Page 1

SD25 Series

Electric Screwdrivers

User’s Manual

Rev B, June 2004

39-30-40409

Page 2

24-Hour

Technical Support

Toll Free in the U.S. and Canada:

1-877-224-7377

All other countries:

(001) 248-596-0600

between 8 a.m. and 5 p.m.

Eastern Standard Time (EST)

NOTE: The part number for the Visual Supervisor (VS) software

program is 464000-03300.

NOTE: A variety of related technical manuals in .pdf format

may be downloaded from www.gsetechmotive.com.

Click on the Technical Info button in the red, left-hand

frame. Select Technical Documentation. Scroll through

the list to find the title of the product you require, and

click!

NOTE: View our latest product literature in .pdf format in

multiple languages at www.gsetechmotive.com. Click on

the Product button in the red, left-hand frame. Select

Product Brochures. Scroll through the list for the name

of the product for which you would like more information,

and click!

SPX GSE tech-motive tool manufactures products under the GSE and tech-motive tool® brand names.

Information and technical diagrams in this manual are subject to change without notice. tech-motive tool is

a registered trademark. Products and services referred to in this book may be either trademarks and/or

registered trademarks of their respective owners.

© 2003-2004 SPX CORPORATION. ALL RIGHTS RESERVED.

Page 3

LIMITED WARRANTY

SPX GSE tech-motive tool warrants its PRODUCTS to be free from defects in materials and workmanship for the

lesser of (1) one year from the date of shipment from the manufacturing facility in Michigan, U.S.A. OR

(2) one-million cycles except for the products noted below:

GSE tech-motive crowfoot, tubenut and hold & drive heads 250,000 cycles

rd

3

-party crowfoot, tubenut, hold-and-drive torque multiplier or other heads manufacturer’s warranty

56 and 116 Series nutrunners 500,000 cycles

PRODUCTS include GSE tech-motive tool brand fastening tools, controllers and cables, GSE brand sensors an d

instruments, and anti-lock brake testing systems. Fuses and batteries are not covered under warranty.

For PRODUCTS verified as defective at SPX GSE tech-motive tool’s manufacturing facility,

SPX GSE tech-motive tool shall have the option, in its sole discretion, to repair or replace the products or

components. SPX GSE tech-motive tool shall not be liable for any installation charges, expenses of the Buyer for

repairs or replacement, damages from delay or loss of use, or other indirect or consequential damages of any kind.

The warranty does not cover any product that has been modified without the approval of SPX GSE tech-motive tool,

used for a purpose other than that for which it was intended, used in a manner inconsistent with any instructions,

subjected to unusual physical stress, environmental or electrical conditions, or whose original identification marks

have been removed or altered.

Whenever the PRODUCTS are to be incorporated in a system, the design of which originated with the Buyer,

SPX GSE tech-motive warrants only that the PRODUCTS shall be free of defects in materials and workmanship and

offers no other warranty.

In the event that a product is repaired or replaced under the terms of the warranty, the warranty period for the

repaired or replacement product shall be limited to the remaining portion of the original warranty.

Any warranty extended by the original manufacturer of peripheral equipment, such as printers, recorders, plotters,

etc., included with a SPX GSE tech-motive tool product or system shall be extended to the Buyer and shall be the

only warranty offered.

Transportation charges for materials shipped to the manufacturing facility for warranty repair are to be paid by the

Buyer. SPX GSE tech-motive tool will pay for shipping to return items repaired or replaced under warranty.

THIS LIMITED WARRANTY IS EXCLUSIVE, AND SPX GSE tech-motive tool MAKES NO OTHER WARRANTY OF

ANY KIND WHATSOEVER, WHETHER EXPRESSED, IMPLIED OR STATUTORY, WITH RESPECT TO THE

PRODUCTS OR PARTS MANUFACTURED BY IT, WHETHER AS TO MERCHANTABILITY, FITNESS FOR A

PARTICULAR PURPOSE OR ANY OTHER MATTER OR WARRANTY OF ANY KIND. No agent, employee or

representative of SPX GSE tech-motive tool has the authority to bind SPX GSE tech-motive tool in any affirmation,

representation, or warranty concerning the Products or parts except as stated her ein.

THIS REMEDY SHALL BE THE EXCLUSIVE REMEDY AVAILABLE FOR ANY NONCONFORMITIES IN

MATERIALS OR WORKMANSHIP, OR FOR ANY DAMAGES RESULTING FROM ANY OTHER CAUSE

WHATSOEVER. SPX GSE tech-motive tool SHALL NOT, IN ANY EVENT, BE LIABLE FOR ANY SPECIAL,

INDIRECT, INCIDENTAL OR CONSEQUENTIAL DAMAGES OF ANY KIND, NATURE OR DESCRIPTION,

WHETHER FOR NONCONFORMITIES IN MATERIALS OR WORKMANSHIP UNDER ANY WARRANTY, IN

CONTRACT, TORT, NEGLIGENCE, STRICT LIABILITY, OR FOR ANY OTHER REASON.

Page 4

CUSTOMER SATISFACTION

Please Read This!

As a valued customer, your opinion and satisfaction are important to SPX GSE tech-motive

tool. Please let us know what you think of our product(s).

