Spirit XE500, XE400, XE200, XE300, XE100 User Manual

SERVICE MANUAL

XE100

XE200

XE300

XE400

XE500

Table of Contents

Troubleshooting Guide

Electronic System……………………………………………….3

Mechanical System……………………………………………...4

Repair Procedures |

|

Procedure 1 (Test adapter for voltage).…………………………5 |

|

Procedure 2 (Test wire harness)........…………………………..5 |

|

Procedure 3 (Test gear motor)..............………………………...6 |

|

Procedure 4 (Alignment of sensor and magnet)...……………….6 |

|

Procedure 5 (Adjustment of brake cable)……………………….7 |

|

Procedure 6 (Incline controller wiring)....................................... |

7 |

Procedure 7 (XE Engineering mode)………………………........8 |

|

Procedure 8 (XE400/500 Incline calibration................................ |

8 |

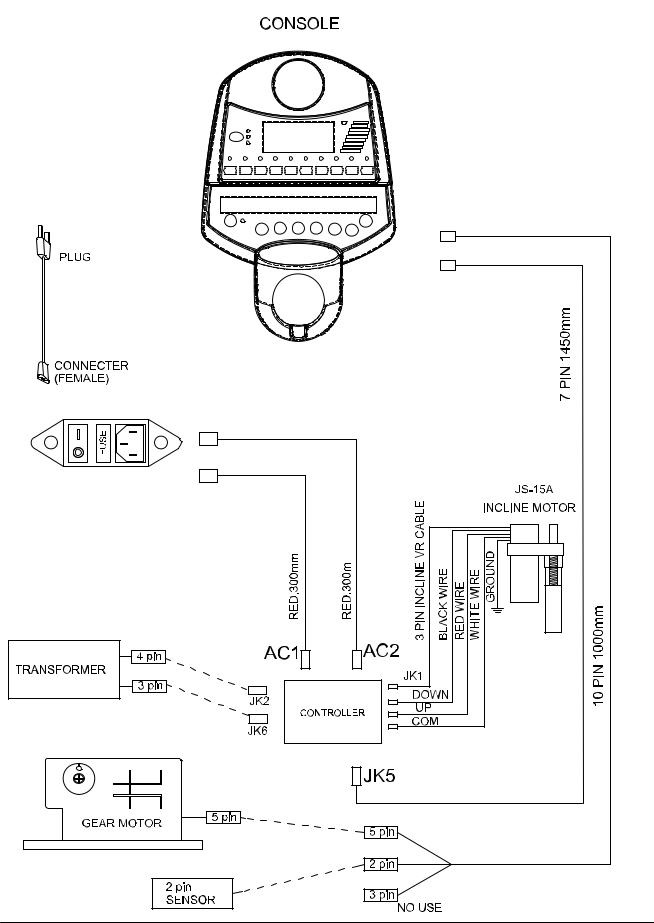

Procedure 9 (XE400/500 wiring schematic)................................ |

9 |

Warranty |

|

Contacting Customer Service…………………………………....10 |

|

XE Warranty……………………………………………............11 |

|

Warranty Policy………………………………………………….12 |

|

Parts Order Form………………………………………………...13 |

|

Warranty Labor Credit Form…………………………………….14 |

|

XE100 |

|

Exploded View...…………………………………………………15 |

|

Parts List......................................................................................... |

16-18 |

XE200 |

|

Exploded View....………………………………………………...19 |

|

Parts List...................................................................................... |

20-22 |

XE300 |

|

Exploded View....………………………………………………...23 |

|

Parts List...................................................................................... |

24-27 |

XE400 |

|

Exploded View............................................................................. |

28 |

Parts List...................................................................................... |

29-32 |

XE500 |

|

Exploded View.............................................................................. |

33 |

Parts List....................................................................................... |

