Page 1

Springer Tracts in Mechanical Engineering

Yong Chen

Automotive

Transmissions

Design, Theory and Applications

Page 2

Springer Tracts in Mechanical Engineering

Series Editors

Seung-Bok Choi, College of Engineering, Inha University, Incheon, Korea

(Republic of)

Haibin Duan, Beijing University of Aeronautics and Astronautics, Beijing, China

Yili Fu, Harbin Institute of Technology, Harbin, China

Carlos Guardiola, CMT-Motores Termicos, Polytechnic University of Valencia,

Valencia, Spain

Jian-Qiao Sun, University of California, Merced, CA, USA

Young W. Kwon, Naval Postgraduate School, Monterey, CA, USA

Page 3

Springer Tracts in Mechanical Engineering (STME) publishes the latest developments in Mechanical Engineering - quickly, informally and with high quality. The

intent is to cover all the main branches of mechanical engineering, both theoretical

and applied, including:

• Engineering Design

• Machinery and Machine Elements

• Mechanical Structures and Stress Analysis

• Automotive Engineering

• Engine Technology

• Aerospace Technology and Astronautics

• Nanotechnology and Microengineering

• Control, Robotics, Mechatronics

• MEMS

• Theoretical and Applied Mechanics

• Dynamical Systems, Control

• Fluids Mechanics

• Engineering Thermodynamics, Heat and Mass Transfer

• Manufacturing

• Precision Engineering, Instrumentation, Measurement

• Materials Engineering

• Tribology and Surface Technology

Within the scope of the series are monographs, professional books or graduate

textbooks, edited volumes as well as outstanding PhD theses and books purposely

devoted to support education in mechanical engineering at graduate and

post-graduate levels.

Indexed by SCOPUS. The books of the series are submitted for indexing to

Web of Science.

Please check our Lecture Notes in Mechanical Engineering at http://www.springer.

com/series/11236 if you are interested in conference proceedings.

To submit a proposal or for further inquiries, please contact the Springer Editor in

your country:

Dr. Mengchu Huang (China)

Email: mengchu.Huang@springer.com

Priya Vyas (India)

Email: priya.vyas@springer.com

Dr. Leontina Di Cecco (All other countries)

Email: leontina.dicecco@springer.com

More information about this series at http://www.springer.com/series/11693

Page 4

Yong Chen

Automotive Transmissions

Design, Theory and Applications

123

Page 5

Yong Chen

Hebei University of Technology

Tianjin, China

ISSN 2195-9862 ISSN 2195-9870 (electronic)

Springer Tracts in Mechanical Engineering

ISBN 978-981-15-6702-5 ISBN 978-981-15-6703-2 (eBook)

https://doi.org/10.1007/978-981-15-6703-2

Jointly published with China Machine Press

The print edition is not for sale in China (Mainland). Customers from China (Mainland) please order the

print book from: China Machine Press.

ISBN of the Co-Publisher’s edition: 978-7-111-59945-6

© China Machine Press and Springer Nature Singapore Pte Ltd. 2021

This work is subject to copyright. All rights are reserved by the Publishers, whether the whole or part

of the material is concerned, specifically the rights of translation, reprinting, reuse of illustrations,

recitation, broadcasting, reproduction on microfilms or in any other physical way, and transmission

or information storage and retrieval, electronic adaptation, computer software, or by similar or dissimilar

methodology now known or hereafter developed.

The use of general descriptive names, registered names, trademarks, service marks, etc. in this

publication does not imply, even in the absence of a specific statement, that such names are exempt from

the relevant protective laws and regulations and therefore free for general use.

The publishers, the authors, and the editors are safe to assume that the advice and information in this

book are believed to be true and accurate at the date of publication. Neither the publishers nor the

authors or the editors give a warranty, express or implied, with respect to the material contained herein or

for any errors or omissions that may have been made. The publishers remain neutral with regard to

jurisdictional claims in published maps and institutional affiliations.

This Springer imprint is published by the registered company Springer Nature Singapore Pte Ltd.

The registered company address is: 152 Beach Road, #21-01/04 Gateway East, Singapore 189721,

Singapore

Page 6

Foreword

Professor Chen Yong has been engaged in the research and development of

automotive transmissions for a long time. He worked in the world famous automatic transmission company (JATCO) of Nissan Motor for 19 years, and completed

the development and mass production of many automatic transmission products;

after that, he worked in domestic automobile enterprises for nine years, leading the

independent research and development of manual and automatic transmissions of

Geely Automobile, and achieved fruitful results; now, he is devoted to academic

study in colleges and universities and committed to sorting out and systematically

refining his practical experience and technical accumulation of transmission

research over 30 years, and sharing it with others so as to benefit the industry and

help the development and progress of China’s automotive transmission business.

The book Theory, Design and Application of Automotive Transmissions of the

leading coauthor Chen Yong accumulates the profound knowledge and valuable

experience of first-class transmission experts and scholars at home and abroad,

elaborates the international advanced technology and development trend of automotive transmissions and emphatically explains the mature design theory in the

automotive transmission field and the latest international research and application

progress. It can be used as an engine ering technical book for automotive and

transmission R&D engineers and a reference book for graduates and undergraduates to learn basic theories and carry out academic research. It is a rare masterpiece

of both theory and practice.

Zhao Fuquan

Rotating Chairman of FISITA (2018–2020)

President of Automotive Industry

and Technology Strategy Institute

Tsinghua University, China

v

Page 7

Preface

In order to change the output torque and speed of the engine and other power

systems, it is usually necessary to install a transmission in the transport machinery.

This book deals mainly with the transmissions of road vehicles. Under different

driving conditions, such as standing start, climbing, turning and acceleration, the

torque and speed required by the driving wheel of the vehicle are constantly

changing, while the range of torque and speed change that the engine can provide is

limited. The transmission is to adjust the performance of the engine by changing the

gear ratio and transfer the engine power to the wheels smoothly, reliably and

economically, so as to adapt well to the demands of external load and road conditions and achieve the best match between the characteristic field provided by the

engine and that required by the vehicle.

The automotive transmission is a high technology and process level of typical

products in mass production, and its development and design shall be oriented to

market demands while meeting environmental and regulatory requirements.

Regulatory requirements (such as energy conservation and emissions policies) and

user requirements must be fully considered. The main design objective of the

automotive transmission is to achieve the optimal transformation from engine or

motor power to the vehicle driving force within the wide speed range of the vehicle,

so as to ensure the dynamic property, acceleration and fuel economy of the vehicle.

Meanwhile, the application reliability and service life of new technologies and

processes shall be considered. The transmission design will be increasingly challenging given the increasing demand for fuel consumption, emissions and driveability, especially shift comfort and response speed. The current types of

transmission for passenger vehicles, including Manual Transmission (MT),

Automatic Transmission (AT), Dual Clutch Transmission (DCT), Continuously

Variable Transmission (CVT) and Automated Mechanical Transmission

(AMT) will remain largely unchanged for a long time. However, the application of

hybrid transmissions will grow substantially. The first author of this book worked

as a senior technician in the AT&CVT R&D in the R&D center of JATCO in Japan

for 19 years and was in charge of the R&D of AT and MT in Geely Automobile for

a long time after returning from abroad. He was deeply aware of the rapid progress

vii

Page 8

viii Preface

of transmission technology and accelerated R&D cycle brought by computer

simulation techno logy, and also deeply aware of the urgent demand for systematic

explanation of the transmission development technology in the research and

development.

Therefore, the main purpose of this book is to systematically summarize the

main technical areas of the MT and AT development technology based on practical

development experience, comprehensively elaborate the theory and development

characteristics of the transmissions and display the main development processes

of the transmissions. In particular, many development processes are based on the

experience of trial and error. As a reference book providing main technical information for the research and development of transmission technology, this book is

suitable for engineers working in the field of automobiles and related power

transmission machines and graduate students at school. I would also like to thank

Dr. Guo Lishu, senior technical expert of Geely Commercial Vehicle Research

Institute, Dr. Gao Bingzhao of the College of Automotive Engineering, Jilin

University, for their hard work in this book. I would like to thank Dr. Tian Hua

from SGM Powersoon Research Institute, my doctoral student Zang Libin, Qiu

Zizhen, Li Guangxin, Wei Changyin, my assistant Cao Zhan and other graduate

students from the NEV Research Center of the Hebei University of Technology, as

well as others who have worked hard for this book. I would like to thank the Tianjin

Science and Technology Association for subsidizing this book.

