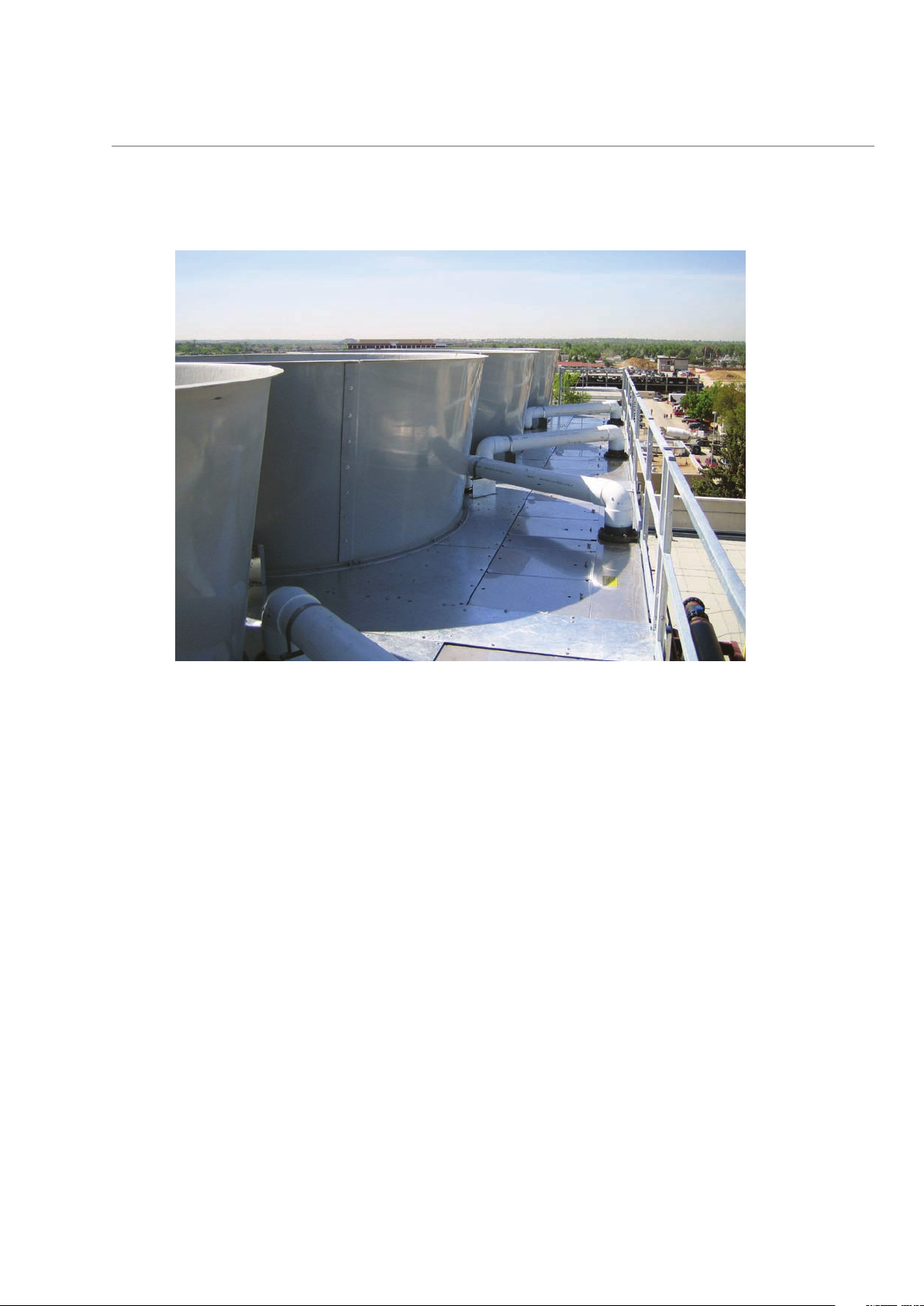

NC Class Stainless Steel towers are factory

assembled, crossflow cooling towers, designed to

serve air conditioning and refrigeration systems as well

as light to medium industrial process loads on clean

water. They evolve from a factory-assembled concept

of towers pioneered by Marley some 50 years ago, and

incorporate all of the design advancements that our

customers have found valuable. The NC Class has been

designed specifically for sound control and tonnage

density and represents the current state of the art in

this cooling tower category.

This booklet not only relates the language to use in

describing an appropriate NC Class cooling tower—

but also defines why certain items and features are

important enough to specify with the intention of

insisting upon compliance by all bidders. The left-hand

column of pages 4 thru 22 provides appropriate text for

the various specification paragraphs, whereas the right

hand column comments on the meaning of the subject

matter and explains its value.

Pages 4 thru 10 indicate those paragraphs which will

result in the purchase of a basic cooling tower—one

that accomplishes the specified thermal performance,

but which will lack many operation—and maintenanceenhancing accessories and features that are usually

desired by those persons who are responsible for the

continued and continuing operation of the system of

which the tower is part. It will also incorporate those

standard materials which testing and experience has

proven to provide acceptable longevity in normal

operating conditions.

Pages 11 thru 22 provide paragraphs intended to add

those features, components and materials that will

customize the tower to meet the user's requirements.

Space does not permit definition and explanation of all

of the possible options that can be applied to the

NC Class. We realize that you, the purchaser, must

be happy with the tower's characteristics, and we are

prepared to provide—or provide for—any reasonable

enhancement that you are willing to define and

purchase. Your needs will become part of the

continuing evolution of this Marley product line.