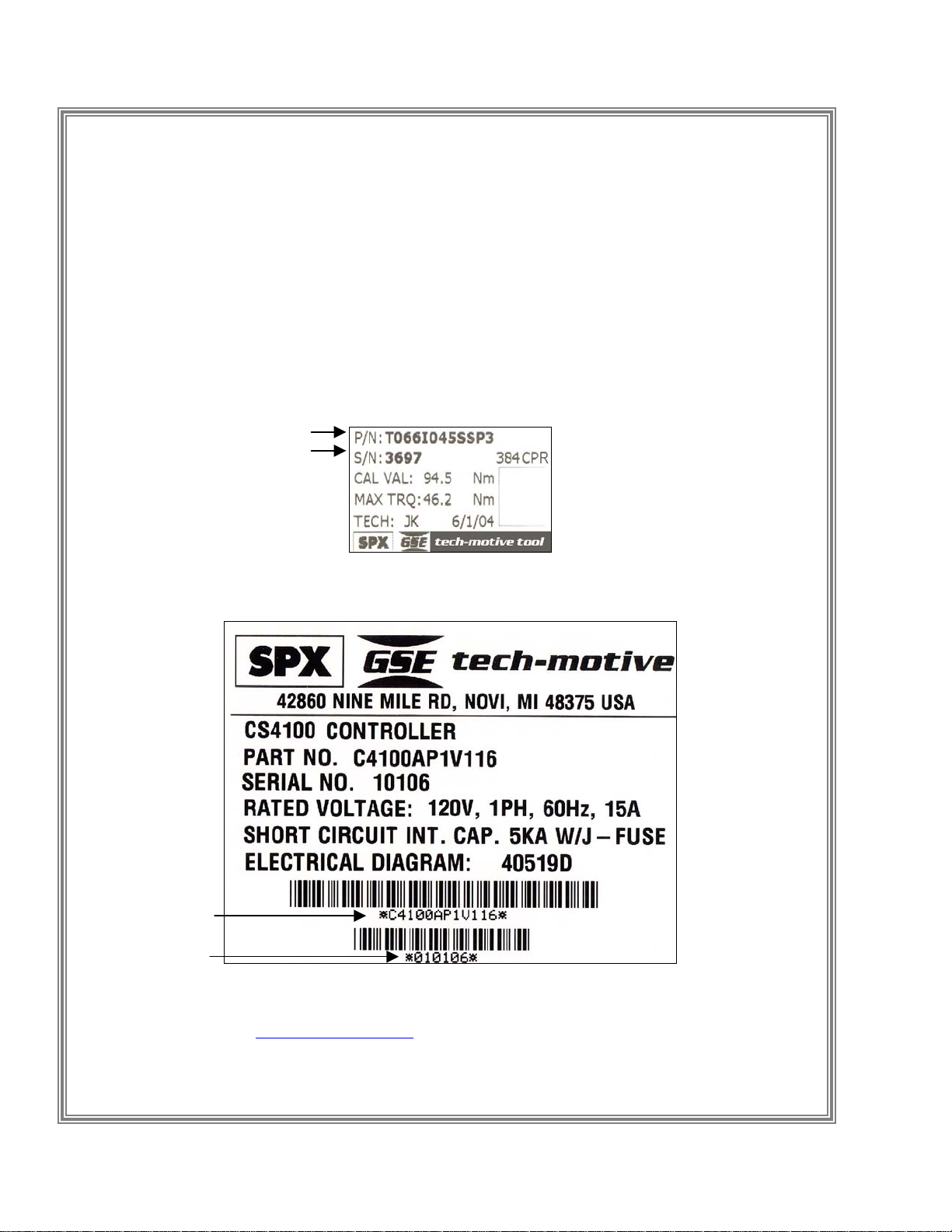

Write the part number and serial number of the product(s) you have purchased before you begin our

brief online survey. The numbers are located on a sticker affixed to the handle of the nutrunner or

screwdriver, and exterior or interior of the controller.

Tool Label

Controller Label

Part Number

Serial Number

Part Number

Serial Number

To complete the survey:

1. Visit our website www.gsetechmotive.com

2. Click the Customer Satisfaction Survey link located below the gray buttons in the red, left-hand frame.

3. Fill in the fields and click the appropriate choices.

4. Click the “Submit to GSE tech-motive tool” button.

Page 5

Preface

Our GSE tech-motive tool SD25 Series Screwdriver is easy to operate and comes with a manual that

includes instructions to help you use it safely, make minor adjustments, and perform routine

maintenance.

Who Should Use This Manual

This manual is written for the engineers and technicians, who will set up, use and maintain

GSE tech-motive tool SD25 Series screwdrivers.

How to Use This Manual

This manual introduces you to the SD25 Series Screwdriver and provides general safety and electrical

safety guidelines for using it, and covers installation, adjustment, calibration and troubleshooting of

the screwdrivers.

For the latest revision of drawings, please contact our Technical Service Department at

1-248-596-0600.

Conventions

The following conventions are used throughout this manual for the safety of personnel, equipment,

software, and data. The conventions include warnings, cautions, and notes, as follows:

WARNING!

!

CAUTION!

NOTE:

?

It can be dangerous to personnel and/or machine systems,

if operating instructions are not followed. The information

appears in a box in italicized boldface type.

There may be damage to equipment, and loss of software

and data, if operating instructions are not followed. The

information is indented and in italicized boldface type.

Information that adds to your knowledge of the equipment

and/or software. The information is indented and italicized.