Tianjin, China Yong Chen

Page 9

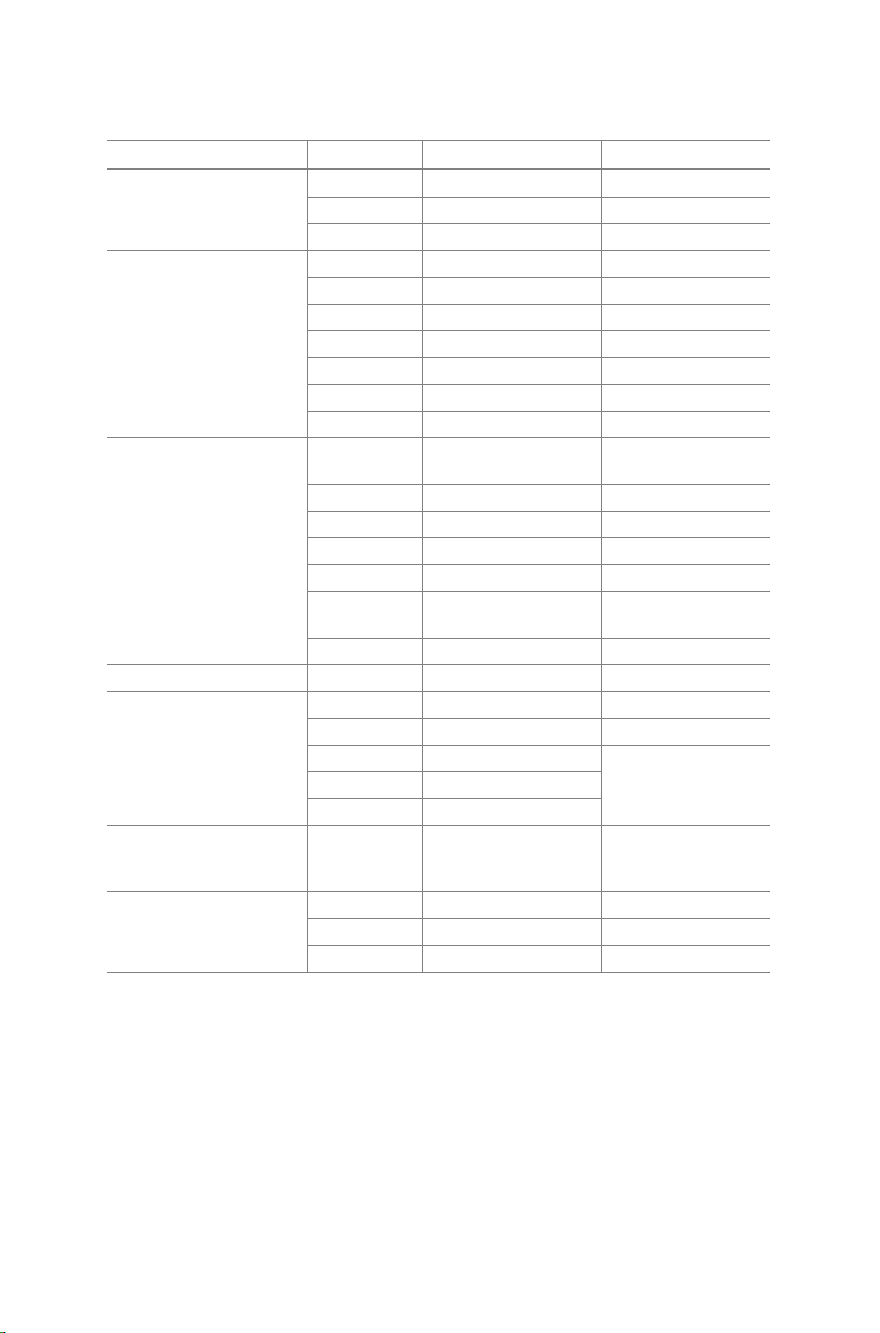

Contents

1 Introduction .......................................... 1

1.1 Transmission Functions and Requirements

1.2 Types, Advantages and Disadvantages of Transmissions

1.3 Basic Structure of Transmission

........................ 12

1.4 Development Status and Trend of Transmission

Bibliography

.......................................... 21

................ 2

...... 3

............ 14

2 Manual Transmission

2.1 Overview

................................... 23

........................................ 23

2.2 Transmission Drive Mechanism

2.3 Synchronizer

..................................... 26

2.4 Transmission Operating Mechanism

2.5 Determination of Gear Ratio

.......................... 42

2.6 Joint Working of Engine and Transmission

2.7 Shift Performance Evaluation

2.8 New Technologies of MT

Bibliography

.......................................... 60

3 Automatic Transmission

3.1 Overview

........................................ 61

................................. 61

......................... 54

............................ 54

3.2 Composition and Control Principle of AT

3.3 Mechanical Structure of AT

.......................... 66

3.4 AT Speed Change Process Analysis

3.5 Hydraulic Control System of AT

3.6 Electronic Control System of aT

3.7 AT Performance Tests

3.8 Development Direction of aT

Bibliography

.......................................... 108

............................... 99

......................... 103

........................ 23

..................... 38

............... 49

................ 63

..................... 78

....................... 84

....................... 98

ix

Page 10

x Contents

4 Continuously Variable Transmission ........................ 109

4.1 Overview

4.2 Composition of CVT

........................................ 109

............................... 111

4.3 Composition and Drive Theory of VDT Belt .............. 117

4.4 Composition and Principle of Hydraulic Control System

4.5 CVT Electronic Control System

4.6 Control of CVT

................................... 145

4.7 Main Performance Tests of Metal Belt CVT

4.8 CVT Upgrade

Bibliography

..................................... 148

.......................................... 153

........................ 140

............... 145

...... 129

5 Dual Clutch Transmission

................................ 155

5.1 Overview ........................................ 155

5.2 System Composition and Working Principle of DCT

5.3 Typical Design Scheme of DCT

5.4 Dual Clutch

5.5 Select-Shift Actuator

...................................... 162

................................ 177

5.6 Hydraulic Control System

5.7 Control System Hardware Design

5.8 Control System Software Design

....................... 159

............................ 180

...................... 190

....................... 195

........ 157

Bibliography .......................................... 199

6 Automated Mechanical Transmission

6.1 Overview

........................................ 201

....................... 201

6.2 Composition and Working Principle of AMT Control

System

.......................................... 202

6.3 Shifter .......................................... 207

6.4 Clutch

6.5 Select-Shift Actuator

6.6 Hydraulic Control System

6.7 AMT Control Strategy

6.8 AMT Performance Evaluation Indexes

Bibliography

7 Transmission for New Energy Vehicle

7.1 Overview

7.2 Power and Economy Performance of HEV

7.3 AMT Hybrid Transmission

7.4 AT Hybrid Transmission

7.5 CVT Hybrid Transmission

7.6 DCT Hybrid Transmission

7.7 Planetary Gear Hybrid Transmission

7.8 Electric Vehicle Transmission

7.9 Other Hybrid Power Plants

Bibliography

.......................................... 210

................................ 214

............................ 217

.............................. 222

................... 227

.......................................... 232

...................... 233

........................................ 233

................ 235

........................... 240

............................. 243

............................ 248

............................ 254

.................... 257

......................... 261

........................... 267

.......................................... 271

Page 11

Contents xi

8 Transmission Design .................................... 273

8.1 Gear Design

8.2 Shaft Design

...................................... 273

...................................... 292

8.3 Bearing Selection and Design ......................... 297

8.4 Case Design

8.5 Parking Mechanism Design

8.6 Synchronizer Design

8.7 Selection of Seals

8.8 Transmission Ventilation Design

8.9 Transmission Tests

Bibliography

...................................... 300

........................... 308

................................ 328

.................................. 345

....................... 350

................................. 351

.......................................... 356

9 Transmission Fluid

9.1 MTF

9.2 ATF

........................................... 357

............................................ 358

9.3 CVTF

9.4 DCTF

..................................... 357

.......................................... 358

.......................................... 360

9.5 Performance Requirements and Tests for Transmission

Fluid

........................................... 362

9.6 Selection of Transmission Fluid

........................ 366

Bibliography .......................................... 369

10 Design of Hydraulic Torque Conve rter

...................... 371

10.1 Working Principle and Characteristics of Hydraulic Torque

Converter

10.2 Pre-design of Hydraulic Torque Converter

........................................ 371

................ 383

10.3 Blade Shape Design ................................ 391

10.4 Numerical Simulation and Analysis of Internal Flow Field

of Hydraulic Torque Converter

10.5 Parameter Adjustment of Hydraulic Torque Converter

10.6 Hydraulic Torque Converter Matching with Engine

Bibliography

11 Planetary Gear Drive

.......................................... 435

................................... 437

........................ 409

........ 428

......... 432

11.1 Theoretical Calculation of Transmission Efficiency

of Planetary Gear Train

11.2 Transmission Efficiency Test of Planetary Gear Train

.............................. 439

........ 454

11.3 Theoretical Calculation of Vibration and Noise

of Planetary Gear Train

11.4 Vibration and Noise Test of Planetary Gear Train

Bibliography

.......................................... 483

.............................. 464

........... 470

12 Electronic Control System of Auto matic Transmission

12.1 Introduction to AT Electronic Control System

12.2 AT Control System Development

...................... 488

............. 485

.......... 485

Page 12

xii Contents

12.3 Validation of System Validity ......................... 503

12.4 Control Strategies of AT

............................. 506

12.5 Modeling of Hydraulic Torque Converter with Lockup

Clutch

12.6 Lockup Clutch Oil Circuit

.......................................... 507

............................ 508

12.7 Study on Control Strategies for Lockup Process of Lockup

Clutch

Bibliography

.......................................... 510

.......................................... 532

13 Automobile and Transmission Vibration and Noise

13.1 Vibration and Noise Foundation

13.2 Automobile Vibration and Noise

....................... 533

....................... 537

............ 533

13.3 Typical Automobile Vibration and Noise ................. 545

13.4 Analysis of Transmission Vibration and Noise

13.5 Typical Transmission Vibration and Noise Control

Bibliography

.......................................... 569

............. 553

.......... 563

Page 13

Chapter 1

Introduction

Since the small torque range of the automobile engine cannot adapt to the requirements of automobile driving under various road conditions, the transmission that can

change the speed ratio and drive torque is adopted in the automotive drivetrain to

make the torque and speed output by the engine and other power systems vary in

a considerable range. This book deals mainly with the transmissions of road vehicles. Under different driving conditions, such as standing start, climbing, turning

and acceleration, the torque and speed required by the driving wheel of the vehicle

are constantly changing, while the range of torque and speed change that the engine

can provide is limited. The transmission is to adjust the performance of the engine

by changing the gear ratio and transfer the engine power to the wheels smoothly,

reliably and economically, so as to adapt well to the demands of external load and

road conditions and achieve the best match between the characteristic field provided

by the engine and that required by the vehicle.

The automotive transmission is a high technology and process level of typical

products in mass production, and its development and design shall be oriented to

market demands and fully consider the user requirements while meeting environmental and regulatory requirements (such as energy conservation and emissions

policies), as shown in Fig. 1.1. The main design objective of the automotive transmission is to achieve the optimal transformation from engine or motor power to the

vehicle driving force within the wide speed range of the vehicle, so as to ensure

the dynamic property, acceleration and fuel economy of the vehicle. Meanwhile,

the application reliability and service life of new technologies and processes shall

be considered. The transmission design will be increasingly challenging given the

increasing demand for fuel consumption, emissions and driveability, especially shift

comfort and response speed. The current types of transmission for passenger vehicles, including manual transmission (MT), automatic transmission (AT), continuously variable transmission (CVT), dual clutch transmission (DCT) and automated

mechanical transmission (AMT) will remain largely unchanged for a long time.

However, the hybrid transmissions will be more widely used and their number will

increase dramatically. The author of this book worked as a senior technician in the

© China Machine Press and Springer Nature Singapore Pte Ltd. 2021

Y. C h e n, Automotive Transmissions, Springer Tracts in Mechanical Engineering,

https://doi.org/10.1007/978-981- 15-6703-2_1

1

Page 14

2 1 Introduction

Consumer demands: comfort and economy

Apply more advanced and efficient technology

Wide speed ratio and

multiple gears

Shift smoothness and economy

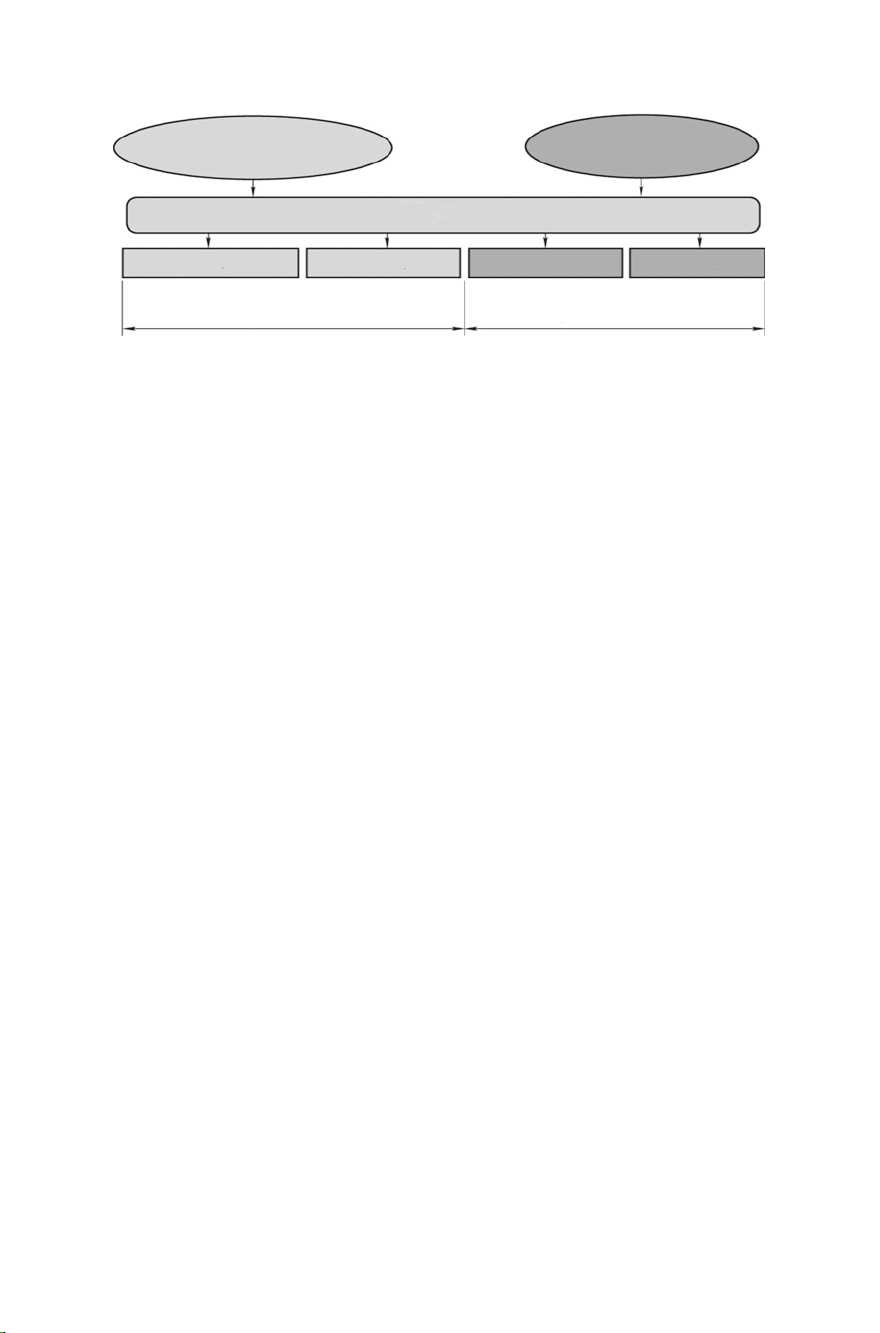

Fig. 1.1 Transmission design requirements

Shift strategy

optimization

Regulatory requirements: low-carbon,

efficient and environmentally friendly

Improve transmission

efficiency

Low-carbon, efficient and environmentall

Lightweight design

y friendly

AT&CVT R&D in the R&D center of JATCO in Japan for 19 years and was in charge

of the R&D of AT and MT in Geely Automobile for a long time after returning from

abroad. He was deeply aware of the rapid progress of transmission technology and

accelerated R&D cycle brought by computer simulation technology, and also deeply

aware of the urgent demand of the R&D personnel for systematic explanation of the

transmission development technology.

Based on the author’s over 30 years of practical experience in the development of

automotive transmissions at home and abroad, this book systematically summarizes

the main technical areas of the MT and AT development technology, comprehensively elaborates the theory and development characteristics of the transmissions

and displays the main development processes of the transmissions. Many development processes are based on the experience of trial and error. As a reference book

providing main technical information for the research and development of transmission technology, this book is suitable for engineers in the field of automobiles and

related power transmission machines and graduate students at school.

1.1 Transmission Functions and Requirements

The function of the transmission is to change the torque and speed of the engine

according to the requirements of the vehicle in different driving conditions, so that

the vehicle has the right traction and speed, and keeps the engine working in the most

favorable working conditions. To ensure the vehicle reversing and the powertrain

separation, the transmission must have forward as well as reverse and neutral. When

power output is required, power output devices shall also be provided.

Main requirements for the transmission:

(1) Guarantee good dynamic and economic indicators of the vehicle. This require-

ment is met by choosing the appropriate transmission gear number and gear

ratio according to the vehicle dead weight capacity, engine performance parameters, tire performance parameters and vehicle use requirements in the overall

vehicle design.