Page 4

Specifications

Specification Value

Marley / NC Class Stainless Cooling Tower / Specifications: Base

4

1.0 Base:

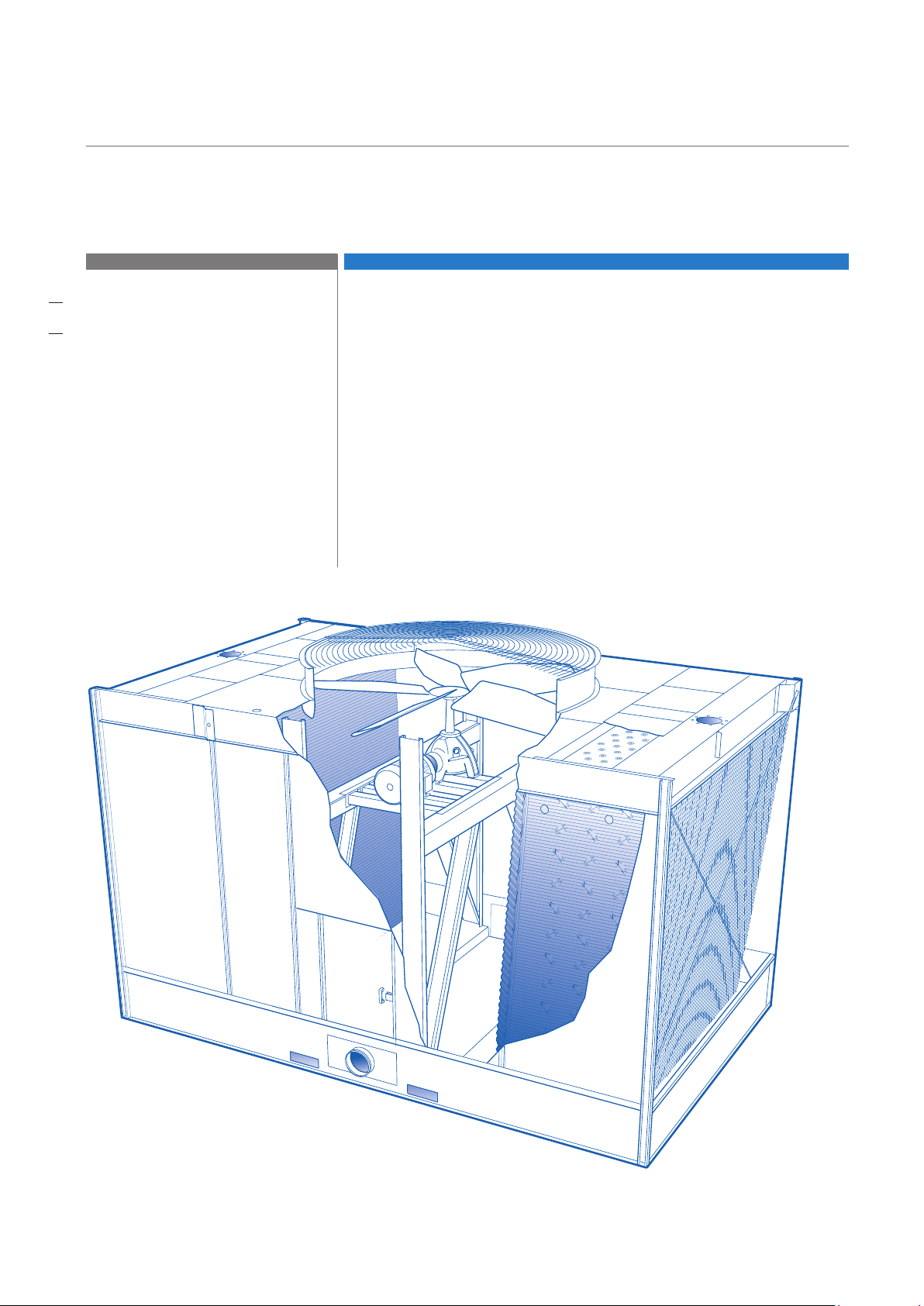

1.1 Provide an induced draft, crossflow

type, factory assembled, film fill,

industrial duty, stainless steel cooling

tower situated as shown on the plans.

The limiting overall dimensions of

the tower shall be _____ wide, _____

long, and _____ high. Total operating

kilowatt of all fans shall not exceed

____ kW, consisting of ___ @ _____

kW motor(s). Tower shall be similar and

equal in all respects to Marley Model

____________.

■ Your specification base establishes the type, configuration, base materi-

al and physical limitations of the cooling tower to be quoted. During the

planning and layout stages of your project, you will have focused your

attention on a cooling tower selection that fits your space allotment,

and whose power usage is acceptable. Limitations on physical size and

total operating horsepower avoid the introduction of unforeseen operational and site-related influences. Specifying the number of cells, and

the maximum fan kW/cell will work to your advantage.

The benefit of crossflow towers is that they are inherently easy to operate, access and maintain. Compared to counterflow towers, crossflow

towers have a spacious plenum between banks of fill for easy access to

all of the tower’s internal components, plus the water distribution system is adjacent to the fan deck and can be maintained during operation.

The NC is also available unassembled for on-site assembly.

Page 5

Specifications

Specification Value

Marley / NC Class Stainless Cooling Tower / Specifications: Base

5

2.0 Thermal Performance and Efficiency:

2.1 The tower shall be capable of cooling

_____ m

_____ °C at a design entering air wetbulb temperature of _____ C and its

thermal rating shall be Certified by the

Cooling Technology Institute.

2.2 The tower shall be capable of a mini-

mum _____ m

ASHRAE Standard 90.1.

2.3 CTI Certification notwithstanding,

the cooling tower manufacturer shall

guarantee that the tower supplied

will meet the specified performance

conditions when the tower is installed

according to plan. If, because of a

suspected thermal performance deficiency, the owner chooses to conduct

an on-site thermal performance test

under the supervision of a qualified,

disinterested third party in accordance

with CTI or ASME standards during the

first year of operation; and if the tower

fails to perform within the limits of

test tolerance; then the cooling tower

manufacturer will pay for the cost of

the test and will make such corrections

as are appropriate and agreeable to the

owner to compensate for the performance deficiency.

3

/h of water from ____ °C to

3

/h/kilowatt efficiency per

■ CTI Certification means that the tower

has been tested under operating conditions and found to perform as rated by

the manufacturer under those circumstances. It assures the buyer that the

tower is not intentionally or inadvertently undersized by the manufacturer.

■ The minimum efficiency per ASHRAE

Standard 90.1 for induced draft open cooling towers applied to comfort

cooling is 8.68 kW @ 35/29.5/24. There are no efficiency requirements for

non-comfort cooling applications. If you want greater efficiency you can

require it by specifying a higher ASHRAE Standard 90.1 m

■ CTI certification alone is not sufficient to assure you that the tower

will perform satisfactorily in your situation. Certification is established

under relatively controlled conditions, and towers seldom operate

under such ideal circumstances. They are affected by nearby structures,

machinery, enclosures, effluent from other towers, etc. Responsible and

knowledgeable bidders will take such site-specific effects into consideration in selecting the tower—but the specifier must insist by the written

specification that the designer/manufacturer guarantee this “real world”

performance. Any reluctance on the part of the bidder should cause you

some concern.

3

/h/kilowatt.

3.0 Warranty:

3.1 The entire tower, including structure, casing, basins, decking, fan(s),

motor(s), and all mechanical drive components (including belts, if used) shall

be warranted against failure due to

defects in materials and workmanship

for a period of five (5) years from the

date of shipment to the job. Towers not

covered by a warranty of this scope

will not be accepted.

4.0 Design Loading:

4.1 The tower structure, anchorage and all

its components shall be designed by

licensed structural engineers per the

International Building Code to withstand a wind load of 1.44k/Pa, as well

as a .3g seismic load. The fan deck

and hot water basin covers shall be

■ It is important to understand the distinction between structure and

anchorage. Specifying that only the anchorage meet these require-

ments means the tower can become non-functional, even fall down, yet

remain attached to the foundation. Specifying structure will require the

tower to remain operational.

The indicated design values are the minimum allowables under accepted design standards. They give you assurance that the tower can be

➠

Page 6

Specifications

Specification Value

Marley / NC Class Stainless Cooling Tower / Specifications: Base

6

designed for 2.4kPa live load or a 91kg

concentrated load. Guardrails, where

specified, shall be capable of withstanding a 890N concentrated live load

in any direction, and shall be designed

in accordance with OSHA guidelines.

5.0 Construction:

5.1 Except where otherwise specified, all

components of the cooling tower shall

be fabricated of heavy-gauge, series

300 stainless steel. The tower shall be

capable of withstanding water having a

chloride content (NaCl) up to 750 mg/L;

a sulfate content (SO4) up to 1200

mg/L; a calcium content (CaCO3) up to

800 ppm; silica (SiO2) up to 150 mg/L;

and design hot water temperatures

up to 52°C. The circulating water shall

contain no oil, grease, fatty acids, or

organic solvents.

5.2 The specifications, as written, are

intended to indicate those materials

that will be capable of withstanding

the above water quality in continuing

service, as well as the loads described

in paragraph 4.1. They are to be regarded as minimum requirements. Where

component materials peculiar to individual tower designs are not specified,

the manufacturers shall take the above

water quality and load carrying capabilities into account in the selection of

their materials of manufacture.

shipped, handled, hoisted—and ultimately operated in a normal cooling

tower environment. Most NC Class models will withstand significantly

higher wind and seismic loads. If your geographic location dictates

higher wind load or seismic load values, please make the appropriate

changes, after discussion with your Marley sales representative.

Note: Some countries and states (Florida) require structure not anchor-

age. Check with you local officials.

1.44k/Pa windload, .3g seismic load—applicable for most applications

but consult the local code official for actual requirements.

2.4kPa live load, 890N concentrated load—ensures the tower can be

safely accessed for routine maintenance when a guardrail is installed as

well ensuring the end user complies with government safety laws.