34-38 |

2

Troubleshooting Guide

ELECTRONIC SYSTEM

|

No power to the console |

1. Unit must be plugged into an outlet with power |

||||

|

|

|

2. Test adapter for voltage with a volt meter. (Procedure 1) |

|||

|

|

|

3. Disconnect console, test harness for voltage. (Procedure 2) |

|||

|

|

|

|

|

|

|

|

No resistance change |

1. When the UP or DOWN buttons are pressed, listen for the sound |

||||

|

|

|

of the gear motor running. |

|||

|

|

|

2. If you cannot hear the motor running, remove the console and |

|||

|

|

|

set the volt meter to the ohms setting. |

|||

|

|

|

-Measure between the red and the yellow wires; it |

|||

|

|

|

should be around 5K ohms +/- (500 ohms). |

|||

|

|

|

-Measure between the red and orange wires and then |

|||

|

|

|

between the yellow and orange wires. These two measure |

|||

|

|

|

ments should add up to the measurement between the red |

|||

|

|

|

and yellow. |

|||

|

|

|

-If these measurements are correct, then the potentiometer |

|||

|

|

|

on the gear motor is good. |

|||

|

|

|

-Measure between the black and brown wires. The meter |

|||

|

|

|

should read close to a short, about 1-5 ohms. |

|||

|

|

|

If all of these readings are correct, the motor and harness are |

|||

|

|

|

good and the console needs to be replaced. |

|||

|

|

|

If any of the readings are not correct, the problem is either the |

|||

|

|

|

harness or the gear motor. In this case, you need to take the |

|||

|

|

|

same measurements from the wires directly on the gear motor. |

|||

|

|

|

(Procedure 3) |

|||

|

|

|

3. If you do hear the motor running, make sure the motor cable is |

|||

|

|

|

properly connected to both the gear motor and the brake, and |

|||

|

|

|

the cable is properly adjusted. (Procedure 5) |

|||

|

|

|

|

|

|

|

|

Incline does not work |

1. Varify that the incline motor wires are plugged in correctly |

||||

|

|

|

where the rail assy. connects to the main body of the unit. (should be |

|||

|

|

|

black to black, red to red, white to white, and the 3 wire harness |

|||

|

|

|

connected) |

|||

|

|

|

2. Check to be sure that all wires are connected to the incline |

|||

|

|

|

controller correctly. |

|||

|

|

|

|

|||

|

No speed, distance, or RPM reading |

1. Check for proper alignment of speed sensor. (Procedure 4) |

||||

|

|

|

2. Check flywheel for magnet. (Procedure 4) |

|||

3

Troubleshooting Guide

MECHANICAL SYSTEM

Resistance too high |

1. See Procedure 5 in repair procedures section. |

Thumping noise

1.Clean and lube wheels and rails.

2.If there is still a thump, check for loose bolts.

3.If there is still a thump, order new pedal arm bushing housings with IGOS plastic bushing.

Squeaking noise in the pedal

1. Order and install a new connecting arms.

(XE100 &XE200)

Adjustable pedal not staying in the desired position

1. Order and install new threaded bushing and crank pin.

(XE300)

Slide wheels jumping off

of the track

1.Clean wheels and tracks with rubbing alcohol. All of the sticky and/or dirty lube must be removed from both the wheels and the tracks.

2.If the aluminum track has been damaged, order a new aluminum track.

4

Repair Procedures

PROCEDURE 1: Test adapter for voltage

1.1Plug adapter into a working outlet.

1.2Turn on meter to test for DC voltage.

1.3Put one lead into the end of the plug and the other lead to the metal on the outside.

1.4 The adapter will be labeled 9VDC or 12VDC. When testing, the reading should be a few volts higher than the label says. If there is less voltage than what the label says, you need to replace the adapter.

PROCEDURE 2: Test harness for power supply voltage

2.1After you have tested the adapter for voltage, plug in the machine and take the console off of the unit.

2.2Turn on the meter to test for DC voltage.

2.3Put one lead on the 1st wire and the other lead on the 3rd wire.

Triangle always points to pin # 1

Put leads from meter HERE and HERE

2.4 You should have basically the same voltage here as you had when you tested the adapter. If the reading is vastly different, the harness needs to be replaced.

5

Repair Procedures

PROCEDURE 3: Test gear motor

3.1If unit is an XE550, go to motor test in engineering mode (Procedure 8).

3.2Take off right shroud so you can access the gear motor.

3.3Turn meter on setting to check for DC voltage.

3.4Check for voltage between the yellow and the red wires. (Should be around 4.5v for 350/550)

3.5Check for voltage between the yellow and orange. Check for voltage between the red and orange. These two voltages should added together should total the voltage that you had between the yellow

and red.