Page 15

1.1 Transmission Functions and Requirements 3

(2) Reliable work and easy control. Automatic gear dropping, gear mixing and

shift impact are not allowed in the transmission during the vehicle driving.

(3) High safety. Guarantee the safe and reliable vehicle driving in any working

conditions.

(4) Small in size and light in weight. This requirement is met by reasonable use of

engineering plastics and other non-metallic materials, and the use of advanced

material forming technology and heat treatment technology.

(5) Low cost. Minimize the cost under the premise of meeting the vehicle

requirements for the transmission.

(6) High transmission efficiency. In order to reduce the gear engagement loss and

bearing friction loss, it is necessary to improve the manufacture and assembly

quality of components and reduce the gear churning loss. For example, the

proper lubricating oil and installed capacity can be selected to reduce the

churning loss and friction loss, thus improving the transmission efficiency.

(7) Low noise. This requirement can be met by adopting helical gears, selecting

a reasonable modification coefficient, making the axial modification and

profile modification and improving the manufacturing accuracy and assembly

stiffness.

(8) Meet the maximum input torque requirements.

(9) Meet the drive mode requirements.

(10) Meet the vehicle layout and installation requirements.

(11) Meet the reliable ramp parking requirements except for the MT.

(12) Meet the limp home requirements.

(13) With respect to the electrical controlled transmission, the hardware of the

control system shall meet the requirements of electromagnetic compati-

bility and anti-interference, and the software shall meet the requirements of

ISO26262, ASPICE, AUTOSAR and other standards.

(14) Consider factors such as driving pleasure and shift comfort and minimize the

shift impact.

1.2 Types, Advantages and Disadvantages of Transmissions

I. Types of automotive transmissions

Depending on the fixation of the gear ratio, the transmission may be classified into

stepped transmission and continuously variable transmission (CVT). The stepped

transmission, with fixed gear ratio, including ordinary transmission and planetary

transmission, is gear-driven and mostly widely used; the CVT, with the gear ratio

changing in a certain range, includes electric and hydraulic types. The variable speed

drive component of the electric CVT is DC series motor and the drive component of

the hydraulic CVT is hydraulic torque converter. The CVT can overcome the sudden

shift, slow throttle response, high fuel consumption and other shortcomings of the

AT and is mostly used in trolley buses and heavy-duty vehicles.

Page 16

4 1 Introduction

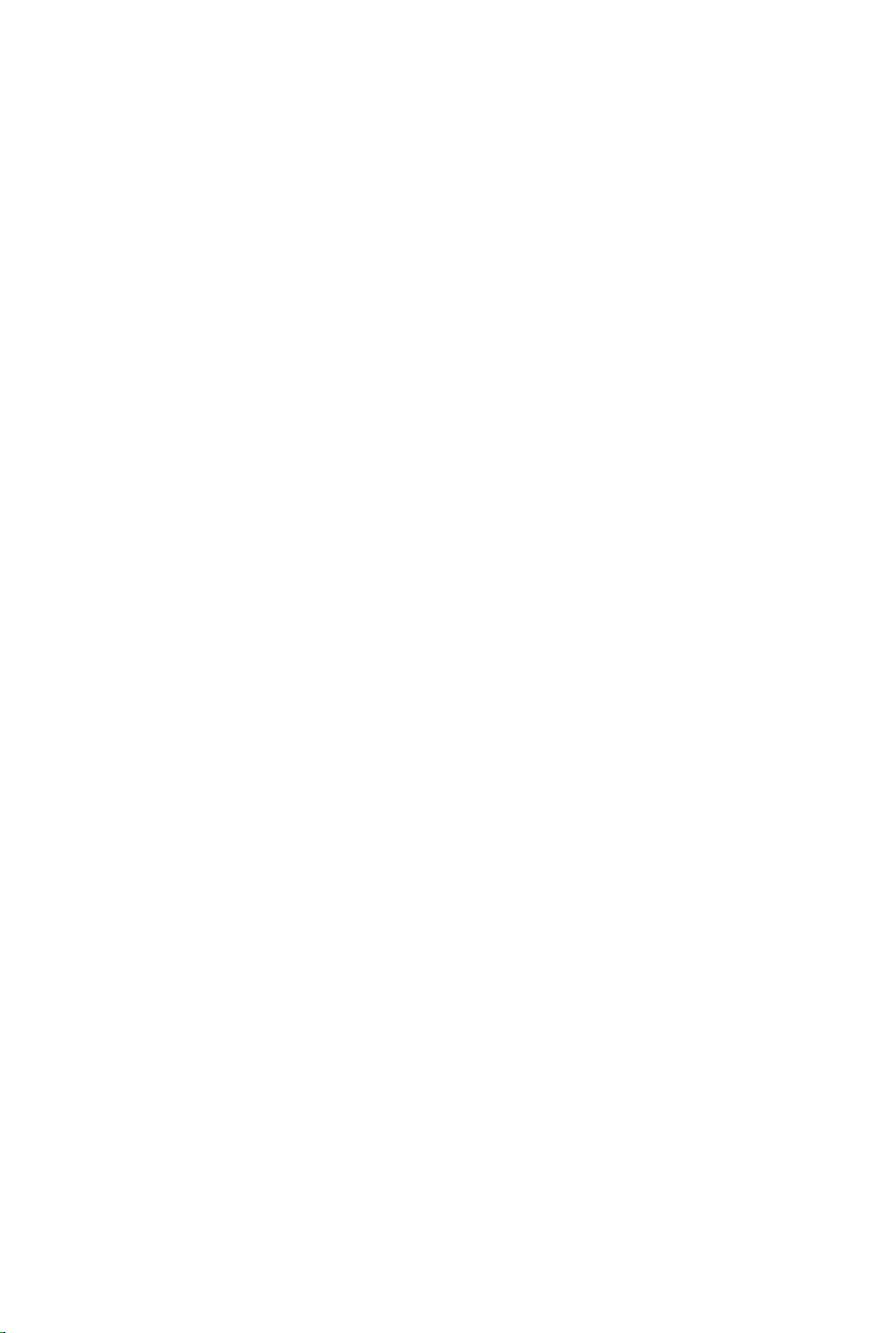

The transmissions used in the passenger vehicles currently include MT, AT, CVT,

DCT, AMT and VIT, as well as the BEV transmission and HEV transmission evolved

on the basis of the above transmissions, as shown in Fig. 1.2.

1. Manual transmission

Manual transmission (MT) is also known as mechanical transmission. The engaging

position of the gears in the transmission is changed by moving the gear shift lever

by hand, thus changing the gear ratio to achieve variable speed. It take a place

in the transmission family because of its high transmission efficiency, high torque

transfer, easy manufacture, low cost, simple structure, low fuel consumption, short

acceleration time and short development cycle. The current MT is mainly 5 speed or

6 speed MT, covering SUV, middle-sized vehicles and compact vehicles. In order to

reduce fuel consumption and improve driving pleasure, the transfer torque increases

MT

Drive

system

AT

NEV

transmi

ssion

HEV transmission BEV transmission

Fig. 1.2 Main types of transmissions for passenger vehicles

AMT CVT

DCT

AT

Page 17

1.2 Types, Advantages and Disadvantages of Transmissions 5

step by step and the 6 speed transmission in the MT will become the mainstream.

ZF and BMW are developing the 7 speed MT currently.

2. Automatic transmission

The automatic transmission (AT) is also known as stepped AT. According to the

different arrangement modes of shafts, AT can be divided into fixed shaft AT and

rotating shaft AT. Due to the large space occupied by the fixed shaft (parallel shaft),

it is impossible to achieve more gears (limited to 5-speed and 6-speed), which is

currently the main technology of Honda. The vastmajority of transmission companies

use the rotating shaft technology solutions. AT may be divided into 4AT, 5AT, 6AT,

7AT, 8AT and 9AT by gear. GM, Volkswagen and other automotive companies have

begun to develop 10AT. With mature technology and small size, 4AT is still the main

AT carried by small cars, although its comfort and economy are poor; 5AT is slightly

better than 4ATin terms of comfort and economy,but has still obvious abrupt shift and

limited late development space; 6AT has relatively superior economy and comfort

and has become a mainstream trend for small, compact and middle-sized vehicles;

7AT and 8AT have been adopted by Lexus, BMW, Audi, Benz and other highend imported models. 8AT has been successfully developed by domestic Shengrui

Transmission Co., Ltd. and installed in Landwind; 9AT represents the innovation of

science and technology has been developed successfully by ZF and Aisin Seiki.

3. Continuously variable transmission

The continuously variable transmission (CVT) becomes an important branch of automotive automatic transmission field since it can produce continuously changing gear

ratio, achieve the best match between the engine and powertrain, simplify the operation, reduce the driver’s labor intensity, increase driving safety, driving smoothness

and comfort and improve emission. CVT is classified into metal pushing V-belt type

CVT, chain type CVT and KRG. With light weight, small volume, simple s tructure,

smooth shift, relatively high cost, inconvenient maintenance and limited carrying

capacity, the metal pushing V-belt type CVT is used in small and compact cars and

has more room for improvement because of its unparalleled comfort. The chain type

CVT is the main technology of Schaeffler in terms of CVT and has higher transmission efficiency and more compact structure than the metal pushing V-belt type CVT,

but its disadvantage is that the protruding pin on the side of the chain will produce

noise when it comes into contact with the pulley point. At present, the KRG may be

unfamiliar to most people, but this kind of transmission may become the mainstream

transmission for low-emission vehicles in the future. Its low cost, high efficiency,

simple structure and multiple advantages in function and comfort deserve people’s

attention.

4. Dual clutch transmission

The dual clutch transmission (DCT), as a new AT, arranges the transmission gears by

odevity respectively on the two input shafts connected with two clutches, completes

Page 18

6 1 Introduction

the shift process and achieves power shift through the alternate switching of clutches.

DCT has the advantages of AT and AMT. With high transmission efficiency, simple

structure and low production cost, it guarantees the dynamic and economy performance of the vehicle and greatly improves the vehicle operating comfort. DCT is

divided into DDCT and WDCT. DDCT is also divided into electro-hydraulic DDCT

and electric DDCT. The former is complicated in structure, needs to be improved

in reliability and is used in Volkswagen vehicles; the latter is simple and reliable

in structure and will become the mainstream trend in the development of small and

medium torque AT in the future. With large carrying capacity, WDCT will be used

greatly in the intermediate class and above vehicles.

5. Automated mechanical transmission

The automated mechanical transmission (AMT), based on the traditional fixed shaft

transmission, controls the hydraulic or electric actuating system through the electronic control unit by use of the electronic technology and automatic transmission

theory to achieve the clutch disengagement and engagement, gear selecting and

shifting, so as to achieve the automatic control of start and shift. AMT has a certain

development space in mini and small cars due to its high transmission efficiency,

easy manufacturing and low cost, but it has not much development space in models

above the compact level due to power failure in the shift process.

The AMT usually consists of electrically controlled hydraulic AMT and electrically driven AMT. The AMT with the core of electro-hydraulic actuator in the

electrically controlled hydraulic AMT has been widely applied in Chery QQ3, Riich

M1, Chevrolet Sail, SAIC MG3 and other models; compared with the electrically

controlled hydraulic AMT, the electrically driven AMT has simpler structure, better

reliability and lower cost and is the mainstream trend of AMT development.

6. Vit

VIT is a new concept of high-power and high-efficiency mechanical CVT successfully developed on the basis of the meshing principle of sliding vane CVT movable

teeth. The working surface of the sliding vane CVT movable teeth is overlapped by

a series of sliding vanes and any shape of meshed tooth profile can be formed by

free stepless slip of the sliding vanes. This design idea is equivalent to the “differentiation and reintegration” of the gears. That is, any required tooth profile, i.e. the

sliding vane CVT movable teeth can be formed by organic combination of multiple

elements. Since the slip direction of the sliding vanes is different from the force direction, the sliding vanes are free to deform with the current meshed tooth profile, while

the force direction is perpendicular to the free slip direction or the angle between

them is self-locking in the equivalent friction angle during the power transmission.

Therefore, the sliding vanes will not change the shape of the tooth profile when

bearing force. With the “rigid and flexible fusion, and movable teeth solidification”

effect, high carrying capacity and transmission efficiency, VIT is the true sense of

“movable teeth meshing CVT” and is applied in saloon cars, passenger cars, trucks

and other high-power and high-torque vehicles.