■ For pure resistance to corrosion—coupled with the capability to meet

stringent fire and building codes—there is no substitute for stainless

steel! No paints or electrostatically-applied coatings, however exotic

they may be, can match stainless steel's ability to withstand adverse

operating conditions.

Although SPX Cooling Technologies makes use of many structural FRP

components in various other product lines, they are held to a relative

minimum in the NC Class Stainless line. This is to assure that there will

be no question as to the structural integrity, fire resistance, and life

expectancy in the mind of the owner.

Except for those unusual operating situations where the circulating

water may be so laden with suspended solids, algae, fatty acids, product fibers, active organisms reflected in BOD, and the like that plugging of film type fill is a probability, the NC Class Stainless is relatively

immune to poor water quality. Where such conditions do exist, however, thought should be given to the prevention of such carryover—or

to the use of a Marley splash-fill product. Please discuss your situation

with your Marley sales representative.

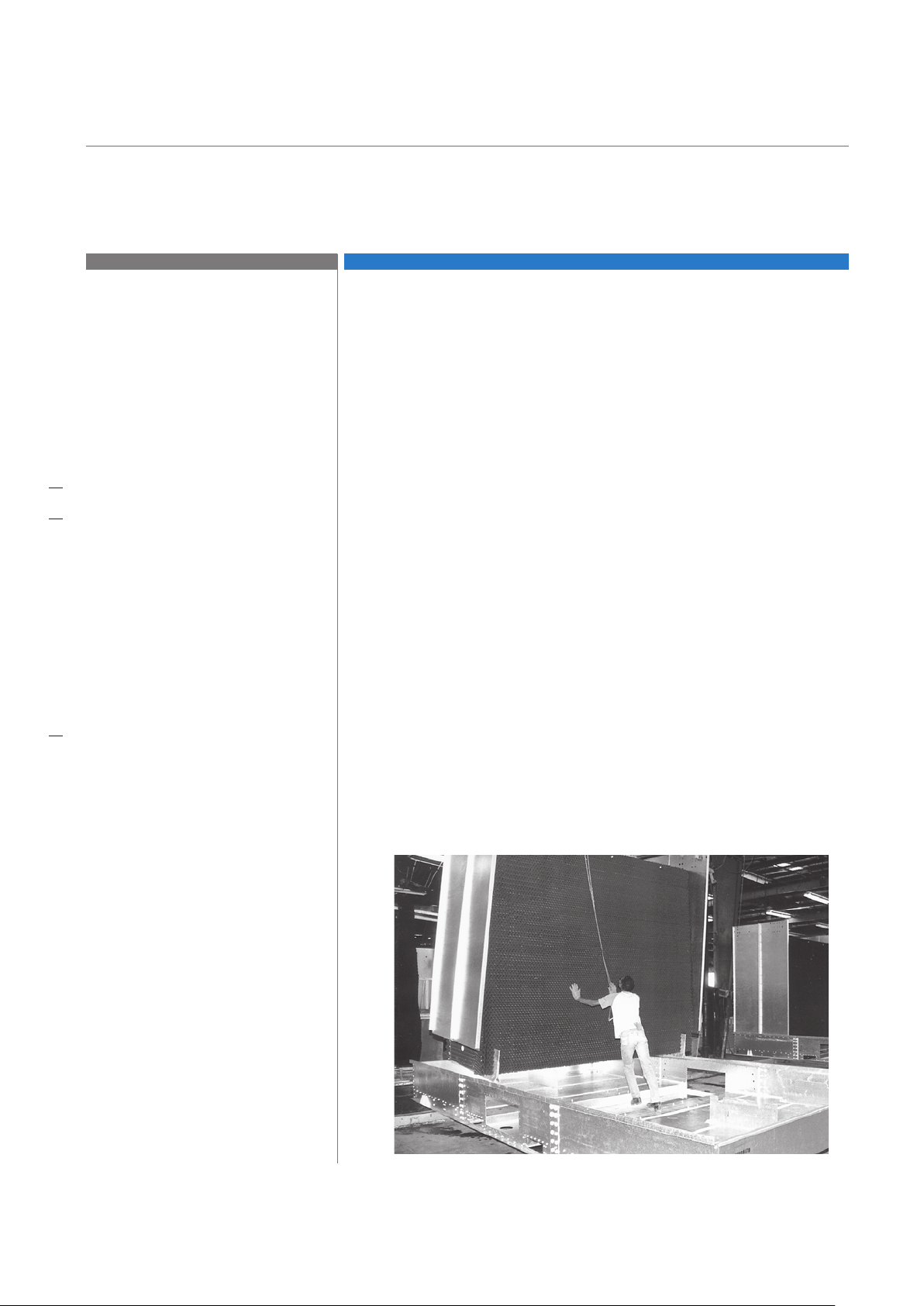

Factory Assembly

Page 7

Specifications

Specification Value

Marley / NC Class Stainless Cooling Tower / Specifications: Base

7

5.3* The tower shall include all design and

material modifications necessary to

meet the fire rating requirements of

Factory Mutual. The product proposed

shall be listed in the FM Approval

Guide, latest edition.

*Standard on models NC8301 thru NC8309. Available

as an option on models NC8310 thru NC8312.

6.0 Mechanical Equipment:

6.1 Fan(s) shall be propeller-type, incor-

porating wide-chord aluminum alloy

blades and galvanized hubs. Blades

shall be individually adjustable.

Maximum fan tip speed shall be 66

m/s. Fan(s) shall be driven through a

right angle, industrial duty, oil lubricated, geared speed reducer that requires

no oil changes for the first five (5)

years of operation. The gearbox bearings shall be rated at an L

service

10A

life of 100,000 hours or greater.

6.1 (alternate)* Fan(s) shall be propeller-

type, incorporating wide-chord aluminum alloy blades and galvanized hubs.

Blades shall be individually adjustable.

Fan(s) shall be driven through a onepiece multi-groove, solid back V-type

belt, pulleys, and tapered roller bearings. Bearings shall be rated at an L

10A

service life of 40,000 hours or greater.

*Currently available on Models NC8304 through

NC8309.

6.2 Motor(s) shall be ____ kW maximum,

TEFC, 1.15 service factor, variable

torque, and specially insulated for cooling tower duty. Speed and electrical

characteristics shall be ______ RPM,

single-winding, ___ phase, ____ hertz,

____ volts. Motor shall operate in the

shaft-horizontal position, and nameplate kilowatt shall not be exceeded at

design operation.

■ The Marley NC is the only crossflow

cooling tower approved for single-cell

FM installations. This could have a very

beneficial effect upon your fire insurance

premiums. Towers not able to meet FM

requirements may require the inclusion

of a fire protection sprinkler system to

achieve a comparable level of insurance premium cost. Even if you are not

insured by FM, this requirement ensures that each cell will contain any

fire that may occur without losing the ability of limited operations and

capacity.

■ Propeller-type fans require only half the operating hp of blower-type

fans. However, they should be readily adjustable to permit compensation for jobsite conditions.

With NC, the choice is yours. The exclusive Marley System5

Geareducer

®

requires no oil changes for five years, offering you

unmatched reliability and low maintenance. Ideal for owners concerned

about downtime or maintenance costs. Currently available on 49 NC

models, the Marley Power Belt drive system features all-aluminum

sheaves, power band belts and long-life bearings for dependable service.

TEFC motors offer additional benefits over TEAO motors whose only

source of cooling is the flow of air produced by the cooling tower fan.

This air rate is not always ideal due to motor position, blockage, etc.

TEFC ensures the motor will always be cooled properly.