June 2004 T-40409-A Page i

Page 6

SD25 Series Screwdrivers

Abbreviations

The most common abbreviations used throughout this manual are:

DCM device control module

EEPROM electrically erasable programmable read only memory

ESD electro-static discharge

ITI intelligent tool interface

LED light-emitting diode

STM standard test method

TCM tool control module

VS Visual Supervisor is the setup, fastening, data collection and diagnostics software

program designed by SPX GSE tech-motive tool

References

CS2000 Mini Controller Hardware Overview Manual (part number 39-30-38810)

CS2000/CS4000 Mini Controller and CS4100 Controller Network and Interface Supplement

(part number 30-30-40477)

Mobile Fastening System II (MFS II) User’s Guide (part number 39-30-37700)

Visual Supervisor User’s Guide (part number 39-30-34823)

Page ii T-40409-A 39-30-40409

Page 7

Contents

Preface ..................................................................................................................................... i

Who Should Use This Manual..........................................................................................i

How to Use This Manual...................................................................................................i

Conventions.......................................................................................................................i

Abbreviations....................................................................................................................ii

References ........................................................................................................................ii

SD25 Series Screwdrivers..................................................................................................... 1

Electro-static Discharge (ESD) ......................................................................................2

Think Safety First!.................................................................................................................. 3

General Machine Safety.................................................................................................. 3

Electrical Safety............................................................................................................... 5

Contents

Getting Started....................................................................................................................... 6

Viewing Screwdriver Functions..................................................................................... 7

Installing the Screwdriver............................................................................................... 8

Using Visual Supervisor Setup...................................................................................... 9

Tightening a Fastener................................................................................................... 11

Loosening a Fastener ................................................................................................... 11

Reversing the Screwdriver........................................................................................... 12

Attaching a Pistol Grip Handle..................................................................................... 12

Mapping Screwdriver Functions ........................................................................................14

Disabling the Push-to-Start Function.......................................................................... 14

Enabling the Push-to-Start Function........................................................................... 15

Mapping Outputs for a Single-Spindle........................................................................ 16

Mapping Outputs for a Single-Spindle........................................................................ 17

Troubleshooting Your Screwdriver.................................................................................... 19

Maintaining Your Screwdriver ............................................................................................ 20

Reading the Screwdriver Part Numbers........................................................................... 21

Specifications and Parts ..................................................................................................... 22

Specifications................................................................................................................ 22

Screwdriver Accessories.............................................................................................. 23

June 2004 T-40409-A Page iii

Page 8

SD25 Series Screwdrivers

(This page is left blank intentionally.)

Page iv T-40409-A 39-30-40409

Page 9

SD25 Series Screwdrivers

Thank you for purchasing the GSE tech-motive tool SD25 Series Screwdriver, available in in-line and

pistol grip versions.

The SD25 Series In-line Screwdriver is a compact, lightweight tool of aluminum construction,

weighing one pound and measuring 9.4-in length. It provides a push-to-start output spindle and/or

trigger-start for operator preference, a forward/reverse direction button, high intensity headlights, and

torque good, high and low indicator lights. It also has a multi-purpose (auxiliary) button that can be

used for a variety of functions.

SD25 Series In-line Screwdriver

The SD25 Series Pistol Grip Screwdriver is the In-line screwdriver with an attached lightweight

aluminum pistol grip handle (part number 49-SD-10111).

Each SD25 Series Screwdriver has the capability to interface to a computer through a laptop computer

attached to the GSE tech-motive tool CS2000 Mini Controller or CS2100 Controller.

SD25 Series Pistol Grip Screwdriver

NOTE:

Other accessories are available for the SD25 Series screwdrivers.

For more information, please visit our website at

http://www.gsetechmotive.com

then click on the Products button.

?

June 2004 T-40409-A Page 1

Page 10

SD25 Series Screwdrivers

Electro-static Discharge (ESD)

The SD25 Series Screwdriver is well suited for use in electro-static discharge (ESD) safe work areas.

The screwdriver has been tested and meets the requirements of ESD Standard (S) 20.20, and also

section 5.1.3 of ESD Standard Test Methods (STM) 13.1.

Page 2 T-40409-A 39-30-40409

Page 11

Think Safety First!

Working with fastening tools can be dangerous if safe and proper procedures are not followed. As

with all machinery, certain hazards can be involved with the operation of the product. Using these

tools with caution will considerably lessen the possibility of personal injury. If, however, safety

precautions are overlooked or ignored pers onal injury to the operator can result.

Always use common sense and exercise caution when using these tools. They can produce torque that,

unless properly compensated for, could cause personal injury. Remember, your personal safety is your

responsibility.

Only GSE tech-motive tool-qualified service technicians should perform the procedures covered in

this manual. If you are an operator or service technician, you should become familiar with the

contents of this manual before operating, servicing, or performing maintenance on any part of the

fastening system, including the SD25 Series screwdrivers. Familiarization with all components of the

system can minimize the possibility that an accident or injury might occur.

SPX GSE tech-motive tool assumes no responsibility for personal injury or damage to equipment

resulting from misuse of these tools. After reviewing this manual you should also review all safety

procedures provided by your company and the equipment installer.

WARNING!

!

Failure to follow these rules can result in serious personal

injury.

General Machine Safety

• FOR YOUR OWN SAFETY READ THE INSTRUCTION MANUAL THOROUGHLY

PRIOR TO OPERATING THE TOOL.

• DO NOT WORK IN A DANGEROUS ENVIRONMENT. Do not use power tools in a

damp or wet location or explosive atmosphere, or expose them to rain, oils, or corrosive

fluids.

• KNOW THE LOCATION OF POWER DISCONNECTS PRIOR TO OPERATING

THIS EQUIPMENT.

• KEEP ALL ELECTRICAL PANELS CLOSED DURING OPERATION. High voltage

present inside enclosure panels can result in personal injury. Do NOT bypass or defeat

electrical safety devices. Turn the power actuator to the OFF position prior to any

servicing or maintenance of the controller.