Page 19

1.2 Types, Advantages and Disadvantages of Transmissions 7

7. BEV transmission

The BEV transmission mainly includes single reduction gear, multi-speed transmission and the wheel-side drive motor integrating reducer and motor. At present,

the single speed reducer with fixed speed ratio is mostly used in the small electric vehicles. This drive mode has simple structure and low manufacturing cost, but

it puts forward higher requirements for the traction motor that the traction motor

shall provide higher instantaneous torque in the constant torque area and higher

running speed in the constant power area, so as to meet the vehicle acceleration

performance requirements and maximum speed design requirements. Meanwhile,

the single speed reducer with fixed speed ratio has the problem of low motor utilization efficiency. In order to ensure the maximum vehicle speed, the speed ratio of

the reducer is often relatively small, which makes the traction motor in a longterm high torque and high current working condition, and relatively low motor efficiency, thus wasting the battery energy and reducing the driving range. The electric

vehicle drivetrain tends to be multi-speed to make the electric vehicles better meet

their dynamic performance and reduce their requirements for traction motors and

batteries. Oerlikon Graziano developed a two-speed transmission to match small

electric vehicles. Antonov designed a new efficient 3 speed AT for BEV that optimizes the powertrain size, weight and development costs while improving the energy

efficiency and guaranteeing the dynamic performance.

8. HEV transmission

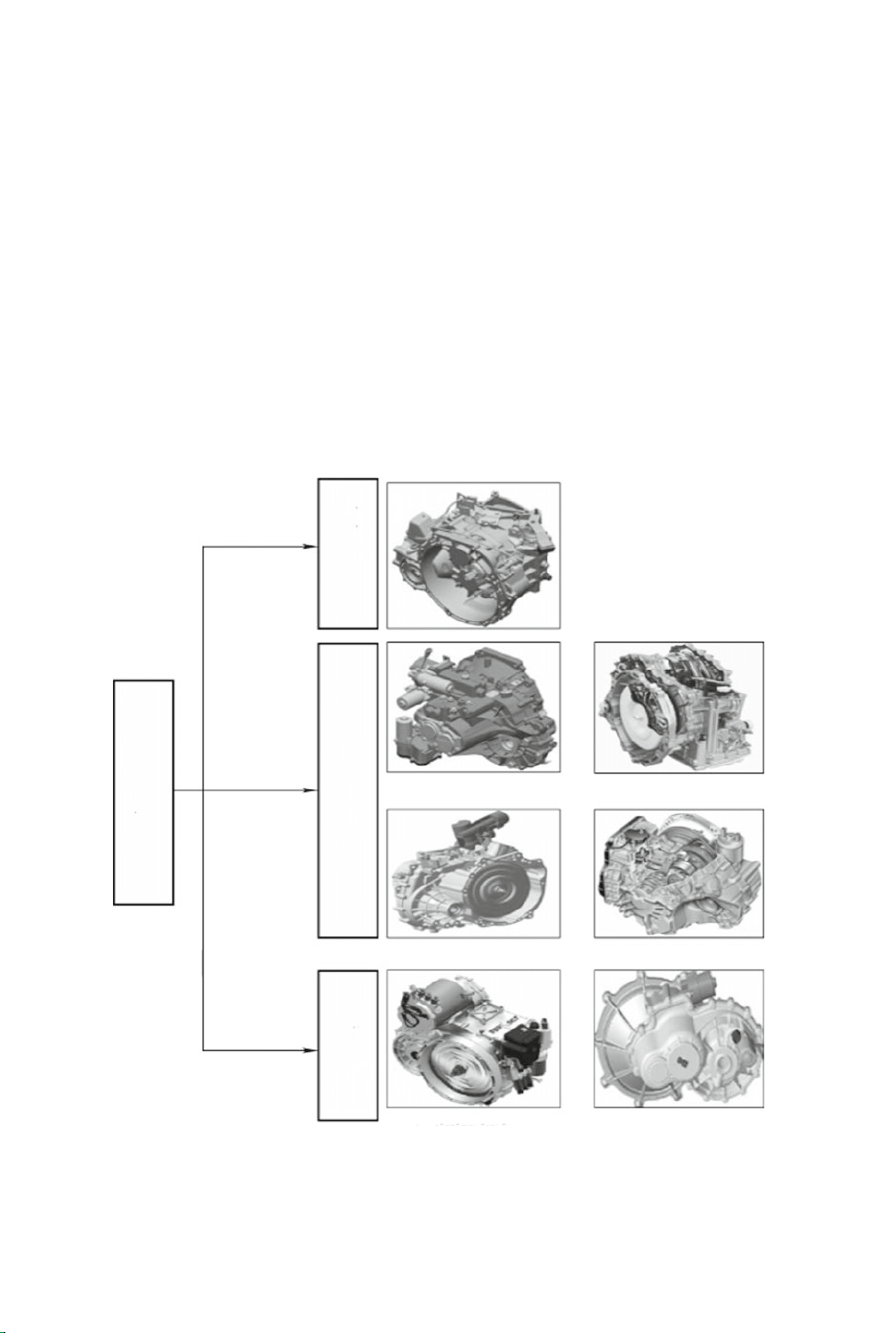

(1) Hybrid drive type: before introducing the HEV transmission, it is important

to know the hybrid drive type. As shown in Fig. 1.3, the hybrid drive mainly

includes tandem hybrid drive, parallel hybrid drive, power-split hybrid drive

and other hybrid drive.

Hybrid drive types

Tandem hybrid drive

P0 hybrid P4 hybrid

Fig. 1.3 Hybrid drive types

Parallel hybrid drive

P1 hybrid

Power-split hybrid drive

P2 hybrid

Other hybrid drive

P3 hybrid

Page 20

8 1 Introduction

(1) Tandem hybrid drive. The engine is completely decoupled from the driving

wheel and simply drives the generator to charge the power battery, which

drives another motor through the motor controller to keep the vehicle

moving. This scheme has low overall efficiency due to many power drive

links, but it is comfortable because the engine is completely decoupled

from the driving wheel.

(2) Parallel hybrid drive. Depending on the motor arrangement on the whole

vehicle, it is divided into P0 (BSG), P1 (ISG), P2, P3 and P4 structural

hybrid drives. In P0 structural hybrid drive, the motor is integrated in the

position of the generator of the traditional engine, playing the role of power

generation, assistance and starting, and acting as the generator in energy

recovery to recover the braking energy; in P1 structural hybrid drive, the

motor is integrated at the output end of the engine crankshaft, playing the

role of power generation, assistance and starting, and acting as the generator

in energy recovery to recover the braking energy; in P2 structural hybrid

drive, the motor is also integrated between the engine and the transmission.

The difference is that the motor is connected to the engine and transmission separately through the clutch, playing the role of power generation,

assistance and starting, and acting as the generator in energy recovery to

recover the braking energy. The motor drives the vehicle alone, either fully

hybrid or plug-in hybrid, which is one of the main forms of hybrid drive;

in P3 structural hybrid drive, the motor is integrated at the output end of

the transmission, playing the role of assistance and power generation, and

acting as the generator in energy recovery to recover the braking energy.

The motor drives the vehicle alone, either fully hybrid or plug-in hybrid;

in P4 structural hybrid drive, the engine drives a drive axle and the motor

drives the other drive axle. The motor plays the role of assistance and

power generation and acts as the generator in energy recovery to recover

the braking energy. The motor can also drive the vehicle alone, either fully

hybrid or plug-in hybrid.

(3) Power-split hybrid drive. It integrates the engine and two motors by means

of the planetary gear train to achieve various functions of the hybrid drive.

A typical example is Toyota Prius HEV, also known as the eCVT because

of the use of planetary gear train and motors to shift the output end of the

engine and planetary gear train.

(4) Other hybrid drive. A typical example is Honda Fit 7DCTH hybrid drive,

in which, the motor is connected to an input shaft of 7DCT through the

drive mechanism, forming a new and unique drive form. In this scheme, the

motor needs to be synchronously tracked in shift of each gear connected

with the motor input shaft, so as to reduce the difference between the active

and passive speeds of the synchronizer and prolong the service life of the

response synchronizer.

Page 21

1.2 Types, Advantages and Disadvantages of Transmissions 9

(2) Common transmissions on HEV: the traditional automotive transmissions are

used in HEVs, among which AT is more widely used, as follows:

The AMT is the ideal choice for HEV transmissions. The electrically driven transmission based on AMT is characterized by coupling the motor used in the NEV

with AMT through high-intensity silent chain drive, which solves the power failure

problem during shift. This new electrically driven transmission fully combines the

advantages of the motor and the AMT to significantly reduce fuel consumption. The

7H-AMT hybrid transmission developed by FEM based on AMT i s characterized by

that the drive motor transfers power through other gears and outputs a certain torque

in the upshift to eliminate the impact caused by power failure during shift.

The application schemes of AT in HEV include coupling the motor at the input

end of the transmission and coupling the motor at the output end of the transmission.

The recent new scheme is to replace the hydraulic torque converter of the AT with

motor.In these schemes, the lubrication system shall be improved and the mechanical

fuel pump of the traditional AT is replaced with an electronic fuel pump or a new

electronic fuel pump is added; otherwise, the EV mode will be difficult to meet the

system lubrication requirements and fast start-stop requirements.

CVT is most frequently used in the mass produced HEVs. The HEV AT is characterized by powertrain integration. That is, the motor is integrated with the transmission, making the system structure more compact, power drive more stable and

control performance better.

The applications of DCT in HEV mainly include that the drive motor is connected

to the input shaft 1 of the transmission through the reducing gear, that the drive motor

is connected to the input shaft 2 of the transmission through the reducing gear and

that the drive motor is connected to the input shaft of the transmission through the

reducing gear. The advantage of the first two schemes is that the motor drive can

change the speed, but the disadvantage is that the motor needs to be synchronously

tracked in the synchronous engagement of the gear of the input shaft connected to the

motor; the advantage of the latter scheme is that the motor may not be synchronously

tracked in the shift, but the disadvantage is that the motor drive cannot change speed.

In addition, the PRIUS hybrid power system is a typical example of PSHEV. The

biggest feature of this system is to use a planetary gear train to couple two motors

and an engine together, so that a single planetary gear train can realize the functions

of CVT. See Table 1.1 for typical hybrid transmission applications.

II. Advantages and disadvantages of transmissions

The transmission, as an important part of the vehicle powertrain system, determines

the power output of the vehicle and has a direct impact on the fuel economy, comfort

and reliability of the vehicle. Different types of transmissions have different characteristics. The advantages and disadvantages of mainstream transmissions in today’s

market are shown in Table 1.2.

Page 22

10 1 Introduction

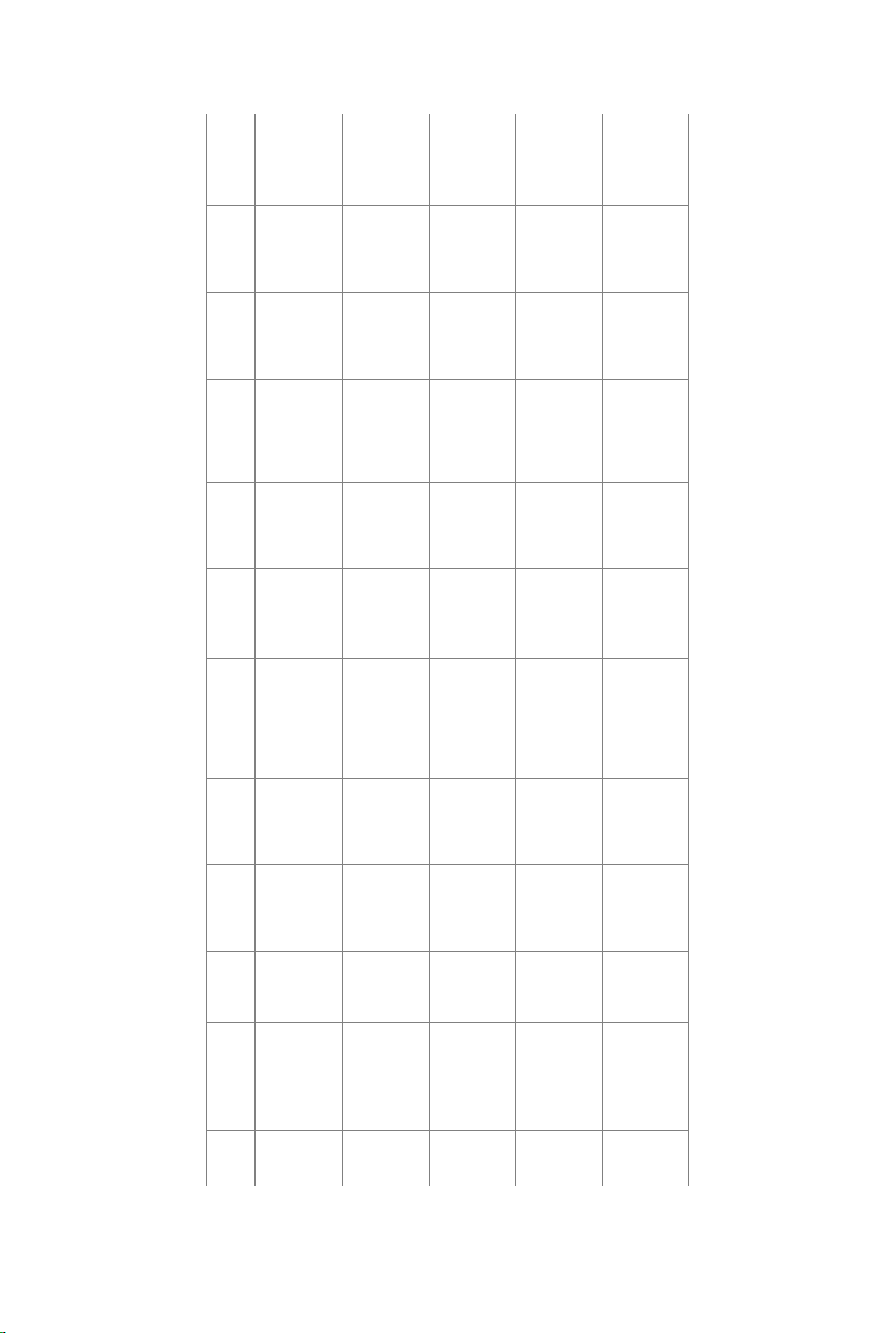

Table 1.1 Typical hybrid transmission applications

Structure Manufacturer Model Transmission

Start-stop-BSG Buick LaCrosse 6AT

Chevrolet Malibu 6AT

Chery A5 BSG Original transmission

ISG (E-M-C-T) Honda Fit Hybrid MT/LVT

Honda CIVIC Hybrid (II) CVT

Honda CIVIC Hybrid (III) CVT

Honda Insight CVT

Honda CR-Z MT/LVT

BMW BMW 7 Hybrid 8AT

Benz Benz S400 Hybrid 7AT

ISG (E-C-M-T) Hyundai Hyundai Sonata hybrid

6AT

power

Nissan Nissan Fuga 7AT

Audi Audi A6 Hybrid 8AT

Audi Q5 Hybrid quattro 8AT

Audi Q7 Hybrid (EOL)