Unless otherwise specified, motor speed will be 1500 RPM on standard

models. Low noise models will use motor speeds appropriate for the

specific model. If you prefer the operating flexibility of two-speed operation, please specify two-speed, single-winding motors which offer full

and half speeds for maximum energy savings. Incidentally, two speed

motors are a better choice than separate “pony” motors which simply

double the problems indicated above and induce parasitic loads during

operation for lower than nameplate efficiency.

6.3 The complete mechanical equipment

assembly for each cell shall be supported by a rigid steel structural support

that resists misalignment between the

motor and the gear reducer.

Page 8

Specifications

Specification Value

Marley / NC Class Stainless Cooling Tower / Specifications: Base

8

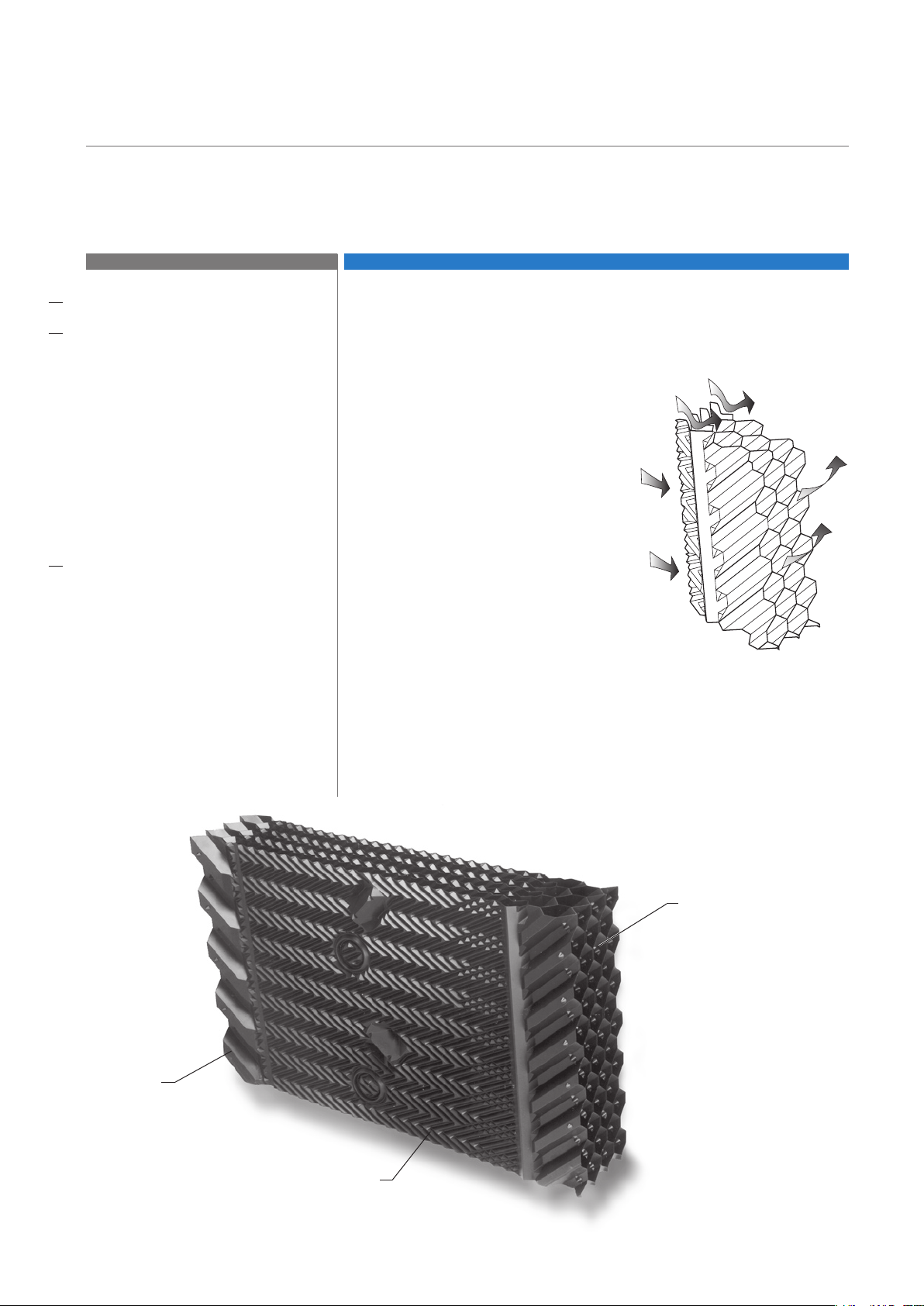

7.0 Fill, Louvers and Drift Eliminators:

7.1 Fill shall be film type, thermoformed

of 0.40mm thick PVC, with louvers

formed as part of each fill sheet. Fill

shall be suspended from hot dip galvanized structural tubing supported

from the tower structure, and shall be

elevated above the floor of the cold

water basin to facilitate cleaning. Air

inlet faces of the tower shall be free of

water splash-out. Fill shall be capable

of withstanding a hot water temperature of 52°C.

7.2 Drift eliminators shall be PVC, triple-

pass, and shall limit drift losses to

0.005% or less of the design water

flow rate.

■ Louvers integral with the fill keep the flowing water within the confines

of the fill. The separate external louvers used by others permit water to

escape the fill and form ice or produce an unsightly situation adjacent

to the tower and waste water. If you

plan to use your tower in the wintertime, particularly for free cooling,

integral louvers will put your operating concerns to rest. Integral louvers

offer the best available technology for

winter operation and water conservation.

Fill options are available for hot water

temperatures up to 60°C.

■ Drift rate varies with design water

loading and air rate, as well as drift

eliminator depth and number of

directional changes. A drift rate of

0.001% is readily available in standard

configuration without premium cost. If a

lower rate is required, please discuss with your

Marley sales representative.

Keep in mind…

• Drift for towers with three-pass high efficiency eliminators constitute a

small percentage of water usage.

• Unlike thermal performance, drift rates are not certified and field drift

tests are cost prohibitive for most applications.

• Drift rates below 0.001 are difficult to measure in the field.

• Certain water treatment chemicals can impact the drift rate.

LOUVERS

DRIFT ELIMINATOR

separate from fill

on some models

FILL

Page 9

Specifications

Specification Value

Marley / NC Class Stainless Cooling Tower / Specifications: Base

9

8.0 Hot Water Distribution System:

8.1 Two stainless steel open basins (one

above each bank of fill) shall receive

hot water piped to each cell of the

tower. These basins shall be installed

and sealed at the factory, and shall be

equipped with removable, stainless

steel covers capable of withstanding

the loads described in paragraph 4.1.

All components of these basins, with

the exception of the nozzles, shall be

stainless steel. The water distribution

system shall be accessible and maintainable during tower fan and water

operation.

8.2 Each basin shall include an inlet

hole and bolt circle to accept a 125#

flange connection per ANSI B16.1.

Removable, interchangeable polypropylene nozzles installed in the floor of

these basins shall provide full coverage

of the fill by gravity flow.

8.3 The water distribution system shall

be accessible and maintainable while

tower is operating.

■ Gravity-flow distribution basins are a feature of crossflow type tow-

ers, resulting in operating pump heads of 3 to 6 meters less than that

encountered in counterflow towers with pressurized spray systems.

Also, these basins are located where they can be easily inspected—

even maintained—while the tower is in operation.

■ Some manufacturers require shutting down the tower to clean the dis-

tribution system. Can you afford to do that?

9.0 Casing, Fan Deck and Fan Guard:

9.1 The casing and fan deck shall be

heavy-gauge stainless steel, and shall

be capable of withstanding the loads

described in paragraph 4.1. The top of

the fan cylinder shall be equipped with

a conical, non-sagging, removable fan

guard, fabricated of welded 8mm and

7 gauge rods, and hot dip galvanized

after fabrication. Fan cylinders 1.5m in

height and over shall not be required to

have a fan guard.