• OBSERVE ALL GOVERNMENT AND/OR COMPANY POWER LOCKOUT

STANDARDS.

• NEVER OPERATE SOLENOID VALVES, LIMIT SWITCHES OR RELAYS

MANUALLY as this practice can create dangerous, unexpected machine movements.

June 2004 T-40409-A Page 3

Page 12

SD25 Series Screwdrivers

• SECURE THE TOOL. Tools that develop torque can produce hazardous torque

reactions. Always be sure that the tool is properly fixtured to absorb reaction as a

fastener is tightened. Never operate a tool capable of high torque without proper

fixturing.

• SECURE WORK. Avoid situations where the part being fastened breaks loose and can

cause damage.

• NEVER TOUCH OR ATTEMPT TO STOP MOVING MACHINERY OR PARTS

WITH YOUR HANDS, OTHER PARTS OF YOUR BODY, OR MAKESHIFT

DEVICES.

• DO NOT OPERATE THE TOOL WHILE UNDER THE INFLUENCE OF ALCOHOL,

DRUGS OR MEDICATION THAT CAN IMPAIR YOUR JUDGMENT.

• REPORT ALL UNSAFE WORKING CONDITIONS OR PRACTICES TO YOUR

SUPERVISOR AND / OR SAFETY DEPARTMENT FOR CORRECTION.

• WEAR APPROVED SAFETY GLASSES AT ALL TIMES.

• DO NOT WEAR JEWELRY, especially bracelets and rings, while operating the

fastening tools. Keep hands and fingers away from all rotating parts and avoid situations

where clothing can become tangled in the tool. Secure loose fitting clothing, neckties,

and long hair. Wear medical alert identification cautiously.

• DO NOT OVERREACH. Keep proper footing and balance at all times.

• KEEP YOUR WORK AREA CLEAN. Do not work on or near slippery floors or

surfaces. Avoid situations where the tool reacts against unexpected obstacles. Do not

operate electrical equipment while standing on a wet floor.

• MAINTAIN TOOLS IN TOP CONDITION. Keep tools properly lubricated and clean.

If any wires become frayed or exposed, replace them immediately. Prevent dirt, grease

or contaminants from getting into the tool.

• REDUCE THE RISK OF UNINTENTIONAL STARTING. Be careful how the tool is

left unattended. Avoid resting it on its throttle/trigger lever to prevent false starts.

• CONTROL THE DIRECTION OF ROTATION. The reaction torque changes direction

when going from forward to reverse. Always be aware of the direction the tool will

rotate prior to using it. If the tool is not fixtured this will allow you to brace for the

proper direction of torque reaction.

• CHECK DAMAGED PARTS. Before further use of a tool, any part of the tool that is

damaged should be carefully checked to ensure that it will operate properly and perform

its intended function. Check for alignment of moving parts, breakage of parts, mounting,

and any other conditions that may affect its operation. Never operate a tool that has

damaged or exposed wires. Never operate a tool that has any part of the powertrain,

other than the output spindle, exposed.

Page 4 T-40409-A 39-30-40409

Page 13

User’s Manual

Electrical Safety

Only qualified and properly trained personnel should perform electrical/electronic

troubleshooting and repair. Consider the following electrical system safety guidelines:

• Before you troubleshoot or service a fastening system station, be sure you have an up-todate and appropriate set of electrical drawings for that station.

• Remove metal items, such as rings, metal necklaces, wristwatches and jewelry, as these

can create electrical hazards. Wear medical alert identification cautiously.

• Wear safety glasses, but avoid wearing those that have metal rims or metal side shields.

• It may be necessary to troubleshoot equipment while the power is ON. ONLY qualified,

trained personnel should do this. During these instances, open only the panels, doors, or

covers that need to be opened. Know the voltage present at all points before you begin

troubleshooting.

• Use properly insulated tools when working on electrical equipment to reduce the

possibility of shock. Make sure the insulation is adequate to safeguard against the high

voltages present.

• If you must work on the electrical system, make sure the Ground Fault Circuit

Interrupter (GFCI) is in the OFF position, or remove the plug from the AC outlet, or turn

off the circuit breaker.

• Do not attempt to modify or repair the machine without the approval of the proper

authorities.

• Use approved fuse pullers when changing fuses.

• Never use jumper wires or fuse substitutes to replace specified fuses.

• Always use fuses of a capacity smaller than or equal to the safe capacity of the line or

the equipment it serves.

• Before you work on any circuit, check it with an appropriate testing device to be sure

voltage is not present.

• Install temporary wiring as safely as possible and replace it with permanent wiring as

soon as possible. Install grounding wherever it is needed in the final installation. If

modifications are made to the system wiring, drawings must be revised to illustrate this

change.

• Know how to deal with electrical fires properly. Keep carbon dioxide and powder

extinguishers handy.

June 2004 T-40409-A Page 5

Page 14

SD25 Series Screwdrivers

Getting Started

All SD25 Series handheld screwdrivers have the following features to provide torque information

right at your fingertips:

• Programmable multi-purpose pushbutton for Cycle Complete, multi-parameter set selection, Data

Send, etc.

• Forward / reverse direction button

• Multi-color light-emitting diode (LED) illumination ring that indicates acceptable, high and low

torque/angle

The SD25 Series Screwdriver can identify its maximum speed and torque capacities to the controller.