Porsche Porsche Panamero S

8AT

Hybrid

Volkswagen Volkswagen Touareg 8AT

Parallel rear axle drive Peugeot Peugeot 3008 6AMT

Series-parallel/dual-motor

single

planetary gear train

Toyota Toyota Prius Single reduction gear

Nissan Nissan Altimn Hybrid Single reduction gear

Ford Fusion Hybrid –

Ford Escape Hybrid

Ford C-MAX Hybrid

Series-parallel/dual-motor

dual

Lexus RX400h/HighlanSer

Hybrid

Single reduction gear

planetary gear train

Series-parallel/dual-motor

three-planetary gear train

Lexus GS450h/LS600h Single reduction gear

BMW BMW X6 7AT

Benz Benz ML450 7AT

Page 23

1.2 Types, Advantages and Disadvantages of Transmissions 11

Unlimited

power

Unlimited

application

power

Unlimited

cost

power

Limited

cost

power

Limited

cost

power

Limited

cost

cost

Life Cost Scope of

Good Low Unlimited

Emission

performance

economy

Reliability Fuel

smoothness

good

High Unlimited

Relatively

good

good

Good Bad Relatively

uninterrupted

power

Good Bad High Limited

Relatively

good

Relatively

good

interruption

High Unlimited

good

Good Relatively

Relatively

good

Relatively

good

approximately

without

interruption

Relatively

low

Relatively

good

good

Power failure Bad Good Relatively

good

Torque Efficiency Comfort Shift

Large High Poor Power failure Good Good Relatively

Transmission

form

Table 1.2 Advantages and disadvantages of transmissions

MT Stepped

manual

Large Low Good Approximately

automatic

AT Stepped

Limited Low Best Power without

CVT Stepless

automatic

Large High Good Power

automatic

DCT Stepped

Large High Relatively

automatic

AMT Stepped

Page 24

12 1 Introduction

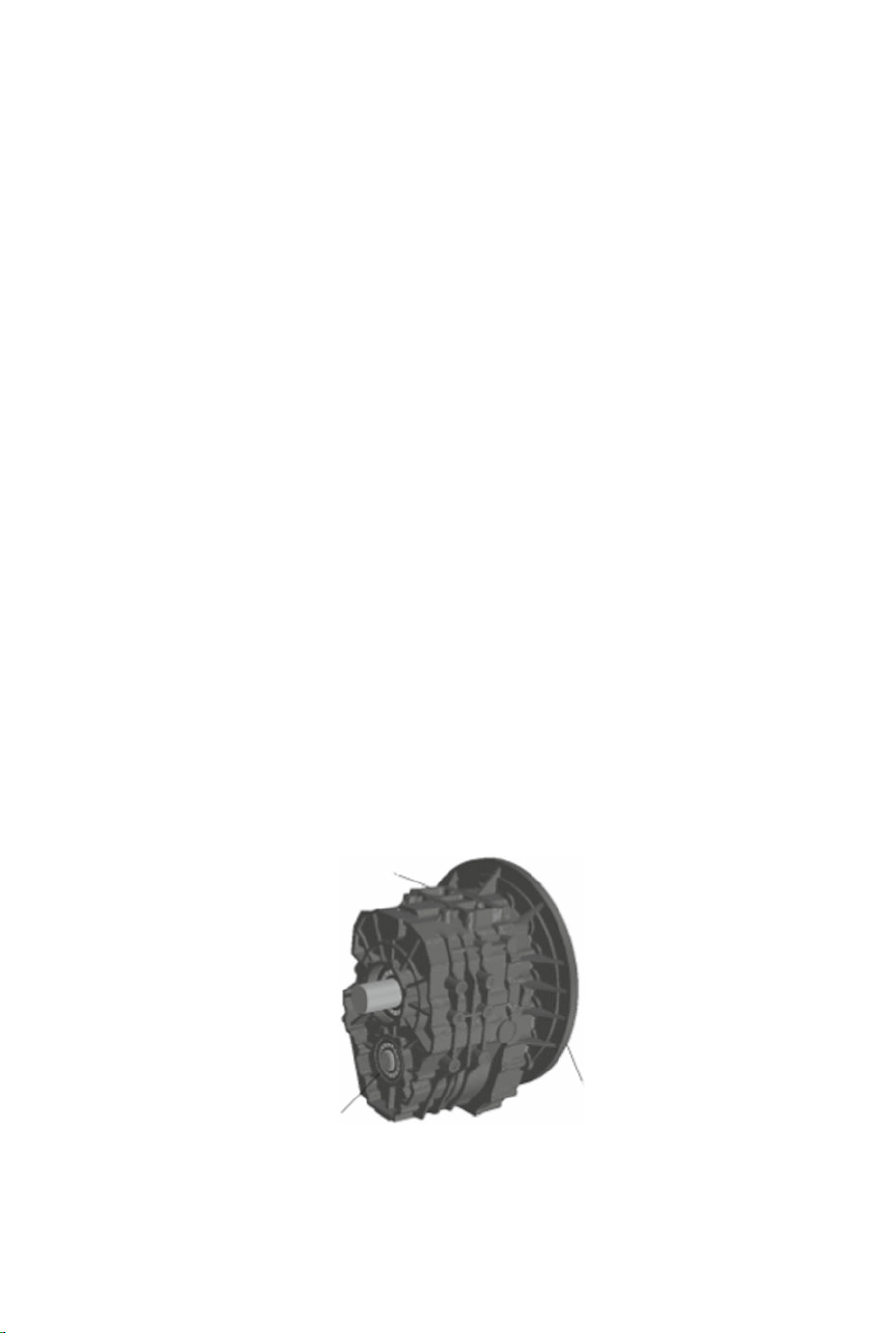

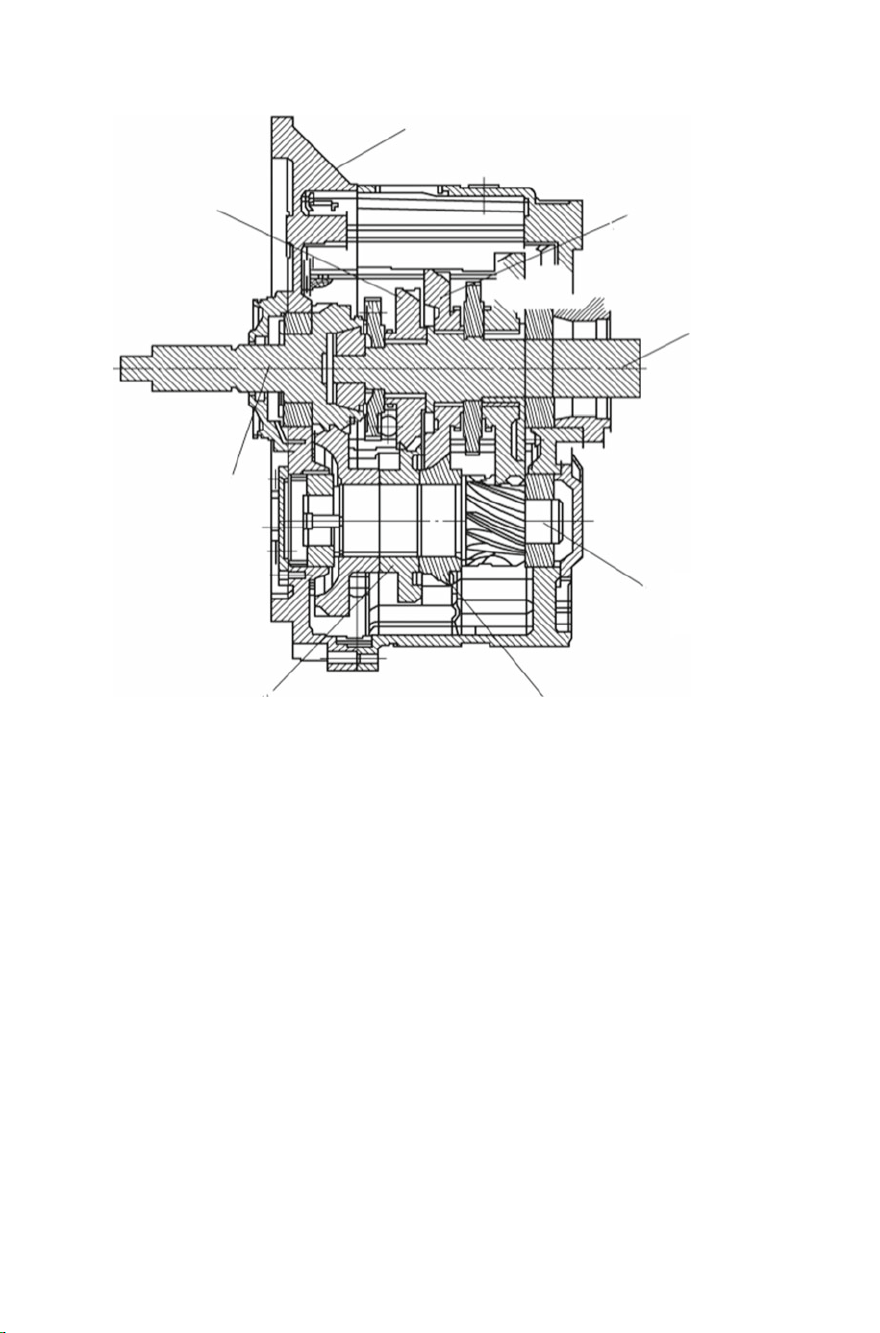

1.3 Basic Structure of Transmission

The transmission consists of a case, a drive part and a shift control device.

1. Case

As the basic part, the case is used to mount and support all parts of the transmission

and to store the lubricating oil, above which, there is a precise bore for mounting

the bearing. The transmission bears variable load, so the case shall be rigid enough,

with complex ribs on the inner, most of which are castings (made of gray cast iron,

commonly HT200), as shown in Fig. 1.4.

For the convenience of installation, the transmission part and the shift control

device are often made into split type, and the transmission cover is bolted to the case

and positioned reliably. The case is provided with refueling and fuel drain hole and

fuel level inspection ruler hole, and the heat dissipation should also be considered.

2. Drive part

The drive part consists of the transmission gears, shaft, bearing and other driving

media. The geometric dimensions of the shaft are determined by the checking calculation of the strength and stiffness; the material is selected mainly depending on

whether its stiffness meets the requirements. The carbon steel has nearly equal elasticity modulus with the alloy steel, so the shaft is generally made of carbon steel

(usually steel 45) and the alloy steel is used only when the gear and shaft are integrated or when the bearing is under heavy load. The gears are usually made of low

carbon alloy steel (e.g. 20CrMnTi and 20MnCrS). The shaft is mostly splined with

the gears and has the advantages of good centering, reliable transmission of power

and small extrusion stress. The spline part and the bearing mounting site of the shaft

are surface hardened. The shaft is mainly supported by a rolling bearing, with simple

lubrication, high efficiency, small radial clearance and reliable axial positioning and

Controller mounting hole

Fig. 1.4 Transmission case

Flange plate

Bearing hole

Page 25

1.3 Basic Structure of Transmission 13

Case

3 speed gear

Input shaft

3 speed gear

Fig. 1.5 Transmission profile

2speed gear

Output shaft

Countershaft

2speed gear

is mainly lubricated by splash lubrication (v>25 m/s, thrown to the wall as long as

the viscosity is appropriate). The transmission profile is shown in Fig. 1.5.