■ Materials other than heavy-gauge steel for fan decks may be unable to

meet your specified loading requirements. See remarks Guardrail and

Ladder on page 13.

In addition steel is excellent at resisting damage, cracking, UV and fire.

The heavy construction of the Marley fan guard generally precludes the

need for stainless

steel material. If

you would prefer

these to be stainless steel, please

adjust the wording of the last sentence accordingly.

Page 10

Marley / NC Class Stainless Cooling Tower / Specifications: Base

10

Specifications

10.0 Access:

10.1 A large stainless steel, rectangular

access door shall be located on both

end panels for entry into the cold

water basin. Doors shall provide

access to the fan plenum area to facilitate inspection and allow maintenance

to the fan drive system.

11.0 Cold Water Collection Basin:

11.1 The collection basin shall be heavy-

gauge S300 stainless steel, and shall

include the number and type of suction

connections required to accommodate

the outflow piping system shown on

the plans. Suction connections shall be

equipped with stainless steel debris

screens. A factory-installed, float-operated, mechanical make-up valve shall

be included. An overflow and drain

connection shall be provided in each

cell of the cooling tower. The basin

floor shall slope toward the drain to

allow complete flush out of debris and

silt which may accumulate. Towers of

more than one cell shall include stainless steel flumes for flow and equalization between cells. The basin shall

be accessible and maintainable while

water is circulating.

Specification Value

■ The access doors on NC8301 and

NC8302 towers are 76cm wide by

84cm high. On NC8303 thru NC8312

the access doors are 122cm high.

Small access doors are prohibitive

and discourage maintenance, which

in turn can impact your operation.

Specifying the size of the door will

cause some bidders to take exception, alerting you to a potential

maintenance headache. Two doors

are standard on all NC Class towers—one in each endwall.

■ The NC tower design offers side-

suctions, side-outlet sumps, and

bottom outlets to accommodate

a significant variety of piping schemes. Unless so specified, the tower

you may be asked to approve may only be available with one type of

suction connection, requiring you to redesign your piping layout.

Page 11

Marley / NC Class Stainless Cooling Tower / Specifications: Options

11

Specifications

Convenience and Safety Options

Guardrail and Ladder:

11.2 Add the following paragraph in

the Access section: The top of the

tower shall be equipped with a sturdy

guardrail, complete with kneerail and

toeboard, designed according to OSHA

guidelines and factory welded into

subassemblies for ease of field installation. Posts, toprails and kneerails

shall be 38mm square tubing. The

guardrail assembly shall be hot dipped

galvanized after welding and capable

of withstanding a 890N concentrated

live load in any direction. Posts shall

be spaced on centers of 2.4m or less.

A 46cm wide aluminum ladder with

76mm I-beam side rails and 32mm

diameter rungs shall be permanently

attached to the endwall casing of the

tower, rising from the base of the

tower to the top of the guardrail.

Ladder Extension:

Specification Value

■ The NC Class cooling tower has been

designed to minimize the need for maintenance personnel to get on top of the tower

to perform maintenance and inspections.

For the comfort and safety of your operating personnel, we recommend that you

specify a ladder and guardrail—and that

you require it of all bidders! Although not

required for safe operation by OSHA many

user's own safety rules may dictate these

options.

Outside the tower, stainless steel guardrail

material is not normally considered necessary. If you air quality is

sufficiently poor to warrant stainless steel, change the specification wording accordingly.

11.2 Add the following to the end of the

above paragraph: Provide a ladder

extension for connection to the foot

of the ladder attached to the tower

casing. This extension shall be long

enough to rise from the roof (grade)

level to the base of the tower. The

installing contractor shall be responsible for cutting the ladder to length;

attaching it to the foot of the tower ladder; and anchoring it at its base.

Ladder Safety Cage:

11.3 Add the following paragraph in the

Access section: A heavy gauge galva-

nized steel safety cage shall surround

the ladder, extending from a point

approximately 2m above the foot of

the ladder to the top of the guardrail.

Ladder Safety Gate:

10.3 Add the following paragraph in the

Access section: A galvanized steel,

self-closing gate shall be provided at

the guardrail level of the ladder.

■ Many towers are installed such that the base of the tower is 61cm

or more above the roof or grade level. This makes it difficult to

get up to the foot of the attached ladder. The ladder extension

alleviates this problem. Marley ladder extensions are available in

standard 1.5m and 3.3m lengths.

■ To meet OSHA guidelines, towers whose fan decks are 6m or

more above roof or grade, and which are equipped with ladders, should have safety cages surrounding the ladders, but with

approximately 2m clear headroom.

Outside the tower, stainless steel safety cage material is not

normally considered necessary. If you air quality is sufficiently

poor to warrant stainless steel, change the specification wording

accordingly.

■ A galvanized self-closing gate located at the guardrail level of

the fan deck, exterior motor access platform and access door

platform. Stainless steel is available with the stainless guardrail

option.

Page 12

Specifications

Specification Value

Marley / NC Class Stainless Cooling Tower / Specifications: Options

12

GUARDRAIL

LADDER

LADDER

EXTENSION

ACCESS DOOR

PLATFORM

Page 13

Specifications

Specification Value

Marley / NC Class Stainless Cooling Tower / Specifications: Options

13

Access Door Platform:

11.2 Add the following paragraph in the

Access section: There shall be an

access platform at the base of the

tower extending from the vertical ladder to the endwall access door. The

platform shall be galvanized steel bar

grating, supported by galvanized steel

framework attached to the tower.

The platform shall be surrounded by a

guardrail, kneerail, and toeboard.

Plenum Walkway

11.2 Add the following paragraph in the

Access section: Provide a factory-

installed, galvanized steel bar grating

walkway extending from one endwall

access door to the other endwall. This

walkway shall be supported by a galvanized steel framework, and the top

of the grating shall be at or above the

cold water basin overflow level.

Interior Mechanical Equipment

Access Platform

NC8303 thru NC8309

11.2 Add the following paragraph in the

Access section: A factory-installed,

elevated galvanized bar grating platform convenient to the care and maintenance of the tower's mechanical

equipment shall be provided.

■ Where towers are installed on an elevated grillage or piers, it is

often difficult to get to—and through—the access door conveniently. This platform provides easy, safe and comfortable access

to that door. It also extends beyond the door to provide ready

access to the optional Control System. See drawing on page 12.

Outside the tower, stainless steel platform material is not normally considered necessary. If you air quality is sufficiently poor to

warrant stainless steel, change the specification wording accordingly.

Interior Mechanical Equipment

Access Platform

NC8310 thru NC8312

11.2 Add the following paragraph in the

Access section: An internal ladder

shall extend upward from the plenum

walkway to an elevated galvanized

bar grating platform convenient to the

care and maintenance of the tower's

mechanical equipment. The platform

shall be surrounded by a sturdy guardrail and kneerail system.

OSHA and other concerned authorities are in the process

NOTE

of developing guidelines regarding the safety procedures and

protective equipment that should be provided maintenance personnel who are required to go inside cooling towers. We feel it

advisable to provide for as much maintenance as possible from

outside the cooling tower and, to that end, offer such options as

Guardrail and Ladder—pg 11, Ladder Extension—pg 11, Ladder

Safety Cage—pg 11, Access Door Platform—pg 13, and Motor

Out of the Airstream—pg 18. Such interior convenience options

as Plenum Walkway—pg 13, that are offered are not meant as

an invitation to perform inside maintenance. They are intended

solely to maximize the comfort and safety of maintenance personnel during the performance of any inside work may become

necessary.