However, you may need to verify that the screwdriver you have is capable of generating the torque

specified in the active parameter set displayed on the controller. If the screwdriver you are connecting

to a controller is not capable of developing the torque specified in the parameter sets it will not run at

all. You should first verify that the screwdriver operates properly.

All SD25 Series screwdrivers have internal memory inside that identifies how the screwdriver was

configured upon manufacture. Because the SD25 Series screwdrivers are highly programmable -through both the factory settings contained in the screwdriver memory and the configuration of your

particular controller -- there are many possible combinations of screwdriver functionality.

• If your screwdrive r has a multi-purpose button installed, you may have it configured to perform

one of several functions.

The Visual Supervisor (VS)-based controller (CS2000 Mini Controller connected to a laptop

computer) allows you to look at all of the factory or configured settings inside the screwdriver. VS

also allows you to change the software selectable Inputs and Outputs, change torque settings, add

parameters, enable and define the function of all switches on the screwdriver. To use the VS setup

program, open it on the laptop computer connected to the CS2000 Mini Controller. Then click on the

tool icon in the menu tree on the left side of the screen. Refer to Using Visual Supervisor Setup on

page 9 for further details.

If you have any questions about the functionality of your screwdriver, contact your sales agent or the

SPX GSE tech-motive tool Technical Service Department for assistance.

Page 6 T-40409-A 39-30-40409

Page 15

Viewing Screwdriver Functions

Before you operate your SD25 Series screwdriver, become familiar its functionality:

User’s Manual

NOTE:

?

• Th rottle/trigger lever or the push-to-start function starts and stops the screwdriver

• Forward/reverse switch runs the screwdriver in clockwise or counterclockwise direction

• LED illumination ring indicates acceptable, high and low torque/angle

• Headlights illuminate the fastening area

These are shown in the diagram below.

LED illumination ring

The factory sets the functions of the screwdriver and the

position of the buttons/lever in relationship to the head. Each

function can be re-assigned to a different button or switch using

VS.

Multi-purpose (auxiliary) button

Forward/reverse switch

Throttle/trigger lever

Headlight

Push-to-start

Customer supplied bits

NOTE:

Some screwdrivers, such as those designated for fixtured

remote usage, do not have a throttle/trigger lever, a

forward/reverse switch, or a multi-purpose button.

?

June 2004 T-40409-A Page 7

Page 16

SD25 Series Screwdrivers

r

Installing the Screwdriver

Use the following procedure to install SD25 Series screwdrivers to the CS2000 Mini Controller.

Installing the Screwdriver

1. Identify the slot on the screwdriver connector into which the screwdriver cable

plugs.

2. Align the red dot on the grip of the screwdriver cable connector to the slot on the

screwdriver connector.

Grip

Slot into screwdriver

connecto

3. Insert the screwdriver cable connector into the slot on the screwdriver connector

and push firmly. There is a click when the cable is correctly inserted.

4. Connect the large end of the screwdriver cable to the controller.

5. Turn on power to the controller.

You will see messages on the controller display during initialization, and the screwdriver

lights will flash momentarily.

If the screwdriver lights continue to flash, read the scrolling message on the controller

display. Typically, this will read “Invalid Parameter Set X.” Fix the parameter set in the

controller via VS.

NOTE:

?

Red dot

To remove the cable from the screwdriver, slide the grip on the

screwdriver cable connector away from the screwdriver and at

the same time firmly pull the screwdriver and cable connector

apart.

Screwdriver-tocontroller cable

To fix the invalid parameter set:

• Click on the Parameter Set that displays a red and black

the tab that also displays the

to the Visual Supervisor User’s Guide (part number 39-30-34823) for details.

If the parameter set does not need to be corrected, and a message other than “TRQ=” or

“ANG=” continues to scroll across the controller display, it is likely to be a message

indicating a data error or an operational problem. If a data error or operational problem

occurs, refer to Troubleshooting Your Screwdriver on page 19.

Page 8 T-40409-A 39-30-40409

. Correct the value that is highlighted in red. Refer

next to it and click on

Page 17

6. Become familiar with how the screwdriver operates and feels.

Press the throttle/trigger lever and cycle the screwdriver in the air (not on a fastener).

Press the forward/reverse button, then press the throttle/trigger lever and watch the

output drive change direction.

OR

Press the throttle/trigger lever to enable the cycle, position the screwdriver on a fastener

and push down to start the cycle. Press the forward/reverse button, then press the

throttle/trigger lever and push down to start the cycle again and watch the fastener turn

in the opposite direction.

Using Visual Supervisor Setup

The information that appears under the General Information tab for the selected screwdriver is

displayed when a screwdriver is attached to the controller. The electrically erasable programmable

read only memory (EEPROM) chip inside the screwdriver transmits data to the analog intelligent tool

interface (ITI) board inside the controller.

User’s Manual

If there is no screwdriver attached, the General Information tab, the User Information tab, and all

parameter set and sequence tabs are unavailable.

The values on the General Information tab vary with the attached screwdriver.

June 2004 T-40409-A Page 9

Page 18

SD25 Series Screwdrivers

In the following table, all of the left column fields are defined in the order they appear on your screen,

followed by all the second column fields.

1st Column Field Definition

Model Number

Build Date

Serial Number

Minimum Torque

Maximum Torque

Minimum Speed

Maximum Speed

Calibration Torque

Calibration Counts

Angle Counts/Rev

Last Calibration

Last Repair

GSE tech-motive tool part number for the screwdriver.

The date the screwdriver was manufactured.

Alphanumeric serial number of the screwdriver.