3. Shift control device

In MT, the driver controls the shift, while in AT, the electronic actuating system

completes shift partly or entirely relying on a lot of automation technology. The

neutral, reverse and park are still completed by the driver by controlling the shift

control device. The elements in the shift control device are selected according to the

transmission type and vehicle type. The engaging elements of the transmission for

passenger vehicles mainly include:

(1) Internal engaging elements: shift f ork (Fig. 1.6a), shift synchronizer (Fig. 1.6b),

locking device, multi-disk clutch and brake.

(2) External engaging elements: shift level system, inhaul cable and gear shift lever

Page 26

14 1 Introduction

Fig. 1.6 (b) Shift

synchronizer

1.4 Development Status and Trend of Transmission

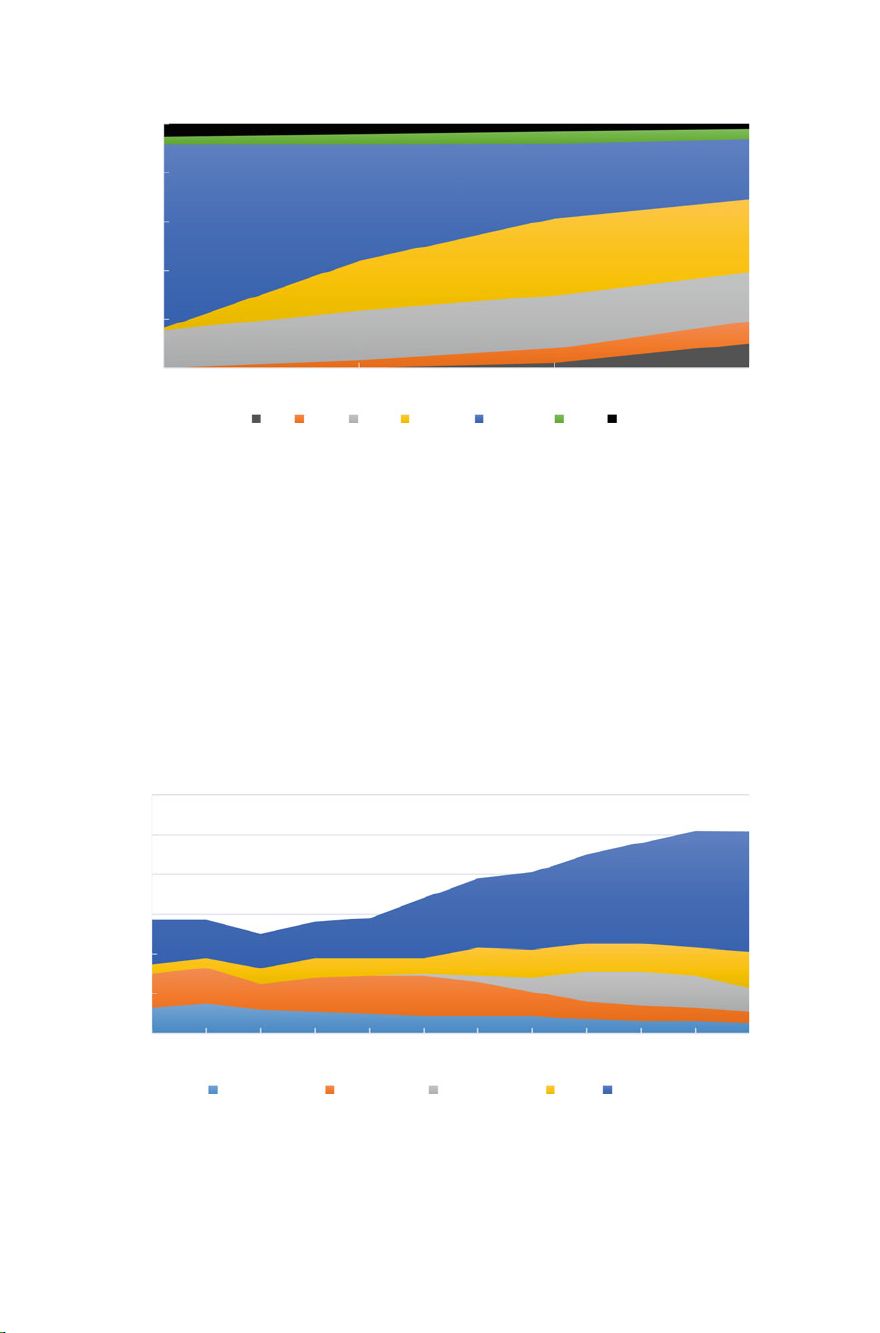

I. Development status of transmissions

The demand for transmissions varies greatly from region to region. The CVT has

benefited to a certain extent from the continued demand among Japanese users for

small cars that change speeds automatically, making it the best-selling AT type in

Japan. Figure 1.7 shows the demand for transmissions in Japan. The main transmis-

sion enterprises in Japan develop to the high gears (8 and 9) AT. Moreover, the CVT

is developing fast and gradually developing towards high torque.

AT possesses absolute advantage in the US, mainly because the consumers require

simple control and comfortable driving of vehicles but are not sensitive to fuel

consumption, thus forming the AT-dominated AT market in the US. Figure 1.8 shows

the demand for transmissions in the US. The main transmission enterprises in the

US are currently targeting the 6AT. With the continuous development of the wet

clutch technology of BorgWarner, the WDCT will also grow rapidly in the US. The

700

10,000 units

600

500

400

300

200

100

0

2007 2008 2009 2010 2011 2012 2013 2014 2015 2016 2017 2018

3-5 speed AT 6 speed AT 8-9 speed AT CVT DCT&AMT

Fig. 1.7 Demand for transmission in Japan

Year

Page 27

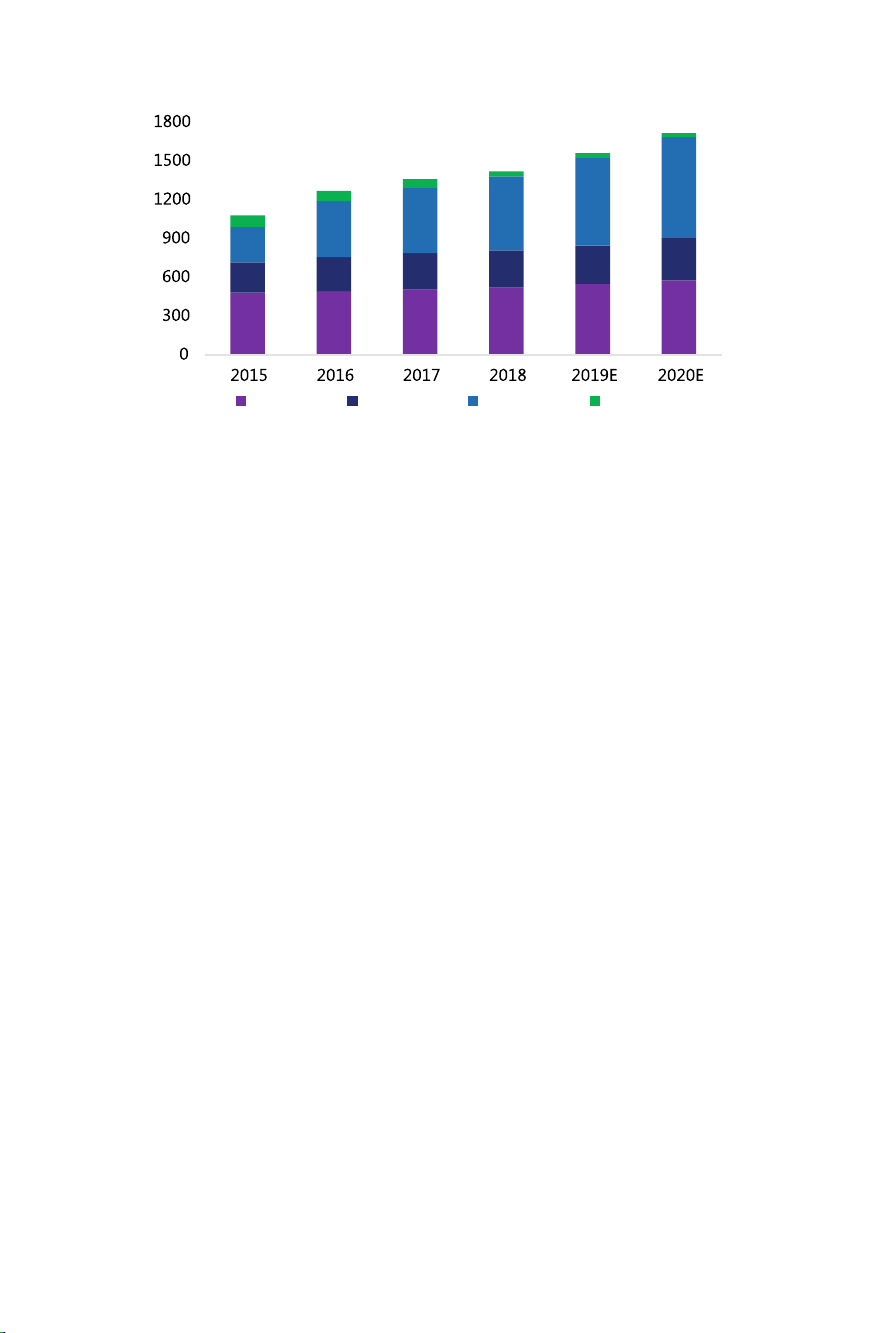

1.4 Development Status and Trend of Transmission 15

100%

80%

60%

40%

20%

0%

2015 2020 2025 2030

EV DHT CVT AT9/10 AT6/7/8 DCT MT

Fig. 1.8 Demand for transmission in the US

Year

higher gear AT produced by the European transmission company is adopted for the

high-grade vehicles.

The European consumers pay attention to driving experience and driving pleasure, like the feeling brought by manual control of the machinery, and think a great

deal of fuel consumption. Therefore, after emergence, the DCT with energy saving

and kinetic characteristics immediately became the darling of the European market.

Figure 1.9 shows the demand for transmissions in Europe. The main transmission

enterprises in Europe have developed towards the high speed (8 and 9) AT and

DCT, and the engineering companies are also pushing the hybrid power technology

vigorously.

600

10,000 units

500

400

300

200

100

0

2007 2008 2009 2010 2011 2012 2013 2014 2015 2016 2017 2018

3-5 speed AT 6 speed AT 8-9 speed AT CVT DCT&AMT

Fig. 1.9 Demand for transmission in Europe

Year

Page 28

16 1 Introduction

10,000 units

AT CVT DCT AMT

Fig. 1.10 Demand for transmission in China

In China, an emerging auto market, the traditional AT was the main choice for

previously automatic transmission vehicles. However, in recent years, the biggest

factors influencing consumers’ decision to buy cars are “price” factors (vehicle

fuel consumption and vehicle price). The number of vehicles assembled with DCT

has increased significantly, and the share of vehicles assembled with CVT has also

increased. Figure 1.10 shows the demand for transmissions in China. Due to accumulated experience in MT development and good process inheritance of AMT and DCT,

the transmission technology develops rapidly in recent years with the involvement

of the engineering companies with outstanding transmission development capability,

and the companies are also trying to make breakthroughs in the AT and CVT fields.