Page 14

Specifications

Specification Value

Marley / NC Class Stainless Cooling Tower / Specifications: Options

14

Control Options

Fan Motor Starter Control Panel:

6.4 Add the following paragraph in

the Mechanical Equipment section: Each cell of the cooling tower

shall be equipped with a UL listed

control system in a IP14 or IP56 outdoor enclosure capable of controlling

single-speed or two-speed motors as

required, and designed specifically for

cooling tower applications. The panel

shall include a main fused disconnect

or main circuit breaker with an external

operating handle, lockable in the off

position for safety. Across-the-line magnetic starters or solid-state soft-start

starters as required shall be controlled

with a thermostatic or solid-state

temperature controller. Door mounted

selector switches shall be provided to

enable automatic or manual control

and wired for 240VAC control. Control

circuit to be wired out to terminal

blocks for field connection to a remote

vibration switch, overload trip alarms

and remote temperature control devices. The temperature controller shall be

adjustable for the required cold-water

temperature. If a thermostatic controller is used it shall be mounted on the

side of the tower with the temperature

sensing bulb installed in the cold water

basin using a suspension mounting

bracket. If a solid-state temperature

controller is used the controller will be

door mounted on the control panel.

The temperature controller will display

two temperatures, one for outgoing

water and the other for set point.

Water temperature input shall be

obtained using a three-wire RTD with

dry well in the outlet water piping and

wired back to the solid-state temperature controller in the control panel.

■ If it is your opinion that the control system for the cooling tower

be part of the tower manufacturer’s responsibility, we are in

wholehearted agreement with you. Who better to determine the

most efficient mode and manner of a cooling tower’s operation—

and to apply a system most compatible with it—than the designer and manufacturer of the cooling tower?

Marley variable speed drives are also available for the ultimate in

temperature control, energy management and mechanical equipment longevity. See specifications on page 16.

Page 15

Specifications

Specification Value

Marley / NC Class Stainless Cooling Tower / Specifications: Options

15

Vibration Limit Switch:

6.5 Add the following paragraph in the

Mechanical Equipment section: A

single-pole, double-throw vibration

limit switch in a IP56 housing shall be

installed on the mechanical equipment

support for wiring into the fan motor

shutdown circuit. The purpose of this

switch will be to interrupt power to the

motor in the event of excessive vibration. It shall be adjustable for sensitivity, and shall require manual reset.

Basin Heater:

11.2 Add the following paragraph in the

Cold Water Basin section: Provide a

system of electric immersion heaters

and controls for each cell of the tower

to prevent freezing of water in the

collection basin during periods of shutdown. The system shall consist of one

or more stainless steel electric immersion heaters installed in threaded couplings provided in the side of the basin.

A IP56 enclosure shall house a magnetic contactor to energize heaters; a

transformer to provide 24-volt control

circuit power; and a solid-state circuit

board for temperature and low water

cut-off. A control probe shall be located

in the basin to monitor water level

and temperature. The system shall be

capable of maintaining 5°C water temperature at an ambient air temperature

of _____ °C.

■ Unless specified otherwise, a

Metrix switch will be provided.

A double-pole, double-throw

model is also available. If

purchased in conjunction with

the Control System, it is also

factory-wired. The requirement

for manual reset assures that

the cooling tower will be visited to determine the cause of

excess vibration.

■ The Marley basin heater components described at left represent our rec-

ommendation for a reliable automatic system for the prevention of basin

freezing. They are normally shipped separately for installation at the jobsite by the installing contractor. When purchased in conjunction with the

enhanced Control System option, however, they are customarily factorymounted and tested.

Submerged in basin water,

in which zinc ions are present, copper immersion heaters must not be used. Insist

upon stainless steel.

The ambient air temperature

that you insert in the specifications should be the lowest

1% level of winter temperature prevalent at site.

Electric Water Level Control:

11.1 Replace this paragraph with the fol-

lowing: The collection basin shall be

heavy-gauge series 300 stainless steel

and shall include the number and type

of suction connections required to

accommodate the out-flow piping system shown on the plans. Suction connections shall be equipped with stainless steel debris screens. A solid-state

water level control system to monitor

the water level with a multi-relay control panel pre-wired and mounted in

a IP56 nonmetallic enclosure shall be

provided. The system shall consist of

water level sensing and control units

■ Solid-state liquid level controls provide you with state of the art sys-

tems to control and monitor the water level in your cooling tower collection basin. Relays operating in conjunction with suspended stainless

steel electrode probes monitor basin water levels, providing simple

solenoid-valve water makeup or discrete on/off signals to more sophisticated automation controls. Optional configurations might include

makeup along with high and low water level alarm and cutoff, or pump

cutoff. Packaged systems including any of these variations are available.

Consult you Marley sales representative or download a copy of ACCNC-9D from spxcooling.com for additional information.

➠

Page 16

Specifications

Specification Value

Marley / NC Class Stainless Cooling Tower / Specifications: Options

16

in quantities and locations as indicated

on the drawings. An overflow and drain

connection shall be provided in each

cell of the cooling tower. The basin

floor shall slope toward the drain to

allow complete flush out of debris and

silt which may accumulate. Towers of

more than one cell shall include stainless steel flumes for flow and equalization between cells. The basin shall

be accessible and maintainable while

water is circulating.

Fan Motor Variable Speed Drive:

Marley All Weather ACH550 System

6

.4 Add the following paragraph in the

Mechanical Equipment section when

VFD is used with customers Building

Management System:

listed Variable Speed Drive system in a

IP10 indoor, IP52 indoor or IP14 outdoor

enclosure shall be provided. The VFD

shall use PWM technology with IGBT

switching and integrated bypass design.

VFD out put switching shall not cause

mechanical issues with gearbox teeth

or drive shafts. The VFD shall catch a fan

spinning in the reverse direction without

tripping. The panel shall include a main

disconnect with short circuit protection

and external operating handle, lockable

in the off position for safety. The VFD

system shall receive a speed reference

signal from the Building Management

System monitoring the tower cold-water

temperature. As an option to receiving

the speed reference signal from a building management system, the drive must

have the capability to receive a 4-20 ma

temperature signal from an RTD transmitter. The VFD shall have an internal PI

regulator to modulate fan speed maintaining set point temperature. The drive's

panel display shall be able to display the

set-point temperature and cold-water

temperature on two separate lines. The

bypass shall include a complete magnetic bypass circuit and with capability

to isolate the VFD when in the bypass

mode. Transfer to the bypass mode shall

be manual in the event of VFD failure.

Once the motor is transferred to the

by-pass circuit the fan motor will run at

constant full speed. The bypass circuit

will not modulate ON and OFF based on

A complete UL

■ Marley Variable Speed Drive systems are designed to combine absolute

temperature control with ideal energy management. The cooling tower

user selects a cold water temperature and the drive system will vary the

fan speed to maintain that temperature. Precise temperature control is

accomplished with far less stress to the mechanical equipment components. The improved energy management provides fast payback to the

user.

Page 17

Specifications

Specification Value

Marley / NC Class Stainless Cooling Tower / Specifications: Options

17

cold-water temperature. The application

must be able to handle very cold water

while VFD is in a by-pass mode. Operator

controls shall be mounted on the front of

the enclosure and shall consist of start

and stop control, bypass/VFD selection,

Auto/Manual selections, manual speed

control. To prevent heating problems

in the cooling tower fan motor and to

assure proper gear reducer lubrication

the VFD system shall de energize the

motor once 25% motor speed is reached

and cooling is no longer required. The

cooling tower manufacturer shall supply

VFD start-up assistance. Tower vibration

testing throughout the speed range is

required to identify and lockout any natural frequency vibration levels which may

exceed CTI guidelines.

Marley Premium VFD System

6.4 Add the following paragraph in

the Mechanical Equipment section

when VFD is used as a stand alone

system:

Speed Drive system in a IP52 indoor or

IP14 outdoor enclosure shall be provided.