3.6Press the START button and press the UP button. Check for voltage between the black and the brown wires. You should get 4-6 volts. (As you can see, you will need someone to help you with this step.)

PROCEDURE 4: Alignment of speed sensor and magnet

4.1Using a flat screw driver or a knife, take off the round disc cover on the left side of the unit.

4.2Turn the pedal so the bigger opening is at the top of the hole. (See picture below)

4.3 Sensor should be pointing directly at the large pulley and there should be a magnet in the on the pulley.

Magnet

Magnet

Sensor

6

Repair Procedures

PROCEDURE 5: Adjusting brake cable

5.1Take right and left shrouds off.

5.2On the left side of the unit you will find the brake inside of the flywheel.

5.3Using an open end wrench, loosen the small lock nut.

5.4Using the same wrench, loosen the longer nut. As you loosen the nut you will see this gap get smaller.

5.5The smaller the gap is, the easier the resistance will be at level 1. Dont adjust out the gap completely.

5.6Tighten down the lock nut.

PROCEDURE 6: Incline controller wiring

Red wire from on/off switch |

Red wires |

|

|

|

|

Red wire from on/off switch |

Black wires |

from transformer |

|

||

|

from transformer |

|

Main wire harness

Red wire from Incline motor

White wire from

Incline motor

Black wire from |

Harness from |

|

Incline motor |

Incline motor |

7 |

|

|

PROCEDURE 7: Engineering Mode

1.Press and hold the START, ENTER, and STOP buttons until display beeps.

2.“ENGINEERING MODE” will scroll across the screen, press ENTER.

3.Press the UP and/or DOWN buttons to scroll through the following sub menus:

-Key Test

-Display Test

-Functions

-Security

-Factory Set

-Exit

4.Press ENTER to access the desired program.

5.Press STOP to exit Engineering Mode.

- Key Test

Press ENTER. Press all buttons on console.

- Display Test

Press ENTER. Console will test each segment or LED. Look to see if there are any burned out or not working.

- Functions |

|

Sleep Mode On/Off --------------------- |

Press ENTER to turn on or off. |

Pause Mode On/Off -------------------- |

Press ENTER to turn on or off. |

Odometer Reset ------------------------- |

Press ENTER to reset. |

Units English/Metric -------------------- |

Press ENTER to change. |

Beep Sound On/Off --------------------- |

Press ENTER to turn on or off. |

Motor Test-------------------------------- |

Press ENTER to begin the test. |

Safety On/Off (XE300 calls it “Inc Max”)--- Press ENTER to turn on or off. |

|

Exit --------------------------------------- |

Press ENTER to exit the functions menu. |

- Security |

|

Child Lock On/Off ------- |

Press ENTER to turn on or off. |

- Factory Set

Press ENTER to go back to original factory settings. This will reset saved user programs.

- Exit

Press ENTER to exit Engineering Mode.

PROCEDURE 8: XE400 and XE500 Incline Calibration

If the console shows an incline error or does not seem to physically be at the incline displayed, the unit needs to be calibrated. Press and hold the START and level UP keys for 5 seconds. The message window wil show “Calibration”; press ENTER. The calibration process is automatic and the system will restart when finished.

8

PROCEDURE 9: XE400 & XE500 Wiring Schematic

9

CONTACTING CUSTOMER SERVICE

It is the responsibility of the Dealer to assemble and setup any Spirit product they have sold, as well as diagnose problems and perform service, regardless of the product’s location. Recognizing the importance of insuring the consumer’s satisfaction, Spirit technical support will always be available to assist the Dealer in diagnosing a problem. All warranties are valid from the original date of purchase by the original purchaser.

PARTS ORDERS |

Fax 870-930-9013 |

Fax your order using a completed parts purchase order to (870) 930-9013. Please do not call to place your parts orders, fax only. Service technicians are available to assist in the repair of treadmills. If taking parts orders by telephone, technical service calls will go unanswered. Standard shipping is FedEx ground. If you need an order shipped by another method, you must pay for shipping.

CUSTOMER SERVICE |

Call 800-258-4555 |

Calling from Store Location

Dial 1 to reach the first available technician, or select the extension number for a particular technician. You must have the serial number of the machine when you call.