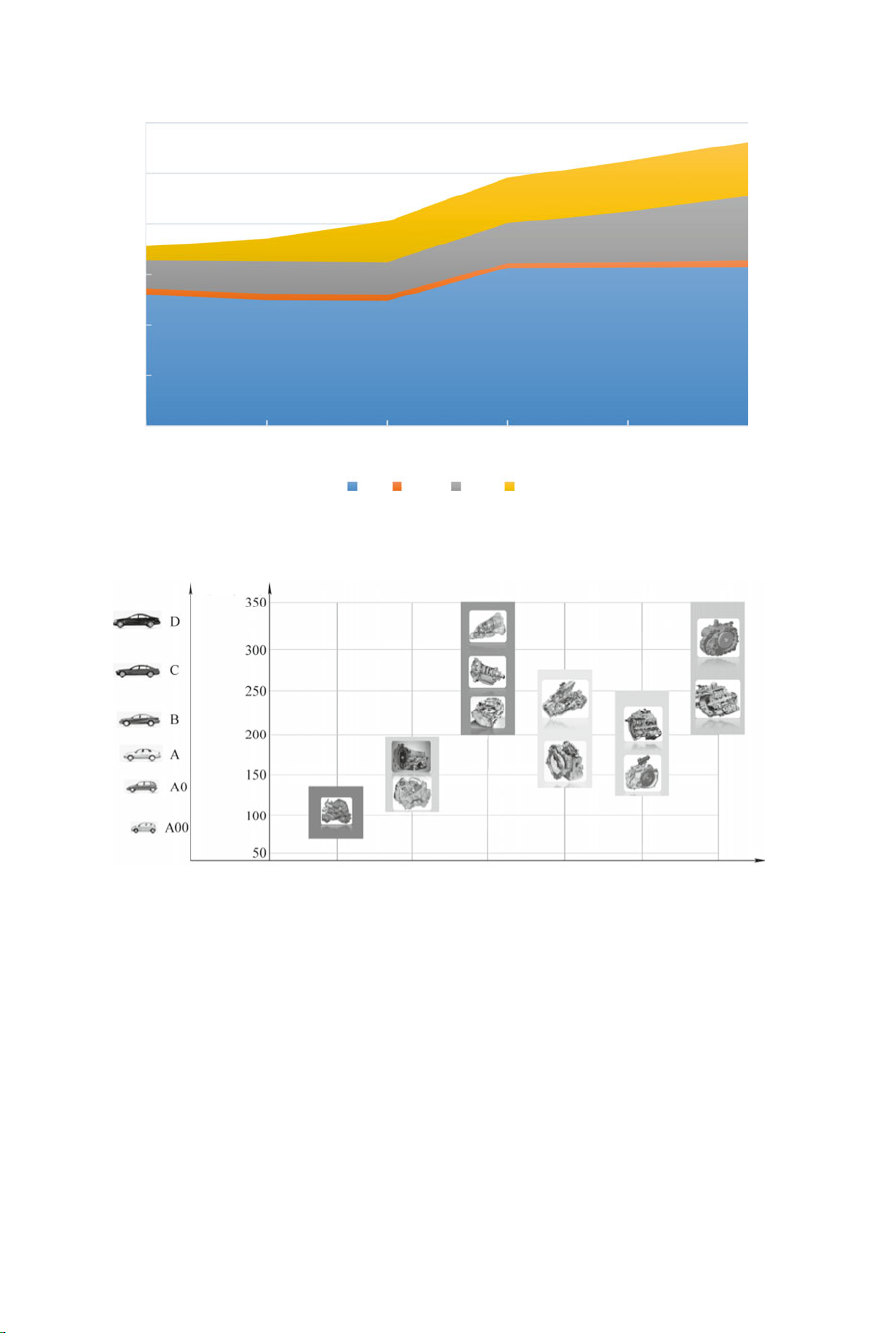

As AT continues to be multi-speed, DCT grows most and the demand for the AT

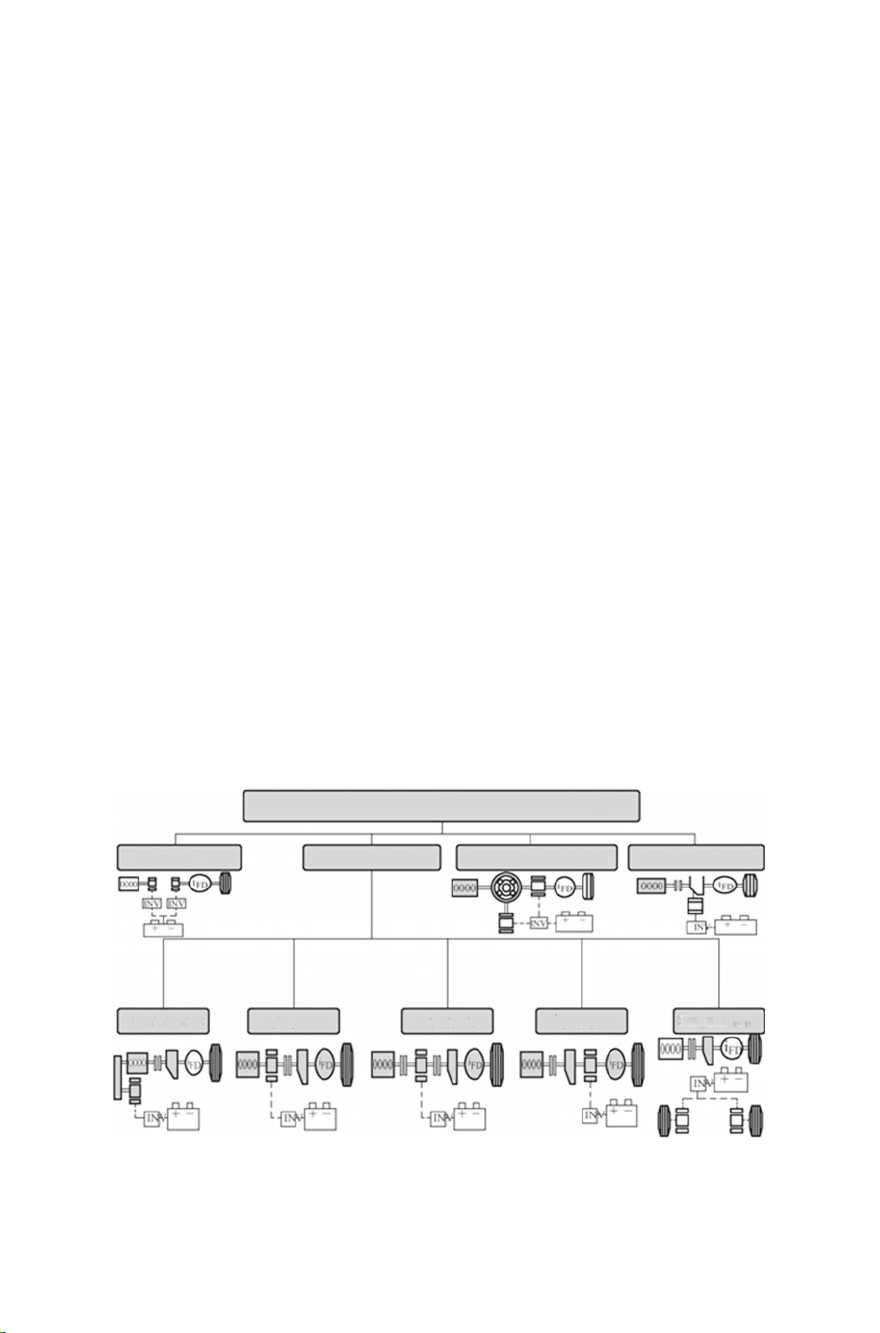

is increasing year by year. Figure 1.11 shows the demand for AT.

The carrying status of the AT in the passenger vehicles in China is shown in

Fig. 1.12. The 4 speed and 5- speed ATs are mainly assembled in 1.3–1.6 L small

cars and compact cars; the 6-7-8 speed ATs are mainly assembled in the vehicles with

the displacement of 2.0 L and above; the CVT (without hydraulic torque converter) is

mainly assembled in 1.5–1.8 L compact cars; the CVT (hydraulic torque converter)

is mainly assembled in 1.5–2.5 L vehicles; the DDCT is mainly assembled in the

vehicles with the displacement of 2.0 L and below and the WDCT in the vehicles with

the displacement above 2.0 L; the number of applications of turbocharged engine

and DCT combination will increase rapidly.

II. Development trend of transmissions

Energy conservation, environmental protection, safety and high efficiency is the

theme of the development of automotive transmissions, with the pursuit of comfort,

economy and safety from the perspective of consumers and the pursuit of high efficiency, low carbon and environmental protection from the perspective of regulations.

Thus, the transmission companies are required to apply advanced and efficient design,

manufacturing and control technologies and advanced materials to achieve wide gear

Page 29

1.4 Development Status and Trend of Transmission 17

60

Million units

50

40

30

20

10

0

2013 2015 2017 2018 2019 2020

AT AMT CVT DCT

Fig. 1.11 Demand for AT

Torque /(N.m)

Year

5-6 speed AMT 4-5 speed AT 6~8 speed AT CVT DDCT WDCT

Fig. 1.12 Carrying status of the AT in the passenger vehicles in China

ratio and multi-speed of transmission, optimization of the shift strategy,improvement

of the transmission efficiency and light weight of transmissions.

1. Development trend of MT

(1) Multi-speed and large gear ratio of transmission: the three-axis 6 speed

transmission was gradually replacing the dual-axis 5 speed transmission

under thedominance of some European, American and Japanese companies

from twoor three years ago. The 7speed MT supplied by ZF for Porsche 911

Carrera and Carrera S was used in the passenger vehicles for the first time.

Page 30

18 1 Introduction

With increased low speed gear ratio and more reasonable gear, it achieves

the comprehensive optimization of dynamic and economy performance.

(2) High efficiency and reduced NVH: the following measures can be taken

to improve the transmission efficiency: multi-speed transmission; reduce

the immersion height of the differential mechanism in the lubricating oil

and change the lubricating mode from traditional gear splash lubrication

to combination of gear splash lubrication and oil guide lubrication, so as to

reduce the churning loss of the lubricating oil; replace the traditional conical

bearing with ball bearing and roller bearing to reduce the bearing friction

loss; use efficient transmission lubricating oil. To meet the requirement

of noise reduction, the best match of the clutch and transmission shaft

with the transmission shall be considered in addition to the corresponding

measures taken for the transmission, such as precise control of the backlash

in circular tooth of the transmission matching gear, selection of appropriate

gear material, application of low noise bearing and full consideration to the

impact of the gear engagement on the transmission structure in the design

phase.

(3) Light weight and low cost: the light weight and low cost can be achieved

by use of advanced forming technology, reasonable plastics and other nonmetallic materials. The lightweight design of the transmission case based

on CAE can shorten the development cycle, reduce the development cost

and improve the product competitiveness.

(4) Further reduce the space occupied by the transmission and optimize the

space and size of all parts. Due to the application of the start-stop system,

a highly integrated solution with low cost and high reliability that can

identify the neutral and reverse is applied through the detection of reliable

neutral position signals.

2. Development trend of AT

(1) Development trend of hydraulic torque converter: flattened hydraulic torque

converter, increasing torque ratio, extended locking range and sliding friction

range and improved hydraulic torque converter range. With the application of

the engine supercharging technique, the engine torque is increasing and higher

requirements are put forward for the vibration reduction of the transmissions.

The torque converter with centrifugal pendulum vibration absorber and the

torque converter with turbine vibration absorber are presented, significantly

improving the vibration damping performance of the torque converter. The

hydraulic part is optimized to improve the hydraulic torque converter capacity

and optimize the axial space.

(2) Multi-speed AT. The 6~9 speed AT is gradually replacing the 4 or 5 speed trans-

mission. With the increased gears, the transmission may have a larger gear ratio

range and a reasonable gear ratio distribution. ZF has successfully developed

9AT and some companies are already working on 10AT.

(3) AT modular design. The modular design is very obvious in AT, including modu-

larization of hydraulic torque converter, modularization of hydraulic valve body,

Page 31

1.4 Development Status and Trend of Transmission 19

modularization of clutch, modularization of brake, etc. According to different

user requirements, various schemes can be realized through different module

combinations, reducing the design changes, shortening the development cycle

and improving the product competitiveness.

(4) Application of multiple solenoid valves. Multiple solenoid valves are adopted

to control the shift, which can significantly improve the shift quality. To control

the system pressure and achieve shift, six PWM solenoid valves with high flow

capacity are set in the 6AT of ZF, simplifying the valve body structure and

improving the comprehensive performance of the transmission. The transmission efficiency can be further improved if the leakage-free solenoid valve or the

near-leakage-free solenoid valve is used.

(5) Component integration to reduce the mass. For example, the ZF6H26 employs

a gear called Lepetler, which reduces the mass of the gear train by 11 kg; in

A750E/A750F of Toyota, 3 clutches are integrated into the same clutch hub;

the dog clutch used for ZF9HP is longer but smaller than the ordinary clutch

and looks like a spline; some transmission companies use magnesium alloy

transmissions, further reducing the weight of the transmission.

(6) Use of new materials and new processes: the application of new lightweight and

high-strength materials and the application of the stamping forming technology

make great contributions to reducing cost and weight.

3. Development trend of CVT

(1) Improve the CVT efficiency

(1) Reduce the cone disk pressing loss. The applied pressing force and the

adjustment and pressing force are optimized by using a torque sensor

to effectively reduce the flow of the hydraulic system in the adjustment

process, so that a smaller hydraulic pump can be used, which not only

reduces the fuel consumption of the pump, but also reduces the related

energy loss.

(2) Reduce the chain loss. The connecting piece and oscillation pin are used,

characterized by high efficiency, small size, reliable work and low noise.

(3) Reduce the hydraulic pump loss and use the low-energy electric hydraulic

pump.

(4) Reduce the CVT bearing loss and replace the hydraulic torque converter

with the clutch.

(2) Reduce the CVT cost. With respect to the processing technology, the cone disk

group stamped by the steel plates can be used as the main part to reduce the

cost and weight and the shaft machined by cold extrusion can also be used to

reduce the cost; according to different market requirements, the dry clutch or

wet clutch can be used instead of the hydraulic torque converter to reduce the

cost; the CVT case may be optimized to reduce the weight and cost.

(3) Comprehensive optimization of the engine and CVT precise control. The torque

sensor has been widely used, especially for small batch supercharged engines,

to optimize the pressing force and achieve precise control of CVT; it can be

Page 32

20 1 Introduction

integrated with the engine for integrated control to further reduce the fuel

consumption and emission.