Minimum usable torque value (in Nm) for the screwdriver. The controller reads this

information from the screwdriver and prevents you from using it on any application

where the target torque is BELOW this value.

Maximum usable torque value (in Nm) for the screwdriver. The controller reads

this information from the screwdriver and prevents you from using it on any

application where the target torque is ABOVE the maximum usable torque value

of the screwdriver.

Minimum usable speed in revolutions per minute (RPM) of the screwdriver.

Maximum free speed value (in RPM) of the screwdriver.

The torque calibration value (in Nm) of the screwdriver.

The analog-to-digital reading (in A to D counts) that the controller reads from the

screwdriver when the shunt calibration circuit in the screwdriver is activated.

The angle scaling factor (in counts per revolution) for the screwdriver.

The date the screwdriver was last calibrated.

The date the screwdriver was manufactured or last repaired.

2nd Column Field Definition

Opposite Rotation

When checked, indicates the screwdriver is an opposite rotation screwdriver: for a

right-handed fastener torque cycle, the motor is run in the reverse direction, and

the torque and angle signals are negative going. When unchecked, indicates the

screwdriver is a standard rotation screwdriver: for a right-handed fastener torque

cycle, the screwdriver motor is run in the forward direction, and the torque and

angle signals are positive-going.

Left-Hand Tightening

Capable

Fixtured Tool

(Also known as Bi-Directional Tightening Capable.) When checked, indicates the

screwdriver has been modified for use in left-hand fastening applications (for

example, reverse torque cycles, such as tightening a left-hand threaded fastener).

When checked, indicates the screwdriver is designed for fixtured applications and

has no on-board controls for cycle start or direction.

Intelligent Wrench

When checked, indicates the tool is not a screwdriver, but an intelligent hand

torque wrench.

Auto Retract

When checked, indicates that the tool is a tubenut tool and the output socket must

be retracted to the open position when the tool trigger is released. This option

does not apply to screwdrivers.

Retract Shutoff Torque

When Auto Retract is checked, defines the shutoff torque setting (in engineering

units) for tubenut tools. This option does not apply to screwdrivers.

Retract Speed

When Auto Retract is checked, defines the speed setting (in RPM) for tubenut

tools. This option does not apply to screwdrivers.

Has a display

When checked, indicates the attached tool has a digital display. This option does

not apply to screwdrivers.

Page 10 T-40409-A 39-30-40409

Page 19

2nd Column Field Definition (continued from previous page)

Has auxiliary pushbutton

Locked Rotor Count

Overtemperature Count

When checked, indicates that a screwdriver with multi-purpose (auxiliary)

pushbutton is attached.

The total number of locked rotor faults the screwdriver has had.

The total number of motor overheating faults the screwdriver has had. Such faults

occur when the winding temperature is higher than 125 degrees Celsius.

Tightening a Fastener

For most fastening operations, make sure the screwdriver turns clockwise when running forward. For

left-hand fastening capable screwdrivers, make sure the screwdriver turns counterclockwise when

running forward.

Once the screwdriver is positioned on a part, you begin the rundown (cycle start) by:

• Pressing the trigger lever on handheld screwdrivers that have the push-to-start function disabled

OR

• Pressing the trigger lever on handheld screwdrivers that have the push-to-start function enabled,

then pushing down firmly on the screwdriver

User’s Manual

OR

• Asserting (activating) the remote start input on fixtured screwdrivers

The cycle start signal must remain active in order to complete the rundown. If the signal is interrupted

- if you release the trigger lever, for example - the screwdriver stops immediately.

When the rundown is complete, you can see the status of the rundown by:

• The illumination of the LEDs on the screwdriver - green for acceptable torque/angle, yellow for

low torque/angle, and red for high torque/angle

• The controller display

• VS software displays the final torque/angle

NOTE:

For details of asserting (activating) remote inputs and reading

the controller display, refer to the appropriate controller manual.

?

Loosening a Fastener

For unfastening operations, make sure screwdriver turns counterclockwise when running forward. For

left-hand fastening capable screwdrivers, make sure the screwdriver turns clockwise when running

forward.

Once the screwdriver is positioned on a part, you begin the rundown (cycle start) by:

• Pressing the trigger lever on handheld screwdrivers

• Asserting (activating) the remote reverse direction input on fixtured screwdrivers

The cycle start signal must remain active in order to complete the rundown. If the signal is interrupted

- if you release the trigger lever, for example - the screwdriver stops immediately.

June 2004 T-40409-A Page 11

Page 20

SD25 Series Screwdrivers

r

r

w

Reversing the Screwdriver

When the screwdriver is put into reverse, by sliding the forward/reverse switch into the reverse settin g

or remotely activating the FWD/REV input, the screwdriver turns in the opposite direction to the

normal fastening direction. Reverse is indicated by the yellow, green and red LEDs chasing in a

counterclockwise direction while the headlights remain lit. For most fastening operations, the

screwdriver turns in a counterclockwise direction when in reverse, but for left-hand fastening

applications it is clockwise.

Attaching a Pistol Grip Handle

The diagram below shows the SD25 Series In-line screwdriver with the throttle/trigger lever and

spring removed and the Pistol Grip handle (part number 49-SD-10111) slid into place.

Multi-purpose (auxiliary) button

Forward/reverse switch

Push-to-start

LED illumination ring

5/32-in scre

Throttle/trigger leve

Throttle/trigger leve

Holds the In-line screwdriver

horizontally in the handle

Pin

Left inset: The pistol grip handle

(part number 49-SD-10111) in detail.