-Charles Wood -----------Customer Support ext. 626

-Terry Jordan ------------ Customer Support ext. 627

-Kevin Thomas --------- -Customer Support ext. 628

-Nathan Price ------------ Customer Support ext. 629

-Carla Nichols ---------- -Customer Support ext. 631

-Travis Lawrence --------Customer Support ext. 633

If the technician you choose is unavailable, leave a detailed message. Leave only one message. Do not call another extension. Do not leave multiple messages. This results in a duplication of effort and keeps our technicians from assisting you and other customers in a prompt manner.

Calling from Customer Location

Dial 0 for an operator. Relay to the operator that you are a dealer and in a customer’s home. You will be assisted by the first available technician.

10

XE ELLIPTICALWARRANTY

Spirit Manufacturing Inc. warrants all its XE elliptical parts for a period of 5 years from the date of retail sale, as determined by sale receipt, or eighteen (18) months from the original factory shipping date, whichever comes first. Spirit’s responsibilities include providing new or remanufactured parts, at Spirit’s option, and technical support to our independent dealers and servicing organizations. In the absence of a dealer or service organization, these warranties will be administered by Spirit directly to a consumer. An extended warranty period applies to the following components:

XE100 - XE200

Frame--------------- |

Lifetime |

Brake--------------- |

Lifetime |

All Parts------------ |

5 years |

Labor--------------- |

1 year |

XE300 - XE400 - XE500

Frame ------------- |

Lifetime |

Brake ------------- |

Lifetime |

All Parts ---------- |

10 years |

Labor ------------- |

1 years |

11

WARRANTY POLICY

Parts Returns

It is very important that you have not only the model number but also the serial number on hand when placing a parts order. If a serial number is provided at the time a warranty parts order is placed the required parts will be sent to you at no charge. If the unit is no longer covered under warranty the parts will be billed to you on 30 day payment terms.

If a warranty replacement part is required to be returned to Spirit it will be noted on the packing list included in your shipment. Also noted on the packing list will be the amount you will be invoiced if the parts are not returned within 30 days.

Parts Required to be Returned for Credit

Upper Electronics - XE Series

Paperwork Requirement: A copy of your invoice or packing list and diagnostic form (if included with replacement part) must be returned with the defective part to receive warranty consideration.

Warranty Labor Reimbursement Procedure

Complete Request for Warranty Labor Credit Form. Fax completed form to (870) 930-9013.

Once Spirit has received your returned parts, your request will be processed and returned by fax to you.

What is Not Covered

1)Failures created due to improper installation or maintenance.

2)Repairs requiring only simple adjustments, fuses, or calibrations.

3)Damages sustained from shipping - Freight claim must be filed with your carrier.

4)Repairs that are made beyond the warranty period.

5)Repairs where the customer is paying the base labor fee to the dealer.

6)Units that are dealer stock or floor models.

7)Trips for diagnostic visit.

8)Residential units in a commercial setting.

Credit will not be issued for repairs in which:

1)Parts required for return are not returned to Spirit within 30 days.

2)All paperwork is not completed or returned.

3)Spirit confirms that work was not completed.

Warranty LaborReimbursement Policy

Spirit has established a set of guidelines that are fair to both independent service companies and to Spirit. Our policy on labor warranty reimbursement is simple...we pay a one time flat completion fee of $80 per service occurrence. Once all work required to complete the repair has been finished and all parts required for return have been returned to Spirit either credit or payment in the amount of $80 will be issued to your company. The one-time flat completion fee of $80 will be paid only when the repair is complete and the unit has been returned to proper working condition. If your company needs consideration for labor or trip fees that are higher than Spirit’s standard fees, they will be evaluated on a case-by-case basis. (e.g. - travel to perform service work in Manhattan). Any change in the fee schedule must be approved in writing by Spirit before any work is performed.

For Dealers That Wish To Use Third Party Service

It is Spirit’s policy that all dealers service products that they sell to end users. If your company chooses to use an independent company for service, you are responsible for all service work. Our labor reimbursement policies apply in every case and any charges in excess of Spirit’s one time flat completion fee will be billed back to the selling dealer. In certain circumstances, we will work directly with an independent service company, but we will not pay for any service that deviates from our policy for dealers wishing to have this arrangement. Dealers will be responsible to the service company for all charges disallowed by Spirit. Any deviation from Spirit policy must be approved in advance in writing.

12

Loading...

Loading...