The VFD shall use PWM technology with

IGBT switching and integrated bypass

design. VFD output switching shall not

cause mechanical issues with gearbox

teeth or drive shafts. The VFD shall catch

a fan spinning in the reverse direction

without tripping. The panel shall include

a main disconnect with short circuit protection and external operating handle,

lockable in the off position for safety.

The system shall include a solid state,

PI temperature controller to adjust frequency output of the drive in response

to the tower cold-water temperature.

The temperature of the cold water and

set point shall be displayed on the door

of the control panel. The bypass shall

include a complete magnetic bypass

circuit with capability to isolate the VFD

when in the bypass mode. Transfer to

the bypass mode shall be automatic in

the event of VFD failure or for specific

trip conditions allowing safe transfer of

utility voltage to the motor. Automatic

bypass with an earth ground condition is

not allowed. The bypass contactor shall

be cycled on and off while operating in

bypass, to maintain the set-point temperature of the cold water. The drive design

A complete UL listed Variable

Page 18

Specifications

Specification Value

Marley / NC Class Stainless Cooling Tower / Specifications: Options

18

shall be operated as a stand- alone system without the need for a BMS system.

Operator controls shall be mounted

on the front of the enclosure and shall

consist of start and stop control, bypass/

VFD selector switch, Auto/Manual

selector switch, manual speed control,

and solid-state temperature controller.

An emergency bypass selector switch

internal to the panel allowing the cooling

tower fan motor to be run at full speed

shall be furnished. To prevent heating

problems in the cooling tower fan motor

and to assure proper gear box lubrication

the VFD system shall de energize the

motor once 25% motor speed is reached

and cooling is no longer required. The

VFD shall include de-icing logic with auto

canceling and adjustable time. Speed

in De-Ice mode shall not exceed 50 %

motor speed. The cooling tower manufacturer shall supply VFD start-up assistance. Tower vibration testing throughout

the speed range is required to identify

and lockout any natural frequency vibration levels which may exceed CTI guidelines.

Miscellaneous Options

Motor out of the Airstream:

6.1 Add the following to the end of this

paragraph: The motor shall be mount-

ed outside the casing of the tower, and

shall be connected to the gear reducer

by a dynamically-balanced, stainless

steel tube and flange driveshaft.

Fan Cylinder Extensions:

9.1 Insert the following after the first

sentence: Fan cylinder extensions

shall be provided to elevate the fan discharge to a height of ___ m above the

fan deck level.

■ For many years, a feature of

Marley cooling towers was that

the electric motors were located

outside the fan cylinders, where

they were easily accessible, and

where they were not subjected to

the constant humidity that exists

inside the tower plenum.

Although improved motor designs

(insulation, bearings, seals, and

lubricants) have now made it feasible for us to locate the motor inside the tower in close-coupled proximity to the Geareducer

be located outside the humid airstream. If you are among those users—

or are among those who see the wisdom of their thinking—please specify this option. If you do, however, please require it of all bidders.

■ Extensions are available in 305mm increments to a maximum height

equal to the diameter of the fan. Such extensions may be considered

necessary in order to elevate the discharge beyond the bounds of an

enclosure. Discuss applicability with your local Marley sales representative.

®

(page 7), many users still prefer the motor to

Page 19

Specifications

Specification Value

Marley / NC Class Stainless Cooling Tower / Specifications: Options

19

Inlet Flow Control Valves:

8.2: Add the following to the end of the

paragraph: Heavy-duty flow-regulator

valves shall be provided at the hot

water inlet connections. These valves

shall be disc-type, with cast iron

bodies and stainless steel operating

stems. There shall be a locking handle

to maintain the valve setting in any

position. Valves shall be right-angle

configuration, precluding the need for

inlet elbows.

Equalizer Flume Weir Gates:

11.2: Add the following paragraph under

Cold Water Collection Basin: The

interconnecting flume between cells

shall be equipped with a removable

cover plate to permit the shutdown of

one cell for maintenance purposes, or

to permit independent cell operation.

Sound Control

1.2 Add the following paragraph under

Base: The cooling tower shall be quiet

operation, and shall produce an overall

level of sound not higher than _______

dB(A) measured at _______ m from the

locations in the table below. All low

noise options and combinations shall

be CTI Certified for thermal performance.

Location 63 125 250 500 1000

Discharge

Air Inlet

Cased Face

Location 2000 4000 8000 Overall dB(A)

Discharge

Air Inlet

Cased Face

Inlet Sound Attenuation

1.3 Add the following paragraph under

Base: The cooling tower shall be

equipped with inlet sound attenuation

baffles positioned and spaced vertically. The baffles will be spaced across

the entire length and extend the full

height of the air inlet. The baffles will

be constructed of perforated sheet

metal and contained within a steel

➠

■ Marley flow-control valves have been a

favorite of users since the 1950s. They

remain serviceable for the life of the tower

and provide a continuing means of flowregulation between hot water basins—and

between cells of multicell towers as well.

■ Where it is your intention to be able to operate both cells of the tower

while the flume cover plate is installed, separate outlet connections,

float valves and overflows must be provided for each cell. Likewise, this

would require separate sensors and controls for basin heater systems,

if installed.

■ Sound produced by a

standard NC Cooling

Tower operating in an

unobstructed environment will meet all but

the most restrictive

noise limitations—and

will react favorably to

natural attenuation.

Where the cooling

tower has been sized

to operate within an

enclosure, the enclosure itself will have a damping effect on sound.

Sound also declines with distance—by about 5 or 6 dB(A) each time the

distance doubles. Where noise at a critical point is likely to exceed an

acceptable limit, you have several options—listed below in ascending

order of cost impact:

• Where only a slight reduction in noise will satisfy—and the source of

concern is in a particular direction—merely turning the cooling tower

may be the answer. Less sound emanates from the cased face of the

cooling tower than does from the air intake face.

• In many cases, noise concerns are limited to nighttime, when ambient noise levels are lower and neighbors are trying to sleep. You can

usually resolve these situations by using two-speed motors—operating

the fans at reduced speed without cycling “after hours”. The natural

nighttime reduction in wet-bulb temperature makes this a very feasible

solution in most areas of the world, but the need to avoid cycling may

cause the cold water temperature to vary significantly.

• A Marley Variable Speed Drive automatically minimize the tower’s

noise level during periods of reduced load and/or reduced ambient

Page 20

Specifications

Specification Value

Marley / NC Class Stainless Cooling Tower / Specifications: Options

20

box which is self supporting. The inlet

attenuation will not be allowed to

impact the thermal performance efficiency of the basic tower configuration.

Outlet Sound Attenuation

1.4 Add the following paragraph under

Base: The cooling tower shall be

equipped with outlet sound attenuation

baffles positioned and spaced horizontally across the entire fan opening. The

baffles will be constructed of perforated sheet metal and contained within

a steel box which is self supporting

and made of the same material as the

tower.

Low Noise Fan

1.4 Replace paragraph 6.1 with the fol-

lowing: Fan(s) shall be propeller-type,

incorporating a minimum of seven

wide-chord aluminum alloy blades

and galvanized hubs. Blades shall be

individually adjustable. Maximum fan

tip speed shall be 56 m/s. Fan(s) shall

be driven through a right angle, industrial duty, oil lubricated, geared speed

reducer that requires no oil changes

for the first five (5) years of operation.

The gearbox bearings shall be rated at

an L

service life of 100,000 hours or

10A

greater.

6.1 (alternate)* Fan(s) shall be propeller-

type, incorporating a minimum of

seven wide-chord aluminum alloy

blades and galvanized hubs. Blades

shall be individually adjustable. Fan(s)

shall be driven through a one-piece

multi-groove, solid back V-type belt,

pulleys, and tapered roller bearings.