Page 12 T-40409-A 39-30-40409

Page 21

User’s Manual

Use the following procedure to attach a Pistol Grip handle (part number 49-SD-10111) to an In-line

screwdriver. Refer to Viewing Screwdriver Functions on page 7 to view an illustration of the

In-line screwdriver that may help you with this procedure.

Attaching a Pistol Grip Handle

1. Remove the screwdriver-to-controller cable, if necessary.

2. Using a 5/32-in punch, hammer out the pin that attaches the throttle/trigger lever

to the In-line screwdriver.

3. Remove the throttle/trigger lever spring. It may fall out when you remove the

throttle/trigger lever so be prepared to catch it.

NOTE:

?

4. Carefully slide the In-line screwdriver into the handle attachment with the

forward/reverse and multi-purpose (auxiliary) buttons positioned on the top.

5. Position the handle on the bottom of the screwdriver, on the side of the

screwdriver opposite to the forward/reverse and multi-purpose (auxiliary) buttons.

6. Slide the pin back into the handle attachment.

You will need to hammer it carefully back into place. Make sure the screwdriver does not

rotate or move in relation to the position of the handle during this process.

7. Using a 5/32-in Allen wrench, tighten the fastener on the handle attachment until it

is secure.

You are now ready to use your Pistol Grip screwdriver.

Put the throttle/trigger lever and spring into a safe place. If, in

the future, you remove the handle attachment, you will need

the throttle/trigger lever and spring to convert the screwdriver

back to the In-line model.

June 2004 T-40409-A Page 13

Page 22

SD25 Series Screwdrivers

•

•

Mapping Screwdriver Functions

This section describes how VS is used to map screwdriver functions to the buttons and switches on

the screwdriver. You can also use VS to change the default mapping. To do this, refer to the Visual

Supervisor User’s Guide (part number 39-30-34823).

Disabling the Push-to-Start Function

Typically, to start a fastening cycle when the push-to-start function on a handheld screwdriver is

disabled:

• Press the throttle/trig ger lever to start the fastening cycle.

• Release the throttle/trigger lever to stop the fastening cycle.

Push-to-start

• Disabled

Throttle/trigger lever

Forward/reverse button

• Press and release to

change the direction

Press to start the fastening cycle

• Release to stop the screwdriver

Multi-purpose (auxiliary) button

Press and release 2 times to change the

parameter set

Page 14 T-40409-A 39-30-40409

Page 23

User’s Manual

The screwdriver inputs are software selectable using VS. To di sable t he p ush-t o -st art fu nc t i on, assi g n

the Cycle On input, Cycle Enable input and the Clear Outputs input to the Trigger. The typical inputs

for a screwdriver with push-to-start fu nct i o n di sabl ed are shown below.

Enabling the Push-to-Start Function

Typically, to start a fastening cycle when the push-to-start function on a handheld screwdriver is

enabled:

• Press the throttle/trigger lever to enable the fastening cycle.

• Push down firmly on the screwdriver to start the fastening cycle.

• Release the throttle/trigger lever to stop the fastening cycle.

OR

• Release the pressure on the screwdriver to stop the fastening cycle.

June 2004 T-40409-A Page 15

Page 24

SD25 Series Screwdrivers

•

•

Push-to-start

• Push to start the fastening cycle

• Release to stop the screwdriver

Throttle/Trigger lever

Forward/reverse button

Press to enable the fastening cycle

• Release to stop the screwdriver

Multi-purpose (auxiliary) button

• Press and release to

change the direction

Press and release 2 times to change the

parameter sets

The screwdriver inputs are software selectable using VS. To enable the push-to-start function, assign

the Cycle On input to Input 8, and assign the Cycle Enable input and Clear Outputs input to the

Trigger. The typical inputs for a screwdriver with push-to-start function enabled are shown below.

Page 16 T-40409-A 39-30-40409

Page 25

Mapping Outputs for a Single-Spindle

Typically, the LEDs and headlights on the screwdriver work in the following way:

• Headlights turn on while the screwdriver is running in forward or reverse.

User’s Manual

NOTE:

Yellow, green and red LEDs chase each other in a

counterclockwise direction while the screwdriver is in reverse.

?

• Green LEDs turn on to indicate a successful cycle completion achieving target torque/angle

within acceptable range.

• Yellow LEDs turn on to indicate lower than acceptable torque/angle.

• Red LEDs turn on to indicate higher than acceptable torque/angle.

The screwdriver outputs are software selectable using VS. To operate the screwdriver as a singlespindle tool, assign the Cycle Good output to Output 2, Cycle Bad output to Output 3, Output 8

(Timed Copy) to Output 7 and the Ready output to Output 8. The typical outputs for operating the

screwdriver as a single-spindle tool are shown below.

NOTE:

The time delay for Output 8 (Timed Copy) can be adjusted

using the Timers tab in VS. For details, refer to the Visual

Supervisor User’s Guide (part number 39-30-34823).

?

June 2004 T-40409-A Page 17

Page 26

SD25 Series Screwdrivers

The typical outputs for screwdriver LEDs are shown below.

Page 18 T-40409-A 39-30-40409

Page 27

Troubleshooting Your Screwdriver

The CS2000 Mini Controller used with the screwdriver has many configurable features and

programmable parameters that control the operation of the fastening system equipment.

GSE tech-motive tool supply the VS software program that provides you with a way to change

parameters that affect operation of the controller and attached screwdriver. If you apply these features

or program the parameters improperly, erroneous data and manufacturing problems can result. Proper

setup of the controller is essential in preventing such situations.