(4) Increase the drive torque. Increasing CVT transfer torque has been the focus

of research and development. The new structure of CVT drivetrain, such as

the steel belt designed by BOSCH using new flexible ring materials, with better

dynamic performance, lower cost, higher efficiency and smaller center distance,

can transfer higher torque. The modular design can meet the special customer

requirements in the rapidly developing market, shorten the R&D cycle, and

improve the market competitiveness. The CVT is one of the coupling mechanisms between the HEV engine and the drive motor. An HEV with a CVT

drivetrain can reduce the fuel consumption by 30% and emissions by 50%.

4. Development trend of DCT

(1) Wide gear ratio, multi-speed and light weight: achieve the wide gear ratio,

multi-speed and light weight on the premise of ensuring transmission efficiency.

(2) Modular design: e.g. electro-hydraulic actuator of the motor-controlled DCT,

gear selecting and shifting actuator and wet dual clutch.

(3) Integrated control: the DCT control is combined with engine, ABS, ESP, EPS

and ACC control to realize the integrated control of the powertrain, improve the

performance of the powertrain and optimize the control effect.

(4) Hybrid powertrain: the DCT is combined with the motor/generator to form the

hybrid powertrain, enabling separate engine drive, separate motor drive, and

combined engine and motor drive. When braking, the motor/generator is in the

generating state, and the kinetic energy of the vehicle is converted into electric

energy and stored. This scheme provides the HEV with a dynamic coupling

device that is easy to implement.

(5) Integration and intelligence: all functions of the transmission are integrated into

one unit to reduce the fault sources and improve reliability. In terms of control

strategy, adaptive control, fuzzy control and other intelligent control methods

are adopted to improve the adaptive ability of DCT.

5. Development trend of AMT

(1) Powertrain integration: the AMT control is combined with engine, ABS, ESP,

EPS and ACC control through integrated control to realize the integrated control

of the powertrain, improve the performance of the powertrain and optimize the

control effect.

(2) Use of new structure: for example, ZEROSHIFT has developed a new AMT

technology that uses a series of sliding claws and tooth sockets to allow both

gears to engage at the same time when shifting gears. It has all the advantages

of a dual clutch, with a simple design and low cost.

(3) Hybrid powertrain: the AMT is combined with the wheel-side motor/generator

to form the hybrid powertrain, enabling separate engine drive, separate motor

drive, and combined engine and motor drive. During the shift, the motor drives

the vehicle to improve the dynamic performance of the vehicle; when braking,

the motor/generator is in the generating state, and the kinetic energy of the

Page 33

1.4 Development Status and Trend of Transmission 21

vehicle is converted into electric energy and stored. This scheme provides the

HEV with a dynamic coupling device that is easy to implement.

(4) Integration and intelligence: all functions of the transmission are integrated into

one unit to reduce the fault sources and improve reliability; in terms of control

strategy, adaptive control, fuzzy control and other intelligent control methods

are adopted to improve the adaptive ability of AMT.

In conclusion, due to the increasing traffic congestion and the increasing number

of female drivers, more and more users choose automatic transmission for the convenience of driving; the ATtechnology continues to be mature, the quality and efficiency

are improving and the coverage of models is increasing; in recent years and in the next

few years, most of the AT in mass production is DCT, and the output of Chinese and

European models based on DCT will exceed that of Japanese models based on CVT;

6AT has entered the mature stage, and the AT with more gears will be mainly applied

to high-end models. The overall market share of AT is flat or slightly decreased; the

market share of the AMT will increase slightly due to fuel consumption and cost. The

self-owned brand AT is increased mainly due to the decrease of DCT and MT, but

the reduction rate will not be too fast due to the limitation of consumers’ purchasing

power. The substantial incentives taken by the government in taxation, subsidies and

other aspects are the main reason for the rapid growth of the NEV market. In order

to meet the fuel consumption standard of 5 L/100 km in 2020, enterprises need to

vigorously develop new energy vehicles.

Bibliography

1. Yong Chen (2008) New development and trend of automatic transmission technologies.

Automot Eng 30(10):938–945

2. Ge A (2001) Automatic transmission (I)—overview of automatic transmission. Automob

Technol (5):1.3

3. Guangqiang Wu, Weibin Yang, Datong Qin (2007) Key technique of dual clutch transmission

control system. Chin J Mech Eng 43(2):13–21

4. Li J, Zhang J, Feng J, et al (2000) Development, current situation and forecast of automated

mechanical transmission. Automob Technol (3):1.3

5. Mingkui Niu, Xiusheng Cheng, Bingzhao Gao et al (2004) A study on shifting characteristics

of dual clutch transmission. Automot Eng 26(4):453–457

6. Yang W, Wu G, Qin D (2007) Drive line system modeling and shift characteristic of dual clutch

transmission powertrain. Chin J Mech Eng 43(7):188–194

7. Niu M, Gao B, Ge A, et al (2004) Dual-clutch type automatic transmission system. Automob

Technol (6):1.3

8. Guo L, Ge A, Zhang T et al (2003) AMT shift process control. Trans Chin Soc Agri Mach

34(2):1.3

9. Yongjun Li, Shuxin Chen, Yong Cui et al (2003) Integrated control of the starting process of

automated mechanical transmission. Automot Eng 25(2):178–181

10. Ge A (2001) Automatic transmission (II)—hydraulic torque converter. Automob Technol

(6):1.5

11. Cao G, Ge A, Zheng L, et al (2005) Clutch engagement control during gear shifting process in

automated manual transmission. Chin J Mech Eng 41(12):234–238

Page 34

22 1 Introduction

13. Lei Y, Yi Y, Ge A (2001) Integrated and intelligent shifting control of automated mechanical

transmission. Automot Eng 23(5):311.314

14. Lun Jin, Xiusheng Cheng, Li Sun et al (2005) Simulation and studies on dual-clutch automatic

transmission. Automob Technol 8:4–7

15. Liao C, Zhang J, Lu Q (2005) Coordinated powertrain control method for shifting process of

automated mechanical transmission in the hybrid electric vehicle. Chin J Mech Eng 41(12):37–

41

16. Qin D, Liu Y, Hu J, et al (2010) Control and simulation of launch with two clutches for dual

clutch transmissions. Chin J Mech Eng 46(18):121.127

17. Yong C, Wenjiang Z, Wenzhong L (2009) Present situation and future trends of automatic

transmission in China. SAE-China Congr Proc

18. BingZhou, Qinghua Jiang, YiYang (2011) Transmissionratio optimization with dual objectives

of power performance and economy for a two-speed electric vehicle. Automot Eng 33(9):792–

797

19. Xiaoming Weng (2009) A study on the shift quality of wet double clutch transmission. Automot

Eng 31(10):927–931

20. Justin K, Anne-Catrin U, Lowy FD (2015) Staphylococcus aureus infections: transmission

within households and the community. Trends Microbiol 23(7):437–44

21. Haydon PG, Giorgio C (2006) Astrocyte control of synaptic transmission and neurovascular

coupling. Physiol Rev 86(3):1009–1031

22. Oh HR, Song H (2012) Energy efficient MAC protocol for delay-sensitive data transmission

over wireless sensor network. Wireless Commun Mob Comput 12(9):755–766

23. Kumnuan U, Prasert A, Dowell SF, et al (2005) Probable person-to-person transmission of

avian influenza A (H5N1). New England J Med 352(4):333–340

24. Clayton D (2010) A generalization of the transmission disequilibrium test for uncertain

haplotype transmission. Am J Hum Genet 65(4):1170–1177

25. Jackson JB, Musoke P, Fleming T et al (2003) Intrapartum and neonatal single-dose nevirapine

compared with zidovudine for preventionof mother-to-child transmission of HIV-1 in kampala,

uganda: 18-month follow-up of the HIVNET 012 randomised trial. Lancet 362(9387):859–868

26. Seto WH, Tsang D, Yung RWH, et al (2003) Effectiveness of precautions against droplets

and contact in prevention of nosocomial transmission of severe acute respiratory syndrome

(SARS). Lancet 361(9368):1519–1520

27. Han SH, Lee JH (2005) An overview of peak-to-average power ratio reduction techniques for

multicarrier transmission. IEEE Wirel Commun 12(2):56–65

Page 35

Chapter 2

Manual Transmission

2.1 Overview

Despite the rapid development of automatic transmission technology, the traditional

engine-matched manual transmission (MT) will continue to play an important role

for some time to come, mainly because of its low cost, high efficiency and reliable

operation. At present, 5 speed MT is mainly used in China, and some cars start to

carry 6 speed MT, covering SUV, middle-sized and compact vehicles. The 6 speed

MT will gradually become the mainstream. ZF and BMW are developing the 7 speed

MT.

By the engine and drive shaft connection mode, the MT may be classified into

FF layout, FR layout and RR layout; by the form and arrangement form of the shaft,

the MT can be classified into two-shaft and three-shaft MT; by the gear type, the

MT can be classified into spur gear and helical gear types; by the synchronizer type,

the MT can be classified into constant pressure, inertial and inertial boost types and

the most widely used type currently is the inertial synchronizer of the structures

including slide, lock pin, lock ring and multi-cone types; by the number of gears,

the MT can usually be classified into 5, 6 and 7 speed transmissions. The FF layout

is mostly used for the cars. With the multi-speed development and restricted by the

spatial and axial dimensions of the transmissions, the three-shaft 6 speed or 7 speed

transmission will gradually become the mainstream transmission.

2.2 Transmission Drive Mechanism

An MT mainly consists of the powertrain, shift system, lubrication system and case.

The powertrain consists of the input shaft, output shaft, gears, bearing, synchronizer

and differential mechanism; the shift system consists of the shift fork, gear shifter

shaft, self-lock device and interlock device. Figure 2.1 is the structural diagram of

MT. The transmission has 6 forward gears and 1 reverse gear (R gear) and is of

© China Machine Press and Springer Nature Singapore Pte Ltd. 2021

Y. C h e n, Automotive Transmissions, Springer Tracts in Mechanical Engineering,

https://doi.org/10.1007/978-981- 15-6703-2_2

23

Page 36

24 2 Manual Transmission

Shift system

Case and lubrication system

Fig. 2.1 Structural diagram of MT

Powertrain

Case and lubrication system

3-parallel shaft structure (1 input shaft and 2 output shafts). It has been widely used

in the FF passenger vehicles because of its small axial distance and easy spatial

arrangement. Figure 2.2 shows the MT drive diagram, where, g1–g17 are gears and

S1–S4 are synchronizers. The drive lines of all gears are as follows:

1 speed drive line: clutch C → input shaft → gear g2 → gear g9 → left shift

of synchronizer S1 → output shaft 1 → gear g7 → gear g17 → differential

mechanism → wheel.

2 speed drive line: clutch C → input shaft → gear g3 → gear g10 → right shift

of synchronizer S1 → output shaft 1 → gear g7 → gear g17 → differential

mechanism → wheel.

3 speed drive line: clutch C → input shaft → gear g5 → gear g12 → right shift

of synchronizer S2 → output shaft 1 → gear g7 → gear g17 → differential

mechanism → wheel.

4 speed drive line: clutch C → input shaft → gear g4 → gear g11 → left shift

of synchronizer S2 → output shaft 1 → gear g7 → gear g17 → differential

mechanism → wheel.

5 speed drive line: clutch C → input shaft → gear g4 g4 → gear g15 → left

shift of synchronizer S3 →

output shaft → gear g13 → gear g17 → differential

mechanism → wheel.

6 speed drive line: clutch C → input shaft → gear g6 → gear g16 → right shift

of synchronizer S3 → output shaft 2 → gear g13 → gear g17 → differential

mechanism → wheel.

Page 37

2.2 Transmission Drive Mechanism 25

Fig. 2.2 MT drive diagram

Input shaft 1

Input shaft

Input shaft2

R speed drive line: clutch C → input shaft → gear g1 → gear g8 → gear g14

→ left shift of synchronizer S4 → output shaft 2 → gear g13 → gear g17 →

differential mechanism → wheel.

Based on the above analysis, the gear ratios of all gears are shown in Table 2.1.

The number of teeth of each gear is represented by Z

, and the subscript i corresponds

i

to the gear label in Fig. 2.2. In reverse gear, the input shaft rotates in the opposite

direction to the output gear of the main reducer; in other gears, the input shaft rotates

in the same direction as the output gear of the main reducer.

Table 2.1 Gear ratio of each gear

Gear K 1 2 3 4 5 6 R

Gear ratio i

Z9×Z

gk

Z2×Z

Z10×Z

17

Z3×Z

7

Z12×Z

17

Z5×Z

7

Z11×Z

17

Z4×Z

7

Z15×Z

17

Z4×Z

7

Z16×Z

17

Z6×Z

13

Z14×Z

17

13

Z1×Z

17

13

Page 38

26 2 Manual Transmission

2.3 Synchronizer

As an important part of MT, the synchronizer has a very important impact on the

main technical indicators of the transmission such as shift portability and smoothness,

can reduce the shift force on the shift knob, and reduce the shift impact and driver

fatigue. An ideal synchronizer should have good synchronization performance and

locking performance, which can not only achieve the shortest synchronization time