Bearings shall be rated at an L

vice life of 40,000 hours or greater.

*Currently available on Models NC8304 through

NC8309.

10A

ser-

temperature without sacrificing the system’s ability to maintain a constant cold water temperature. This is a relatively inexpensive solution,

and can pay for itself quickly in reduced energy costs.

• The most extreme cases may require inlet and discharge sound attenuator sections—however, the static pressure loss imposed by discharge

attenuators may necessitate an increase in tower size. Two stages of

inlet or discharge attenuators supported by the tower and designed and

tested for the most stringent requirements are available as an option.

■ Falling water sound—unlike counterflow towers which allow the water

to free-fall and splash into the cold water collection basin, PVC filmfill crossflow towers have no splashing. This allows a crossflow tower

much lower sound levels at the air inlet than a counterflow tower—

especially induced draft counterflow towers. Even with the “splash-matting” option in a counterflow cold water collection basin, a crossflow

tower air inlet is still quieter. Plus you do not have to worry about clogging the splash matting. Yet another maintenance and operation advantage of the crossflow configuration.

■ NC Class models with the “L” suffix in the model number are the special

low sound editions. To achieve the very lowest possible sound levels

while maintaining efficiency, the best available combination of motor,

gear ratio, fan blade count and blade profile were carefully selected for

every “L” model. All “L” models come with the Low-Noise Fan option.

If you choose the sound attenuator option, the fan will automatically

change to the Low-Noise Fan option.

■ Tip Speed—unlike thermal performance, no certification program exists

for sound. While Marley conducts actual sound tests on all its configurations there are only

a few ways for the

client to ensure

they get a quiet

tower.

• One is to conduct

a field sound test

after installation.

On-site testing

after installation

can however be

inaccurate depending on the environment.

• Another is to conduct a sound test at the factory. However both can be

cost prohibitive for smaller applications.

• Specifying fan blade tip speed is one way to physically force the tower

selection to be quiet. Tip speed is easily checked by multiplying the fan

rpm by the fan circumference at the blade tip (π fan dia). Over 61m/s is

considered high by most people. 51-61 is considered typical and expected. 41-51 would be considered low noise. Below 41 is difficult to hear

above the water noise.

Page 21

Specifications

Specification Value

Marley / NC Class Stainless Cooling Tower / Specifications: Options

21

Ultra Low-Noise Fan

1.4 Replace paragraph 6.1 with the fol-

lowing: Fan(s) shall be propeller-type,

incorporating wide-chord forwardswept FRP blades and galvanized

hubs. Blades shall be individually

adjustable. Maximum fan tip speed

shall be 51 m/s. Fan(s) shall be driven

through a right angle, industrial duty, oil

lubricated, geared speed reducer that

requires no oil changes for the first

five (5) years of operation. The gearbox

bearings shall be rated at an L

vice life of 100,000 hours or greater.

Available on Models NC8302 through NC8312.

Single Hot Water Inlet Connection

per Cell:

8.2 Replace this paragraph with the

following: Each cell of the tower

shall include a single hot water inlet

connection located as shown on the

plans. An internal system of piping

shall deliver water equally to the distribution basins without the need for

balancing valves. This internal piping

system shall require no scheduled

maintenance, and shall be located such

that it does not interfere with normal

maintenance access. The internal piping must extend to the tower exterior.

Removable, interchangeable polypropylene nozzles installed in the floor of

these basins shall provide full coverage

of the fill by gravity flow.

10A

ser-

■ For more severe cases requiring the lowest possible fan sound levels

the Marley “Ultra Low-Noise” fan option is now available on all but the

NC8301 NC Class models. Tower height may increase slightly—obtain

current sales drawings from your Marley sales representative for accurate dimensions. If your requirement calls for inlet and outlet attenuation, you might consider the Ultra Low-Noise fan in lieu of attenuation. Outlet attenuators are not available with the Ultra Low-Noise Fan

option.

■ This option reduces what might otherwise be a complex hot water

piping layout to a simple, single connection per cell. It also avoids an

unsightly (perhaps unsafe) maze of pipe exposed above the top deck of

the tower.

The single inlet connection can be located either in the tower's endwall

casing, or below the cold water basin. The endwall entry point is suitable for single-cell towers, and for those that might be installed in

groups of two cells each. Bottom inlet piping lends itself to closespaced, multicell installations and to those situations where it is appropriate to keep all pipework below the level of the tower.

Be sure to specify that the internal pipe extends to the tower exterior

panel, either the casing panel or collection basin floor. Some manufacturers require the contractor to complete the internal piping adding to

your cost.

Air Inlet Screens:

9.1 Add the following paragraph to the

Casing, Fan Deck and Fan Guard section: The air inlet faces of the tower

shall be covered by 1" mesh hot-dipped

galvanized welded wire screens.

Screens shall be secured to removable

galvanized U-edge frames.

High Wind Load/Seismic Designs:

4.1 Replace this paragraph with the fol-

lowing: The tower structure, anchor-

age and all its components shall

be designed by licensed structural

engineers per the international building code to withstand a wind load of

➠

■ In wooded or windy

areas, these screens help

to keep leaves or blowing

debris out of the cooling tower and circulating

water system.

■ High wind load designs

greater than 30 psf are

available up to 100 psf.

It is important to consult

the local code official for actual requirements. Some manufacturers will

claim their tower is capable but have never had the design reviewed by

a licensed structural expert. Not requiring expert review for high wind

and seismic regions is dangerous to you and the public.

Page 22

Marley / NC Class Stainless Cooling Tower / Specifications: Options

22

Specifications

______ psf, as well as a ______ seismic

load. The fan deck and hot water basin

covers shall be designed for 50 psf live

load or a 200 lb. concentrated load.

Guardrails, where specified, shall be

capable of withstanding a 200 lb. concentrated live load in any direction, and

shall be designed in accordance with

OSHA guidelines.

Multicell Basin Equalizer Outlets:

11.1 Add the following paragraph in the

Access section: A hole and bolt circle

shall be provided in the depressed section of the basin for equalizer piping

between cells. A full-face, .25" thick, 50

durometer gasket shall be provided at

each equalizer location.

Basin Sweeper Piping:

11.1 Add the following paragraph in the

Access section: The cold water basin

shall be equipped with PVC sweeper

piping with plastic eductor nozzles.

The piping should create a grid under

the fill and force all dirt and debris to

the depressed section of the collection

basin.

Specification Value

■ Used as water level equalizers between multicell towers. Not intended

for water migration. Piping and attachment hardware by others. Flat

faced flange required.

■ PVC sweeper piping and Lakos nozzles. Designed for the following

flows at 20 psig:

NC8301 thru NC8304, 33m

NC8305, 47m

3

/h

NC8306 thru NC8312, 64m

3

/h

3

/h

Extended Geareducer Lube Line

with Dipstick:

6.1 Add the following paragraph in the

Mechanical Equipment section: An

external oil level dipstick shall be located adjacent to the motor at the fan

deck surface and shall be accessible

from a portable maintenance ladder.

■ The dipstick option is accessible from a portable maintenance ladder

on one and two cell towers only. Maintenance considerations recommends this option be combined with the ladder and guardrail option on

installations of three or more cells since the dipstick cannot be reached

without accessing the fan deck.

Page 23

Page 24

SPX COOLING TECHNOLOGIES UK LTD.

GREGORY’S BANK

WORCESTER WR3 8AB

UNITED KINGDOM

+44 (0) 1905 720 200

info.uk@spx.com

spxcooling.com

In the interest of technological progress,

all products are subject to design and/or

material change without notice.

©2008 SPX Cooling Technologies

uk_SPEC-SS-NC-08A

Loading...

Loading...