Whenever the data seems to be in error or operational problems occur, refer to one of the following

manuals:

⇒ CS2000 Mini Controller Hardware Overview Manual (part number 39-30- 3 88 1 0)

⇒ CS2100 Controller Hardware Overview Manual (part number 39-30-41886)

⇒ CS2000/CS4000 Mini Controller Network and Interface Supplement (part number 39-30-40477)

⇒ CS4100/2100 Controllers Technical Reference (part number 39-30-41994)

⇒ The online help manual that is part of the VS software

June 2004 T-40409-A Page 19

Page 28

Maintaining Your Screwdriver

Generally, there is no preventive maintenance required for GSE tech-motive tool screwdrivers.

SPX GSE tech-motive tool only recommends trained technicians to perform in-depth maintenance,

such as motor, transducer, or gearing replacement.

NOTE:

For the latest assembly drawing revisions, contact our

Technical Service Department at 1-248-596-0600.

?

June 2004 T-40409-A Page 20

Page 29

Reading the Screwdriver

Part Numbers

All SD25 Series Screwdrivers have an 8-digit prefix that helps you quickly identify the type of

screwdriver you are using, and a longer suffix that provides more details about the screwdriver.

Prefix example: SD25I010

SD 25 I 010

Screwdriver Series

Type: In-line

Capacity lbf-in

User’s Manual

And the suffix:

P

USH-TO-START

TRIGGER EVER

B

OTH TRIGGER AND PUSH-TO-START

M

OUNTED (PUSH-TO-START, NO TRIGGER LEVER, REMOTE START)

A

LUMINUM HEAD

QUICK RELEASE CHUCK, 1/4-IN

HIOS CHUCK, 4 MM

HIOS CHUCK, 5 MM

L

P, L, B, or M A Q2, H4 or H5

June 2004 T-40409-A Page 21

Page 30

Specifications and Parts

This section lists the specifications of your SD25 Series screwdrivers under typical operating

conditions and available screwdriver-to-controller cables.

Specifications

This section lists general specifications, torque and RPM ranges, and length and weight ranges for

SD25 Series screwdrivers.

General Specifications for SD25 Series Screwdrivers

Description Specifications

Motor current

Motor commutation

Screwdriver logic power

Screwdriver pushbuttons*

Screwdriver connector

Screwdriver Display

Screwdriver Headlights

Ambient operating temperature

8A peak

Hall-based, brushless DC motor

24 VDC

Start, direction, auxiliary, push-to-start

High density 26-pin connector

Three indicator / status LEDs for torque/angle

Turn on when screwdriver is running in forward or reverse

0 to 60 C (32 to 140 F)

Relative humidity

* Not available on fixtured screwdrivers

Torque, RPM, Length and Weight Ranges of SD25 Series Screwdrivers

Screwdriver

Type

In-line

In-line

In-line

In-line

June 2004 T-40409-A Page 22

Nm lbf-in ozf-in kgfcm

1.1 10 160 11.5 1700 9.4 in / 239 mm 0.91 lb / 0.41 kg

3.3 20 320 23.0 1100 9.4 in / 239 m m 0.91 lb / 0.41 kg

3.9 35 560 40.3 800 9.4 in / 239 mm 0.91 lb / 0.41 kg

5.6 50 800 57.6 500 9.6 in / 244 mm 1.1 lb / 0.49 kg

Torque Range

0 to 85% R.H. (non-condensing)

RPM Range Length Range Weight Range

Page 31

Screwdriver Accessories

This section lists part numbers for the screwdriver-to-controller cables, suspension bail, reaction

mounting plates, and foam grip available for the SD25 Series screwdrivers.

Screwdriver-to-Controller Cables

Part Number Straight Part Number Right Angle Length

299230-81050 299230-81050R 5 ft / 1.5 m

299230-81100 299230-81100R 10 ft / 3.0 m

299230-81150 299230-81150R 15 ft / 4.6 m

299230-81200 299230-81200R 20 ft / 6.1 m

299230-81250 299230-81250R 25 ft / 7.6 m

299230-81300 299230-81300R 30 ft / 9.1 m

299230-81350 299230-81350R 35 ft / 10.7 m

299230-81400 299230-81400R 40 ft / 12.2 m

299230-81450 299230-81450R 45 ft / 13.7 m

299230-81500 299230-81500R 50 ft / 15.2 m

Screwdriver Suspension Bail

User’s Manual

Part Number Description

49-SD-10112 Vertical Suspension Bail

Screwdriver Mounting Plates

Part Number Description

49-SD-10121 Reaction mounting plate, double flange, for fixtured mounting

49-SD-10125 Reaction mounting plate, single flange, for close fixtured mounting

Screwdriver Foam Grip

Part Number Description

31-80-39445 Foam grip for the SD25 Series In-line Screwdriver

Screwdriver Pistol Grip Attachment for In-line SD25 Screwdriver)

Part Number Description

31-SD-10111 Pistol grip for the SD25 Series In-line Screwdriver

June 2004 T-40409-A Page 23

Page 32

SD25 Series Screwdrivers

(This page is left blank intentionally.)

Page 24 T-40409-A 39-30-40409

Page 33

Page 34

Part Number: 39-30-40409

SPX Corporation

42860 Nine Mile Road

Novi, MI 48375-4122 USA

Phone: (248) 596-0600

Toll free: (800) 795-7875

Fax: (248) 596-0601

Website: www.gsetechmotive.com

© 2003-2004 SPX Corporation. All rights reserved. 6/04

Loading...

Loading...